Page 1

INSTRUCTION MANUAL

D AT E D 6-10-99 PA RT NO. 426-02-651-0032

'Delta International Machinery Corp. 1999

Platinum Edition

14 Band Saw

(Model 28-255)

Page 2

2

TABLE OF CONTENTS

SAFETY RULES...............................................................................................................................................................3

ADDITIONAL SAFETY RULES FOR BAND SAW S........................................................................................................4

UNPACKING AND CLEANING ........................................................................................................................................4

ASSEMBLING THE MOBILE BASE................................................................................................................................5

Raising And Lowering The Mobile Base ..............................................................................................................6

ASSEMBLING THE BAND SAW .....................................................................................................................................6

Assembling Motor To Stand ..................................................................................................................................7

Assembling Motor Pulley .......................................................................................................................................8

Assembling Band Saw To Stand ...........................................................................................................................8

Assembling And Aligning V-Belt; Adjusting Belt Tension..................................................................................8

Assembling Belt And Pulley Guard ......................................................................................................................9

Assembling Switch .................................................................................................................................................9

Assembling Rip Fence .........................................................................................................................................10

CONNECTING BAND SAW TO POWERSOURCE

Power Connections ..............................................................................................................................................12

Motor Specifications ............................................................................................................................................12

Grounding Instructions ........................................................................................................................................13

Extension Cords ...................................................................................................................................................13

OPERATING CONTROLS AND ADJUSTMENTS

Starting And Stopping The Saw ..........................................................................................................................14

Locking The Switch In The OFF Position .......................................................................................................14

Table Insert ............................................................................................................................................................14

T ilting The Table ...................................................................................................................................................15

Adjusting Table S top ............................................................................................................................................15

Adjusting Blade Tension ......................................................................................................................................16

Tracking The Blade ...............................................................................................................................................16

Adjusting Upper Blade Guide Assembly............................................................................................................17

Adjusting Upper Blade Guides And Blade Support Bearing ...........................................................................17

Adjusting Lower Blade Guides And Blade Support Bearing ...........................................................................18

CHANGING THE BLADE ...............................................................................................................................................18

BAND SAW BLADES.....................................................................................................................................................18

OPERATING T H E BANDSAW .......................................................................................................................................19

Cutting Curves ......................................................................................................................................................19

Resawing ...............................................................................................................................................................19

PAR T S , SERVICE A N D W ARRANTY ASSISTANCE....................................................................................................20

W ARRANTY....................................................................................................................................................................20

Page 3

3

SAFETY RULES

W oodworking can be dangerous if safe and proper operating procedures are not followed. As with all machinery, there are cert ain

hazards involved with the operation of the product. Using the machine with respect and caution will considerably lessen the possi bility of personal injury . However, if normal safety precautions are overlooked or ignored, personal injury to the operator may result.

Safety equipment such as guards, push sticks, hold-downs, featherboards, goggles, dust masks and hearing protection can reduce

your potential for injury . But even the best guard won t make up for poor judgment, carelessness or inattention. Always use common

sense and exercise caution in the workshop. If a procedure feels dangerous, don t try it. Figure out an alternative procedure that feels

safer . REMEMBER: Your personal safety is your responsibility .

This machine was designed for cert ain applications only . Delt a Machinery strongly recommends that this machine not be modified

and/or used for any application other than that for which it was designed. If you have any questions relative to a p articular applica tion, DO N O T use the machine until you have first contacted Delt a to determine if it can or should be performed on the product.

DE LTA INTERNATIONAL MACHINERY CORP.

MANAGER OF TECHNICAL SERVICES

246 ALPHA DRIVE

PITTSBURGH, PENNSYLVANIA 15238

(IN CANADA: 644 IMPERIAL ROAD, GUELPH, ONTARIO N1H 6M7)

W ARNING: FAILURE TO FOLLOW THESE RULES

M AY RESULT IN SERIOUS PERSONAL INJURY

1. FOR YOUR O W N SAFETY, READ INSTRUCTION

MANUAL BEFORE OPERATING T H E TO O L. Learn the

tool s application and limit ations as well as the specific

hazards peculiar to it.

2. KEEP GUARDS IN PLACE and in working order .

3. ALWAYSWEAREYEPROTECTION.

4. REMOVEADJUSTING KEYS AND WRENCHES. Form

habit of checking to see that keys and adjusting wrenches are

removed from tool before turning it on.

5. KEEP WORKAREA CLEAN. Cluttered areas and

benches invite accident s.

6. DON T USE IN DANGEROUS ENVIRONMENT. Don t

use power tools in damp or wet locations, or expose them

to rain. Keep work area well-lighted.

7. KEEP CHILDREN A N D VISITO R S A W A Y . All children

and visitors should be kept a safe dist ance from work area.

8. MAKE WORKSHOP CHILDPROOF with p adlocks,

master switches, or by removing st arter keys.

9. DON T FORCE TO O L. It will do the job better and be

safer at the rate for which it was designed.

10. US E RIGHT TO O L. Don t force tool or att achment to do

a job for which it was not designed.

11. WEAR PROPER APPAREL. No loose clothing, gloves,

neckties, rings, bracelet s, or other jewelry to get caught in

moving part s. Nonslip footwear is recommended. Wear

protective hair covering to cont ain long hair .

12. A LW AYS U SE SAFETY GLASSES.W ear safety glasses.

Everyday eyeglasses only have impact resist ant lenses;

they are not safety glasses. Also use face or dust mask if

cutting operation is dusty.

13. SECURE WORK. Use clamp s or a vise to hold work

when practical. It s safer than using your hand and frees

both hands to operate tool.

14. DON T OVERREACH. Keep proper footing and balance

at all times.

15. MAINTAIN TOOLSIN TO P CONDITION. Keep tools

sharp and clean for best and safest performance. Follow

instructions for lubricating and changing accessories.

16. DISCONNECT TOOLS before servicing and when

changing accessories such as blades, bit s, cutters, etc.

17. USERECOMMENDED ACCESSORIES. The use of

accessories and att achments not recommended by Delt a

may cause hazards or risk of injury to persons.

18. REDUCE THE RISK O F UNINTENTIONAL STAR TI N G . Make sure switch is in OFF position before plugging

in power cord.

19. NEVER STAND O N TOOL. Serious injury could occur

if the tool is tipped or if the cutting tool is accident ally

cont acted.

20. CHECK DAMAGEDPARTS. Before further use of the

tool, a guard or other p art that is damaged should be care fully checked to ensure that it will operate properly and

perform it s intended function check for alignment of moving

part s, binding of moving p art s, breakage of p art s, mounting,

and any other conditions that may af fect it s operation. A

guard or other p art that is damaged should be properly

rep aired or replaced.

21. DIRECTION O F FEED. Feed work into a blade or cutter

against the direction of rot ation of the blade or cutter only .

22.

NEVER LEAVE TOOL RUNNING UNATTENDED. TURN

POWEROFF

. Don t leave tool until it comes to a complete

stop.

23. DRUGS, ALCOHOL, MEDICATION. Do not operate

tool while under the influence of drugs, alcohol or any

medication.

24. MAKESURE TOOL IS DISCONNECTED FROM POWER

SUPPLY

while motor is being mounted, connected or re-

connected.

25. W ARNING: The dust generated by cert ain woods and

wood products can be injurious to your health. Always oper ate machinery in well ventilated areas and provide for proper

dust removal. Use wood dust collection systems whenever

possible.

Page 4

4

ADDITIONAL SAFETY RULES FOR BAND SAW S

1. ADJUST the upper blade guide about 1/8 above

the

material being cut.

2. MA KE SURE that blade tension and blade tracking

are properly adjusted.

3. S T O P the machine and wait for the blade to come to

a complete stop before removing scrap pieces from the

table.

4. A L W A Y S keep hands and fingers away from blade.

5. CHECK for proper blade size and type.

6. D O N O T attempt to saw stock that does not have a

flat surface, unless a suit able support is used.

7. HOLD material firmly and feed into blade at a moder -

ate speed.

8. TURN OFFmachine if the material is to be backed

out of an uncompleted cut.

9. M A K E release cut s before cutting long curves.

10. ADDITIONAL INFORMATION regarding the safe

and proper operation of this product is available from the

National Safety Council, 1121 Spring Lake Drive, It asca,

IL 60143-3201 in the Accident Prevention Manual for

Industrial Operations and also in the Safety Dat a Sheets

provided by the NSC. Please also refer to the American

National Standards Institute ANSI 01.1 Safety Requirem e nt s for W oodworking Machinery and the U.S. Department of Labor OSHA 1910.213 Regulations.

11. S AVE THESE INSTRUCTIONS. Refer to them fre -

UNPACKING A ND CLEANING

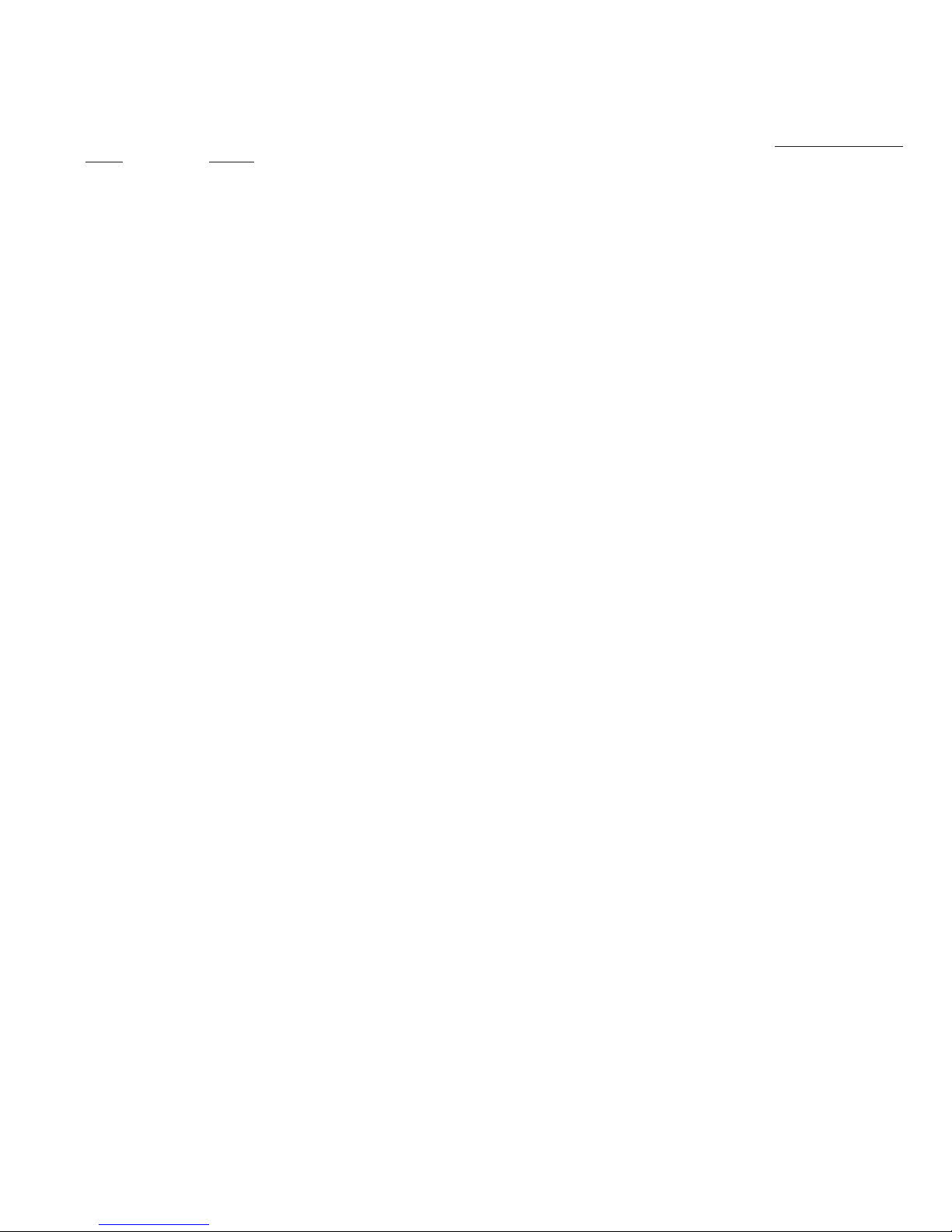

Carefully unp ack the band saw, stand, mobile base, and 12 cap acity rip fence from the shipping cont ainers. Remove

the protective coating from the machined surfaces of the band saw. This coating may be removed with a sof t cloth moist ened with kerosene ( D O NOT use acetone, gasoline or lacquer thinner for this purpose). Af ter cleaning, cover all unpainted surfaces with a good quality p aste wax. Fig. 2, illustrates the component s of the mobile base. Fig. 3, illustrates

the components of the rip fence.

1. Mobile base

2. 5/16-18 x 4 hex head screw

3. 5/16-18 locknut

4. 5/16 hex nut s (2)

5. Flat washers (4)

6. 5/16 x 1-1/2 hex head screws (2)

7. Bolt-on foot lever assembly

8. Caster assembly

1

2

4

5

6

7

3

8

1. 1/4-28 x 1 hex socket head screw (2)

2. 1/4-28 x 1-1/4 hex socket head screw (2)

3. S p acer (2)

4. Hand knob (For resawing operations)

5. 1/4-20 x 2 Round head screw

(For resawing operations)

6. Guide post (For resawing operations)

7. Rear rail

8. Front guide rail

9. Fence assembly

9

8

7

6

5

4

3

2

1

Fig. 2

Fig. 3

Page 5

5

Fig. 4

Fig. 5

Fig. 6

Fig. 7

B

A

C

D

E

G

J

F

K

H

A

F

B

A

L

M

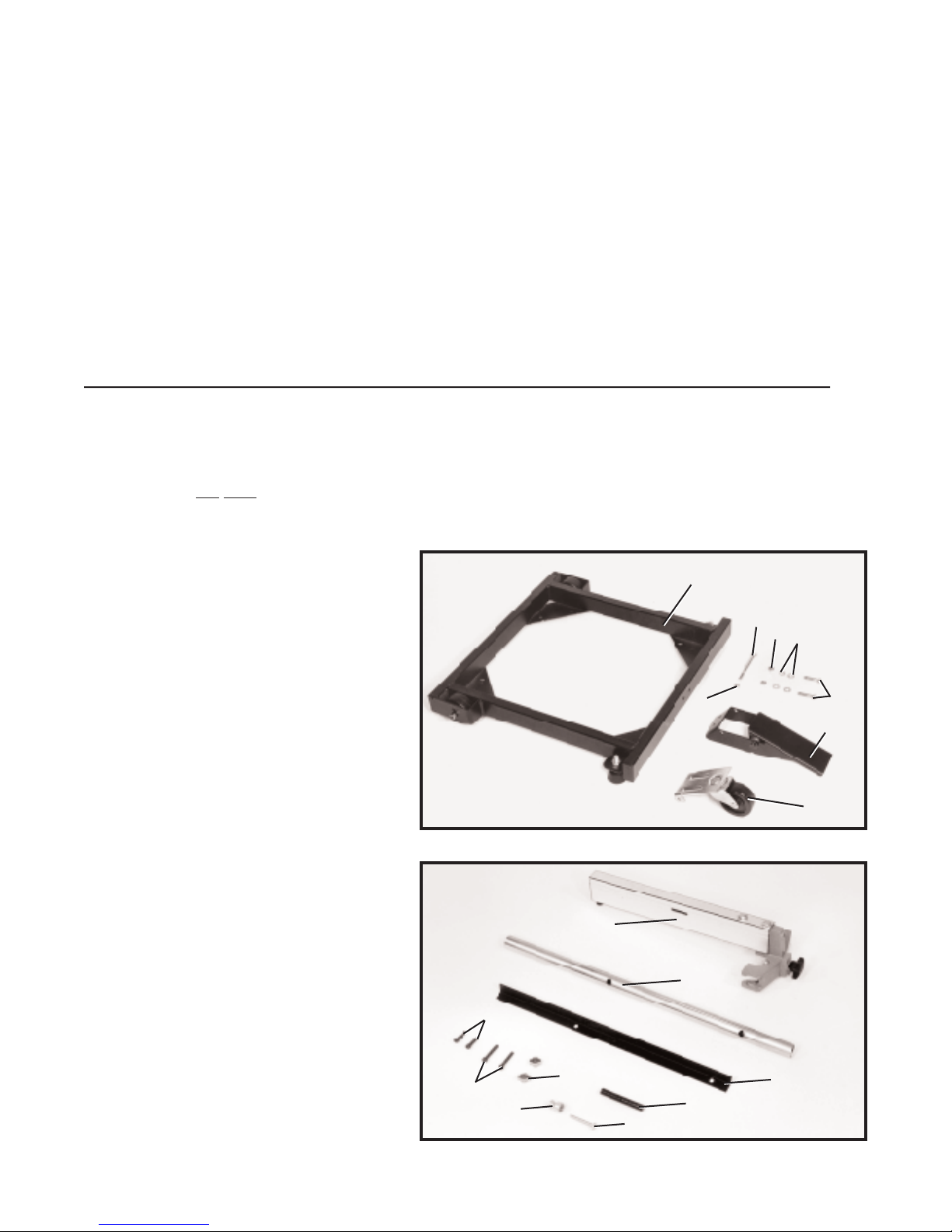

ASSEMBLING THE MOBILE BASE

The mobile base is constructed of heavy gage steel with

welded joint s and features a bolt-on foot lever assembly,

single swivel caster , and rigid wheels. T wo adjust able

foot p ads opposite the rigid wheels assure st able fourcorner cont act when the base is lowered. A convenient

foot-operated control lever raises and lowers the base for

easy movement for cleaning and repositioning.

3. Fig. 6, illustrates the caster assembly (F) and foot

lever assembly (A) fastened to the mobile base (B).

4. W ith the foot lever (A) Fig. 7, in the raised position

as shown, the mobile base should be level with the floor

surface and the two rubber feet, one of which is shown

at (L), should cont act the floor surface. To adjust the rub ber feet, tighten and loosen the hex nut, which is shown

at (M) and the nut which is located directly above the

rubber feet.

5. IMPORTANT:WHENPLACING THE MACHINE ON

THE MOBILE BASE, MAKE CERTAIN FOOT LEVER

(A) F I G . 7, IS IN THE RAISED POSITION A S SHOWN

TO AVOID MOVEMENT OF THE MOBILE BASE.

2. Assemble caster assembly (F) Fig. 5, to mobile base

bracket (G) using the four inch-long screw (H) through

two holes (J) in mobile base bracket (G) and two holes in

caster assembly (F). Fasten in place using locknut (K).

1. Assemble foot lever assembly (A) Fig. 4, to the out side of mobile base (B) with two 1-1/2 inch-long hex head

screws (C), four flat washers (D), and two hex nut s (E).

Page 6

6

Fig. 8

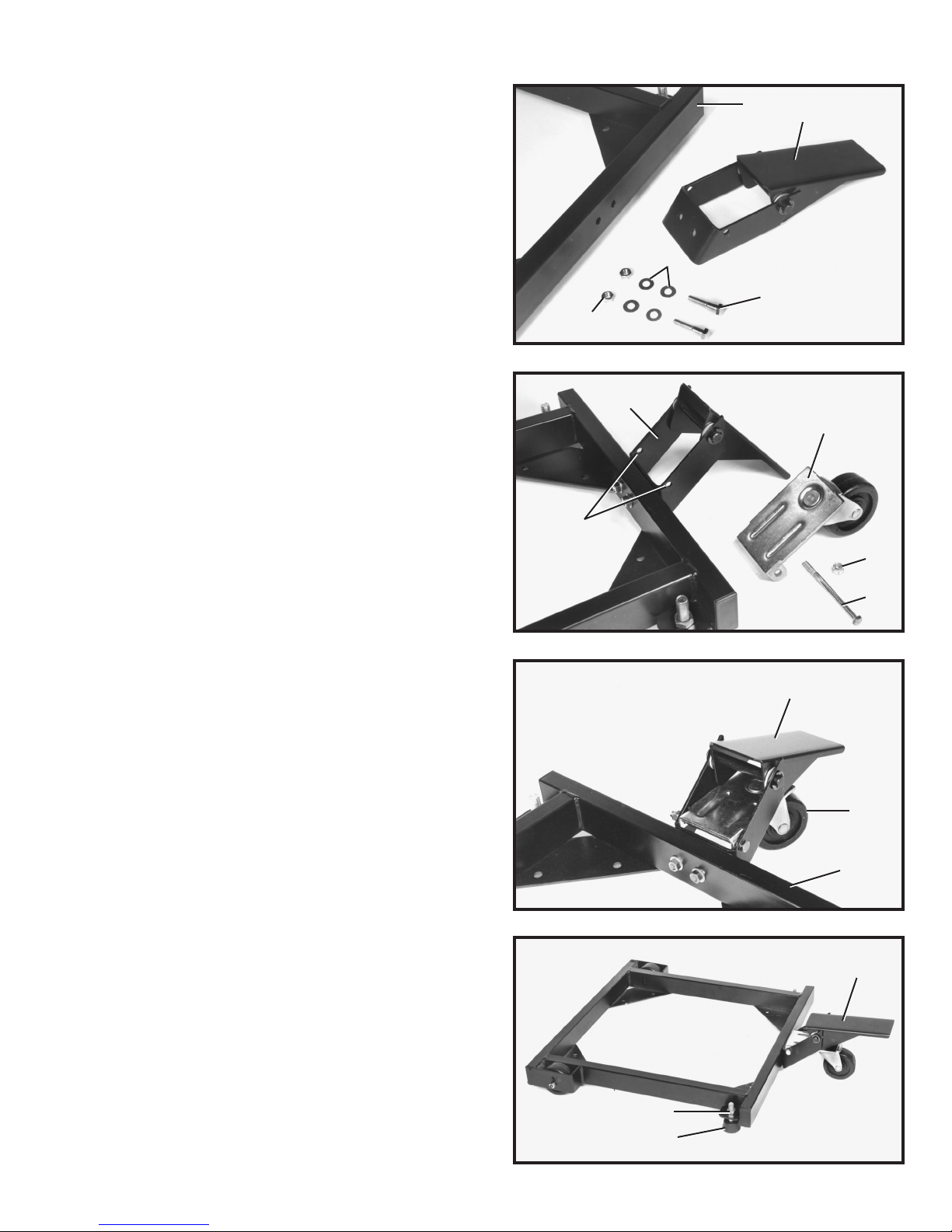

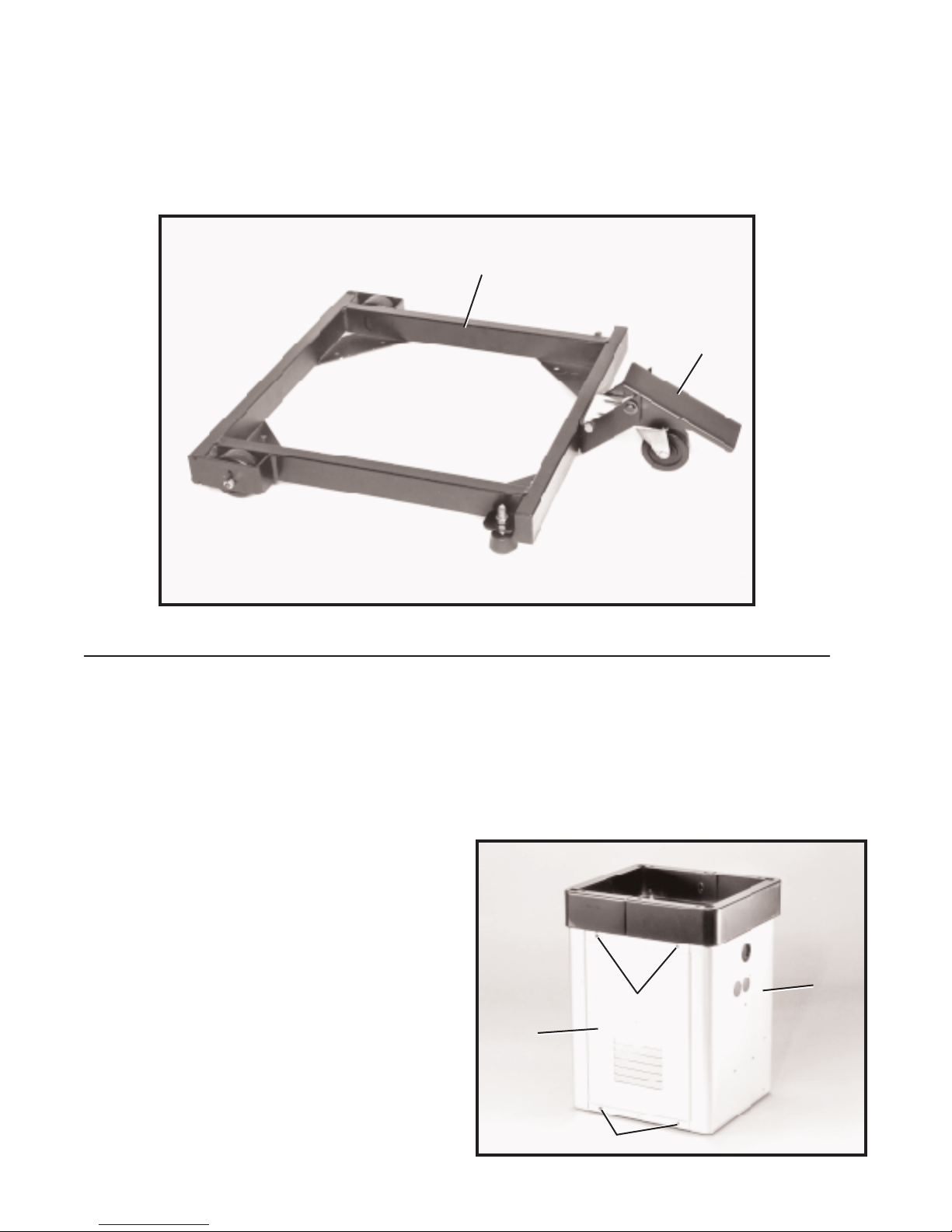

RAISING A N D LOWERING THE MOBILE BASE

1. To raise the mobile base (B) Fig. 8, and allow movement to a new location, push foot lever (A)

downward until the foot lever locks into position.

2. To lower the mobile base (B) Fig. 8, so it is supported by the floor surface, flip foot lever (A) upward.

3. IMPORTANT:TO AVOID PERSONAL INJURY, ALW AYS OPERATE THE MACHINE WITH THE

FOOT LEVER (A) IN THE RAISED POSITION A S SHOWNIN FIG. 5.

B

A

ASSEMBLING THE BAND SAW

The st and is shipped top down inside the shipping cont ainer with the motor mounted to the inside top

of the st and. The on/off switch is wired to the end of the power cord.

The motor must be removed from the inside top of the st and and reassembled to the horizont al mount ing bars inside the st and as follows:

1. Remove the stand (A) Fig. 9, from the shipping con -

tainer being careful not to crimp the switch cord which

extends through the top of the st and. NOTE: Set the

st and on several blocks of wood to raise the st and of f the

floor surface.

2. Remove panel (B) Fig. 9, from st and (A) by removing

two screws (C) and loosening two screws (D). Remove

p anel on opposite side of st and in the same manner.

Fig. 9

D

A

C

B

Page 7

7

3. Remove two mounting screws, one of which is

shown at (E) Fig. 10, that are holding motor (F) to the top

of st and (A ). IMPORTANT:D O NOT REMOVECABLE

TIE (G) T H AT IS HOLDING SWITCH CORD(H) TO VERTICAL MOUNTING BAR (J), UNLESS Y O U A R E USING

THEACCESSORY 28-984 HEIGHT ATTACHMENT O N

THE BAND SAW .THIS CABLE TIE (G),WILL KEEP

THE SWITCH CORD (H) FROM CONTACTING TH E

M O TO R PULLEY O R BELT DURING OPERATION.

Fig. 10

Fig. 1 1

Fig. 12

ASSEMBLING

MOTO RTO STAND

1. To make the motor assembly easier, turn stand (A)

Fig. 1 1, on it s side with two horizont al bars (B) down as

shown.

2. Position motor (C) Fig. 1 1, on two horizont al support

bars (B) as shown, and fasten with four 3/4 long carriage

bolt s, two of which are shown at (D), and four flanged nut s.

IMPORTANT:MA K E CERTAIN M OTOR SHAFT (E) IS

O N THE SAMESIDE OF THESTAND AS THELARGE

OPENING IN THE TO P O F TH E S TA N D BEFORE TIGHTENING CARRIAGE B OLTS (D). Further motor alignment

will be necessary af ter band saw is fastened to st and.

Fig. 13

3. Insert power cord plug (G) Fig. 12, through the bottom hole of the band saw st and to the out side of the st and.

4. Carefully turn the st and right side up.

IMPORTANT:Before assembling the band saw to the stand, we suggest that you place the st and (A) Fig. 13, onto

the mobile base (B), with the foot pedal lever (C) in the raised position as shown, so the wheels (D) and

rubber feet (E) are in full cont act with the floor surface.

A

C

E

D

B

G

Page 8

8

Fig. 14

Fig. 15

Fig. 16

B

D

F

A

C

B

C

A

C

A

B

D

ASSEMBLING

M O TO R PULLEY

Assemble motor pulley (A) Fig. 14, to the motor shaf t

making cert ain set screw (B) in the motor pulley engages

with key (C) in motor shaf t.

ASSEMBLING BANDSAW

TO STAND

1. Carefully place the band saw (A) Fig. 15, onto the

band saw st and (B). NOTE: Position the band saw so the

pulley (C) is over the opening (D) in the st and.

2. Align the four holes in the base of the band saw with

the four mounting holes in the top of the st and and

fasten the band saw to the st and with four 5/16-18 x

1-3/4 hex head screws, three of which are shown at (E)

Fig. 15, with flat washers and flange nut s.

ASSEMBLING AN D

ALIGNING V-BELT;

ADJUSTING BELT TENSION

1. Using a straight edge, align motor pulley (A) Fig. 16,

to the driven pulley (B). If necessary, both pulleys can be

adjusted inward or outward. The motor (C) can also be

adjusted on the motor mounting bars (D).

2. Assemble the V-belt (E) Fig. 16, to pulleys (A) and

(B) and adjust the belt tension by raising or lowering the

motor (C) on the motor mounting bars (D). If necessary,

the motor mounting bars (D) can be repositioned on two

vertical post s (F). NOTE: Make certain the pulleys are

kept in alignment when doing this. Correct belt tension is

obt ained when there is approximately 1 deflection, using

light finger pressure at the centersp an of the pulleys.

E

E

E

Page 9

9

Fig. 17

Fig. 18

ASSEMBLING BELT

A N D PULLEY GUARD

Assemble belt and pulley guard (A) Fig. 17, to the top of

the st and and surrounding the driven pulley with two

3/4-20 x 5/8 hex head screws, flat washers and hex

nut s (B).

ASSEMBLING SWITCH

1. MAKE CERTAIN THE BAND SAW IS DISCONNECTED FROMTHE POWER SOURCE.

2. CAUTION: T H E ON/OFF SWITCH-TO-MOTO R

CORD (F) FIG. 18, IS TIED TO VERTICAL MOUNTING

POST (G) OPPOSITE THE M O TO R PULLEY.THIS

CABLE TIE (H)PREVENTS THE SWITCH-TO-MOTO R

CORD(F), FROM CONTACTING THE BELT O R M O TO R

PULLEY DURING OPERATION. IMPORTA N T:D O N O T

REMOVE THIS CABLE TIE UNLESS Y O U A R E USING

THE ACCESSORY #28-984 HEIGHT ATTACHMENT

WITH THE BAND SAW .

3. Remove two outer hex nuts and lock washers (A)

Fig. 19, from the two screws extending out from the back

of the switch box (B).

4. Insert two screws (C) Fig. 19, located on back of

switch box, into two holes (D) located in the band saw

arm.

5. Fasten the switch box (B) to the band saw arm using

two hex nut s and lockwashers (A) Fig. 20, which were removed in STEP 3.

Fig. 19 Fig. 20

B

A

C

D

A

B

Page 10

10

6. Remove screw and cable clamp (E) Fig. 21, from

lower arm of band saw.

7. Insert switch cord (F) Fig. 21, into clamp (E) which

was removed in STEP 6, and fasten switch cord (F) to

band saw as shown. IMPORTA N T:CHECK AND MAKE

CERTAIN THE ON/OFF SWITCH-TO-MOTOR CORD

(F) F I G . 18, IS NOT CONTACTING M O TO R PULLEY O R

BELT.ADJUST C O RD (F) FIG.18,IF NECESSARY,

THEN TIGHTEN CABLE TIE (H).

Fig. 21

ASSEMBLING RIP FENCE

1. MAKE CERTAIN THE MACHINE IS DISCON-

NECTED FROMTHE POWER SOURCE.

2. Assemble rear guide rail (A) Fig. 22, to band saw

table using 1/4-28 x 1 hex socket head screws (B), at

locations (C). Do not completely tighten hardware at this

time.

3. Assemble front guide rail (D) Fig. 23, to band saw

table using 1/4-28 x 1-1/4 hex socket head screws (E),

and spacers (F), at locations (G). Position sp acers

between t able and guide rail.

Fig. 22

A

B

B

C

Fig. 23

F

F

E

D

G

E

E

F

Page 11

11

Fig. 24 Fig. 25

Fig. 26

5. Insert fence assembly (H) Fig. 25, onto front guide

rail (D). NOTE: Fence assembly (H) will clamp to the

front guide rail only, and simply rest on the rear

guide rail .

6. Determine if the gap between the bottom of fence

(H) Fig. 26, and the top of the saw t able is the same

across the entire length of fence. Fig. 26, illustrates a

fence which is improperly adjusted. If an adjustment is

necessary, the rear fence rail (A) Figs. 26 and 27, has

vertical slot s to allow for height adjustment s.

7. Fig. 27, illustrates a properly adjusted fence (H).

T ighten screws ( C ) Figs. 26 and 27, af ter adjustment s are

made.

D

H

A

C

H

Fig. 27

A

C

H

Fig. 28

H

L

K

J

8. Position the fence assembly (H) Fig. 28, at one edge

of the miter gage slot (J), as shown. T ighten knob (K).

Check to see that the fence assembly is p arallel to the

miter gage slot. If an adjustment is necessary, loosen two

hex head screws (L), and adjust fence assembly so it is

p arallel to the miter gage slot. T ighten screws (L).

4. Fig. 24, illustrates the front and rear guide rails

mounted to the band saw t able.

Page 12

12

Fig. 29

9. Position a combination square (M) Fig. 29, against the side of fence assembly (H), as shown.

T ighten knob (K). Check to see that the fence assembly is perpendicular to the band saw t able. If an

adjustment is necessary, loosen two hex socket head screws (E), and adjust the position of front

guide rail (D). T ighten screws (E).

10. Position the fence assembly (H) Fig. 29, against the saw blade. T ighten knob (K). Check to

see that the pointer (N) is aligned with the 0 (zero) marking on the front guide rail (D). If an adjust ment is necessary, loosen the pointer screw and adjust the pointer. T ighten pointer screw .

H

E

D

K

E

N

M

CONNECTING BAND SAW TO POWERSOURCE

POWERCONNECTIONS

A s e p arate electrical circuit should be used for your tools. This circuit should not be less than #12

wire and should be protected with a 20 Amp fuse. Have a certified electrician replace or rep air a

worn cord immediately. Before connecting the motor to a power line, make sure the switch is in

the OFF position and be sure that the electric current is of the same characteristics as st amped

on the motor nameplate. Running on low volt age will damage the motor .

W ARNING:D O NOT EXPOSE THE TOOL TO RAIN O R OPERATE THE TOOL IN DAMP

LOCATIONS.

M O TO R SPECIFICATIONS

Y our saw is wired for 110-120 volt, 60 HZ alternating current. Before connecting the saw to the

power source, make sure the switch is in the OFF position.

Page 13

13

Fig. 31Fig. 30

GROUNDED OUTLET BO X

CURRENT

CARRYING

PRONGS

GROUNDED OUTLET BO X

GROUNDING MEANS

ADAPTER

CAUTION: IN ALL CASES, MAKE CERTAIN THE RECEPTACLE IN QUESTION IS PROPERLY GROUNDED.

IF Y O U A R E N O T SURE, H AVE A CERTIFIED ELECTRICIAN CHECK THE RECEPTACLE.

This tool is intended for use on a circuit that has an outlet

and a plug that looks like the one shown in Fig. 30. A

temporary adapter, which looks like the adapter illustrated

in Fig. 31, may be used to connect this plug to a 2-pole

recept acle, as shown in Fig. 31, if a properly grounded

outlet is not available. The temporary adapter should be

used only until a properly grounded outlet can be inst alled by a qualified electrician. THIS ADAPTER IS

N O T APPLICABLE IN CANADA. The green-colored

rigid ear , lug, and the like, extending from the adapter

must be connected to a permanent ground, such as a

properly grounded outlet box, as shown in Fig. 31.

GROUNDING INSTRUCTIONS

CAUTION: THIS TO O L MUST BE GROUNDED WHILE IN US E

TO PROTECT THE OPERATO R FROM ELECTRIC SHOCK.

In the event of a malfunction or breakdown, grounding

provides a p ath of least resist ance for electric

current to reduce the risk of electric shock. The motor is

equipped with an electric cord having an equipmentgrounding conductor and a grounding plug. The plug

must be plugged into a matching outlet that is properly

inst alled and grounded in accordance with all local codes

and ordinances.

Do not modify the plug provided - if it will not fit the outlet,

have the proper outlet inst alled by a qualified electrician.

Improper connection of the equipment-grounding conduc tor can result in risk of electric shock. The conductor with

insulation having an outer surface that is green with or

without yellow stripes is the equipment-grounding conduc tor. If rep air or replacement of the electric cord or plug is

necessary, do not connect the equipment grounding con ductor to a live terminal.

Check with a qualified electrician or service personnel if

the grounding instructions are not completely under stood, or if in doubt as to whether the tool is properly

grounded.

Use only 3-wire extension cords that have 3-prong

grounding type plugs and 3-hole recept acles that accept

the tool s plug, as shown in Fig. 30.

R e pair or replace damaged or worn cord immediately.

GROUNDING BLADE IS

LONGEST O F THE THREE BLADES

TO TAL LENGTH OF GAGEOF EXTENSION

CORDIN FEET CORDTO USE

EXTENSION CORDS

Use proper extension cords. Make sure your extension

cord is in good condition and is a 3-wire extension cord

which has a 3-prong grounding type plug and a 3-hole

recept acle which will accept the tool s plug. When using

an extension cord, be sure to use one heavy enough to

carry the current of the band saw. An undersized cord will

cause a drop in line volt age resulting in loss of power and

overheating. Fig. 32 shows the correct size to use depending on cord length. If in doubt, use the next heavier

gage. The smaller the gage number, the heavier the cord.

Fig. 32

0 - 25

26 - 50

51 - 100

101 - 150

16 A W G

16 A W G

14 A W G

12 A W G

Page 14

14

Fig. 33

Fig. 34

Fig. 35

Fig. 36

OPERATING CONTROLS AND ADJUSTMENTS

STARTING A N D

STOPPING THE SAW

1. The on/of f switch is located under the switch shield

(A) Fig. 33. To turn the band saw ON , move switch

trigger (B) upward to the ON position.

LOCKING SWITCH

IN T H E OFF POSITION

W e suggest that when the band saw is not in use, the

on/of f switch trigger be locked in the OFF position using

a padlock (C) Fig. 35, through the two holes in the switch

plate, as shown in Fig. 35. NOTE: Padlock shown is

available as accessory model 50-325.

2. To turn the band saw OFF , simply push down on

the switch shield (A) Fig. 34.

TABLE INSERT

Place t able insert (A) Fig. 36, into the hole provided in

the table surface, making cert ain the pin (B) in the t able

engages one of the indent s in the t able insert.

A

B

A

C

Page 15

15

Fig. 37

Fig. 38

Fig. 39

ADJUSTING TABLE STO P

The band saw is equipped with an adjust able t able stop

(B) Fig. 38, that allows the t able to be set perfectly at

90 degrees with the blade.

Tilt the t able to the lef t until the t able stop (B) Fig. 38,

cont act s the bottom of the t able. Place a square on the

table and against the blade as shown in Fig. 39, and

check to see if the blade is 90 degrees to the t able sur face. If an adjustment is necessary, proceed as follows:

1.Tilt the t able slightly to the right and tighten t able lock

knobs.

2. T urn adjustment nut (C) Fig. 38, right or lef t as nec essary to raise or lower t able stop (B).

3. Lower the t able and make cert ain the t able is

90 degrees to the blade as shown in Fig. 39.

4. It is necessary to remove the adjust able t able stop

(B) Fig. 38, when tilting the t able to the lef t.

TILTING THE TABLE

1. The t able on the band saw can be tilted 45 degrees

to the right and 10 degrees to the lef t. To tilt the t able to

the right, loosen two locking knobs (A) Fig. 37, tilt the

table to the desired angle as shown on scale (D), and

tighten two locking knobs (A).

2.To tilt the t able to the lef t, loosen two locking knobs

(A) Fig. 37, and tilt the t able slightly to the right until you

can gain access to t able stop (B) Fig. 38. Remove t able

stop (B) Fig. 38, and tilt the t able to the lef t angle up to

10 degrees and tighten two locking knobs (A) Fig. 37.

A

D

A

C

B

Page 16

16

Fig. 40

Fig. 41

Fig. 42

TRACKING THE BLADE

DISCONNECT MACHINE FROMPOWER SOURCE.

IMPORTANT:Before tracking the blade, make sure the

blade guides and blade support bearings are clear of the

blade so as not to interfere with the tracking adjustment.

Af ter tension has been applied to the blade, revolve the

wheels slowly forward by hand and watch the blade (A)

Fig. 41, to see that it travels in the center of the upper

tire. If the blade begins to creep toward the front edge,

loosen the wing nut (B) Fig. 42, and tighten the thumb

screw (C). This will tilt the top of the wheel toward the

back of the machine and will draw the blade toward the

center of the tire. If the blade creep s toward the back

edge, turn the thumb screw in the opposite direction.

Adjust the thumb screw (C) Fig. 42, only a fraction of a

turn at a time. NEVER TRACK THE BLADE WHILE

THE MACHINE IS RUNNING. Af ter the blade is tracking

in the center of the tires, tighten the wing nut (B) Fig. 42.

ADJUSTING

BLADE TENSION

DISCONNECT MACHINE FROM POWER SOURCE.

On the back of the upper wheel slide bracket, there is a

series of graduations. These indicate the proper tension

for various wid ths of blades. W ith the blade on the

wheels, turn the knob (A) Fig. 40, to raise or lower the

wheel, until the red fiber washer (B) is in line with the

proper graduation for the size of blade being used.

The graduations will be found correct for average work,

and are not af fected by rebrazing of the saw blade. W e

urge you to use these graduations until you have

become familiar enough with the operation of the Band

Saw to vary the tension for dif ferent kinds of blades or

work. Over-straining is a common cause of blade break age and other unsatisfactory blade performance. Release the tension when the machine is not in use.

C

Page 17

17

ADJUSTING UPPER BLADE

GUIDES AND BLADE

SUPPORT BEARING

DISCONNECT MACHINE FROMPOWER SOURCE.

The upper blade guides and blade support bearings are

adjusted only af ter the blade is tensioned and tracking

properly. To adjust proceed as follows:

1. The upper blade guides (A) Fig. 45, are held in place

by means of the set screws (B). Loosen the set screws

(B) to move the guides (A) as close as possible to the

side of the blade, being careful not to pinch the blade.

Then tighten the screws (B).

2. The guides (A) Fig. 45, should then be adjusted so

that the front edge of the guides are just behind the

gullet s o f the saw teeth. The complete guide block

bracket can be moved in or out by loosening thumb

screw (C) and turning knurled knob (D) Fig. 45. When

guides (A) are set properly, tighten thumb screw (C).

3. The upper blade support bearing (E) Fig. 45, pre vent s the blade from being pushed too far to the rear

which could damage the set in the saw teeth. The sup port bearing (E) should be set 1/64 behind the blade by

loosening thumb screw (F) and turning knurled knob (G)

to move the support bearing (E) in or out.

4. The blade support bearing (E) should also be adjust ed so the back edge of the blade overlap s the out side

diameter of the ball bearing by about 1/16 . The bearing

(E) is set on an eccentric and to change position remove

screw (H) and bearing (E) Fig. 45. Loosen thumb screw

(F), back out screw (G) and re-position shaf t that bearing

(E) is att ached to.

Fig. 43

ADJUSTING UPPER BLADE

GUIDE ASSEMBLY

DISCONNECT MACHINE FROMPOWER SOURCE.

The upper blade guide assembly (A) Fig. 43, should

always be set as close as possible to the top surface of

the material being cut by loosening lock knob (B) a nd

moving the guide assembly (A) to the desired position.

The upper blade guide assembly should also be adjust ed so that the blade guides (A) Fig. 44, are flat with the

blade. If an adjustment is necessary, loosen screw (B)

and rot ate the complete guide assembly (C) until the

blade guides are flat with the blade.

Fig. 44

Fig. 45

Page 18

18

ADJUSTING LOWER BLADE

GUIDES AND BLADE

SUPPORT BEARING

DISCONNECT MACHINE FROMPOWER SOURCE.

The lower blade guides and blade support bearing

should be adjusted at the same time as the upper guides

and bearing as follows:

1. Loosen the two screws (A) Fig. 46, and move the guides

(B) as close as possible to the side of the blade, being care ful not to pinch the blade. Then tighten screws (A).

2. The front edge of the guide blocks (B) should be adjust ed so they are just behind the gullets of the saw teeth

by turning the knurled knob (C) Fig. 46.

3. The lower blade support bearing (D) Fig. 46, should

be adjusted so it is about 1/64 behind the back of the

blade by turning the knurled knob (E).

Fig. 46

D

C

E

A

B

A

CHANGING THE BLADE

MAKE CERTAIN THE MACHINE IS DISCONNECTED FROM THE POWERSOURCE.

NOTE: Blades for the 14 band saw are 93-1/2 in length

1. Open the upper and lower wheel guards.

2. Release tension on the band saw blade.

3. Remove the table adjustment pin and t able insert.

4. Slide the saw blade of f the wheel and guide it out

through the slot in the t able.

5. T o inst all the new saw blade, reverse the above pro cedure. NOTE: Blade teeth should be pointing down ward at the front of the t able.

BAND SAW BLADES

A band saw blade is a delicate piece of steel that is sub jected to tremendous strain. Y ou can obt ain long use

from a band saw blade if you give it fair treatment. B

ensure you use blades of the proper thickness, wid th,

and temper for the various types of material to be cut.

Always use the widest blade possible. Use the narrow

blades only for sawing small, abrupt curves and for fine

delicate work. This will save blades and will produce

better work. Band saw blades may be purchased, welded, set and sharpened ready for use. For cutting wood

and similar materials, we can supply them in wid ths of

1/8, 3/16, 1/4, 3/8, 1/2, and 3/4 inches.

File and set the wood cutting blades whenever you find it

requires pressure to make them cut. If a blade is broken

it can be brazed or welded; however, if it has become

badly work-hardened, it will soon break in another place.

If you are not equipped to file, set and braze or weld

blades, t ake them to a saw filer for reconditioning. Under

average conditions, blades should be resharpened af ter

4 hours of operation.

Any one of a number of conditions may cause a band

saw blade to break. Blade breakage is, in some cases,

unavoidable, being the natural result of the peculiar

stresses to which such blades are subjected. It is, how ever, of ten due to avoidable causes, most of ten to lack of

care or judgment on the p art of the operator in mounting

or adjusting the blade or guides. The most common

causes of blade breakage are: (1) faulty alignment s and

adjustments of the guides; (2) forcing or twisting a wide

blade around a curve of short radius; (3) feeding too fast;

4) dullness of the teeth or absence of suf ficient set;

(5) excessive tightening of the blade; (6) top guide set

too high above the work being cut; (7) using a blade with

a lumpy or improperly finished braze or weld; and (8)

continuous running of the saw blade when not in use for

cutting.

New blades for the st andard 14-inch Band Saw are

93-1/2 inches long. The adjustment will accommodate

blades up to a maximum length of 94 inches and to a

minimum length of 91-1/2 inches. When equipped with

the No. 28-984 Height Att achment, new blades should be

105 inches long; maximum and minimum lengths are

106 and 103-1/2 inches.

Page 19

19

OPERATING T HE BAND SAW

Before st arting the machine, see that all adjustment s are

properly made and the guards are in place. T urn the

pulley by hand to make sure that everything is correct

BEFORE turning on the power.

Keep the top guide down close to the work at all times.

Do not force the material against the blade too hard.

Light cont act with the blade will permit easier following of

the line and prevent undue friction, heating, and work-

hardening of the blade at it s back edge.

KEEP THE SAW BLADE SHARP and you will find that

very little forward pressure is required for average cut ting. Move the stock against the blade steadily and no

faster than will give an easy cutting movement.

A void twisting the blade by trying to turn sharp corners.

Remember, you must saw around corners.

CUTTING C U RVES

When cutting curves, turn the stock carefully so that the

blade may follow without being twisted. If a curve is so

abrupt that it is necessary to repeatedly back up and cut

a new kerf, either a narrow blade is needed or a blade

with more set is required. The more set a blade has, the

easier it will allow the stock to be turned, but the cut is usu ally rougher than where a medium amount of set is used.

In withdrawing the piece being cut, in order to change the

cut, or for any other reason, the operator must be careful

that he does not accident ally draw the blade of f the

wheels. In most cass it is easier and safer to turn the

stock and saw out through the waste material, rather

than try to withdraw the stock from the blade.

Fig. 49Fig. 48

O

P

H

Fig. 47

S

P

O

H

RESAWING OPERATIONS

1. MAKE CERTAIN THE MACHINE IS DISCONNECTED FROMTHE POWER SOURCE.

2. Thread knob (P) Fig. 47, onto 2 long screw (S) and

tighten with a flat-bladed screwdriver .

3.Att ach guide post (O) Fig. 48, to either side of rip

fence assembly (H) with hand knob assembly (P). Position the guide post (O) on the fence assembly so it is

centered with the front edge of the blade. This will pro vide better control while performing intricate cut s.

4. Fig. 49, illustrates a typical resawing operation using

the guide post (O) assembled to the rip fence.

If a number of identically shaped thin pieces are required,

the easiest way to make them is the resawing technique.

In this operation the face of the rip fence can be used, or

to have more control when working with irregular shaped

pieces, a guide post can be used on either side of the

rip fence. T o assemble the guide post to the rip fence,

proceed as follows:

O

Page 20

20

Delt a will rep air or replace, at it s expense and at it s option, any Delt a machine, machine part, or

machine accessory which in normal use has proven to be defective in workmanship or material,

provided that the customer returns the product prepaid to a Delt a factory service center or authorized service st ation with proof of purchase of the product within two years and provides Delt a with

reasonable opportunity to verify the alleged defect by inspection. Delta may require that electric

motors be returned prepaid to a motor manufacturer s authorized station for inspection and repair

or replacement. Delta will not be responsible for any asserted defect which has resulted from nor mal wear, misuse, abuse or repair or alteration made or specifically authorized by anyone other

than an authorized Delta Service facility or representative. Under no circumst ances will Delt a be

liable for incident al or consequential damages resulting from defective product s. This warranty is

Delt a s sole warranty and sets forth the customer s exclusive remedy, with respect to defective

products; all other warranties, express or implied, whether of merchantability , fitness for purpose,

or otherwise, are expressly disclaimed by Delt a.

Delt a Building Trades and Home Shop Machinery

Two Y ear Limited Warranty

Printed in U.S.A.

PARTS, SERVICE O R W ARRANTY ASSISTANCE

All Delt a Machines and accessories are manufactured to

high quality st andards and are serviced by a network of

factory service centers and authorized service st ations

listed in your owner s manual. To obtain additional infor -

mation regarding your Delt a quality product or to obt ain

part s, service or warranty assist ance, please call or fax

Delt a s toll-free hotline number.

Delt a maint ains a modern,

ef ficient Part s Distribution

Center, maint aining an

inventory of over 15,000

part s located in Memphis,

Tennessee.

Highly qualified and experienced Customer Service

Representatives are st anding

by to assist you on weekdays

from 7:00 A.M. to 6:00 P.M.

Memphis time.

Memphis, TN 38118

4290 Raines Road

Phone: (901) 363-8800

800-223-PA R T

FAX: 800-535-6488

Loading...

Loading...