Page 1

INSTRUCTION MANUAL

Portable Single-Stage Dust Collector

(Model 50-820)

D AT E D 6-8-98 PA RT NO. 1348468

'Delta International Machinery Corp. 1998

Page 2

2

TABLE OF CONTENTS

W ARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

IMPORTANT SAFETY RULES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

IMPORTANT SAFETY RULES FOR DUST COLLECTO R S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

UNPACKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

ASSEMBLY

Assembling Intake Flange To Dust Collector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Assembling Support Tube And Connector To Dust Collector Body . . . . . . . . . . . . . . . . . . . . . . . . 6

Assembling Vacuum Hose To Dust Collector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Assembling Dust Bag To Dust Collector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

CONNECTING MACHINE TO POWER SOURCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Motor Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Grounding Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

EXTENSION CORDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

OPERATING CONTROLS AN D ADJUSTMENTS

Starting And S topping Dust Collector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Locking The Switch in The OFF Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Safety Gates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

OPERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

TRANSPORTATION A N D STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Delt a will rep air or replace, at it s expense and at it s option, any Delt a machine, machine part, or machine

accessory which in normal use has proven to be defective in workmanship or material, provided that the

customer returns the product prepaid to a Delt a factory service center or authorized service st ation with

proof of purchase of the product within two years and provides Delta with reasonable opportunity to ver ify the alleged defect by inspection. Delt a may require that electric motors be returned prep aid to a motor

manufacturer s authorized st ation for inspection and repair or replacement. Delt a will not be responsible

for any asserted defect which has resulted from normal wear, misuse, abuse or rep air or alteration made

or specifically authorized by anyone other than an authorized Delta Service facility or representative.

Under no circumstances will Delt a be liable for incidenta l or consequential damages resulting from defec tive products. This warranty is Delt a s sole warranty and set s forth the customer s exclusive remedy, with

respect to defective products; all other warranties, express or implied, whether of merchantability , fitness

for purpose, or otherwise, are expressly disclaimed by Delt a.

Delt a Building Trades and Home Shop Machinery

Two Y ear Limited Warranty

Printed in U.S.A.

Page 3

3

IMPORTANT SAFETY RULES

W oodworking can be dangerous if safe and proper operating procedures are not followed. As with all machinery, there are cert ain

hazards involved with the operation of the product. Using the machine with respect and caution will considerably lessen the possi bility of personal injury . However, if normal safety precautions are overlooked or ignored, personal injury to the operator may result.

Safety equipment such as guards, push sticks, hold-downs, featherboards, goggles, dust masks and hearing protection can reduce

your potential for injury . But even the best guard won t make up for poor judgment, carelessness or inattention. Always use common

sense and exercise caution in the workshop. If a procedure feels dangerous, don t try it. Figure out an alternative procedure that feels

safer . REMEMBER: Your personal safety is your responsibility .

This machine was designed for cert ain applications only . Delt a Machinery strongly recommends that this machine not be modified

and/or used for any application other than that for which it was designed. If you have any questions relative to a p articular applica tion, DO N O T use the machine until you have first cont acted Delta to determine if it can or should be performed on the product.

DE LTA INTERNATIONAL MACHINERY CORP.

MANAGER OF TECHNICAL SE RVICES

246 ALPHA DRIVE

PITTSBURGH, PENNSYLVANIA 15238

(IN CANADA: 644 IMPERIAL ROAD, GUELPH, ONTARIO N1H 6M7)

W ARNING: FAILURE TO FOLLOW THESE RULES

M AY RESULT IN SERIOUS PERSONAL INJURY

1. FOR YOURO W N SAFETY, READ INSTRUCTION

MANUAL BEFORE OPERATING T HE TO O L. Learn the

tool s application and limit ations as well as the specific

hazards peculiar to it.

2. KEEP GUARDS IN PLACE and in working order.

3. ALWAYSWEAREYEPROTECTION.

4. GROUND ALLTOOLS. If tool is equipped with threeprong plug, it should be plugged into a three-hole electrical

recept acle. I f a n adapter is used to accommodate a twoprong recept acle, the adapter lug must be att ached to a

known ground. Never remove the third prong.

5. REMOVE ADJUSTING KEYS AND WRENCHES. Form

habit of checking to see that keys and adjusting wrenches are

removed from tool before turning it on.

6. KEEP WORKAREA CLEAN. Cluttered areas and

benches invite accident s.

7. DON T USE IN DANGEROUS ENVIRONMENT. Don t

use power tools in damp or wet locations, or expose them

to rain. Keep work area well-lighted.

8. KEEP CHILDREN A N D VISITO R S A W AY . All children

and visitors should be kept a safe dist ance from work area.

9. MAKE WORKSHOPCHILDPROOF with p adlocks,

master switches, or by removing st arter keys.

10. DON T FORCE TO O L. It will do the job better and be

safer at the rate for which it was designed.

11. U SE RIGHT TOO L. Don t force tool or att achment to do

a job for which it was not designed.

12. WEARPROPER APPAREL. No loose clothing, gloves,

neckties, rings, bracelet s, or other jewelry to get caught in

moving parts. Nonslip footwear is recommended. Wear

protective hair covering to cont ain long hair.

13. ALW AYS USE SAFETY GLASSES.W ear safety glasses.

Everyday eyeglasses only have impact resist ant lenses;

they are not safety glasses. Also use face or dust mask if

cutting operation is dusty.

14. SECURE WORK. Use clamp s or a vise to hold work

when practical. It s safer than using your hand and frees

both hands to operate tool.

15. D O N T O V E R R E A C H . Keep proper footing and balance

at all times.

16. MAINTAIN TOOLSIN TO PCONDITION. Keep tools

sharp and clean for best and safest performance. Follow

instructions for lubricating and changing accessories.

17. DISCONNECT TOOLS before servicing and when

changing accessories such as blades, bit s, cutters, etc.

18. USERECOMMENDED ACCESSORIES. The use of

accessories and att achments not recommended by Delt a

may cause hazards or risk of injury to persons.

19. REDUCE THE RISK O F UNINTENTIONAL STAR TI NG . Make sure switch is in OFF position before plugging

in power cord.

20. NEVER STAND O NTO O L. Serious injury could occur

if the tool is tipped or if the cutting tool is accident ally

cont acted.

21. CHECK DAMAGEDPARTS. Before further use of the

tool, a guard or other p art that is damaged should be carefully checked to ensure that it will operate properly and

perform it s intended function check for alignment of moving

part s, binding of moving p arts, breakage of p art s, mounting,

and any other conditions that may af fect it s operation. A

guard or other p art that is damaged should be properly

rep aired or replaced.

22. DIRECTION O F FEED. Feed work into a blade or cutter

against the direction of rot ation of the blade or cutter only.

23.

NEVER LEAVE TOOL RUNNING UNATTENDED. TURN

POWEROFF

. Don t leave tool until it comes to a complete

stop.

24. DRUGS, ALCOHOL, MEDICATION. Do not operate

tool while under the influence of drugs, alcohol or any

medication.

25. MAKESURE TOO L IS DISCONNECTED FROM POWER

SUPPLY

while motor is being mounted, connected or re-

connected.

26. W ARNING: The dust generated by cert ain woods and

wood products can be injurious to your health. Always oper ate machinery in well ventilated areas and provide for proper

dust removal. Use wood dust collection systems whenever

possible.

Page 4

4

IMPORTANT SAFETY RULES FOR

DUST COLLECTORS

W ARNING:

Basic precautions should

always be followed when using your dust collector.

To reduce the risk of injury, electrical shock or fire,

comply with the safety rules listed below:

1. READand underst and the instruction manual before

operating the dust collector .

2. D O N O T leave the dust collector plugged into the

electrical outlet. Unplug dust collector from the outlet

when not in use and before servicing, changing bags,

unclogging and cleaning.

3. A L W A Y S turn the power switch OFF before unpluggi ng the dust collector.

4. W ARNING: TO REDUCE THE RISK O F ELECTRICAL SHOCK, do not use on wet surfaces. Do not expose

to rain. S tore indoors.

5. FOLLOWall electrical and safety codes, including

the National Electric Code (NEC) and the Occup ational

Safety and Health Regulations (OSHA). All electrical

connections and wiring should be made by qualified

personnel only.

6. D O N O T use the dust collector to pick up flammable

or combustible liquids, such as gasoline. NEVERuse the

dust collector near any flammable or combustible liquids.

7. U S E the dust collector to pick up wood materials

only . D O N O T use the dust collector to pick up met al

shavings, met al dust, or p arts.

8. NEVER use the dust collector to dissip ate fumes

or smoke. NEVER pick up anything that is burning or

smoking, such as cigarettes, matches or hot ashes.

9. U S E only as described in this manual. U S E only accessories recommended by Delt a.

10. D O N O T pull the dust collector by the power cord.

NEVER allow the power cord to come in contact with

sharp edges, hot surfaces, oil or grease.

11. D O N O T unplug the dust collector by pulling on the

power cord. A L W A Y S grasp the plug, not the cord.

12. D O N O T handle the plug or dust collector with wet

hands.

13. REPLACE a damaged cord immediately. D O N O T

use a damaged cord or plug. If the dust collector is not

operating properly, or has been damaged, lef t outdoors

or has been in cont act with water, return it to an

Authorized Service Center for service.

14. D O N O T use the dust collector as a toy . D ONOT

use near or around children.

15. D O N O T insert fingers or foreign object s into the

dust int ake port. Keep hair , loose clothing, fingers, and all

body parts away from openings and moving part s of the

dust collector .

16. D O N O T use the dust collector without the dust col lection bag in place and properly secured.

17. A L W A Y S use safety gates to cover dust port s when

the dust collector is not in use or mounted to a support ing surface for storage.

18. PERIODICALLY INSPECT dust bag for any cut s,

rip s or tears. NEVER operate the dust collector with a

damaged bag or vacuum hose.

19. The dust collector is designed for home use or light

commercial duty O N LY!

20. CONNECT dust collector to a properly grounded outlet only . See grounding instructions.

SAVE THESE INSTRUCTIONS

Page 5

5

UNPACKING

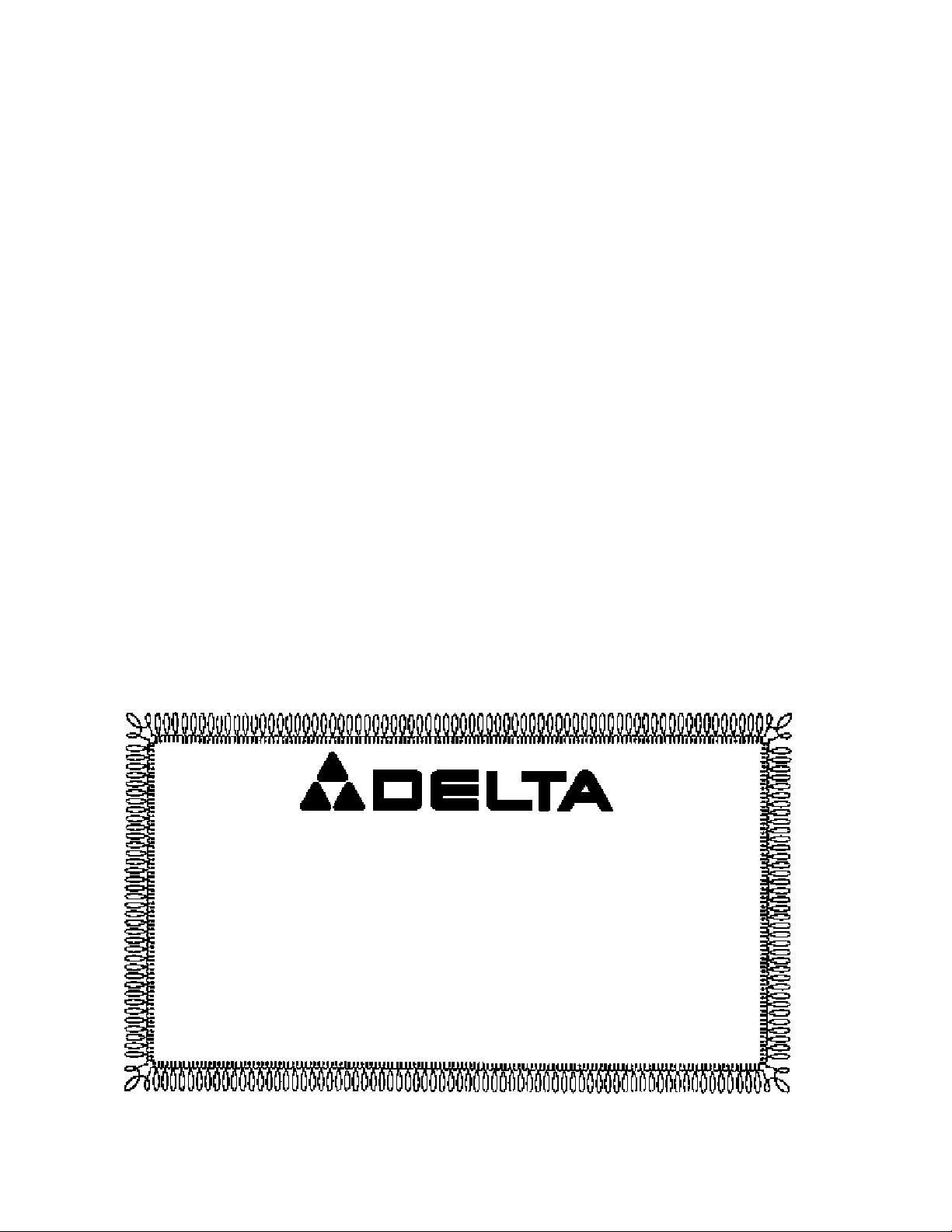

Y our 50-820 Dust Collector is shipped complete in one cont ainer . Carefully remove the dust collector and all

loose p art s from the cont ainer . Figs. 2 and 3 illustrate the component s of the dust collector . W ARNING: D O N O T

CONNECT THE DUST COLLECTO R TO THE POWERSOURCE UNTIL TH E MACHINE IS COMPLETELY

ASSEMBLED AND YO U H AVE READAND UNDERSTAND THE ENTIRE OWNER S MANUAL.

1 -Dust Collector

2 -10’ long, 4 Diameter

Vacuum Hose

3 -Dust Collector Bag

Fig. 2

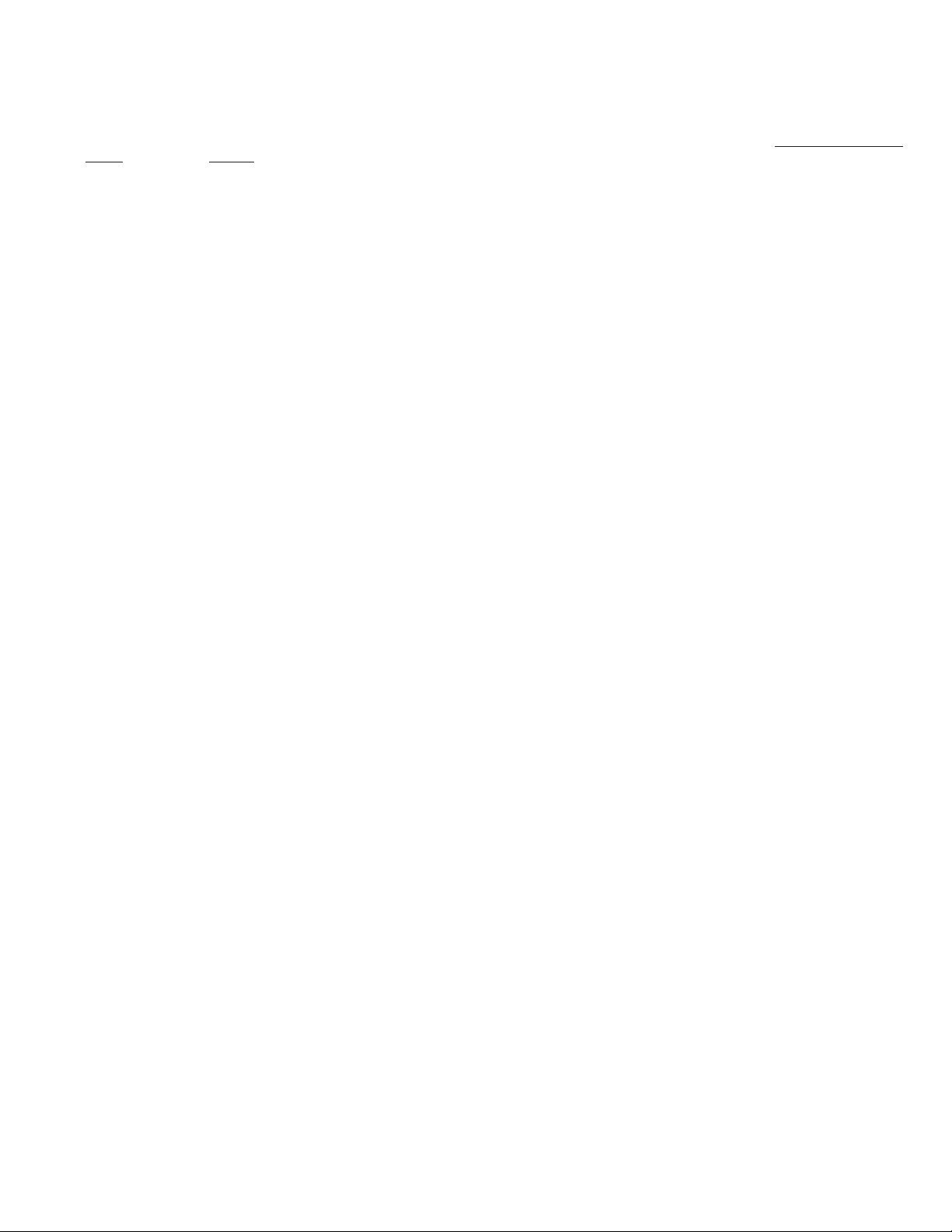

Fig. 3

4 -Dust Collector Hood

5 -Clamps for Tubular

Supports (2)

6-Int ake Flange

7 -Hose Clamps (2)

8 -Angled Support Tu b e

9 -5/16-18 x 5/8

Hex Head Screw

10 -5/16 Flat Washers (2)

11 -5/16-18 Hex Nut

12 -Upper Support T u be

2

1

3

4

5

6

12

7

8

9

11

10

Page 6

6

Fig. 4

ASSEMBLY

Fig. 5

Fig. 6

Fig. 7

ASSEMBLING

INTAKE FLANGE TO

DUST COLLECTO R

1. Loosen and remove four screws (A) Fig. 4, from

flange (B) of air cleaner .

2. Align holes in flange (B) Fig. 4, with four holes in

flange adapter (C) and fasten connector to dust collector

as shown in Fig. 5, with screws (A) removed in STEP 1.

NOTE: WARNING LABEL O N FLANGE ADAPTER (C)

MUST FACE TO WARD THE TOP OF DUST COLLECTOR.

ASSEMBLING SUPPORT

TUBE AND CONNECTOR TO

DUST COLLECTO R BODY

1. Assemble clamp (D) Fig. 6, onto the end of tube

(E) and insert smaller end of angled support tube (F) into

tube (E) and tighten clamp (D), as shown properly

assembled in Fig. 7.

A

C

B

A

A

C

F

D

E

Page 7

7

Fig. 8

Fig. 9

Fig. 10

Fig. 1 1

2. Align hole in upper support tube (G) Fig. 8, with

flange (H) located at the bottom connector (J) and fasten

support tube to flange with screw (K), flat washers (L),

and hex nut (M). NOTE: Flat washers will be positioned

on each side of flange.

3. Place the remaining small clamp (D) Fig. 9, onto the

split end of angle support tube (F). Insert upper support

tube assembly (G) with connector (J) att ached, and tighten

clamp (D) as shown assembled in Fig. 9.

ASSEMBLING

VACUUM HOSE TO

DUST COLLECTO R

1. Place hose clamp (A) Fig. 10, onto one end of 4

diameter vacuum hose (B) and slide hose around con nector (C) as shown in Fig. 11. Tighten hose clamp (A).

G

H

K

L

L

M

J

D

G

F

J

A

B

C

A

Page 8

8

Fig. 12

Fig. 13

Fig. 14

Fig. 15

2. Place the remaining hose clamp (A) Fig. 12, around

the other end of vacuum hose (B) and slide hose (B) onto

connector (C) and tighten hose clamp (A). NOTE: If

desired, connector (C) can be rot ated in the vertical posi tion, as shown in Fig. 13.

ASSEMBLING DUST BAG

TO DUST COLLECTO R

Loosely thread end of dust bag strap (A) through clamp

(B) as shown in Fig. 14. Place open end of dust bag (C)

Fig. 15, over outlet flange (D) and firmly pull strap (A) to

fasten dust collection bag to outlet flange.

C

A

B

C

A

B

C

A

D

Page 9

9

CONNECTING MACHINE TO POWER SOURCE

POWER CONNECTIONS

A s e p arate electrical circuit should be used for your tools. This circuit should not be less than #12 A W G a n d

should be protected with a 20 amp, time lag fuse. Have a certified electrician rep air or replace damaged or

worn cord immediately. Before connecting the motor to the power line, make cert ain the switch is in the OFF

position and be sure that the electric current is of the same characteristics as st amped on the motor nameplate. All line connections should make good cont act. Running on low voltage will damage the motor.

W ARNING: D O N O T EXPOSE THE DUST COLLECTO R TO RAIN O R OPERATETHE MACHINE IN

DAMPLOCATIONS.

M O TO R SPECIFICATIONS

The motor of the Model 50-820 Dust Collector is shipped wired for 120 Volt s. Before connecting the dust

collector to the power source, make cert ain the switch is in the OFF position.

GROUNDING INSTRUCTIONS

W ARNING: THIS TO O L MUST BE GROUNDEDWHILE IN US E TO PROTECT THE OPERATO R FROM

ELECTRIC SHOCK.

This dust collector must be grounded. If it should malfunction or break down, grounding provides a p ath of

least resist ance for electric current to reduce the risk of electric shock. This dust collector is equipped with a

cord having an equipment-grounding conductor and grounding plug. The plug must be inserted into an

appropriate outlet that is properly inst alled and grounded in accordance with all local codes and ordinances.

W ARNING: Improper connection of the equipment-grounding conductor can result in a risk of

electric shock. Check with a qualified electrician or service person if you are in doubt as to whether the out let is properly grounded. Do not modify the plug provided with the dust collector . If it will not fit the outlet, have

a proper outlet inst alled by a qualified electrician.

Fig. 16

Fig. 17

GROUNDED OUTLET BOX

CURRENT

CARRYING

PRONGS

GROUNDING BLADE

IS LONGEST O F THE 3 BLADES

GROUNDED OUTLET BOX

GROUNDING MEANS

ADAPTER

This dust collector is for use on a normal 120-volt circuit

and has a grounded plug that looks like the plug illustrat ed in Fig. 16.

If a properly grounded outlet is not available, a temporary

adapter, shown in Fig. 17, may be used for connecting

the 3-prong grounding type plug to a 2-prong recept acle.

The temporary adapter should be used only until a

properly grounded outlet can be inst alled by a qualified

electrician. The green colored rigid ear, lug, or the like

extending from the adapter must be connected to a

permanent ground such as a properly grounded outlet

box cover. Whenever the adapter is used, it must be held

in place with a met al screw.

NOTE: In Canada, the use of a temporary adapter is

not permitted by the Canadian Electric Code .

Page 10

10

EXTENSION CORDS

Use proper extension cords. Make sure your extension

cord is in good condition and is a 3-wire extension cord

which has a 3-prong grounding type plug and a 3-hole

recept acle which will accept the tool s plug. When using

an extension cord, be sure to use one heavy enough to

carry the current of the dust collector . An undersized cord

will cause a drop in line volt age resulting in loss of power

and overheating. Fig. 18, shows the correct size to use

depending on cord length. If in doubt, use the next heavier

gage. The smaller the gage number, the heavier the cord.

TO TAL LENGTH OF

CORDIN FEET

0-25

26 - 50

51 - 100

101 - 150

GAGEOF EXTENSION

CORDTO USE

16 A W G

16 A W G

14 A W G

12 A W G

Fig. 18

OPERATING CONTROLS & ADJUSTMENTS

Fig. 19

Fig. 20

Fig. 21

W ARNING: BE FORE OPERATING T H E MACHINE,

FOR OPERATO R SAFETY, MAKE CERTAIN THE DUST

INTAKE PORTIS COVEREDWITH THE VACUUM HOSE.

TH E R O TATING FA N INSIDE T H E BLOWER HOUSING IS ACCESSIBLE THROUGH THE DUST INTAKE

PORT A ND IS HAZARDOUS. ALW AYS WEARPROPER

APPAREL.D O NOT WEAR JEWELRY,AN D KEEP

FINGERS A N D ALL FOREIGN OBJECTS OU T OF

THE DUST INTAKE PORT.ALW AYS FOLLOW THE

SAFETY RULES DESCRIBED O N PAGES3 A N D 4 OF

THIS MANUAL.

STARTING A N D STOPPING

DUST COLLECTO R

The ON/OFF power switch (A) Fig. 19, is located on the

side of the motor . To turn the machine ON , move the

switch toggle (B) upward. To turn the switch OFF , move

the switch toggle (B) downward.

LOCKING SWITCH IN

T H E OFF POSITION

W e suggest that when the dust collector is not in use, the

switch be locked in the OFF position. This can be done

by grasping the switch toggle (B) Fig. 20, and pulling it

out of the switch (A) as shown. With the switch toggle

removed, the switch will not operate. However, should

the switch toggle be removed while the machine is

running, the switch can be turned OFF once, but

cannot be rest arted without inserting switch toggle (B).

SAFETY G ATES

1. The dust collector is equipped with two safety gates

(A) Fig. 21. IMPORTANT:When the dust collector is in

use, the safety gates (A) Fig. 21, should always be in the

open position, to allow dust and wood chip s to flow freely

through the vacuum hose (B) and into the dust collection

bag (C).

2. IMPORTA N T:When the dust collector is not in use,

the safety gates (A) Fig. 21, should always be pushed

inward into the closed position over the inlet and outlet

housings (as shown) to avoid anyone coming in cont act

with the fan blade or sharp edges and promote operator

safety .

A

B

A

B

B

A

A

C

Page 11

11

OPERATIONS

Fig. 22

1. This versatile dust collector is light, comp act and can

easily be transported to a variety of locations for use

in and out of the workshop. It s sturdy tubular frame (A)

Fig. 22, featuring four rubber feet, three of which are

shown at (B), allows the dust collector to sit securely on the

floor or supporting shelf without creeping or walking

across the supporting surface during operation.

A

B

B

2. Fig. 23, illustrates the dust collector positioned on the floor and at the rear of a wood

lathe to ef fectively clear the wood chip s away from the work area. Note how the support

tube (A) keeps the vacuum hose and collector hood (B) in position behind the work area,

without hindering the operator.

Fig. 23

B

A

Page 12

12

Fig. 24

Fig. 25

3. Fig. 24 illustrates the dust collector

positioned on a lower shelf and used to

collect dust in a small router applica tion. In this p articular application, the

angular support tube is not being used

to support the dust collector hood and

vacuum hose (B). However, the dust

collector hood is shown clamped at

(C) to the t able top for ef fective dust

collection.

4. The vacuum hose (B) Fig. 25, can

be fitted with a variety of connectors to

accommodate any type of woodworking machine. Fig. 25, illustrates the

dust collector positioned behind a t able

saw and att ached to the dust chute of

the saw through a specially designed

dust connector hood (D) which accept s

a 4 diameter hose.

C

B

B

D

Page 13

13

Fig. 26

Fig. 27

5. Fig. 26 illustrates the dust collector

att ached to a portable bench top planer

through an accessory dust connector

hood.

6. Cleaning out the truck bed is another application for the dust collector ,

as shown in Fig. 27; however, it should

not be us e d t o p ick u p m e t allic object s.

Page 14

14

TRANSPORTATION A N D STORAGE

Fig. 29

Fig. 30

Fig. 28

1. The dust collector features a convenient carrying

handle with rubber grip (A) Figs. 28 and 29, which allows

the unit to be carried easily from one job area to another .

IMPORTANT:THE DUST COLLECTO R WEIGHS

APPROXIMATELY 39 LBS. CARE SHOULD BE TAKEN

WHENLIFTING A N D TRANSPORTING THE MACHINE.

2. In addition to the carrying handle, the machine

features a welded mounting bracket (B) Fig. 28, with hole

for mounting the dust collector to a wall or wooden sup port (when not in use) as shown in Fig. 30. Two rubber

feet (C) Fig. 28, on the tubular frame help s support the

unit for storage and prevent s damage to wall or support ing surface. IMPORTANT:ALW AYS use safety gates to

cover dust port s when the dust collector is not in use or

mounted to a supporting surface for storage.

MAINTENANCE

NOTE: Before any maintenance or service is performed, be sure the dust collector is disconnected from the power source to prevent accident al st arting and the safety gates closed. All main tenance other than the items recommended in this manual should be performed by an authorized

Delt a Service Center.

1. IMPORTA N T:Always disconnect the machine from the power source before performing any

maintenance procedures.

2. The condition of the dust bag should be checked periodically for damage and emptied on a

regular basis. Do not transport the machine with a full dust bag.

3. Clean and apply a dry silicone lubricant monthly to the impeller to remove any dirt or build-up

of pitch, gum and wood shavings.

A

C

B

Loading...

Loading...