Page 1

Smart 2HT transmitter

Issue Feb 10

How can we help you?

Technical Datasheets and IOM Instructions for all

Delta Controls' pressure and temperature

measurement products are available from our

website at www.delta-controls.com.

For Service and Repair enquiries, please contact the

Sales Engineering Teams on +44 (0)20 8939 3500

or email sales@delta-controls.com.

Delta Controls Limited

Island Farm Avenue, West Molesey, Surrey KT8 2UZ, UK

T +44 (0) 20 8939 3500 F +44 (0) 20 8783 1163 E sales@delta-controls.com W www.delta-controls.com

002522-2HT 180210.doc

1

Page 2

CONTENTS

Warranty - - - - - - - - 3

Glossary - - - - - - - - 3 - 4

Product Introduction - - - - - - - - 5

Features

Sensor, Electronics - - - - - - - - 5

Software & Local Display - - - - - - - - 5 - 6

Installation

General - - - - - - - - 6

Mechanical - - - - - - - - 7

Electrical - - - - - - - - 7 - 9

Commissioning

Blind Instrument - - - - - - - - 9 -10

Multi-Drop - - - - - - - - 11

Trouble Shooting - - - - - - - - 11

Specifications - - - - - - - -

Functional, Performance 12

Physical & Drawings - - - - - - - - 13

Certified Products - - - - - - - - 14-15

Options, Spares and Maintenance - - - - - - - - 16

Re-Calibration Procedure - - - - - - - - 16

Product code - - - - - - - - 17

002522-2HT 180210.doc

2

Page 3

WARRANTY

This instrument is guaranteed against faulty workmanship and material for a period of one year from the

date of delivery. The company undertakes to repair, free of charge, ex-works any instrument found to be

defective within the specified period provided the instrument has been used within the specification in

accordance with these instructions and has not been misused in any way. Detailed notice of such defects

and satisfactory proof thereof must be given to the company immediately after the discovery and the

goods have to be returned free of charge to the company, carefully packed and accompanied by a

detailed failure report.

HEALTH AND SAFETY

To comply with health and safety requirements, any returned instrument must be clean and safe to

handle and accompanied by a formal statement to that effect duly signed by an authorised officer of the

user company. Any instrument returned without certification will be quarantined and no action will occur

until cleared. We reserve the right to refuse to handle, and to return to the user, subject to transportation

charge, any instrument for which a declaration of safety is not received.

COPYRIGHT

Copyright © 1994 - 2007 Delta Controls Limited. All rights reserved. No part of this publication may be

reproduced, stored in a retrieval system or transmitted in any form or by any means without the express

prior written permission of Delta Controls Limited.

Copyright © 1994 - 2007 Delta Controls Limited. All rights reserved. All software and firmware supplied

with this instrument, on disc or embedded are the sole property of Delta Controls Limited.

DISCLAIMER

Delta Controls Limited does not authorise or warrant any product for use in life support devices and/or

systems without the express written approval of an officer of the Company. All information contained

within this manual is provided in good faith as a guide only; for specific applications, Delta Controls

Limited should be contacted directly. The information contained within this manual is subject to change

without notice.

NOTE

HART® is a registered trademark of the HART Communication Foundation.

Hastelloy C® is a registered trademark of Cabot Corporation.

Monel® is a registered trademark of International Nickel Co.

GLOSSARY

Characterise Factory procedure used to calibrate the electronics so that sensor errors and

Configurators To take advantage of the extra features within a smart transmitter a "configurator" is

Damping Software function used to increase the response time of the transmitters analogue

Descriptor A sixteen character field for additional identification of the field device, this may

EEPROM Electrically erasable programmable read only memory, that retains its memory even

EMC Electro Magnetic Compatibility, the ability of a product to function without influencing

HART® Highway Addressable Remote Transducer. This protocol has become the de facto

temperature shifts are eliminated.

used. This normally allows viewing and editing of variables via a keyboard and

integral display.

output. This helps to smooth the output when there are rapid input variations.

contain its plant location, or name.

during long term power removal

any other product, or being influenced

standard for digital communications with smart field devices. The HART®

Communications Foundation is the owner of the registered trademark and provides

support for end users and developers.

002522-2HT 180210.doc

3

Page 4

LRL Lower Range Limit (pressure): The lowest measured value (pressure) that the

transmitter can sense, governed by the sensor.

LRV Lower Range Value (pressure): Normally the lowest measured value (pressure) that

the analogue output (mA) of the transmitter can represent, but this may be reversed

with URV (pressure) for reverse analogue outputs (mA).

Master Name used to describe any system that is in control of the slave field devices, HART

can support two masters, primary and secondary.

Message A thirty two character field for additional information, name of installation engineer,

calibration technician etc.

MODEM Modulator \ Demodulator: a device that converts serial computer signals to and from

an FSK (Frequency-Shift-Keyed) format.

Multidrop This mode allows several field devices to share a common twisted pair of cables, a

total of 15 devices may use one cable.

Polling Address Unique number (1 - 15) used to identify an instrument when it is used in a multi-drop

circuit. Transmitters that are not used in a multi-drop configuration have a poll number

of zero.

Protocol A set of rules or specifications that defines the structure of a communications

language.

PV Prime Variable, in this case pressure.

Re-ranging Function that allows the transmitters analogue output to be scaled differently from the

sensors upper and lower range limits (pressure).

SV Secondary Variable, in this case temperature.

Slave Name used to describe any device that will respond when requested to by a master.

Smart A generic name used to describe any field device that can be configured from a

remote location, and shows some form of intelligence.

Span Difference between the upper and lower range values (pressure).

Sputtering A process used to bond glass and other materials to each other at a molecular level.

Tag An eight character field for identification of the transmitter, this is used in long frame

format to build the unique identifier

URL Upper Range Limit (pressure): The highest measured value (pressure) that the

transmitter can sense, governed by the sensor.

URV Upper Range Value (pressure): Normally the highest measured value (pressure) that

the analogue output (mA) of the transmitter can represent, but this may be reversed

with LRV (pressure) for reversed analogue outputs( mA).

002522-2HT 180210.doc

4

Page 5

PRODUCT INTRODUCTION

The Delta HT Series of SMART transmitters accurately measures gauge or absolute pressure and

transmits a traditional 4-20 mA signal as well as a digital signal using the HART® protocol. The HART®

protocol gives the ability to integrate into one system, products from different manufacturers with

predictable functionality and control. HART® has become the most widely used digital communication

system for process instruments and controllers.

These transmitters complement the popular Delta 387 transmitters. Digital technology has been used to

ensure accuracy, stability and range-ability across the full temperature range. Like its smaller brother the

HT series of transmitters features a robust all stainless steel case.

The extensive use of surface-mount components and custom micro-power devices has resulted in a

transmitter that is small, light and self supporting, although pipe mounting brackets are available if

required.

In addition to the remote digital communications, the unit has, as standard, local zero and span

adjustment at the touch of a button. If more than just local span and zero are required, there is a local

display module available, the D-CAL. This can directly access more than 80% of the SMART

transmitter’s commands, for installation, commissioning and maintenance checks. The display may be

fitted within the unit with no change to the external dimensions or supplied in a small hand-held case for

repeated use when configuring blind instruments.

The transmitter is manufactured within a quality system, approved to ISO 9001:2000.

FEATURES

THE SENSOR :-

Gauge and Absolute Pressure - The preferred sensor below 10 Bar is a precision piezo-resistive

transducer, with a silicone fill and a 316 stainless steel diaphragm. Above 10 Bar the sensor is a one

piece, machined diaphragm with a sputtered thin film strain gauge. The diaphragm is specially designed

to optimise the sensor for each range. The wetted parts of the sensor (diaphragm and inlet) can be

selected from stainless steel, Monel or Hastelloy C to suit the process fluid being used. Gauge or

absolute reference can be offered on all ranges.

THE ELECTRONICS :-

The heart of the HT transmitter is an electronics module that uses surface mount technology

and a 16 bit micro-controller, supervising all functions of the transmitter and performing

continuous self checks to make sure the software is running properly.

The micro-controller takes the digital output from the sensor electronics and, using calibration

coefficients, compensates the sensor signal for linearity and local temperature. Because the actual

pressure is now digitised, any mathematical function may be applied to change the output. This allows

conversion between different engineering units to be shown and square root extraction to be applied

where required.

Any changes to the transmitter configuration are stored in EEPROM which is non volatile in the event of

power supply failure. If a power failure occurs the transmitter will restart safely and signal digitally to a

controller that a power failure has occurred.

The digital, linearised signal is fed to the output circuits. One signal is converted into a 4 to 20 mA

current, the other is a superimposed audio tone conforming to the HART® protocol.

The input and output circuits of the transmitter are fully protected against over voltage, reverse polarity

and RFI ; the local display/configurator is IP rated and protected against RFI.

THE SOFTWARE :-

The software controls all functions of the transmitter, continuous self-diagnostics, communications,

pressure calculations and display (if fitted). The firmware program is permanently stored within the

micro-controller, all calibration and run time variables are stored in EEPROM. The software has built-in

checks for sensor failure, loss of voltage reference and many other very unlikely failures. The software

also contains complex algorithms for temperature and sensor linearisation, to mathematically

characterises the sensor and electronics over its full temperature range to guarantee accuracy and

repeatability. Within the software there is also a powerful state machine which is the set of statements

that make decisions within the local configurator, and allows the transmitter to be set up as required.

002522-2HT 180210.doc

5

Page 6

THE DISPLAY / CONFIGURATOR (“D_CAL”) :-

The Local display unit is constructed from a single stainless steel puck that when fitted gives the

transmitter a protection rating of IP 54 with the cover removed. The unit continuously shows prime

variable and units of measure in monitor mode. If current or percentage output is required, then this may

be selected on the D-CAL. The display unit also allows access to the state machine that generates a

user friendly menu with access to the internal HART® functions that are commonly used for installation

and maintenance.

To browse, edit and store information from the menu two buttons are used, CHANGE and SELECT. The

SELECT button, when held for 2 seconds, saves a selected value to EEPROM. If the selection is invalid

or out of range the transmitter will not store the change and will reply {REJECTED}.

For full detail, see the D-CAL Manual

INSTALLATION ( GENERAL )

The final accuracy of the transmitter depends to a great

extent on the proper installation of the unit and impulse

piping. Care should be taken to minimise the effects of

vibration, shock and temperature fluctuations. Care

should also be taken to make sure that the transmitter is

in a accessible position, where possible.

Before installation of the unit, ensure that the pressure

range and maximum working pressures selected are

compatible with the expected system pressure. Adequate

lengths of impulse lines, or siphons should be used to

ensure that very high temperature process media do not

come into direct contact with the unit. Precautions should

also be taken against the media freezing within the unit.

As the best location for the transmitter in relation to the process depends upon the process medium,

please consider the following points before installation.

• Keep all impulse lines as short as possible, and of the same length.

• Avoid high points in liquid and low points in gas lines.

• Use piping large enough to prevent blockage.

• Make sure there are no unaccounted static heads that will give false readings.

• Make sure that the transmitter is isolated from high process temperatures.

The 2HT is designed to be self supporting and can be mounted in any position. Brackets are, however,

available should wall or pipe mounting be required.

The pressure connection should be tightened using a 50 mm ( 2" ) AF spanner on the flats of the lower

body, and the appropriate spanner on the pipe-work connector.

DO NOT USE A COMPRESSION WRENCH ON THE 2HT BODY TO TIGHTEN THE PRESSURE

CONNECTION.

Typical Pipe Mounts for 2HT

002522-2HT 180210.doc

6

Page 7

MECHANICAL INSTALLATION

Conduit connection

The 2HT series Transmitters are supplied with either M20 x 1.5 or 1/2" NPT internally threaded electrical

connection. To prevent condensation build-up in the conduit entering the instrument housing, the

following piping layout should be followed. Additional considerations must be made if transmitters are to

be mounted in hazardous areas.

If cable is used a suitable gland should be chosen so that protection rating and hazardous area

certification is not affected, in accordance with site or national codes of practice.

ELECTRICAL INSTALLATION

Cable selection

The HART protocol is designed to be used over conventional instrument cables, but there are limitations

on the usable length, depending on the type of cable used. These limitation are concerned with two

things :-

(i) keeping interference at a level low enough not to affect the reliability of the communication, and

(ii) ensuring a proper signal level at the receiver.

Interference.

Each HART loop consists of a pair of wires, these should be twisted together to reduce interference

from external electromagnetic fields. Please note that the full benefit of a twisted pair is not obtained

because the HART signal is not symmetrically balanced on the two wires. For all but the very shortest

cable runs, screening is necessary for protection against interference. There may be a single screen

covering a number of twisted cables, or, better, each twisted pair may have its own individual screen. All

screens should be connected together and connected to ground at one point only, typically near the

control room.

Signal Level

The main factor that affects the signal level is cable capacitance. The signal level is degraded as the

cable capacitance rises. As a general rule the product of the total resistance and the total capacitance

must be less than 65 microseconds.

Cable capacitance is measured per meter so multiply the nominal value by the length of cable run. For

each HART device allow 5 nF x the CN number.

To limit the possible effects of interference and signal degradation the following rules are imposed in the

HART specification :-

Maximum overall length, individually screened pairs :- 3000 metres

Maximum length, multiple pairs with only an overall screen :- 1500 metres

( Rload + Rbarrier + Rmiscellaneous ) ohms x ( Ccable + Cdevices ) farads <= 65uS

002522-2HT 180210.doc

7

Page 8

Do not mix non-HART compatible signals within the same cable run.

Cable should be run through a sealed metal gland rated IP66, to avoid moisture ingress in to the

housing and provide a strong mechanical fixing. For EEx d applications the use of approved cable and

glands is a mandatory requirement

Recommended wiring practice

It is recommended that the field wiring be trimmed to length

as follows. This will then allow access to the zero and span

buttons and prevent fouling of the display cable if fitted.

Recommendations for Power supply :-

The DC power supply should have less than 2% ripple, and be able to source at least 24 mA for a single

transmitter and 100 mA for a multi-drop system, at a nominal 24 volts.

RECEIVER PSU

+

-

250

ohm

ADDITIONAL INSTRUMENTS

The terminal block inside the instrument has three connections, signal, return and ground. For

convenience there is an internal ground as well as two external connections.

The Delta transmitter will run with reverse polarity and has over voltage protection as standard.

GND

INTERNAL

CASE

GROUND

7mm

+VE

-VE

30mm

45mm

60mm

GND

002522-2HT 180210.doc

8

Page 9

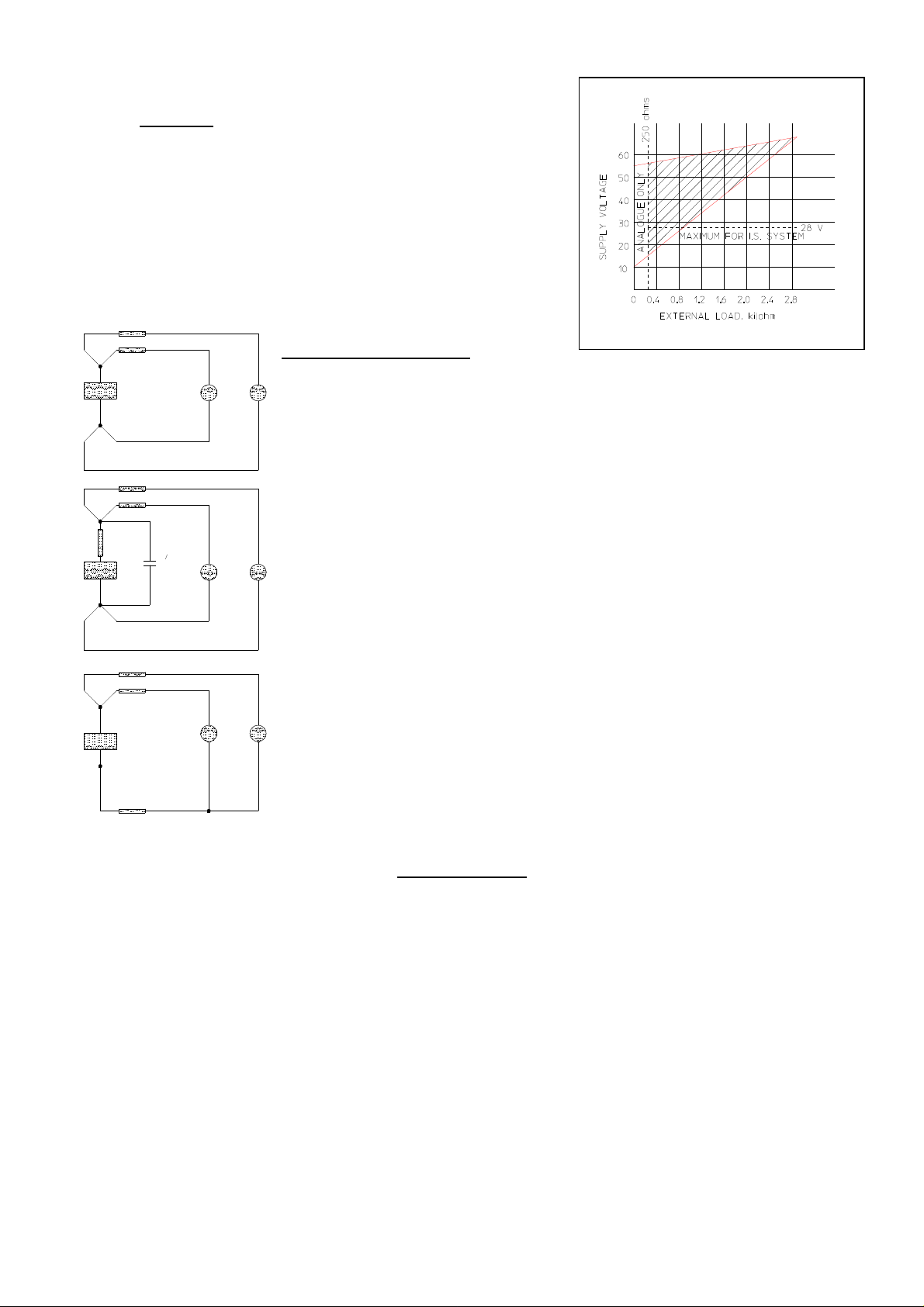

Loop load

The required loop voltage is based on the loop resistance. To

determine the total resistance, add the resistance of all the units

within the loop (except the transmitter). The required supply

voltage can be determined by reference to the graph. Note that

there must be a minimum of 250 ohms within the loop for digital

communication to take place.

RL 2

RL 1

+VE

PSU

0 V

Tx 1 Tx 2

Factors to be considered.

The ideal system with no cross-talk, this assumes that the PSU has zero

impedance at the HART signalling frequencies. Note that separate positive and

ground lines are run to each instrument. Cables are spaced, or screened, to

prevent capacitive coupling between loops.

RL 2

RL 1

+VE

RS

PSU

0 V

10000 uF

Tx 1 Tx 2

The HART protocol requires the PSU series resistance ( RS ) to be less than 10

ohms. Most power supplies will meet this requirement, but with the addition of

distribution wiring and in line fuses care must be taken. If required a 10000 uF

electrolytic capacitor of suitable working voltage may be connected across the

common terminals for the HART loop.

RL 2

RL 1

+VE

PSU

0 V

RC

Tx 1 Tx 2

Common resistance (RC) this can be caused by high cable resistance, or by

grounding multiple loops in the field rather than in the control room. To prevent

high cable resistance resulting from grounding null loop, each loop wire should

be wired back to the psu.

COMMISSIONING

The Commissioning and Transmitter Function sections of this manual assumes a blind instrument or

one fitted with a DELTA local display Configurator. Blind instruments can be re-ranged and zeroed as

standard, using the one touch Zero and Span Buttons.

When the transmitter is shipped it has a fixed upper and lower range limit (URL, LRL) that is dictated by

the sensor used. The upper and lower range values can be set, (URV, LRV) to any value from LRL to

URL so long as the minimum span is not breached. The URV can be set lower than the LRV this will

reverse the transmitter’s analogue output, and give a 20 to 4 mA output.

The engineering units that are displayed and transmitted by the unit may be changed.

There are four ways to re-range the transmitter, each one makes changes to the setting of the URV and

LRV.

1 :- With the zero and span buttons that are fitted on a blind instrument.

2 :- Enter a URV and LRV directly from the “DCAL” configurator (D-CAL).

3 :- Use the Zero and Span options from the local display.

4 :- Using a Universal Hand-held communicator (e.g. Rosemount 375)

002522-2HT 180210.doc

9

Page 10

Re-ranging using the Zero and Span Buttons, Blind Instrument.

The transmitter can have its LRV and URV set using the local keys mounted on the top circuit board. To

set these values a pressure source should be used that has a calibrated accuracy three to five times

better than the desired instrument accuracy, a loop current indicator is also required. Alternatively the

instrument can use the process to generate the required pressures.

1 :- Apply the LRV pressure to the instrument.

2 :- Wait 20 seconds, for the pressure to stabilise.

3 :- Press the [ZERO] button and hold it for 3 seconds.

4 :- Check the loop current equals 4 mA.

5 :- Apply the URV pressure to the instrument.

6 :- Wait 20 seconds, for the pressure to stabilise.

7 :- Press the [SPAN] button and hold it for 3 seconds.

8 :- Check the loop current equals 20 mA.

For reversed analogue output the zero and span buttons are pushed in the reverse order, swap over

commands 3 and 7. To initially reverse the current output it will be necessary to set the zero (LRV) to at

least 5% of the instrument’s full range so that when the span key is pressed the change is not rejected

by the minimum span limit.

Note: the lower and upper range values must fall within the lower and upper range limits, and meet the

minimum and maximum span specifications allowed by the transmitter, if they do not the zero or span

will not be set.

Zero, Span and Rangeability

Forward Action, 4 to 20 mA

Apply the lower range value. This may be achieved once the unit is

installed, or in the workshop with a pressure source. Allow the unit to

settle. Press and hold the zero key for two seconds. 4 mA output will

be set.

Apply the upper range value. Allow the unit to settle, press and hold

the span key for two seconds. 20 mA output will be set.

If the unit is being re-ranged rather than being trimmed the zero may

need to be checked to achieve full accuracy.

Reverse Action, 20 to 4 mA

Apply the lower range value. This may be achieved once the unit is

installed, or in the workshop with a pressure source. Allow the unit to

settle. Press and hold the span key for two seconds. 20 mA output

will be set.

Apply the upper range value. Allow the unit to settle press and hold

the zero key for two seconds. 4 mA output will be set.

If the unit is being re-ranged rather than being trimmed the zero may

need to be checked to achieve full accuracy.

These buttons are automatically disabled when the DCAL is

plugged in via its 10-way IDC connector. They may also be

remotely disabled over the HART® network.

002522-2HT 180210.doc

10

Page 11

MULTI-DROP CONFIGURATION

Multi-dropping transmitters refers to the practice of connecting several units to a single transmission

line. The analogue signal is switched to 4 mA on all units and communication takes place digitally only.

Each message is sent with a unique number that identifies the field device.

The HART® system limits the number of instruments that can be connected in this way to 15. For

Intrinsically Safe installations, maximum permissible circuit current reduces the limit to four. When a

multi-drop system is designed, consideration must be given to the length of transmission line, update

rate required from each transmitter and total power requirement. Multi-drop systems are not

recommended for Intrinsically Safe installations. Each transmitter is identified by a unique number from

1 to 15 and responds to HART® commands that are sent to that address.

Note that the transmitter is sent from the factory with its address set to 0 this disables multi-drop and

allows 4 to 20 mA and digital communication only.

There is no way to change the polling locally. This is for safety reasons, so that the address can only

be changed once digital communication has been established from Hart master.

The use of a separate HART® Multiplexer is permissible, but outside the scope of this manual.

TROUBLE SHOOTING

The integrity of a HART® loop can be validated using several methods, if a local display is fitted the

{SHOWHART}, {FIXLOOP} and {SELFTEST} methods provide a high level of confidence, for lower level

testing or if a local display is not present the use of a simple oscilloscope and voltmeter can be used.

Note: in an Intrinsically Safe application restrictions may apply to the instruments being used.

Analogue Loop Tests.

Is the voltage at the instrument, across the terminals, above the lift-off voltage of the instrument,

typically 9 to 12 volts, see the functional specifications?

Measure the DC voltage across the load resistor, derive the loop current using the calculation :Loop Current = DC Voltage / Load Resistor

This should be between 4 and 20 mA and representative of the measured prime variable, unless the

device is in multi-drop mode where the current will approximately equal 4 mA multiplied by the number

of devices within the loop.

Is the loop grounded properly, normally in one place, at the power supply?

Is the screen of the cable grounded at one end only, normally at the control room?

Are the cables isolated from other high current cables?

Is the cable of the correct grade and not to long, see cable selection and signal level?

Are the barriers HART compliant and is the power supply low impedance?

002522-2HT 180210.doc

11

Page 12

FUNCTIONAL SPECIFICATIONS

Service :- Liquid, Gas or Vapour

Ranges :- 0 ~ 1 to 0 ~ 1000 Bar

( 0 ~ 16 to 0 ~ 16,000 psi )

Sensor Limits:- 2 * URL Overpressure Stainless Steels except range GA, 0

to 1000 bar = 1.5 * URL

1.5 * URL Overpressure Monel & Hastelloy

Output :- 4 to 20 mA DC 2 Wire System with digital AC signal

superimposed on to it, using the HART protocol.

Power Supply :-

Load Limits :- Dependent upon installation and PSU, See chart in Electrical

Hazardous Area

Certifications :Zero Elevation &

Suppression:-

Normal or Reverse

action :Temperature Limits:- Operating :- -40 to +85 Degrees C

Failure Mode

Alarms:Humidity Limits :- 0 to 100% RH

Turn-on Time :- Less than 6 Seconds, This includes full self diagnostics

Volumetric

Displacement :Damping :- 0 to 39 Seconds, in addition to the sensor response time.

9 to 55 Volts DC (Subject to 28 V maximum on Intrinsically

Safe installations)

Installation

See Certified Products

Can be set anywhere within the sensor limits as long as the

span is greater or equal to the minimum span, and URV does

not exceed URL

Set by reversing the upper and lower range values. See

Zero, Span and Rangeability

Storage :- -50 to +110 Degrees C

Display :- -30 to +80 Degrees C

High or Low (Analogue) for a major transmitter malfunction.

< 1 microlitre

PERFORMANCE SPECIFICATIONS

Accuracy

Stability

Temperature Effect

Overrange Effect

Power Up

Vibration Effect

Power Supply

Effect

Mounting Position

Effect

RFI Effects

For spans of 1 : 1 to 10 : 1

+/- 0.1 % of SPAN, Including Linearity, Hysteresis and

Repeatability

For spans below 10 : 1

+/-0.15 % of SPAN

Typically less than 0.15 % URL per annum

Total effect +/- 0.10 % at Max. Span over ambient range

Zero shift, 0.2 % of URL

Less than 6 seconds, including Diagnostics, Display and

Memory tests

5 g Peak sinusoidal at 5 Hz to 200 Hz without deleterious

effect

<0.005% of URL per volt

Zero shift, less than 10 mm H2O for a 10° tilt in any plane.

With the cover on and/or display in place, in accordance

with IEC 6100-4-3, 80 Hz to 1 Ghz at 10 V/m, 1 GHz to 2.7

GHz at 3 V/m. See Declaration of Conformity for the EMC

Directive 89/336/EEC. For full compliance with

susceptibility performance, the screen of the cable must be

directly connected to the enclosure via a cable gland that

makes a 360o connection.

002522-2HT 180210.doc

12

Page 13

PHYSICAL SPECIFICATIONS

Electrical connections :- Female M20 x 1.5 or Female ½ " NPT

Process Connection :- ½ " NPT External, G ½ " A to ISO 228 or

High Pressure Cone and Thread ("Autoclave")

Process Wetted Parts :- Below 10 Bar 316 St. St. inlet and Diaphragm

316 St. St. inlet with 17-4PH or 15-5PH Diaphragm

as standard; Monel and Hastelloy available.

Non- Wetted Parts :- Lower body, Case & Lid :- 316 Stainless Steel

Mounting Hardware :- 316 Stainless Steel

Protection :- IP 66

Mounting :- Direct process mounting as standard.

On 50 mm dia. ( 2" ) pipe using mounting bracket kit.

Wall mounting with kit.

Weight :- 1.6 kg ( 3.5 lb) Blind Instrument

Display, add 200 grams ( 0.44 lb )

95mm

DIAMETER

96mm

ELECTRICAL ENTRY

M20 x 1.5 INT. OR AS

SPECIFIED

Approximate

60mm

DIAMETER

PROCESS ENTRY

1/2" NPT EXT. OR AS

SPECIFIED

m

m

0

5

1

m

m

6

9

Dimensions are

WEATHERPROOF

Models A2HT, R2HT, F2HT, 42HT

The instruments have been tested for dust and water penetration to EN 60529 and have been rated

IP66 with cover in place and conduit entry suitably sealed. Third party test report for water available on

request.

In addition, the instruments, when fitted with the built-in D-CAL configurator, meet IP54 requirements,

enabling configuration to be performed under damp conditions. DO NOT LEAVE INSTRUMENTS

OPEN UNNECESSARILY!

002522-2HT 180210.doc

13

Page 14

CERTIFIED PRODUCTS

FLAMEPROOF

EEx d :- Model R2HT

Apparatus Certificate Number :- ITS03ATEX11187

Compliance with EN 50014:1997, EN 50018:2000 II 2 G. See Declaration of Conformity for ATEX.

EExd IIC T4 (Tamb = -40 to +85°C)

EExd IIC T6 (Tamb = -40 to +60°C)

Note:

Flameproof model R2HT with display fitted (see page 17, signal input code 2 or B) gas group reduced

to II B+ H

2

EExd IIB+H2 T4 (Tamb = -40 to +85°C)

EExd IIB+ H2 T6 (Tamb = -40 to +60°C)

INTRINSICALLY SAFE

Ex ia Approval :- Model 42HT

Apparatus Certificate Number :- ITS03ATEX21213X

EN 60079-0:2006, EN 60079-11:2007, EN 60079-26:2007

Ga Ex ia IIC T4 (T

Conformity for ATEX.

Safety Parameters :- Ui = 30 Volts

Ii = 130.9 mA

Pi = 0.66 Watts

Li = 30 uH

Ci = 16 nF

Special Conditions :-

1. The pressure transmitter may be fitted with an integral display or alternatively, when the blanking

plate is removed, a hand held display may be inserted into the socket provided. The removal of the

blanking cover is only permitted in a non-hazardous area.

2. The pressure transmitters intended for operation at 50 V dc do not meet the requirements of EN

50020:2002 clause 6.4.12 (Electrical Strength Test). This shall be taken into account when

installing the apparatus in a potentially explosive atmosphere.

–20 to 80oC) II 1 G See Declaration of

amb

SYSTEM

The user/installer is responsible for ensuring the safety parameters of the circuit/system are not

exceeded. Refer to IEC 60079 -14: Electrical apparatus for explosive gas atmospheres - Electrical

installations in hazardous areas (other than mines) and EN 60079 –25: Electrical apparatus for

explosive gas atmospheres - intrinsically safe systems

USA EXPLOSIONPROOF AND INTRINSICALLY SAFE

FM:- Model F2HT

F2HT Report Number 1B5A6.AE

Approved for Explosionproof Class I, Division 1, Groups B C & D

Dust-Ignition-Proof Class II/III, Division 1, Groups E F & G

Intrinsically Safe Class I, II, III Division 1, Groups A B C D E F & G

(

Entity requirements, Control Drawing No 2/14307, Entity Parameters: V Max =30 V, I Max = 130.9 mA, Ci = 8.85 nF,

Li = 30 µH, P Max = 0.67 W)

NEMA 4X

002522-2HT 180210.doc

14

Page 15

002522-2HT 180210.doc

15

Page 16

OPTIONS

Mounting Stainless steel wall and pipe clamps are available as an optional way of

mounting the unit.

Display / Configurator The D-CAL configurator / display may be ordered with the transmitter or

retrofit at a later date, without compromise to the certifications. This unit is

not loop powered and can only be used with the Delta Controls HT range of

SMART Transmitters.

SPARES

Lid 'O' Ring :- Spares No. 155042

Display 'O' Ring :- Spares No. 155043

Display Overlay :- Spares No. 9020311

Lid ( Free Blank ) :- Spares No. 9420004

Lid ( Free Windowed ) :- Spares No. 9400123

Display Assembly :- Spares No. 9400124

MAINTENANCE

The unit requires no maintenance as standard, but it is recommended that all cable terminals be

checked for tightness at standard site maintenance intervals. Please note that all of the circuit boards

within the unit are protected against water damage so it is unnecessary to apply any other form of

protection, as this may void the products warranty.

RE-CALIBRATION

The 2HT series instruments are designed for long and stable lifetime operation.

The nature of a combined analogue / digital instrument such as this, is that the Analogue to Digital

Converter that processes the sensor input measures the total permitted pressure range of the

instrument, irrespective of the chosen output of the 4 to 20 mA range. Changes in the selected

4 to 20 mA output are made against the stored, compensated values of pressure conversion.

From time to time, however, it will be necessary to check, and, if required, trim the scaling of the A-D

converter against a local pressure standard.

The method used by the 2HT series, assumes that the two most important calibration points for the

chosen application are the Lower and Upper Range Values set for the 4 to 20 mA output. These, not

the instrument’s zero and nominal Upper Range Limit, are the values to be applied to the instrument

when trimming the ADC.

Apparatus Needed

A accurate pressure supply (+/- 0.03% of value)

A Delta D-CAL Communicator (as the procedure requires a Device Specific command, only software

versions 5.00 and later may be trimmed via HART® )

Method

Apply a pressure value equal to the instrument’s selected Lower Range Value. In the ACCESS2 menu

of the D-CAL, go to {TRIM LRV}[SELECT]

{HIT SAVE} will be displayed, there are two choices :[SELECT] or [CHANGE] To abort and return to the {TRIM LRV} menu

[[SELECT]] Press and hold for two seconds to store the ADC offset value, {SAVED} will be

displayed to show that the command is successful.

Now apply a pressure value equal to the instrument’s selected Upper Range Value, and repeat the

above sequence, with {TRIM URV}.

The ADC is then set to the site standard. For full explanation of the D-CAL functions, see the D-CAL

Configurator Manual.

002522-2HT 180210.doc

16

Page 17

9

PRODUCT CODE

1

1 :- Enclosure 4 = EEx ia (Intrinsically Safe)

2 :- Model, 2HT = Gauge and Absolute Pressure

3 :- Electrical Entry 1 = M20 Internal

4 :- Wetted Parts R = All 316 Stainless Steel

5 :- Ranges (Bar) DA = 1 D2 = 2 DE = 6

EA = 10 EB = 16 ED = 40

FA = 100 FD = 400 FE = 600

GA = 1000

6 :- Pressure Reference G = Gauge A = Absolute

7 :- Signal Output 1 = Blind Instrument, 50 Volt Isolation

8 :- Process Connection J = ½ " NPT External

9 :- Options and Treatments Codes on Application

10 :- Special Engineering Codes on Application

2

3

4

5

Note that not all options are available on all models!

R = EEx d

A = Weatherproof

F = Factory Mutual approved

2 = ½" NPT Internal

S = 17-4PH or 15-5 PH Sensor, 316 Process connection

T = All Monel

U = All Hastelloy

C = Hastelloy sensor, 316 Process connection

D = 17-7 PH sensor, 316 Process connection

2 = Local Indicator, 50 Volt Isolation

A = Blind Instrument, 500 Volt Isolation

B = Local Indicator, 500 Volt Isolation

N = G ½"A to ISO 228

V = “Autoclave” High pressure connections

6

7

8

10

Delta Controls Limited

Island Farm Avenue, West Molesey, Surrey KT8 2UZ, UK

T +44 (0) 20 8939 3500 F +44 (0) 20 8783 1163 E sales@delta-controls.com W www.delta-controls.com

002522-2HT 180210.doc

17

Loading...

Loading...