Page 1

14" Band Saw

Scies à ruban

de 355 mm

28-206, 28-276

10" Contractors Saw

(Model 36-978/36-979)

(14 po)

Sierra de Cinta

de 14 pulg.

Instruction Manual

Manuel d’utilisation

Manual de instrucciones

FRANÇAIS 26 ESPAÑOL 50

A20096 - 09-11-06 - Rev. A

Copyright © 2006 Delta Machinery

www.deltamachinery.com

(800) 223-7278 - US

(800) 463-3582 - CANADA

Page 2

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS ....................2

SAFETY GUIDELINES - DEFINITIONS .....................3

GENERAL SAFETY RULES .......................................4

ADDITIONAL SPECIFIC SAFETY RULES ................5

FUNCTIONAL DESCRIPTION ...................................7

CARTON CONTENTS ...............................................7

ASSEMBL Y .................................................................10

OPERA TION ...............................................................16

TROUBLESHOOTING ................................................21

MAINTENANCE ..........................................................24

SERVICE .....................................................................24

ACCESSORIES ...........................................................25

WARRANTY ................................................................25

FRANÇAIS ..................................................................26

ESPAÑOL ....................................................................50

IMPORTANT SAFETY INSTRUCTIONS

Read and understand all warnings and operating instructions before using any tool

or equipment. When using tools or equipment, basic safety precautions should always be followed

to reduce the risk of personal injury. Improper operation, maintenance or modification of tools or

equipment could result in serious injury and property damage. There are certain applications for which

tools and equipment are designed. Delta Machinery strongly recommends that this product NOT be modified and/or

used for any application other than for which it was designed.

If you have any questions relative to its application DO NOT use the product until you have written Delta Machinery and

we have advised you. Contact us online at www.deltamachinery.com or by mail at Technical Service Manager, Delta

Machinery, 4825 Highway 45 North, Jackson, TN 38305. In Canada,125 Mural St. Suite 300, Richmond Hill, ON, L4B 1M4)

Information regarding the safe and proper operation of this tool is available fr om the following sources:

• Power Tool Institute, 1300 Sumner Avenue, Cleveland, OH 44115-2851or online at www.powertoolinstitute.org

• National Safety Council, 1121 Spring Lake Drive, Itasca, IL 60143-3201

• American National Standards Institute, 25 W est 43r d Street, 4 floor, New York, NY 10036 www .ansi.org - ANSI 01.1

Safety Requirements for Woodworking Machines

• U.S. Department of Labor regulations www .osha.gov

SAVE THESE INSTRUCTIONS!

SAFETY GUIDELINES - DEFINITIONS

It is important for you to read and understand this manual. The information it contains relates to protecting YOUR SAFETY

and PREVENTING PROBLEMS. The symbols below are used to help you recognize this information.

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious

injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious

injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate

injury.

Used without the safety alert symbol indicates a potentially hazardous situation which, if not avoided,

may result in property damage.

CALIFORNIA PROPOSITION 65

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities

contains chemicals known to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment, al ways

wear NIOSH/OSHA approved, properly fit ting face mask or res pi ra tor when us ing such tools.

2 - English

Page 3

GENERAL SAFETY RULES

Failure to follow these rules may result in serious personal injury.

1. FOR YOUR OWN SAFETY, READ THE INSTRUCTION

MANUAL BEFORE OPERATING THE MACHINE. Learning

the machine’s application, limitations, and specific hazards

will greatly minimize the possibility of accidents and injury.

2. WEAR EYE AND HEARING PROTECTION. ALWAYS

USE SAFETY GLASSES. Everyday eyeglasses are NOT

safety glasses. USE CERTIFIED SAFETY EQUIPMENT.

Eye protection equipment should comply with ANSI Z87.1

standards. Hearing equipment should comply with ANSI

S3.19 standards.

3. WEAR PROPER APPAREL. Do not wear loose clothing,

gloves, neckties, rings, bracelets, or other jewelry which may

get caught in moving parts. Nonslip protective footwear is

recommended. Wear protective hair covering to contain long

hair .

4. DO NOT USE THE MACHINE IN A DANGEROUS

ENVIRONMENT. The use of power tools in damp or wet

locations or in rain can cause shock or electrocution. Keep

your work area well-lit to prevent tripping or placing arms,

hands, and fingers in danger .

5. MAINTAIN ALL TOOLS AND MACHINES IN PEAK

CONDITION. Keep tools sharp and clean for best and safest

performance. Follow instructions for lubricating and changing

accessories. Poorly maintained tools and machines can further

damage the tool or machine and/or cause injury.

6. CHECK FOR DAMAGED PARTS. Before using the machine,

check for any damaged parts. Check for alignment of moving

parts, binding of moving parts, breakage of parts, and any

other conditions that may affect its operation. A guard or any

other part that is damaged should be properly repaired or

replaced with Delta or factory authorized replacement

parts. Damaged parts can cause further damage to the

machine and/or injury.

7. KEEP THE WORK AREA CLEAN. Cluttered areas and benches

invite accidents.

8. KEEP CHILDREN AND VISITORS AWAY. Your shop is a

potentially dangerous environment. Children and visitors can be

injured.

9. REDUCE THE RISK OF UNINTENTIONAL STARTING. Make

sure that the switch is in the "OFF" position before plugging

in the power cord. In the event of a power failure, move the

switch to the "OFF" position. An accidental start-up can cause

injury. Do not touch the plug’s metal prongs when unplugging

or plugging in the cord.

10. USE THE GUARDS. Check to see that all guards are in place,

secured, and working correctly to prevent injury.

11. REMOVE ADJUSTING KEYS AND WRENCHES BEFORE

STARTING THE MACHINE. Tools, scrap pieces, and other

debris can be thrown at high speed, causing injury .

12. USE THE RIGHT MACHINE. Don’t force a machine or an

attachment to do a job for which it was not designed. Damage

to the machine and/or injury may result.

13. USE RECOMMENDED ACCESSORIES. The use of

accessories and attachments not recommended by Delta

may cause damage to the machine or injury to the user .

14. USE THE PROPER EXTENSION CORD. Make sure your

extension cord is in good condition. When using an extension

cord, be sure to use one heavy enough to carry the current

your product will draw. An undersized cord will cause a drop

in line voltage, resulting in loss of power and overheating. See

the Extension Cord Chart for the correct size depending on

the cord length and nameplate ampere rating. If in doubt, use

the next heavier gauge. The smaller the gauge number, the

heavier the cord.

15. SECURE THE WORKPIECE. Use clamps or a vise to hold the

workpiece when practical. Loss of control of a workpiece can

cause injury.

16. FEED THE WORKPIECE AGAINST THE DIRECTION OF

THE ROTATION OF THE BLADE, CUTTER, OR ABRASIVE

SURFACE. Feeding it from the other direction will cause the

workpiece to be thrown out at high speed.

17. DON’T FORCE THE WORKPIECE ON THE MACHINE.

Damage to the machine and/or injury may result.

18. DON’T OVERREACH. Loss of balance can make you fall into

a working machine, causing injury.

19. NEVER STAND ON THE MACHINE. Injury could occur if the tool

tips, or if you accidentally contact the cutting tool.

20. NEVER LEAVE THE MACHINE RUNNING UNATTENDED.

TURN THE POWER OFF. Don’t leave the machine until it comes

to a complete stop. A child or visitor could be injured.

21. TURN THE MACHINE "OFF", AND DISCONNECT THE

MACHINE FROM THE POWER SOURCE before installing or

removing accessories, changing cutters, adjusting or changing

set-ups. When making repairs, be sure to lock the start switch

in the "OFF" position. An accidental start-up can cause injury .

22. MAKE YOUR WORKSHOP CHILDPROOF WITH

PADLOCKS, MASTER SWITCHES, OR BY REMOVING

STARTER KEYS. The accidental start-up of a machine by a

child or visitor could cause injury.

23

. STAY ALERT, WATCH WHAT YOU ARE DOING, AND USE

COMMON SENSE. DO NOT USE THE MACHINE WHEN

YOU ARE TIRED OR UNDER THE INFLUENCE OF DRUGS,

ALCOHOL, OR MEDICA TION. A moment of inattention while

operating power tools may result in injury .

24. USE OF THIS TOOL CAN GENERATE AND

DISBURSE DUST OR OTHER AIRBORNE PARTICLES,

INCLUDING WOOD DUST, CRYSTALLINE SILICA DUST

AND ASBESTOS DUST. Direct particles away from face

and body. Always operate tool in well ventilated area and

provide for proper dust removal. Use dust collection system

wherever possible. Exposure to the dust may cause serious

and permanent respiratory or other injury, including silicosis (a

serious lung disease), cancer, and death. Avoid breathing the

dust, and avoid prolonged contact with dust. Allowing dust to

get into your mouth or eyes, or lay on your skin may promote

absorption of harmful material. Always use properly fitting

NIOSH/OSHA approved respiratory protection appropriate for

the dust exposure, and wash exposed areas with soap and

water .

3 - English

Page 4

ADDITIONAL SPECIFIC SAFETY RULES

Failure to follow these rules may result in serious personal injury.

1. DO NOT OPERATE THIS MACHINE UNTIL it is

assembled and installed according to the instructions.

2. OBTAIN ADVICE from your supervisor, instructor, or

another qualified person if you are not familiar with the

operation of this tool.

3. FOLLOW ALL WIRING CODES and recommended

electrical connections.

4. USE THE GUARDS WHENEVER POSSIBLE. Check to

see that they are in place, properly adjusted, secured, and

working correctly.

5. USE PROPER BLADE SIZE and type.

6. ADJUST THE UPPER BLADE GUIDE so that it is about

1/8" above the workpiece.

7. PROPERLY ADJUST the blade tension, tracking, blade

guides, and blade support bearings.

8. KEEP ARMS, HANDS, AND FINGERS away from the

blade.

9. AVOID AWKWARD OPERATIONS and hand positions

where a sudden slip could cause a hand to move into the

blade.

10. NEVER START THE MACHINE before clearing the table

of all objects (tools, scrap pieces, etc.).

11. NEVER START THE MACHINE with the workpiece

against the blade.

12. HOLD WORKPIECE FIRMLY against the table. DO NOT

attempt to saw a workpiece that does not have a flat

surface against the table.

13. HOLD WORKPIECE FIRMLY and feed into blade at a

moderate speed.

14. NEVER REACH UNDER THE TABLE while the machine

is running.

15. TURN THE MACHINE "OFF" to back out of an

uncompleted or jammed cut.

16. MAKE "RELIEF" CUTS prior to cutting long curves.

17. TURN THE MACHINE "OFF" and wait for the blade to

stop prior to cleaning the blade area, removing debris

near the blade, removing or securing workpiece, or

changing the angle of the table. A coasting blade can be

dangerous.

18. NEVER PERFORM LA YOUT, ASSEMBL Y, or set-up work

on the table/work area when the machine is running.

19. TURN THE MACHINE "OFF" AND DISCONNECT THE

MACHINE from the power source before installing or

removing accessories, before adjusting or changing setups, or when making repairs.

20. TURN THE MACHINE "OFF", disconnect the machine

from the power source, and clean the table/work area

before leaving the machine. LOCK THE SWITCH IN THE

"OFF" POSITION to prevent unauthorized use.

21. ADDITIONAL INFORMATION regarding the safe

and proper operation of power tools (i.e. a safety

video) is available from the Power Tool Institute, 1300

Sumner Avenue, Cleveland, OH 44115-2851 (www.

powertoolinstitute.com). Information is also available

from the National Safety Council, 1121 Spring Lake

Drive, Itasca, IL 60143-3201. Please refer to the

American National Standards Institute ANSI 01.1 Safety

Requirements for Woodworking Machines and the

U.S. Department of Labor OSHA 1910.213 Regulations.

SAVE THESE INSTRUCTIONS.

Refer to them often

and use them to instruct others

4 - English

.

Page 5

POWER CONNECTIONS

A separate electrical circuit should be used for your machines. This circuit should not be less than #12 wire and

should be protected with a 20 Amp time lag fuse. If an extension cord is used, use only 3-wire extension cords which

have 3-prong grounding type plugs and matching receptacle which will accept the machine’s plug. Before connecting

the machine to the power line, make sure the switch (s) is in the "OFF" position and be sure that the electric current is

of the same characteristics as indicated on the machine. All line connections should make good contact. Running on

low voltage will damage the machine.

Do not expose the machine to rain or operate the machine in damp locations.

MOTOR SPECIFICATIONS

Your machine is wired for 120/240 volts, 60 HZ alternating current. Before connecting the machine to the power

source, make sure the switch is in the "OFF" position.

GROUNDING INSTRUCTIONS

This machine must be grounded while in use to protect the operator from electric shock.

1. All grounded, cor d-connected machines:

In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current to

reduce the risk of electric shock. This machine is equipped with an electric cord having an equipment-grounding

conductor and a grounding plug. The plug must be plugged into a matching outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

Do not modify the plug provided - if it will not fit the outlet, have the proper outlet installed by a qualified electrician.

Improper connection of the equipment-grounding conductor can result in risk of electric shock. The conductor with

insulation having an outer surface that is green with or without yellow stripes is the equipment-grounding conductor.

If repair or replacement of the electric cord or plug is necessary, do not connect the equipment-grounding conductor

to a live terminal.

Check with a qualified electrician or service personnel if the grounding instructions are not completely understood, or

if in doubt as to whether the machine is properly grounded.

Use only 3-wire extension cords that have 3-prong grounding type plugs and matching 3-conductor receptacles that

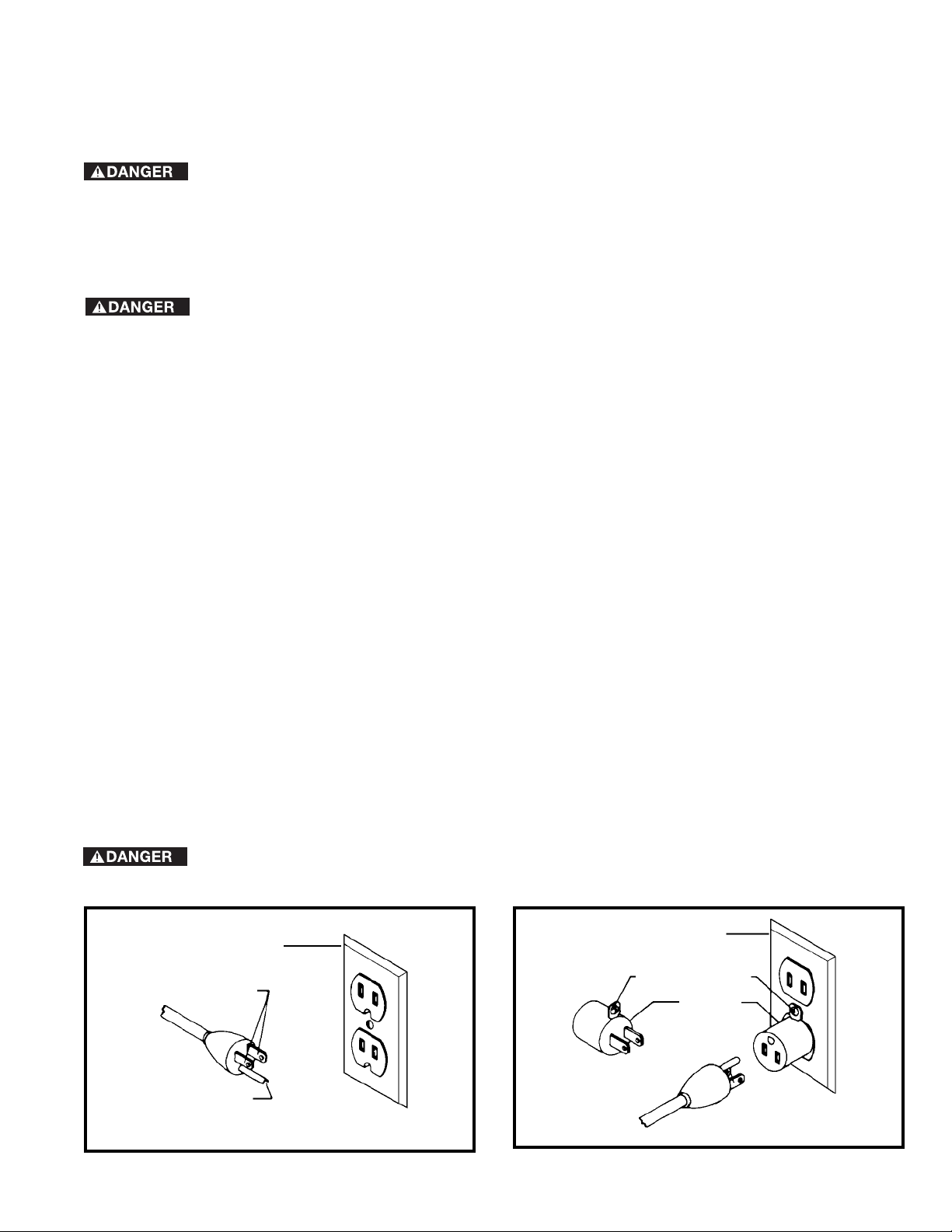

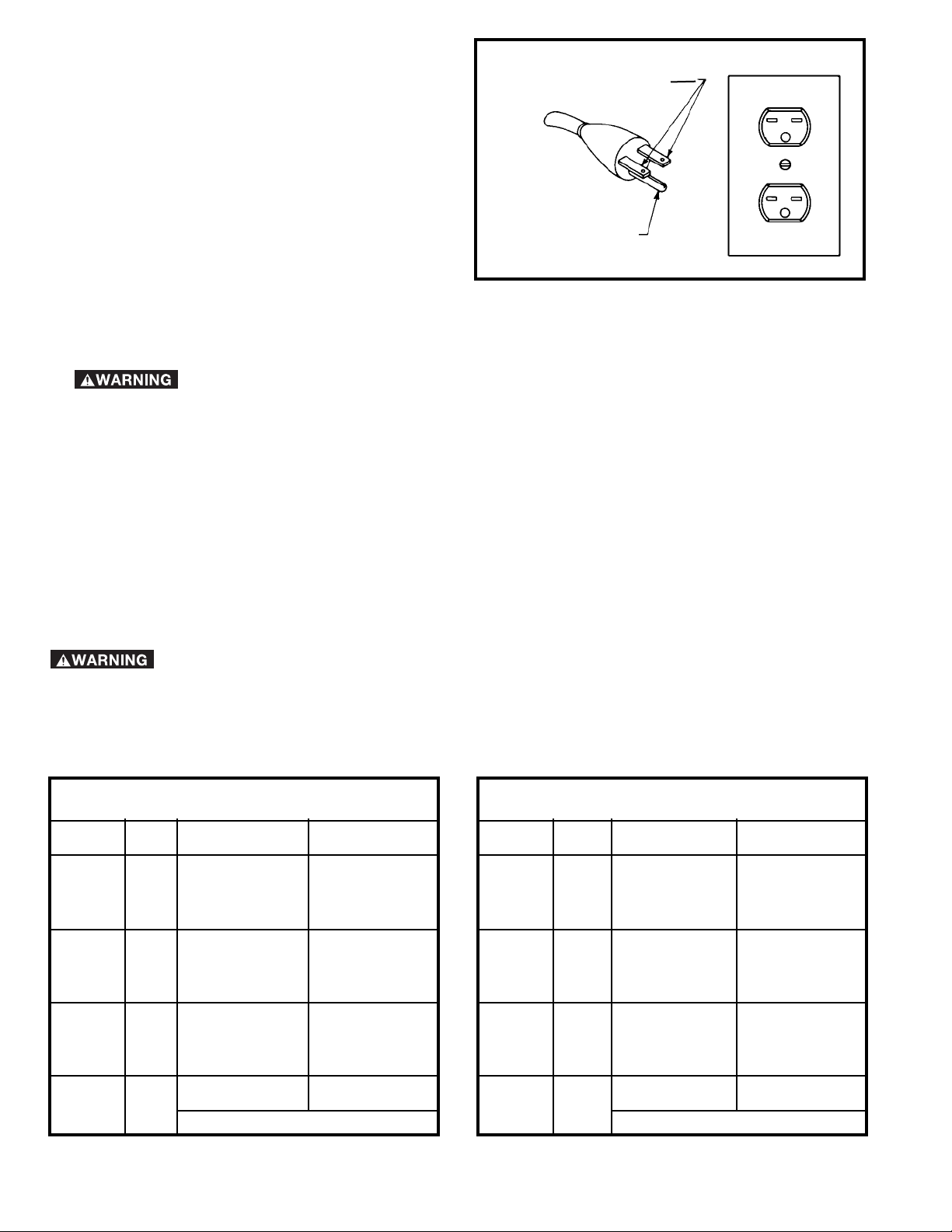

accept the machine’ s plug, as shown in Fig. A.

Repair or replace damaged or worn cord immediately.

2. Grounded, cord-connected machines intended for use on a supply circuit having a nominal rating less

than 150 volts:

If the machine is intended for use on a circuit that has an outlet that looks like the one illustrated in Fig. A, the

machine will have a grounding plug that looks like the plug illustrated in Fig. A. A temporary adapter, which looks like

the adapter illustrated in Fig. B, may be used to connect this plug to a matching 2-conductor receptacle as shown

in Fig. B if a properly grounded outlet is not available. The temporary adapter should be used only until a properly

grounded outlet can be installed by a qualified electrician. The green-colored rigid ear, lug, and the like, extending

from the adapter must be connected to a permanent ground such as a properly grounded outlet box. Whenever the

adapter is used, it must be held in place with a metal screw .

NOTE: In Canada, the use of a temporary adapter is not permitted by the Canadian Electric Code.

In all cases, make certain that the receptacle in question is properly grounded. If you

are not sure, have a qualified electrician check the receptacle.

GROUNDED OUTLET BOX

CURRENT

CARRYING

PRONGS

GROUNDING BLADE

IS LONGEST OF THE 3 BLADES

GROUNDING BLADE

IS LONGEST OF THE 3 BLADES

Fig. A Fig. B

Fig. A Fig. B

5 - English

GROUNDED OUTLET BOX

GROUNDING MEANS

ADAPTER

Page 6

3. 240 VOLT SINGLE PHASE OPERATION

The motor supplied with your machine is a dual

voltage, 120/240 volt motor. It is shipped readyto-run for 120 volt operation. However, it can be

converted for 240 volt operation.

A qualified electrician should do the conversion, or

the machine can be taken to an Authorized Delta

Service Center. When completed, the machine must

conform to the National Electric Code and all local

codes and ordinances.

The machine is converted by re-wiring the motor

for 240 volts, installing a 240 volt plug on the power

supply cord and replacing the switch with one that is

rated for 240 volt operation.

Be sure the 240 volt plug is only used in an outlet

having the same configuration as the plug illustrated

in Fig. C. No adapter should be used with the 240

volt plug.

In all cases, make certain that

the receptacle in question is properly grounded.

If you are not sure, have a qualified electrician

check the receptacle.

GROUNDED OUTLET BOX

CURRENT

CARRYING

PRONGS

GROUNDING BLADE

IS LONGEST OF THE 3 BLADES

Fig. C

EXTENSION CORDS

Use proper extension cords. Make sure your extension cord is in good condition and is a 3wire extension cord which has a 3-prong grounding type plug and matching receptacle which will accept the

machine’s plug. When using an extension cord, be sure to use one heavy enough to carry the current of the

machine. An undersized cord will cause a drop in line voltage, resulting in loss of power and overheating. Fig.

D-1 or D-2, shows the correct gauge to use depending on the cord length. If in doubt, use the next heavier

gauge. The smaller the gauge number, the heavier the cord.

MINIMUM GAUGE EXTENSION CORD

RECOMMENDED SIZES FOR USE WITH STATIONARY ELECTRIC MACHINES

Ampere Total Length Gauge of

Rating Volts of Cord in Feet Extension Cord

0-6 120

0-6 120 25-50 16 AWG

0-6 120 50-100 16 AWG

0-6 120 100-150 14 AWG

6-10 120

6-10 120 25-50 16 AWG

6-10 120 50-100 14 AWG

6-10 120 100-150 12 AWG

10-12 120

10-12 120 25-50 16 AWG

10-12 120 50-100 14 AWG

10-12 120 100-150 12 AWG

12-16 120

12-16 120 25-50 12 AWG

12-16 120

up to

25 18 AWG

up to

25 18 AWG

up to

25 16 AWG

up to

25 14 AWG

GREATER THAN 50 FEET NOT RECOMMENDED

MINIMUM GAUGE EXTENSION CORD

RECOMMENDED SIZES FOR USE WITH STATIONARY ELECTRIC MACHINES

Ampere Total Length Gauge of

Rating Volts of Cord in Feet Extension Cord

0-6 240

0-6 240 50-100 16 AWG

0-6 240 100-200 16 AWG

0-6 240 200-300 14 AWG

6-10 240

6-10 240 50-100 16 AWG

6-10 240 100-200 14 AWG

6-10 240 200-300 12 AWG

10-12 240

10-12 240 50-100 16 AWG

10-12 240 100-200 14 AWG

10-12 240 200-300 12 AWG

12-16 240

12-16 240 50-100 12 AWG

12-16 240

up to

50 18 AWG

up to

50 18 AWG

up to

50 16 AWG

up to

50 14 AWG

GREATER THAN 100 FEET NOT RECOMMENDED

Fig. D-1

Fig. D-2

6 - English

Page 7

FUNCTIONAL DESCRIPTION

FOREWORD

Model 28-206 is a 1 Hp, 120/240 volt, 2-speed unit with a quick blade-tensioning device and an enclosed stand.

Model 28-276 is a 3/4 Hp, 120/240 volt, 1-speed unit with a quick blade-tensioning device and an open stand.

UNPACKING AND CLEANING

Carefully unpack the machine and all loose items from the shipping container(s). Remove the rust-preventative oil from

unpainted surfaces using a soft cloth moistened with mineral spirits, paint thinner or denatured alcohol.

Do not use highly volatile solvents such as gasoline, naphtha, acetone or lacquer thinner for cleaning your machine.

After cleaning, cover the unpainted surfaces with a good quality household floor paste wax.

NOTICE: The photo on the manual cover illustrates the current pr oduction model. All other illustrations contained in the

manual are representative only and may not depict the actual labeling or accessories included. These ar e are intended

to illustrate technique only.

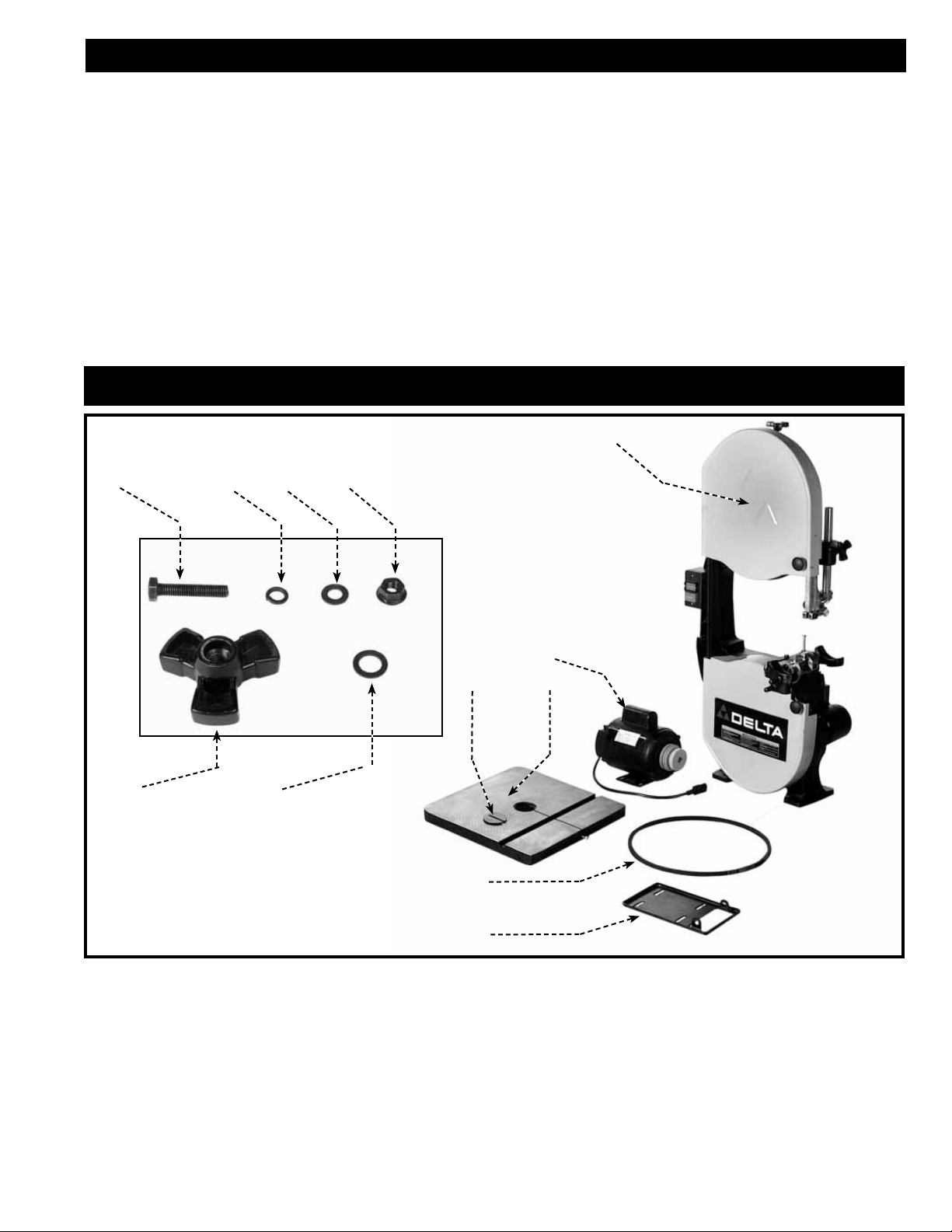

CARTON CONTENTS

1

7

11

8 9 10

12

2

4

5

6

3

1. Band Saw

2. Motor

3. Table

4. Table Insert

5. Belt

6. Motor Mounting Plate

7. M8x 1.25 x 40mm (4) (for assembling saw to

stand)

8. M8 Lockwasher (4) (for assembling saw to stand)

9. M8 Flat Washer (4) (for assembling saw to stand)

10. M8x1.25 Hex nut (4) (for assembling saw to stand)

11. Table Knob (2)

12. M13 Flat Washer (2)

7 - English

Page 8

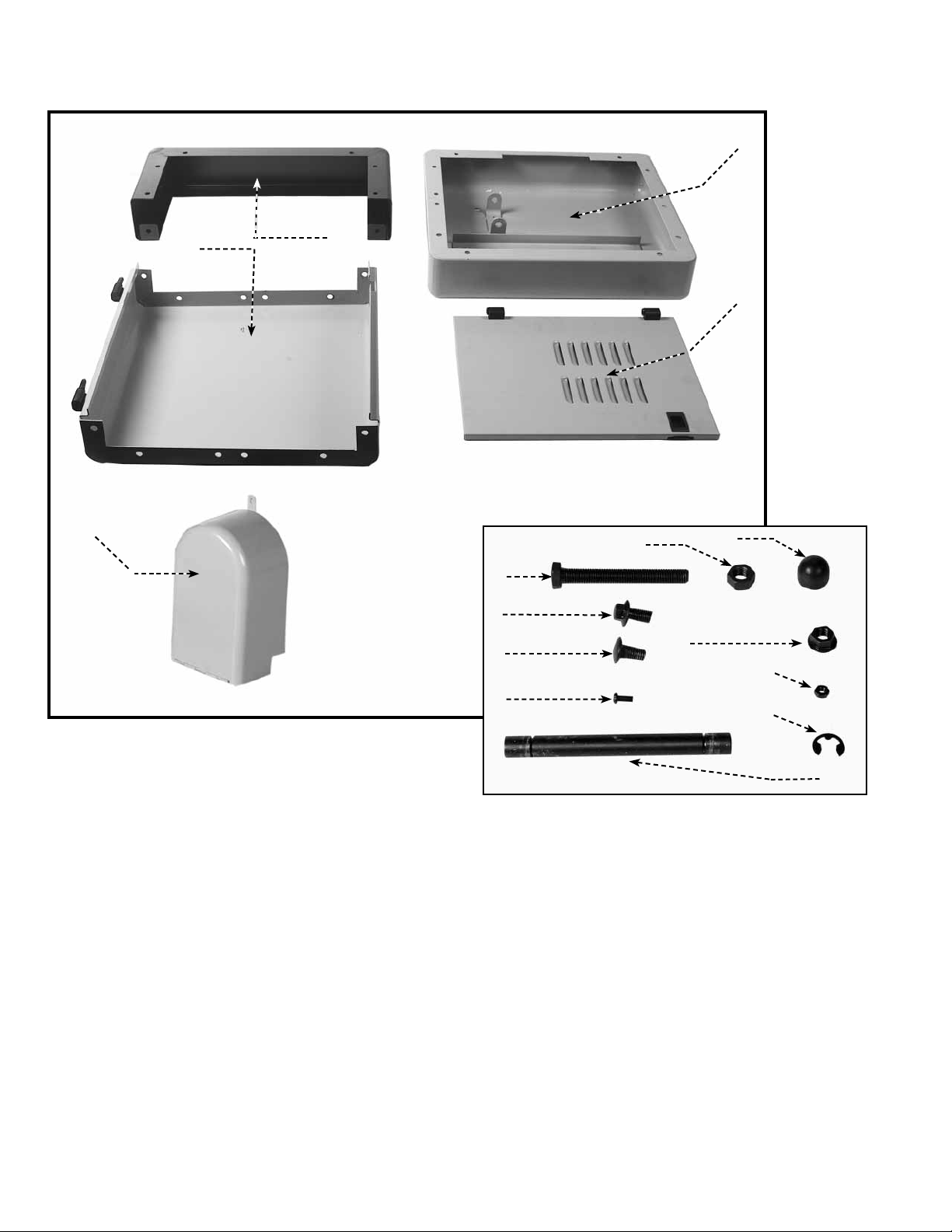

MODEL 28-206 ENCLOSED STAND PARTS

3

2

5

1

4

11

6

7

8

12

13

14

1. Base (2)

2. Side (2)

3. Stand Top

4. Door (2)

5. Pulley Guard

6. M10x1.5x100mm Hex Head Screw

7. M8x1.25x16mm Hex Head Flange Screw (26)

8. M8x1.25x16mm Round Head Flange Screw (4)

9

15

10

9. M5x0.8x10mm Pan Head Screw (2)

10. Shaft (for attaching motor plate to top of stand)

11. M10 x 1.5 Hex nut

12. Dampening Cap

13. M8x1.25 Hex Flange Nut (30)

14. M5x0.8 Hex Nut (2)

15. 9mm C ring (2)

8 - English

Page 9

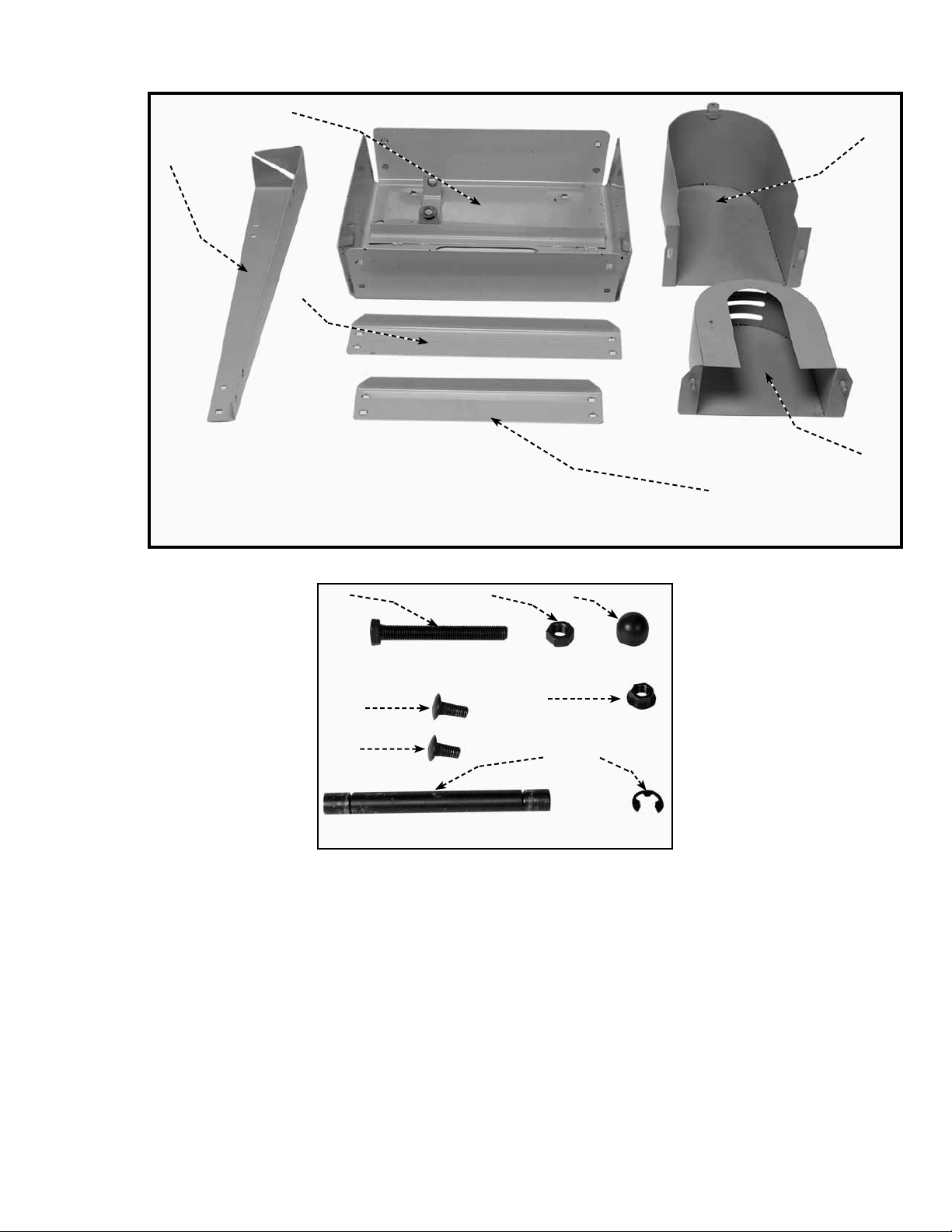

MODEL 28-276 OPEN STAND PARTS

2

5

1

3

6

4

1. Legs (4)

2. Stand Top

3. Long Brace (2)

4. Short Brace (2)

5. Upper Pulley Guard

7 8

10

11

9

12

13

14

8. M10x1.5 Hex Nut

9. Dampening Cap

10. M8x1.25x16mm Round Head Flange Screw (4)

11. M8x1.25x16mm Carriage Head Screw (32)

12. M8x1.25 Hex Flange Nut (38)

6. Lower Pulley Guard

7. M10x1.5x80mm Hex Head Screw

13. Shaft (for attaching motor plate to top of stand)

14. 9mm C ring (2)

9 - English

Page 10

ASSEMBLY

ASSEMBLY TOOLS REQUIRED

13mm Open- End Wrench - 8mm Open-End Wrench - Adjustable Wrench

ASSEMBLY TIME ESTIMATE

Assembly for this machine takes 2 hours or less.

For your own safety, do not connect the machine to the power source until the machine is

completely assembled and you read and understand the entire instruction manual.

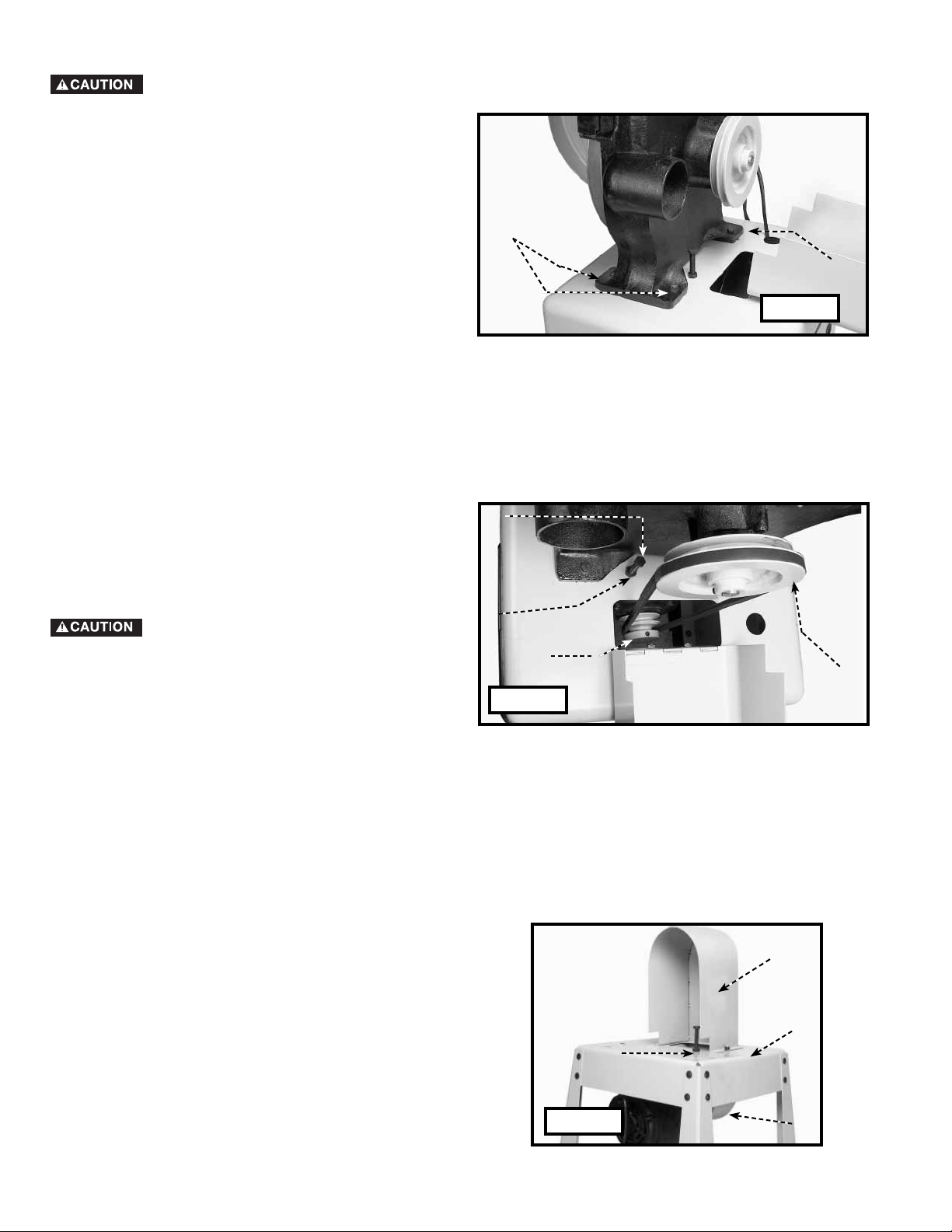

MODEL 28-206 ENCLOSED STAND ASSEMBLY

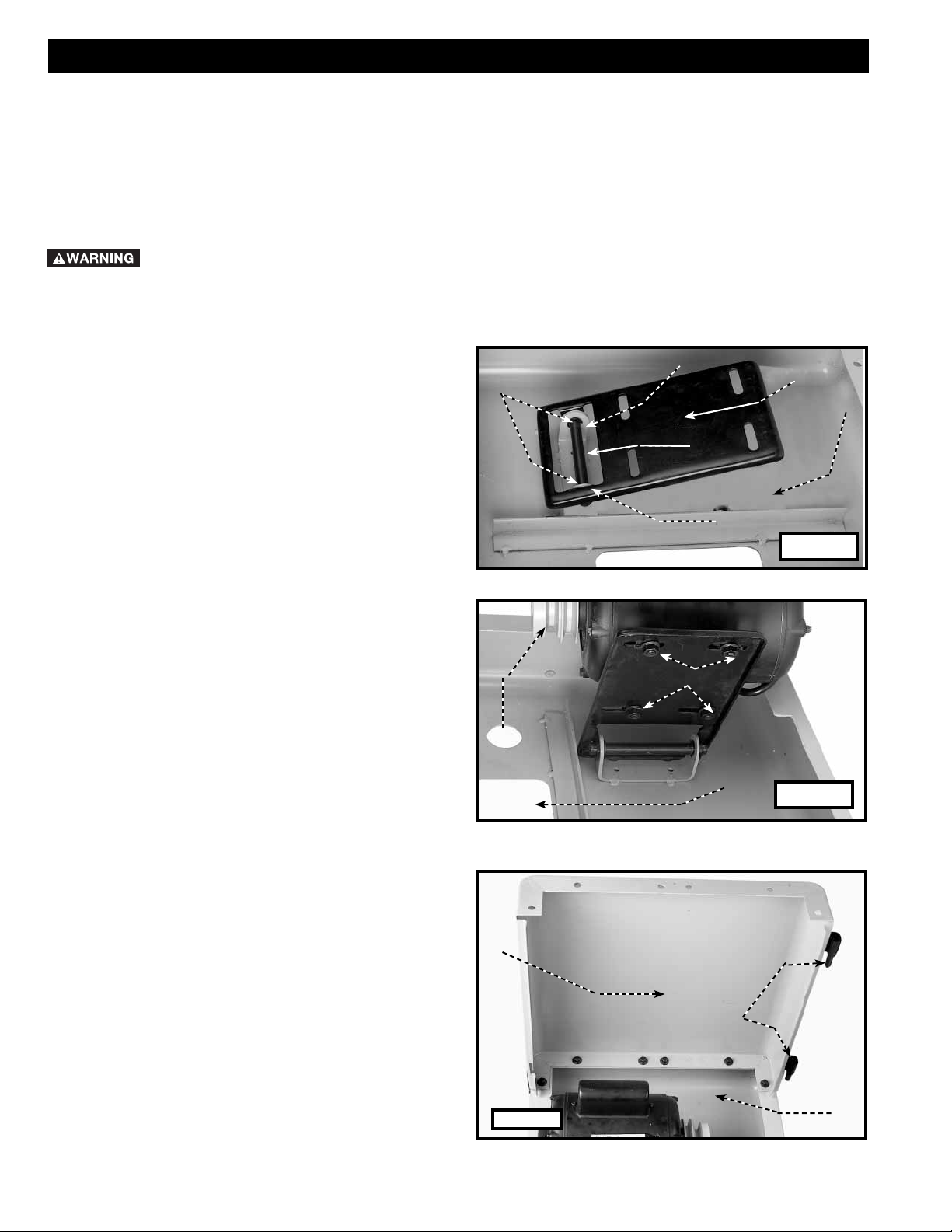

1. Place the stand top (A) Fig. 5 on a flat surface.

2. Align the two holes in the motor mounting plate (E)

Fig. 5 with the two holes (B) in the stand top (A).

3. Insert the shaft (D) through the holes in the motor

mounting plate and the holes in the stand top.

4. Attach the two "C" rings (C) Fig. 5 on the shaft.

5. Align the four holes on the motor bracket with the

four holes (C) Fig. 6 on the motor mounting plate.

NOTE: Confirm that the motor pulley (A) Fig. 6 is

mounted on the same side as the belt opening hole

(B).

6. Insert a round head flange screw (M8 x 1.25 x

16mm) through the hole in the motor bracket and

the hole in the motor mounting plate.

7. Thread a hex flange nut (M8x1.25) on the screw.

8. Repeat this process for the three remaining holes.

C

B

D

C

C

A

B

E

A

Fig. 5

Fig. 6

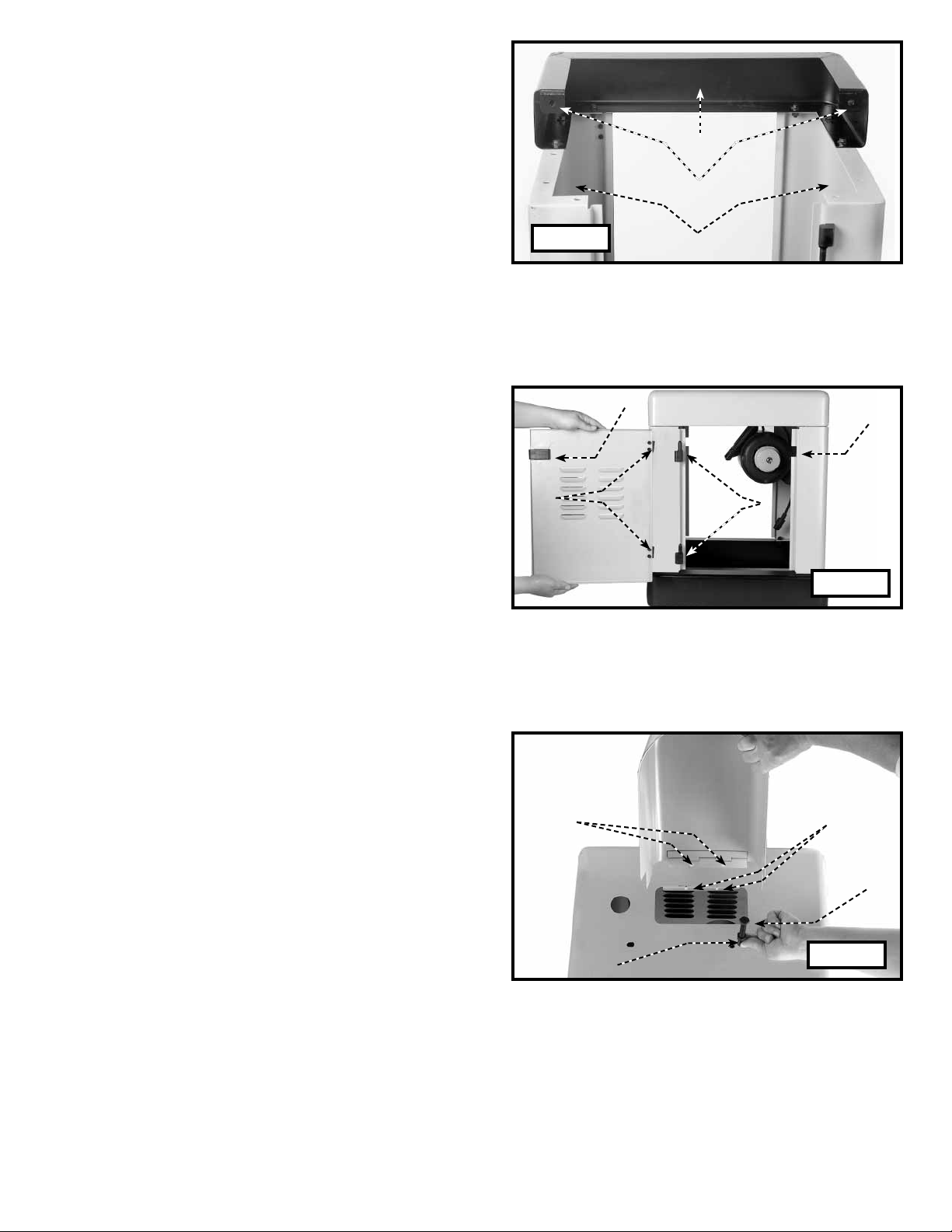

9. Align the holes in the side (A) Fig. 7 with the holes in

the stand top (B).

NOTE: Confirm that the hinge catches (C) Fig. 7 are

pointed toward the stand top.

10. Insert a hex head flange screw (M8x1.25x16mm)

through the hole in the side of the stand and the hole

in the top of the stand.

11. Thread a flange nut (M8x1.25)on the screw.

NOTE: Loosely tighten the hardware for further

adjustment.

12. Repeat this process for the five remaining holes.

13. Attach the other stand side in the same manner.

10 - English

A

Fig. 7

C

B

Page 11

14. Align the holes in the base (A) Fig. 8, with the holes

in the two sides (B).

15. Insert a hex head flange screw (M8x1.25x16mm)

through the hole in the side of the stand (B) Fig. 8,

and through the hole in the base (A).

16. Thread a hex flange nut (M8x1.25) on the screw.

NOTE: Loosely tighten the hardware for further

adjustment.

17. Repeat this process for the five remaining holes.

18. Attach the other side of the base in the same

manner.

19. Attach the two bases together by inserting a hex

head flange screw (M8x1.25x16mm) through the

hole (C) Fig. 8 in each base, and thread a hex flange

nut (M8x1.25) on the screw.

20. Turn the stand over so that it is resting on the base.

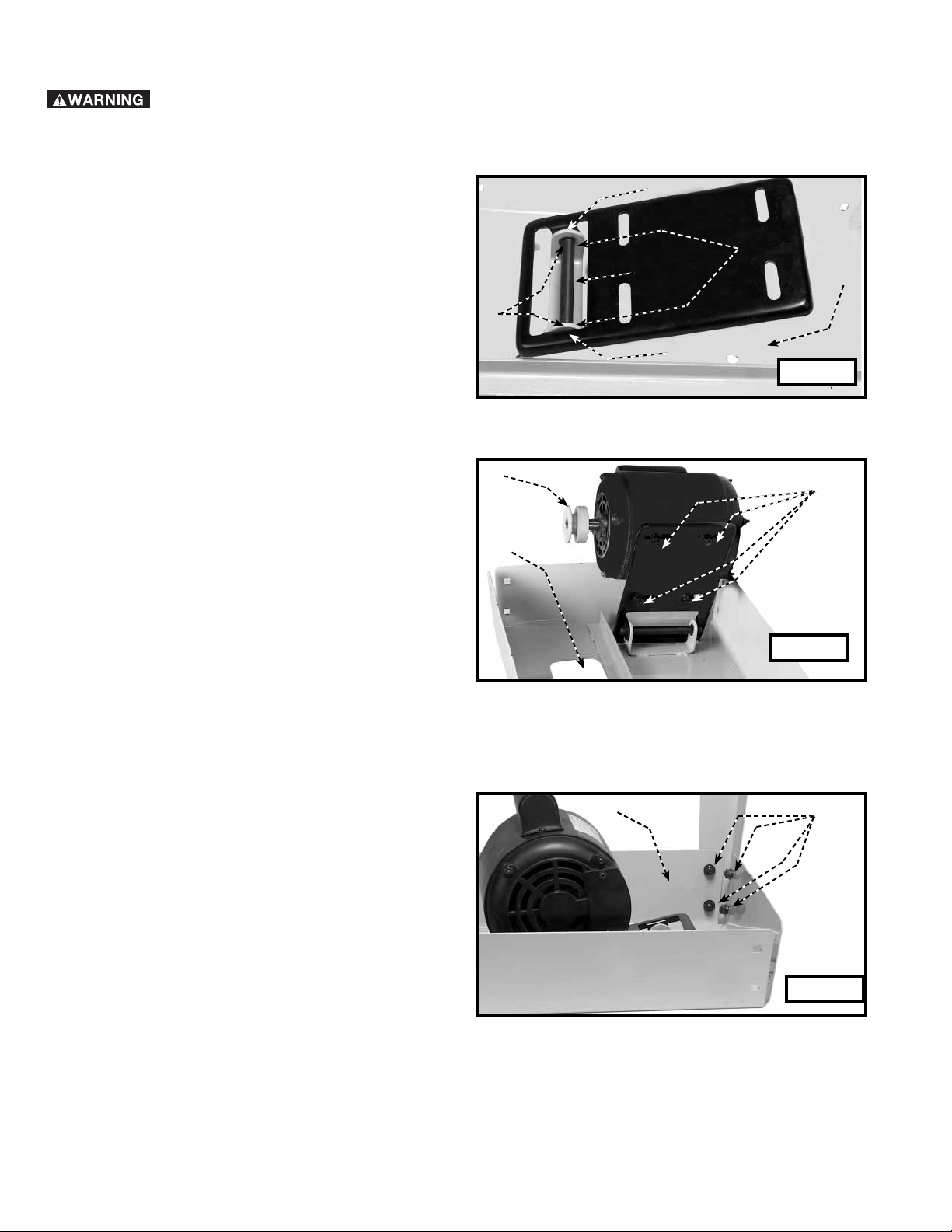

21. Slide the two hinges of the door (A) Fig. 9 over the

hinge catches (B) on the stand.

22. Close the door until the door latch (C) Fig. 9,

engages with the side (D).

23. Attach the other door in the same manner.

Fig. 8

A

A

C

B

C

D

B

24. Thread a hex nut (M10x1.5) on a hex head screw

(M10x1.5x100mm) approximately 1/4".

25. Thread the hex head screw (C) into the hole (A) Fig.

10 in the top of the stand.

26. Place the damping cap (A) Fig. 10A on the threaded

end of the screw (C).

27. Align the holes (D) Fig. 10 on the hinges attached to

the pulley guard with the two holes (B) in the top of

the stand.

28. Insert a pan head screw (M5x0.8x10mm) through

the hole (D) Fig. 10 in the hinge, and the hole (B) in

the top of the stand.

29. Thread a hex nut (M5x0.8) on the screw and tighten

securely.

30. Repeat this process for the remaining hole in the

hinge and the top of the stand.

31. Confirm that the stand is level.

32. Tighten all hardware securely.

Fig. 9

D

A

B

C

Fig. 10

11 - English

Page 12

MODEL 28-276 OPEN STAND ASSEMBLY

For your own safety, do not connect the machine to the power source until the machine is

completely assembled and you read and understand the entire instruction manual.

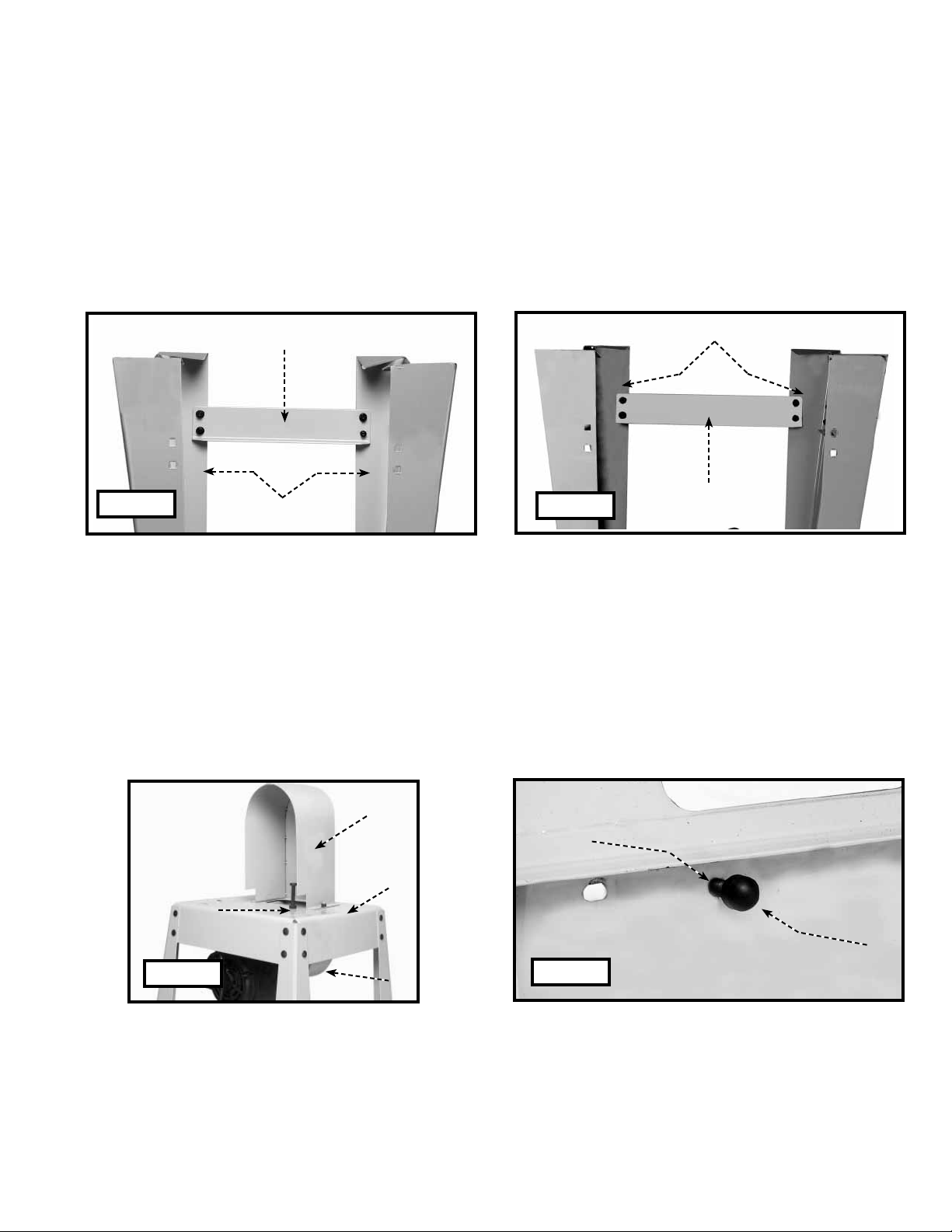

1. Place the stand top (A) Fig. 11 on a flat surface.

2. Align the two holes in the motor mounting plate (E)

Fig. 11 with the two holes (B) in the stand top (A).

3. Insert the shaft (D) through the holes in the motor

mounting plate and the holes in the stand top.

4. Attach the two "C" rings (C) Fig. 11 to the shaft.

5. Align the four holes on the motor bracket with the

four holes (C) Fig. 12, on the motor mounting plate.

NOTE: Confirm that the motor pulley (A) Fig. 12 is

mounted on the same side and the belt-opening

hole (B).

6. Insert a round head flange screw (M8x1.25x16mm)

through the hole in the motor bracket and the hole

in the motor mounting plate.

7. Thread a hex flange nut (M8x1.25) on the screw.

8. Repeat this process for the three remaining holes.

E

C

D

B

E

Fig. 11

A

B

Fig. 12

A

C

9. Align the four holes (A) Fig. 13 in the leg with the four

holes in the side of the stand top (B).

10. Insert a hex head flange screw (M8x1.25x16mm)

through the hole in the leg and through the hole in

the top of stand.

11. Thread a flange nut (M8x1.25) on the screw.

NOTE: Loosely tighten the hardware for further

adjustment.

12. Repeat this process for the three remaining holes.

13. Attach the other three stand legs in the same

manner.

12 - English

B

A

Fig. 13

Page 13

14. Align the four holes in the short brace (A) Fig. 14 with the four holes in the two legs (B).

15. Insert a carriage head bolt (M8x1.25x16mm) through the hole in the stand and the hole the short brace.

16. Thread a flange nut (M8x1.25) on the screw.

NOTE: Loosely tighten the hardware for further adjustment.

17. Repeat this process for the three remaining holes.

18. Attach the remaining short brace to the opposite side of the stand in the same manner.

19. Align the four holes in the long brace (A) Fig. 15 with the four holes in the two legs (B).

20. Insert a carriage head bolt (M8x1.25x16mm) through the hole in the stand and the hole in the long brace.

21. Thread a flange nut (M8x1.25) on the screw.

NOTE: Loosely tighten the hardware for further adjustment.

22. Repeat this process for the three remaining holes.

23. Attach the remaining long brace to the opposite side of the stand in the same manner.

A

Fig. 14

24. Turn the stand right side up.

25. Thread a hex nut (M10x1.5) on a hex head screw (M10x1.5x80mm) approximately 1/4".

26. Thread the hex head screw into the hole (A) Fig. 16 in the top of the stand. Place the damping cap (A) Fig. 16A on

the threaded end of the screw (C).

27. Confirm that the stand is level.

28. Securely tighten all hardware.

NOTE: Pulley guards (D) and (C) will be attached after the belt has been installed.

B

Fig. 15

B

A

Fig. 16

D

C

B

A

A

C

13 - English

Fig. 16A

Page 14

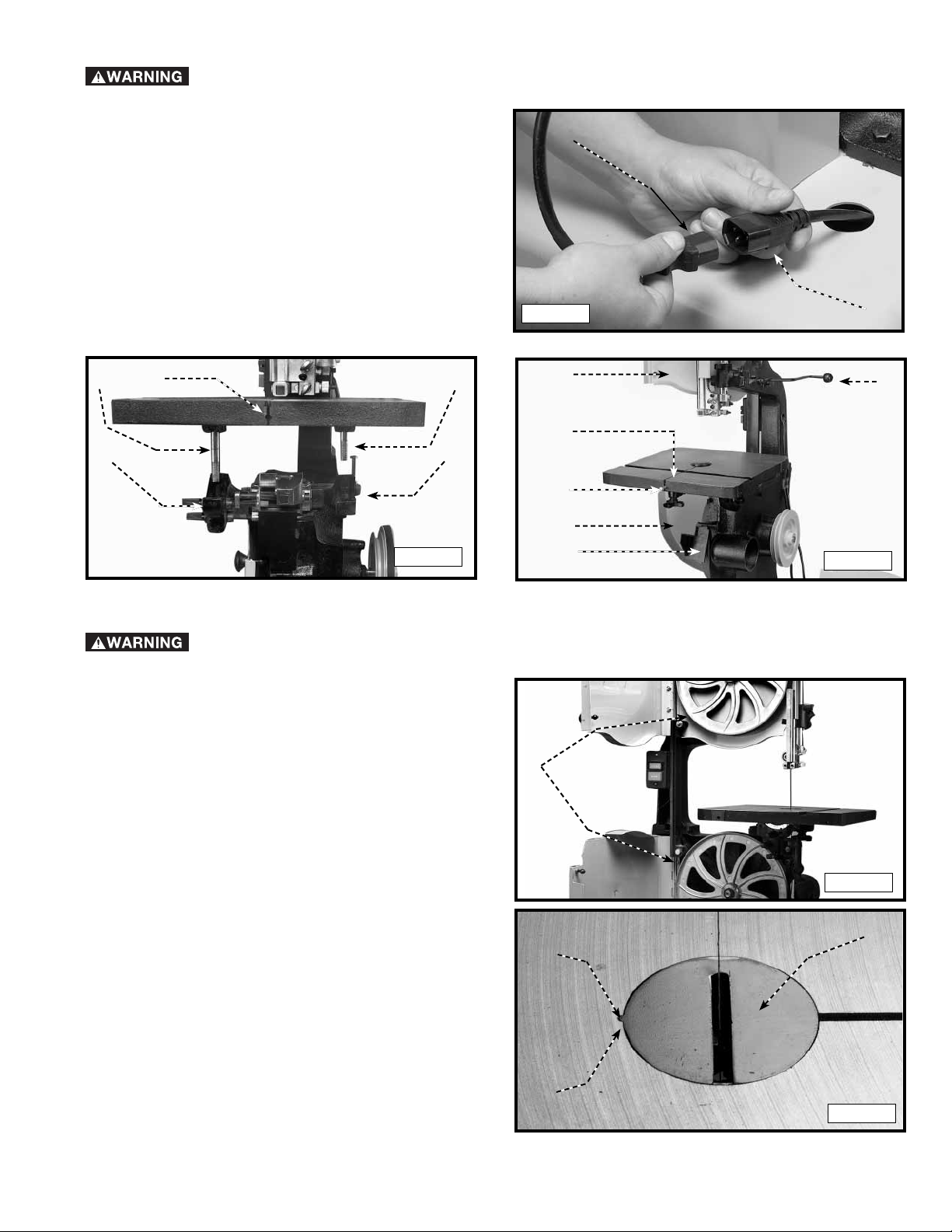

ATTACHING THE SAW TO THE STAND

THE BAND SAW IS VERY HEAVY. Use a helper when you attach the saw to the stand.

1. Place the band saw on top of the stand as shown in

Fig. 17.

NOTE: Confirm that the pulley is on the same side

of the stand as the pulley guard.

2. Align the four holes in the saw with the four holes in

the top of the stand.

3. Place an M8 lockwasher and a M8 flat washer on a

hex head screw (M8x1.25x40mm). Insert the screw

through one of the holes (A) in the saw and the

stand.

4. Thread a hex nut (M8x1.25) on the screw and tighten

securely.

5. Repeat this process for the other hole (A).

6. Attach the belt to the saw and motor pulley. See the

section "ATTACHING BELT TO SAW AND MOTOR

PULLEY".

7. Repeat STEPS 3 AND 4 for the two remaining holes (B) Fig. 17 (one of which is shown).

A

ATTACHING THE BELT TO THE SAW AND MOTOR PULLEY

B

Fig. 17

1. Place the belt over the saw pulley (A) Fig. 18.

NOTE: The model 28-276 has a one-step pulley. The

model 28-206 has a two-step pulley (Fig. 18).

2. Lift the motor and place the other end of the belt

around the motor pulley (B) Fig. 18. The weight of

the motor will provide the correct belt tension.

Operate the machine ONLY with all the

guards in place and secure.

3. Check the alignment of the motor and saw pulley.

4. Loosen the four bolts (C) Fig. 12 that hold the motor

bracket to the motor mounting plate, and adjust the

position of the motor until the motor pulley and saw

pulley are aligned.

5. Tighten the four bolts that were loosened in STEP 4.

6. Turn bolt (C) Fig. 18, clockwise, until the dampening cap contacts the motor.

7. Back the bolt (C) Fig. 18 out approximately 1/4" and tighten the nut (D) against the top of the stand to hold bolt

(C) in place.

NOTE: Do not use the bolt and dampening washer to tension the belt. These two parts prevent the motor from

rising excessively when the motor starts.

C

D

B

A

Fig. 18

ATTACHING THE PULLEY GUARDS

NOTE: The illustration in Fig. 18A shows the stand

without the band saw for clarity.

1. Insert the two threaded studs on the lower pulley

guard (C) Fig 18A through the two holes in the top

of the stand (B).

2. Align the two holes in the upper pulley guard (D)

Fig. 18A with the two threaded studs on the lower

pulley guard (C). Place the upper pulley guard on the

studs of the lower pulley guard.

3. Thread a hex flange nut (M8x1.25) on each of the

studs and tighten securely.

A

Fig. 18A

D

B

C

14 - English

Page 15

CONNECTING MOTOR CORD TO SWITCH ASSEMBLY

Disconnect the machine from the power source!

Insert the motor plug (A) Fig. 18B into the receptacle (B) of the

switch-to-motor cord.

B

ATTACHING THE TABLE TO THE SAW

1. Remove the band saw blade.

2. Align the two table studs (A) Fig. 19 in the bottom of the

table with the two holes in the trunnion assemblies (B).

NOTE: Confirm that the slot (C) Fig. 19 is facing toward the

front.

3. Place an M13 flat washer on the table stud and thread the

table knob on the table stud.

4. Repeat this process for the remaining table stud.

Fig. 18B

A

A

B

C

A

B

Fig. 19

ATTACHING BLADE TO THE SAW

Disconnect the machine from the power source!

NOTE: The 14" band saw uses 93-1/2" length blades.

1. Remove the table pin (A) Fig. 20 from the table.

2. Open the two wheel guard doors (B) Fig. 20 and the blade

guard door (C).

3. Confirm that the quick tension lever (D) Fig. 20 is

positioned to the left of the machine.

NOTE: Install the blade with the teeth pointing down, toward

the table.

4. Slide the band saw blade, (teeth facing out), through the

slot (E) Fig. 20 in the band saw table.

5. Place the blade around the two wheel assemblies (A) Fig.

21.

6. Replace the table pin (A) Fig. 20.

7. Close the two wheel-guard doors (B) Fig. 20 and the blade

guard door (C).

8. Move the quick tension lever (D) Fig. 20 to the right .

9. See the section "OPERATING CONTROLS AND

ADJUSTMENTS" to adjust the blade tension and

tracking.

B

D

E

A

B

C

Fig. 20

A

Fig. 21

A

C

TABLE INSERT

Place the table insert (A) Fig. 22 in opening of table.

NOTE: A tab (B) on the insert fits into the notch (C) in table

opening.

15 - English

B

Fig. 22

Page 16

OPERATION

OPERATIONAL CONTROLS AND ADJUSTMENTS

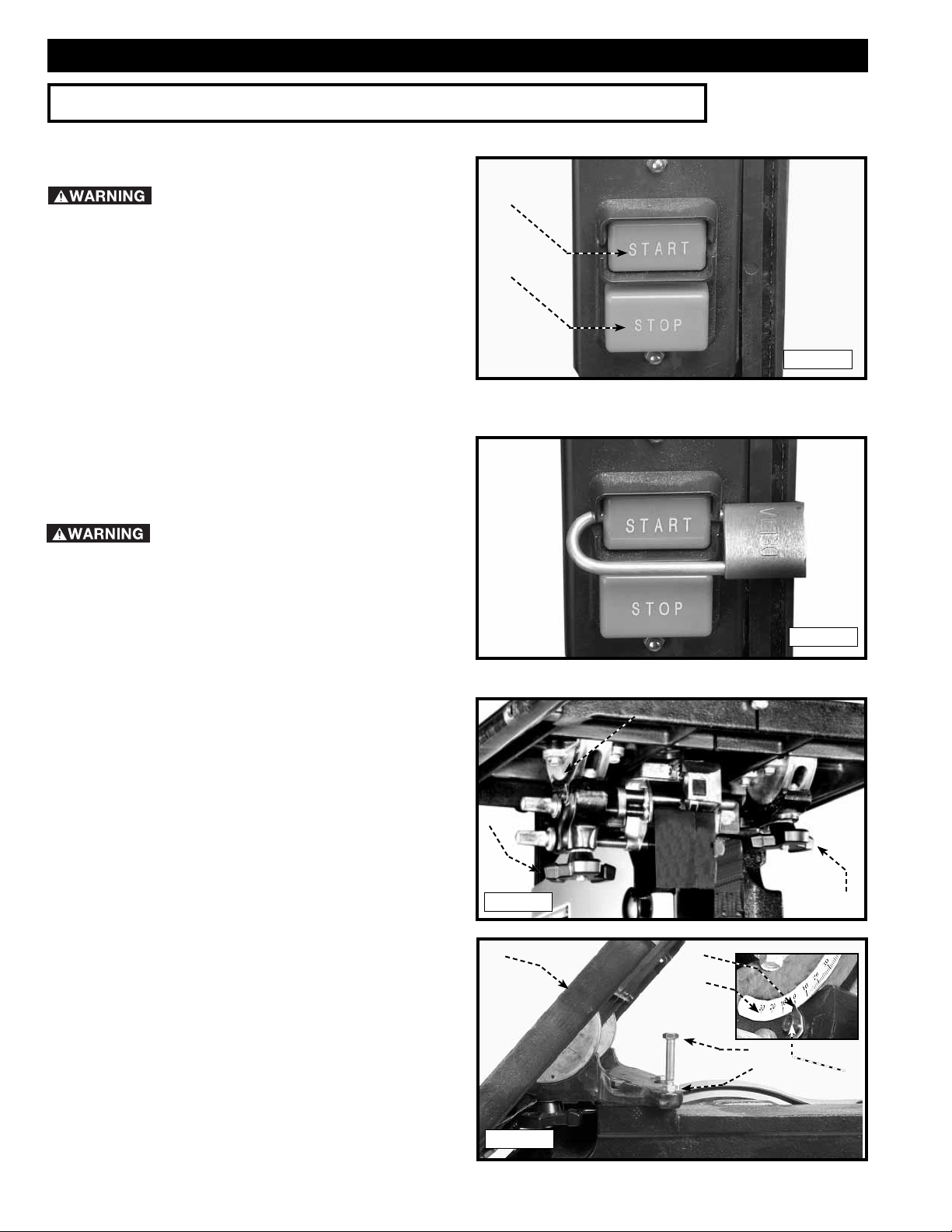

STARTING AND STOPPING THE SAW

Make sure that the switch is in the

“OFF” position before plugging cord into outlet. Do

not touch the plug’s metal prongs when unplugging

or plugging in the cord

The power switch is located on the left side of the

machine. To turn the machine "ON", push the green

start button (A) Fig. 23. To turn the machine "OFF", push

the red stop button (B).

A

B

LOCKING THE SWITCH IN THE "OFF" POSITION

IMPORTANT: When the tool is not in use, the switch

should be locked in the "OFF" position to prevent

unauthorized use, using a padlock (Fig. 24) with a 3/16"

diameter shackle.

In the event of a power outage (such

as a breaker or fuse trip), always move the switch to

the “OFF” position until the main power is restored.

Fig. 23

Fig. 24

TILTING THE TABLE

You can tilt the band saw table 45 degrees to the right

and 10 degrees to the left.

1. To tilt the table to the right, loosen the two locking

knobs (A) Fig. 25, tilt the table to the desired angle

as shown on the scale (D) Figs. 25 and 26, and

tighten two locking knobs (A).

2. To tilt the table (C) Fig. 26 to the left, loosen the two

locking knobs (A) Fig. 25 and tilt the table to the right

until you have access to the table stop (A) Fig. 26.

Remove the table stop (A) Fig. 26, and tilt the table

to the left 10 degrees. Tighten the two locking knobs

(A) Fig. 25.

A

Fig. 25

C

D

A

E

D

A

B

F

16 - English

Fig. 26

Page 17

ADJUSTING THE TABLE STOP

This machine is equipped with an adjustable table stop

(A) Fig. 26 that allows the table to be set at 90 degrees

to the blade.

Tilt the table (C) Fig. 26 to the left until the table stop

(A) Fig. 26 contacts the table. Place a square on the

table against the blade (Fig. 27). If the blade is not 90

degrees to the table surface:

1. Tilt the table slightly to the right and tighten the table

lock knobs.

2. Loosen the locknut (B) Fig. 26 to free the adjusting

screw (A) Fig. 26. Tur n the adjusting screw (A) right

or left to raise or lower the table stop, then tighten

the locknut (B).

Fig. 27

3. Lower the table. Check the angle with the square.

4. When the table is 90 degrees to the blade, confirm

that the pointer (E) Fig. 26 is set to 0°. If not, loosen

the screw (F) Fig. 26 and move the pointer to 0°.

Tighten the screw.

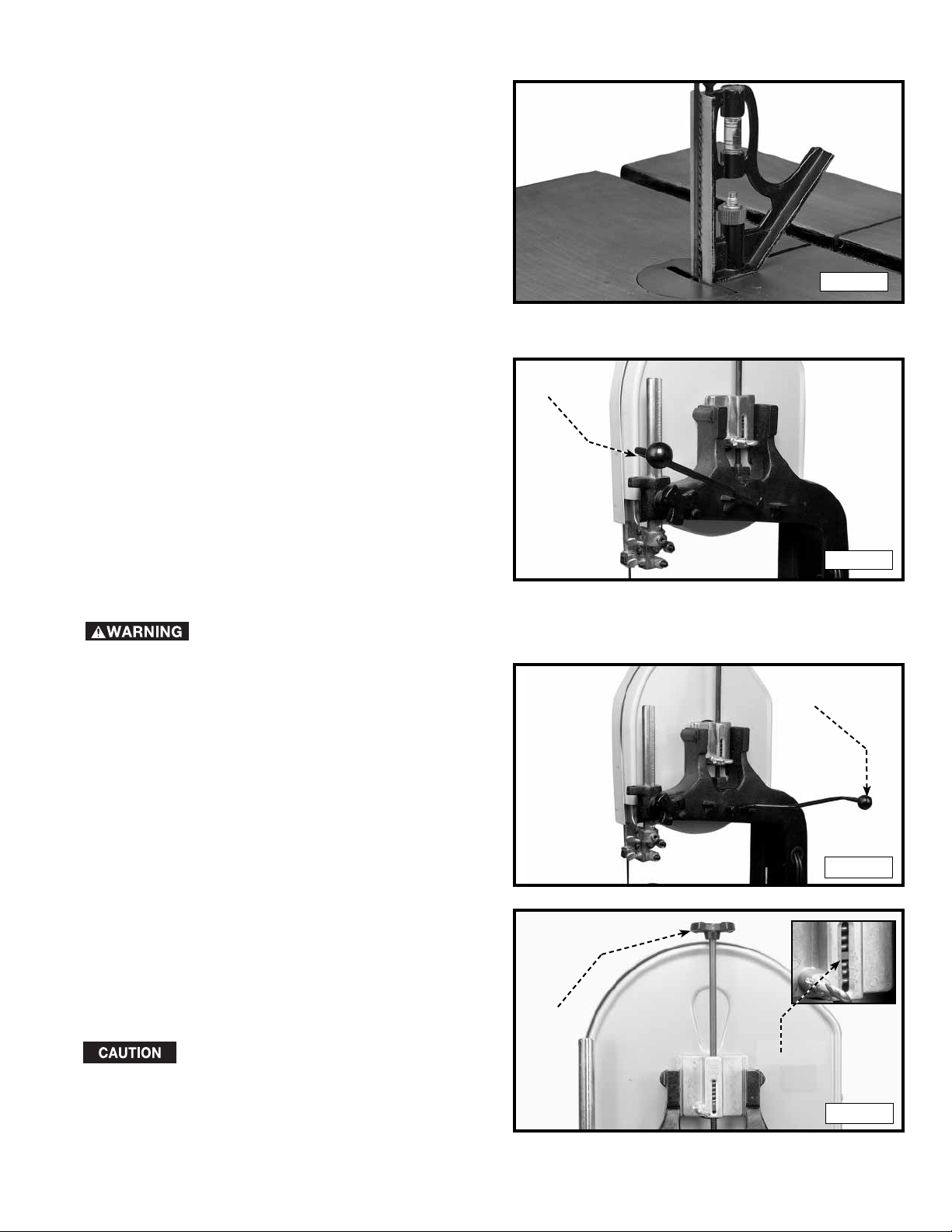

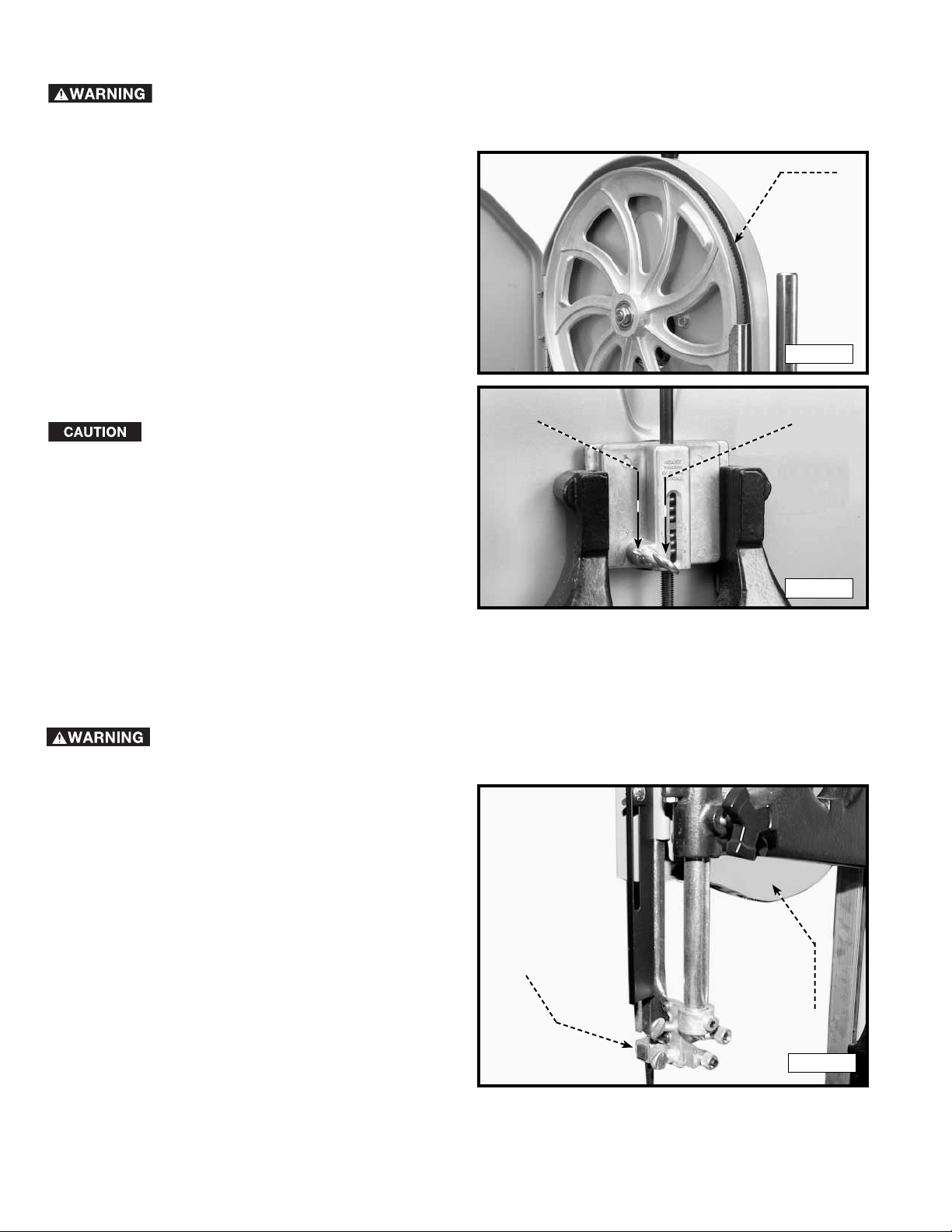

ADJUSTING BLADE TENSION

Disconnect the machine from the power source!

The machine is equipped with a tension handle (A) Fig.

28. To apply tension, move the tension handle (A) Fig. 28

toward the back. To release the blade tension, move the

tension handle (A) Fig. 29 toward the front.

To adjust the blade tension, move the blade tension

handle toward the back (Fig. 29). A scale is located

on the back of the upper wheel slide bracket. The

graduations on the scale indicate the proper tension for

various widths of blades. With the blade on the wheels,

turn the knob (A) Fig. 30 to raise or lower the wheel until

the red fiber washer (B) Fig. 30 is in line with the proper

graduation for the size of the blade used.

A

Fig. 28

A

Fig. 29

This scale is correct for average work and will not be

affected by rebrazing of the saw blade. Use these

graduations until you become familiar enough with

the operation of the band saw to vary the tension for

different kinds of blades or work.

Over-straining the blade is a common

cause of breakage and/or poor performance. Release

the tension when the machine is not in use.

17 - English

A

B

Fig. 30

Page 18

TRACKING THE BLADE

Disconnect the machine from the power source!

IMPORTANT: Before tracking the blade, confirm that

the blade guides and blade support bearings are clear

of the blade.

After applying tension to the blade, rotate the wheels

slowly forward by hand and observe the blade’s

movement. The blade (A) Fig. 31 should travel in the

center of the upper tire. If the blade creeps toward the

front edge, loosen the wing nut (B) Fig. 32 and turn the

thumb screw (C) clockwise. This action draws the blade

toward the center of the tire. If the blade creeps toward

the back edge, turn the thumb screw in the opposite

direction. Adjust the thumb screw (C) Fig. 32 only a

fraction of a turn each time.

Never track the blade while the machine

is running.

After the blade is tracking in the center of the tires,

tighten the wing nut (B) Fig. 32.

A

Fig. 31

B

C

Fig. 32

VERTICAL ADJUSTMENT OF THE UPPER BLADE GUIDE ASSEMBLY

Disconnect the machine from the power source!

To adjust the blade guides and bearings:

Set the upper blade guide assembly (A) Fig. 33 as close

as possible to the top surface of the workpiece. Loosen

the lock knob (B) and move the guide assembly (A) to

the desired position.

A

B

Fig. 33

18 - English

Page 19

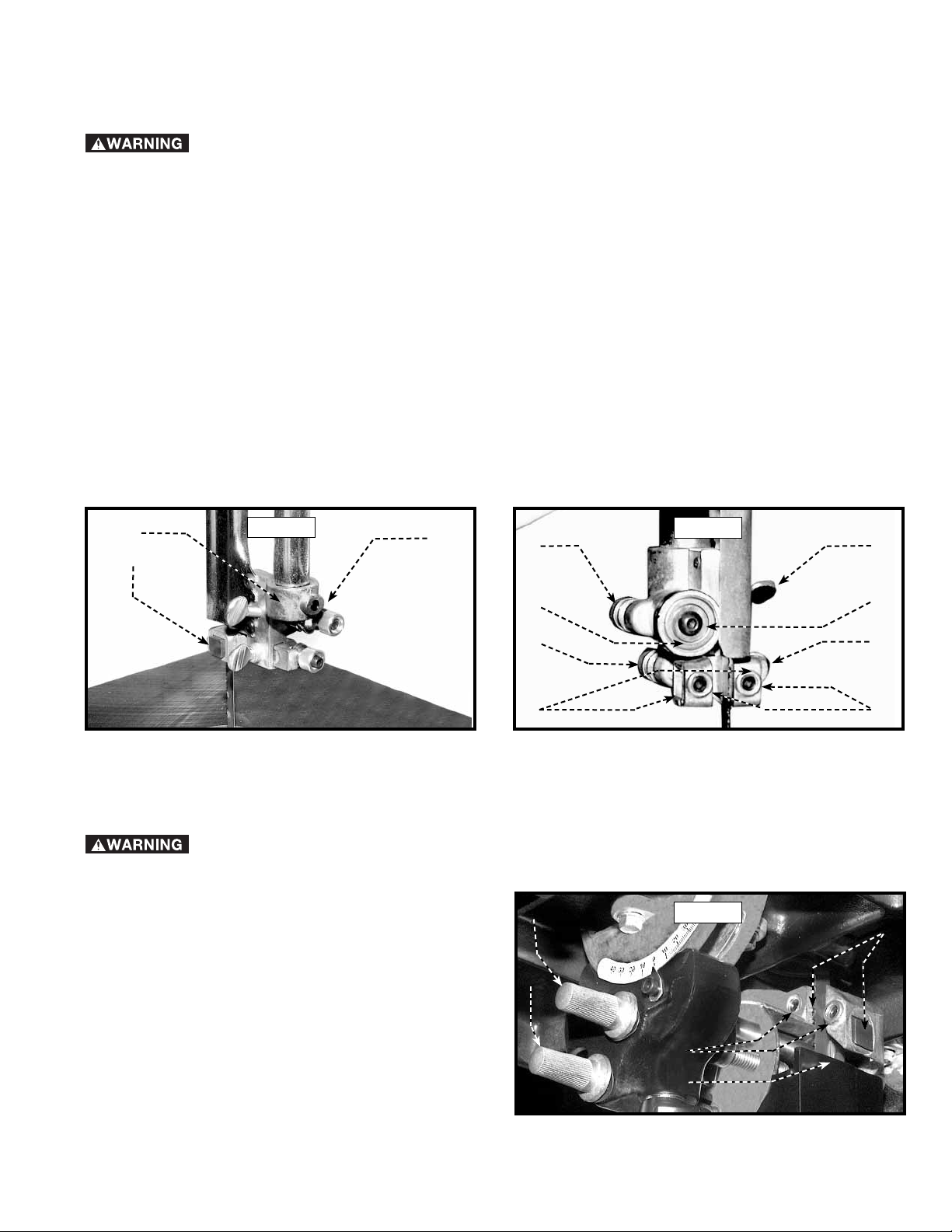

ADJUSTING THE UPPER BLADE GUIDES AND BLADE SUPPORT BEARING

Adjust the upper blade guides and blade support bearings ONLY AFTER the blade has the correct tension and is tracking

properly. To adjust:

Disconnect the machine from the power source!

1. Confirm that the bottom blade guides and support bearings are not touching the blade.

2. Observe the upper blade guide assembly. The blade guides (A) Fig. 34 should be parallel to the blade. To adjust, loosen

the screw (B) and rotate the complete guide assembly (C). When the blade guides are parallel with the blade, tighten the

screw (B).

3. Adjust the guides (A) Fig. 35 so that the front edge of the guides are just behind the "gullets" of the saw teeth. You can

move the complete guide block bracket in or out by loosening the thumb screw (C) and turning the knurled knob (D) Fig.

35. When the guides (A) are set properly, tighten the thumb screw (C).

5. Two set screws (B) Fig. 35 hold the upper blade guides (A) in place. Loosen the set screws (B) to move the guides (A).

Place them as close as possible to the side of the blade. (Do not pinch the blade). Tighten the screws (B).

6. The upper blade support bearing (E) Fig. 35 prevents damage to the set in the saw teeth by keeping the blade held

forward. Set the support bearing (E) 1/64" behind the blade. Loosen the thumb screw (F) and turn the knurled knob (G) to

move the support bearing (E) in or out.

7. Adjust the blade support bearing (E) so that the back edge of the blade overlaps the outside diameter of the ball bearing

by about 1/16". The bearing (E) is set on an eccentric. To change the position, remove the screw (H) and bearing (E) Fig.

35. Loosen the thumb screw (F), and back out the knurled knob from the set screw. Remove the hex shaft from the hole,

and rotate it to move the eccentric for the bearing.

8. When the blade guide wears so that it cannot be adjusted close to the blade, loosen the screw (B) Fig. 35 and reverse

the blade guides (A) Fig. 35.

C

Fig. 34

B

G

Fig. 35

A

E

D

A

ADJUSTING LOWER BLADE GUIDES AND BLADE SUPPORT BEARING

Adjust the lower blade guides and blade support bearing after the the upper guides and bearing have been adjusted.

Disconnect the machine from the power source!

1. Turn the knurled knob (C) Fig. 36 to adjust the front

edge of the guide blocks (B) Fig. 36 so that they are

just behind the "gullets" of the saw teeth.

NOTE: The support bearing (D) Fig. 36 should not be

touching the back of the blade.

2. Loosen the two screws (A) Fig. 36. Move the guides

(B) as close as possible to the side of the blade, being

careful not to pinch the blade. Tighten the screws (A).

3. Turn the other knurled knob (E) to adjust the lower

blade support bearing (D) Fig. 36 so that it is about

1/64" behind the back of the blade.

E

Fig. 36

C

A

D

F

H

C

B

B

19 - English

Page 20

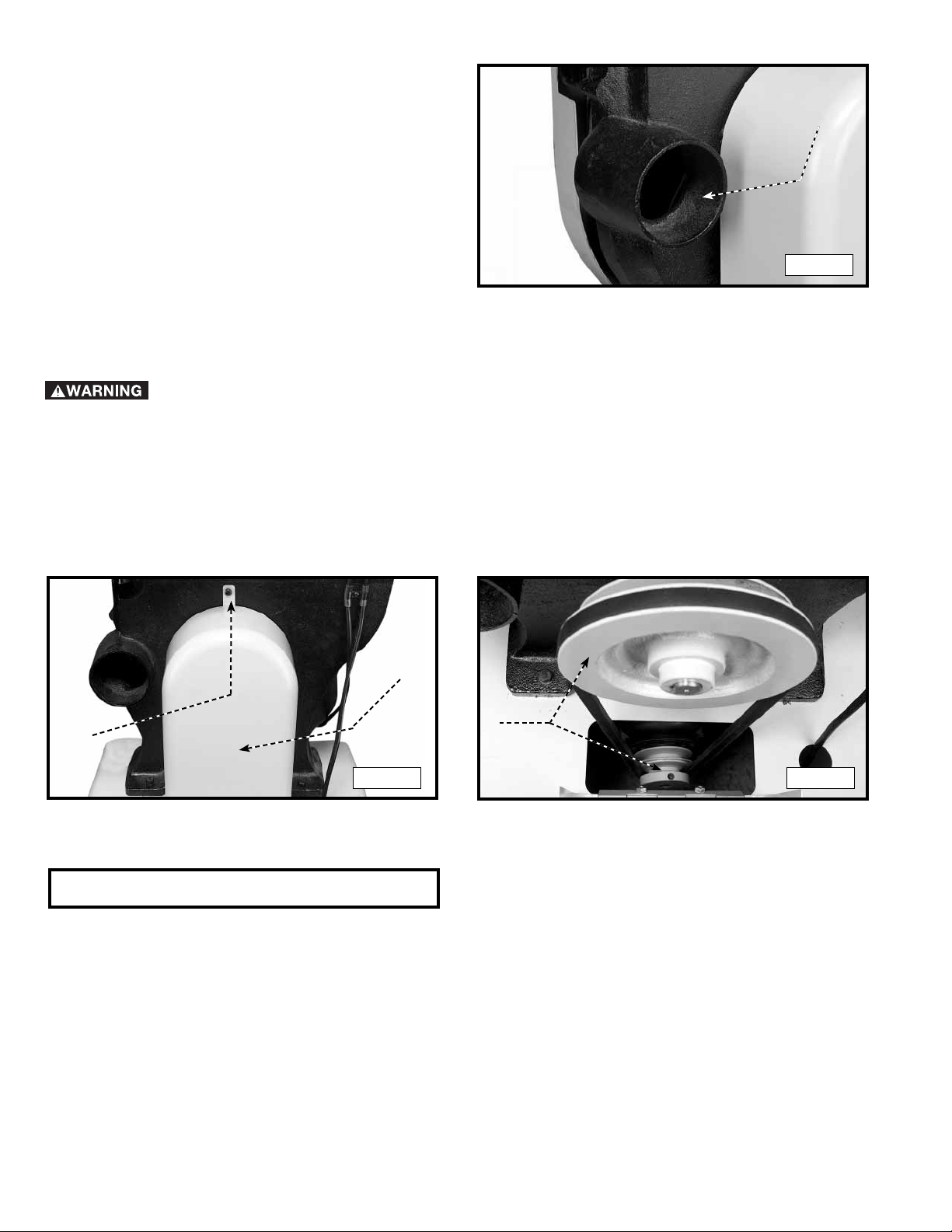

DUST PORT

A dust port (A) Fig. 36A enables you to connect your band

saw to a dust collector.

NOTE": The dust port is 4" O.D.

A

Fig. 36A

CHANGING BLADE SPEED FOR MODEL 28-206 ONLY

Disconnect the machine from the power source!

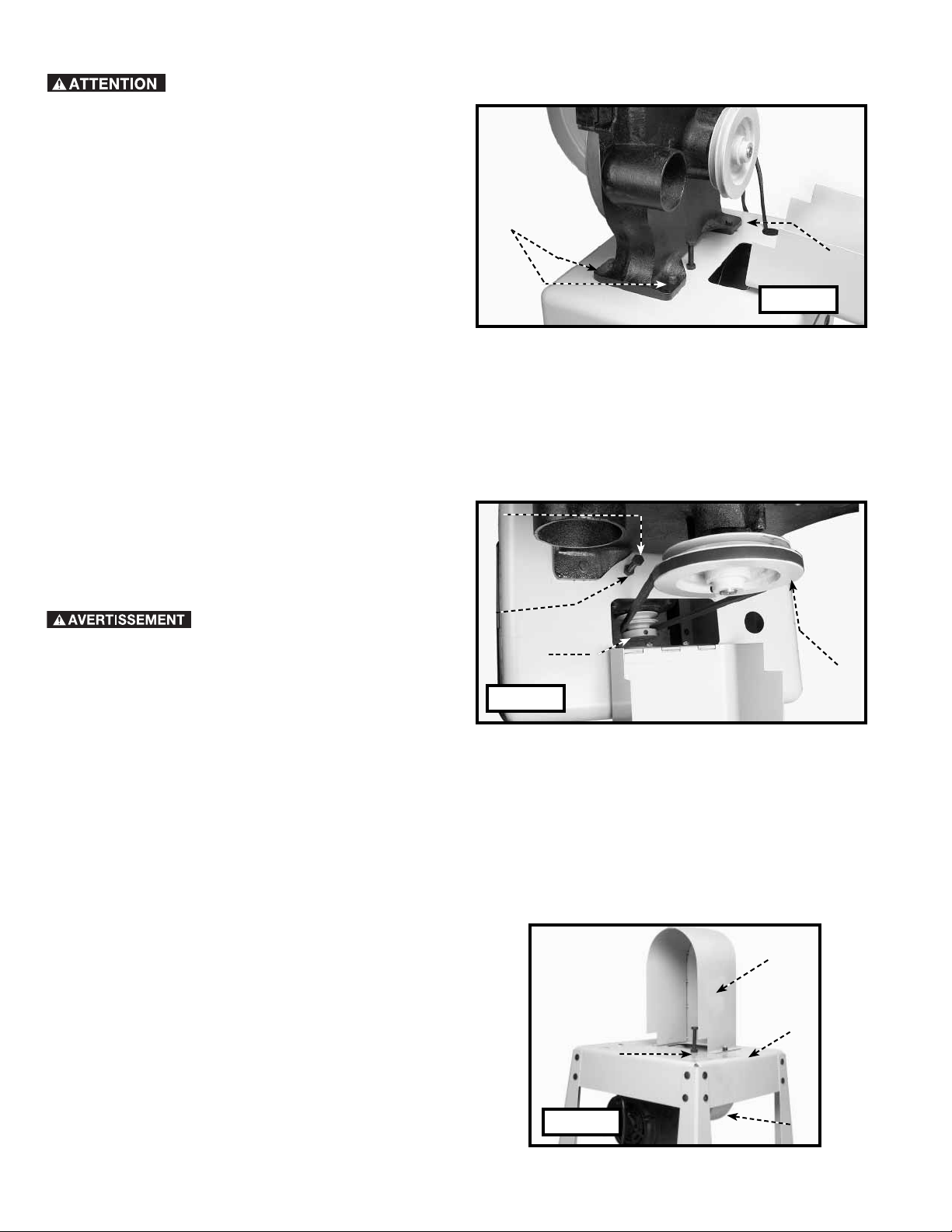

1. Remove the pulley guard (A) Fig. 37 by removing screw (B).

2. Lift the motor, place the belt on the selected step of the pulleys (A) Fig;. 38, and release the motor.

3. The motor has two speeds: 3300 fpm (good for general work), and 2500 fpm (used for resaw work).

NOTE: The motor will achieve 3300 fpm with the belt placed on the large motor pulley and the small saw pulley. The motor will

achieve 2500 fpm with the belt placed on the small motor pulley and the large saw pulley.

A

B

Fig. 37 Fig. 38

A

MACHINE USE

Before applying power to the machine, make all necessary adjustments and ensure that all guards are in place and

are secure. Turn the upper wheel by hand to visually inspect the machine.

Keep the top guide within 1/8" of the workpiece. Do not force the workpiece against the blade. Light pressure will

produce a smoother cut and prevent excess friction and heating of the blade. Keep the workpiece moving at a slow

and consistent rate.

To prevent twisting of the blade, avoid making sharp corner cuts.

KEEP THE SAW BLADE SHARP.

20 - English

Page 21

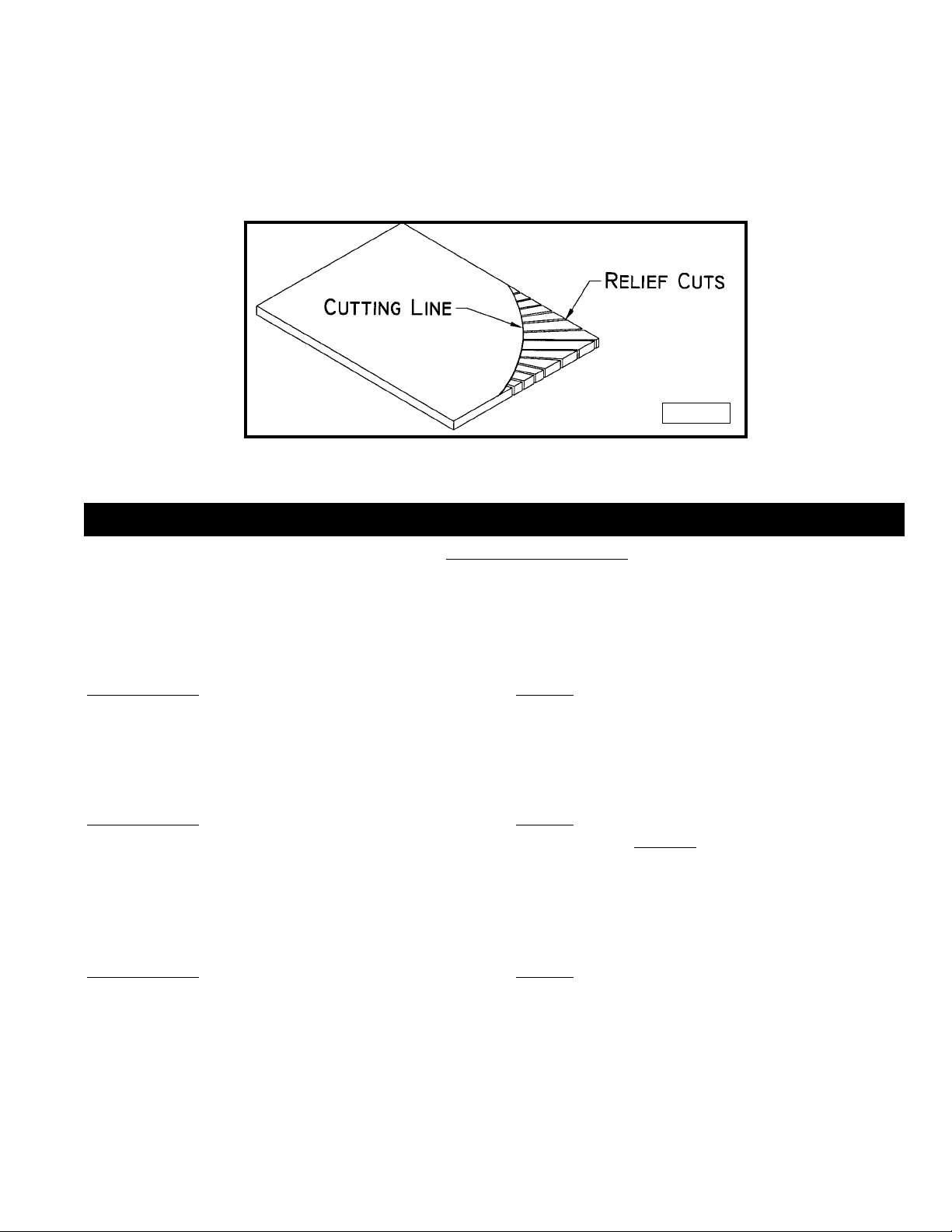

CUTTING CURVES

Turn the stock carefully so that the blade follows without twisting. For very abrupt curves, consider using a narrower

blade, or a blade with more set. Another solution to this problem is to make relief cuts (Fig. 39).

When you withdraw the workpiece or change the cut, be careful not to accidentally pull the blade off of the wheels.

The preference is to turn the stock and saw out through the waste material.

Fig. 39

TROUBLESHOOTING GUIDE

For assistance with your machine, visit our website at www.deltamachinery.com for a list of service centers or call the

DELTA Machinery help line at 1-800-223-7278 (In Canada call 1-800-463-3582).

In spite of how well a band saw is maintained, problems can occur. The following troubleshooting guide will help you solve

the more common problems:

Trouble: SAW WILL NOT START.

Probable Cause Remedy

1. Saw not plugged in. 1. Plug in saw.

2. Fuse blown or circuit breaker tripped. 2. Replace fuse or reset circuit breaker.

3. Cord damaged. 3. Have cord replaced.

Trouble: BREAKER KICKS OUT FREQUENTLY.

Probable Cause Remedy

1. Extension cord too light or too long. 1. Replace with adequate size cord.

2. Feeding stock too fast. 2. Feed stock more slowly.

3. Blade in poor condition (dull, warped, gummed). 3. Clean or replace blade.

4. Low voltage supply. 4. Contact an electrician.

Trouble: BAND SAW VIBRATES EXCESSIVELY.

Probable Cause Remedy

1. Machine not mounted securely to stand. 1. Tighten all mounting hardware.

2. Stand on uneven surface. 2. Reposition on flat level surface.

3. Worn belt. 3. Replace belt.

4. Pulley not aligned. 4. Adjust pulleys.

5. Motor not fastened securely. 5. Tighten all mounting hardware.

21 - English

(continued on next page)

Page 22

Trouble: BAND SAW DOES NOT COME UP TO SPEED.

Probable Cause Remedy

1. Low voltage due to improper extension cord size. 1. Replace with adequate size cord.

2. Low voltage. 2. Contact an electrician.

Trouble: BLADES BREAK.

Probable Cause Remedy

1. Blade not tensioned properly. 1. Adjust blade tension.

2. Blade guides improperly adjusted. 2. Check and adjust blade guides.

3. Blade support bearing improperly adjusted. 3. Adjust blade support bearing.

4. Blade wheel tracking adjustment improperly set. 4. Check and adjust blade tracking.

5. Bad weld on blade. 5. Replace the blade.

6. Worn tires. 6. Replace tires.

7. Forcing wide blade around short radius. 7. Change to a narrower blade.

8. Dull blade or insufficient set. 8. Replace blade.

9. Upper blade guide set too high. 9. Set upper blade guide within 1/8" of workpiece.

10. Continuous running of machine when not actually 10. Turn off machine when not performing cutting

cutting. operation.

Trouble: BLADE WILL NOT TRACK.

Probable Cause Remedy

1. Blade too loose 1. Adjust tension

2. Upper wheel not properly adjusted. 2. Adjust upper wheel.

3. Improperly adjusted blade support bearing. 3. Adjust blade support bearing.

Trouble: CUT DOES NOT AGREE WITH SETTING ON THE TILT SCALE.

Probable Cause Remedy

1. Pointer out of adjustment 1. Adjust pointer.

Trouble: BLADE WILL NOT STAY ON WHEEL.

Probable Cause Remedy

1. Blade not tensioned properly. 1. Adjust blade tension.

2. Blade guides improperly adjusted. 2. Check and adjust blade guides.

3. Blade support bearing improperly adjusted. 3. Adjust blade support bearing.

4. Blade wheel not tracking properly. 4. Check and adjust blade tracking.

5. Bad weld on blade. 5. Replace the blade.

6. Worn tires. 6. Replace tires.

Trouble: BAND SAW MAKES UNSATISFACTORY CUTS.

Probable Cause Remedy

1. Blade not tensioned properly. 1. Adjust blade tension.

2. Blade guides improperly adjusted. 2. Check and adjust blade guides.

3. Blade support bearing improperly set. 3. Adjust blade support bearing.

4. Blade wheel not tracking properly. 4. Check and adjust blade tracking.

5. Bad weld on blade. 5. Replace the blade.

6. Worn tires. 6. Replace tires.

7. Incorrect blade for work being done. 7. Change the blade.

8. Dull blade or insufficient set. 8. Replace blade.

9. Upper blade guide set too high. 9. Set upper blade guide within 1/8" of work piece.

22 - English

Page 23

BAND SAW BLADES

A band saw blade is a delicate piece of steel that is subjected to tremendous strain. You can

obtain long use from a band saw blade if you use it properly. Use blades of proper thickness, width

and temper for the various types of material and cuts.

Always use the widest blade possible. Use narrow blades only for sawing small, abrupt curves

and for fine, delicate work. This will save blades and will produce better cuts. For cutting wood

and similar materials, Delta offers blades in widths of 1/8", 1/4", 3/8", and 1/2".

Any one of a number of conditions may cause a band saw blade to break. Blade breakage is, in

some cases, unavoidable, being the natural result of the peculiar stresses to which blades are

subjected. Blades will break often due to avoidable causes, such as the lack of care to the blade

or the blade not being properly adjusted to the band saw. The most common causes of blade

breakage are:

(1) faulty alignments and adjustments of the guides.

(2) forcing or twisting a wide blade around a curve of short radius.

(3) feeding the work piece too fast into the blade.

(4) dullness of the teeth, or absence of sufficient set.

(5) improperly tensioned blade.

(6) top guide set too high above the work piece being cut.

(7) using a blade with a lumpy or improperly finished braze or weld.

(8) continuous running of the saw blade when not cutting.

Use blades that are 93½" in length on this machine.

Always use a sharp blade. Keep it free from gum and pitch. Clean frequently with a stiff fiber

brush.

Narrow blades are used for cutting small circles or curves while the wider blades are best suited

for straight cutting such as ripping.

A new blade, in most cases, will perform better and last longer than a re-sharpened blade.

Ensure that the blade guides are adjusted properly.

Do not force or twist the blade around a curve or a very short radius.

Feed the workpiece through the blade at a consistent rate, allow the blade to do the cutting – do

not feed the work piece too fast.

Do not apply excessive tension to the blade. The tension is only necessary to drive the blade

without slipping on the wheels. Narrow blades require less tension than wider blades.

23 - English

Page 24

MAINTENANCE

KEEP MACHINE CLEAN

Periodically blow out all air passages with dry compressed air. All plastic parts should be cleaned with a soft damp

cloth. NEVER use solvents to clean plastic parts. They could possibly dissolve or otherwise damage the material.

Wear certified safety equipment for eye, hearing and respiratory pr otection while using compressed air.

FAILURE TO START

Should your machine fail to start, check to make sure the prongs on the cord plug are making good contact in the

outlet. Also, check for blown fuses or open circuit breakers in the line.

LUBRICATION & RUST PROTECTION

Apply household floor paste wax to the machine table, extension table or other work surface weekly. Or use a commercially

available protective product designed for this purpose. Follow the manufacturer’s instructions for use and safety.

To clean cast iron tables of rust, you will need the following materials: a sheet of medium Scotch-Brite™ Blending Hand

Pad, a can of WD-40® and a can of degreaser. Apply the WD-40 and polish the table surface with the Scotch-Brite pad.

Degrease the table, then apply the protective product as described above.

SERVICE

REPLACEMENT PARTS

Use only identical replacement parts. For a parts list or to order parts, visit our website at

can also order parts from your nearest factory-owned branch, or by calling our Customer Care Center at 1-800-223-7278 to

receive personalized support from highly-trained technicians.

servicenet.deltamachinery .com.

You

FREE WARNING LABEL REPLACEMENT

If your warning labels become illegible or are missing, call

T O RE DUCE T HE RISK OF I NJURY US E R MUS T REA D T HE I NS TRUCT ION MANUA L BE F ORE

ESPECIALLY IF CUTTING MATERIALS THAT CONTAIN TOXIC PRESERVATIVES. WHEN OPERATING THIS TOOL, DO NOT WEAR GLOVES,

NECK TI E S , J E W E L RY , LOOSE CLOT HI NG OR LONG HAI R. LACE RA TION HA Z A RD. KEEP HANDS AND FINGERS AWAY FROM BLADE. DO

NOT RE MOV E J A M ME D OR S CRA P P I E CE S UNTI L T HE BLA DE HA S ST OP P E D A ND P OWE R OFF. DIS CONNE CT MACHI NE FROM P OWE R

SOURCE BE FORE ME A K I NG RE P A IRS OR A DJUSTME NTS. MA K E CE RTA IN T HA T BL A DE TEE TH P OINT DOW NWA RD TOWA RD THE TA BL E .

MAINTAIN PROPER ADJUSTMENT OF BLADE TRACKING AND TENSION, BLADE GUIDES AND THRUST BEARINGS. ALWAYS CLAMP

STOCK FIRMLY IN PLACE BEFORE CUTTI NG AND USE AUXILIARY SUPPORT F OR LONG MATERIAL. GUARDS SHOULD BE IN PLACE

AND US E D A T ALL TIME S. A DJ US T UP P E R BL A DE GUA RD/GUI DE TO WI THI N 1 /4” ( 6 .35 M M) OF WORK P I E CE . A LWA YS HOLD

WORKPIECE FI RMLY AGAINST TABLE WHEN CUTTING. SHOCK HAZARD. DO NOT EXPOSE TO RAIN OR USE IN DAMP LOCATIONS. DO

NOT OP E RA T E W HILE UNDE R THE INFL UE NCE OF DRUGS, A LCOHOL OR ME DI CA TION.

PROTECCIÓN A DE CUADA P A RA OJOS Y V ÍAS RE S P I RA TORI A S , E N E S P E CIAL S I CORTA MA TERI A LES QUE CONTIENE N CONS E RV A NTES

T ÓX ICOS. CUA NDO OP E RE E S TA HE RRA M IENTA , NO UT I LI CE GUA NTE S, CORBA TAS , J OY A S , ROP A HOLGADA NI E L CABE LL O LARGO

SUELTO. PEL IGRO DE LACE RA CI ÓN. M ANTE NGA LAS MA NOS Y LOS DE DOS LE J OS DE LA HOJ A . NO RE TIRE LAS P IE Z A S A TA S CA DA S

O DE DE S CA RT E HA S TA QUE LA HOJ A S E HA Y A DE TENI DO Y A P A GA DO. DES CONE CTE LA MÁ QUI NA DE LA FUENTE DE A LIME NTACI ÓN

ANTES DE REALI ZAR REPARACIONES O AJUSTES. ASEGÚRESE DE QUE LOS DIENTES DE LA HOJA APUNTEN HACIA ABAJO HACI A L A

MESA. MANTENGA EL AJUSTE ADECUADO DEL SEGUIMIENTO Y LA TENSIÓN DE LA HOJA, DE LAS GUÍAS DE LA HOJA Y DE LOS

RODAMIENTOS DE EMPUJE. SIEMPRE SUJETE EL MAT ERIAL F I RMEMENTE EN SU LUGAR ANTES DE REALI ZAR CORTES Y UTIL I CE

UN SOP ORTE A UX IL I A R P A RA E L MA TERIA L LA RGO. L A S GUA RDA S DE BE N E S TAR E N S U LUGAR Y S E DE BE N US A R E N TODO

MOMENTO. AJUSTE L A GUARDA O LA GUÍA SUPERIOR DE LA HOJA HASTA UNA DISTANCI A DE 6,35 MM (1/4” ) DE LA PI EZA DE

T RA BA J O. S IEM P RE S UJ E TE LA P I E Z A DE TRABA J O CON FIRME Z A CONT RA LA ME S A CUA NDO RE A LI CE LOS CORT E S . RIES GO DE

DESCARGA ELÉCTRICA. NO EX P ONGA A LA LLUVIA NI UT I LI CE E N LUGARE S HÚM E DOS . NO OPE RE BA JO L A INF LUE NCIA DE

DROGAS , ALCOHOL O M E DICA CIÓN

T OUJ OURS P ORTER UNE P ROTECTION OCUL A IRE E T RES P IRATOIRE P A RTICUL IÈ RE ME NT L ORS DE LA COUP E DE M A TI È RE S

CONT E NA NT DE S A GE NTS DE CONS E RV A TION T OX IQUE S . NE P A S P ORTER DE GA NTS, NI CRA V A TES , NI BI JOUX OU V Ê TEM E NTS

AMP LES E T COUV RIR L E S CHE V E UX LONGS LORS DE L’UT I LISA TI ON DE L’OUT I L. RI S QUE DE L A CÉ RA T ION. ÉLOI GNE R LE S MA INS

ET L ES DOIGTS DE LA LAME. NE PAS RETIRER LES PI ÈCES COINCÉES OU LES CHUT ES AVANT L’ARRÊT COMPLET DE LA L AME ET

DE L’OUTIL . DÉBRANCHER L’APPAREIL DE LA SOURCE D’ALI MENTATION AVANT TOUTES RÉPARATIONS OU RÉGLAGES. S’ ASSURER

QUE LES DE NTS DE LA LA ME P OINTENT VE RS LE BA S , E N DIRECTION DE LA TABLE. MA I NTENI R LE RÉ GLAGE CORRE CT DE

L’ALIGNEMENT ET LA TENSION DE LA LAME, DES GUIDES DE LAME ET DES PALIERS DE BUTÉE. TOUJOURS FIXER SOLIDEMENT

LA PI ÈCE AVANT DE LA COUPER ET UTILI SER UN SUPPORT AUXIL I AI RE POUR LES PI ÈCES LONGUES. TOUJOURS UTI L I SER LES

DI S P OS IT I FS DE P ROTE CT I ON E T L E S M A INT E NI R E N P LACE . RÉ GL E R LE P ROT È GE - LAME /GUI DE S UP É RI E UR À MOI NS DE 6 ,3 5

MM (1/4 PO) DE LA PIÈCE. T OUJOURS APPUYER SOLI DEMENT LA PI ÈCE CONTRE LA TABLE LORS DE LA COUPE. RIS QUE DE CHOC

ÉLECTRIQUE. NE PAS L’EXPOSER À LA PLUIE ET NE PAS L’UTIL I SER DANS UN ENDROIT HUMIDE. NE PAS UTILISER L’APPAREIL

SOUS L’ E M P RIS E DE DROGUE S , D’A LCOOL OU DE MÉ DI CA ME NT.

OPERA TING BA NDS A W. ALWAYS WEAR PROPER EYE AND RESPIRATORY PROTECTION

.

1-800-223-7278

PARA REDUCIR EL RIESGO DE LESIONES, EL USUARIO DEBE LEER EL MANUAL

DE I NS TRUCCI ONE S ANT E S DE OPE RA R L A S IERRA DE BA NDA . SIEMPRE USE

L’ UT IL I S A TEUR DOIT LI RE LE MODE D’ E M PL OI AV A NT D’UT I LI S E R

L A S CI E À LAM E RUBA N A F IN DE RÉ DUI RE L E RI S QUE DE BLES S URE .

for a free replacement.

A16208

24 - English

Page 25

SERVICE AND REPAIRS

All quality tools will eventually require servicing and/or replacement of parts. For information about Delta Machinery, its factoryowned branches, or an Authorized Warranty Service Center, visit our website at www.deltamachinery .com or call our Customer

Care Center at 1-800-223-7278. All repairs made by our service centers are fully guaranteed against defective material and

workmanship. We cannot guarantee repairs made or attempted by others.

You can also write to us for information at Delta Machinery, 4825 Highway 45 North, Jackson, Tennessee 38305 - Attention:

Product Service. Be sure to include all of the information shown on the nameplate of your tool (model number, type, serial number,

etc.)

ACCESSORIES

A complete line of accessories is available from your Delta Supplier, Porter-Cable • Delta Factory Service Centers, and

Delta Authorized Service Stations. Please visit our Web Site www.deltamachinery.com for a catalog or for the name of

your nearest supplier.

Since accessories other than those offered by Delta have not been tested with this product, use

of such accessories could be hazardous. For safest operation, only Delta recommended accessories should be

used with this product.

WARRANTY

To register your tool for warranty service visit our website at www.deltamachinery.com.

Two Year Limited New Product Warranty

Delta will repair or replace, at its expense and at its option, any new Delta machine, machine part, or machine accessory which in normal

use has proven to be defective in workmanship or material, provided that the customer returns the product prepaid to a Delta factory service

center or authorized service station with proof of purchase of the product within two years and provides Delta with reasonable opportunity

to verify the alleged defect by inspection. For all refurbished Delta product, the warranty period is 180 days. Delta may require that electric

motors be returned prepaid to a motor manufacturer’ s authorized station for inspection and r epair or replacement. Delta will not be responsible

for any asserted defect which has resulted from normal wear, misuse, abuse or repair or alteration made or specifically authorized by anyone

other than an authorized Delta service facility or representative. Under no circumstances will Delta be liable for incidental or consequential

damages resulting from defective products. This warranty is Delta’ s sole warranty and sets forth the customer’s exclusive remedy, with respect

to defective products; all other warranties, express or implied, whether of merchantability, fitness for purpose, or otherwise, are expressly

disclaimed by Delta.

25 - English

Page 26

LES INSTRUCTIONS IMPORTANTES DE SURETE

d'utiliser n'importe quel outil ou n'importe quel équipement. En utilisant les outils ou l'équipement,

les précautions de sûreté fondamentales toujours devraient être suivies pour réduire le risque de

blessure personnelle. L'opération déplacée, l'entretien ou la modification d'outils ou d'équipement ont

pour résultat la blessure sérieux et les dommages de propriété. Il y a de certaines applications pour lequel outils et

l'équipement sont conçus. La Delta Machinery recommande avec force que ce produit n'ait pas modifié et/ou utilisé

pour l'application autrement que pour lequel il a été conçu.

Si vous avez n'importe quelles questions relatives à son application n'utilisent pas le produit jusqu'à ce que vous

avez écrit Delta Machinery et nous vous avons conseillé. La forme en ligne de contact à www.deltamachinery.com

Courrier Postal: Technical Service Manager, Delta Machinery, 4825 Highway 45 North, Jackson, TN 38305.

125 Mural St. Suite 300, Richmond Hill, ON, L4B 1M4.

Information en ce qui concerne l'opération sûre et correcte de cet outil est disponible des sources suivantes:

• Power Tool Institute, 1300 Sumner Avenue, Cleveland, OH 44115-2851 ou en ligne www.powertoolinstitute.org

• National Safety Council, 1121 Spring Lake Drive, Itasca, IL 60143-3201

• American National Standards Institute, 25 West 43rd Street, 4 floor, New York, NY 10036 www.ansi.org - ANSI 01.1

Safety Requirements for Woodworking Machines

• U.S. Department of Labor regulations www.osha.gov

Lire et comprendre toutes instructions d'avertissements et opération avant

Dans Canada,

MESURES DE SÉCURITÉ - DÉFINITIONS

Ce guide contient des renseignements importants que vous deviez bien saisir. Cette information porte sur VOTRE SÉCURITÉ

et sur LA PRÉVENTION DE PROBLÈMES D’ÉQUIPEMENT. Afin de vous aider à identifier cette information, nous avons

utilisé les symboles ci-dessous. Veuillez lire attentivement ce guide en portant une attention particulière à ces

sections.

Indique un danger imminent qui, s'il n'est pas évité, causera de graves blessures ou la mort.

ou la mort

dommages; mineures ou moyennes.

.

Indique la possibilité d’un danger qui, s’il n’est pas évité, pourrait causer de graves blessures

Indique la possibilité d’un danger qui, s’il n’est pas évité, peut causer des dommages à la propriété.

S

ans le symbole d’alerte.

Indique la possibilité d'un danger qui, s'il n'est pas évité,

peut causer des

LA PROPOSITION DE CALIFORNIE 65

activités de construction peut contenir des produits chimiques qui sont reconnus, par l'état de la Californie, de causer

le cancer, les anomalies congénitales ou autres maux de reproduction. Ces produits chimiques comprennent, entre

autres :

• le plomb provenant des peintures à base de plomb;

• la silice cristalline provenant de briques, de béton ou d'autres produits de maçonnerie

• l'arsenic et le chrome provenant du bois de charpente traité chimiquement

Le risque d'exposition à ces produits dépend de la fréquence d'exécution de ce genre de travaux. Afin de réduire l'exposition

à ces produits chimiques, travaillez dans un endroit bien aéré et utilisez de l'équipement de sécurité approuvé,

un masque facial ou respirateur homologué MSHA/NIOSH bien ajusté lorsque vous utilisez de tels outils.

La poussière produite par le ponçage électrique le sciage, le meulage, le perçage et autres

portez toujours

CONSERVEZ CES INSTRUCTIONS!

26 - French

Page 27

RÈGLES DE SÉCURITÉ GÉNÉRALES

directives sur la sécurité, l’assemblage, l’utilisation et l’entretien de ce Guide de l’utilisateur.

Lisez le Guide de l’utilisateur. Ne tentez pas d’utiliser cet appareil avant d’avoir lu les

L ’INOBSERVATION DE CES RÈGLES PEUT CONDUIRE À DES BLESSURES GRAVES.

1. POUR SA SÉCURITÉ PERSONNELLE, LIRE LA NOTICE

D’UTILISATION, AVANT DE METTRE LA MACHINE EN

MARCHE, et pour aussi apprendre l’application et les limites de

la machine ainsi que les risques qui lui sont particuliers ainsi, les

possibilités d’accident et de blessures seront beaucoup réduites.

2. PORTEZ DES DISPOSITIFS DE PROTECTION DES YEUX ET DE

L'OUÏE. UTILISEZ TOUJOURS DES LUNETTES DE SÉCURITÉ.

Des lunettes ordinaires ne constituent PAS des lunettes de sécurité.

UTILISEZ DES ÉQUIPEMENTS DE SÛRETÉ HOMOLOGUÉS.

Les dispositifs de protection des yeux doivent être conformes aux

normes ANSI Z87.1. Les dispositifs de protection de l'ouïe doivent

être conformes aux normes ANSI S3.19.

3. PORTER UNE TENUE APPROPRIÉE. Pas de cravates, de gants,

ni de vêtements amples. Enlever montre, bagues et autres bijoux.

Rouler les manches. Les vêtements ou les bijoux qui se trouvent

pris dans les pièces mobiles peuvent entraîner des blessures.

4. NE PAS UTILISER LA MACHINE DANS UN ENVIRONNEMENT

DANGEREUX. L’utilisation d’outils électriques dans des endroits

humides ou sous la pluie peut entraîner des décharges électriques

ou une électrocution. Garder la zone de travail bien éclairée pour

éviter de trébucher ou d’exposer les doigts, les mains ou les bras à

une situation dangereuse.

5. GARDER LES OUTILS ET LES MACHINES EN PARFAIT ÉTAT.

Garder les outils affûtés et propres afin d’obtenir le meilleur et le

plus sûr rendement. Suivre les instructions pour lubrifier et changer

les accessoires. Les outils et les machines mal entretenus peuvent

se dégrader davantage, et/ou entraîner des blessures.

6. INSPECTER LES PIÈCES POUR DÉCELER TOUT DOMMAGE.

Avant d’utiliser la machine, la vérifier pour voir s’il n’y a pas de

pièces endommagées. Vérifier l’alignement des pièces mobiles et si

ces pièces ne se coincent pas, la rupture de pièces, ou toute autre

condition pouvant en affecter le fonctionnement. Toute pièce ou

protecteur endommagé doit être réparé ou remplacé. Les pièces

endommagées peuvent dégrader davantage la machine et/ou

entraîner des blessures.

7. GARDER L’AIRE DE TRAVAIL PROPRE. Les zones et établis

encombrés favorisent les accidents.

8. GARDER LES ENFANTS ET LES VISITEURS À DISTANCE.

L’atelier est un lieu potentiellement dangereux. Les enfants et les

visiteurs peuvent se blesser .

9. ÉVITER LE DÉMARRAGE ACCIDENTEL. S’assurer que

l’interrupteur est sur « OFF » (ARRÊT) avant de brancher le cordon.

En cas de coupure de courant, placer l’interrupteur à la position

« OFF » (ARRÊT). Un démarrage accidentel peut entraîner des

blessures.

10. UTILISER LES DISPOSITIFS PROTECTEURS. Vérifier que tous les

dispositifs protecteurs sont bien en place, bien fixés et en bon état

de marche pour éviter les blessures.

11. ENLEVER LES CLÉS DE RÉGLAGE ET CELLES DE SERRAGE

AVANT DE METTRE LA MACHINE EN MARCHE. Les outils, les

chutes et les autres débris peuvent être projetés violemment et

blesser .

12. UTILISER LA BONNE MACHINE. Ne pas forcer la machine ou

l’accessoire à faire un travail pour lequel il n’a pas été conçu. Des

dommages à la machine et/ou des blessures pourraient s’ensuivre.

13. UTILISER LES ACCESSOIRES RECOMMANDÉS. L’utilisation

d’accessoires non recommandés par Delta peut endommager la

machine et blesser l’utilisateur .

14. UTILISER LE CORDON PROLONGATEUR APPROPRIÉ.

S’assurer que le cordon prolongateur est en bon état. Lorsqu’un

cordon prolongateur est utilisé, s’assurer que celui-ci est d’un

calibre suffisant pour l’alimentation nécessaire à la machine. Un

cordon d’un calibre insuffisant entraînera une perte de tension

d’où une perte de puissance et surchauffe. Voir le tableau sur les

cordons prolongateurs pour obtenir le calibre approprié selon la

longueur du cordon et l’ampérage de la machine. S’il y a un doute,

utiliser un cordon d’un calibre supérieur. Plus le chiffre est petit, plus

le fil est gros.

15. FIXER LA PIÈCE. Utilisez les brides ou l'étau quand vous ne

pouvez pas fixer l'objet sur la table et contre la barrière à la main ou

quand votre main sera dangereusement près de la lame (à moins

de 6").

16. AVANCER LA PIÈCE DANS LE SENS CONTRAIRE À LA

ROTATION DE LA LAME, DE LA FRAISE OU DE LA SURFACE

ABRASIVE. L’alimentation dans l’autre sens peut entraîner une

projection violente de la pièce.

17. NE P AS FORCER LA MACHINE EN A V ANÇANT LA PIÈCE TROP

VITE. Des dommages et/ou des blessures peuvent s’ensuivre.

18. NE PAS SE PENCHER AU-DESSUS DE LA MACHINE. Une perte

de l’équilibre peut entraîner une chute sur la machine en marche et

causer des blessures.

19. NE JAMAIS MONTER SUR LA MACHINE. On peut se blesser

gravement si la machine bascule ou si l’on touche accidentellement

son outil tranchant.

20. NE JAMAIS LAISSER LA MACHINE EN MARCHE SANS

SURVEILLANCE. COUPER LE COURANT. Ne pas quitter la

machine tant qu’elle n’est pas complètement arrêtée. Un enfant ou

un visiteur pourrait se blesser .

21. METTRE LA MACHINE À L’ARRÊT « OFF » ET LA

DÉBRANCHER avant d’installer ou d’enlever des accessoires,

d’ajuster ou de changer des montages, ou lors des réparations. Un

démarrage accidentel peut entraîner des blessures.

22. METTRE L’ATELIER À L’ABRI DES ENFANTS AU MOYEN

DE CADENAS, D’INTERRUPTEURS PRINCIPAUX OU EN

ENLEVANT LES BOUTONS DES DISPOSITIFS DE MISE EN

MARCHE. Le démarrage accidentel de la machine par un enfant

ou un visiteur peut entraîner des blessures.

23. RESTER VIGILANT, ATTENTIF, ET FAIRE PREUVE DE BON

SENS. NE PAS UTILISER LA MACHINE LORSQUE L’ON EST

FATIGUÉ OU SOUS L’INFLUENCE DE DROGUES, D’ALCOOL

OU DE MÉDICAMENTS. Un instant d’inattention lors de l’utilisation

d’outils électriques peut entraîner des blessures graves.

24.

PEUT PRODUIRE ET DISPERSER DE LA POUSSIÈRE OU

D'AUTRES PARTICULES EN SUSPENSION DANS L'AIR,

TELLES QUE LA SCIURE DE BOIS, LA POUSSIÈRE DE

SILICIUM CRISTALLIN ET LA POUSSIÈRE D'AMIANTE. Dirigez

les particules loin du visage et du corps. Faites toujours fonctionner

l'outil dans un espace bien ventilé et prévoyez l'évacuation de la

poussière. Utilisez un système de dépoussiérage chaque fois que

possible. L'exposition à la poussière peut causer des problèmes

de santé graves et permanents, respiratoires ou autres, tels que

la silicose (une maladie pulmonaire grave) et le cancer, et même le

décès de la personne affectée. Évitez de respirer de la poussière et

de rester en contact prolongé avec celle-ci. En laissant la poussière

pénétrer dans vos yeux ou votre bouche, ou en la laissant

reposer sur votre peau, vous risquez de promouvoir l'absorption

de substances toxiques. Portez toujours des dispositifs de

protection respiratoire homologués par NIOSH/OSHA, appropriés à

l'exposition à la poussière et de taille appropriée, et lavez à l'eau et

au savon les surfaces de votre corps qui ont été exposées.

L'UTILISATION DE CET OUTIL

27 - French

Page 28

RÈGLES SPÉCIFIQUES ADDITIONNELLES DE SÛRETÉ

L’inobservation de ces règles peut se solder par des blessures graves.

1. NE PAS FAIRE FONCTIONNER CET APPAREIL avant qu’il ne

soit assemblé et installé conformément aux directives.

2. CONSULTER le superviseur, instructeur, ou autre

personne qualifiée si vous n’êtes pas familiarisé avec le

fonctionnement de cet outil.

3. SUIVRE TOUS LES CODES DE CÂBLAGE et les connexions

électriques recommandées.

4. UTILISER LES DISPOSITIFS DE PROTECTION CHAQUE

FOIS QUE POSSIBLE. Vérifier qu’ils sont bien en place,

correctement réglés, fixés et fonctionnent correctement.

5. UTILISER LA BONNE T AILLE DE LAME et le bon type.

6. AJUSTER LE GUIDE SUPÉRIEUR DE LA LAME pour qu’il soit

environ à 3,2 mm (1/8 po) au-dessus de la pièce.

7. AJUSTER CORRECTEMENT la tension de la lame,

l’alignement, les guides de lame et les roulements d’appui

de la lame.

8. ÉLOIGNER LES BRAS, MAINS, ET LES DOIGTS de la lame.

9. ÉVITER LES OPÉRATIONS MALADROITES et éviter de placer

les mains à un endroit où un glissement soudain pourrait

amener la main sur la lame.

10. NE JAMAIS DÉMARRER L’APPAREIL avant d’avoir

débarrassé la table de tous les objets (outils, déchets de

découpe, etc.).

11. NE JAMAIS DÉMARRER L’APPAREIL avec la pièce contre la

lame.

12. TENIR FERMEMENT LA PIÈCE contre la table. NE P AS

essayer de scier une pièce qui ne comporte pas un côté plat

contre la table.

13. TENIR FERMEMENT LA PIÈCE et l’acheminer sous la lame à

une vitesse modérée.

14. NE JAMAIS SE PENCHER SOUS LA TABLE alors que

l’appareil est en marche.

15. ÉTEINDRE L’APPAREIL pour reculer lors d’une coupe

incomplète ou d’une lame coincée.

16. FAIRE DES COUPES DE « REDRESSEMENT » avant de

couper de longues courbes.

17. ÉTEINDRE L’APPAREIL et attendre que la lame s’immobilise

avant de nettoyer la section de la lame, de retirer les

débris près de la lame, de retirer et de fixer la pièce ou de

modifier l’angle de la table. Une lame débrayée peut être

dangereuse.

18. NE JAMAIS EFFECTUER D’OPÉRA TIONS DE TRAÇAGE,

D’ASSEMBLAGE, ou de réglage sur la table/l’espace de

travail lorsque l’appareil est en marche.

19. ÉTEINDRE L’APPAREIL ET COUPER LE COURANT avant

d’installer ou de retirer des accessoires, avant tout réglage

ou modifications de ceux-ci ou lors de réparations.

20. ÉTEINDRE L’APPAREIL, couper le courant, et nettoyer

la table/l’espace de travail avant de quitter l’appareil.

VERROUILLER L ’INTERRUPTEUR EN POSITION « D’ARRÊT

» pour éviter toute utilisation non autorisée.

21. DES INFORMATIONS SUPPLÉMENTAIRES (c.-à-d., une

vidéo sur la sécurité), indiquant comment utiliser des

outils électriques correctement et en toute sécurité,

sont disponibles auprès du Power Tool Institute, 1300

Sumner Avenue, Cleveland, OH 44115-2851, États-Unis

(www.powertoolinstitute.com). Des renseignements sont

également disponibles auprès du National Safety Council,

1121 Spring Lake Drive, Itasca, IL 60143-3201 É.-U. Se

reporter à la norme ANSI 01.1 de l’American National

Standards Institute concernant les machines de travail

du bois, ainsi qu’à la réglementation OSHA 1910.213. du

ministère américain du travail.

CONSERVER CES DIRECTIVES.

Les consulter souvent et les utiliser pour donner des directives aux

autres.

28 - French

Page 29

RACCORDEMENTS ÉLECTRIQUES

Un circuit électrique séparé doit être utilisé pour les machines. Les fils de ce circuit doivent être au moins de calibre 12. Ce circuitdoit

être protégé par un fusible temporisé de 20 A. Si on utilise un cordon prolongateur, ce cordon doit être à trois fils, avoir unefiche à

trois broches et une prise de courant à trois cavités, mise à la terre qui correspond à la fiche de la machine. Avant debrancher la

machine, s’assurer que l’interrupteur (les interrupteurs) se trouve(nt) en position « OFF » (ARRÊT) et que le courantélectrique présente

les mêmes caractéristiques que celles qui sont inscrites sur la machine. Toutes les connexions électriquesdoivent établir un bon

contact. Le fonctionnement sur une basse tension endommagera la machine.

Ne pas exposer la machine a la puie, et ne pas l'utiliser dans des endroits humides.

SPÉCIFICATIONS DU MOTEUR

Cette machine est câblée pour un fonctionnement sur un courant alternatif de 120 volts 60 Hz. Avant de brancher la machine,

s’assurer que l’interrupteur se trouve à la position « OFF » (ARRÊT).

INSTRUCTIONS DE MISE À LA TERRE

DÉCHARGES ÉLECTRIQUES.