Page 1

DELTA 6 in. x 89 in. OsciLLATing

EDgE sAnDEr

Ponceuse oscillante pour champs de

15,24 cm x 226,06 cm

Lijadora de borde oscilante de

15,24 cm x 226,06 cm

Français (16)

Español (30)

www.DeltaMachinery.com

Operating Instructions and Parts Manual

Manuel d’utilisation

Manual de instrucciones

INSTRUCTIVO DE OPERACIÓN, CENTROS

DE SERVICIO Y PÓLIZA DE GARANTÍA.

LÉASE ESTE INSTRUCTIVO

ANTES DE USAR EL PRODUCTO.

31-482

Page 2

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS ................................... 2

SAFETY GUIDELINES - DEFINITIONS .................................... 3

GENERAL SAFETY RULES ...................................................... 3

POWER CONNECTIONS .......................................................... 5

MOTOR SPECIFICATIONS ....................................................... 5

GROUNDING INSTRUCTIONS ................................................ 5

EXTENSION CORDS ................................................................ 6

KEY FEATURES AND COMPONENTS .................................... 6

FUNCTIONAL DESCRIPTION .................................................. 7

PRODUCT SPECIFICATIONS ................................................... 7

UNPACKING ..............................................................................7

ASSEMBLY ................................................................................ 8

Cabinet Assembly ............................................................... 8

Mounting the Table to the Cabinet ...................................... 8

Sanding Belt ........................................................................ 9

Drum Guard ......................................................................... 9

Contour Sanding Table ...................................................... 10

Workpiece Support ............................................................10

Sanding Fence ................................................................... 11

ADJUSTMENTS ....................................................................... 11

Changing the Sanding Angle ............................................ 11

Re-tensioning the Platen Locking Lever ........................... 11

Changing the Sanding Belt ............................................... 11

Adjusting the Belt Tracking................................................ 12

Adjusting the Motor Mount Tracking ................................ 12

Re-positioning the Table Height ........................................ 12

MAINTENANCE PROCEDURES ............................................ 13

Routine Inspection

Lubrication

Cleaning the Sanding Belts

TROUBLESHOOTING ............................................................. 13

ACCESSORIES ........................................................................ 14

WARRANTY .............................................................................14

FRANÇAIS ................................................................................ 16

ESPAÑOL .................................................................................32

IMPORTANT SAFETY INSTRUCTIONS

READ AND UNDERSTAND ALL WARNINGS AND OPERATING INSTRUCTIONS BEFORE USING THIS

EQUIPMENT. Failure to follow all instructions listed below, may result in electric shock, fire, and/or

serious personal injury or property damage.

Woodworking can be dangerous if safe and proper operating procedures are not followed. As with all

machinery, there are certain hazards involved with the operation of the product. Using the machine with

respect and caution will considerably lessen the possibility of personal injury. However, if normal safety

precautions are overlooked or ignored, personal injury to the operator may result. Safety equipment such

as guards, push sticks, hold-downs, featherboards, goggles, dust masks and hearing protection can reduce your

potential for injury. But even the best guard won’t make up for poor judgment, carelessness or inattention. Always

use common sense and exercise caution in the workshop. If a procedure feels dangerous, don’t try it. Figure out

an alternative procedure that feels safer. REMEMBER: Your personal safety is your responsibility. For additional

information please visit our website www.DeltaMachinery.com.

This machine was designed for certain applications only. DELTA® Power Equipment Corporation

strongly recommends that this machine not be modified and/or used for any application other than

that for which it was designed. If you have any questions relative to a particular application, DO NOT use the

machine until you have first contacted DELTA® to determine if it can or should be performed on the product.

If you have any questions relative to its application DO NOT use the product until you have written DELTA

Equipment Corporation and we have advised you. Contact us online at www.DeltaMachinery.com or by mail at

Technical Service Manager, DELTA® Power Equipment Corporation, 4825 Highway 45 North, Jackson, TN 38305.

Information regarding the safe and proper operation of this tool is available from the following sources:

• Power Tool Institute, 1300 Sumner Avenue, Cleveland, OH 44115-2851or online at www.powertoolinstitute.com

• National Safety Council, 1121 Spring Lake Drive, Itasca, IL 60143-3201

• American National Standards Institute, 25 West 43rd Street, 4 floor, New York, NY 10036 www.ansi.org - ANSI 01.1

Safety Requirements for Woodworking Machines

• U.S. Department of Labor regulations www.osha.gov

®

Power

2

Page 3

SAFETY GUIDELINES - DEFINITIONS

This manual contains information that is important for you to know and understand. This information relates to

protecting YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we

use the symbols below. Please read the manual and pay attention to these sections.

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious

injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious

injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate

injury.

Used without the safety alert symbol indicates potentially hazardous situation which, if not avoided,

may result in property damage.

GENERAL SAFETY RULES

WARNING FAILURE TO FOLLOW THESE RULES MAY RESULT IN SERIOUS PERSONAL INJURY.

FOR YOUR OWN SAFETY, READ AND UNDERSTAND THE INSTRUCTION MANUAL BEFORE OPERATING THE

•

UNIT.

Learn the unit’s application and limitations as well as the specific hazards peculiar to it.

KEEP WORK AREA CLEAN.

•

DON’T USE IN DANGEROUS ENVIRONMENT.

•

Keep work area well-lighted.

KEEP CHILDREN AND VISITORS AWAY.

•

DISCONNECT UNIT

•

CHECK DAMAGED PARTS.

•

before servicing.

Cluttered areas and benches invite accidents.

Don’t use this unit in damp or wet locations, or expose it to rain.

All children and visitors should be kept a safe distance from work area.

Before further use of the unit, properly repair or replace any part that is damaged.

FAILURE TO FOLLOW THESE RULES MAY RESULT IN SERIOUS INJURY.

1. Read and understand the warnings posted on the

machine and in this manual. Failure to comply with

all of these warnings may cause serious injury.

2. Replace the warning labels if they become

obscured or removed.

3. This Oscillating Edge Sander is designed

and intended for use by properly trained and

experienced personnel only. If you are not familiar

with the proper and safe operation of an edge

sander, do not use until proper training and

knowledge have been obtained.

4. Do not use this machine for other than its intended

use. If used for other purposes, Delta Power

Equipment Company, Inc. disclaims any real or

implied warranty and holds itself harmless from any

injury that may result from that use.

5. Always wear approved safety glasses/face shields

while using this Oscillating Edge Sander.

6. Before operating this edge sander, remove tie,

rings, watches and other jewelry, and roll sleeves

up past the elbows. Remove all loose clothing and

confine long hair. Non-slip footwear or anti-skid

floor strips are recommended. Do not wear gloves.

7. Wear ear protectors (plugs or muffs) during

extended periods of operation.

8. Some dust created by power sanding, sawing,

grinding, drilling and other construction activities

contain chemicals known to cause cancer,

birth defects or other reproductive harm. Some

examples of these chemicals are:

• Lead from lead based paint.

• Crystalline silica from bricks, cement and other

masonry products.

• Arsenic and chromium from chemically treated

lumber.

Your risk of exposure varies, depending on how often

you do this type of work. To reduce your exposure to

these chemicals, work in a well-ventilated area and

work with approved safety equipment, such as face or

dust masks that are specifically designed to filter out

microscopic particles.

1. Do not operate this machine while tired or under

the influence of drugs, alcohol or any medication.

2. Make certain the switch is in the OFF position

before connecting the machine to the power

source.

3. Make certain the machine is properly grounded.

4. Make all machine adjustments or maintenance with

the machine unplugged from the power source.

continued on page 4

3

Page 4

5. Form a habit of checking to see that all extra

equipment such as adjusting keys, wrenches,

scrap, stock, and cleaning rags are removed away

from the machine before turning on.

6. Keep safety guards in place at all times when the

machine is in use. If removed for maintenance

purposes, use extreme caution and replace the

guards immediately when maintenance is complete.

7. Make sure the edge sander is firmly secured to the

floor before use.

8. Check damaged parts. Before further use of the

machine, a guard or other part that is damaged

should be carefully checked to determine that it will

operate properly and perform its intended function.

Check for alignment of moving parts, binding of

moving parts, breakage of parts, mounting and

any other conditions that may affect its operation.

A guard or other part that is damaged should be

properly repaired or replaced.

9. Provide for adequate space surrounding work area

and non-glare, overhead lighting.

10. Keep the floor around the machine clean and free of

scrap material, oil and grease.

11. Keep visitors a safe distance from the work area.

Keep children away.

12. Make your workshop child proof with padlocks,

master switches or by removing starter keys.

13. Give your work undivided attention. Looking

around, carrying on a conversation and “horseplay” are careless acts that can result in serious

injury.

14. Maintain a balanced stance at all times so that you

do not fall or lean against the sanding belt or other

moving parts. Do not overreach or use excessive

force to perform any machine operation.

15. Use the right tool at the correct speed and feed

rate. Do not force a tool or attachment to do a job

for which it was not designed. The right tool will do

the job better and safer.

16. Use recommended accessories; improper

accessories may be hazardous.

17. Maintain machinery with care. Follow instructions

for lubricating and changing accessories.

18. Turn off the machine before cleaning. Use a brush

or compressed air to remove dust or debris — do

not use your hands.

19. Do not stand on the machine. Serious injury could

occur if the machine tips over.

20. Never leave the machine running unattended. Turn

the power off and do not leave the machine until it

comes to a complete stop.

21. At all times hold the stock firmly.

22. Do not use this sander for other than it intended

use. If used for other purposes, Delta Power

Equipment Company Inc., disclaims any real or

implied warranty and holds itself harmless for any

injury or damage which may result from that use.

SAVE THESE INSTRUCTIONS.

Refer to them often and use them to instruct others.

4

Page 5

POWER CONNECTIONS

A separate electrical circuit should be used for your machines. This circuit should not be less than #12 wire and

should be protected with a 20 Amp time lag fuse. If an extension cord is used, use only 3-wire extension cords

which have 3-prong grounding type plugs and matching receptacle which will accept the machine’s plug. Before

connecting the machine to the power line, make sure the switch (s) is in the "OFF" position and be sure that the

electric current is of the same characteristics as indicated on the machine. All line connections should make good

contact. Running on low voltage will damage the machine.

DO NOT EXPOSE THE MACHINE TO RAIN OR OPERATE THE MACHINE IN DAMP LOCATIONS.

MOTOR SPECIFICATIONS

Your machine is wired for 120/240 volts, 60 HZ alternating current. Before connecting the machine to the power

source, make sure the switch is in the "OFF" position.

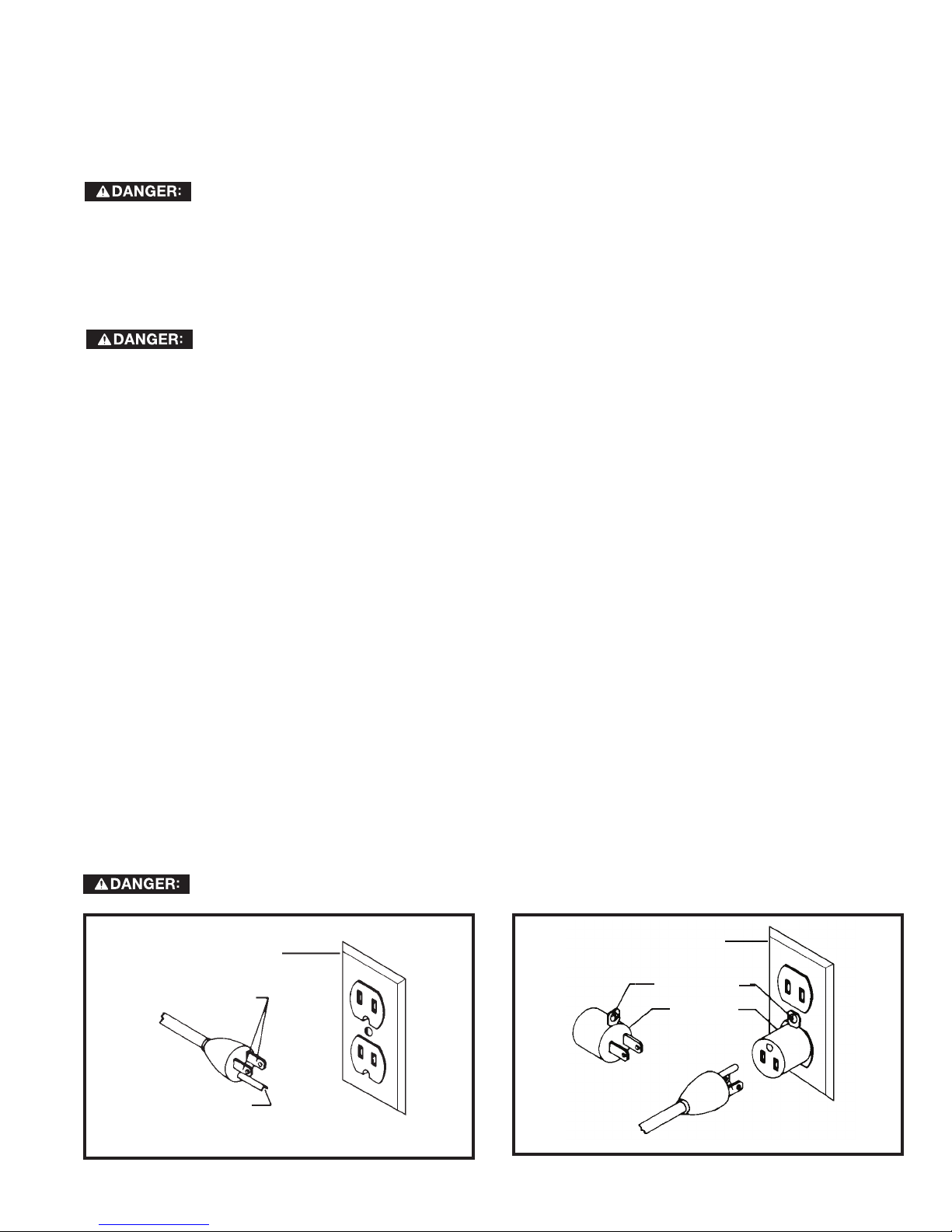

GROUNDING INSTRUCTIONS

THIS MACHINE MUST BE GROUNDED WHILE IN USE TO PROTECT THE OPERATOR FROM

ELECTRIC SHOCK.

1. All grounded, cord-connected machines:

In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current to

reduce the risk of electric shock. This machine is equipped with an electric cord having an equipment-grounding

conductor and a grounding plug. The plug must be plugged into a matching outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

Do not modify the plug provided - if it will not fit the outlet, have the proper outlet installed by a qualified electrician.

Improper connection of the equipment-grounding conductor can result in risk of electric shock. The conductor with

insulation having an outer surface that is green with or without yellow stripes is the equipment-grounding conductor.

If repair or replacement of the electric cord or plug is necessary, do not connect the grounding conductor to a live

terminal.

Check with a qualified electrician or service personnel if the grounding instructions are not completely understood,

or if in doubt as to whether the machine is properly grounded.

Use only 3-wire extension cords that have 3-prong grounding type plugs and matching 3-conductor receptacles that

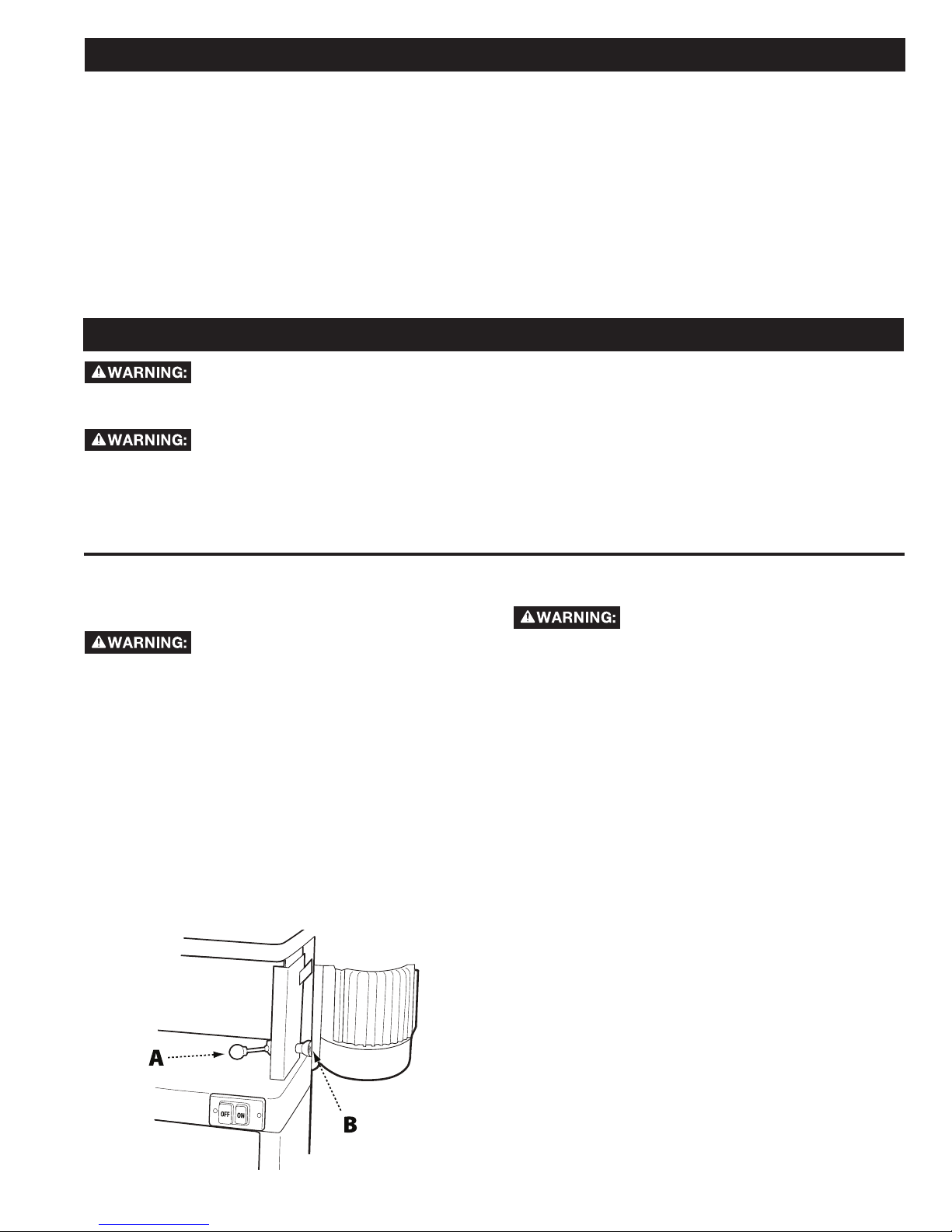

accept the machine’s plug, as shown in Fig. A.

Repair or replace damaged or worn cord immediately.

2. Grounded, cord-connected machines intended for use on a supply circuit having a nominal rating less than

150 volts:

If the machine is intended for use on a circuit that has an outlet that looks like the one illustrated in Fig. A, the

machine will have a grounding plug that looks like the plug illustrated in Fig. A. A temporary adapter, which looks like

the adapter illustrated in Fig. B, may be used to connect this plug to a matching 2-conductor receptacle as shown

in Fig. B if a properly grounded outlet is not available. The temporary adapter should be used only until a properly

grounded outlet can be installed by a qualified electrician. The green-colored rigid ear, lug, and the like, extending

from the adapter must be connected to a permanent ground such as a properly grounded outlet box. Whenever the

adapter is used, it must be held in place with a metal screw.

NOTE: In Canada, the use of a temporary adapter is not permitted by the Canadian Electric Code.

IN ALL CASES, MAKE CERTAIN THE RECEPTACLE IN QUESTION IS PROPERLY GROUNDED.

IF YOU ARE NOT SURE, HAVE A QUALIFIED ELECTRICIAN CHECK THE RECEPTACLE.

GROUNDED

OUTLET BOX

CURRENT

CARRYING

PRONGS

GROUNDING BLADE

IS LONGEST OF THE 3 BLADES

FIG. A FIG. B

GROUNDED OUTLET BOX

GROUNDING

MEANS

ADAPTER

5

Page 6

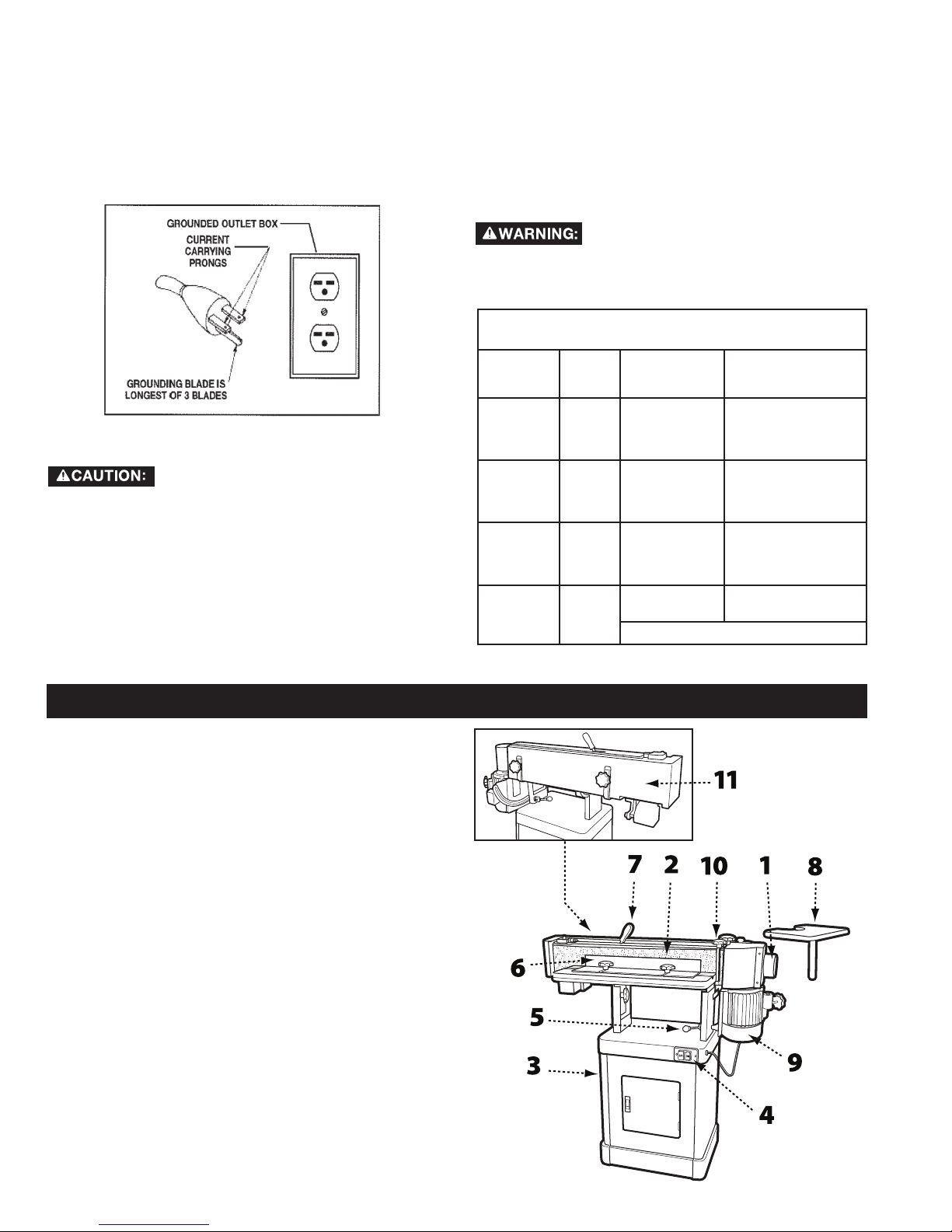

3. 240 Volt Single-Phase Operation

The motor supplied with your machine is a dual voltage, 120/240 volt motor. It is shipped ready-to-run for 120 volt

operation. However, it can be converted for 240 volt operation.

A qualified electrician should do the conversion, or the machine can be taken to an Authorized Delta Service Center.

When completed, the machine must conform to the National Electric Code and all local codes and ordinances.

The machine is converted by re-wiring the motor for 240 volts, installing a 240 volt plug on the power supply cord and

replacing the switch with one that is rated for 240 volt operation. Be sure the 240 volt plug is only used in an outlet

having the same configuration as the plug illustrated in Fig. C. No adapter should be used with the 240 volt plug.

In all cases, make certain that the

receptacle in question is properly

grounded. If you are not sure, have a qualified

electrician check the receptacle.

MINIMUM GAUGE EXTENSION CORD

RECOMMENDED SIZES FOR USE WITH STATIONARY ELECTRIC MACHINES

FIG. C

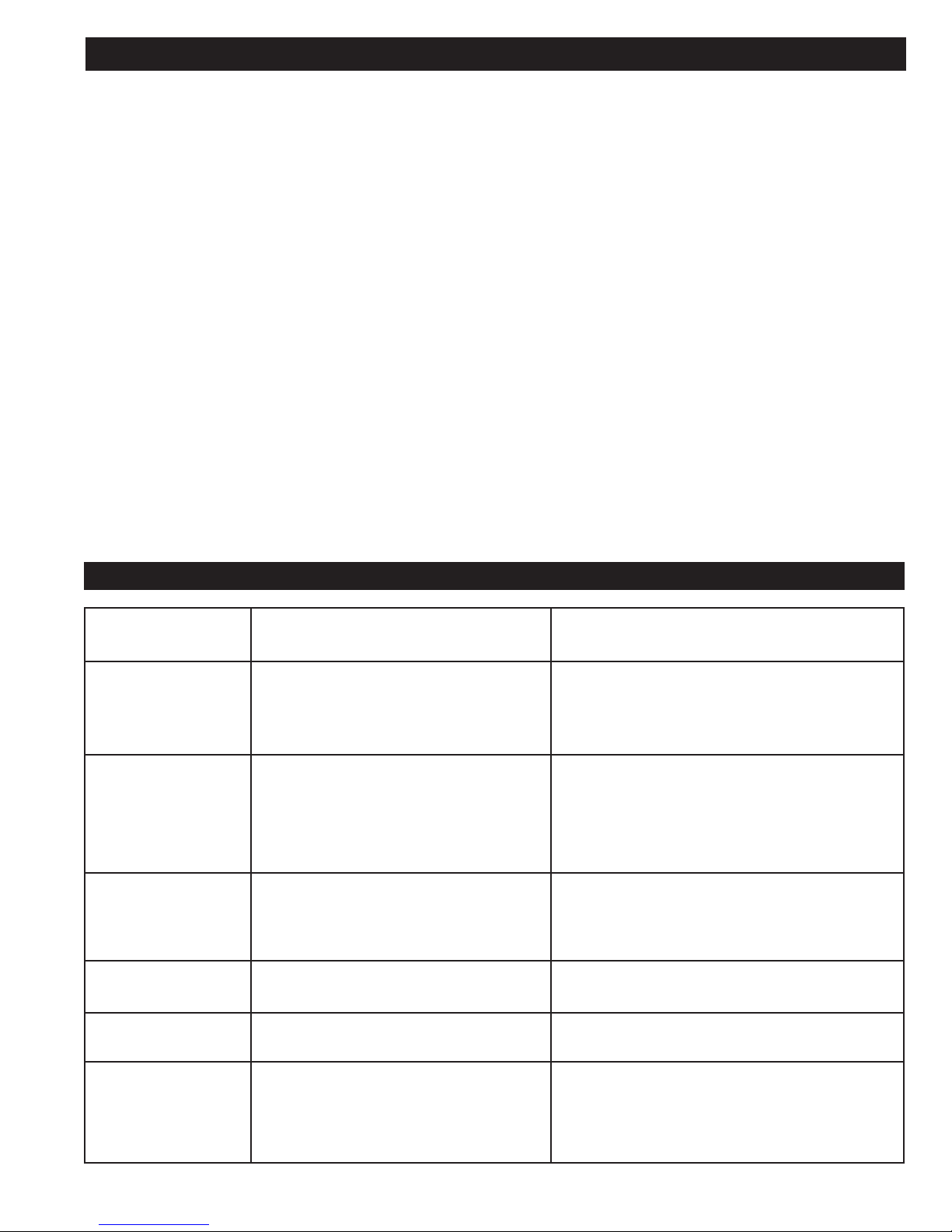

EXTENSION CORDS

Use proper extension cords. Make

sure your extension cord is in good

condition and is a 3-wire extension cord which has a

3-prong grounding type plug and matching

receptacle which will accept the machine’s plug.

When using an extension cord, be sure to use one

heavy enough to carry the current of the machine.

An undersized cord will cause a drop in line voltage,

resulting in loss of power and overheating. Fig. D

shows the correct gauge to use depending on the

cord length. If in doubt, use the next heavier gauge.

The smaller the gauge number, the heavier the cord.

Ampere

Rating

0-6

0-6

0-6

0-6

6-10

6-10

6-10

6-10

10-12

10-12

10-12

10-12

12-16

12-16

12-16

Volts Total Length

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

of Cord in

Feet

up to 25

25-50

50-100

100-150

up to 25

25-50

50-100

100-150

up to 25

25-50

50-100

100-150

up to 25

25-50

GREATER THAN 50 FEET NOT RECOMMENDED

FIG. D

Gauge of Extension

Cord

18 AWG

16 AWG

16 AWG

14 AWG

18 AWG

16 AWG

14 AWG

12 AWG

16 AWG

16 AWG

14 AWG

12 AWG

14 AWG

12 AWG

KEY FEATURES AND COMPONENTS

1-Dust Collection Port

2-Sanding Belt

3-Cabinet

4-Power Switch

5-Platen Lock

6-Support Fence

7-Belt Tensioning Lever

8-Contour Sanding Table

9-1-1/2HP Induction Motor

10-Workpiece Support

11-Rear Belt Guard

FIG. 1

6

Page 7

FUNCTIONAL DESCRIPTION

The DELTA® Oscillating Edge Sander is a professional-grade tool designed for both straight and angled edge-face

sanding as well as contour sanding. It is capable of sanding in either the vertical or horizontal plane. Your DELTA®

Oscillating Edge Sander comes with a 100 grit sanding belt and is mounted on a cabinet base that provides ample

storage space for accessories. This tool is powered by a 1-1/2HP, 120/240V induction motor that drives the sanding

belt and provides an oscillation stroke of ½” at a rate of 108 strokes per minute.

PRODUCT SPECIFICATIONS

Model 31-482

Fence (HxL) 4” x 24”

Abrasive Belt Size (WxL) 6” x 89”

Dust Chute Diameter 4”

Contour Sanding Table Size 9-3/4” x 11-3/4”

Table Size (LxW) 10” x 29-3/4”

Table Tilt 0-90°

Motor 1-1/2HP, 120/240V, 1PH, 60Hz, TEFC

Sanding Belt Speed 3900 FPM

Oscillation Stroke ½”

TOOLS NEEDED

FOR ASSEMBLY

• Two 12mm wrenches or

sockets

• 10mm wrench or socket

• Flat head screw driver

• Phillips head screw

driver

• Rubber mallet

Oscillations per Minute 108

Overall Dimensions (LxWxH) 51”x26.5”x20”

Net Weight, approximate 218

Shipping Weight, approximate 233

UNPACKING

Your Oscillating Edge Sander comes packed in a single container. Open the shipping container and check that all

parts are present and in good condition:

DESCRIPTION (QUANTITY)

Front Cabinet Panel with Door (1)

Rear Cabinet Panel (1)

Side Cabinet Panels (2)

Cabinet Shelf (1)

Rubber Feet (4)

Lock Knob - 35mm (1)

Lock Knob - 20mm (1)

Lock Knob - 12mm (2)

Contour Sanding Table (1)

Drum Guard/Dust Port (1)

Compare the contents of your container with the parts list to make sure all

parts are present and intact. Report any missing or damaged parts to your

distributor. Prior to tool assembly and use, read this manual thoroughly

to familiarize yourself with proper assembly, maintenance and safety

procedures.

Owner’s Manual (1)

Warranty Card (1)

Table Assembly (1)

Back Stop Bracket (1)

Belt Tension Handle (1)

Belt Tracking Tool (1)

Miter Gauge Assembly (1)

Sanding Belt (1)

Mounting Bracket (1)

HARDWARE

5/16” x 5/8” Screws (4)

5/16” Flat Washers (22)

5/16” Hex Nuts (12)

5/16” x 5/8” Hex Cap Bolts (8)

5/16” x 1-1/4” Hex Cap Bolts (2)

5/16” Flat Washers (4)

5/16” Lock Washers (10)

M5x10 Pan Head Screws (2)

M5 Flat Washers (2)

M5 Lock Washers (2)

1/4" x 5/8” Hex Cap Bolts (5)

1/4" Flat Washers (5)

1/4” Lock Washers (5)

10-24 x 3/4 Socket Head Cap

Screws (2)

Pan Head Screws (3)

T-Nuts (2)

7

Page 8

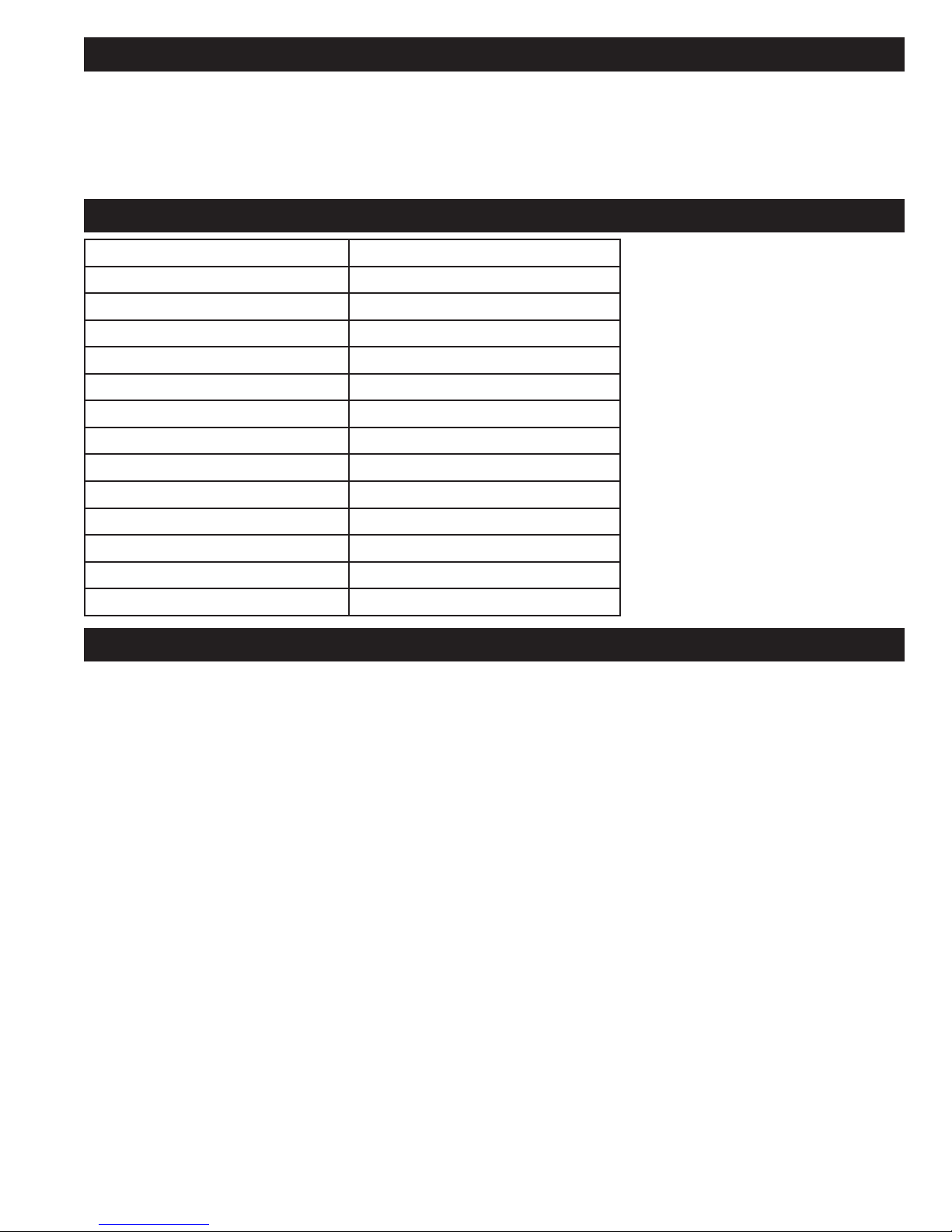

CABINET ASSEMBLY

TOOLS REQUIRED

• 12mm wrench

• Phillips head screw driver

Before beginning assembly, clean all rust protected

surfaces with a mild solvent. Do not use paint or lacquer

thinner, gasoline, or mineral spirits; as these will damage

painted surfaces.

NOTE: To ensure the top cabinet surface, where you will

mount the tool, is level and flush, assemble the cabinet

upside down on a flat surface.

1. Referring to Fig. 2, attach the four rubber pads (A) to

the bottoms of the side panels (B) with four each 5/16”

x 5/8” screws, 5/16” flat washers and 5/16” hex nuts.

2. Use four 5/16” x 5/8” hex cap screws, eight 5/16” flat

washers, four 5/16” lock washers, and four 5/16” hex

nuts to attach the side panels (B) to the front panel (C).

Hand tighten only.

3. Attach the rear cabinet panel (D) to the side panels

using four 5/16” x 5/8” hex cap screws, eight 5/16” flat

washers, four 5/16” lock washers, and four 5/16” hex

nuts.

4. Turn cabinet right side up on a level surface and ensure

the top edges of all panels are flush.

5. Install the cabinet shelf (E) to the inside of the cabinet

using two M5x10 pan head screws, two M5 flat

washers and two M5 lock washers.

6. Tighten all hardware.

PARTS

• Rubber Feet (4)

• Side Cabinet Panels (2)

• Front Cabinet Panel with

Door (1)

• Rear Cabinet Panel (1)

• Cabinet Shelf (1))

HARDWARE NEEDED

• 5/16” x 5/8” screws (4)

• 5/16” flat washers (20)

• 5/16” hex nuts (12)

• 5/16” x 5/8” hex cap bolts (8)

• 5/16” lock washers (8)

• M5x10 pan head screws (2)

• M5 flat washers (2)

• M5 lock washers (2)

FIG. 2

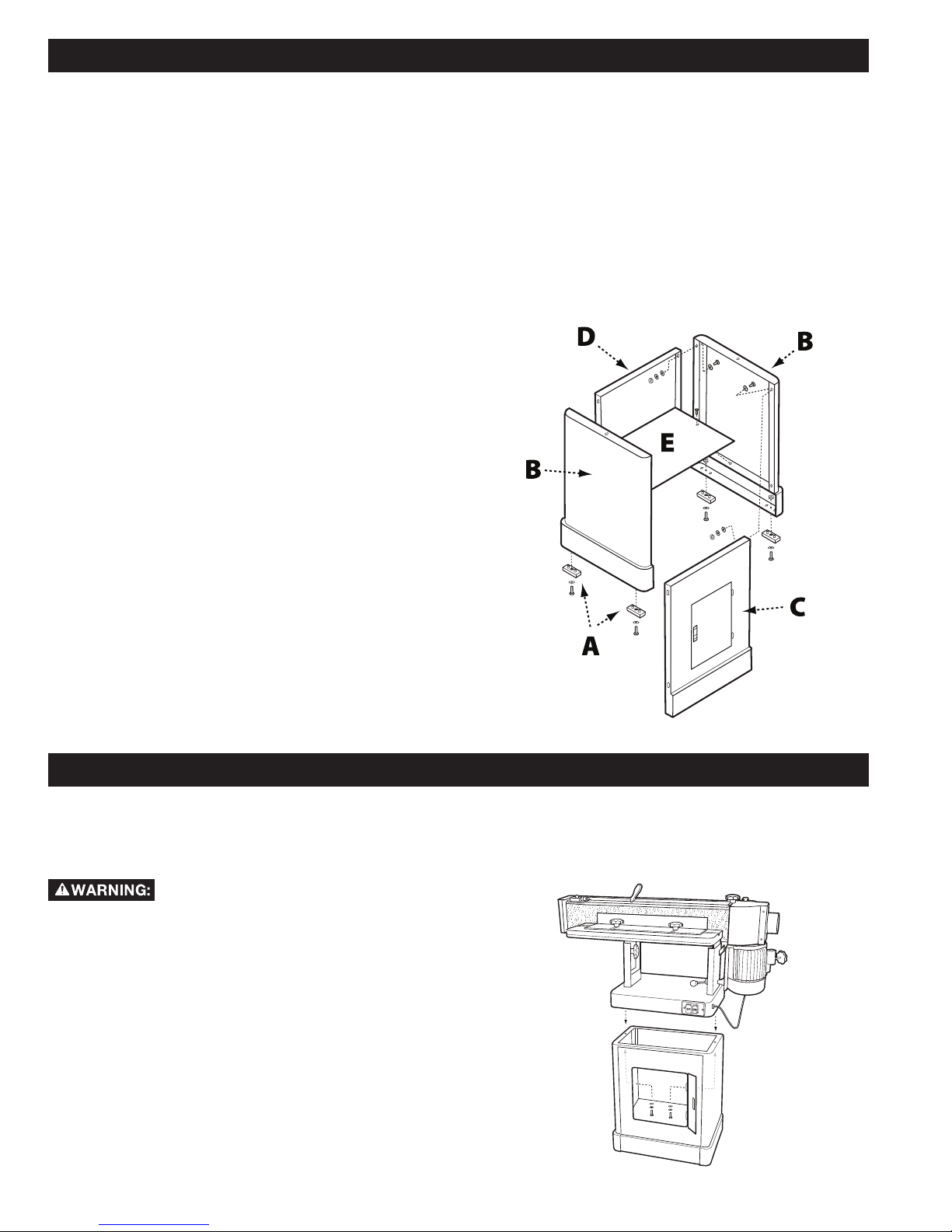

MOUNTING THE TABLE ASSEMBLY TO THE CABINET

TOOLS REQUIRED

• 12 mm wrench

This step requires two adults. The table

assembly is heavy, be careful when

lifting it onto the stand! Failure to comply may cause

serious injury and/or damage to the sander and/or

property!

1. With the aid of another person, carefully lift the table

assembly onto the cabinet and position it so that the

two holes in the base of the table assembly align with

the holes located on either end of the cabinet. See

Fig. 3.

2. Open the cabinet door and, from inside the cabinet,

feed a 5/16” x 1-1/4” hex cap screw up through both

holes and secure using a 5/16” lock washer and 5/16”

flat washer. See Fig. 5.

3. Tighten hardware using a 12mm socket wrench.

PARTS

• Table Assembly

HARDWARE NEEDED

• 5/16” x 1-1/4” hex cap screws (2)

• 5/16” lock washers (2) 5/16” flat washers (2)

FIG.3

8

Page 9

INSTALLING THE SANDING BELT

TOOLS REQUIRED

• Rubber Mallet

1. From the rear of the machine, unlock the sanding

platen assembly by pulling the lock handle(A)

toward you as indicated in Fig. 4. Rotate the

sanding platen assembly to the vertical position.

2. Push the lock handle back to its original position to

lock the platen assembly in place.

NOTE: Do not turn or rotate the lock handle as this will

change the tension of the locking assembly and make it

necessary for adjustment before using the tool.

3. Remove the belt guard by loosening the two lock

knobs (B) and sliding the belt guard to the right.

4. Place the handle (D) onto the belt tensioning lever

and gently tap into place using a rubber mallet.

PARTS

• 6” x 89” sanding belt

• Belt tensioning lever handle

HARDWARE NEEDED

• None

5. Move the lever in the direction indicated on the

label to release tension on the belt.

6. Fit the belt onto the sanding platen so that the

edge of the belt (E) is even with the edge of the

rollers (F) as shown in Fig. 5.

NOTE: Make sure that direction arrow on belt matches

the direction indicator on the top of the sanding

platen.

7. Return the belt tensioning lever to the Tight

position. Rotate the belt by hand in the direction

indicated by the arrow to ensure proper belt

tracking. If the belt tracking needs adjustment,

see Belt Tracking Adjustment on page 12.

FIG. 4

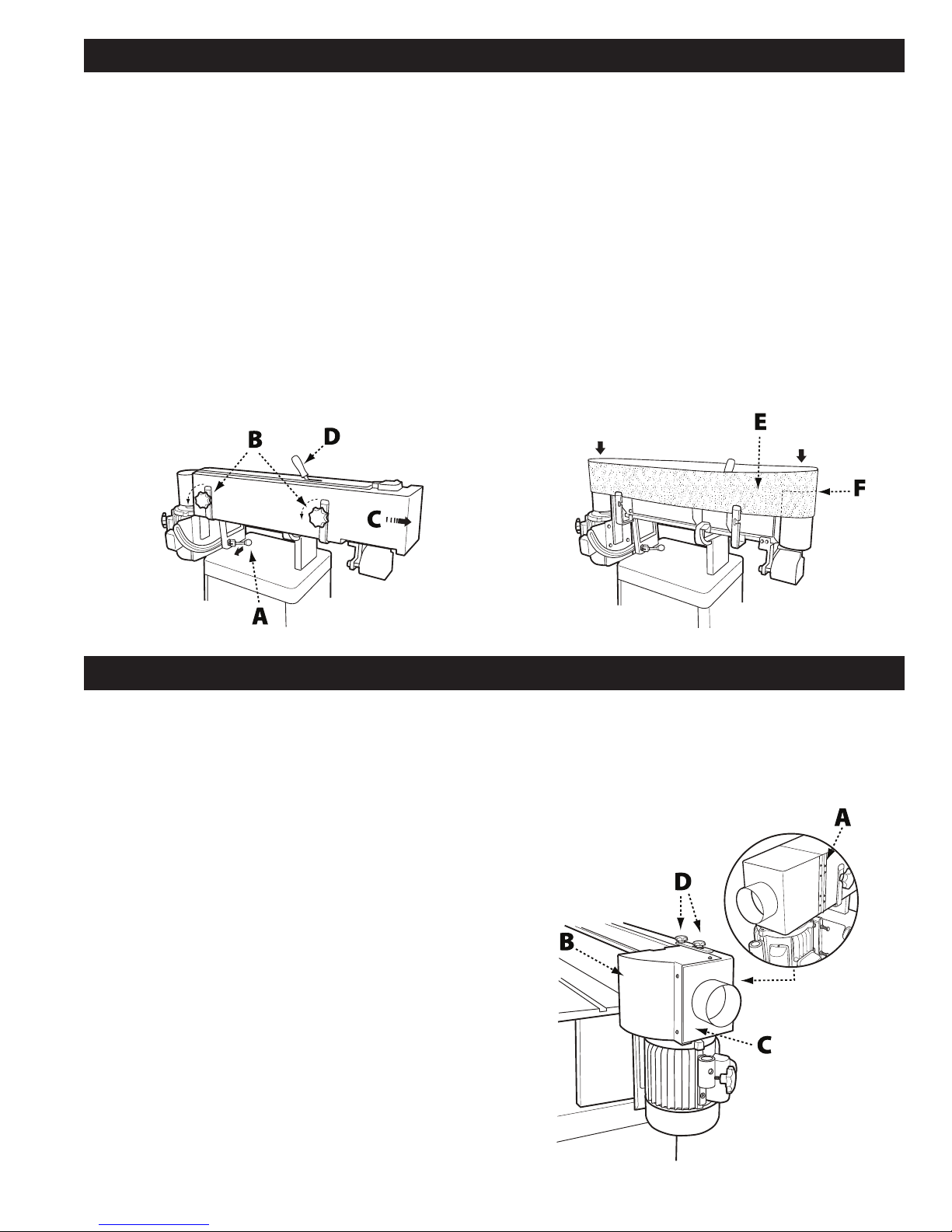

INSTALLING DRUM GUARD

TOOLS REQUIRED

• Phillips head screw driver

• Flat head screw driver

1. Attach one side of the hinge assembly (A) to the

rear belt guard using four Phillips head screws.

2. Place the drum guard (B) over the dust chute (C) as

shown in Fig. 6.

3. Secure the other side of the hinge to the drum

guard with the four remaining Phillips head screws.

4. Make sure the drum guard is in the closed position,

covering the drive belt.

NOTE: If the drum guard does not clear the motor case,

loosen the two lock knobs on the rear belt guard and

raise the rear belt guard slightly then retighten the lock

knobs.

5. Assemble one 12 mm flat washer on each of the

two 12mm lock knobs (D) and insert one lock knob

through the slot in the connection plate and the

other through the hole in the connection plate.

6. Tighten both knobs until secure.

To reposition the drum guard, loosen both lock knobs,

open or close the cover, then retighten the lock knobs.

PARTS

• Hinge

• Drum Guard

• 12mm Lock Knobs (2)

9

FIG. 5

HARDWARE NEEDED

• 8 Phillips head screws

• (size/type) washers (2)

FIG. 6

Page 10

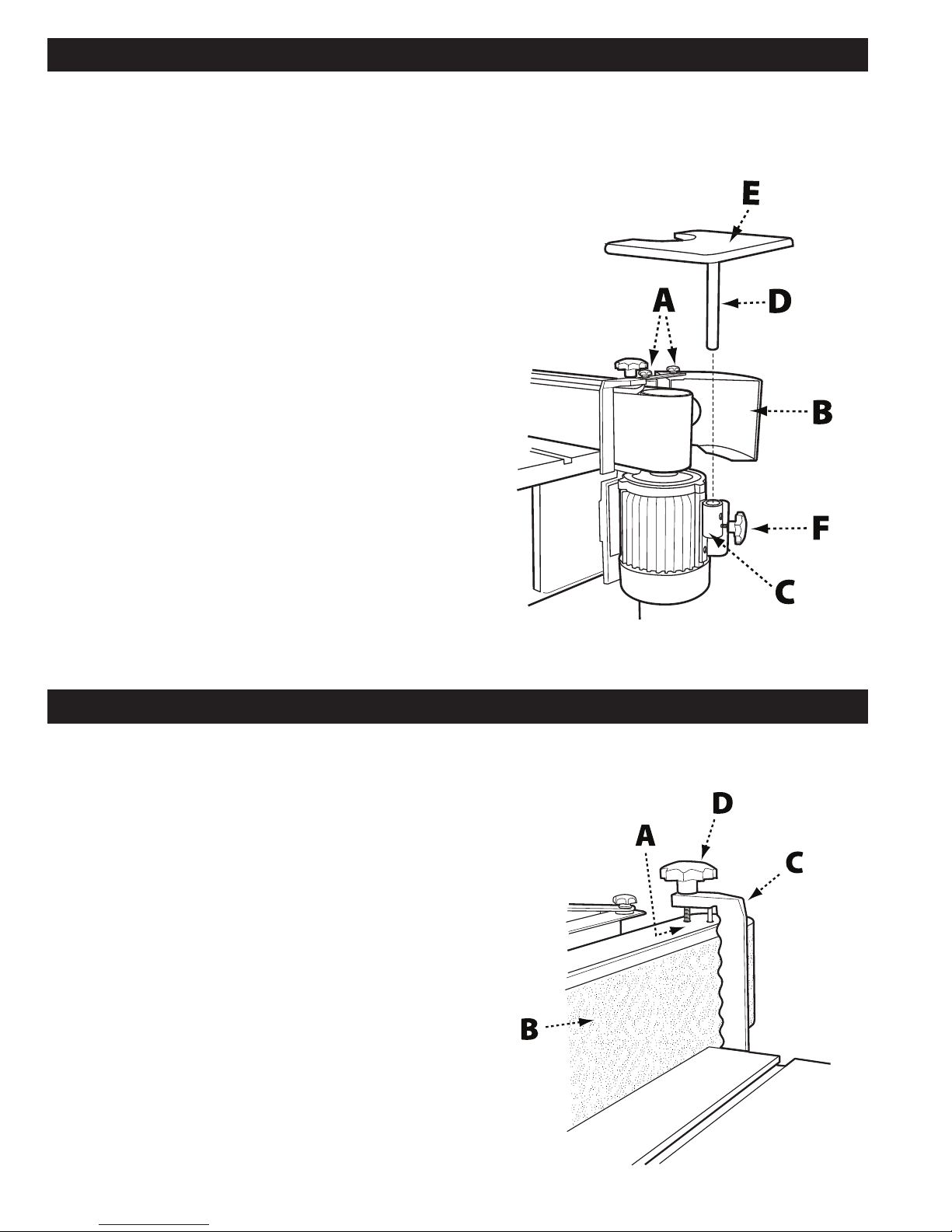

INSTALLING THE CONTOUR SANDING TABLE

TOOLS REQUIRED

• 12 mm socket wrench

1. Loosen the lock knobs (A) on the drum guard (B)

and rotate the drum guard back and out of the

way. Retighten the lock knobs.

2. Attach the mounting bracket (C) to the side of the

motor housing and secure using the two 10-24 x

3/4 socket head cap screws, as shown in Fig. 7.

The longer end of the mounted bracket should be

at the bottom.

3. Insert the mounting pole (D) into the contour

sanding table (E) and secure with 12mm hex cap

bolt and lock nut.

4. Insert the mounting pole/table assembly into the

mounting bracket. Ensure there is clearance on all

sides between the sanding belt and the contour

sanding table.

5. Secure the mounting pole/table assembly to the

mounting bracket using the (20mm) lock knob (F).

PARTS

• Contour Sanding Table

• Mounting Pole

• Mounting Bracket

• 20mm Lock Knob

HARDWARE NEEDED

• 10-24 x 3/4 Socket Head Cap Screws (2)

• 12mm Hex Cap Bolt

Important: When the contour sanding table is not in

use, the drum guard/dust port should always be in the

closed position so the drive drum is not in view.

INSTALLING THE WORKPIECE SUPPORT

TOOLS REQUIRED

• None

1. Locate the two holes (A) on the right hand side of

the top of the sanding platen. See Fig. 8.

2. Insert the pin of the workpiece support (C) into the

hole closest to the front.

3. Secure the workpiece support to the sanding

platen by screwing the (35mm) lock knob (D) into

the tapped hole closest to the rear.

4. Ensure the workpiece support is as close to the

sanding belt (B) as possible without touching it.

5. Tighten the lock knob.

PARTS

• Workpiece Support

• (35mm) Lock Knob

FIG. 7

HARDWARE NEEDED

• None

FIG. 8

10

Page 11

INSTALLING THE SANDING FENCE

TOOLS REQUIRED

• None

1. Slide the two T-nuts into the slot located on the

sanding table.

2. Position the sanding fence so that one of the

t-nuts is aligned with one of the positioning slots.

3. Place a 5/16” flat washer onto a (12mm) lock knob

and thread the lock knob into the t-nut.

PARTS

• Sanding Fence

• Two (12mm) Lock Knobs

ADJUSTMENTS

Before making any adjustments to the tool, disconnect the machine from the power source.

TO ADJUST THE SANDING ANGLE

Before making any adjustments to the tool, disconnect the machine from the power source.

1. Loosen the platen locking lever by pulling forward.

2. Move the sanding platen to the desired position.

Use a combination square between the table and

sanding platen to get precise angles.

HARDWARE NEEDED

• T-Nuts (2)

• 5/16” Flat Washers (2)

4. Reposition the sanding fence so that the other

positioning slot is aligned with second t-nut.

5. Place a 5/16” flat washer onto the second (12mm)

lock knob and thread the lock knob into the

second t-nuts.

6. Position the fence to the desired distance from the

belt and securely tighten both lock knobs.

3. Hold the platen steady and push the platen locking

lever back to the locked position.

TO ADJUST THE TENSION ON

THE PLATEN LOCKING LEVER

Before making any adjustments to the

tool, disconnect the machine from the

power source.

1. Loosen the platen locking lever (A) and rotate the

platen into the horizontal (flat) position. Do not lock.

2. Adjust tension on the eccentric block by tightening

the nylon nut (B) with a 14mm wrench. See Fig. 9.

Turn the nut in ¼-turn increments and test locking

handle for proper tension.

3. The platen locking lever is properly tensioned when

it requires positive force to move the eccentric

block from one side to the other.

4. Ensure the platen and motor assembly remains

stationary when the platen locking lever is in the

locked position. Re-adjust as necessary.

TO CHANGE THE SANDING BELT

Before making any adjustments to the

tool, disconnect the machine from the

power source.

1. Ensure the sanding platen is locked in the vertical

(upright) position. Reposition if needed. (Refer to

Adjusting the Sanding Angle at the top pf this page).

2. Remove the belt guard by loosening the two lock

knobs and sliding the belt guard to the right.

3. Release tension on the belt by moving the belt

tensioning lever to the Loose position as indicated

on the label on top of the guard.

4. Remove the old belt by working it up and over the

rollers.

5. Fit the new belt onto the sanding platen. Note:

Make sure that direction arrow on belt matches the

direction indicator on the top of the sanding platen.

The edge of the belt should be even with the edge

of the rollers.

6. Re-tension the belt by moving the belt tensioning

lever to the Tight position.

7. Rotate the belt by hand in the direction indicated

by the arrow to ensure proper belt tracking. Note:

Belts stretch with wear. When replacing a belt, you

may have to adjust tracking. See Belt Tracking

Adjustment on page 12.

8. Reinstall the belt guard and tighten the lock

handles.

FIG. 9

11

Page 12

ADJUSTMENTS

TO ADJUST THE BELT

TRACKING

Tools Needed: Belt Tracking Tool (provided)

Before making any adjustments to the

tool, disconnect the machine from the

power source.

1. Rotate the belt by hand from left to right and

observe whether the belt is tracking above or below

the edges of the rollers.

2. Using the belt tracking tool (provided) loosen the

micro adjust lock nut.

3. Based on whether the belt is tracking up or

down, turn the micro adjusting screw in 1/4 – turn

increments to the left or right until the belt tracks

MOTOR MOUNT TRACKING

ADJUSTMENT

Tools Needed: Two 1/2" Wrenches

Note: The Motor Mount Tracking Adjustment is a

course adjustment. Use the Belt Tracking Adjustment

first for fine adjustment. If it cannot be adjusted, then

use the procedure described below.

Before making any adjustments to the tool, disconnect

the machine from the power source.

1. Loosen the four motor mount

nuts (A) just enough so the tracking

screws can be turned to make an adjustment. See

Fig. 11.

2. Loosen the two locking hex nuts that secure the

tracking screws.

3. Turn one screw a 1/4-turn and rotate the sanding

belt by hand to observe which direction the

adjustment is causing the belt to move. If it is

evenly on the rollers when rotated by hand. See

Fig. 10.

4. Re-tighten the micro adjusting nut.

NOTE: The Belt Tracking Adjustment provides a minor

adjustment that

should correct

most tracking

problems. If

the tracking

problem persists,

use the Motor

Mount Tracking

Adjustment (next

section).

FIG. 10

traveling in the direction needed to correct the

problem, go to step 5.

4. If the belt tracks in the wrong direction, back off

a 1/4-turn and tighten the other screw a quarter

turn. This should start the belt moving in the proper

direction.

5. Tighten both

locking nuts and

motor mount

nuts.

6. Return to the

Belt Tracking

Adjustment

section (previous

page) to fine tune

the tracking.

FIG. 11

TO ADJUST THE SANDING

TABLE HEIGHT

Before making any adjustments to the

tool, disconnect the machine from the

power source.

Never position the sanding table below

the sanding belt! Keep an overlap

of at least 1/16” between table and sanding belt to

avoid material and/or fingers getting caught! Failure to

comply may cause serious injury!

1. There are two height elevation lock knobs (A) one

on either side of the table support, shown in Fig. 12.

Loosen both lock knobs just enough to allow the

sanding table to move up and down.

The table is very heavy. Loosen lock

knobs slowly and just enough to create

play in table Failure to comply may cause serious injury!

2. Raise or lower

work table to

desired level.

3. Tighten the

lock knobs.

FIG. 12

12

Page 13

MAINTENANCE PROCEDURES

Your Oscillating Edge Sander requires little

maintenance beyond the routine inspection,

lubrication, and cleaning.

ROUTINE INSPECTION

It is a good idea to routinely inspect any quality

woodworking tool in order to keep it in optimum

condition. This includes inspecting all hardware for

tightness, ensuring drive belts are in good condition,

and cleaning debris and grime from any surfaces and

moving parts.

LUBRICATION

The sealed motor of your Oscillating Edge Sander

is maintenance-free. However, it is recommended

that you periodically lubricate the gears in the gear

box using a quality #2 grease or equivalent. To keep

the sander table and other bare metal parts in good

working condition, apply an occasional coat of quality

paste wax, free of silicone or synthetics

CLEANING THE SANDING BELT

Regularly inspect and, if necessary, clean the sanding

belt with a high quality gum rubber belt cleaner. If you

notice sanding performance is significantly decreasing,

it may be time to replace the sanding belt. Refer to

directions on page 11.

TROUBLESHOOTING GUIDE

TROUBLE POSSIBLE CAUSE

1. Sander unplugged from wall or motor

Sander will not start

Sanding belt does

not come up to

speed

Machine vibrates

excessively

Abrasive belt keeps

tearing

Sanded edge not

square

2. Fuse blown or circuit breaker tripped

3. Cord damaged

1. Extension cord too light or too long

2. Motor not wired for proper voltage

3. Low current

1. Stand on uneven floor

2. Motor mounts are loose

3. Tension spring is worn or broken

1. Belt is running in the wrong direction

1. Table not square to sanding platen 1. Use a square to adjust table to sanding platen

SOLUTION

1. Check all plug connections

2. Replace fuse or reset circuit breaker

3. Replace cord

1. Replace with adequate size and length cord

(see Recommended Extension Cord Gauges

on page 6)

2. Refer to motor junction cover for proper wiring

3. Contact a qualified electrician

1. Adjust stand so that it rests evenly on the floor

2. Tighten motor mount bolts

3. Replace spring

1. Arrow on the sanding belt and machine

should be pointing in the same direction.

Sanding marks on

wood

1. Wrong grit sanding belt

2. Feed pressure too great

3. Sanding against the grain

1. Use coarser grit for stock removal and fine grit

for finish sanding.

2. Never force work into sanding platen

3. Sand with the grain

13

Page 14

ACCESSORIES

A complete line of accessories is available from your DELTA® Supplier, DELTA® Factory Service Centers, and

DELTA® Factory Service Centers, and DELTA® Authorized Service Centers. Please visit our Web Site www.

DeltaMachinery.com for an online catalog or for the name or your nearest supplier.

Since accessories other than those offered by DELTA® have not been tested with this product,

use of such accessories could be hazardous. For safest operation, only DELTA® recommended

accessories should be used with this product.

PARTS, SERVICE OR WARRANTY ASSISTANCE

All DELTA® Machines and accessories are manufactured to high quality standards and are serviced by a network of

DELTA® Factory Service Centers and DELTA® Authorized Service Centers. To obtain additional information regarding

your DELTA® quality product or to obtain parts, service, warranty assistance, or the location of the nearest service

center, please call 1-800-223-7278.

WARRANTY

To register your tool for warranty service visit our website at www.DeltaMachinery.com.

Five Year Limited New Product Warranty

DELTA® will repair or replace, at its expense and at its option, any new DELTA® machine, machine part, or machine accessory which in normal

use has proven to be defective in workmanship or material, provided that the customer returns the product prepaid to a DELTA

center or authorized service station with proof of purchase of the product within five years and provides DELTA

to verify the alleged defect by inspection. For all refurbished DELTA

for any asserted defect which has resulted from normal wear, misuse, abuse or repair or alteration made or specifically authorized by anyone

other than an authorized DELTA

damages resulting from defective products. Some states do not allow the exclusion or limitation of incidental or consequential damages, so

the above limitation or exclusion may not apply to you. This warranty is DELTA

with respect to defective products; all other warranties, express or implied, whether of merchantability, fitness for purpose, or otherwise, are

expressly disclaimed by DELTA

1-800-223-7278. This warranty gives you specific legal rights and you may have other rights which vary in certain states or provinces.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For products sold in Latin America,

see country specific warranty information contained in the packaging, call the local company or see website for warranty

information.

®

service facility or representative. Under no circumstances will DELTA® be liable for incidental or consequential

®

. For further detail of warranty coverage and warranty repair information, visit www.DeltaMachinery.com or call

®

product, the warranty period is 180 days. DELTA® will not be responsible

®

’s sole warranty and sets forth the customer’s exclusive remedy,

®

with reasonable opportunity

®

factory service

14

Page 15

REPLACEMENT PARTS

Use only identical replacement parts. For a parts list or to order parts, visit our website at www.DeltaMachinery.com/service. You can

also order parts from your nearest factory-owned branch, Authorized Warranty Service Center or by calling Technical Service Manager at

1-800-223-7278 to receive personalized support from one of our highly-trained representatives.

FREE WARNING LABEL REPLACEMENT

If your warning labels become illegible or are missing, call

1-800-223-7278

for a free replacement.

Warning

For Your Own Safety, Read Instructions

Manual Before Operafting Sander

1. Wear eye protection

2. Suport work piece with backstop or

work table

3. Maintain 1/16 inch maximum clearance

between table and sanding belt.

SERVICE AND REPAIRS

All quality tools will eventually require servicing and/or replacement of parts. For information

about DELTA® Power Equipment Corporation, its factory-owned branches, or to locate an

Authorized Warranty Service Center, visit our website at www.DeltaMachinery.com/service

or call our Customer Care Center at 1-800-223-7278. All repairs made by our service centers are fully

guaranteed against defective material and workmanship. We cannot guarantee repairs made or attempted by

others. By calling this number you can also find answers to most frequently asked questions 24 hours/day.

You can also write to us for information at DE LTA

Jackson, TN 38305 - Attention: Technical Service Manager. Be sure to include all of the information shown

on the nameplate of your tool (model number, type, serial number, date code, etc.)

®

Power Equipment Corporation, 4825 Highway 45 North,

15

Page 16

IMPORTANTES CONSIGNES DE SÉCURITÉ

ASSUREZ-VOUS D’AVOIR BIEN LU ET COMPRIS TOUTES LES MISES EN

GARDE ET LES CONSIGNES D’UTILISATION AVANT D’UTILISER CET

ÉQUIPEMENT. Le fait de ne pas respecter toutes les instructions ci-dessous,

peut avoir pour conséquence : choc électrique, incendie et/ou blessures graves ou dégâts matériels.

Le travail du bois peut être dangereux si des procédures d’utilisation sécuritaires et adéquates ne sont pas

respectées. Comme c’est le cas pour toute pièce de machinerie, certains dangers sont assortis à l’utilisation de

ce produit. En utilisant cet appareil selon les directives et avec prudence, vous réduirez grandement la possibilité

de blessures. Cependant, si les précautions normales de sécurité sont négligées ou ignorées, la personne utilisant

l’appareil pourra être blessée. L’équipement de sécurité comme les dispositifs de protection, bâtons poussoir,

dispositif de retenue à ressort, cales-guide, lunettes, masques anti-poussière et protecteurs d’oreilles peut réduire

les risques de blessures. Mais même les dispositifs de protection les plus efficaces ne pourront vous protéger

contre un manque de jugement, de soin ou d’attention. Utilisez toujours votre bon sens et faites preuve de prudence

dans l’atelier. Si une manœuvre vous semble dangereuse, ne la tentez pas. Essayez plutôt de trouver une autre

solution qui vous paraît plus sûre. RAPPELEZ-VOUS : Vous êtes responsable de votre propre sécurité. Pour des

renseignements complémentaires, rendez-vous sur notre site web à l’adresse www.DeltaMachinery.com.

Cet appareil a été conçu seulement pour certains types d’utilisation. DELTA® Power

Equipment Corporation recommande fortement que cet appareil ne soit ni modifié ni utilisé à

toute autre fin que celles pour lesquelles il a été conçu. Si vous avez des questions sur un type d’utilisation en

particulier, N’UTILISEZ PAS l’appareil avant d’avoir d’abord contacté DELTA® pour déterminer si elle peut ou si elle

devrait être réalisée avec ce produit.

Si vous avez des questions sur son utilisation, N’UTILISEZ PAS le produit tant que vous n’avez pas écrit à

DELTA® Power Equipment Corporation et obtenu une réponse de leur part. Contactez-nous en ligne sur www.

DeltaMachinery.com ou par courrier à l’adresse suivante : responsable du service technique, DELTA® Power

Equipment Corporation, 4825 Highway 45 North, Jackson, TN 38305.

• Les informations concernant l’utilisation sûre et correcte de cet outil sont disponibles auprès des sources suivantes :

• Power Tool Institute, 1300 Sumner Avenue, Cleveland, OH 44115-2851 ou en ligne sur HYPERLINK http://www.

powertoolinstitute.com/ www.powertoolinstitute.com

• National Safety Council, 1121 Spring Lake Drive, Itasca, IL 60143-3201

• American National Standards Institute, 25 West 43rd Street, 4 floor, New York, NY 10036 HYPERLINK http://www.

ansi.org/ www.ansi.org - ANSI 01.1 Exigences de sécurité pour machines à bois

• U.S. Department of Labor regulations www.osha.gov

CONSIGNES DE SÉCURITÉ - DÉFINITIONS

Ce manuel contient des informations qu’il est important de connaître et de comprendre. Ces informations ont pour

but d’assurer VOTRE SÉCURITÉ et de PRÉVENIR LES PROBLÈMES D’ÉQUIPEMENT. Pour vous aider à reconnaître

ces informations, nous utilisons les symboles ci-dessous. Veuillez lire le manuel et prêter attention à ces sections-là.

indique une situation dangereuse imminente qui, si elle n’est pas évitée, provoquera la mort ou une

blessure grave.

indique une situation dangereuse potentielle qui, si elle n’est pas évitée, provoquera la mort

ou une blessure grave.

indique une situation dangereuse potentielle qui, si elle n’est pas évitée, peut provoquer une

blessure mineure ou modérée.

utilisé sans le symbole d’alerte de sécurité indique une situation potentiellement dangereuse qui,

si elle n’est pas évitée, peut entraîner des dommages matériels.

FRANÇAIS

16

Page 17

RÈGLES DE SÉCURITÉ GÉNÉRALES

LE NON-RESPECT DE CES RÈGLES RISQUE D’ENTRAÎNER DES BLESSURES GRAVES.

POUR VOTRE PROPRE SÉCURITÉ, LISEZ ET COMPRENEZ BIEN LE MANUEL D’UTILISATION AVANT DE

•

FAIRE FONCTIONNER L’APPAREIL.

rattachés.

GARDEZ LA ZONE DE TRAVAIL PROPRE.

•

N’UTILISEZ PAS CET APPAREIL DANS UN ENVIRONNEMENT DANGEREUX.

•

endroit humide ou mouillé, et ne l’exposez pas à la pluie. Gardez votre lieu de travail bien éclairé.

MAINTENEZ LES ENFANTS ET LES VISITEURS À L’ÉCART.

•

distance sécuritaire de l’aire de travail.

DÉBRANCHEZ L’APPAREIL

•

VÉRIFIEZ LES PIEZAS ENDOMMAGÉES.

•

endommagée.

LE NON-RESPECT DE CES RÈGLES PEUT ENTRAÎNER DES BLESSURES GRAVES.

avant toute opération d’entretien.

Apprenez à connaître son utilité et ses limites, ainsi que les dangers qui lui sont

Les aires et bancs de travail encombrés attirent les accidents.

N’utilisez pas cet appareil dans un

Tous les enfants et visiteurs doivent demeurer à une

Avant d’utiliser l’appareil, réparez ou remplacez toute partie

1. Lisez et comprenez les avertissements affichés sur

l’appareil et dans ce manuel. Ne pas se conformer

à tous ces avertissements peut entraîner des

blessures graves.

2. Remplacez les étiquettes d’avertissement si elles

sont masquées ou supprimées.

3. Cette ponceuse oscillante pour champs est conçue

et destinée pour être utilisée par un personnel

dûment formé et expérimenté seulement. Si vous

n’êtes pas habitué avec le fonctionnement adéquat

et sécuritaire d’une ponceuse oscillante pour

champs, évitez de l’utiliser avant d’avoir reçu la

formation et acquis les connaissances appropriées.

4. N’utilisez pas cet appareil à toute autre fin que

l’usage prévu. Autrement, Delta Power Equipment

Company, Inc. décline toute garantie réelle ou

implicite et se dégage de toute responsabilité

pour toute blessure qui pourrait résulter de cette

utilisation.

5. Portez toujours des lunettes de protection ou des

écrans faciaux approuvés pendant l’utilisation de

cette ponceuse oscillante pour champs.

6. Avant d’utiliser cette ponceuse oscillante pour

champs, enlevez cravate, bagues, montres et

autres bijoux et retroussez vos manches au-dessus

du coude. Retirez tous les vêtements amples et

retenez les cheveux longs. Il est recommandé de

porter des chaussures antidérapantes ou de poser

des bandes de plancher antidérapantes. Ne portez

pas de gants.

7. Portez des protecteurs pour l’ouïe (bouchons

ou manchons) pendant les longues périodes de

fonctionnement.

8. Certaines poussières produites par les activités de

ponçage, de sciage, de meulage, de perçage ainsi

que d’autres activités de construction peuvent

contenir des produits chimiques pouvant causer

le cancer, des anomalies congénitales ou d’autres

problèmes liés aux fonctions reproductrices. En

voici des exemples :

• Plomb de peintures à base de plomb;

• Silice cristalline de briques, de ciment et d’autres

produits de maçonnerie;

• Arsenic et chrome de bois de sciage traité

chimiquement.

Votre risque à ces expositions varie, selon la

fréquence à laquelle vous effectuez ce genre

d’activité. Pour réduire l’exposition à ces produits

chimiques, travaillez dans un endroit bien ventilé et

avec de l’équipement de protection approuvé, comme

les masques antipoussières spécialement conçus pour

filtrer les particules microscopiques

1. N’utilisez pas cet appareil en état de fatigue ou avec

les facultés affaiblies par la drogue, l’alcool ou les

médicaments.

2. Avant de brancher l’appareil sur la source

d’alimentation, assurez-vous que l’interrupteur est

en position « OFF » (Arrêt).

3. Assurez-vous que la machine est correctement

mise à la terre.

4. Faites les réglages de la machine ou son entretien

seulement lorsque celle-ci est débranchée de la

source d’alimentation.

5. Prenez l’habitude de vérifier que tout l’équipement

supplémentaire tel que les clés de réglage, les clés

à molette, la ferraille, le matériel et les chiffons de

nettoyage a été éloigné de la machine avant de la

mettre en marche.

6. Gardez les dispositifs de protection en place en tout

temps lorsque l’appareil est utilisé. Faites preuve

d’une extrême prudence s’ils sont enlevés à des

fins d’entretien et remettez-les en place dès la fin de

l’entretien.

7. Assurez-vous que la ponceuse oscillante pour

champs est solidement fixée au plancher avant de

l’utiliser.

8. Vérifiez s’il y a des pièces endommagées. Avant

d’utiliser l’appareil, il faut vérifier soigneusement

17

Page 18

le dispositif de protection ou toute autre partie

endommagée afin de s’assurer qu’ils fonctionnent

correctement et rempliront leur fonction prévue.

Vérifiez l’alignement des pièces mobiles et

leurs joints, tout bris de pièce et du cadrage et

toute autre condition qui pourrait en modifier le

fonctionnement. Un dispositif de protection

endommagé, ou toute autre pièce endommagée

doit être réparé et remplacé adéquatement.

9. Prévoyez un espace suffisant autour de la zone de

travail et un éclairage en plongée non éblouissant.

10. Gardez le plancher autour de l’appareil propre et

exempt de débris, d’huile et de graisse.

11. Gardez les visiteurs à une distance sécuritaire de la

zone de travail. Tenez les enfants à distance.

12. Rendez votre atelier à l’épreuve des enfants au

moyen de cadenas, de commutateurs principaux

ou en retirant les clés de mise en marche.

13. Concentrez-vous uniquement sur votre travail.

Regarder aux alentours, tenir une conversation

et faire du chahut sont des actes négligents qui

peuvent entraîner des blessures graves.

14. Maintenez une posture équilibrée en tout temps

pour éviter de tomber ou de vous appuyer contre

la courroie de ponçage ou d’autres pièces mobiles.

Évitez de vous étirer ou d’utiliser une force

excessive pour effectuer toute opération avec

l’appareil.

15. Utilisez l’outil approprié à la bonne vitesse et au

bon débit d’alimentation. Ne forcez pas un outil ou

un accessoire à effectuer une tâche pour laquelle il

n’a pas été conçu. Le bon outil fera mieux le travail

et sera plus sécuritaire.

16. Utilisez les accessoires recommandés; les

accessoires inadéquats peuvent être dangereux.

17. Entretenez les appareils avec soin. Suivez les

indications pour le graissage et le changement

d’accessoires.

18. Débranchez l’appareil avant le nettoyage. Utilisez

une brosse ou de l’air comprimé pour enlever la

poussière ou des débris; n’utilisez pas vos mains.

19. Ne vous tenez pas debout sur l’appareil. Des

blessures graves pourraient se produire si l’appareil

se renverse.

20. Ne laissez jamais l’appareil en marche sans

surveillance. Débranchez l’appareil et ne le laissez

pas sans surveillance jusqu’à son arrêt complet.

21. Tenez la poignée fermement en tout temps.

22. N’utilisez pas cette ponceuse pour d’autres fins

que celles pour lesquelles elle est prévue. Si elle

est utilisée à d’autres fins, Delta Power Equipment

Company, Inc. décline toute garantie réelle ou

implicite et se dégage de toute responsabilité

pour toute blessure qui pourrait résulter de cette

utilisation.

CONSERVER CES CONSIGNES.

Consultez-les souvent et utilisez-les pour enseigner aux autres.

18

Page 19

BRANCHEMENTS

Il faut utiliser un circuit électrique séparé pour vos appareils. Les fils du circuit doivent avoir un calibre d’au moins

12 et être protégés par un fusible à action différée de 20 ampères. Si vous utilisez une rallonge, ne prenez que des

rallonges à 3 fils avec fiche de mise à la terre à 3 branches et un réceptacle correspondant qui acceptera la prise de

l’appareil. Avant de brancher l’appareil à la ligne électrique, assurez-vous que le ou les interrupteurs sont en position

« OFF » (Arrêt) et que le courant électrique a les mêmes caractéristiques que celui indiqué sur l’appareil. Toutes les

connexions électriques doivent établir un bon contact. Une utilisation à basse tension endommagera l’appareil.

N’UTILISEZ PAS L’APPAREIL DANS UN ENDROIT HUMIDE OU MOUILLÉ, ET NE L’EXPOSEZ

PAS À LA PLUIE.

SPÉCIFICATIONS DU MOTEUR

L’appareil est conçu pour être alimenté par un courant alternatif de 120/240 volts et 60 Hz. Avant de brancher

l’appareil à la source d’alimentation, assurez-vous que l’interrupteur est en position « OFF » (Arrêt).

DIRECTIVES DE MISE À LA TERRE

CET APPAREIL DOIT ÊTRE MIS À LA TERRE LORSQU’IL EST EN MARCHE POUR PROTÉGER

CELUI QUI LE MANIPULE D’UNE DÉCHARGE ÉLECTRIQUE.

1. Pour tous les appareils branchés avec un cordon d’alimentation et mis à la terre :

En cas de mauvais fonctionnement ou d’une panne, la mise à la terre fournit un chemin de moindre résistance au

courant pour réduire le risque de décharge électrique. Cet appareil est équipé d’un cordon électrique possédant

un conducteur de terre et une fiche de terre. La fiche doit être branchée sur une prise correspondante qui a été

correctement installée et mise à la terre conformément à tous les codes et règlements locaux.

Ne pas modifier la fiche fournie; si elle n’entre pas dans la prise, faites installer une prise adéquate par un électricien

qualifié.

Un branchement incorrect du conducteur pour la mise à la terre peut entraîner un risque de décharge électrique.

Le fil conducteur avec un isolant comportant une surface extérieure verte, avec ou sans rayures jaunes, est le

conducteur de terre. S’il faut remplacer ou réparer le cordon électrique ou la fiche, ne branchez pas le conducteur de

terre à une borne sous tension.

Si les instructions de mise à la terre ne sont pas complètement comprises, ou si vous doutez que l’appareil soit

correctement relié à la terre, vérifiez avec un électricien qualifié ou le personnel de service.

Utilisez uniquement des rallonges à 3 fils avec fiche de mise à la terre à 3 branches et des réceptacles

correspondants qui accepteront la prise de l’appareil, telles qu’illustrées à la Fig. A.

Réparez ou remplacez immédiatement un cordon abîmé ou usé.

2. Pour les machines mises à la terre et branchées à un cordon d’alimentation utilisées sur un circuit

d’alimentation de régime nominal inférieur à 150 volts :

Si l’appareil est utilisé sur un circuit dont la prise de courant ressemble à celle illustrée à la Fig. A, la machine aura

alors une fiche de mise à la terre semblable à celle illustrée à la Fig. A. Un adaptateur temporaire, qui ressemble à

celui illustré à la Fig. B, peut être utilisé pour brancher cette fiche à un réceptacle à 2 conducteurs correspondant,

comme l’illustre la Fig. B, s’il n’existe aucune prise de courant correctement mise à la terre. Vous pouvez utiliser

un adaptateur temporaire seulement jusqu’à ce qu’une prise correctement mise à la terre puisse être installée par

un électricien qualifié. La patte rigide verte, la cosse et tout élément semblable sortant de l’adaptateur doivent

être correctement branchés à une masse permanente comme une boîte de sortie mise à la terre. Chaque fois que

l’adaptateur est utilisé, il doit être maintenu en place par une vis métallique.

REMARQUE : Au Canada, le Code électrique canadien n’autorise pas l’utilisation d’un adaptateur temporaire.

DANS TOUS LES CAS, ASSUREZ-VOUS QUE LE RÉCEPTACLE EN QUESTION EST BIEN MIS À

LA TERRE. EN CAS DE DOUTE, DEMANDER À UN ÉLECTRICIEN PROFESSIONNEL DE

VÉRIFIER LA PRISE.

PRISE DE

TERRE

FICHES

CONDUCTRICES DE

COURANT

FICHE DE MISE À

LA TERRE EST LA PLUS LONGUE DES 3 FICHES

FIG. A FIG. B

BOÎTE DE PRISE DE TERRE

BORNIERS

MOYENS

ADAPTATEUR

19

Page 20

3. Fonctionnement monophasé à 240 volts

Le moteur fourni avec la machine est un moteur bitension de 120/240 volts. Il est livré, prêt à fonctionner, sous

tension de 120 volts. Toutefois, il peut être converti au fonctionnement sous tension de 240 volts.

Faire appel à un électricien qualifié pour effectuer la conversion ou aux services d’un centre de réparation agréé

Delta. Une fois la conversion effectuée, l’appareil doit être conforme au Code électrique national et à tous les codes

et règlements locaux.

La conversion de l’appareil requiert un recâblage du moteur pour 240 volts, avec l’installation d’une fiche

de 240 volts au cordon d’alimentation et le remplacement de l’interrupteur par un autre homologué pour un

fonctionnement à 240 volts. Assurez-vous que la fiche de 240 volts s’insère seulement dans une prise ayant la même

configuration que la fiche illustrée à la Fig. C. Aucun adaptateur ne devrait être utilisé avec la fiche de 240 volts

BOÎTE DE SORTIE MISE À LA TERRE

BROCHES

CONDUCTRICES

question est bien mis à la terre. Si vous n’êtes pas

Dans tous les cas, assurezvous que le réceptacle en

certain, faites vérifier le réceptacle par un électricien

qualifié.

AUGE MINIMUM POUR CORDON PROLONGATEUR

CALIBRES RECOMMANDÉS POUR UNE UTILISATION AVEC DES APPAREILS ÉLECTRIQUES STATIONNAIRES

LA LAME DE MISE À LA TERRE

EST LA PLUS LONGUE DES

TROIS LAMES

FIG. C

RALLONGES

MISE EN GARDE-Utilisez des

rallonges adéquates. Assurezvous que la rallonge a 3 fils, est en bon état et est

munie d’une fiche de mise à la terre à 3 branches et

un réceptacle correspondant qui acceptera la prise de

l’appareil. Lorsque vous utilisez une rallonge, assurezvous qu’elle est suffisamment puissante pour prendre

en charge le courant de l’appareil. Un cordon sousdimensionné provoquera une chute de tension de ligne

causant une perte de courant et à une surchauffe. La

figure D illustre le bon calibre à utiliser selon la longueur

de la rallonge. Dans le doute, utilisez le prochain calibre

le plus élevé. Plus le numéro du calibre est petit, plus

lourde sera la rallonge.

Ampérage

Service

Nominal

0 À 6

0 À 6

0 À 6

0 À 6

6 À 10

6 À 10

6 À 10

6 À 10

10 À 12

10 À 12

10 À 12

10 À 12

12 À 16

12 À 16

12 À 16

Volts Longueur Totale Du Cordon

120

120

120

50 À 100 (15,24 À 30,48 M)

120

100 À 150 (30,48 À 45,72 M)

120

120

120

50 À 100 (15,24 À 30,48 M)

120

100 À 150 (30,48 À 45,72 M)

120

120

120

50 À 100 (15,24 À 30,48 M)

120

100 À 150 (30,48 À 45,72 M)

120

120

120

En Pieds

JUSQU’À 25 (7,62 M)

25 À 50 (7,62 À 15,24 M)

JUSQU’À 25 (7,62 M)

25 À 50 (7,62 À 15,24 M)

JUSQU’À 25 (7,62 M)

25 À 50 (7,62 À 15,24 M)

JUSQU’À 25 (7,62 M)

25 À 50 (7,62 À 15,24 M)

LES RALLONGES DE PLUS DE 50 PIEDS (15,24 M) NE SONT PAS

RECOMMANDÉES

FIG. D

Jauge Des Fils

Électriques De

La Rallonge

18 AWG

16 AWG

16 AWG

14 AWG

18 AWG

16 AWG

14 AWG

12 AWG

16 AWG

16 AWG

14 AWG

12 AWG

14 AWG

12 AWG

CARACTÉRISTIQUES ET COMPOSANTES IMPORTANTES

1- Goulotte à poussière

2- Courroie de ponçage

3- Armoire

4- Interrupteur d’alimentation

5- Verrouillage de patin

6- Barrière du support

7- Levier de tension de la courroie

8- Table de ponçage pour contour

9 - Moteur à induction de 1 1/2 HP

10 - Support de pièce

11- Protège-courroie arrière

FIG. 1

20

Page 21

DESCRIPTION DU FONCTIONNEMENT

La ponceuse oscillante pour champs DELTAMD est un outil de calibre professionnel conçu pour le ponçage des

surfaces droites et à angle ainsi que pour le ponçage de contour. Elle peut poncer en plan vertical ou horizontal. La

ponceuse oscillante DELTAMD est accompagnée d’une courroie de ponçage de calibre 100 grains et est montée sur

une base d’une armoire qui procure un ample espace de rangement pour les accessoires. Cet outil est alimenté par

un moteur à induction de 1 1/2 HP et de 120/240 V qui fait fonctionner la courroie de ponçage en un va-et-vient de

1,27 cm à un débit de 108 coups la minute.

SPÉCIFICATIONS DU PRODUIT

Modèle 31-482

Barrière (h x L) 10,16 cm x 60,96 cm

Taille de la courroie de ponçage (l x h) 15,24 cm x 226,06 cm

Diamètre de la goulotte à poussière 10,16 cm

Taille de la table de ponçage pour contour 24,77 cm x 29,85 cm

Taille de la table (L x l) 25,4 cm x 75,57 cm

Inclinaison de la table 0 ° à 90 °

Moteur 1 1/2 hP, 120/240 V, 1 Ph, 60 hz, TEFC

Vitesse de la courroie de ponçage 108 FPM

Course d’oscillation 1,27 cm

Oscillations par minute 108

OUTILS

NÉCESSAIRES

POUR

L’ASSEMBLAGE

• Deux clés ou douilles de

12 mm

• Clé ou douille de 10 mm

• Tournevis à tête plate

• Tournevis à tête Phillips

• Maillet en caoutchouc

Dimensions hors-tout (L x l x H) : 129,54 cm x 67,31 cm x 50,8 cm

Poids net approximatif 218

Poids approximatif à l’expédition 233

La ponceuse oscillante pour champs vient dans un seul emballage. Ouvrez l’emballage d’expédition et vérifiez que

toutes les pièces s’y trouvent et qu’elles sont en bon état :

DESCRIPTION (QUANTITÉ)

Panneau avant de l’armoire avec

porte (1)

Panneau arrière de l’armoire (1)

Panneaux latéraux de l’armoire (2)

Tablette de l’armoire (1)

Pieds en caoutchouc (4)

Bouton de verrouillage - 35 mm (1)

Bouton de verrouillage - 20 mm (1)

Bouton de verrouillage - 12 mm (2)

Table de ponçage pour contour (1)

Protège-tambour/Goulotte à

poussière (1)

Comparez le contenu de votre emballage à la liste des pièces pour

vous assurer que toutes les pièces s’y trouvent et qu’elles sont intactes.

Signalez toute pièce manquante ou endommagée à votre distributeur.

Avant de passer à l’assemblage de l’appareil et à son utilisation, lisez

attentivement le présent manuel pour vous familiariser avec les procédures

d’assemblage, d’entretien et de sécurité appropriées.

DÉSEMBALLAGE

Manuel du propriétaire (1)

Bon de garantie (1)

Ensemble de la table (1)

Support d’arrêt arrière (1)

Poignée de tension de la courroie (1)

Outil de suivi de la courroie (1)

Assemblage de la jauge à onglets (1)

Courroie de ponçage (1)

Support de fixation (1)

21

QUINCAILLERIE

Vis de 5/16 po x 5/8 po (4)

Rondelles plates de 5/16 po (22)

Écrous hexagonaux de 5/16 po (12)

Boulons à tête hexagonale de 5/16 po

x 5/8 po (8)

Boulons à tête hexagonale de 5/16 po

x 1 1/4 po (2)

Rondelles plates de 5/16 po (4)

Rondelles de blocage de 5/16 po (10)

Vis à tête cylindrique M5x10 (2)

Rondelles plates M5 (2)

Rondelles de blocage M5 (2)

Boulons à tête hexagonale 1/4 po x

5/8 po (5)

Rondelles plates 1/4 po (5)

Rondelles de blocage 1/4 po (5)

Vis à six pans creux 10-24 x 3/4 (2)

Vis à tête cylindrique (3)

Écrous à pointes à enfoncer (2)

Page 22

ASSEMBLAGE DE L’ARMOIRE

OUTILS REQUIS

• Clé de 12 mm

• Tournevis à tête Phillips

Avant de commencer l’assemblage, nettoyez toutes les surfaces

protégées de la rouille avec un solvant léger. N’utilisez pas de diluant à

peinture ou à peinture-laque, d’essence ou d’essences minérales; ces

produits pourraient endommager les surfaces peintes.

REMARQUE : Pour vous assurer que la surface supérieure de l’armoire

où vous installerez l’outil est à niveau et droite, assemblez l’armoire à

l’envers sur une surface plane.

1. En vous reportant à la Fig. 2, fixez les quatre coussinets en

caoutchouc (A) sous les panneaux latéraux (B) avec quatre vis

de 5/16 po x 5/8 po, quatre rondelles plates de 5/16 po et quatre

écrous hexagonaux de 5/16 po.

2. Utilisez quatre vis à tête hexagonale de 5/16 po x 5/8 po, huit

rondelles plates de 5/16 po, quatre rondelles de blocage de 5/16 po

et quatre écrous hexagonaux de 5/16 po pour fixer les panneaux

latéraux (B) au panneau avant (C). Serrez à la main seulement.

3. Fixez le panneau arrière de l’armoire (D) aux panneaux latéraux

à l’aide de quatre vis à tête hexagonale de 5/16 po x 5/8 po, huit

rondelles plates de 5/16 po, quatre rondelles de blocage de 5/16 po

et quatre écrous hexagonaux de 5/16 po.

4. Tournez l’armoire à l’endroit sur une surface à niveau et assurezvous que les rebords supérieurs de tous les panneaux sont de

niveau.

5. Installez la tablette (E) de l’armoire à l’intérieur de l’armoire à l’aide

de deux vis à tête cylindrique M5x10, deux rondelles plates M5 et

deux rondelles de blocage M5.

6. Serrez toute la quincaillerie.

PIÈCES

• Pieds en caoutchouc (4)

• Panneaux latéraux de l’armoire (2)

• Panneau avant de l’armoire avec porte (1)

• Panneau arrière de l’armoire (1)

• Tablette de l’armoire (1) )

QUINCAILLERIE REQUISE

• Vis de 5/16 po x 5/8 po (4)

• Rondelles plates de 5/16 po (20)

• Écrous hexagonaux de 5/16 po (12)

• Boulons à tête hexagonale de 5/16 po x

5/8 po (8)

• Rondelles de blocage de 5/16 po (8)

• Vis à tête cylindrique M5x10 (2)

• Rondelles plates M5 (2)

• Rondelles de blocage M5 (2)

FIG. 2

MONTAGE DE L’ENSEMBLE DE LA TABLE À L’ARMOIRE

OUTILS REQUIS

• Clé de 12 mm

Cette étape nécessite la présence

de deux adultes. L’ensemble de la

table est lourd, soyez prudent lorsque vous le soulevez

pour le poser sur le socle! Le non-respect peut entraîner

de graves blessures ou des dommages à la ponceuse ou à

des biens!

1. Avec l’aide d’une autre personne, soulevez avec

soin l’ensemble de la table sur le cabinet et posezle de manière à ce que les deux orifices à la base de

l’ensemble de la table soient alignés à ceux de l’une des

extrémités de l’armoire. Voir Fig. 3.

2. Ouvrez la porte de l’armoire et de l’intérieur de l’armoire,

insérez une vis à tête hexagonale de 5/16 po x 1 1/4 po

par les deux orifices puis serrez avec une rondelle de

blocage de 5/16 po et d’une rondelle plate de 5/16 po.

Voir Fig. 5.

3. Serrez la quincaillerie à l’aide d’une clé à douilles de

12 mm.

PIÈCES

• Ensemble de la table

QUINCAILLERIE REQUISE

• Vis à tête hexagonale de 5/16 po x 1 1/4 po (2)

• rondelles de blocage de 5/16 po (2)

• Rondelles plates de 5/16 po (2)

FIG.3

22

Page 23

INSTALLATION DE LA COURROIE DE PONÇAGE

OUTILS REQUIS

• Maillet en caoutchouc

1. De l’arrière de l’appareil, déverrouillez l’assemblage

du patin en tirant sur la poignée de verrouillage (A)

en votre direction, comme indiqué à la Fig. 4. Faites

pivoter l’assemblage du patin en position verticale.

2. Poussez la poignée de verrouillage dans sa position

d’origine pour fixer l’assemblage du patin en place.

REMARQUE : Ne faites pas tourner ou pivoter la

poignée de verrouillage afin d’éviter de changer la

tension de l’assemblage de verrouillage et procédez à

des réglages au besoin avant d’utiliser l’outil.

3. Retirez la protège-courroie en desserrant les deux

boutons de verrouillage (B) en faisant glisser la

protège-courroie vers la droite.

4. Placez la poignée (D) sur le levier de tension de la

courroie en tapotant légèrement à l’aide du maillet

en caoutchouc.

PIÈCES

• Courroie de ponçage de 15,2 cm x 226,1 cm

• Poignée du levier de tension de la courroie

QUINCAILLERIE

REQUISE

• Aucune

5. Déplacez le levier dans la direction indiquée sur

l’étiquette pour relâcher la tension de la courroie.

6. Ajustez la courroie au patin de ponçage de manière

à ce que l’extrémité de la courroie (E) soit de niveau

avec celle des rouleaux (F), comme indiqué à la Fig. 5.

REMARQUE : Assurez-vous que la flèche de direction de

la courroie concorde avec l’indicateur de direction de

la partie supérieure du patin de ponçage.

7. Remettez le levier de tension de la courroie en

positon resserrée. Faites pivoter la courroie

manuellement dans la direction indiquée par la

flèche pour assurer un alignement adéquat de

la courroie. Si un réglage du suivi la courroie est

nécessaire, consultez la section Réglage du suivi

de la courroie à la page 12.

INSTALLATION DU PROTÈGE-TAMBOUR

OUTILS REQUIS

• Tournevis à tête Phillips

• Tournevis à tête plate

1. Fixez un côté de l’assemblage de la charnière (A) à la protègecourroie arrière à l’aide de quatre vis à tête Phillips.

2. Placez le protège-tambour (B) sur la goulotte à poussière (C),

comme indiqué à la Fig. 6.

3. Fixez fermement l’autre côté de la charnière au protège-tambour

avec les quatre vis à tête Phillips restantes.

4. Assurez-vous que le protège-tambour est en position fermée et

couvre la courroie de transmission.

REMARQUE : Si le protège-tambour ne dégage pas le boîtier du moteur,

desserrez légèrement les deux boutons de verrouillage qui se trouvent

sur la protège-courroie arrière, soulevez la protège-courroie arrière puis

resserrez les boutons de verrouillage.

5. Assemblez une rondelle plate de 12 mm sur chacun des deux

boutons de verrouillage de 12 mm (D) et insérez l’un des boutons

de verrouillage à travers la fente de la plaque de raccordement et

l’autre par l’orifice de la plaque de raccordement.

6. Serrez les deux boutons fermement.

Pour remettre le protège-tambour en position, desserrez les deux

boutons de verrouillage, ouvrez ou fermez le couvercle, puis resserrez

les boutons de verrouillage.

PIÈCES

• Charnière

• Protège-tambour

• Boutons de verrouillage de 12 mm (2)

FIG. 4

FIG. 5

QUINCAILLERIE

REQUISE

• 8 vis à tête Phillips

• Rondelles (dimension/type) (2)

FIG. 6

23

Page 24

INSTALLATION DE LA TABLE DE PONÇAGE POUR CONTOUR

OUTILS REQUIS

• Clé à douilles de 12 mm

1. Desserrez les boutons de verrouillage (A) du

protège-tambour (B) et faites pivoter le protègetambour vers l’arrière, hors de portée. Resserrez

les boutons de verrouillage.

2. Fixez le support de fixation (C) au côté du caisson

moteur et fixez solidement à l’aide de deux vis à

six pans creux 10-24 x 3/4, comme indiqué à la

Fig. 7. L’extrémité la plus longue du support fixé

devrait être en bas.

3. Insérez la barre de fixation (D) dans la table de

ponçage pour contour (E) et fixez solidement à

l’aide d’un boulon à tête hexagonale de 12 mm et

d’un contre-écrou.

4. Insérez la barre de fixation/ensemble de la table

dans le support de fixation. Assurez-vous qu’il y a

un dégagement de tous les côtés entre la courroie

de ponçage et la table de ponçage pour contour.

5. Fixez fermement la barre de fixation/ensemble de

la table au support de fixation à l’aide du bouton

de verrouillage (20 mm) (F).

Important : Lorsque la table de ponçage pour contour

n’est pas utilisée, le protège-tambour/goulotte à

poussière doivent toujours être en position fermée

afin que le tambour ne soit pas visible..

PIÈCES

• Table de ponçage pour contour

• Barre de fixation

• Support de fixation

• Bouton de verrouillage de 20 mm

QUINCAILLERIE REQUISE

• Vis à six pans creux 10-24 x 3/4 (2)

• Boulon à tête hexagonale 12 mm

FIG. 7

INSTALLATION DU SUPPORT DE LA PIÈCE

OUTILS REQUIS

• Aucun

1. Situez les deux orifices (A) du côté droit de la

partie supérieure du patin de ponçage. Voir Fig. 8.

2. Insérez la goupille du support de la pièce (C) dans

l’orifice le plus rapproché de l’avant.

3. Fixez solidement le support de la pièce au patin

de ponçage en vissant le bouton de verrouillage

(35mm) (D) dans l’orifice bouché le plus rapproché

de l’arrière.

4. Assurez-vous que le support de la pièce est aussi

rapproché que possible de la courroie de ponçage

(B), sans qu’il n’y touche.

5. Serrez le bouton de verrouillage.

PIÈCES

• Support de la pièce