Page 1

INSTRUCTIONS

Deluxe Shaper Fence

(Model 43-812)

(Model 43-812X)

PART NO. 432-02-651-0039 - 06-09-03

Copyright © 2003 Delta Machinery

To learn more about DELTA MACHINERY

visit our website at: www.deltamachinery.com.

For Parts, Service, Warranty or other Assistance,

please call

1-800-223-7278 (In Canada call 1-800-463-3582).

Page 2

2

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

Used without the safety alert symbol indicates potentially hazardous situation which, if not avoided, may

result in property damage.

This manual contains information that is important for you to know and understand. This information relates to protecting YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use the

symbols to the right. Please read the manual and pay attention to these sections.

SAFETY GUIDELINES - DEFINITIONS

NOTICE: THE MANUAL COVER PHOTO ILLUSTRATES THE MODEL 43-812. ALL OTHER ILLUSTRATIONS ARE

OF THE 43-812 WITH THE EXCEPTION OF THE 43-812X CARTON CONTENTS AND FIG 3A.

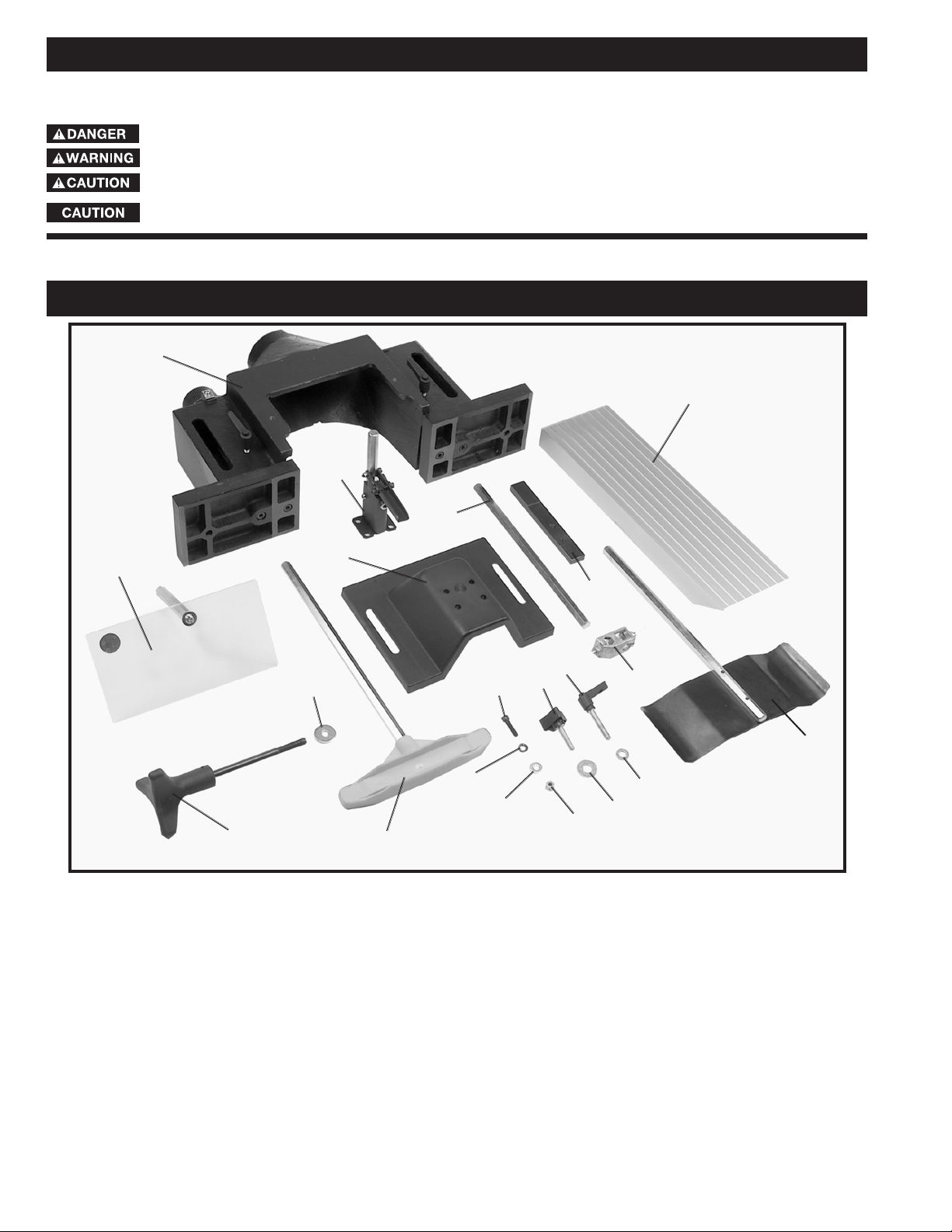

MODEL 43-812 CARTON CONTENTS

Fig. 2

1

2

17

18

20

5

4

3

14

13

12

11

10

19

16

15

9

8

7

6

1. Fence Body

2. Left and Right fence halves (2)

3. Clear Plastic Guard

4. Guard Mounting Bracket

5. Top Cover

6. Rod for fence guard

7. Lock Bars (2) for fence halves

8. Fence Locking Handles (2) for mounting fence

to shaper

9. 1/2" Flat Washers (2) for fence locking handles

10. Holddown for fence guard

11. 1/4-20x1" Hex Soc. Hd. Screw (4) for mounting

guard mounting bracket to top cover

12. 1/4" Lock Washers for mounting guard mounting

bracket to top cover (4)

13. 1/4" Flat Washers for mounting guard mounting

bracket to top cover (4)

14. 1/4-20 Hex Nuts (4) for mounting guard mounting

bracket to top cover

15. Lock Knobs (2) for mounting top cover to

fence body

16. 1/2" Flat washers (2) for mounting top cover to

fence body

17. Locking Levers for fence halves (2)

18. 11/32" Flat Washers for locking levers (2)

19. Brackets for fence guard (4)

20. Spring clamp for fence guard

* 5/32" T-handle allen wrench (* not shown)

Page 3

3

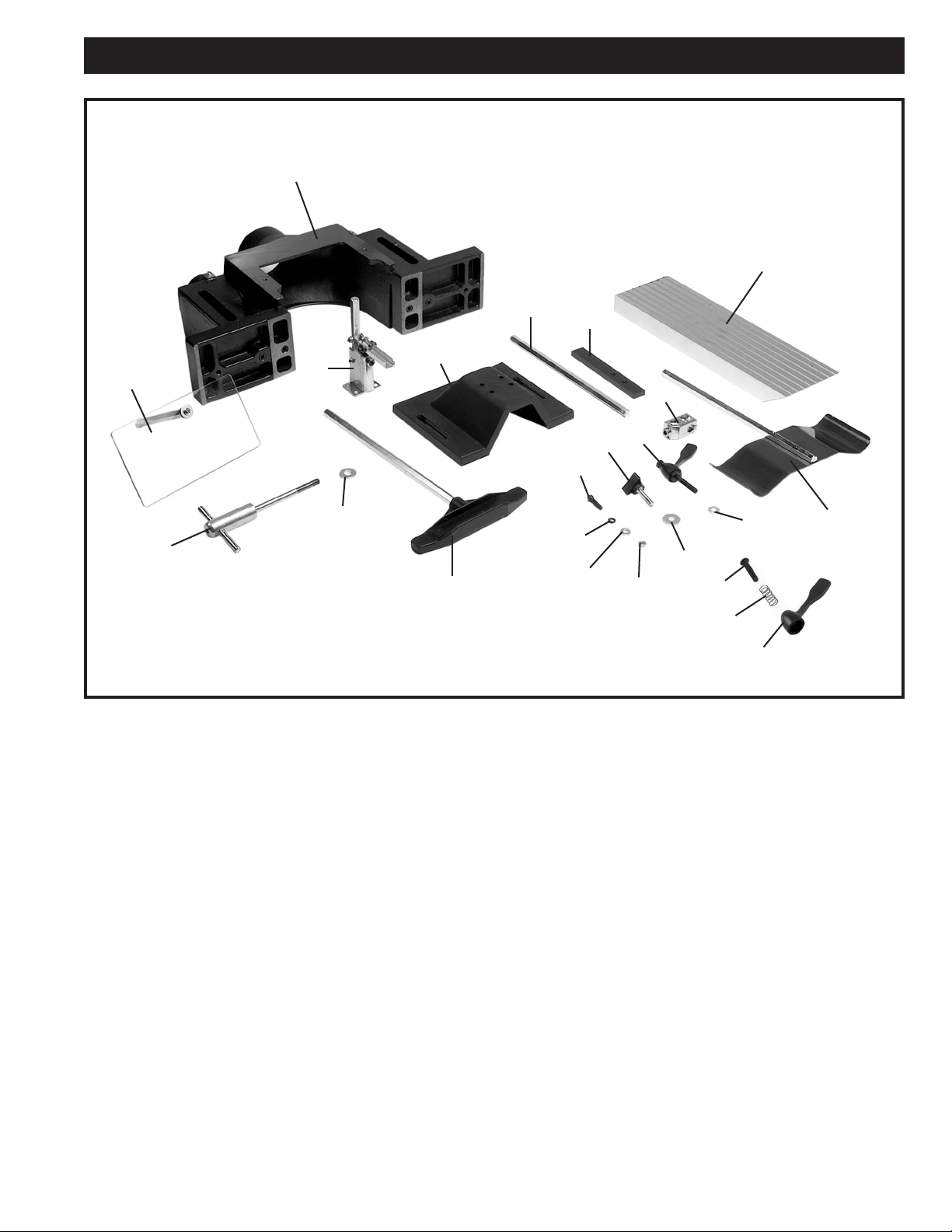

MODEL 43-812X CARTON CONTENTS

1. Fence Body

2. Left and Right fence halves (2)

3. Clear Plastic Guard

4. Guard Mounting Bracket

5. Top Cover

6. Rod for fence guard

7. Lock Bars (2) for fence halves

8. Fence Locking Handles (2) for mounting fence

to shaper

9. 1/2" Flat Washers (2) for fence locking handles

10. Holddown for fence guard

11. 1/4-20x1" Hex Soc. Hd. Screw (4) for mounting

guard mounting bracket to top cover

12. 1/4" Lock Washers for mounting guard mounting

bracket to top cover (4)

13. 1/4" Flat Washers for mounting guard mounting

bracket to top cover (4)

14. 1/4-20 Hex Nuts (4) for mounting guard mounting

bracket to top cover

15. Lock Knobs (2) for mounting top cover to

fence body

16. 1/2" Flat washers (2) for mounting top cover to

fence body

17. Locking Levers for fence halves (2)

18. 11/32" Flat Washers for locking levers (2)

19. Brackets for fence guard (4)

20. Spring clamp for fence guard

21. 1/4-20x1½" Pan Head Screw (2) for fence lock knob

22. Spring (2) for fence lock knob

23. Fence Lock Knob (2)

* 5/32" T-handle allen wrench (* not shown)

Fig. 2A

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

Page 4

4

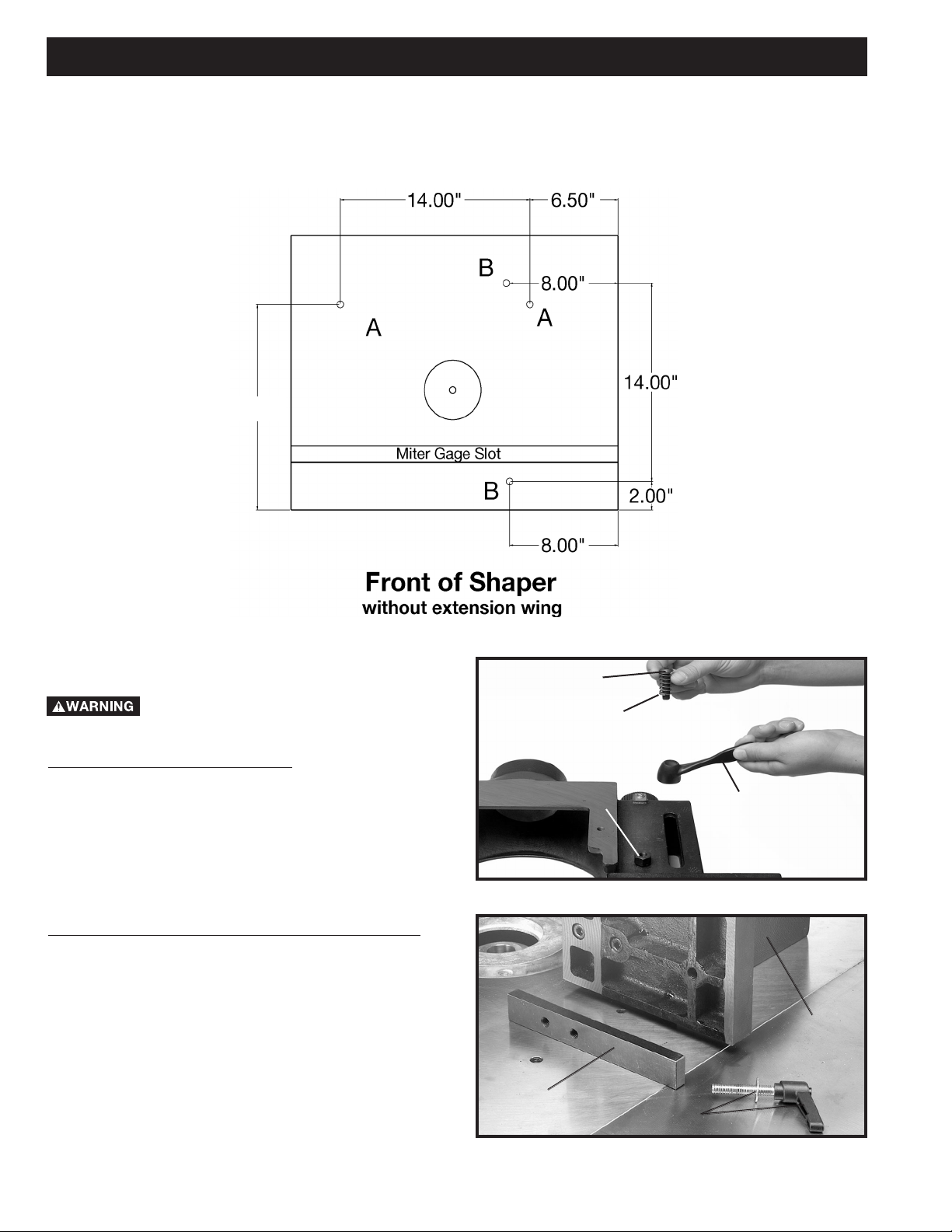

If you are assembling this fence to an early model Heavy Duty Shaper, the table will need to have four holes drilled and

tapped to accept the fence locking handles. The four holes are indicated at (A) and (B) Fig. 3. Using measurements

from Fig. 3, mark and drill the top of the shaper table in the desired locations using a 21/64" diameter drill bit, then tap

the four holes using a 3/8"-24 tap (not supplied). NOTE: Two holes (A) Fig. 3, will permit the fence to be mounted

parallel to the miter gage slot, and two holes (B) will permit the fence to be mounted 90 degrees to the miter gage slot.

Fig. 3

FENCE TO SHAPER TABLE

DISCONNECT MACHINE FROM

POWER SOURCE.

FOR MODEL 43-812X ONLY

1. Place the fence lock knob (A) Fig. 3A, on the hex

head screw (B). Place spring (C) on 1/4-20x1½" pan

head screw (D). Insert screw (D) through the hole in the

fence lock knob (A) and thread into the hex head screw

(B) and tighten securely. Repeat this process for the

remaining fence lock knob.

FOR BOTH MODELS 43-812 AND 43-812X

2. Place fence body (C) Fig. 4, on the table as shown,

and locate the two fence locking levers with 11/32"

washers (D) and fence lock bars (E).

Fig. 4

C

D

E

15.75"

ASSEMBLY

Fig. 3A

A

B

C

D

Page 5

5

Fig. 5

Fig. 6

Fig. 7

Fig. 9

Fig. 8

4. Locate the two fence locking handles and 1/2"

washers, one of which is shown at (F) Fig. 7, and fasten

fence body (C) through the slot in fence body to one of

the set of holes located on the shaper table illustrated in

Fig. 3.

5. Figure 8, illustrates fence body (C) fastened to the

table with the two fence locking handles (F).

6. Loosen locking lever (D) Fig. 9, and slide rear of

fence half (G) onto locking bar (E). Assemble remaining

fence half in the same manner. Then tighten locking

lever (D).

3. Fasten bar (E) to the front of the fence half using

the locking lever and 11/32" flat washers (D), as shown

in Figs. 5 and 6. Assemble the remaining bar to the other

fence half in the same manner. NOTE: Locking levers

(D) are spring-loaded and can be repositioned by

pulling out the handle and repositioning it on the nut

located underneath the hub of the handle.

D

E

E

D

F

C

F

C

G

E

D

Page 6

6

Fig. 10

Fig. 11

Fig. 13

Fig. 14

7. Align the four holes in the bottom of the guard

mounting bracket (H) Fig. 10 with the four holes in the

top of the top cover (J). Place a 1/4" lockwasher onto a

1/4-20x1" screw. Insert the screw through the hole in the

guard mounting bracket (H) and the top cover (J). Place

a 1/4" flat washer onto the screw and thread a 1/4-20

hex nut onto the screw and tighten securely. Repeat this

process for the three remaining holes in the guard

mounting bracket and the top cover.

8. Assemble top cover (J) Fig. 11, to top of fence body

(C) using the two locking knobs (K) and 1/2" flat washers

(L).

9. Fig. 12, illustrates top cover (J) properly assembled

to the fence body.

GUARDS TO FENCE BODY

1. Assemble guard bracket (A) Fig. 13, and hex rod (B)

to upright hex shaft (C) as shown.

2. Assemble two guard brackets (A) Fig. 14, and clear

plastic guard (D) to holddown (E) as shown.

H

J

M

N

O

P

J

C

K

L

Fig. 12

B

C

A

D

E

A

L

K

L

K

J

Page 7

7

Fig. 15

Fig. 16

Fig. 17

Fig. 18

3. Assemble holddown/clear plastic guard assembly to

hex rod (B) as shown in Fig. 15.

4. Assemble guard bracket (A) Fig. 16, and spring

clamp (F) to hex rod (B) as shown, then tighten all set

screws.

5. The spring guard (F), holddown (E), and clear plastic

guard (D) can be flipped up out of the way as shown

in Fig. 17, by lifting up on locking lever (G), when not in

use or when making adjustments. CAUTION: When the

guard assembly is in the down position as shown in

Fig. 16, make certain locking lever (G) is in the locked

position as shown.

6. Fig. 18, illustrates complete fence and guard

assembly mounted 90 degrees to miter gage slot.

B

B

A

G

F

F

E

D

G

Page 8

8

FENCE CONTROLS

AND ADJUSTMENTS

1. The fence halves (A) Fig. 19, should

be adjusted endwise so the opening at the spindle is

never more than is required to clear the cutter.

2. To adjust the fence halves (A) Fig. 19 endwise, loosen

the two fence locking levers (B), slide the fence halves to

the required positions, and tighten locking levers (B).

3. Each fence half (A) Fig. 19, can be moved

independently, in or out, depending on the type of

shaping operation that is being performed. To move the

fence halves in or out, loosen one of the lock knobs (C)

and turn one of the adjusting knobs (D), depending on

which fence half is being moved. Turn knob (D) until the

correct setting is obtained and tighten lock knob (C).

4. The complete fence assembly can be rapidly

positioned on the table by loosening two clamp handles

(E) Fig. 19, moving the fence assembly to the desired

position and tightening the two clamp handles (E).

5. Indicator pointers (F) Fig. 20, are supplied to give the

exact dimension each fence half is moved.

Make sure that the pointer does not rub

against the adjusting knobs, if the pointer does rub

against the adjustment knob the pointer will have to

be adjusted. Loosen the round head screw (G) Fig.

20, that holds the pointer to the fence assembly and

pull the pointer out until it does not come in contact

with the adjusting knob and then retighten the round

head screw.

Fig. 19

Fig. 20

OPERATING CONTROLS AND ADJUSTMENTS

Fig. 21

Fig. 22

6. Using a straight edge (G) Fig. 21, check to see if the two fence halves (H) are parallel to each

other. If parallelism cannot be achieved by adjusting one of the two fence halves (H) in or out,

shims (J) Fig. 22 (not supplied), can be placed between the fence mount (K) and the ram (M),

which is bolted to fence mount (K).

A

A

B

B

C

C

E

E

D

D

F

G

H

G

K

M

J

Page 9

9

Fig. 23

Fig. 24 Fig. 25

GUARD CONTROLS AND ADJUSTMENTS

DISCONNECT MACHINE FROM POWER SOURCE.

The spring clamp (A) Fig. 23, holddown (B), and clear plastic guard (C) are fully adjustable to

provide safe protection for most applications. NOTE: For certain applications, the spindle guard

supplied with the shaper may have to be used or a custom guard may need to be fabricated.

1. Using a square (not shown), check to see if shaft (D) Fig. 23, on spring clamp (A) is 90 degrees

to the table surface. If an adjustment is necessary, proceed as follows:

Lift up on guard locking handle (E) Fig. 24, loosen lock nut (F), and turn screw (G) until shaft (D)

Fig. 23, is 90 degrees to the table surface. Then tighten lock nut (F) Fig. 24.

Push down on guard locking handle (E) Figs. 24 and 25, until it locks in place as shown in Fig.

25. If the locking action is too loose or tight, loosen screw (H) Fig. 25, and adjust cam washer (J),

then tighten screw (H). Repeat this adjustment on the screw and cam washer located on the other

side of guard locking handle (E).

C

A

D

B

E

F

G

E

H

J

Page 10

10

4. Loosen set screws on guard mounting bracket (P) Fig. 27, and adjust spring clamp (N) so it will provide

inward pressure on workpiece, then tighten set screws. NOTE: Set screws on guard mounting bracket (R)

Fig. 27, can be loosened to provide additional extension of guard assembly.

TURN THE CUTTER BY HAND TO MAKE CERTAIN CUTTER DOES NOT CONTACT ANY

OF THE GUARDING OR FENCE HALVES BEFORE CONNECTING THE SHAPER TO

POWER SOURCE.

Always make certain guard locking handle (E) Fig. 27, is in the locked position as shown

and all set screws on guarding assembly are tight before turning shaper on.

Fig. 26

2. Adjust holddown (B) Fig. 26, by placing a piece of material which will be used on the table as shown.

Loosen set screws on guard mounting bracket (K) and adjust holddown (B) over top of workpiece to provide

some downward pressure and tighten set screws.

3. Adjust clear plastic guard (L) Fig. 26, by loosening set screws on guard mounting bracket (M) and

locating the guard so it will deflect the wood chips and provide protection from reaching the cutter, then

retighten set screws.

Fig. 27

K

L

M

B

P

E

R

N

Page 11

11

PARTS, SERVICE OR WARRANTY ASSISTANCE

All Delta Machines and accessories are manufactured to high quality standards and are serviced by a network

of Porter-Cable • Delta Factory Service Centers and Delta Authorized Service Stations. To obtain additional

information regarding your Delta quality product or to obtain parts, service, warranty assistance, or the location

of the nearest service outlet, please call 1-800-223-7278 (In Canada call 1-800-463-3582).

A complete line of accessories is available from your Delta Supplier, Porter-Cable • Delta Factory Service Centers,

and Delta Authorized Service Stations. Please visit our Web Site

www.deltamachinery.com for a catalog or

for the name of your nearest supplier.

Since accessories other than those offered by Delta have not been tested with this

product, use of such accessories could be hazardous. For

safest operation, only Delta

recommended accessories should be used with this product.

ACCESSORIES

Two Year Limited New Product Warranty

Delta will repair or replace, at its expense and at its option, any new Delta machine, machine part, or machine accessory

which in normal use has proven to be defective in workmanship or material, provided that the customer returns the product

prepaid to a Delta factory service center or authorized service station with proof of purchase of the product within two

years and provides Delta with reasonable opportunity to verify the alleged defect by inspection. For all refurbished Delta

product, the warranty period is 180 days. Delta may require that electric motors be returned prepaid to a motor

manufacturer’s authorized station for inspection and repair or replacement. Delta will not be responsible for any asserted

defect which has resulted from normal wear, misuse, abuse or repair or alteration made or specifically authorized by

anyone other than an authorized Delta service facility or representative. Under no circumstances will Delta be liable for

incidental or consequential damages resulting from defective products. This warranty is Delta’s sole warranty and sets

forth the customer’s exclusive remedy, with respect to defective products; all other warranties, express or implied, whether

of merchantability, fitness for purpose, or otherwise, are expressly disclaimed by Delta.

Page 12

The following are trademarks of PORTER-CABLE·DELTA (Las siguientes son marcas registradas de PORTER-CABLE S.A.): Auto-Set®,

BAMMER®, B.O.S.S.®, Builder’s Saw®, Contractor’s Saw®, Contractor’s Saw II™, Delta®, DELTACRAFT®, DELTAGRAM™, Delta Series

2000™, DURATRONIC™, Emc²™, FLEX®, Flying Chips™, FRAME SAW®, Homecraft®, INNOVATION THAT WORKS®, Jet-Lock®,

JETSTREAM®, ‘kickstand®, LASERLOC®, MICRO-SET®, Micro-Set®, MIDI LATHE®, MORTEN™, NETWORK™, OMNIJIG®, POCKET

CUTTER®, PORTA-BAND®, PORTA-PLANE®, PORTER-CABLE®&(design), PORTER-CABLE®PROFESSIONAL POWER TOOLS, Posi-Matic®,

Q-3®&(design), QUICKSAND®&(design), QUICKSET™, QUICKSET II®, QUICKSET PLUS™, RIPTIDE™&(design), SAFE GUARD II®, SAFELOC®, Sanding Center®, SANDTRAP®&(design), SAW BOSS®, Sawbuck™, Sidekick®, SPEED-BLOC®, SPEEDMATIC®, SPEEDTRONIC®,

STAIR EASE®, The American Woodshop®&(design), The Lumber Company®&(design), THE PROFESSIONAL EDGE®, THE PROFESSIONAL

SELECT®, THIN-LINE™, TIGER®, TIGER CUB®, TIGER SAW®, TORQBUSTER®, TORQ-BUSTER®, TRU-MATCH™, TWIN-LITE®,

UNIGUARD®, Unifence®, UNIFEEDER™, Unihead®, Uniplane™, Unirip®, Unisaw®, Univise®, Versa-Feeder®, VERSA-PLANE®, WHISPER

SERIES®, WOODWORKER’S CHOICE™.

Trademarks noted with ™ and ® are registered in the United States Patent and Trademark Office and may also be registered in other

countries. Las Marcas Registradas con el signo de ™ y ® son registradas por la Oficina de Registros y Patentes de los Estados Unidos y

también pueden estar registradas en otros países.

PORTER-CABLE • DELTA SERVICE CENTERS

(CENTROS DE SERVICIO DE PORTER-CABLE

• DELTA)

Parts and Repair Service for Porter-Cable •Delta Machinery are Available at These Locations

(Obtenga Refaccion de Partes o Servicio para su Herramienta en los Siguientes Centros de Porter-Cable

•

Delta)

Authorized Service Stations are located in many large cities. Telephone 800-438-2486 or 731-541-6042 for assistance locating one.

Parts and accessories for Porter-Cable

·

Delta products should be obtained by contacting any Porter-Cable·Delta Distributor, Authorized

Service Center, or Porter-Cable

·

Delta Factory Service Center. If you do not have access to any of these, call 800-223-7278 and you will

be directed to the nearest Porter-Cable

·

Delta Factory Service Center. Las Estaciones de Servicio Autorizadas están ubicadas en muchas

grandes ciudades. Llame al 800-438-2486 ó al 731-541-6042 para obtener asistencia a fin de localizar una. Las piezas y los accesorios

para los productos Porter-Cable

·

Delta deben obtenerse poniéndose en contacto con cualquier distribuidor Porter-Cable·Delta, Centro

de Servicio Autorizado o Centro de Servicio de Fábrica Porter-Cable

·

Delta. Si no tiene acceso a ninguna de estas opciones, llame al

800-223-7278 y le dirigirán al Centro de Servicio de Fábrica Porter-Cable

·

Delta más cercano.

ARIZONA

Tempe 85282 (Phoenix)

2400 West Southern Avenue

Suite 105

Phone: (602) 437-1200

Fax: (602) 437-2200

CALIFORNIA

Ontario 91761 (Los Angeles)

3949A East Guasti Road

Phone: (909) 390-5555

Fax: (909) 390-5554

San Leandro 94577 (Oakland)

3039 Teagarden Street

Phone: (510) 357-9762

Fax: (510) 357-7939

COLORADO

Arvada 80003 (Denver)

8175 Sheridan Blvd., Unit S

Phone: (303) 487-1809

Fax: (303) 487-1868

FLORIDA

Davie 33314 (Miami)

4343 South State Rd. 7 (441)

Unit #107

Phone: (954) 321-6635

Fax: (954) 321-6638

Tampa 33609

4538 W. Kennedy Boulevard

Phone: (813) 877-9585

Fax: (813) 289-7948

GEORGIA

Forest Park 30297 (Atlanta)

5442 Frontage Road,

Suite 112

Phone: (404) 608-0006

Fax: (404) 608-1123

ILLINOIS

Addison 60101 (Chicago)

400 South Rohlwing Rd.

Phone: (630) 424-8805

Fax: (630) 424-8895

Woodridge 60517 (Chicago)

2033 West 75th Street

Phone: (630) 910-9200

Fax: (630) 910-0360

MARYLAND

Elkridge 21075 (Baltimore)

7397-102 Washington Blvd.

Phone: (410) 799-9394

Fax: (410) 799-9398

MASSACHUSETTS

Braintree 02185 (Boston)

719 Granite Street

Phone: (781) 848-9810

Fax: (781) 848-6759

Franklin 02038 (Boston)

Franklin Industrial Park

101E Constitution Blvd.

Phone: (508) 520-8802

Fax: (508) 528-8089

MICHIGAN

Madison Heights 48071 (Detroit)

30475 Stephenson Highway

Phone: (248) 597-5000

Fax: (248) 597-5004

MINNESOTA

Minneapolis 55429

5522 Lakeland Avenue North

Phone: (763) 561-9080

Fax: (763) 561-0653

MISSOURI

North Kansas City 64116

1141 Swift Avenue

Phone: (816) 221-2070

Fax: (816) 221-2897

St. Louis 63119

7574 Watson Road

Phone: (314) 968-8950

Fax: (314) 968-2790

NEW YORK

Flushing 11365-1595 (N.Y.C.)

175-25 Horace Harding Expwy.

Phone: (718) 225-2040

Fax: (718) 423-9619

NORTH CAROLINA

Charlotte 28270

9129 Monroe Road, Suite 115

Phone: (704) 841-1176

Fax: (704) 708-4625

OHIO

Columbus 43214

4560 Indianola Avenue

Phone: (614) 263-0929

Fax: (614) 263-1238

Cleveland 44125

8001 Sweet Valley Drive

Unit #19

Phone: (216) 447-9030

Fax: (216) 447-3097

OREGON

Portland 97230

4916 NE 122 nd Ave.

Phone: (503) 252-0107

Fax: (503) 252-2123

PENNSYLVANIA

Willow Grove 19090

520 North York Road

Phone: (215) 658-1430

Fax: (215) 658-1433

TEXAS

Carrollton 75006 (Dallas)

1300 Interstate 35 N, Suite 112

Phone: (972) 446-2996

Fax: (972) 446-8157

Houston 77055

West 10 Business Center

1008 Wirt Road, Suite 120

Phone: (713) 682-0334

Fax: (713) 682-4867

WASHINGTON

Auburn 98001(Seattle)

3320 West Valley HWY, North

Building D, Suite 111

Phone: (253) 333-8353

Fax: (253) 333-9613

CANADIAN PORTER-CABLE • DELTA SERVICE CENTERS

ALBERTA

Bay 6, 2520-23rd St. N.E.

Calgary, Alberta

T2E 8L2

Phone: (403) 735-6166

Fax: (403) 735-6144

BRITISH COLUMBIA

8520 Baxter Place

Burnaby, B.C.

V5A 4T8

Phone: (604) 420-0102

Fax: (604) 420-3522

MANITOBA

1699 Dublin Avenue

Winnipeg, Manitoba

R3H 0H2

Phone: (204) 633-9259

Fax: (204) 632-1976

ONTARIO

505 Southgate Drive

Guelph, Ontario

N1H 6M7

Phone: (519) 836-2840

Fax: (519) 767-4131

QUÉBEC

1515 ave.

St-Jean Baptiste,

Québec, Québec

G2E 5E2

Phone: (418) 877-7112

Fax: (418) 877-7123

1447, Begin

St-Laurent, (Montréal),

Québec

H4R 1V8

Phone: (514) 336-8772

Fax: (514) 336-3505

Loading...

Loading...