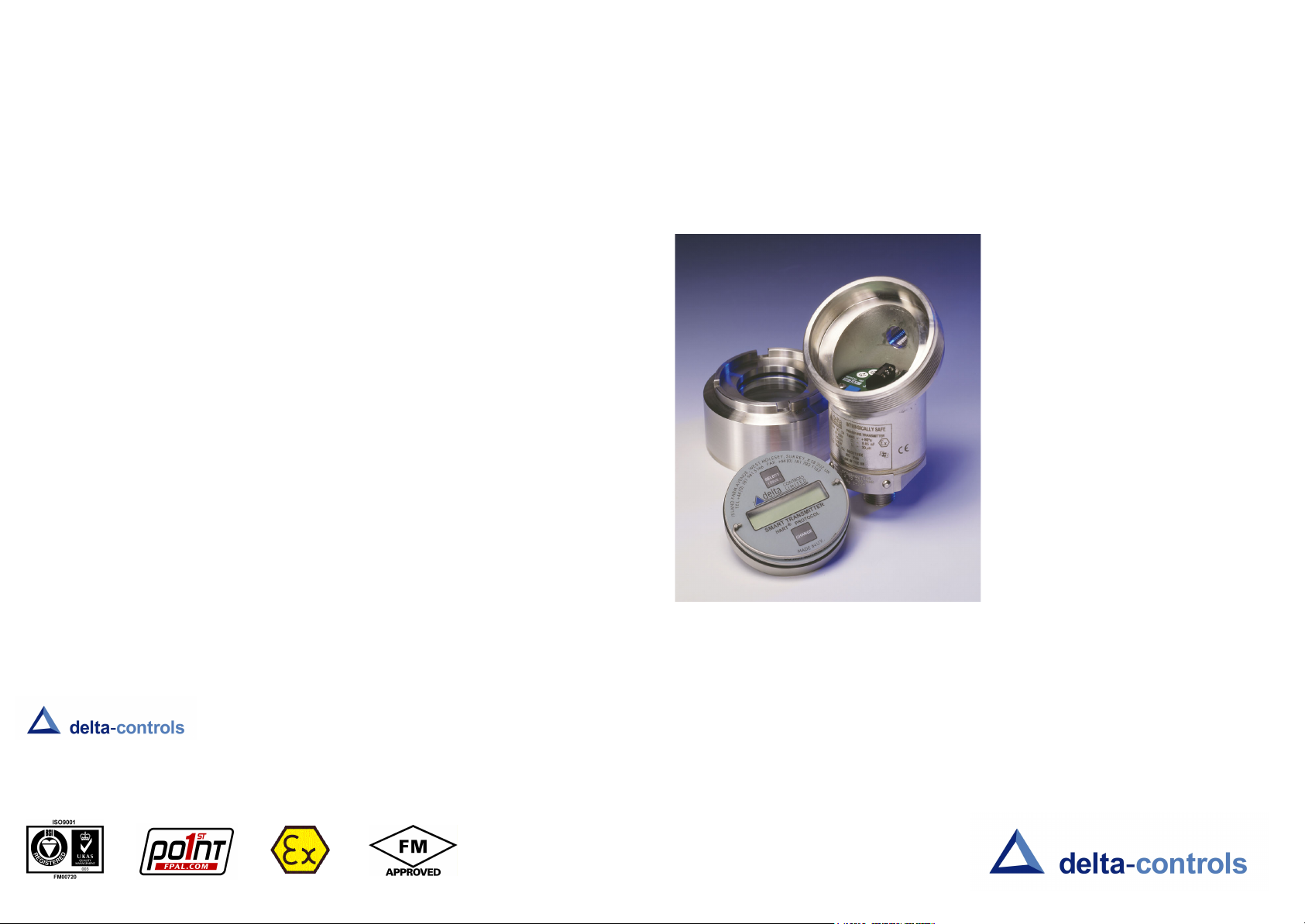

Page 1

How can we help you?

Technical Datasheets and IOM Instructions for all Delta Controls'

pressure and temperature measurement products are available

from our website at www.delta-controls.com.

D-CAL

CONFIGURATOR

For Service and Repair enquiries, please contact the Sales

Engineering Teams on +44 (0)20 8939 3500 or email

sales@delta-controls.com.

Delta Controls Limited

Island Farm Avenue, West Molesey, Surrey KT8 2UZ, UK

T +44 (0) 20 8939 3500 F +44 (0) 20 8783 1163 E sales@delta-controls.com W www.delta-controls.com

OPERATING MANUAL

Stock Number 002522/DCAL - Revised Nov. 2009

Page 2

WARRANTY

Commissioning and Set-up Examples

We guarantee this instrument against faulty workmanship and material for a period of one year from

the date of delivery. The company undertakes to repair, free of charge, ex-works any instrument

found to be defective within the specified period provided the Instrument has been used within the

specification in accordance with these instructions and has not been misused in any way. Detailed

notice of such defects and satisfactory proof thereof must be given to the company immediately

after the discovery and the goods have to be returned free of charge to the company, carefully

packed and accompanied by a detailed failure report.

HEALTH AND SAFETY

To comply with health and safety requirements, any returned instrument must be clean and safe

to handle and accompanied by a formal statement to that effect duly signed by an authorised

officer of the user company. Any instrumen t returned without certification will be quarantined and

no action will occur until cleared. We reserve the right to refuse to handle, and to return to the

user, subject to transportation charge, any instrument for which a declaration of safety is not

received.

COPYRIGHT

Copyright © 1994 - 1999 Delta Controls Limited. All rights reserved. No part of this publication

may be reproduced, stored in a retrieval system or transmitted in any form or by any means

without the express prior written permission of Delta Controls Limited.

Copyright © 1994 - 1999 Delta Controls Limited. All rights reserved. All software and firmware

supplied with this instrument, on disc or embedded are the sole property of Delta Controls Limited.

DISCLAIMER

Delta Controls Limited does not authorise or warrant any product for use in life support devices

and/or systems without the express written approval of an officer of the Company. All information

contained within this manual is provided in good faith as a guide only; for specific applications,

Delta Controls Limited should be contacted directly. The information contained within this manual

is subject to change without notice.

NOTE

HART® is a registered trademark of the HART Communication Foundation.

Hastelloy C® is a registered trademark of Cabot Corporation.

Monel ® is a registered trademark of International Nickel Co.

How to Trim the 4 to 20 mA current loop.

Objective:- To trim the current loop to match site standards.

From Monitor mode:-

the transmitter will display {VIEW}

Press [CHANGE] {ACCESS 1}

Press [CHANGE] {ACCESS 2}

Press [SELECT] {INPUT}

Press [CHANGE] {OUTPUT}

A Press [SELECT] {FIXLOOP}

Press [SELECT] Follow the instructions for FIXLOOP, set the loop

to 4.00 mA. CAUTION

fixed and independent of the applied pressure.

the analogue output is now

Press [SELECT] Return to FIXLOOP {FIXLOOP}

Press [CHANGE] {TRIMLOOP}

Press [SELECT] {TRIM 4 mA}

Press [SELECT] Follow the instructions for trim 4 mA

Press [SELECT] {TRIM 4 mA}

Press [CHANGE] {TRIM 20 mA}

Press [CHANGE] {ESCAPE}

Press [SELECT] {TRIMLOOP}

Press [CHANGE] {ESCAPE}

Press [CHANGE] {FIX LOOP}

Press [SELECT] Follow the instructions for FIXLOOP, set the

loop to 20.00 mA.

Press [SELECT] Return to FIXLOOP {FIXLOOP}

Press [CHANGE] {TRIMLOOP}

Press [CHANGE] {TRIM 4 mA}

Press [CHANGE] {TRIM 20 mA}

Press [SELECT] Follow the instructions for trim 20 mA

Press [CHANGE] {TRIM 20 mA}

Press [CHANGE] {ESCAPE}

Press [SELECT] {TRIMLOOP}

Press [CHANGE] {ESCAPE}

Press [CHANGE] {FIX LOOP}

Press [SELECT] Follow the instructions for FIXLOOP, set the

loop to 0.00 mA and the loop will be released.

Note 1 If the difference in analogue output to site standard is large, the above procedure may need to

Note 2 The loop may also be released by command {RESET} in ACCESS1.

Note 3 On Version 5.00 and later, FIXLOOP times out after 20 minutes.

1

be repeated to correct the error. Restart the procedure from "A".

30

Page 3

Commissioning and Set-up Examples

How to change the engineering units.

Objective:- Change the engineering units from the default, pascals, to Bar.

From Monitor mode:Press [CHANGE] the transmitter will display {VIEW}

Press [CHANGE] {ACCESS 1}

Press [SELECT] {INPUT}

Press [SELECT] {PV UNITS}

Press [SELECT] {Pascal}

Press [CHANGE] The display will flash the next available unit, press change until, Bar is

displayed, press and hold select for two seconds to save the new units. All engineering units will

be displayed with the new selection.

D-CAL CONFIGURATOR MANUAL

CONTENTS

Warranty, Contents ......................... 1 - 2

Document Conventions ......................... 3 - 4

Specification ......................... 5

Installation ......................... 6

Hart Commands ......................... 7 - 8

Configuration ......................... 9

How to set the range of a 0 to 10 Bar instrument.

Objective:- Re-range the transmitter 0 to 3 Bar, without reference to a pressure source

From Monitor mode:Press [CHANGE] the transmitter will display {VIEW}

Press [CHANGE] {ACCESS 1}

Press [SELECT] {INPUT}

Press [SELECT] {PV UNITS}

Press [CHANGE] {RANGEHI}

Press [SELECT] {10.000 BAR}

Press [CHANGE] The display will clear, the first character will flash.

The new URV can now be set to three bar, the value is entered in the selected engineering units.

Use the change and sel ect keys to enter the value, select the sign first, ( + ), then repeatedly

press change until the desired character is displayed, ( 3 ), select it, repeatedly press change until

the decimal point character is shown, ( o ), select it, repeatedly press select until the last character

is flashing, when select is pressed the whole display will flash, press and hold select for two

seconds to save the new value.

The URV of the transmitter is now set to 3.0 Bar, the instrument will output 20 mA for an input

pressure of 3.0 Bar.

If the instrument is re-ranged with reference to a pressure source, the digital display may need to

be trimmed using TRIM URV, TRIM LRV to match a site pressure standard. This can improve the

accuracy at large turndowns; the accuracy of the pressure source used for reference must be

considered.

Monitor mode ...................... 10

Menu Layout ........................ 11 - 12

View Mode ........................ 13 - 14

Access 1 ......... ............... 15 - 22

Access 2 ........................ 23 - 28

Examples ........................ 29 - 30

Password restricted Access ......................... 11

We, Delta Controls Limited,

as the manufacturer of the apparatus listed, declare under our sole responsibility that the products listed

below

to which this declaration re lates are in conformity w ith the following standards or other norma tive

documents

and thereby conform with the requirements of Council Directive 89/336

Authorised by R B Harrison, Managing Director

Island Farm Avenue,

West Molesey, Surrey

KT8 2UZ, England.

Pressure Transmitters A - 2HT, 4 - 2HT, F - 2HT, R - 2HT

EN 50 082-2 : 1992

EN 50 081-1 : 1992

29

2

Page 4

DOCUMENT CONVENTIONS

Used within this manual to show

how a command or other

message is displayed within the

menu.

[SELECT]{ENABLED}[SELECT]{2222}

The first character will be flashing, use the change and select keys to enter the password

number you require. When the last character is set the display will flash.

There are now two options :-

[SELECT] Press briefly to abort and return to the {ACCESS 1} menu.

[[SELECT]] Press and hold to save the new code.

{ACCESS 2}

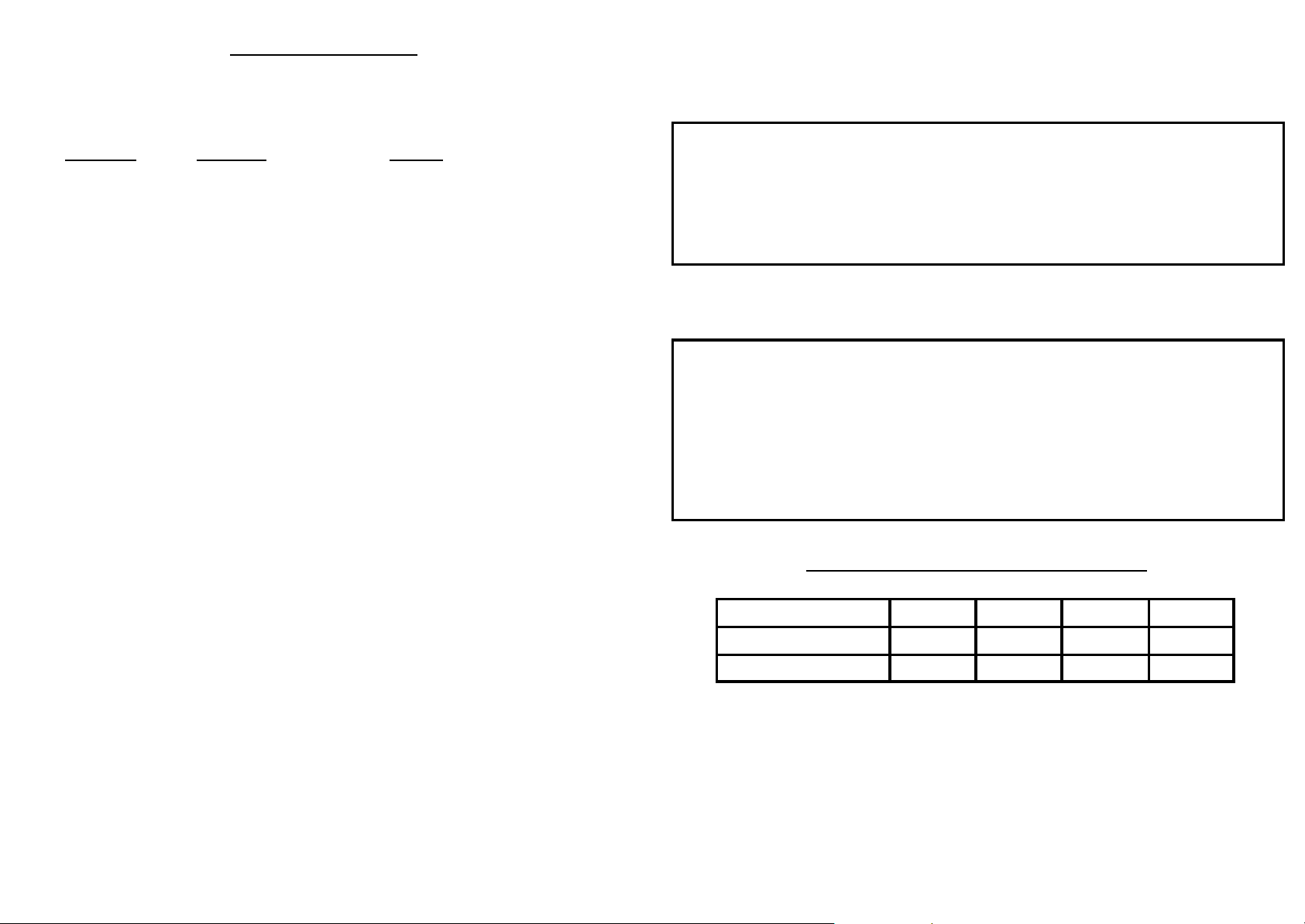

This manual uses the following typographical conventions to describe the functionality of the

transmitter. The blind instrument has two buttons, marked ZERO and SPAN. The D-CAL has two

buttons, marked SELECT (SAVE) and CHANGE

Convention Description Function

[ZERO] [SPAN] Bold and bracketed

denotes a single

operation of a key.

Press and hold for

around two seconds

[SELECT]

[CHANGE]

[[SELECT]] Bold and double

{MENU} The menu option

When the keys, or functions, are discussed within the text they will be referred to by their name in

lower case, without brackets. The zero and span buttons are mounted on the upper board,

while the select and change buttons are part of the display module.

Denotes a single, short

operation of a key on

the local display unit

bracketed

Press and hold for

around two seconds

bracketed, e.g.

{RANGELO}

Used to set the LRV and URV of

the blind transmitter

Used to navigate the menu

system, and request a change to

an entry.

The save function used to store a

change to the EEprom

The screen will respond with

{SAVED}

{ACCESS 2}[SELECT]

Once select is pressed the state of the password is shown either enabled or disabled press

[CHANGE] until the desired state is shown.

There are now two options :-

[SELECT] To abort and return to the {ACCESS 2} menu.

[[SELECT]] Used to save the new state.

When {SAVED} is displayed press [SELECT] to return to {ACCESS 2}.

Once the access level has been enabled the password can be checked or changed.

From {PASSWORD}{ACCESS 2} :-

When {SAVED} is displayed press [SELECT] to return to {ACCESS 1}.

DO NOT FORGET TO LOG YOUR NEW PASSWORD

3

DATE SHIPPED

ACCESS 1 1111

ACCESS 2 2222

28

Page 5

{ACCESS 2}

DOCUMENT CONVENTIONS

READ THIS SECTION BEFORE ENABLING THE PASSWORD

{PASSWORD}[SELECT]

The password function controls access to the menu levels of the transmitter. It acts only on the

local D_CAL configurator, but can be turned on or off both locally and remotely. It is assumed that

where the transmitter forms part of an extended HART® system, that the system itself or local site

disciplines will ensure that only authorised operatives gain access. If changes are made in a

restricted menu, the transmitter will auto matically abort to monitor mode after 5 minutes. The

transmitter is shipped with the passwords set to 1111 and 2222 respectively, but not enabled. If

the numbers are changed and not recorded there is no way access can be gained. If this happens

Delta can supply a unique secondary ACCESS 2 code.

{ACCESS 1}[SELECT]

Once select is pressed the state of the password is shown either enabled or disabled. Press

[CHANGE] until the desired state is shown.

There are now two options :-

[SELECT] Press briefly to abort and return to the {ACCESS 1} menu.

[[SELECT] ] Press and hold to save the new state.

When {SAVED} is displayed press [SELECT] to return to {ACCESS 1}.

Once the access level has been enabled the password can be checked or changed.

From {PASSWORD}{ACCESS 1} :-

[SELECT]{ENABLED}[SELECT]{1111}

The first character will be flashing, use the change and select keys to enter the password number

you require. When the last character is set the display will flash.

There are now two options :[SELECT] To abort and return to the {ACCESS 1} menu.

[[SELECT]] Used to save the new code.

When {SAVED} is displayed press [SELECT] to return to {ACCESS 1}.

When commands are described in this manual, a set format is followed. At the top of the page, the

access level is shown, e.g. {ACCESS2}

What you see on the screen is shown in “curly” brackets, e.g. {RANGEHI}, followed by a

short explanation of the commands functionality or special points to note.

You then press [SELECT], [CHANGE] or [[SELECT]] as required - see page 4.

The manual explains the edits or changes that can be made, and how to return to the menu .

If you get lost within the menu system the layout on page 12 - 13 gives a full over view.

Please note :- After 5 minutes the display returns to monitor mode automatically.

Display and Edit Functions

All commands and functions are displayed as eight characters for clarity. Where

messages, descriptions or values with engineering units are shown that require more than eight

characters, the display will scroll or toggle.

Once a menu options value is displayed and the change button pressed, edit mode is

activated.

There are four forms of editing, used for different functions :-

1. Template, Used for {TRIMLOOP}

2. Scrolling, Used to enter values that are longer than the display {DESCRIPT}

3. Text, Used to edit the text strings and messages that fit on screen {TAG}

4. Choice, enable \ disable, Used for turning functions on and off {SHOWHART}

All of these edits used the change and select keys in th e same way, change to cycle

the digits to the one you want, select to move to the next character, when the display flashes

[[SELECT]] to save, [SELECT] to abort.

DO NOT FORGET TO LOG YOUR NEW PASSWORD

27

4

Page 6

LOCAL DISPLAY

{ACCESS 2}

PERFORMANCE SPECIFICATION :-

The local display / configurator is not connected via the signal loop, but accesses the micro

processor directly. This allows the unit to display a digital representation of the

measured

variables and settings without the inaccuracies or loop loading or an analogue meter.

Temperature Effect :- The local display can operate over the range -30 to +85, but at very

low temperatures the display slows down to allow the characters to be

displayed properly, this is controlled by the microcontroller.

Response Time :- This is dependent upon menu option and temperature

but is typically less than 1 second.

RFI Effect :-

Switch Life :- 10,000,000 operations

PHYSICAL SPECIFICATION :-

The local display / configurator is connected to the top board using a 10 way IDC connector which

carries the information and power to the unit. The case is constructed of 316 stainless steel and

has a keyboard overlay and 'O' ring seal that gives it protection to IEC IP65 with the lid removed.

The keyboard is resistant to most industrial solvents and has full EMI protection. If the overlay

becomes damaged on site the overlay may be replaced in the field.

The display can be turned to any angle within the enclosure to suit the mounting position, this

will not affet the accuracy or protection rating. When the display is fitted the lid has a clear glass

window fitted, scratch resistant and impact resistant to seven joules.

The display is fully protected against RFI effects.

To perform the next two steps the use of a suitably calibrated DMM is required. The

loop current is monitored and entered into the transmitter, the unit then uses this as an

offset to calibrate its output. Because the process is iterative trim 4 mA and trim 20 mA

may have to be repeated if the error is excessive

L CAUTION Make sure that the loop is isolated or safe !!

{TRIMLOOP}[ SELECT]{TRIM 4 mA}[ SELECT]

This command will be rejected if FIXLOOP has not been set to 4.00 mA

An edit template is displayed, enter the reading from the DMM.

When change is pressed the first character starts to flash, change cycles the numerals

while select moves to the next character. When the last numeral is reached the whole

display flashes and you have two choices.

[SELECT] Aborts the edit and returns to {FIXLOOP}

[[SELECT]] Performs the [SAVE] function and resets the loop current.

The DMM should show the corrected reading.

{TRIMLOOP}[SELECT]{TRIM 20 mA}[SELECT]

Weight:- Add 200 grams (0.44 lb) to instrument.

5

This command will be rejected if FIXLOOP has not been set to 20.00 mA

An edit template is displayed, enter the reading from the DMM.

When change is pressed the first character starts to flash, change cycles the numerals while

select moves to the next character. When the last numeral is reached the whole display flashes

and you have two choices.

[SELECT] Aborts the edit and returns to {FIXLOOP}

[[SELECT] ] Performs the [SAVE] function and sets the loop current.

The DMM should show the corrected reading.

26

Page 7

{ACCESS 2}

The FIXLOOP and trim functions are used to remove any differences between calibration

and site current standards. The electronics generates and monitors the output current

continuously but variations in site standards may require the output gain and zero to be

trimmed. The FIXLOOP command may also be used to calibrate other instruments and

controllers within the loop, by controlling the current within the loop .

{FIXLOOP}[SELECT]

This command will fix the loop at any current from 3.8 mA to 22 mA.

Set the value to 0.00 to release control of the loop.

When change is pressed the first character starts to flash, change cycles the numerals

while select moves to the next character. When the last numeral is reached the whole

display flashes and you have two choices.

LOCAL CONFIGURATOR INSTALLATION & WIRING

L CAUTION Make sure that the loop is isolated or safe !!

The local configurator / display is connected to the transmitter with a length of ribbon cable which

carries power, display drive and switch signals to the microprocessor. The cable is terminated in

an IDC connector that fits into the header on the top connection board, the plug is keyed to ensure

correct polarisation. PLEASE NOTE the transmitter should have its loop wiring fitted before the

display is connected which will ensure the display cable is not damaged.

When the display is connected the assembly can be pushed into place, check that the 'O' ring is

serviceable and apply light silicon grease if necessary. Engage the display and with firm pressure

on the outside edge push the unit home until the display face is level with the top of the housing.

DO NOT apply pressure to the clear window as you may damage the display.

Once the display unit is fitted the zero and span buttons on the top board are disabled, access to

the zero and span options being made through the menu system :-

{ACCESS 2}, {INPUT},{ZERO KEY} or {SPAN KEY}

[SELECT] Aborts the edit and returns to {FIXLOOP}

[[SELECT]] Performs the [SAVE] function and sets the loop current.

L CAUTION Make sure that the loop is isolated or safe !!

(see Section on ACCESS2 for details)

When necessary the unit may be removed by using the handle provided, with firm pressure and

your thumb on the edge of the housing.

DO NOT ROTATE THE DISPLAY IN -SITU

If the display needs to be rotated for ease of viewing the display unit should be removed and then

re-seated in its new position.

25

6

Page 8

Commands and HART Numbers used by 2HT

1 U M

{ACCESS 2}

(Only user-accessible commands are listed)

Number Class Local Description

0 U V Read Unique Identifier 1

Read Primary Variable

2 U M Read PV Current and Percentage of Range

3 U M Read Dynamic Variables and PV Current

6 U Write Polling Address

12 U V Read Message

13 U V Read Tag, Descriptor, Date

14 U V Read Primary Variable Sensor Information

15 U V Read Primary Variable Output Information

16 U V Read Final Assembly Number

17 U 1 Write Message

18 U 1 Write Tag, Descriptor, Date

34 C 1 Write Primary Variable Damping Value

35 C 1 Write Primary Variable Range Values

36 C 2 Set Primary Variable Upper Range Value

37 C 2 Set Primary Variable Lower Range Value

38 C 1 Reset Configuration Changed Flag

40 C 2 Enter / Exit Fixed PV Current Mode

41 C 1 Perform Transmitter Self Test

42 C 1 Perform Master Reset

43 C 2 Set Primary Variable Zero

44 C 1 Write Primary Variable Units

45 C 2 Trim Primary Variable Current DAC Zero

46 C 2 Trim Primary Variable Current DAC Gain

47 C 1 Write Primary Variable Transfer Function

48 C Read Additional Status

53 C Write Secondary Variable Units (Temperature)

COMMANDS U Universal C Common D Device Specific

LOCAL ACCESS M Monitor V View

(D-CAL) 1 Access Level 1 2 Access Level 2

With the local display fitted, access to the zero and span keys on the top circuit board is

restricted, and their operation is disabled by the software. The two functions are now available

through the menu structure. They may look similar to the trim functions but it must be remembered

they change only the upper and lower range values, which represent the analogue output. The

two keys do not modify the factory calibration.

{ZERO KEY}[SELECT]

This command is the same as pressing the zero key on the top board. The lower range value

(LRV) is set to the applied pressure and is represented by 4 mA.

Before the value is saved, the desired pressure must be applied to the instrument, and allowed

to settle.

{HIT SAVE} will be displayed, there are two choices :-

[SELECT] or To abort and return to the {ZERO KEY} menu.

[CHANGE]

[[SELECT]] Used to store the new lower range value, {SAVED} will be displayed

to show that the command is successful.

{SPAN KEY}[SELECT]

This command is the same as pressing the span key on the top board. The upper range value

(URV) is set to the applied pressure and is represented by 20 mA.

Before the value is saved, the desired pressure must be applied to the instrument, and allowed

to settle.

{HIT SAVE} will be displayed, there are two choices :-

[SELECT] or To abort and return to the {SPAN KEY} menu.

[CHANGE]

[[SELECT] ] Used to store new upper range value, {SAVED} will be

displayed to show that the command is successful.

NB To give a reversed output, apply the higher pressure when the zero key is pressed and vice

versa.

7

24

Page 9

{ACCESS 2}

The (TRIMxxx) functions are used to trim the Lower and Upper Range Values of the analogue to

digital converter (ADC) to an accurately generated, external pressure standard. This is used if the

instrument is found to differ from the site standard, for whatever reason. The command can also

be used to increase the measurement accuracy of a turned down instrument.

{TRIM LRV}[SELECT]

Apply a pressure equal to the LRV pressure (usually, but not necessarily zero!!) to the

instrument, and allowed to settle. NOTE:- the accuracy of the reference pressure should be 3 -

5 times better than the instrument.

{HIT SAVE} will be displayed, there are two choices :-

[SELECT] or [CHANGE] To abort and return to the {TRIM LRV} menu

[[SELECT]] Press and hold for two seconds to store the ADC offset value,

{SAVED} will be displayed to show that the command is successful.

{TRIM URV}[SELECT]

The URV may be trimmed to increase the accuracy of the transmitter when using large

turndowns. Apply a pressure equal to the LRV pressure. NOTE:- the accuracy of the reference

pressure should be 3 - 5 times better than the instrument.

{HIT SAVE} will be displayed, there are two choices :-

[SELECT] or[CHANGE] To abort and return to the {TRIM URV} menu.

[[SELECT]] Press and hold to store the ADC offset value, {SAVED} will be

displayed to show that the command is successful.

Commands and HART Numbers used by 2HT

Number Class Local Description

135 D 1 Restore Factory Defaults

148 D V View Trim settings

149 D 2 Set PV Trim Span

151 D 2 Set Password Access for D-CAL

152 D V View Model Number

COMMANDS U Universal C Common D Device Specific

LOCAL ACCESS M Monitor V View

(D-CAL) 1 Access Level 1 2 Access Level 2

HART Commands

These commands are not supported by the transmitter, but will be decoded when the

SHOWHART command is enabled.

Number Class Description

33 C Read Transmitter Variables

39 C EEprom Control

50 C Read Dynamic Variable Assignments

51 C Write Dynamic Variables Assignments

52 C Set Transmitter Variable Zero

54 C Read Transmitter Variable Information

55 C Write Transmitter Variable Damping Value

56 C Write Transmitter Variable Sensor Serial Number

57 C Read Unit Tag, Descriptor, Date

58 C Write Unit Tag, Descriptor, Date

59 C Write Number of response preambles

108 C Write Burst Mode Command Number

109 C Burst Mode Control

110 C Read All Dynamic Variables

23

8

Page 10

Configuration using the Local Display

{ACCESS 1}

View This menu option is an unprotected level, most of the internal parameters can

Access 1 This is a protected option; a password may be set if required to restrict access

Access 2 This is a protected option; a password maybe set if required to restrict access to

Please Note :- When the transmitter is shipped from Delta the passwords are set to their

If you become locked out a master password maybe issued by Delta but an administration cost

may be charged at their discretion.

Passwords only apply to the D-CAL local configurator. It is assumed that access via a host

computer or a hand-held configurator will be adequately controlled by the system itself or

site access discipline.

be viewed using this selection but no changes can be made. Intended for

recording and logging instrument set-ups.

to the choices within this section. The passwords are set and enabled within

{ACCESS 2}.This menu option contains information that can be viewed, edited

and saved to re-configure the transmitter, using its built-in data as reference.

the choices within this section. This section contains the highest level of menu

options, and consists of choices for commissioning, low level protection and

setting of passwords. It also contains fundamental calibration and setting

procedures which require reference to external standards.

default of {1111} and {2222}, if you edit and save, the new passwords become

the default and stay resident even when loop power is removed.

DO NOT FORGET TO LOG YOUR PASSWORD.

{SHOWHART}[SELECT]

This command, when enabled displays all decoded incoming HART messages by their

number on the display. It may be disabled or left enabled, the default is disabled. The transmitter

will decode all messages that are on the HART bus, and will decide if it needs to reply to them.

SHOWHART will display all messages, even if they are intended for another transmitter,

this allows the digital integrity of the line to be checked.

The command numbers are displayed in monitor mode, and will overwrite the prime

variable display, the numbers can be decoded using the command summary on page 58, this

gives the command numbers available to the transmitter.

The state of the SHOWHART flag is shown, press [CHANGE] until the required state is shown.

There are now two options :[SELECT] Press briefly to abort and return to the

{SHOWHART} menu.

[[SELECT]] Press and hold to save the new state.

9

22

Page 11

{ACCESS 1}

CONFIGURATION USING THE D-CAL

{SELFTEST}[SELECT]

If you suspect the functionality of the transmitter, SELFTEST when passed will give a very high

confidence level of the transmitters output, this is an extension of the tests that the unit performs

on itself at all times.

The screen will blank, test the display, memory, etc. and if all tests pass the unit will respond

{MEM OK}, if a test fails the results will be shown on the screen.

[SELECT] To return to the {SELFTEST} menu.

L CAUTION The transmitter will be off line for 2 seconds, and will respond to HART®

host requests as busy.

{RESET}[SELECT]

This is a master reset of the transmitter, it is equivalent to cycling the power, a SELFTEST is

performed. Please note that the analogue current is set to 4 mA at the beginning of the test.

When [SELECT] is pressed the reset function will begin.

{RESTORE}[SELECT]

The restore command is used to reset the analogue output calibration values which were

established during factory calibration. Please note the URV and LRV, zero and span trims and

analogue trims will be reset.

{HIT SAVE} will be displayed, there are two choices :-

[SELECT] or To abort and return to the {RESTORE} menu.

[CHANGE]

[[SELECT] ] Press and hold to initiate the restore function,

{SAVED} will be displayed...or

[SELECT] Press and release to return to the {RESTORE} menu.

configuration and commissioning. It uses an alphanumeric display so that engineering units and

The local D-CAL Configurator unit gives the operator a user friendly interface for

menu titles may be shown. Wherever possible the HART® functions have been placed in a logical

position within this structure. The two buttons, change and select are used to navigate though the

selections.

MONITOR MODE

When the unit is first turned on the default is monitor mode, the unit will display the Prime

Variable, cycling between the value and the engineering units. Press the [SELECT] button to cycle

through the other displays available.

Primary Variable

This shows the actual pressure (gauge, absolute or differential) that the unit is currently

sensing. The default unit of measurement is the Pascal, from which all other engineering units

are calculated. Each time the selected engineering units for pressure are changed, all values

displayed from the menu system will use these selected units. Note that the displayed value

covers the full range of permitted input pressure, irrespective of the “turndown” selected for

the 4 to 20 mA output.

Loop Current

This displays the current within the control loop. If the loop has been fixed (see

{FIXLOOP}), it will show the fixed value and not reflect the value of the input.

Temperature

This shows the temperature of the sensor. While it is used primarily for the compensation

of the transmitter, it is useful for diagnostics and general information. It is not the temperature

of the process but can give an indication depending upon installation practice.

Percentage

This is the selected output of the transmitter expressed as a percentage. When the

square root function is selected for a flow application, this will therefore show the percentage

of the selected flow range. Engineering units for flow are not available.

{SHOWHART}

If the command {SHOWHART} has been enabled under access level 1, then in monitor

mode, the transmitter will also show any received HART® commands. The command is

displayed as the command number and is automatically cleared after two seconds.

21

10

Page 12

MONITOR and VIEW

DISPLAY

MONITOR PV LOOP CURRENT

SENSOR TEMP

% OUTP UT

{ACCESS 1}

{TAG}[SELECT]

Monitor mode is the default

of the display, it shows prime

variable, loop current and sensor

temperature. Prime variable is always

displayed, cycling between value and

engineering units, this is to allow

engineering units to be shown

without scrolling the display. It is quite

normal for the D-Cal unit to change its

scroll and cycle speed aid clarity at

lower temperatures.

RESTRICTED ACCESS

To gain access to a

restricted level the following steps

should be performed.

{--> 0***} With '0' flashing.

Use the select and change keys to

enter the code number. When the

last digit is selected a decision is

made, if the number is correct the

menu level is entered, other wise the

menu will abort to {ACCESS 1}

If the wrong number is entered

access will be denied.

VIEW

ACCES S 1

ACCES S 2

ACCESS 2

INPUT TRIM LRV

TRIM URV

ZERO KEY

SPAN KEY

ESCA PE

OUTPUT FIX LOO P

TRIM LOOP

ESCA PE

PASSWOR D ACCES S 1

ACCES S 2

ESCA PE

TRIM 4mA

TRIM 20mA

ESCA PE

An eight character alphanumeric field for identification e.g. {TANK6} {LEVEL9}

The tag is displayed on screen, there are two options :-

[SELECT] To abort displayed tag and return to the TRANSMTR menu.

[CHANGE] Used to edit the display. See page 5 ' Display and Edit '

{MESSAGE}[SELECT]

A 32 character alphanumeric field for any information set by site practice e.g..

{CHECKED BY SIMON 29 02 92} or {HIGH PRESSURE SERVICE}

The message is displayed on screen, there are two options :-

[SELECT] To abort displayed message and return to the TRANSMTR menu.

[CHANGE] Used to edit the display. See page 5 ' Display and Edit '

{DESCRIPT}[SELECT]

A 16 character alphanumeric field for additional identification of the transmitter

e.g.. {TANK 6} {LEVEL 9} {UNIT 27} etc.

The Description is displayed on screen, there are two options :-

[SELECT] To abort displayed message and return to the TRANSMTR

menu.

ESCA PE

The access restrictions apply to local configuration only. It is assumed that remote access, via

a portable HART® configurator on a host computer, is adequately access-protected.

11

{DATE}[SELECT]

The date may be the next calibration day, last re-zeroed, according to site practice.

The date is entered in the form DD MM YY

The information is sent digitally in the form MM DD YY.

The date is displayed on screen, there are two options :-

[SELECT] To abort displayed message and return to the TRANSMTR menu.

[CHANGE] Used to edit the display. See page 5 ' Display and Edit '

20

Page 13

(Nb There is no Page 18)

{ACCESS 1}

{OUTPUT}[SELECT]

The transmitter’s analogue output and percentage display may be linear or square root, selected

by this function. The PV display of engineering units is linear at all times. There is no facility for

displaying engineering units of flow. If this is required, then a separate Flow Computer should be

used.

The output function is displayed; there are two options :-

[SELECT] To abort and return to {OUTPUT}.

[CHANGE] Used to edit the display.

{LINEAR} This is the default condition and provides a linear analogue output and

percentage display with reference to applied pressure input.

{SQ ROOT} This applies square root extraction to the analogue output and percentage display

with reference to applied pressure, often used for flow calculation. This is available on pressure

and differential pressure units, as standard software is used for both.

INPUT

OUTPUT

TRAN SMTR

CONTROL

ACCESS 1

PV UN ITS

RANGE HI

RANGE LO

DAMPING

BURNOUT

ESCA PE

LINEAR

SQ ROOT

TA G

MESSAGE

DESCRI PT

DATE

ESCA PE

SELF TEST

RES ET

RESTOR E

SHOWHART

ESCA PE

SELECT

CHANGE

INPUT SENSOR

RANGE HI

OUTPUT

ADDRES STRAN SMTR

MESSAGE

VIEW

RANGE LO

DAMPING

BURNOUT

ESCA PE

TA G

DESCRI PT

DATE

MODEL NO

PRVT LAB

DEV ID

VERSION

ESCA PE

SER NO

HI LIMIT

LO LIMIT

MIN SPAN

ESCA PE

19

ESCA PE

ESCA PE

Both Access 1 and Access 2 can be protected by passwords. Before they are enabled, it is

recommended that you read the section on Passwords. The D-CAL unit will default to Monitor

Mode if there are no keystrokes for five minutes.

12

Page 14

{VIEW}

The view menu is not protected by a password, as no changes can be made from within this menu

option. After five minutes it will return to the monitor mode.

{INPUT} [SELECT] Enter the input menu

{SENSOR} [SELECT] Enter the sensor menu

{SER NO} [SELECT] Show the sensor serial number, in decimal

{HILIMIT} [SELECT] Show the sensor URL in engineering units

{LOLIMIT} [SELECT] Show the sensor LRL in engineering units

{MINSPAN} [SELECT] Show the sensor’s minimum available span, If

{RANGEHI} [SELECT] Show, in engineering units, the transmitter URV

{RANGELO} [SELECT] Show, in engineering units, the sensor LRV

{DAMPING} [SELECT] Show the damping value in seconds. This is

{BURNOUT} [SELECT] This shows which direction the analogue output

Pressing {CHANGE} wil move down through the menu.

At the end of each sub-menu, select {ESCAPE} to return to the higher menu.

this is exceeded when using turndowns greater

than 20 to 1 an error will be reported.

corresponding to 20 mA

corresponding to 4 mA.

applied to the analogue and digital output

signals.

will go in event of a fatal sensor failure.

13

18

Page 15

{INPUT} continued

{ACCESS 1}

{VIEW}

{OUTPUT} [SELECT] This shows the function that is applied to the

analogue output. The options are {LINEAR} AND

{SQ ROOT}

{DAMPING}[SELECT]

The damping command is used to slow the rate of change of the output signal, it modifies both

the analogue and digital signal.

The damping value is displayed in seconds, there are two option :-

[SELECT] To abort displayed tag and return to {DAMPING} menu.

[CHANGE] Used to edit the display.

Damping uses a fixed template and will accept values between 0 and 39 seconds.

{BURNOUT}

Burnout is used to sense a failure of the sensing element. It drives the analogue output either

upscale or downscale depending upon its setting.

Once select is pressed the state of the burnout flag is shown either upscale or downscale. Press

[CHANGE] until the desired state is shown.

There are now two options :-

[SELECT] To abort and return to the {BURNOUT} menu.

[[SELECT] ] Press and hold to save the new state.

Pressing {CHANGE} wil move down through the menu.

At the end of each sub-menu, select {ESCAPE} to return to the higher menu.

{TRANSMTR}

{ADDRESS}

{TAG} [SELECT] Shows the tag, 8 characters.

{MESSAGE} [SELECT] Shows the message, 32 characters.

{DESCRIPT} [SELECT] Shows the description, 16 characters.

{DATE} [SELECT] Shows the date. When using the HART® format

{PRVT LAB} [SELECT] This shows the distributors number if the

{DEV ID} [SELECT] This shows the device identification number in

[SELECT] Enter the Transmitter menu

[SELECT] Shows the polling address of the instrument, 0 for

point to point, 1 -15 for multi-drop. If the value is set

from 1 - 15 the analogue value is set to 4 mA.

for remote communications the date is transmitted

as MM DD YY format. On the display it is shown

as DD MM YY

instrument is being sold under a badging

agreement, see HART® common tables

decimal, this is combined with the manufacturers

id and device type

(Nb There is no Page 18)

17

{VERSION} [SELECT] The software version, original manufacturer and

copyright notice will be displayed.

14

Page 16

{ACCESS 1}

{ACCESS 1}

{INPUT} [SELECT]

{PV UNITS}[SELECT]

Because the measured pressure is converted to a digital number the way the number

is displayed can be scaled to represent different engineering units, this affects the digital and

local display signals.

The prime variable (PV) units of measure are displayed, there are two choices :-

[SELECT] To abort and return to the {OUTPUT} menu.

[CHANGE] Used to change the units of measure. There are set choices of units dependent

upon which output function is enabled.

LINEAR & SQUARE ROOT

{ InH20 }

{ InHG }

{ FtH20 }

{ mmH20 }

{ mmHG }

{ PSI }

{ Bar }

{ mBar

{ Gm/SQcm }

{ KG/SQcm }

{ PaScal }

{ KPaScal }

{Torr }

{ Atm }

Once the required units are displayed they can be selected and saved [[SELECT]]

or [SELECT] to abort to the {PV UNITS} menu.

{INPUT} continued

{RANGEHI}[SELECT]

This is the pressure represented by 20 mA and may be less than range low to achieve reverse

action of the analogue output. This allows the analogue output of the transmitter to be re-ranged

without using a reference. It also sets a value to which { TRIM URV } will be set

under {ACCESS2}, below.

The URV is displayed followed by the engineering units there are two options :-

[SELECT] To abort displayed tag and return to {RANGEHI} menu.

[CHANGE] Used to edit the display.

The edit featu re does not use a template because the values are entered in the current

engineering units. The screen is blank with a flashing {+} sign, work along the display entering

the value, use the character after {9} to depict a decimal point.

When the last character is reached [[SELECT]] will save the value and 20 mA will now represent

this new pressure on the analogue loop.

{RANGELO}[SELECT]

This is the pressure represented by 4 mA and may be greater than range high to achieve reverse

action of the analogue output. This allows the analogue output of the transmitter to be re-ranged

without using a reference. It also sets a value to which { TRIM LRV } will be set under

{ACCESS2}, below.

The display, options and edit features are the same as for RANGEHI.

This pressure will now be represented by 4 mA on the analogue loop.

Any change to the prime variable units will change all engineering units that are displayed,

upper and lower range limits, upper and lower range values and alarms.

The display may need to scroll to display the longer engineering units.

15

Pressing {CHANGE} will move down through the menu.

At the end of each sub-menu, select {ESCAPE} to return to the higher menu.

16

Loading...

Loading...