Page 1

1

DATED 11-25-98

INSTRUCTION MANUAL

PART NO. 1349463

© Delta International Machinery Corp. 1998

18" Variable Speed Scroll Saw

(Model 40-650, Type 2)

Quick

Quality

Quiet

Page 2

2

TABLE OF CONTENTS

SAFETY RULES..................................................................................................................................3

ADDITIONAL SAFETY RULES FOR SCROLL SAWS ........................................................................4

UNPACKING AND CLEANING ........................................................................................................5-6

ASSEMBLY INSTRUCTIONS..............................................................................................................6

Assembling Stand ..............................................................................................................................6

Fastening Scroll Saw To Stand ..........................................................................................................7

Assembling Rear Leg Height Extension ............................................................................................8

Assembling Holddown Foot ..............................................................................................................8

Rotating Table To 90 Degree Position ................................................................................................8

Assembling Table Insert ....................................................................................................................8

CONNECTING SCROLL SAW TO POWER SOURCE........................................................................9

Extension Cords ................................................................................................................................9

Grounding Instructions ......................................................................................................................9

FASTENING STAND TO SUPPORTING SURFACE..........................................................................10

OPERATING CONTROLS AND ADJUSTMENTS

On-Off Power Switch........................................................................................................................10

Variable Speed Control ....................................................................................................................10

Locking On-Off Switch In The “OFF” Position ................................................................................10

Dust Blower ......................................................................................................................................11

Adjusting Blade Tension ..................................................................................................................11

Adjusting Clamping Action Of Blade Holders ..................................................................................12

Adjusting Holddown ........................................................................................................................12

Changing Blades ..............................................................................................................................13

Tilting The Table................................................................................................................................14

Adjusting 90 And 45 Degree Positive Stops For Table ....................................................................14

Aligning Lower Blade Holder With Upper Blade Holder ..................................................................15

Brush Inspection And Replacement ................................................................................................15

Fuse Replacement............................................................................................................................16

BLADE BREAKAGE ..........................................................................................................................16

CHOICE OF BLADE AND SPEED ....................................................................................................16

Page 3

3

Page 4

4

ADDITIONAL SAFETY RULES

FOR SCROLL SAWS

1. WARNING: Do not operate your scroll saw until it is

completely assembled and installed according to the

instructions.

2. IF YOU ARE NOT thoroughly familiar with the operation of Scroll Saws, obtain advice from your supervisor, instructor or other qualified person.

3. YOUR SCROLL SAW STAND MUST be fastened to

the floor if there is any tendency for the stand to move

during operation.

4. THIS SCROLL SAW is intended for indoor use only.

5. MAKE SURE blade is properly tensioned before

operating saw.

6. TO AVOID blade breakage ALWAYS adjust blade

tension correctly.

7. MAKE SURE the blade teeth point downward

toward the table.

8. NEVER turn the saw “ON” before clearing the table

of all objects (tools, scraps of wood, etc.).

9. DO NOT cut material that is too small to be safely

supported.

10. AVOID awkward hand positions where a sudden

slip could cause a hand to move into the blade.

11. ALWAYS keep hands and fingers away from blade.

12. ALWAYS adjust holddown foot for each new

operation.

13. DO NOT USE dull or bent blades.

14. DO NOT attempt to saw material that does not

have a flat surface, unless a suitable support is used.

15. MAKE “relief” cuts before cutting long curves.

16. NEVER attempt to cut a curve that is too tight for

the blade being used.

17. WHEN backing a blade out of a workpiece, the

blade may bind in the saw kerf. This is usually caused

by sawdust in the kerf. If this happens, turn “OFF” the

switch and remove plug from power source outlet.

Wedge open the kerf and back blade out of the workpiece.

18. ALWAYS hold the work firmly against the table.

19. DO NOT feed the material too fast while cutting.

Only feed the material fast enough so that the blade will

cut.

20. NEVER start the Scroll Saw with the stock pressed

against the blade.

21. WHEN cutting a large workpiece MAKE SURE the

material is supported at table height.

22. USE CAUTION when cutting material which is

irregular in cross section which could pinch the blade

before the cut is completed. A piece of moulding for

example must lay flat on the table and not be permitted to rock while being cut.

23. USE CAUTION when cutting round material such as

dowel rods or tubing. They have a tendency to roll

while being cut causing the blade to “bite.” Use a Vblock to control the piece.

24. ALWAYS release blade tension before loosening the

blade holder.

25. MAKE CERTAIN table tilting lock is tightened before

starting the machine.

26. NEVER reach under the table while the machine is

running.

27. NEVER perform layout, assembly or set-up work on

the table while the saw is operating.

28. ALWAYS STOP the saw before removing scrap

pieces from the table.

29. SHOULD any part of your Scroll Saw be missing,

damaged or fail in any way, or any electrical component

fail to perform properly, shut off switch and remove

plug from power supply outlet. Replace missing, damaged or failed parts before resuming operation.

30. ADDITIONAL INFORMATION regarding the safe and

proper operation of this product is available from the

National Safety Council, 1121 Spring Lake Drive, Itasca,

IL 60143-3201, in the Accident Prevention Manual for

Industrial Operations and also in the Safety Data Sheets

provided by the NSC. Please also refer to the American

National Standards Institute ANSI 01.1 Safety Requirements for Woodworking Machinery and the U.S. Department of Labor OSHA 1910.213 Regulations.

31. SAVE THESE INSTRUCTIONS. Refer to them frequently and use them to instruct other users.

Page 5

5

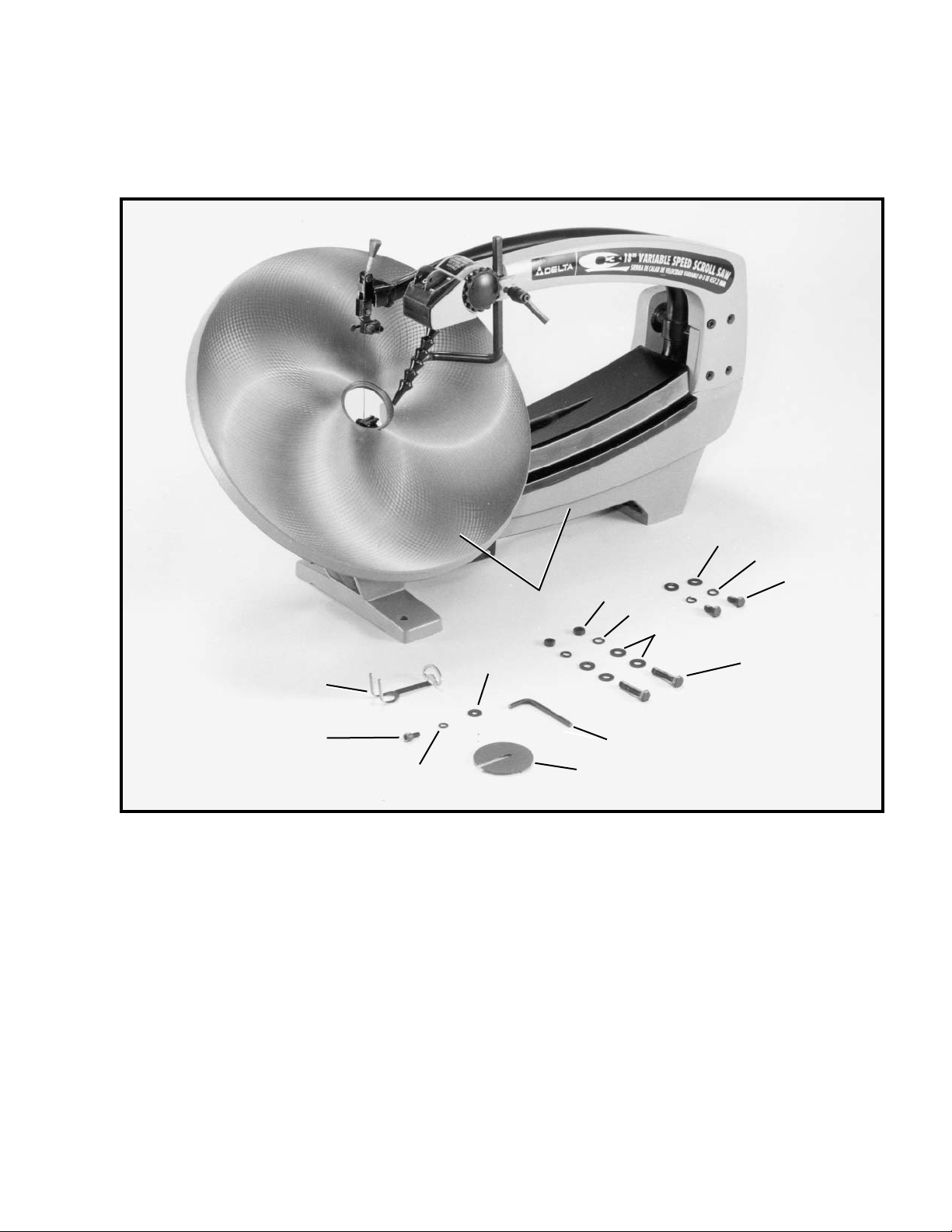

Fig. 2

UNPACKING AND CLEANING

Your new scroll saw and stand is shipped complete in one container. Carefully unpack the saw, stand and all loose

items from the shipping container. Figure 2 illustrates the saw and all loose items and Figure 3 illustrates the stand

and all related parts. Remove the protective coating from the saw table surface. This coating may be removed with a

soft cloth moistened with kerosene (do not use acetone, gasoline or lacquer thinner for this purpose). After cleaning,

cover the table surface with a good quality paste wax. Buff out the wax thoroughly to prevent it from rubbing into

your workpieces.

1 - Scroll Saw

2 - Holddown Foot

3 - 1/2" Long Hex Socket Head Screw - for

fastening holddown foot to rod

4 - Lockwasher - for fastening holddown foot

to rod

5 - Flat Washer - for fastening holddown foot

to rod

6 - Table Insert

7 - 5mm Wrench

8 - 1-1/2" Long Hex Head Screws - for fas-

tening front of saw to stand (2)

9 - Flat Washers - for fastening front of saw

to stand (4)

10 - Lockwashers - for fastening front of saw

to stand (2)

11 - Hex Nuts - for fastening front of saw to

stand (2)

12 - 5/8" Long Hex Head Screws - for fastening rear of saw to stand (2)

13 - Lockwashers - for fastening rear of saw

to stand (2)

14 - Flat washers - for fastening rear of saw to

stand (2)

12

13

14

18

9

10

11

1

2

5

4

3

7

6

Page 6

6

Fig. 3

ASSEMBLING STAND

1. Assemble the stand, as shown in Fig. 4,

using the 24 carriage bolts, flat washers and

hex nuts. NOTE: The round holes on the top

of the two top braces (A) are to be positioned

toward the rear leg (B) and all three legs are

positioned outside the bottom shelf and top

braces. DO NOT TIGHTEN STAND MOUNTING HARDWARE AT THIS TIME.

ASSEMBLY INSTRUCTIONS

WARNING: FOR YOUR OWN SAFETY, DO NOT CONNECT THE SCROLL SAW TO THE POWER

SOURCE UNTIL THE MACHINE IS COMPLETELY ASSEMBLED AND YOU HAVE READ AND

UNDERSTOOD THE ENTIRE OWNERS MANUAL.

20 - Height Adjustment Bracket for rear leg

21 - Flat Washers (28)

22 - 5/8" long (8mm) Carriage Bolts (28)

23 - Hex Nuts (28)

15 - Bottom Shelf

16 - Legs (3)

17 - Left Top Brace

18 - Right Top Brace

19 - Front Top Brace

Fig. 4

15

18

17

19

20

21

22

23

16

A

A

B

Page 7

7

Fig. 5

Fig. 6

Fig. 7

Fig. 8

3. Figure 8 illustrates the saw (H) fastened to

the stand (J). Place the stand on a level surface and securely tighten all stand mounting

hardware.

2. Fasten the rear of the saw to the stand

using the two

5/8" long screws (F) Fig. 6, and lock washers

(G). The 5/8" long screws (F) are also shown in

Fig. 7, and are threaded up into the threaded

holes located on bottom of saw base.

FASTENING SCROLL SAW

TO STAND

1. Place scroll saw on top braces of stand

and fasten front of saw to top front brace

using the two 1-1/2" long screws (A) Fig. 5,

flat washers (B) and two flat washers (C), lock

washers (D) and hex nuts (E) from below.

B

A

C

B

A

D

E

H

J

G

F

F

F

Page 8

8

Fig. 9

Fig. 10

Fig. 11

Fig. 12

ASSEMBLING

HOLDDOWN FOOT

1. With wrench supplied, assemble holddown

foot (A) Fig. 10, to rod (B) using 1/2² hex socket head screw (C)

with lockwasher and flat washer. Prongs of

holddown foot (A) should straddle blade.

2. Adjustment to holddown rod (B) Fig. 10,

can be made by loosening lock handle (D) and

raising or lowering rod (B). Tighten lock handle

(D). NOTE: Lock handle (D) Fig.10, is springloaded and can be repositioned by pulling

outward on the handle and repositioning it on

the stud located underneath the hub of handle

(D).

ASSEMBLING REAR LEG

HEIGHT EXTENSION

1. A height extension (A) Fig. 9, is supplied

with your stand and can be assembled to the

rear leg of the stand, as shown, using the four

carriage bolts (B), flat washers and nuts supplied. The height extension enables you to tilt

the saw forward during operation if desired.

Five holes are supplied in the extension (A) to

vary the degree of tilt.

ROTATING TABLE TO

90 DEGREE POSITION

1. The saw is shipped with the table tilted 45

degrees to the right, as shown in Fig. 11. To

move the table to the 90 degree position,

loosen lock handle (A) and rotate table all the

way to the left. Then tighten lock handle (A).

NOTE: Lock handle (A) is spring-loaded and

can be repositioned by pulling out the handle

and repositioning it on the stud located underneath the hub of the handle.

2. Fig. 12 illustrates the table (B) in the 90

degree position.

ASSEMBLING TABLE INSERT

1. Assemble the table insert (C) Fig. 12, to

opening in the center of the table (B) as

shown.

A

C

B

D

A

B

C

B

A

Page 9

9

CONNECTING SCROLL SAW TO POWER SOURCE

IMPORTANT: BEFORE CONNECTING THE SAW TO THE POWER LINE, MAKE SURE THE SWITCH IS IN THE “OFF”

POSITION.

Fig. 15Fig. 14

GROUNDED OUTLET BOX

CURRENT

CARRYING

PRONGS

GROUNDING BLADE IS

LONGEST OF THE 3 BLADES

GROUNDED OUTLET BOX

GROUNDING MEANS

ADAPTER

In the event of a malfunction or breakdown, grounding

provides a path of least resistance for electric current to

reduce the risk of electric shock. This tool is equipped

with an electric cord having an equipment-grounding

conductor and a grounding plug. The plug must be

plugged into a matching outlet that is properly installed

and grounded in accordance with all local codes and

ordinances.

Do not modify the plug provided - if it will not fit the outlet, have the proper outlet installed by a qualified electrician.

Improper connection of the equipment-grounding conductor can result in risk of electric shock. The conductor

with insulation having an outer surface that is green with

or without yellow stripes is the equipment-grounding

conductor. If repair or replacement of the electric cord or

plug is necessary, do not connect the equipment

grounding conductor to a live terminal.

Check with a qualified electrician or service personnel if

the grounding instructions are not completely understood, or if in doubt as to whether the tool is properly

grounded.

Use only 3-wire extension cords that have 3-prong

grounding type plugs and 3-hole receptacles that accept

the tool's plug, as shown in Fig. 14.

Repair or replace damaged or worn cord immediately.

If a properly grounded outlet is not available, a temporary

adapter, shown in Fig. 15, may be used for connecting

the 3-prong grounding type plug to a 2-prong receptacle.

The temporary adapter should be used only until a properly grounded outlet can be installed by a qualified electrician. The green colored rigid ear, lug, or the like

extending from the adapter must be connected to a permanent ground such as a properly grounded outlet box

cover. Whenever the adapter is used, it must be held in

place with a metal screw.

NOTE: In Canada, the use of a temporary adapter is

not permitted by the Canadian Electric Code.

CAUTION: IN ALL CASES, MAKE CERTAIN THE

RECEPTACLE IN QUESTION IS PROPERLY

GROUNDED. IF YOU ARE NOT SURE, HAVE A CERTIFIED ELECTRICIAN CHECK THE RECEPTACLE.

GROUNDING INSTRUCTIONS

CAUTION: THIS TOOL MUST BE GROUNDED WHILE IN USE TO PROTECT THE OPERATOR FROM ELECTRIC

SHOCK.

EXTENSION CORDS

The use of any extension cord will cause some loss of

power. To keep this loss to a minimum, make sure the

extension cord is in good condition and is a 3-wire extension cord which has a 3-prong grounding type plug

and a

3-pole receptacle which will accept the tool’s plug. When

using an extension cord, be sure to use one heavy

enough to carry the current of the scroll saw. An undersized cord will cause a drop in line voltage resulting in

loss of power and overheating. Fig. 13, shows the correct size to use depending on cord length. If in doubt,

use the next heavier gage. The smaller the gage number,

the heavier the cord.

Fig. 13

EXTENSION CORD SIZE

LENGTH OF EXTENSION

CORD IN FEET

120 VOLT WIRE SIZE REQUIRED

(AWG - American Wire Gage)

18 AWG

16 AWG

16 AWG

14 AWG

0-25

26 - 50

51 - 100

101 - 150

Page 10

10

FASTENING STAND TO SUPPORTING SURFACE

If there is any tendency for the scroll saw to move during operation, the scroll saw stand must be

fastened to the floor.

Fig. 17

OPERATING CONTROLS AND ADJUSTMENTS

ON-OFF POWER SWITCH

The on-off switch (A) Fig. 16, is located on the top of the arm, as shown. To turn the saw “ON” push

down on the “ON” portion of the switch and to turn the saw “OFF” push down on the “OFF” portion of the switch.

VARIABLE SPEED CONTROL

Your scroll saw can be operated at speeds of 300 to 2000 cutting strokes per minute by rotating

control knob (B) Fig. 16. With the control knob (B) rotated all the way toward the front of the

machine the speed will be 300 cutting strokes per minute and with the control knob (B) rotated all

the way to the rear, the speed will be 2000 cutting strokes per minute. A series of numbers are provided on the control knob, as shown, and a witness line (C) is provided on the arm to be used for

reference.

Fig. 16

LOCKING ON-OFF SWITCH

IN “OFF” POSITION

IMPORTANT: We suggest that when the scroll

saw is not in use, the on-off switch be locked in

the “OFF” position using a padlock (A), as

shown in Fig. 17. Available as an accessory

from Delta is the 50-325 padlock, shown at (A).

A

C

B

A

Page 11

11

Fig. 18

DUST BLOWER

A dust blower (A) Fig. 18, is provided, and can

be moved to direct air to the most effective

point on the cutting line.

ADJUSTING BLADE TENSION

Tension is applied to the blade when the blade tension lever (A) Fig. 19, is in the rear position, as

shown. When the lever (A) is moved forward, as shown in Fig. 20, blade tension is released.

To increase tension on the blade, rotate tension lever (A) Fig. 20, clockwise; to decrease blade tension, rotate tension lever counterclockwise. NOTE: When adjusting blade tension, the lever (A) Fig.

20, should be in the full forward position.It is only necessary to adjust blade tension knob when a

different type of blade is assembled to the blade holders. It is not necessary to adjust blade tension

when the blade is removed from and replaced in only the upper blade holder, as in performing inside

cutting operations. Adjusting proper tension on the blade is usually accomplished by trial and error;

however, a good method to use is to pluck the rear of the blade like guitar string after the tension

lever is moved to the rear. A high-pitched tone of the blade usually indicates proper tension. Thicker

blades require more tension (a higher pitched sound) while finer blades require less tension.

Fig. 20Fig. 19

A

A

A

Page 12

12

ADJUSTING CLAMPING ACTION OF BLADE HOLDERS

Different widths of scroll saw blades will make it necessary to adjust the clamping action of the blade holders. It should

be noted, however, that very little adjustment is necessary and very little clamping force is required to hold the blade

satisfactorily. As a rule of thumb, looking down at the table with the table insert slot in the 6 o’clock position, resistance

on the blade locking lever should be felt when the upper blade locking lever reaches the 7 o’clock position, or when

the lower blade locking lever reaches the 5 o’clock position.

Fig. 21

Fig. 22

Fig. 23

ADJUSTING HOLDDOWN

1. The holddown (A) Fig. 23, should be adjusted so it

contacts the top surface of the work being cut by loosening lock handle (B) and moving holddown rod (C) up or

down. Then tighten lock handle (B).

2. When bevel cutting (table tilted), the holddown (A)

Fig. 23, can be tilted to match the angle of the table by

loosening screw (D), tilting holddown (A) and tightening

screw (D).

1. Move the blade holder clamping lever (A) Fig. 21, to

the rear (open) position as shown.

2. Turn adjustment knob (B) Fig. 21, clockwise to tighten or counterclockwise to loosen the clamping action on

the blade holder. NOTE: Very little movement of the knob

(B) is necessary to make the adjustment.

A

B

A

C

D

3. Move lever (A) Fig. 22, forward after adjusting the

blade clamping action.

4. Adjust clamping action on lower blade holder in the

same manner.

Page 13

13

Fig. 25

3. Push blade holder clamping lever (C) Fig. 25, to the

rear as shown. This will automatically release the blade

(D) from the upper blade holder (E).

4. Push lower blade holder clamping lever (F) Fig. 26,

to the rear. This will automatically release blade (D) from

lower chuck.

5. Remove blade from lower chuck.

6. Insert new blade into the lower and upper blade

holders in the same manner, making certain the blade

teeth are pointing down toward the table.

7. Apply blade tension by referring to section, “ADJUSTING BLADE TENSION.” NOTE: NEVER push down

on blade tension knob (B) Fig. 25, to compress tension

spring.

C

E

D

CHANGING BLADES

1. WARNING: TO AVOID INJURY FROM ACCIDENTAL

STARTING, ALWAYS TURN SWITCH “OFF” AND REMOVE POWER CORD PLUG FROM ELECTRICAL OUTLET BEFORE REMOVING OR REPLACING BLADE.

2. Remove table insert (A) Fig. 24, and release blade

tension by pulling tension lever (B) forward, as shown.

Fig. 24

A

B

Fig. 26

F

D

B

Page 14

14

Fig. 27

Fig. 28

Fig. 29

Fig. 31

ADJUSTING 90 AND 45

DEGREE POSITIVE STOPS

FOR TABLE

1. Loosen table lock handle and move the table all the

way to the left and tighten table lock handle.

2. Using a square (A) Fig. 29, check to see if the table

is 90 degrees to the saw blade, as shown.

3. If the table is not at 90 degrees to the blade, adjust

the table accordingly, making certain screw (B) Fig. 30,

contacts bottom of table surface when table is 90

degrees to the blade. Screw (B) can be adjusted by

loosening nut (C), thread screw (B) in or out the desired

distance and tighten nut (C).

4. Tilt table all the way to the right, as shown in Fig.

31,

and tighten table lock handle.

5. Using a square (D) Fig. 31, check to see if the table

is 45 degrees to the saw blade, as shown.

6. If the table is not at 45 degrees to the blade, adjust

the table accordingly, making certain screw (E) Fig. 30,

contacts side of base when the table is at 45 degrees

to the blade.

TILTING THE TABLE

1. The table on your scroll saw can be tilted up to 45

degrees to the right for bevel cutting operations by loosening table lock handle (A) Fig. 27. Tilt the table to the

desired angle and tighten lock handle (A). A scale and

pointer (B) Fig. 27, is provided to determine the angle of

tilt.

2. The table can also be tilted up to 15 degrees to the

left for bevel cutting operations by lowering the stop

block (C) Fig. 27, and tilting the table to the desired

angle, as shown in Fig. 28. Tighten lock handle (A).

Fig. 30

B

A

C

C

A

C

B

E

D

Page 15

15

BRUSH INSPECTION

AND REPLACEMENT

CAUTION: BEFORE INSPECTING THE BRUSHES, DISCONNECT THE MACHINE FROM THE

POWER SOURCE.

Brush life varies. It depends on the load on

the motor. Check the brushes after the first 50

hours of use for a new machine or after a new

set of brushes has been installed. After the

first check, examine them after about 10

hours of use until such time that replacement

is necessary.

The brush holders, one of which is shown at

(A) Fig. 34, are located i-n the motor housing

opposite each other. Fig. 35 illustrates one of

the brushes removed for inspection. When the

carbon (B) on either brush is worn to 3/16" in

length or if either spring (C) or shunt wire is

burned or damaged in any way, replace both

brushes. If the brushes are found serviceable

after removing, reinstall them in the same

position as removed.

Fig. 32

Fig. 33

Fig. 34

Fig. 35

ALIGNING LOWER BLADE

HOLDER WITH UPPER

BLADE HOLDER

The lower blade holder has been aligned with

the upper blade holder at the factory and further alignment should not be necessary; however, to check or adjust the alignment, proceed as follows:

1. MAKE CERTAIN THE MACHINE IS DISCONNECTED FROM THE POWER SOURCE.

2. Remove the table insert and place a small

straight edge (A) Fig. 32, against the side of

the saw blade (B) as shown in Fig. 32.

3. While holding the straight edge (A) Fig. 32,

against the saw blade, carefully move the cutting arm (E) up and down in a cutting motion.

CAUTION: Do not use excessive force on the

cutting arm. The saw blade should contact the

straight edge during the entire cutting stroke.

4. If an alignment is necessary, rotate adjustment screw (C) Fig. 33, to move the lower

blade holder (D) left or right, until the saw

blade is in consistent contact with the straight

edge during the entire cutting stroke.

A

B

C

D

A

B

C

E

Page 16

16

BLADE BREAKAGE

Blade breakage is usually caused by one or more of the following:

1. Bending the blade during installation.

2. Improper blade tension.

3. Improper blade selection for the work

being cut.

4. Forcing the work into the blade too rapidly.

5. Cutting too sharp a turn for the blade

being used.

6. Improper blade speed.

CHOICE OF BLADE AND SPEED

Your scroll saw will accept a wide variety of 5" flat end blades and can be operated at any speed

from 300 to 2000 cutting strokes per minute. Consider the following as a general guideline for

selecting a blade and operating speed.

1. Use a finer blade for cutting thin workpieces, for hard materials, or when a smoother cut is

required.

2. Use a coarser blade for cutting thick workpieces, when making straight cuts or for medium

to soft materials.

3. Use a blade that will have 2 teeth in the workpiece at all times.

4. Most blade packaging is marked with the size of the wood the blade is intended to cut and

the minimum radius which can be cut with that blade.

5. Slower speeds are generally more effective than faster speeds when using thin blades and

making intricate cuts.

6. Always start at a slow speed and gradually increase the speed until the optimum cutting

speed is obtained.

Fig. 36

FUSE REPLACEMENT

A fuse holder (A) Fig. 36, and fuse (B) are

located up under the rear of the machine and

should be removed and checked if the

machine does not operate. If the fuse (B) is

bad, replace it with a 4 amp fuse.

B

A

Loading...

Loading...