Page 1

14 in. Steel Frame Band Saw

Scie à ruban

avec structure en acier

355,6 mm (14 po)

Sierra cinta de bastidor

de acero de 355.6 mm

(14 pulg.)

Français (20)

Español (38)

www.DeltaMachinery.com

Instruction Manual

Manuel d’utilisation

Manual de instrucciones

INSTRUCTIVO DE OPERACIÓN, CENTROS

DE SERVICIO Y PÓLIZA DE GARANTÍA.

LÉASE ESTE INSTRUCTIVO

ANTES DE USAR EL PRODUCTO.

28-400

Page 2

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS ................................... 2

SAFETY GUIDELINES - DEFINITIONS ....................................3

GENERAL SAFETY RULES ......................................................3

ADDITIONAL SPECIFIC SAFETY RULES ...............................4

POWER CONNECTIONS ..........................................................5

MOTOR SPECIFICATIONS ....................................................... 5

GROUNDING INSTRUCTIONS ................................................5

EXTENSION CORDS ................................................................ 6

KEY FEATURES AND COMPONENTS ....................................7

FUNCTIONAL DESCRIPTION ..................................................7

PRODUCT SPECIFICATIONS ...................................................8

UNPACKING ..............................................................................8

ASSEMBLY ................................................................................9

Stand Assembly ..................................................................9

Secure Table To Table Trunnion System ............................. 9

Attach the Saw to the Stand ...

Install Blade Tensioning Knob ...........................................10

Install Band Saw Blade .....................................................10

Adjust the Blade Tracking ................................................11

Insert Throat Plate .............................................................11

Square Table to Blade ......................................................11

............................................ 9

OPERATION ............................................................................12

STARTING AND STOPPING THE SAW ............................12

Using the Safety Key to Lock the

Switch In the "Off" Position ..........................................

Selecting Proper Cutting Speed ....................................... 12

Tilting the Table ..................................................................13

Positioning The Upper Blade Guide..................................13

Cutting Curves ...................................................................14

ADJUSTMENTS .......................................................................14

Adjusting the Blade Tension .............................................. 14

Adjusting the Blade Guides and Bearings ........................15

Adjusting the Blade Tracking............................................. 15

MAINTENANCE PROCEDURES ............................................16

Lubrication ........................................................................16

TROUBLE SHOOTING ...........................................................16

ABOUT BAND SAW BLADES .................................................18

TIPS ..........................................................................................18

ACCESSORIES ........................................................................ 18

WARRANTY .............................................................................18

REPLACEMENT PARTS ..........................................................19

SERVICE AND REPAIRS .........................................................19

FRANÇAIS ................................................................................20

ESPAÑOL

.................................................................................38

.....12

IMPORTANT SAFETY INSTRUCTIONS

READ AND UNDERSTAND ALL WARNINGS AND OPERATING INSTRUCTIONS BEFORE USING

THIS EQUIPMENT. Failure to follow all instructions listed below, may result in electric shock, fire,

and/or serious personal injury or property damage.

Woodworking can be dangerous if safe and proper operating procedures are not followed. As with all

machinery, there are certain hazards involved with the operation of the product. Using the machine with

respect and caution will considerably lessen the possibility of personal injury. However, if normal safety

precautions are overlooked or ignored, personal injury to the operator may result. Safety equipment such

as guards, push sticks, hold-downs, featherboards, goggles, dust masks and hearing protection can reduce your

potential for injury. But even the best guard won’t make up for poor judgment, carelessness or inattention. Always

use common sense and exercise caution in the workshop. If a procedure feels dangerous, don’t try it. Figure out

an alternative procedure that feels safer. REMEMBER: Your personal safety is your responsibility. For additional

information please visit our website www.DeltaMachinery.com.

that for which it was designed. If you have any questions relative to a particular application, DO NOT use the

machine until you have first contacted DELTA® to determine if it can or should be performed on the product.

If you have any questions relative to its application DO NOT use the product until you have written DELTA® Power

Equipment Corporation and we have advised you. Contact us online at www.DeltaMachinery.com or by mail at

Technical Service Manager, DELTA® Power Equipment Corporation, 99 Roush Street, Anderson, SC 29625.

Information regarding the safe and proper operation of this tool is available from the following sources:

• Power Tool Institute, 1300 Sumner Avenue, Cleveland, OH 44115-2851or online at www.powertoolinstitute.com

• National Safety Council, 1121 Spring Lake Drive, Itasca, IL 60143-3201

• American National Standards Institute, 25 West 43rd Street, 4 floor, New York, NY 10036 www.ansi.org - ANSI 01.1

Safety Requirements for Woodworking Machines

• U.S. Department of Labor regulations www.osha.gov

This machine was designed for certain applications only. DELTA® Power Equipment Corporation

strongly recommends that this machine not be modified and/or used for any application other than

2

Page 3

SAFETY GUIDELINES - DEFINITIONS

This manual contains information that is important for you to know and understand. This information relates to

protecting YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we

use the symbols below. Please read the manual and pay attention to these sections.

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious

injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious

injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate

injury.

Used without the safety alert symbol indicates potentially hazardous situation which, if not avoided,

may result in property damage.

GENERAL SAFETY RULES

WARNING FAILURE TO FOLLOW THESE RULES MAY RESULT IN SERIOUS PERSONAL INJURY.

FOR YOUR OWN SAFETY, READ AND UNDERSTAND THE INSTRUCTION MANUAL BEFORE OPERATING THE

•

UNIT.

Learn the unit’s application and limitations as well as the specific hazards peculiar to it.

KEEP WORK AREA CLEAN.

•

DON’T USE IN DANGEROUS ENVIRONMENT.

•

Keep work area well-lighted.

KEEP CHILDREN AND VISITORS AWAY.

•

DISCONNECT UNIT

•

CHECK DAMAGED PARTS.

•

before servicing.

Cluttered areas and benches invite accidents.

Don’t use this unit in damp or wet locations, or expose it to rain.

All children and visitors should be kept a safe distance from work area.

Before further use of the unit, properly repair or replace any part that is damaged.

FAILURE TO FOLLOW THESE RULES MAY RESULT IN SERIOUS INJURY.

1. Read and understand the warnings posted on the

machine and in this manual. Failure to comply with

all of these warnings may cause serious injury.

2. Replace the warning labels if they become

obscured or removed.

3. This machine is designed and intended for use by

properly trained and experienced personnel only.

If you are not familiar with the proper and safe

operation of a band saw, do not use until proper

training and knowledge have been obtained.

4. Do not use this machine for other than its intended

use. If used for other purposes, DELTA® Power

Equipment Corporation disclaims any real or

implied warranty and holds itself harmless from any

injury that may result from that use.

5. Always wear approved safety glasses/face shields

while using this band saw.

6. Before operating this band saw, remove tie, rings,

watches and other jewelry, and roll sleeves up past

the elbows. Remove all loose clothing and confine

long hair. Non-slip footwear or anti-skid floor strips

are recommended. Do not wear gloves.

7. Wear ear protectors (plugs or muffs) during

extended periods of operation.

8. Some dust created by power sanding, sawing,

grinding, drilling and other construction activities

contain chemicals known to cause cancer,

birth defects or other reproductive harm. Some

examples of these chemicals are:

• Lead from lead based paint.

• Crystalline silica from bricks, cement and other

masonry products.

• Arsenic and chromium from chemically treated

lumber.

Your risk of exposure varies, depending on how often

you do this type of work. To reduce your exposure to

these chemicals, work in a well-ventilated area and

work with approved safety equipment, such as face or

dust masks that are specifically designed to filter out

microscopic particles.

9. Do not operate this machine while tired or under

the influence of drugs, alcohol or any medication.

10. Make certain the switch is in the OFF position

before connecting the machine to the power

source.

11. Make certain the machine is properly grounded.

12. Make all machine adjustments or maintenance with

the machine unplugged from the power source.

13. Form a habit of checking to see that all extra

equipment such as adjusting keys, wrenches,

scrap, stock, and cleaning rags are removed away

from the machine before turning on.

continued on page 4

3

Page 4

14. Keep safety guards in place at all times when the

machine is in use. If removed for maintenance

purposes, use extreme caution and replace the

guards immediately when maintenance is complete.

15. Make sure the tool is firmly secured to the floor

before use.

16. Check damaged parts. Before further use of the

machine, a guard or other part that is damaged

should be carefully checked to determine that it will

operate properly and perform its intended function.

Check for alignment of moving parts, binding of

moving parts, breakage of parts, mounting and

any other conditions that may affect its operation.

A guard or other part that is damaged should be

properly repaired or replaced.

17. Provide for adequate space surrounding work area

and non-glare, overhead lighting.

18. Keep the floor around the machine clean and free of

scrap material, oil and grease.

19. Keep visitors a safe distance from the work area.

Keep children away.

20. Make your workshop child proof with padlocks,

master switches or by removing starter keys.

21. Give your work undivided attention. Looking

around, carrying on a conversation and “horseplay" are careless acts that can result in serious

injury.

22. Maintain a balanced stance at all times so that you

do not fall or lean against the tool or its moving

parts. Do not overreach or use excessive force to

perform any machine operation.

23. Use the right tool at the correct speed and feed

rate. Do not force a tool or attachment to do a job

for which it was not designed. The right tool will do

the job better and safer.

24. Use recommended accessories; improper

accessories may be hazardous.

25. Maintain machinery with care. Follow instructions

for lubricating and changing accessories.

26. Turn off the machine before cleaning. Use a brush

or compressed air to remove dust or debris — do

not use your hands.

27. Do not stand on the machine. Serious injury could

occur if the machine tips over.

28. Never leave the machine running unattended. Turn

the power off and do not leave the machine until it

comes to a complete stop.

29. At all times, hold the stock firmly.

30. Do not use this tool for other than it intended use. If

used for other purposes, DELTA® Power Equipment

Corporation disclaims any real or implied warranty

and holds itself harmless for any injury or damage

which may result from that use.

Familiarize yourself with the following safety notices

used in this manual:

This means that if precautions are not heeded, it may

result in minor injury and/or possible machine damage.

This means that if precautions are not heeded, it may

result in serious injury or possibly even death.

ADDITIONAL SPECIFIC SAFETY RULES

1. Use proper blade size and type.

2. Adjust the upper blade guide so that it is about

1/8” above the workpiece.

3. Properly adjust the blade tension, tracking, blade

guides, and blade support bearings.

4. Never start the machine with the workpiece

against the blade.

5. Hold workpiece firmly and feed into blade at a

moderate speed.

6. Turn the machine “off” to back out of an

uncompleted or jammed cut.

SAVE THESE INSTRUCTIONS.

Refer to them often and use them to instruct others.

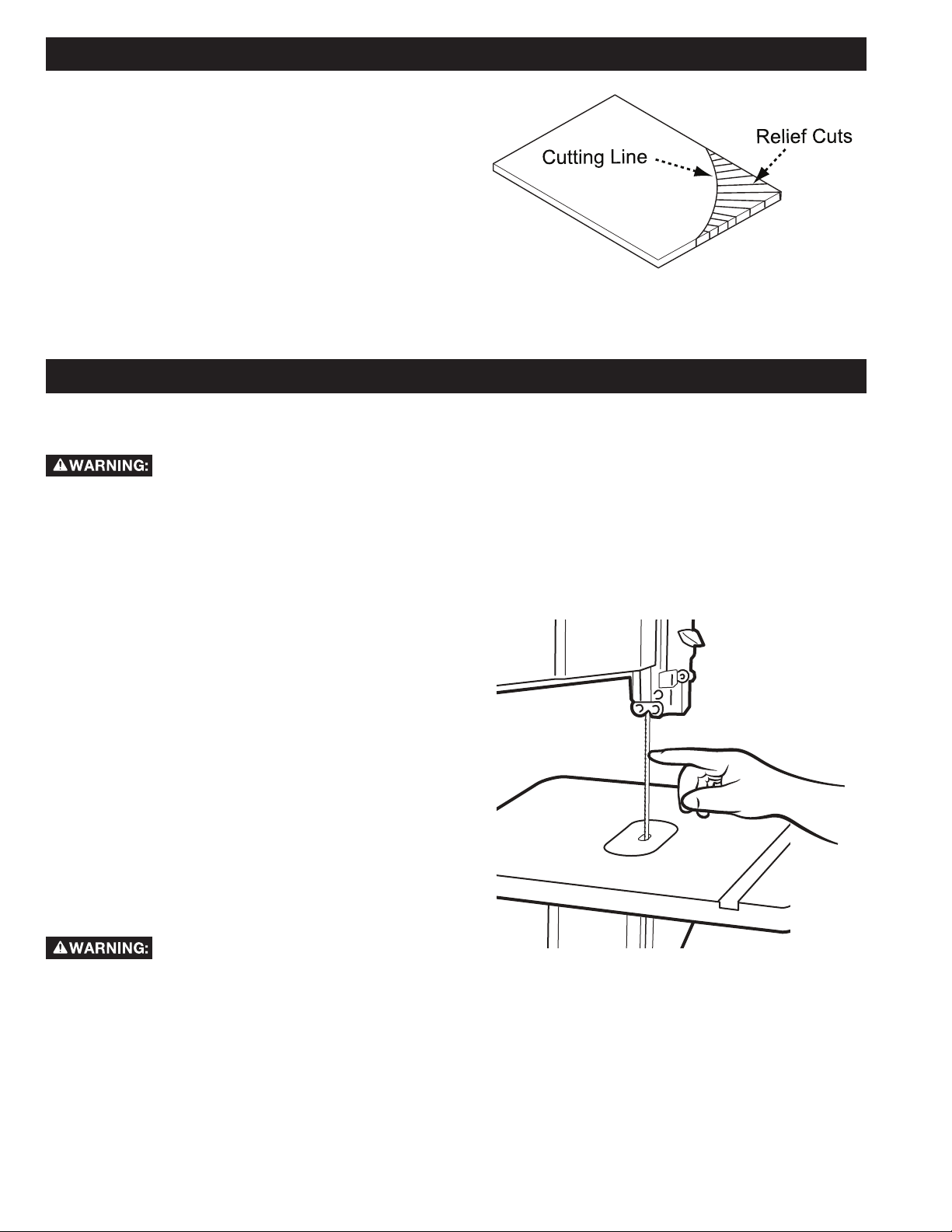

7. Make “relief” cuts prior to cutting long curves.

8. Turn the machine “off” and wait for the blade to

stop prior to cleaning the blade area, removing

debris near the blade, removing or securing

workpiece, or changing the angle of the table. A

coasting blade can be dangerous.

4

Page 5

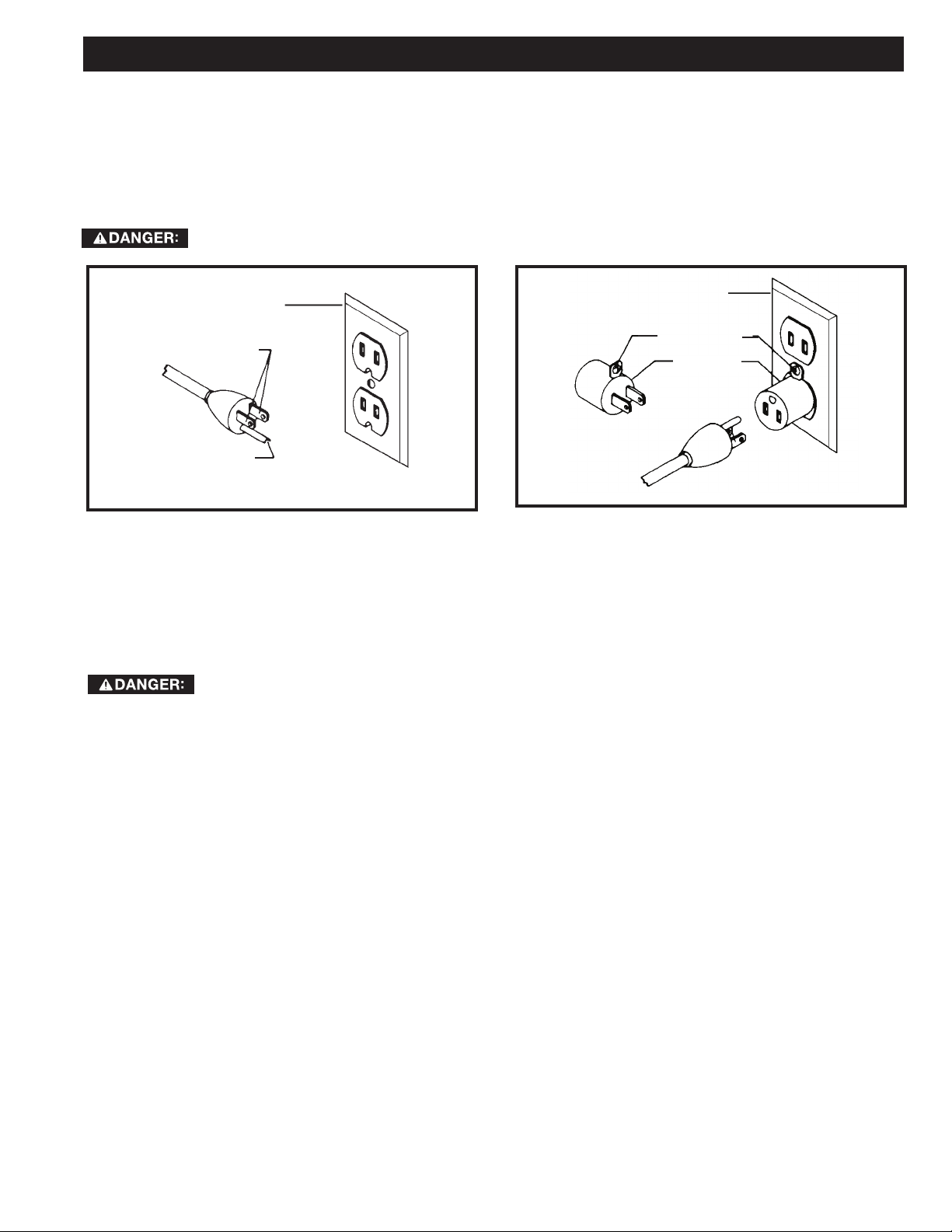

POWER CONNECTIONS

A separate electrical circuit should be used for your machines. This circuit should not be less than #12 wire and

should be protected with a 20 Amp time lag fuse. If an extension cord is used, use only 3-wire extension cords

which have 3-prong grounding type plugs and matching receptacle which will accept the machine’s plug. Before

connecting the machine to the power line, make sure the switch (s) is in the "OFF" position and be sure that the

electric current is of the same characteristics as indicated on the machine. All line connections should make good

contact. Running on low voltage will damage the machine.

DO NOT EXPOSE THE MACHINE TO RAIN OR OPERATE THE MACHINE IN DAMP LOCATIONS.

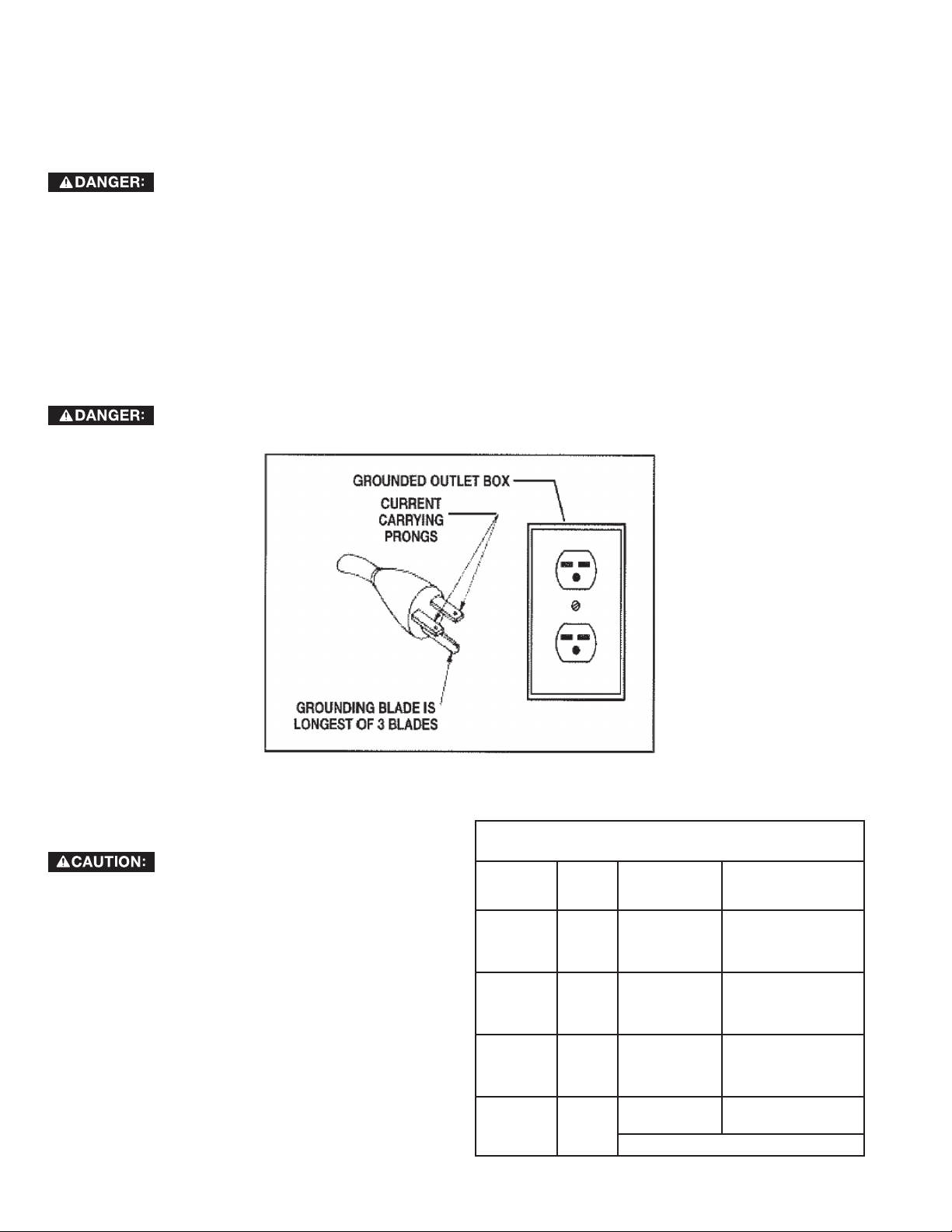

GROUNDED

OUTLET BOX

CURRENT

CARRYING

PRONGS

GROUNDING BLADE

IS LONGEST OF THE 3 BLADES

FIG. A FIG. B

GROUNDED OUTLET BOX

GROUNDING

MEANS

ADAPTER

MOTOR SPECIFICATIONS

Your machine is wired for 120/240 volts, 60 HZ alternating current. Before connecting the machine to the power

source, make sure the switch is in the "OFF" position.

GROUNDING INSTRUCTIONS

THIS MACHINE MUST BE GROUNDED WHILE IN USE TO PROTECT THE OPERATOR FROM

ELECTRIC SHOCK.

1. All grounded, cord-connected machines:

In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current to

reduce the risk of electric shock. This machine is equipped with an electric cord having an equipment-grounding

conductor and a grounding plug. The plug must be plugged into a matching outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

Do not modify the plug provided - if it will not fit the outlet, have the proper outlet installed by a qualified electrician.

Improper connection of the equipment-grounding conductor can result in risk of electric shock. The conductor with

insulation having an outer surface that is green with or without yellow stripes is the equipment-grounding conductor.

If repair or replacement of the electric cord or plug is necessary, do not connect the equipment-grounding conductor

to a live terminal.

Check with a qualified electrician or service personnel if the grounding instructions are not completely understood,

or if in doubt as to whether the machine is properly grounded.

Use only 3-wire extension cords that have 3-prong grounding type plugs and matching 3-conductor receptacles that

accept the machine’s plug, as shown in Fig. A.

Repair or replace damaged or worn cord immediately.

2. Grounded, cord-connected machines intended for use on a supply circuit having a nominal rating less than

150 volts:

If the machine is intended for use on a circuit that has an outlet that looks like the one illustrated in Fig. A, the

machine will have a grounding plug that looks like the plug illustrated in Fig. A. A temporary adapter, which looks like

the adapter illustrated in Fig. B, may be used to connect this plug to a matching 2-conductor receptacle as shown

in Fig. B if a properly grounded outlet is not available. The temporary adapter should be used only until a properly

5

Page 6

grounded outlet can be installed by a qualified electrician. The green-colored rigid ear, lug, and the like, extending

from the adapter must be connected to a permanent ground such as a properly grounded outlet box. Whenever the

adapter is used, it must be held in place with a metal screw.

NOTE: In Canada, the use of a temporary adapter is not permitted by the Canadian Electric Code.

In all cases, make certain that the receptacle in question is properly grounded. If you are not sure, have a qualified

electrician check the receptacle.

IN ALL CASES, MAKE CERTAIN THE RECEPTACLE IN QUESTION IS PROPERLY GROUNDED.

IF YOU ARE NOT SURE, HAVE A QUALIFIED ELECTRICIAN CHECK THE RECEPTACLE.

3. 240 VOLT Single-Phase Operation:

The motor supplied with your machine is a dual voltage, 120/240 volt motor. It is shipped ready-to-run for 120 volt

operation. However, it can be converted for 240 volt operation.

A qualified electrician should do the conversion, or the machine can be taken to an Authorized Delta Service Center.

When completed, the machine must conform to the National Electric Code and all local codes and ordinances.

The machine is converted by re-wiring the motor for 240 volts, installing a 240 volt plug on the power supply cord

and replacing the switch with one that is rated for 240 volt operation. Be sure the 240 volt plug is only used in an

outlet having the same configuration as the plug illustrated in Fig. C. No adapter should be used with the 240 volt

plug.

IN ALL CASES, MAKE CERTAIN THE RECEPTACLE IN QUESTION IS PROPERLY GROUNDED.

IF YOU ARE NOT SURE, HAVE A QUALIFIED ELECTRICIAN CHECK THE RECEPTACLE.

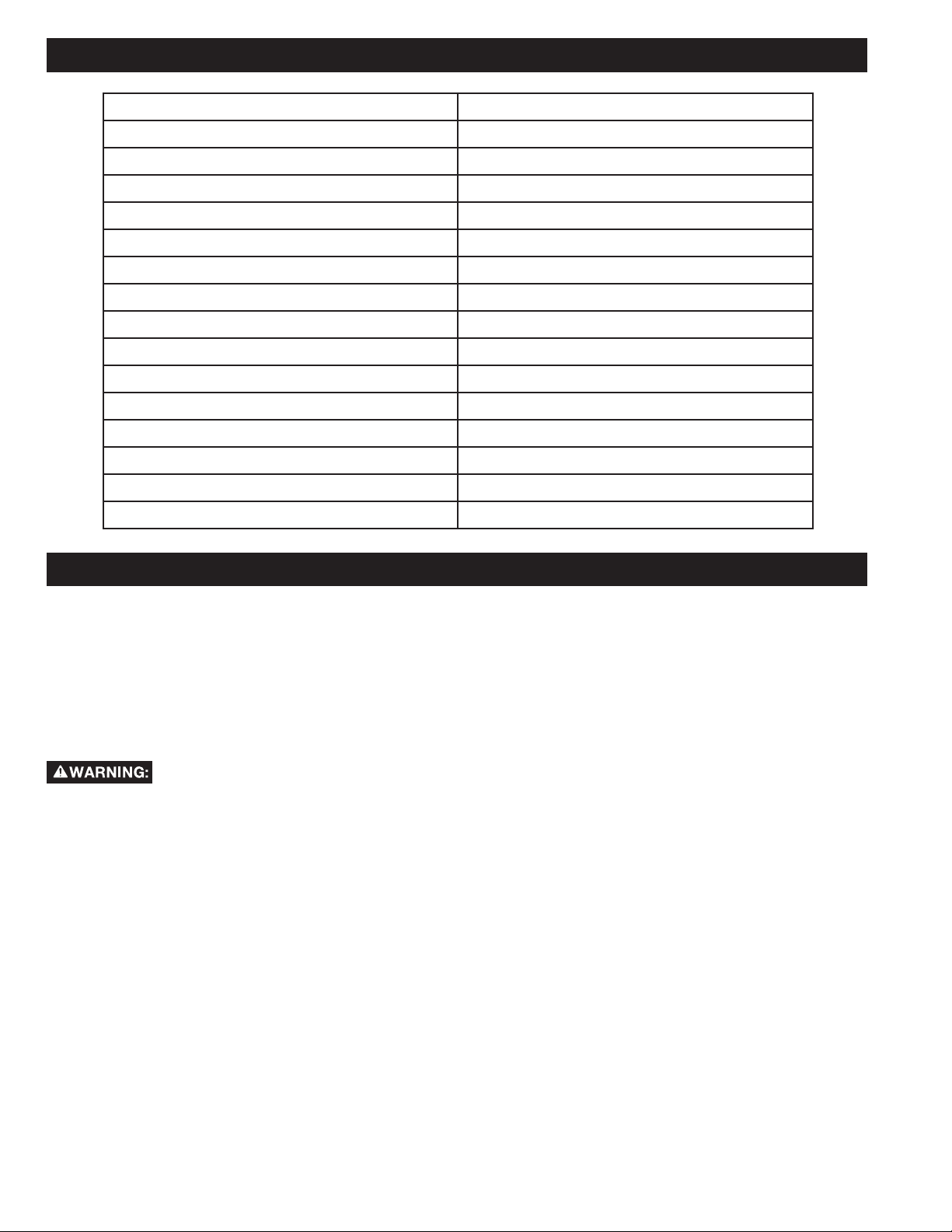

EXTENSION CORDS

Use proper extension cords.

Make sure your extension cord is

in good condition and is a 3-wire extension cord

which has a 3-prong grounding type plug and

matching receptacle which will accept the

machine’s plug. When using an extension cord,

be sure to use one heavy enough to carry the

current of the machine. An undersized cord will

cause a drop in line voltage, resulting in loss of

power and overheating. The table shows the

correct gauge to use depending on the cord

length. If in doubt, use the next heavier gauge.

The smaller the gauge number, the heavier the

cord.

FIG. C

6

MINIMUM GAUGE EXTENSION CORD

RECOMMENDED SIZES FOR USE WITH STATIONARY ELECTRIC MACHINES

Ampere

Rating

0-6

0-6

0-6

0-6

6-10

6-10

6-10

6-10

10-12

10-12

10-12

10-12

12-16

12-16

12-16

Volts Total Length

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

of Cord in

Feet

up to 25

25-50

50-100

100-150

up to 25

25-50

50-100

100-150

up to 25

25-50

50-100

100-150

up to 25

25-50

GREATER THAN 50 FEET NOT RECOMMENDED

Gauge of Extension

Cord

18 AWG

16 AWG

16 AWG

14 AWG

18 AWG

16 AWG

14 AWG

12 AWG

16 AWG

16 AWG

14 AWG

12 AWG

14 AWG

12 AWG

Page 7

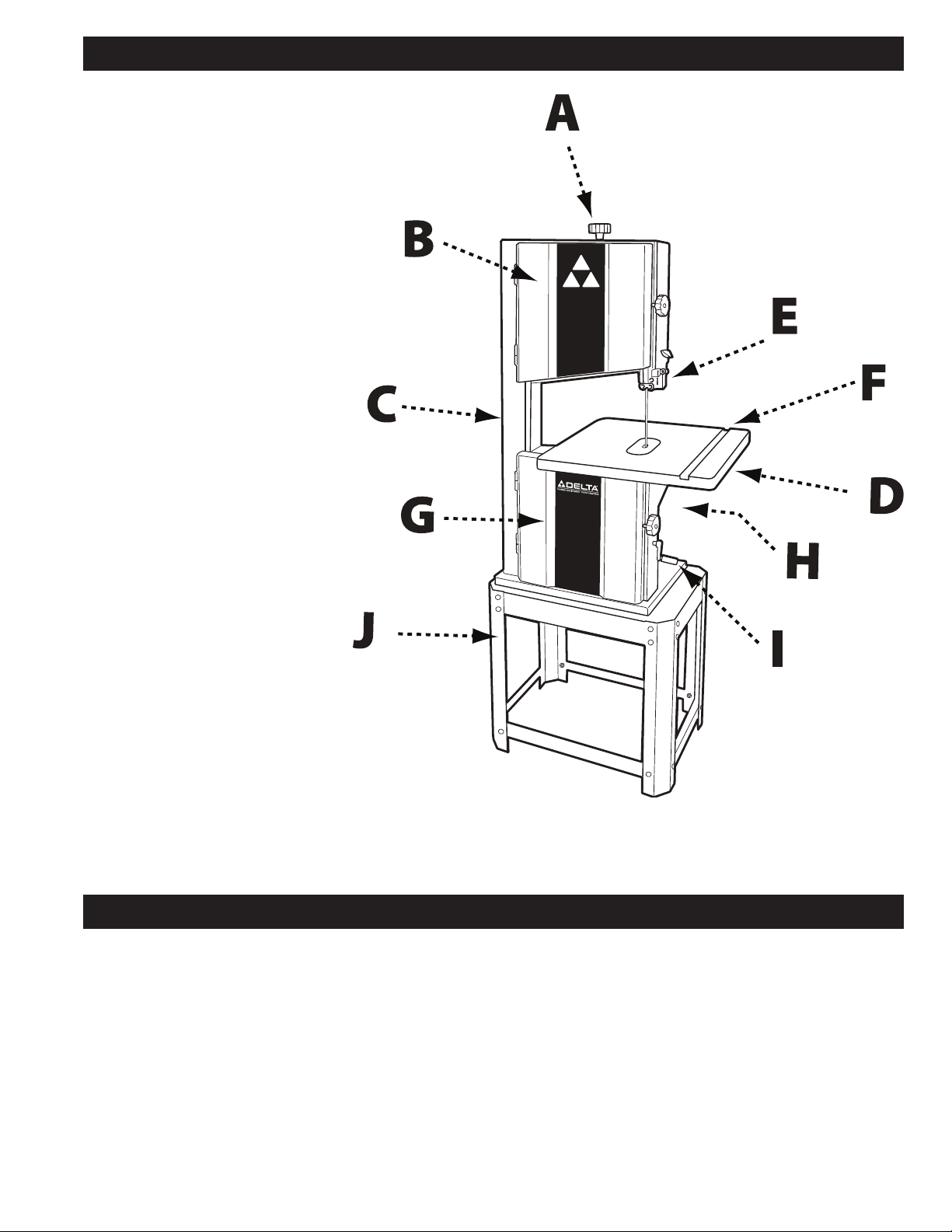

KEY FEATURES AND COMPONENTS

A. Blade Tensioning Knob

B. Upper Wheel Guard

C. Power Switch

D. Cast Iron Tilting Table

E. Blade Guide Assembly

F. Miter Gauge T-Slot

G. Lower Wheel Guard

H. 1 HP Motor

I. Belt Tensioning Handle

J. Tool Stand

FIG. 1

FUNCTIONAL DESCRIPTION

The DELTA® 14" Steel Frame Band Saw, MODEL 28-400, is designed for various re-sawing, cross-cutting and

ripping operations for material up to 6 " in height and 13-5/8 " in width. It features a 1HP, two-speed motor and can

accommodate blades from 1/8 " to 3/4 " in width.

7

Page 8

PRODUCT SPECIFICATIONS

Motor 1 HP, 120V

Cutting Capacity - Height 6"

Cutting Capacity - Width 13-5/8"

Minimum Blade Width 1/8"

Maximum Blade Width 3/4"

Blade Length 93-1/2"

Blade Speed - Low 1620 ft./min (490m/min.)

Blade Speed - High 3340 ft./min (990m/min)

Table Size 15-3/4" X 18-7/8"

Table T-Slot Size (DxW) 3/8" X 3/4"

Table Height From Floor 40-3/4"

Table Tilt 3° left - 45° right

Dust Port Diameter 4"

Overall Dimensions (HxWxD) 27" X 19" X 65-1/2"

Net Weight 180 Lbs.

Shipping Weight 165 Lbs.

UNPACKING

Carefully unpack the machine and all loose items from the shipping container(s). Remove the rust-preventative oil

from unpainted surfaces using a soft cloth moistened with mineral spirits, paint thinner or denatured alcohol.

Do not use highly volatile solvents such as gasoline, naphtha, acetone or lacquer thinner for cleaning your machine.

After cleaning, cover the unpainted surfaces with a good quality household floor paste wax.

NOTICE: The manual cover illustrates the current production model. All other illustrations contained in the manual

are representative only and may not depict the actual labeling or accessories included. These are intended to

illustrate technique only.

The machine is heavy, be careful when removing it from the shipping container! Failure to comply

may cause serious injury and/or damage to the sander and/or property!

Your DELTA® 14" Steel Frame Band Saw comes packed in a single container. Use a safety strap to avoid tip-over

when lifting machine. Check shipping carton and machine for damage before unpacking.

Open the shipping container. Carefully remove packaging materials, parts and machine from shipping carton. Always

check for and remove protective shipping materials around motors and moving parts. Lay out all parts on a clean

work surface and check that all parts are present and in good condition:

DESCRIPTION (QUANTITY)

• Stand Legs (4)

• Bottom Stand Braces (4)

• Stand Top (1)

• Stand Hardware Pack (1)

• Cast Iron Work Table (1)

• Top Trunnion (1)

• 93 ½" Band Saw Blade (1)

• Blade Tensioning Handle (1)

• Throat Plate (1)

• Hardware Pack (1)

CONTENTS OF STAND

HARDWARE PACK

• M6 X 16 Carriage Bolts (24)

• M6 FLAT Washers (24)

• M6 HEX Nuts (24)

• Rubber Feet (4)

8

CONTENTS OF TOOL

HARDWARE PACK

• M8 X 20 Hex Bolts (8)

• M6 Lock Washers (4)

• M6 Flat Washers (4)

• (size) Trunnion Feed Bolt (1)

• 8MM Flat Washer (1)

• Table Tilt Locking Wing Nut (1)

• M8 Flat Washers (4)

• M8 Lock Washers (4)

• M8 Hex Nuts (4)

Page 9

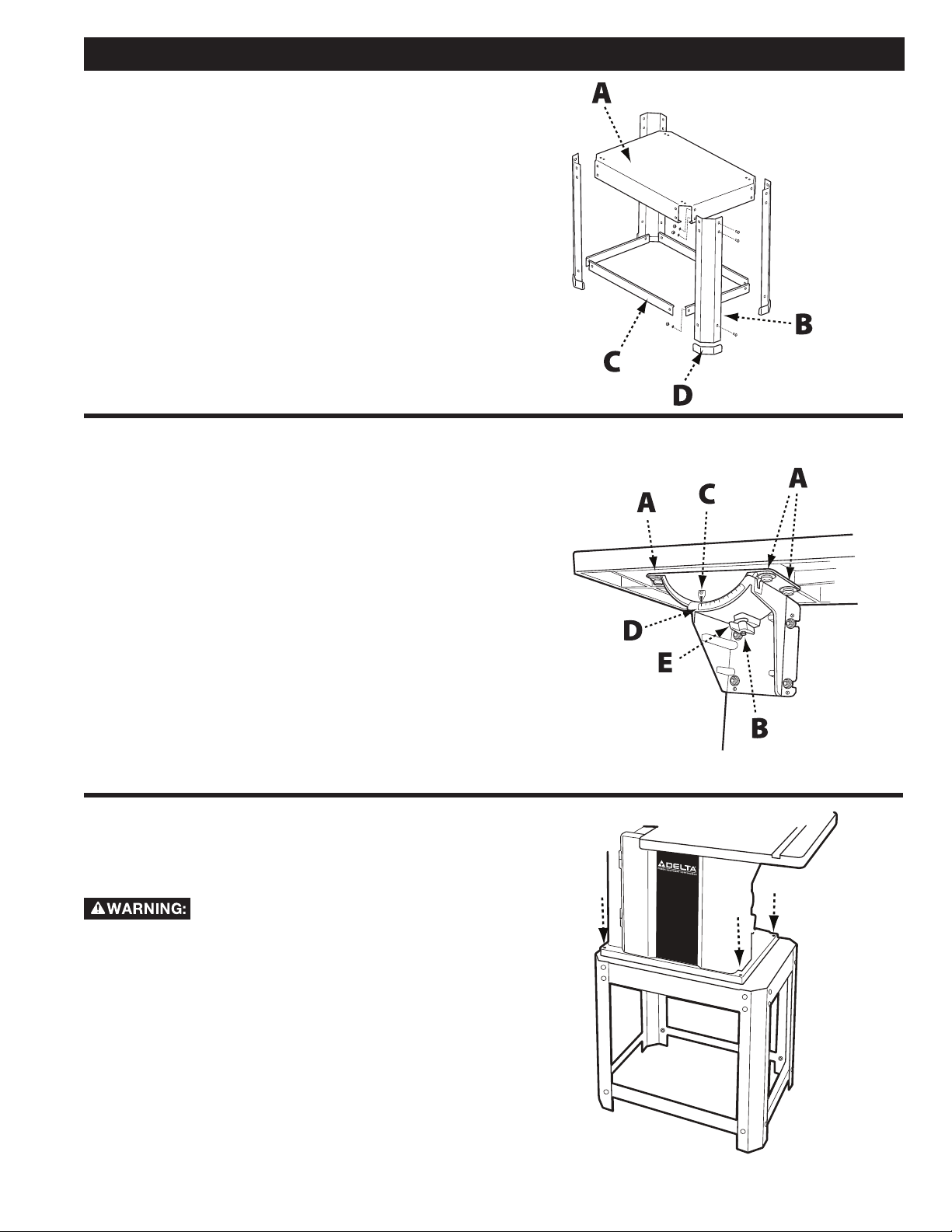

ASSEMBLY

STAND ASSEMBLY

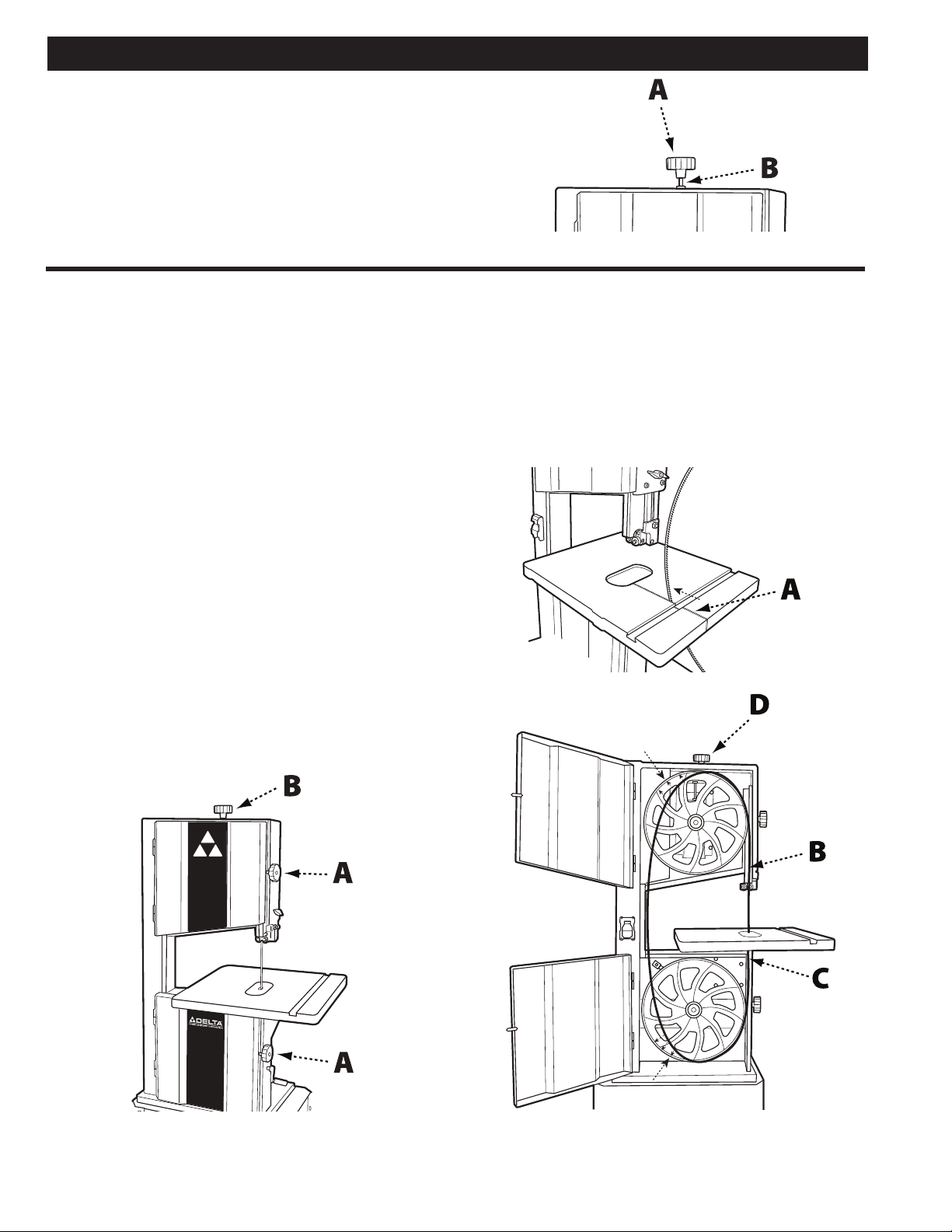

Refer to Figure 2

• Place top surface (A) upside down on a level surface.

Attach the four legs (B) to the top using M6 X 16

carriage bolts, M6 flat washers, and M6 hex nuts.

• Attach bottom rail supports (C) using M6 X 16

carriage bolts, M6 flat washers, and M6 hex nuts.

• Place rubber feet (D) on bottom of legs. Turn

assembled stand upright.

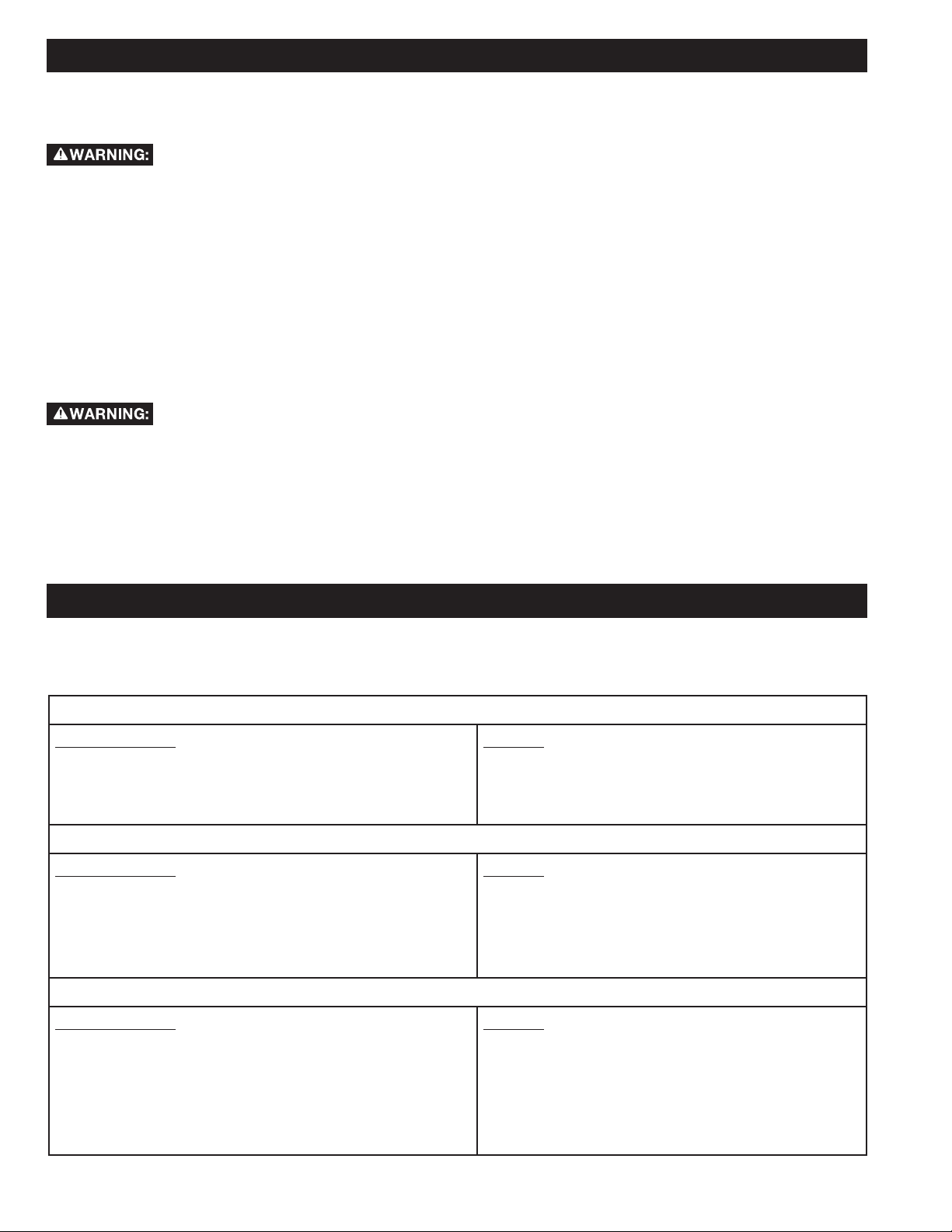

SECURE TABLE TO TABLE TRUNNION SYSTEM

Refer to Figure 3

FIGURE 2

• Locate the four mounting holes (A) in the upper

trunnion and attach the upper trunnion to the

underside of the table using four M8 X 20 hex bolts,

M6 lock washers, and M6 flat washers

• Position the table assembly so that the upper

trunnion fits into the lower trunnion and the trunion

feed bolt (B) extends through the slot in the lower

trunnion.

NOTE: The table tilt indicator (C) on the top trunnion

should align with table tilt scale (D) on the bottom

trunnion.

• Secure trunnion feed bolt using an 8MM flat washer

and black table tilt locking wing nut (E).

ATTACHING THE SAW TO THE STAND

See Figure 4.

This step requires two adults. The

DELTA® 14" Steel Frame Band Saw is

heavy, be careful when lifting and

handling it! Failure to comply may cause serious injury

and/or damage to the machine and/or property!

Carefully lift the saw onto the assembled stand and

align the four holes in base of the saw with the holes in

the top of the stand. Secure saw to the stand using four

M8 X 20 hex head bolts with M8 flat washer, M8 lock

washer and M8 hex nut.

FIGURE 3

FIGURE 4

9

Page 10

ASSEMBLY

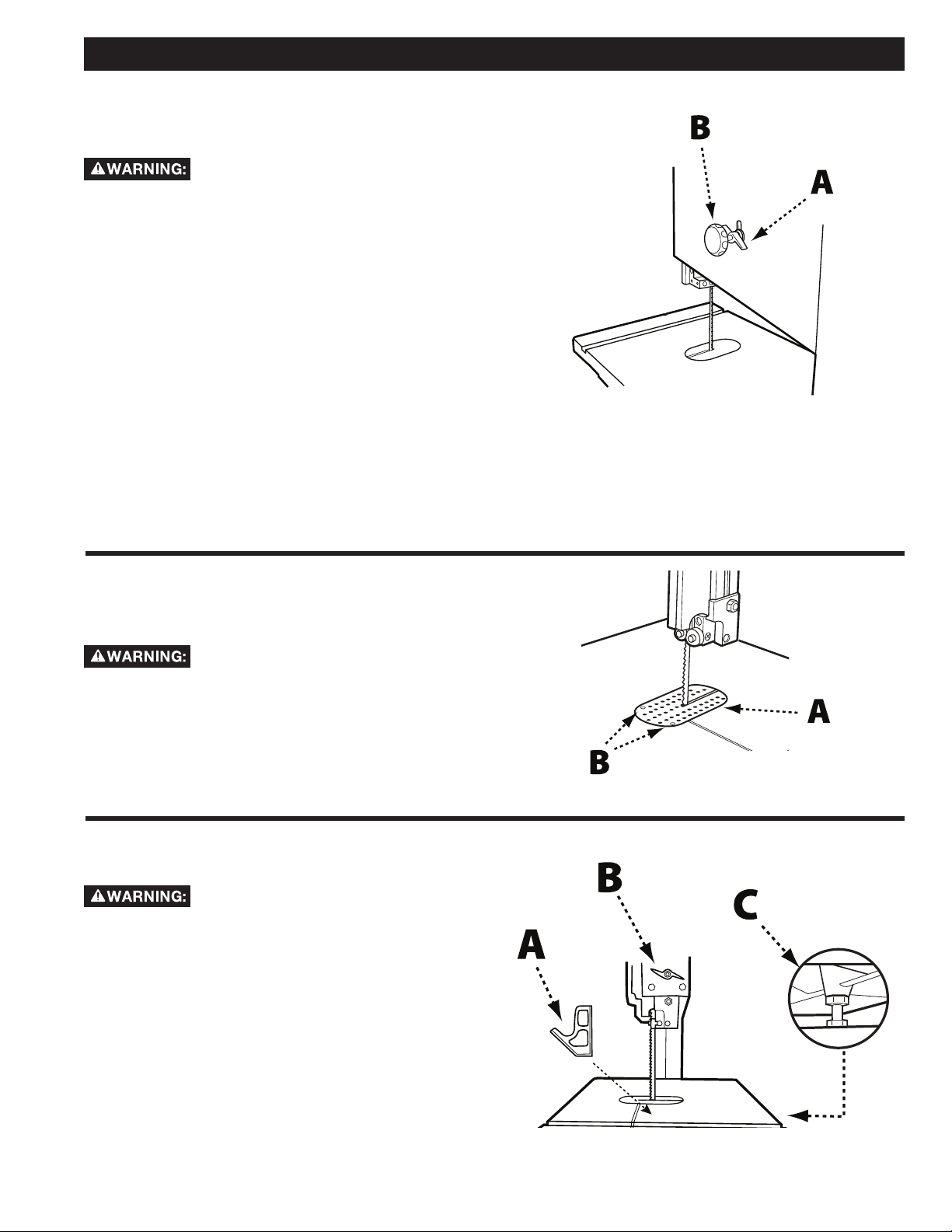

INSTALL BLADE TENSIONING KNOB

• Fit the blade tensioning knob (A) onto the blade

tensioning spindle (B) located at the top of the

machine.

INSTALL BAND SAW BLADE

• Open the upper and lower cabinets of the saw by

turning the cabinet lock knobs (A) clockwiseSee

Figure 6.

• Locate the blade tensioning knob (B) at the top of

the machine and turn it counterclockwise several

rotations to lower the upper flywheel.

• Carefully feed the blade through the slot in the table

(A), ensuring that the blade teeth are pointing down

toward the table. See Figure 7.

• Once the blade is in the throat of the saw table, rotate

it clockwise 90°, toward you. The blade teeth should

now be facing you.

• Carefully slide the blade through the upper slot (B)

and lower slot (C) located to the right of the wheel

guard.

• Loop the upper part of the blade over the upper tire

and the lower part of the blade over the lower tire.

See Figure 8. If you need to create additional slack,

rotate the blade tensioning knob (D) counterclockwise

until the blade can be slipped over both flywheels

• Tighten the blade tensioning knob until there is

sufficient tension on blade. (See “Adjusting the Blade

Tension", page 13).

FIGURE 5

FIGURE 7

FIGURE 6

NOTE: Once your DELTA® Band Saw is set up, you may want to cut several scraps of various species and

thicknesses of wood. Check for bowing in the cut and add more tension to the blade if necessary. Different blade

sizes will also require different tension settings.

10

Page 11

ASSEMBLY

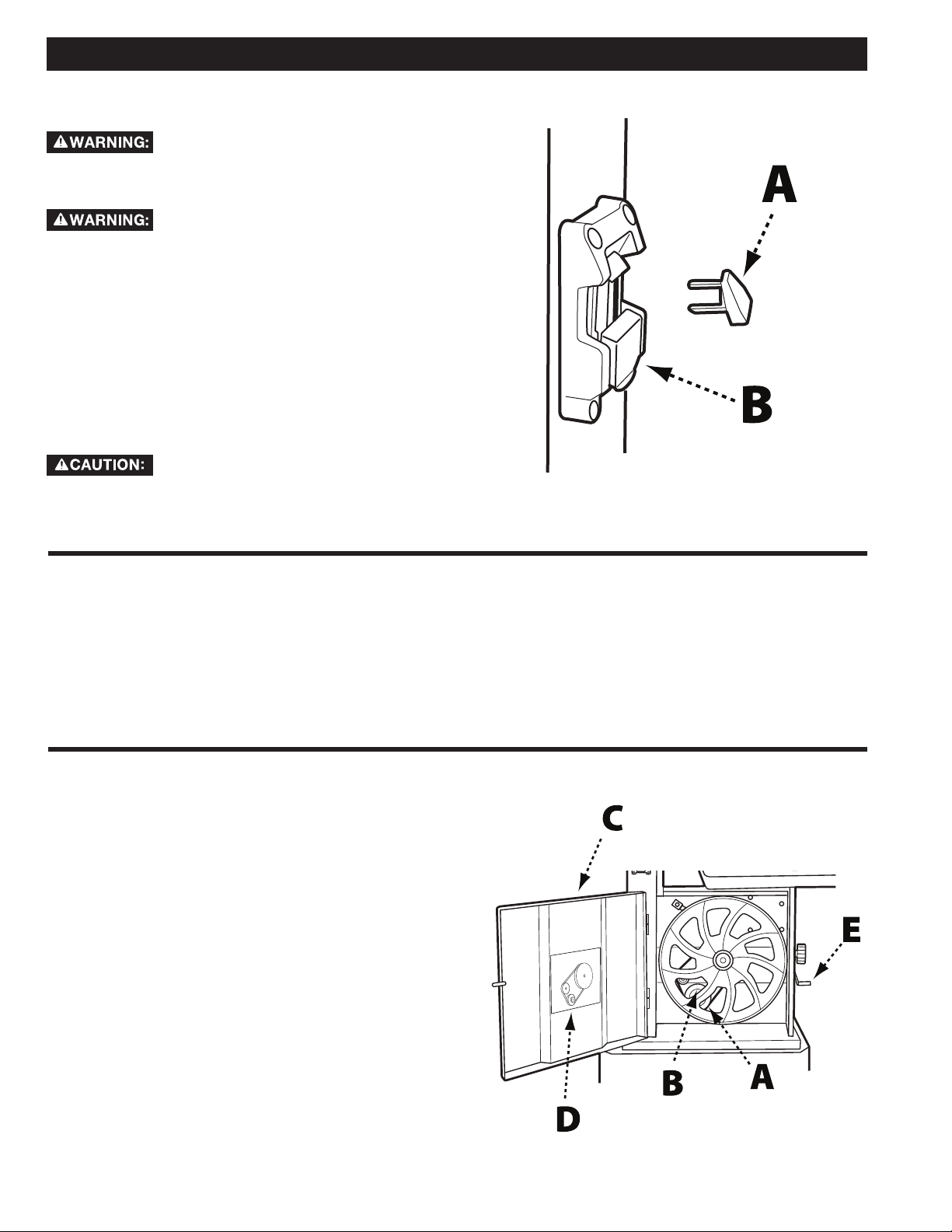

ADJUST THE BLADE TRACKING

See Figure 9.

Disconnect the machine from the

power source before making any

adjustments!

IMPORTANT: Before tracking the blade, confirm that

the blade guides and blade support bearings are clear

of the blade.

• After applying tension to the blade, open the upper

wheel guard.

• Rotate the wheel slowly forward by hand and observe

the blade’s movement. It should travel in the center of

the upper tire.

• If the blade creeps toward the front edge, unlock the

blade tracking lock (A) and turn the blade tracking

knob (B) clockwise until the blade consistently tracks

in the middle of the tire.

• If the blade creeps towards the rear of the tire, adjust

the blade tracking knob counterclockwise.

• Lock the blade tracking lock and close and lock the

upper wheel guard.

FIGURE 9

INSERT THROAT PLATE

See Figure 10.

Disconnect the machine from the

power source!

• Fit the throat plate (A) in the throat of the table so that

the tab on the throat plate fits into the notch in table.

• Check to ensure the front of the throat plate is not

higher than the table surface. To adjust the height of

the throat plate, rotate the two set screws (B) either

up or down

SQUARE TABLE TO BLADE

Disconnect the machine from the

power source!

Place a carpenters square (A) against the front and

back side of the blade and check the alignment of the

table. If the table is out of square, refer to Figure 11 and

proceed as follows:

• Raise the upper blade guide assembly by loosening

the lock knob (B).

• Loosen the flange nut (C) on the lower trunnion using

a 12MM open end wrench and adjust the set screw

until the table is square with the blade from the front

and back.

• Tighten the flange nut and use the square to confirm

proper position of the table

• Check the pointer on the tilt scale, located on the

lower trunnion, and reset if necessary to read 0°.

FIGURE 10

FIGURE 11

11

Page 12

OPERATION

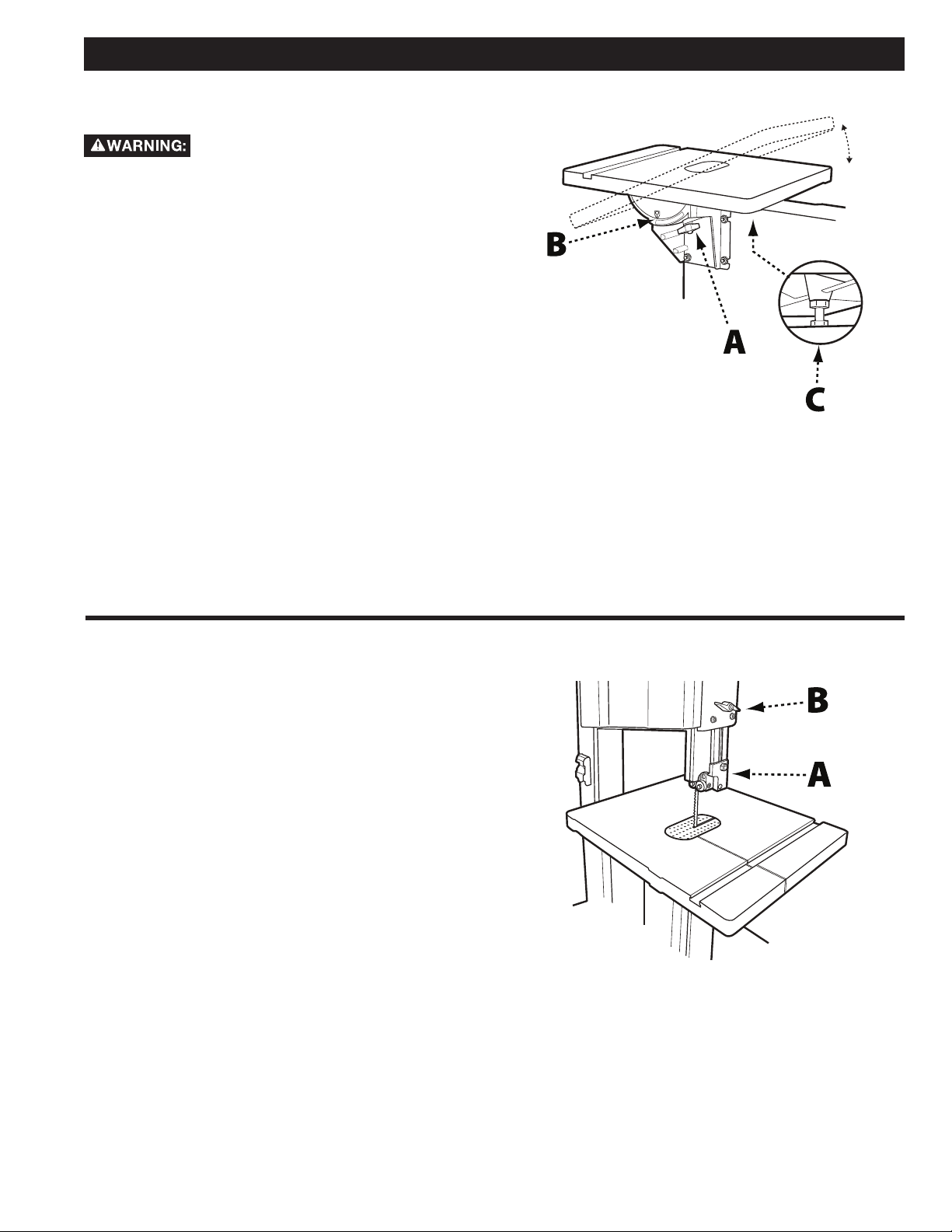

STARTING AND STOPPING THE SAW

Make sure that the switch is in the

“OFF" position before plugging cord

into outlet. Do not touch the plug’s metal prongs when

unplugging or plugging in the cord

Do not attempt to operate this tool

without first connecting it to an

adequate dust collection system

NOTE: The DELTA

a Safety Key (A), shown in Figure 12. The Safety Key

must be in place in order to operate the machineBefore

attempting to turn on the band saw, ensure the Safety

Key is installed.

The power switch is located on the left side of the

machine. To turn the machine "ON", ensure the yellow

safety key is installed and lift the red power switch (B)

To turn the machine "OFF", press up on the red power

switch.

switch to the “OFF" position until the main power is

restored.

®

14" Steel Frame Band Saw uses

In the event of a power outage (such as

a breaker or fuse trip), always move the

FIGURE12

USING THE SAFETY KEY TO LOCK THE SWITCH

IN THE "OFF" POSITION

When the tool is not in use, the switch should be

locked in the “OFF" position. This can be done by

grasping the Safety Key (A), shown in Figure 12 above,

and pulling it out of the switch. With the Safety Key

removed the switch will not operate. Should the Safety

Key be removed while the machine is running, the

switch can be turned “OFF" once, but cannot be

restarted without inserting the Safety Key.

IMPORTANT: Store the Safety Key away from the tool

to prevent unauthorized use

SELECTING PROPER CUTTING SPEED

Your DELTA® 14" Steel Frame Band Saw has two

cutting speeds: low (1620 ft./min )and high (3340 ft./

min). The cutting speed is determined based on which

of the two pulley wheels, shown in Figure 13 is in use.

The larger diameter pulley wheel (A) is used for the

lower cutting speed while the smaller diameter wheel

(B) is used for the higher speed.

• To change the cutting speed, open the lower wheel

guard (C).

• Refer to the diagram and instructions (D) posted on

the inside of the wheel guard.

• Reduce tension on the pulley belt using the belt

tensioning knob (E).

• Place belt on the proper wheels and hand turn to

ensure it tracks in the center of both wheels.

• Re-tension pulley belt using the belt tensioning knob.

• Close the lower wheel guard.

FIGURE 13

12

Page 13

OPERATION

TILTING THE TABLE

Disconnect the machine from the

power source!

See Figure 14.

You can tilt the band saw table up to 45° to the right. To

tilt the table to the right.

• Loosen the black table tilt locking wing nut (A),

located underneath the lower trunnion.

• Tilt the table to the desired angle as shown on the tilt

scale (B).

• Retighten the table tilt locking wing nut.

The table can also be tilted 3° to the left for

applications such as cutting cast moldings. To tilt the

table to the left:

• Follow the instructions above and tilting the table to

the right. The table should be tilted enough to allow

access to the 0° stop bolt (C) located on the lower

trunnion.

• Remove the 0° stop bolt.

• Loosen the table tilt locking wing nut, tilt the table all

the way to left.

• Retighten the table tilt locking wing nut.

FIGURE 14

POSITIONING THE UPPER BLADE GUIDE

IMPORTANT: Proper positioning of the upper blade

guide is required to ensure an accurate cut. It also

serves to prevent operators fingers from coming in

contact with the saw blade.

See Figure 15.

The upper blade guide (A) should be positioned

approximately 1/16" above the top of the workpiece,

just high enough to allow the workpiece to pass under

the blade guide assembly.

To set the upper blade guide to the proper height:

• Loosen the lock knob (B) and move the blade guide

assembly to the desired position.

• Retighten the lock knob.

IMPORTANT: Prior to using the band saw, always

check guide post lock knob and tighten if necessary.

FIGURE 15

13

Page 14

OPERATION

CUTTING CURVES

Turn the stock carefully so that the blade follows

without twisting. For very abrupt curves, consider

using a narrower blade, or a blade with more set.

Another solution to this problem is to make relief cuts

(Figure 16)

When you withdraw the workpiece or change the cut,

be careful not to accidentally pull the blade off of the

wheels. The preference is to turn the stock and saw out

through the waste material.

ADJUSTMENTS

ADJUSTING THE BLADE TENSION

FIGURE 16

Disconnect the machine from the power

source before making any adjustments!

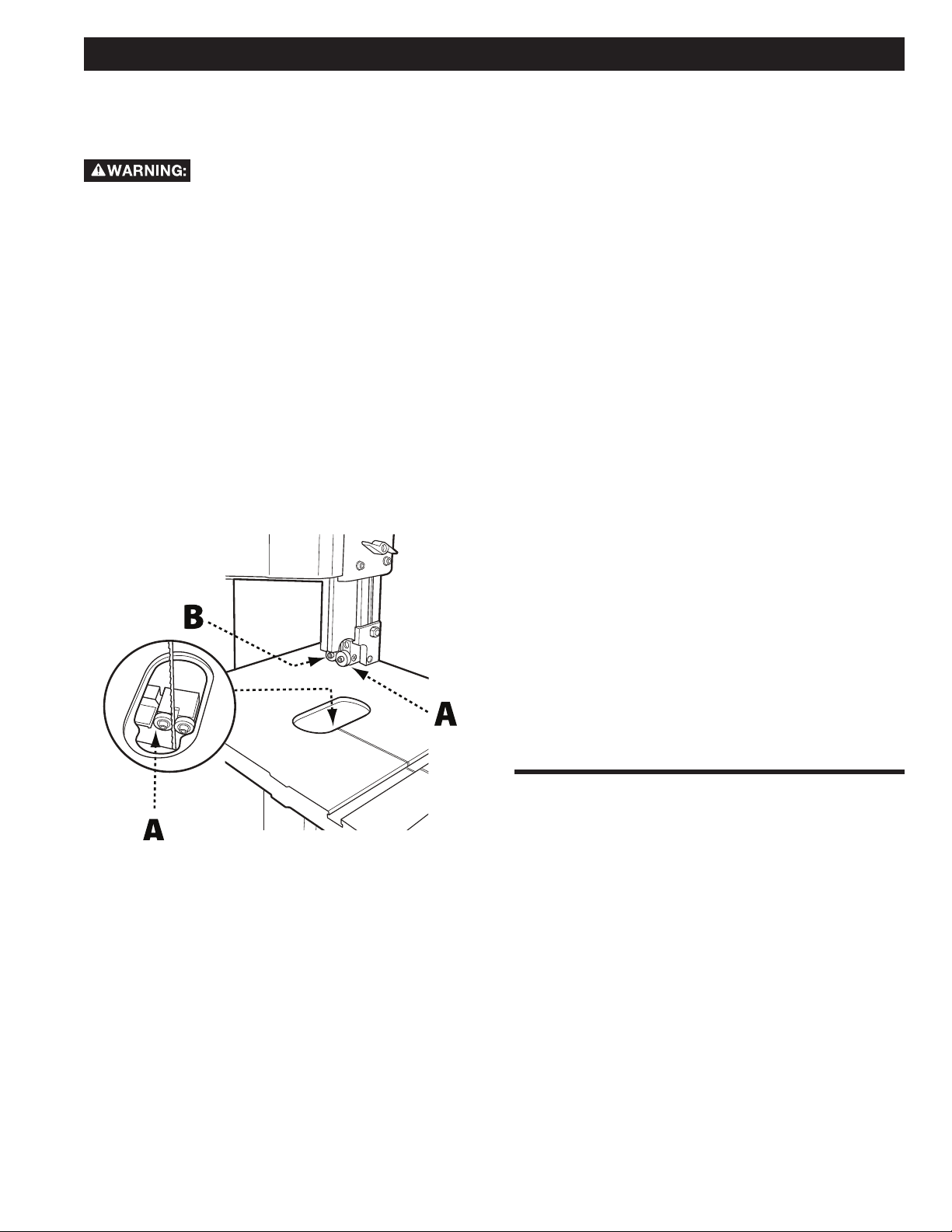

See Figure 17 (show set up as in sample to the

rightCaption: A standard blade should have

approximately 1/4" deflection on either side.)

Unless you have a tension meter, achieving optimum

blade tension is a matter of trial and error. There are a

number of suggested methods for achieving the proper

tension.

Most blade manufacturers recommend 15,000 psi to

20,000 psi for a common carbon-steel blade. Stronger

bimetal, spring-steel, and carbide-tipped blades

generally require 25,000 psi to 30,000 psi. The tighter

the blade is stretched, the more rigid it becomes and

the less tendency it will have to deflect in the cut.

It should be noted that maximum blade tension is

only required for the most demanding cuts, such as

re-sawing dense hardwoods or stock of maximum

thickness.

NOTE: DELTA® Timber Wolf® band saw blades are

recommended as they are designed to operate with

less tension, thus increasing their serviceable life.

Follow the tensioning directions on the package

To check and adjust the blade tension on your DELTA®

14" Steel Frame Band Saw, do the following:

Disconnect the machine from the power

source before making any adjustments!

• If the blade deflects more than 1/4", increase

the tension on the blade by tightening the blade

tensioning knob at the top of the machine (refer to B

in Figure 6, page 9).

• If the blade does not deflect at all, it may be too tight.

Loosen the blade tensioning knob slightly until there

is a minimal amount of deflection.

• Set the upper blade guide assembly about 6 in. off

the table.

• Use a moderate amount of pressure with your index

finger to push the blade sideways in both directions.

The blade should not deflect more than 1/4" in either

direction.

FIGURE 17

14

Page 15

ADJUSTMENTS

ADJUSTING THE BLADE GUIDES AND BEARINGS

See Figure 18.

Disconnect the machine from the

power source before making any

adjustments!

Adjust the upper blade guides and blade support

bearings only after the blade has the correct tension

and is tracking properly.

The DELTA® 14" Steel Frame Band Saw features two

upper and lower side bearings and two upper and

lower rear bearings that can be adjusted in order to

ensure straight and consistent cuts. It is recommended

that you periodically check the position of all bearings

and adjust if necessary.

SIDE BEARINGS

The upper and lower side bearings (A) should be

positioned so that there is approximately 1/64" gap on

either side of the blade. To adjust the position of the

bearings, side-to-side, do the following:

• Use a 3MM Allen wrench to loosen the bearing

screws (B).

• Reposition the bearings and tighten the bearing the

screws.

The upper and lower side bearings also adjust back

and forth and should be positioned so that the front

edge of the bearings is just behind the blade gullet. To

adjust the position of the bearings, front-to-back, do

the following:

• Use a 13MM open wrench to loosen the top retaining

nut and a 10MM open wrench to loosen the bottom

retaining nut. (The bottom retaining nut can be made

more accessible by tilting the table slightly.)

• With the retaining nut loosened, both upper side

bearings or both lower side bearings will move back

and forth as a unitPosition them so that the front edge

of the bearings are just behind the blade gullet.

• Re-tighten the retaining nuts.

REAR BEARINGS

NOTE: The upper and lower side bearings must both be

set in place prior to adjusting the upper and lower rear

bearings.

The upper and lower rear bearings should be

positioned so that they nearly touch the blade.

FIGURE 18

• To adjust, use a 3MM Allen wrench to loosen the

bearing screws.

• Reposition the bearings and tighten the bearing the

screws.

ADJUSTING BLADE TRACKING

See “Adjust Blade Tracking" in the Assembly section of

this manual on page 10.

15

Page 16

MAINTENANCE

STARTING AND STOPPING THE SAW

Make sure that the switch is in the

"OFF" postion. To reduce the risk of

injury, turn unit off and disconnect it from power source

before installing and removing accessories, before

adjusting or when making repairs.

An accidental start-up can cause injury.

KEEP MACHINE CLEAN

Periodically blow out all air passages with dry

compressed air. All plastic parts should be cleaned with

a soft damp cloth.

NEVER use solvents to clean plastic parts. They could

possibly dissolve or otherwise damage the material.

Wear certified safety equipment for eye,

hearing and respiratory protection while

using compressed air

FAILURE TO START

Should your machine fail to start, check to make sure

the prongs on the cord plug are making good contact

in the outlet. Also, check for blown fuses or open

circuit breakers in the line.

LUBRICATION & RUST PROTECTION

Apply household floor paste wax to the machine table,

extension table or other work surface weekly. Or use a

commercially available protective product designed for

this purpose. Follow the manufacturer’s instructions for

use and safety.

To clean cast iron tables of rust, you will need the

following materials: a sheet of medium Scotch-Brite™

Blending Hand Pad, a can of WD-40® and a can of

degreaser. Apply the WD-40 and polish the table

surface with the Scotch-Brite pad.

Degrease the table, then apply the protective product

as described above.

TROUBLESHOOTING

In spite of how well a band saw is maintained, problems can occur. The following troubleshooting guide will help you

solve the more common problems:

TROUBLE: SAW WILL NOT START.

Probable Cause

1. Saw not plugged in.

2. Fuse blown or circuit breaker tripped.

3. Cord damaged.

TROUBLE: BREAKER KICKS OUT FREQUENTLY.

Probable Cause

1. Extension cord too light or too long.

2. Feeding stock too fast.

3. Blade in poor condition (dull, warped, gummed).

4. Low voltage supply.

TROUBLE: BAND SAW VIBRATES EXCESSIVELY.

Probable Cause

1. Machine not mounted securely to stand.

2. Stand on uneven surface.

3. Worn belt.

4. Pulley not aligned.

5. Motor not fastened securely.

Remedy

1. Plug in saw.

2. Replace fuse or reset circuit breaker.

3. Have cord replaced.

Remedy

1. Replace with adequate size cord.

2. Feed stock more slowly.

3. Clean or replace blade.

4. Contact an electrician

Remedy

1. Tighten all mounting hardware.

2. Reposition on flat level surface.

3. Replace belt.

4. Adjust pulleys.

5. Tighten all mounting hardware.

16

Page 17

TROUBLESHOOTING

TROUBLE: BAND SAW DOES NOT COME UP TO SPEED.

Probable Cause

1. Low voltage due to improper extension cord size.

2. Low voltage.

TROUBLE: BLADES BREAK.

Probable Cause

1. Blade not tensioned properly.

2. Blade guides improperly adjusted.

3. Blade support bearing improperly adjusted.

4. Blade wheel tracking adjustment improperly set.

5. Bad weld on blade.

6. Worn tires.

7. Forcing wide blade around short radius.

8. Dull blade or insufficient set.

9. Upper blade guide set too high.

TROUBLE: BLADE WILL NOT TRACK.

Probable Cause

1. Blade too loose

2. Upper wheel not properly adjusted.

3. Improperly adjusted blade support bearing.

Remedy

1. Replace with adequate size cord.

2. Contact an electrician.

Remedy

1. Adjust blade tension.

2. Check and adjust blade guides.

3. Adjust blade support bearing.

4. Check and adjust blade tracking.

5. Replace the blade.

6. Replace tires.

7. Change to a narrower blade.

8. Replace blade.

9. Set upper blade guide within 1/8" of workpiece.

Remedy

1. Adjust tension

2. Adjust upper wheel.

3. Adjust blade support bearing.

TROUBLE: CUT DOESN’T MATCH SETTING ON TILT SCALE.

Probable Cause

1. Pointer out of adjustment

Remedy

1. Adjust pointer.

TROUBLE: BLADE WILL NOT STAY ON WHEEL.

Probable Cause

1. Blade not tensioned properly.

2. Blade guides improperly adjusted.

3. Blade support bearing improperly adjusted.

4. Blade wheel not tracking properly.

5. Bad weld on blade.

6. Worn tires.

Remedy

1. Adjust blade tension.

2. Check and adjust blade guides.

3. Adjust blade support bearing.

4. Check and adjust blade tracking.

5. Replace the blade.

6. Replace tires.

TROUBLE: BAND SAW MAKES UNSATISFACTORY CUTS.

Probable Cause

1. Blade not tensioned properly.

2. Blade guides improperly adjusted.

3. Blade support bearing improperly set.

4. Blade wheel not tracking properly.

5. Bad weld on blade.

6. Worn tires.

7. Incorrect blade for work being done.

8. Dull blade or insufficient set.

9. Upper blade guide set too high.

Remedy

1. Adjust blade tension.

2. Check and adjust blade guides.

3. Adjust blade support bearing.

4. Check and adjust blade tracking.

5. Replace the blade.

6. Replace tires.

7. Change the blade.

8. Replace blade.

9. Set upper blade guide within 1/8" of work piece.

17

Page 18

ABOUT BAND SAW BLADES

You can obtain long use from a band saw blade if you

use it properly. Use blades of proper thickness, width

and temper for the various types of material and cuts.

Always use the widest blade possible. Use narrow

blades only for sawing small, abrupt curves and for

fine, delicate work. This will save blades and will

produce better cuts. For cutting wood and similar

materials, DE LTA® offers blades in widths of 1/8", 1/4",

3/8", 1/2", and 3/4".

Any one of a number of conditions may cause a band

saw blade to break. Blade breakage is, in some cases,

unavoidable, being the natural result of the peculiar

stresses to which blades are subjected. Blades will

break often due to avoidable causes, such as the lack

of care to the blade or the blade not being properly

adjusted to the band saw. The most common causes

of blade breakage are:

• Faulty alignments and adjustments of the guides.

• Forcing or twisting a wide blade around a curve of

short radius.

• Feeding the work piece too fast into the blade.

• Dullness of the teeth, or absence of sufficient set.

• Improperly tensioned blade.

• Top guide set too high above the work piece being

cut.

• Using a blade with a lumpy or improperly finished

braze or weld.

• Continuous running of the saw blade when not

cutting.

TIPS:

• Use blades that are 93½" in length on this machine.

• Always use a sharp blade. Keep it free from gum

and pitch. Clean frequently with a stiff fiber brush.

• Narrow blades are used for cutting small circles or

curves while the wider blades are best suited for

straight cutting such as ripping.

• A new blade, in most cases, will perform better and

last longer than a re-sharpened blade.

• Ensure that the blade guides are adjusted properly.

• Do not force or twist the blade around a curve or a

very short radius.

• Feed the workpiece through the blade at a

consistent rate, allow the blade to do the cutting –

do not feed the work piece too fast.

• Do not apply excessive tension to the blade. The

tension is only necessary to drive the blade without

slipping on the wheels. Narrow blades require less

tension than wider blades.

ACCESSORIES

A complete line of accessories is available from your DELTA® Supplier, DELTA® Factory Service Centers, and

DELTA® Factory Service Centers, and DELTA® Authorized Service Centers. Please visit our Web Site www.

DeltaMachinery.com for an online catalog or for the name or your nearest supplier.

Since accessories other than those offered by DELTA® have not been tested with this product,

use of such accessories could be hazardous. For safest operation, only DELTA® recommended

accessories should be used with this product.

WARRANTY

To register your tool for warranty service visit our website at www.DeltaMachinery.com.

Five Year Limited New Product Warranty

DELTA® will repair or replace, at its expense and at its option, any new DELTA® machine, machine part, or machine accessory which in normal

use has proven to be defective in workmanship or material, provided that the customer returns the product prepaid to a DELTA

center or authorized service station with proof of purchase of the product within five years and provides DELTA

to verify the alleged defect by inspection. For all refurbished DELTA

for any asserted defect which has resulted from normal wear, misuse, abuse or repair or alteration made or specifically authorized by anyone

other than an authorized DELTA

damages resulting from defective products. Some states do not allow the exclusion or limitation of incidental or consequential damages, so

the above limitation or exclusion may not apply to you. This warranty is DELTA

with respect to defective products; all other warranties, express or implied, whether of merchantability, fitness for purpose, or otherwise, are

expressly disclaimed by DELTA

1-800-223-7278. This warranty gives you specific legal rights and you may have other rights which vary in certain states or provinces.

®

service facility or representative. Under no circumstances will DELTA® be liable for incidental or consequential

®

. For further detail of warranty coverage and warranty repair information, visit www.DeltaMachinery.com or call

®

product, the warranty period is 180 days. DELTA® will not be responsible

®

’s sole warranty and sets forth the customer’s exclusive remedy,

®

with reasonable opportunity

®

factory service

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For products sold in Latin America,

see country specific warranty information contained in the packaging, call the local company or see website for warranty

information.

18

Page 19

PARTS, SERVICE OR WARRANTY ASSISTANCE

All DELTA® machines and accessories are manufactured to high quality standards and are serviced by a network of

DELTA® Factory Service Centers and DELTA® Authorized Service Centers. To obtain additional information regarding

your DELTA® quality product or to obtain parts, service, warranty assistance, or the location of the nearest service

center, please call 1-800-223-7278.

REPLACEMENT PARTS

Use only identical replacement parts. For a parts list or to order parts, visit our website at www.DeltaMachinery.

com

. You can also order parts from your nearest factory-owned branch, Authorized Warranty Service

Center or by calling Technical Service Manager at 1-800-223-7278 to receive personalized support from one of our

highly-trained representatives.

FREE WARNING LABEL REPLACEMENT

If your warning labels become illegible or are missing,

call

1-800-223-7278

for a free replacement.

SERVICE AND REPAIRS

All quality tools will eventually require servicing and/or replacement of parts. For information

about DELTA® Power Equipment Corporation, its factory-owned branches, or to locate an

Authorized Wa rra nty Service Center, visi t our websit e at www. D eltaM achinery.com

or call our Customer Care Center at 1-800-223-7278. All repairs made by our service centers are fully

guaranteed against defective material and workmanship. We cannot guarantee repairs made or attempted by

others. By calling this number you can also find answers to most frequently asked questions 24 hours/day.

You can also write to us for information at DELTA® Power Equipment Corporation, 99 Roush Street,

Anderson, SC 29625 - Attention: Technical Service Manager. Be sure to include all of the information shown

on the nameplate of your tool (model number, type, serial number, date code, etc.)

19

Page 20

CONSIGNES DE SÉCURITÉ IMPORTANTES

ASSUREZ-VOUS D’AVOIR BIEN LU ET COMPRIS TOUTES LES MISES EN GARDE ET LES

CONSIGNES D’UTILISATION AVANT D’UTILISER CET ÉQUIPEMENT. Le fait de ne pas

respecter toutes les instructions ci-dessous pourrait causer une électrocution, des incendies, et/ou des blessures

personnelles ou des dommages matériels graves.

La menuiserie peut être dangereuse si des procédures d’utilisation sécuritaires et adéquates ne sont

pas respectées. Comme c’est le cas pour toute pièce de machinerie, l’utilisation de ce produit comporte

certains dangers. En utilisant cet appareil selon les directives et avec prudence, vous réduirez de façon

importante les risques de blessures corporelles. Cependant, si les précautions normales de sécurité

sont négligées ou ignorées, la personne qui utilise l’appareil pourrait être blessée. L’équipement de protection

comme les gardes, les poussoirs, les dispositifs de retenue, les planches de protection, les lunettes de sécurité,

les masques antipoussières et la protection pour l’ouïe peut réduire le risque de blessure. Cependant, même le

meilleur dispositif de protection ne peut compenser un mauvais jugement, un manque de prudence ou d'inattention.

Utilisez toujours le bon sens et soyez prudent dans l’atelier. Si une manœuvre a l’air dangereuse, ne l’effectuez

pas. Essayez plutôt de trouver un moyen plus facile. RAPPELEZ-VOUS : vous êtes responsable de votre sécurité

personnelle. Pour des renseignements complémentaires, rendez-vous sur notre site Web à l’adresse suivante

www.DeltaMachinery.com.

Cet appareil a été conçu seulement pour certaines utilisations. DELTA® Power Equipment

Corporation recommande fortement que cet appareil ne soit pas modifié ni utilisé pour

toutes autres fins que celles pour lesquelles il a été conçu. Si vous avez des questions sur une utilisation en

particulier, N’UTILISEZ PAS l’appareil avant d’avoir d’abord communiqué avec DELTA® pour déterminer si cette

utilisation peut ou si elle devrait être faite sur ce produit.

Si vous avez des questions relativement à son utilisation, N’UTILISEZ PAS le produit tant que vous n’aurez pas

communiqué par écrit avec DELTA

en ligne à www.DeltaMachinery.com ou par courrier à l’adresse suivante : Responsable du service technique, DELTA®

Power Equipment Corporation, 99 Roush Street, Anderson, SC 29625.

Des renseignements au sujet de l’utilisation sécuritaire et appropriée de cet appareil sont disponibles auprès des

sources suivantes :

• Power Tool Institute, 1300 Sumner Avenue, Cleveland, OH 44115-2851 ou en ligne sur www.powertoolinstitute.com

• National Safety Council, 1121 Spring Lake Drive, Itasca, IL 60143-3201

• American National Standards Institute, 25 West 43rd Street, 4 floor, New York, NY 10036 www.ansi.org - ANSI 01.1

Safety Requirements for Woodworking Machines

• Réglementation du Département américain du travail (OSHA) à l’adresse www.osha.

®

Power Equipment Corporation et obtenu une réponse de sa part. Contactez-nous

gov

CONSIGNES DE SÉCURITÉ - DÉFINITIONS

Ce manuel contient des renseignements qu'il est important de connaître et de comprendre. Ces renseignements ont pour

but d’assurer VOTRE SÉCURITÉ et de PRÉVENIR LES PROBLÈMES D’ÉQUIPEMENT. Pour vous aider à reconnaître ces

renseignements, nous utilisons les symboles ci-dessous. Veuillez lire le manuel et prêter attention à ces sections.

Indique une situation extrêmement dangereuse qui, si elle n’est pas évitée, entraînera la mort ou une

blessure grave.

Indique une situation potentiellement dangereuse qui, si elle n’est pas évitée, pourrait

entraîner la mort ou une blessure grave.

Indique une situation potentiellement dangereuse qui, si elle n’est pas évitée, peut entraîner une

blessure mineure ou modérée.

Utilisé sans le symbole d’avertissement, indique une situation potentiellement dangereuse qui, si elle

n’est pas évitée, peut endommager l’appareil.

20

Page 21

RÈGLES DE SÉCURITÉ GÉNÉRALES

LE NON-RESPECT DE CES RÈGLES PEUT ENTRAÎNER DES BLESSURES PERSONNELLES

GRAVES.

POUR VOTRE PROPRE SÉCURITÉ, ASSUREZ-VOUS D’AVOIR BIEN LU ET COMPRIS LE MANUEL D’UTILISATION

•

AVANT DE FAIRE FONCTIONNER L’APPAREIL.

que les dangers qui lui sont rattachés.

MAINTENEZ L’AIRE DE TRAVAIL PROPRE.

•

NE PAS UTILISER DANS UN ENVIRONNEMENT DANGEREUX.

•

mouillé, et ne l’exposez pas à la pluie. Gardez votre lieu de travail bien éclairé.

MAINTENEZ LES ENFANTS ET LES VISITEURS À L’ÉCART.

•

distance sécuritaire de l’aire de travail.

DÉBRANCHEZ L’APPAREIL

•

VÉRIFIEZ LA PRÉSENCE DE PIÈCES ENDOMMAGÉES.

•

pièce endommagée.

avant toute opération d’entretien.

LE NON-RESPECT DE CES RÈGLES PEUT ENTRAÎNER DES BLESSURES GRAVES.

Apprenez à connaître son domaine d’utilisation et ses limites, ainsi

Les aires et les bancs de travail encombrés sont propices aux accidents.

N’utilisez pas cet appareil dans un endroit humide ou

Tous les enfants et visiteurs doivent demeurer à une

Avant d’utiliser l’appareil, bien réparer ou remplacer toute

1. Assurez-vous de lire et comprendre les

avertissements affichés sur l’appareil et dans ce

manuel. Le non respect de tous ces avertissements

peut entraîner des blessures graves.

2. Remplacez les étiquettes d’avertissement si elles

sont masquées ou supprimées.

3. Cet appareil est conçu pour l’utilisation par un

personnel qualifié et expérimenté seulement. En

cas de non familiarité avec le bon fonctionnement

sécuritaire d’une scie à ruban, ne pas l’utiliser avant

d’avoir reçu la formation et les connaissances

appropriées.

4. Ne pas utiliser cet appareil pour autre chose que

son usage prévu. S’il est utilisé à d’autres fins,

DELTA® Power Equipment Corporation décline

toute garantie réelle ou implicite et se dégage de

toute responsabilité pour toute blessure qui pourrait

résulter de cette utilisation.

5. Portez toujours des lunettes/masque de protection

agréés durant l’utilisation de cette scie à ruban.

6. Avant d’utiliser cette scie à ruban, enlevez cravate,

bagues, montres et autres bijoux, et retroussez vos

manches au-dessus du coude. Retirez tous les

vêtements amples et retenez les cheveux longs.

Il est recommandé de porter des chaussures

antidérapantes ou de poser des bandes de plancher

antidérapantes. Ne pas porter de gants.

7. Portez des protecteurs pour l’ouïe (bouchons ou

manchons) pendant les longues périodes de

fonctionnement.

8. Certaines poussières créées par le ponçage

mécanique, le sciage, le broyage, le perçage

et d’autres activités de construction contiennent

des produits chimiques identifiés comme causes

de cancer, d’anomalies congénitales ou d’autres

préjudices liés à la reproduction. En voici des

exemples :

• plomb de peintures à base de plomb;

• silice cristalline de briques, de ciment et d’autres

produits de maçonnerie;

• arsenic et chrome de bois de sciage traité

chimiquement.

Votre risque lié à ces expositions varie selon la

fréquence à laquelle vous faites ce genre d’activité.

Pour réduire l’exposition à ces produits chimiques,

travaillez dans un endroit bien ventilé et avec de

l’équipement de protection approuvé, comme les

masques antipoussières spécialement conçus pour filtrer

les particules microscopiques.

9. N'utilisez pas cet appareil en état de fatigue ou avec

les facultés affaiblies par la drogue, l’alcool ou les

médicaments.

10. Avant de brancher l’appareil sur la source

d’alimentation, assurez-vous que l’interrupteur est en

position « OFF » (Arrêt).

11. Assurez-vous que l'appareil est correctement mis

à la terre.

12. Ne faites les réglages de l'appareil ou son entretien

que lorsque celui-ci est débranché de la source

d’alimentation.

13. Prenez l’habitude de vérifier que tout l’équipement

supplémentaire tel que les clés de réglage, les clés

à molette, la ferraille, le matériel et les chiffons de

nettoyage a été éloigné de l'appareil avant de le

mettre en marche.

14. Gardez les dispositifs de protection en place en tout

temps lorsque l’appareil est utilisé. Faites preuve

d’une extrême prudence s’ils sont enlevés à des

fins d’entretien et remettez-les en place dès la fin de

l’entretien.

15. Assurez-vous que l'outil est solidement fixé au sol

avant de l’utiliser.

16. Vérifiez si des pièces sont endommagées. Avant

d’utiliser l’appareil, il faut vérifier soigneusement

le dispositif de protection ou toute autre pièce

endommagée afin de s’assurer que l’appareil

fonctionnera correctement et remplira sa fonction

prévue. Vérifiez l’alignement des pièces mobiles

et leurs joints, tout bris de pièce et du cadrage

et toute autre condition qui pourrait en modifier

le fonctionnement. Un garde ou une autre pièce

endommagée doivent être réparés ou remplacés

sans tarder.

suite à la page 4

21

Page 22

17. Prévoyez un espace suffisant autour de la zone de

travail et un éclairage en plongée non éblouissant.

18. Gardez le plancher autour de l’appareil propre et

exempt de débris, d’huile et de graisse.

19. Gardez les visiteurs à une distance sécuritaire de la

zone de travail. Tenez les enfants à distance.

20. Rendez votre atelier à l’épreuve des enfants au

moyen de cadenas, de commutateurs principaux ou

en retirant les clés de mise en marche.

21. Concentrez-vous uniquement sur le travail. Regarder

aux alentours, tenir une conversation et faire

du chahut sont des actes négligents qui peuvent

entraîner des blessures graves.

22. Maintenez une position équilibrée en tout temps afin

de ne pas tomber ou de ne pas vous appuyer sur

l'outil ou sur ses pièces mobiles. Évitez de vous étirer

ou d’utiliser une force excessive pour effectuer toute

opération avec l’appareil.

23. Utilisez l’outil approprié à la bonne vitesse et au

bon débit. Ne forcez pas un outil ou un accessoire

à effectuer une tâche pour laquelle il n’a pas été

conçu. Le bon outil fera mieux le travail et sera plus

sécuritaire.

24. Utilisez les pièces recommandées ; les accessoires

inadéquats peuvent être dangereux.

25. Entretenez les appareils avec soin. Suivez

les indications relatives à la lubrification et au

changement d’accessoire.

26. Débranchez l’appareil avant le nettoyage. Utilisez une

brosse ou de l’air comprimé pour enlever la poussière

ou des débris ; n’utilisez pas vos mains.

27. Ne vous tenez pas debout sur l’appareil. Des

blessures graves pourraient se produire si l’appareil

se renverse.

28. Ne jamais laisser l’appareil sans surveillance lorsqu’il

est en marche. Débranchez l’appareil et ne le laissez

pas sans surveillance jusqu’à son arrêt complet.

29. Tenez la poignée fermement en tout temps.

30. N’utilisez pas cet outil pour d’autres fins que celles

pour lesquelles il est prévu. S'il est utilisé à d’autres

fins, DELTA

toute garantie réelle ou implicite et se dégage de

toute responsabilité pour toute blessure qui pourrait

résulter de cette utilisation.

Familiarisez-vous avec les règles de sécurité

enseignées dans ce manuel :

Cela signifie que le non-respect des précautions peut

entraîner des blessures superficielles et/ou endommager

l’appareil.

Cela signifie que le non-respect des précautions peut

causer des blessures graves pouvant même entraîner la

mort.

®

Power Equipment Corporation décline

RÈGLES DE SÉCURITÉ SPÉCIFIQUES SUPPLÉMENTAIRES

1. Utilisez une taille et un type de lame appropriés.

2. Réglez le guide de lame supérieur afin qu'il soit

environ à 3,2 mm (1/8 po) au-dessus de la pièce.

3. Réglez correctement la tension de la lame, le suivi,

les guides de lame et les paliers de support de

lame.

4. Ne mettez jamais en route l'appareil lorsque la

pièce est appuyée contre la lame.

5. Tenez fermement la pièce et insérez-la dans la

lame à une vitesse modérée.

6. Arrêtez l'appareil pour sortir d'une coupe

inachevée ou coincée.

7. Effectuez des coupes en « relief » avant de couper

de longues courbes.

8. Éteignez l'appareil et attendez que la lame s'arrête

avant de nettoyer la zone de la lame, de retirer

les débris à proximité de la lame, de retirer ou

de sécuriser la pièce ou de modifier l'angle de la

table. Une lame qui tourne au débrayé peut être

dangereuse.

CONSERVEZ CES CONSIGNES.

Consultez-les souvent et utilisez-les pour enseigner aux autres.

22

Page 23

RACCORDEMENTS ÉLECTRIQUES

Un circuit électrique séparé devrait être utilisé pour vos appareils. Les fils du circuit doivent être au moins de calibre

12 et être protégés par un fusible à action différée de 20 ampères. Si vous utilisez une rallonge, ne prenez que des

rallonges à trois fils avec des fiches de mise à la terre à trois broches et le réceptacle correspondant qui acceptera la

fiche de l’appareil. Avant de brancher l’appareil sur l’alimentation, assurez-vous que le commutateur est en position

« OFF » (« Arrêt ») et que le courant électrique que vous allez utiliser possède les mêmes caractéristiques que celui

indiqué sur l’appareil. Tous les raccordements doivent établir un bon contact. Une utilisation en basse tension

endommagera l’appareil.

NE PAS UTILISER L’APPAREIL DANS UN ENDROIT HUMIDE OU MOUILLÉ ET NE PAS

L’EXPOSER À LA PLUIE.

BOÎTE DE COURANT

DE MISE À LA TERRE

BROCHES

PORTEUSES DE

COURANT

LA BROCHE DE

MISE À LA TERRE EST LA PLUS

LONGUE DES TROIS

FIG. A FIG. B

BOÎTE DE COURANT

DE MISE À LA TERRE

MOYENS DE MISE

À LA TERRE

ADAPTATEUR

SPÉCIFICATIONS DU MOTEUR

Votre appareil est câblé pour un courant alternatif de 120/240 V, 60 Hz. Avant de brancher l’appareil à la source

d’alimentation, assurez-vous que l’interrupteur est en position « OFF » (Arrêt).

INSTRUCTIONS DE MISE À LA TERRE

CET APPAREIL DOIT ÊTRE MIS À LA TERRE LORSQU’IL EST UTILISÉ POUR PROTÉGER

L’OPÉRATEUR CONTRE L’ÉLECTROCUTION.

1. Pour tous les appareils branchés par un cordon d’alimentation et mis à la terre :

En cas de mauvais fonctionnement ou de panne, la mise à la terre fournit un chemin de moindre résistance au courant

électrique visant à réduire le risque d’électrocution. Cet appareil est équipé d’un cordon électrique possédant un

conducteur de terre et une fiche de terre. La fiche doit être branchée sur une prise correctement installée et mise à la

terre conformément à tous les codes et règlements locaux.

Ne pas modifier la fiche prévue. Si elle n’entre pas dans la prise, faire installer une prise appropriée par un électricien

agréé.

Le raccordement inapproprié du conducteur de terre de l’équipement peut provoquer l’électrocution. Le fil conducteur

avec un isolant comportant une surface extérieure verte, avec ou sans rayures jaunes, est le conducteur de terre. Si la

réparation ou le remplacement du cordon électrique ou de la fiche est nécessaire, ne branchez pas le conducteur de

terre à une borne sous tension.

Si les consignes de mise à la terre ne sont pas complètement comprises ou en cas de doute concernant la mise à la

terre de l’appareil, se renseigner auprès d’un électricien ou du personnel de service agréés.

Utiliser uniquement des rallonges à trois fils avec des fiches de mise à la terre à trois broches et des réceptacles à 3

conducteurs adaptés à la fiche de l’appareil, comme indiqué à la Fig. A.

Réparez ou remplacez immédiatement tout cordon endommagé ou usé.

2. Appareils raccordés à un cordon et mis à la terre, destinés à une utilisation sur un circuit d’alimentation ayant

une puissance nominale inférieure à 150 volts :

Si l'appareil doit être utilisé sur un circuit avant une sortie semblable à celle illustrée à la Fig. A, il dispose d'une fiche

de terre ressemblant à celle illustrée à la Fig. A. Un adaptateur temporaire, qui ressemble à l'adaptateur illustré à la Fig.

B, peut être utilisé pour connecter cette fiche à un réceptacle à 2 conducteurs correspondant comme indiqué à la Fig.

B si une sortie correctement mise à la terre n'est pas disponible. L'adaptateur temporaire doit uniquement être utilisé

jusqu'à ce qu'une sortie correctement mise à la terre puisse être installée par un électricien qualifié. L'oreille

23

Page 24

verte rigide, la cosse et autres semblables dépassant de l'adaptateur doivent être connectés à une mise à la terre

permanente comme une boîte de courant correctement mise à la terre. Quand l'adaptateur est utilisé, il doit toujours

être maintenu en place avec une vis métallique.

REMARQUE : au Canada, l'utilisation d'un adaptateur temporaire n'est pas autorisée par le Code canadien de

l'électricité.

Dans tous les cas, assurez-vous que le réceptacle en question est bien mis à la terre. Si vous n'êtes pas certain, faites

vérifier le réceptacle par un électricien qualifié.

DANS TOUS LES CAS, ASSUREZ-VOUS QUE LE RÉCEPTACLE EN QUESTION EST BIEN RELIÉ

À LA TERRE. SI VOUS N’ÊTES PAS CERTAIN, FAITES VÉRIFIER LE RÉCEPTACLE PAR UN

ÉLECTRICIEN QUALIFIÉ.

3. Fonctionnement monophasé 240 VOLTS :

Le moteur fourni avec votre appareil fonctionne sous deux tensions, 120 et 240 volts. Il est expédié prêt à l'utilisation en

mode 120 volts. Cependant, il peut être converti pour le fonctionnement sur 240 volts.

La conversion doit être exécutée par un électricien qualifié, sinon vous pouvez apporter votre appareil au Centre de

service Delta autorisé. Lorsque la conversion est complétée, l'appareil doit être conforme au Code électrique national

et tous les codes et règlements locaux.

L'appareil se convertit en reconfigurant le câblage du moteur à 240 volts, en installant une fiche de 240 volts sur le

cordon d'alimentation et en remplaçant l'interrupteur par un autre adapté au fonctionnement sous 240 volts. Assurezvous que la fiche de 240 volts est uniquement utilisée avec une sortie ayant la même configuration que la fiche illustrée

à la Fig. C. Aucun adaptateur ne doit être utilisé avec la fiche de 240 volts.

DANS TOUS LES CAS, ASSUREZ-VOUS QUE LE RÉCEPTACLE EN QUESTION EST BIEN RELIÉ À

LA TERRE. SI VOUS N’ÊTES PAS CERTAIN, FAITES VÉRIFIER LE RÉCEPTACLE PAR UN

ÉLECTRICIEN QUALIFIÉ.

BOÎTE DE COURANT DE MISE À LA TERRE

BROCHES

PORTEUSES DE

COURANT

LA BROCHE DE

MISE À LA TERRE EST LA

PLUS LONGUE DES TROIS

RALLONGES

Utilisez des rallonges

appropriées. Assurez-vous que la

rallonge est en bon état et qu’il s’agit d’une

rallonge à trois fils avec une fiche de mise à la

terre à trois broches et d’un réceptacle

correspondant à la fiche de l’appareil. Lorsque

vous utilisez une rallonge, assurez-vous qu’elle soit

de calibre suffisamment élevé pour assurer

l’alimentation de l’appareil. Une rallonge d’un

calibre trop petit provoquera une chute de tension,

entraînant une perte de puissance et une

surchauffe. Le tableau indique le bon calibre à

utiliser en fonction de la longueur de la rallonge. En

cas de doute, utiliser le calibre immédiatement

supérieur. Plus le numéro de calibre est petit, plus

le cordon est épais.

FIG. C

CALIBRE MINIMUM POUR RALLONGE

CALIBRES RECOMMANDÉS POUR UTILISATION SUR DES APPAREILS

Intensité Volts Longueur totale du

0-6

0-6

0-6

0-6

6-10

6-10

6-10

6-10

10-12

10-12

10-12

10-12

12-16

12-16

12-16

24

ÉLECTRIQUES STATIONNAIRES

cordon en mètres (pieds)

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

jusqu'à 7,6 (25)

7,6-15,2 (25-50)

15,2-30,5 (50-100)

30,5-45,7 (100-150)

jusqu'à 7,6 (25)

7,6-15,2 (25-50)

15,2-30,5 (50-100)

30,5-45,7 (100-150)

jusqu'à 7,6 (25)

7,6-15,2 (25-50)

15,2-30,5 (50-100)

30,5-45,7 (100-150)

jusqu’à 7,6 (25)

7,6-15,2 (25-50)

UNE LONGUEUR DE PLUS DE 15,2 MÈTRES (50 PIEDS)

Calibre de la

rallonge

18 AWG

16 AWG

16 AWG

14 AWG

18 AWG

16 AWG

14 AWG

12 AWG

16 AWG

16 AWG

14 AWG

12 AWG

14 AWG

12 AWG

N’EST PAS RECOMMANDÉE.

Page 25

CARACTÉRISTIQUES ET COMPOSANTES

A. Poignée de tension de la lame

B. Garde-roue supérieur

C. Interrupteur

D. Table en fonte inclinable

E. Ensemble de guide de lame

F. Rainure en T pour guide à onglets

G. Garde-roue inférieur

H. Moteur 1 HP

I. Poignée de tension de la courroie

J. Support d'outil

FIGURE 1

DESCRIPTION DU FONCTIONNEMENT

La scie à ruban avec structure en acier 355,6 mm (14 po) DELTA®, MODÈLE 28-400, est conçue pour diverses

opérations de refente, coupe croisée et coupe longitudinale pour les matériaux jusqu'à 152,4 mm (6 po) de

hauteur et 346,1 mm (13-5/8 po) de largeur. Elle possède un moteur 1HP à deux vitesses et peut accueillir des

lames de 3,2 mm (1/8 po) à 19,1 mm (3/4 po) de large.

25

Page 26

CARACTÉRISTIQUES DU PRODUIT

Moteur 1 HP, 120 V

Capacité de coupe - hauteur 152,4 mm (6 po)

Capacité de coupe - largeur 346,1 mm (13-5/8 po)

Largeur minimale de la lame 3,2 mm (1/8 po)

Largeur maximale de la lame 19,1 mm (3/4 po)

Longueur de la lame 237,5 cm (93-1/2 po)

Vitesse de lame - basse 494 m/min (1 620 pi/min)

Vitesse de lame - élevée 1 018 m/min (3 340 pi/min)

Taille de la table 400,1 mm x 479,4 mm (15-3/4 po x 18-7/8 po)

Taille de la rainure en T de la table (PxL) 9,5 mm x 19,1 mm (3/8 po x 3/4 po)

Hauteur de la table par rapport au sol 103,5 cm (40-3/4 po)

Inclinaison de la table 3° gauche - 45° droite

Diamètre du port de poussière 101,6 mm (4 po)

Dimensions totales (HxLxP) 68,6 cm x 48,3 cm x 166,4 cm (27 po x 19 po x 65-1/2 po)

Poids net 81,6 kg (180 lb)

Poids à l'expédition 74,8 kg (165 lb)

DÉBALLAGE

Déballez minutieusement l’appareil et toutes les pièces détachées de la ou des boîtes d’expédition. Retirez l'huile

anti-corrosion des surfaces non peintes avec un chiffon doux humidifié de spiritueux minéraux, de diluant de

peinture ou d'alcool dénaturé.

N'utilisez pas de solvants hautement volatiles comme de l'essence, du naphta, de l'acétone ou du diluant de vernis

pour nettoyer votre appareil.

Après le nettoyage, couvrez les surfaces non peintes d’une bonne cire à planchers de qualité résidentielle.

AVIS : la couverture du manuel illustre le modèle de production actuel. Toutes les autres illustrations du manuel sont

uniquement à titre représentatif et peuvent ne pas illustrer l'étiquetage ou les accessoires réellement inclus. Elles

servent uniquement à illustrer la technique.

L’appareil est lourd, soyez prudent lorsque vous le retirez de l’emballage d’expédition! Le

non-respect des indications peut entraîner des blessures graves et/ou endommager la scie

à bande et/ou le matériel!

Votre scie à ruban avec structure en acier 355,6 mm (14 po) DELTA® est livrée dans un emballage unique. Placez

une sangle de sécurité autour de l’appareil pour éviter qu’il ne se bascule lors du levage. Vérifiez que l’emballage

d’expédition et l’appareil ne sont pas endommagés avant de le déballer.

Ouvrez l’emballage d’expédition. Enlevez soigneusement les matériaux d’emballage, les pièces et l’appareil de

l’emballage d’expédition. Toujours vérifier et retirer les matériaux d’emballage de protection autour des moteurs et

des pièces mobiles. Étalez toutes les pièces sur une surface de travail propre et vérifiez que toutes les pièces sont

présentes et en bon état :

DESCRIPTION (QUANTITÉ)

• Pieds de support (4)

• Lattes latérales inférieures de

support (4)

• Haut de support (1)

• Pack matériel de support (1)

• Table de travail en fonte (1)

• Tourillon supérieur (1)

• Lame de scie à ruban 237,5 cm

(93-1/2 po) (1)

• Poignée de tension de la lame (1)

• Plaque lumière (1)

• Pack matériel (1)

CONTENU DU PACK

MATÉRIEL DE SUPPORT

• Boulons de carrosserie

M6 X 16 (24)

• Rondelles PLATES M6 (24)

• Écrous HEXAGONAUX M6 (24)

• Pieds en caoutchouc (4)

26

CONTENU DU PACK D'OUTILS

• Boulons hexagonaux M8 X 20 (8)

• Rondelles de blocage M6 (4)

• Rondelles plates M6 (4)

• Boulon d'entraînement du

tourillon (taille) (1)