Page 1

INSTRUCTION MANUAL

MACHINERY

DATED 6-22-00 PART NO. 1345771

Copyright © 2000 Delta Machinery

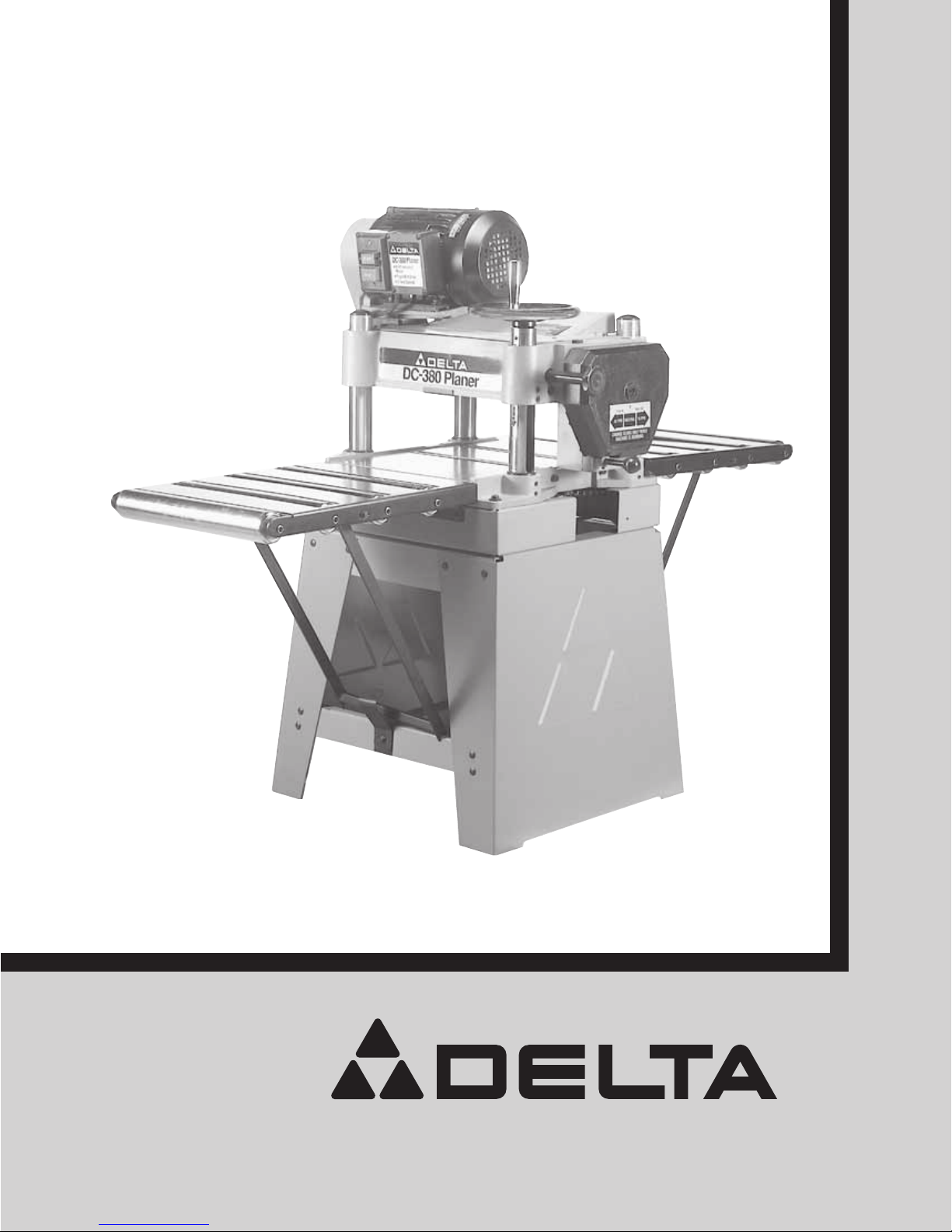

50-785 Accessory Planer Stand

and Roller Extension Tables

Planer Stand shown with

Delta Model DC-380

15

″ Planer

Page 2

2

INTRODUCTION

This manual illustrates the stand with roller extension tables assembled to a Delta DC-380 15″ Planer. The accessory

heavy-duty steel planer stand not only gives a stable support surface for the 15″ planer, but is equipped with two roller

extension tables that provide added work support and prevent sniping of the wood when planing longer workpieces. Each

table features four (4) large 2-1/4″ diameter rollers which will allow smoother, easier infeed and outfeed operations.

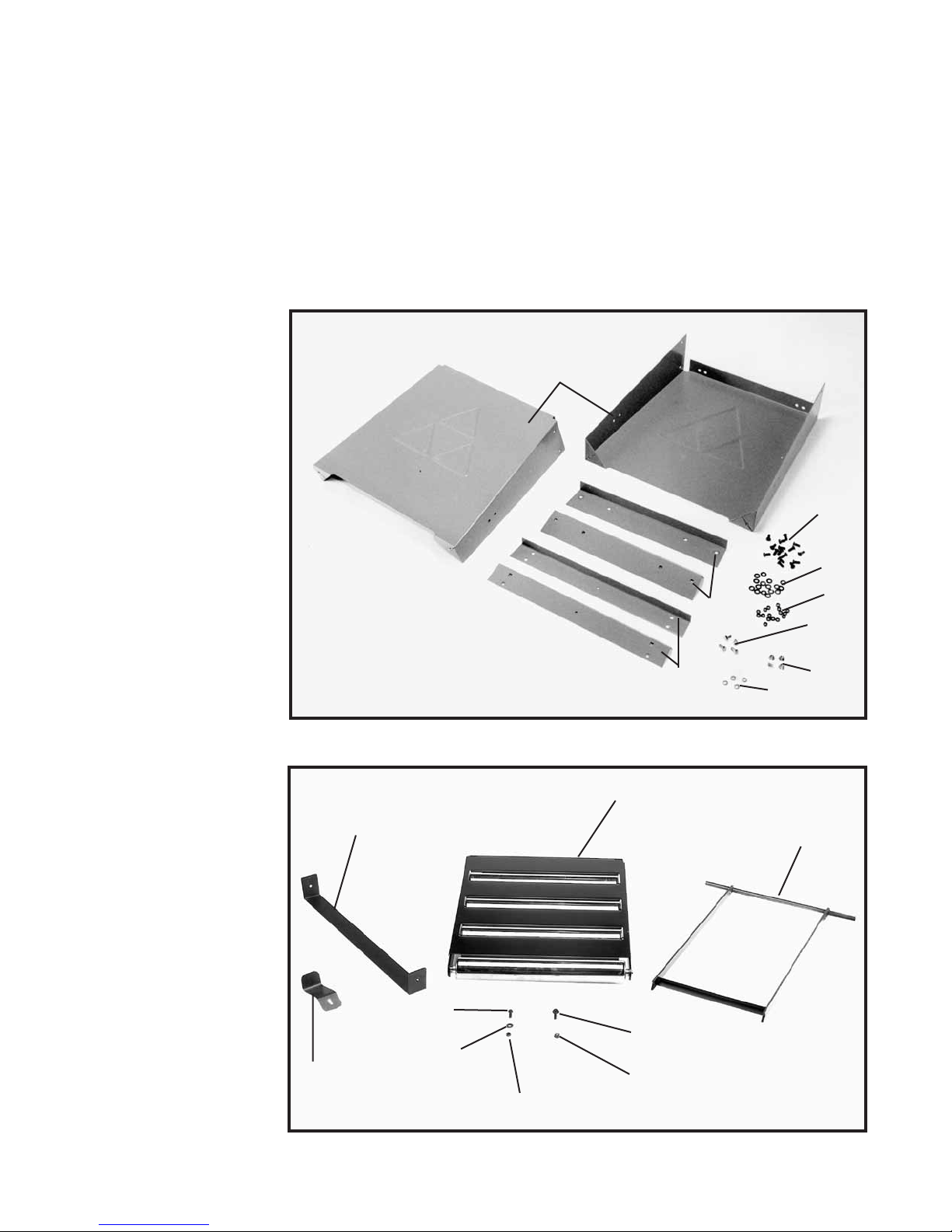

UNPACKING AND CLEANING

Your 15″ planer stand with roller extension tables is shipped in one container. Carefully remove the protective coating

from the machined surfaces of the extension tables. This coating may be removed with a soft cloth moistened with

kerosene. DO NOT USE ACETONE, GASOLINE OR LACQUER THINNER FOR THIS PURPOSE. Figure 2, illustrates

the components of the stand. Figure 3 illustrates the components of the roller extension tables.

Fig. 2

Fig. 3

1. Side Supports (2)

2. Upper Stand Support

Brackets (2)

3. Lower Stand Support

Brackets (2)

4. 5/16-18 x 3/4

″ Carriage

Head Screws (16)

5. M8 Flat Washers (16)

6. 5/16-18 Hex Nuts (16)

7. M8 x 30MM Hex Head

Screws (4)

8. M8 Flange Nuts (4)

9. M8.1 Lockwashers (4)

10. Stand Supports (2)

11. Roller Extension Tables (2)

12. 1/4-20 x 3/4″ Hex Head

Screws (6)

13. 1/4″ Flat Washers (8)

14. 1/4-20 Hex Nuts (2)

15. M6 x 20 Hex Flange

Screws (6)

16. M6 Flange Nuts (6)

17. Clips (2)

18. Leg Support

1

2

3

7

8

9

6

5

4

11

10

17

15

16

12

14

13

18

Page 3

3

Fig. 4

Fig. 6

Fig. 5

ASSEMBLING PLANER TO STAND

1. Carefully lift the planer (E) Fig. 5, onto the stand (B) as

shown. CAUTION: EXTREME CARE SHOULD BE TAKEN

WHEN LIFTING THE PLANER ONTO THE STAND AS

THE CUTTERHEAD KNIVES ARE EXTREMELY SHARP

AND THE PLANER IS VERY HEAVY. IF IT IS NOT DONE

MECHANICALLY, A MINIMUM OF FOUR PEOPLE ARE

REQUIRED TO MANUALLY LIFT THE MACHINE.

2. Align the four holes in the bottom of the planer (E)

Fig. 5, with the mounting holes in the top of stand (B), and

mount the planer to the stand with four M8 x 30MM hex

head screws (F) Fig. 5, lockwashers and flange nuts.

NOTE: Screws (F) Fig. 6, one of which is shown, are

started upward from the inside of stand (B). Later planer

models may not need flange nuts.

3. Once the planer is assembled to the stand, push

down on top of the planer so the legs of the stand adjust

to the floor surface. Tighten all stand mounting

hardware.

ASSEMBLING STAND

1. Assemble the two longer support brackets (A) Fig. 4,

one of which is shown, to the inside of end panels (B) with

eight 5/16-18 x 3/4″ carriage head screws (C), flat

washers, and 5/16-18 hex nuts. DO NOT COMPLETELY

TIGHTEN HARDWARE AT THIS TIME.

2. Assemble the two shorter support brackets (D) Fig. 4,

to the inside top of end panels (B) with the remaining

eight 5/16-18 x 3/4″ carriage head screws (C), flat washers

and 5/16-18 hex nuts. DO NOT COMPLETELY TIGHTEN

HARDWARE AT THIS TIME. NOTE: Make certain the top

lip of support brackets (D) are positioned under the top

lips of end panels (B) as shown in Fig. 4.

B

D

B

A

C

E

B

E

B

F

F

Page 4

4

Fig. 7

Fig. 8

Fig. 9

Fig. 10

ASSEMBLING SUPPORT

BRACKETS TO ROLLER

EXTENSION TABLES

1. Place extension table (A) Fig. 7, on a firm supporting

surface. Align ends of support assembly (B) Fig. 7, with

slotted holes (C) at both sides of extension table (A), and

fasten support bracket assembly to extension table with

two 1/4-20 x 3/4″ hex head screws and flat washers (D).

IMPORTANT: In the position shown in Fig. 7, make

certain the longer side of notches (E) will be closest to

hinge (F) of support table.

2. Assemble the remaining support bracket to other

extension table in the same manner.

ASSEMBLING ROLLER

EXTENSION TABLES TO

PLANER AND STAND

1. Assemble bracket clips (A) and leg support (F) Fig. 8,

to the front and rear lower stand brackets (B), one of

which is shown assembled, with two 1/4-20 x 3/4″ hex

head screws (C), four flat washers (D) and two 1/4-20 hex

nuts (E). Adjustment to height of clip can be made later.

2. Align the three holes in the hinge of extension table

(G) Fig. 9, with three holes in the front of the planer base

(H) and loosely fasten the extension table to the planer as

shown with three M6 x 20MM hex flange screws (K) and

flange nuts. NOTE: Only finger tighten the three screws at

this time as height adjustment to the table will be

necessary as explained later in STEP 4. Later planer

models may not need flange nuts.

3. Place the notches at the bottom of extension table

support (B) Fig. 10, so the longer edge of the support

rests on the ledge of bottom support bracket (L) as

shown. Adjust bracket clip (A) so it contacts the horizontal

support bar (M). Tighten screw (N) after adjustment is

made.

NOTE: Clip (A) acts as a safety device so the

extension table will not fall accidentally during operation

of the planer. Assemble the remaining roller extension

table to the rear of the planer in the same manner.

B

E

F

C

D D

A

B

A

C

E

D

G

K

K

H

L

B

M

N

A

F

Page 5

5

Fig. 12Fig. 11

Fig. 13

Fig. 14

P

A

G

B

G

4. IMPORTANT: Make certain the rollers on the

extension tables are level with the table surface of the

planer. This will provide maximum work support and

prevent sniping of the wood being planed.

5. Place a straight edge (P) Fig. 11, on the table surface

and extending out of the entire surface of the table

extension rollers as shown. Align the two surfaces and

carefully tighten three screws (K) Fig. 9, that are holding

the extension table to the base of the planer. Readjust

bracket clip (A) if necessary.

6. When not in use, the roller extension tables (G) Fig. 12,

one of which is shown, can be lowered in front and back

of the planer to prevent accidental movement, which

could result in misalignment of the rollers. To lower the

tables, raise the end of extension table (G) Fig. 13,

slightly to relieve pressure on the table support (B) and

move the table support inward away from clip (A), while

lowering extension table (G).

7. Fig. 14, illustrates the stand with roller extension

tables assembled to a Delta 15″ DC-380 Planer.

A

Page 6

6

Delta will repair or replace, at its expense and at its option, any Delta machine, machine part, or

machine accessory which in normal use has proven to be defective in workmanship or material,

provided that the customer returns the product prepaid to a Delta factory service center or authorized service station with proof of purchase of the product within two years and provides Delta with

reasonable opportunity to verify the alleged defect by inspection. Delta may require that electric

motors be returned prepaid to a motor manufacturer’s authorized station for inspection and repair

or replacement. Delta will not be responsible for any asserted defect which has resulted from

normal wear, misuse, abuse or repair or alteration made or specifically authorized by anyone other

than an authorized Delta Service facility or representative. Under no circumstances will Delta be

liable for incidental or consequential damages resulting from defective products. This warranty is

Delta’s sole warranty and sets forth the customer’s exclusive remedy, with respect to defective

products; all other warranties, express or implied, whether of merchantability, fitness for purpose,

or otherwise, are expressly disclaimed by Delta.

MACHINERY

Delta Building Trades and Home Shop Machinery

Two Year Limited Warranty

MACHINERY

PARTS, SERVICE OR WARRANTY ASSISTANCE

All Delta Machines and accessories are manufactured to high quality standards and are serviced by a

network of Porter-Cable/Delta Factory Service Centers and Delta Authorized Service Stations. To obtain

additional information regarding your Delta quality product or to obtain parts, service, warranty assistance, or

the location of the nearest service outlet, please call 1-888-848-5175.

Printed in U.S.A.

Loading...

Loading...