Page 1

Hollow Chisel

Mortiser

Mortaiseuse

à bédane creux

14-651

Mortajadora de

cincel hueco

A19592 - 09-15-06

Copyright © 2006 Delta Machinery

Instruction Manual

Manuel d’utilisation

Manual de instrucciones

FRANÇAIS (15) ESPAÑOL (27)

www.deltamachinery.com

(800) 223-7278 - US

(800) 463-3582 - CANADA

Page 2

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS ....................2

SAFETY GUIDELINES - DEFINITIONS .....................3

GENERAL SAFETY RULES .......................................3

ADDITIONAL SPECOFOC SAFETY RULES .............4

FUNCTIONAL DESCRIPTION ...................................6

CARTON CONTENTS ...............................................6

ASSEMBLY ................................................................. 7

OPERATION ...............................................................10

TROUBLESHOOTING ................................................12

MAINTENANCE .......................................................... 12

SERVICE ..................................................................... 13

ACCESSORIES ...........................................................13

WARRANTY ................................................................14

FRANÇAIS ..................................................................15

ESPAÑOL .................................................................... 27

IMPORTANT SAFETY INSTRUCTIONS

Read and understand all warnings and operating instructions before using any tool

or equipment. When using tools or equipment, basic safety precautions should always be followed

to reduce the risk of personal injury. Improper operation, maintenance or modification of tools or

equipment could result in serious injury and property damage. There are certain applications for which

tools and equipment are designed. Delta Machinery strongly recommends that this product NOT be modified and/or

used for any application other than for which it was designed.

If you have any questions relative to its application DO NOT use the product until you have written Delta Machinery and

we have advised you. Contact us online at www.deltamachinery.com or by mail at Technical Service Manager, Delta

Machinery, 4825 Highway 45 North, Jackson, TN 38305. In Canada,125 Mural St. Suite 300, Richmond Hill, ON, L4B 1M4)

Information regarding the safe and proper operation of this tool is available from the following sources:

• Power Tool Institute, 1300 Sumner Avenue, Cleveland, OH 44115-2851or online at www.powertoolinstitute.org

• National Safety Council, 1121 Spring Lake Drive, Itasca, IL 60143-3201

• American National Standards Institute, 25 West 43rd Street, 4 floor, New York, NY 10036 www.ansi.org - ANSI 01.1

Safety Requirements for Woodworking Machines

• U.S. Department of Labor regulations www.osha.gov

SAVE THESE INSTRUCTIONS!

SAFETY GUIDELINES - DEFINITIONS

It is important for you to read and understand this manual. The information it contains relates to protecting YOUR SAFETY

and PREVENTING PROBLEMS. The symbols below are used to help you recognize this information.

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious

injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious

injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate

injury.

Used without the safety alert symbol indicates a potentially hazardous situation which, if not avoided,

may result in property damage.

CALIFORNIA PROPOSITION 65

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities

contains chemicals known to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment, al ways

wear NIOSH/OSHA approved, properly fit ting face mask or res pi ra tor when us ing such tools.

2 - English

Page 3

GENERAL SAFETY RULES

Failure to follow these rules may result in serious personal injury.

1. FOR YOUR OWN SAFETY, READ THE INSTRUCTION

MANUAL BEFORE OPERATING THE MACHINE. Learning

the machine’s application, limitations, and specific hazards

will greatly minimize the possibility of accidents and injury.

2. WEAR EYE AND HEARING PROTECTION. ALWAYS

USE SAFETY GLASSES. Everyday eyeglasses are NOT

safety glasses. USE CERTIFIED SAFETY EQUIPMENT.

Eye protection equipment should comply with ANSI Z87.1

standards. Hearing equipment should comply with ANSI

S3.19 standards.

3. WEAR PROPER APPAREL. Do not wear loose clothing,

gloves, neckties, rings, bracelets, or other jewelry which may

get caught in moving parts. Nonslip protective footwear is

recommended. Wear protective hair covering to contain long

hair.

4. DO NOT USE THE MACHINE IN A DANGEROUS

ENVIRONMENT. The use of power tools in damp or wet

locations or in rain can cause shock or electrocution. Keep

your work area well-lit to prevent tripping or placing arms,

hands, and fingers in danger.

5. MAINTAIN ALL TOOLS AND MACHINES IN PEAK

CONDITION. Keep tools sharp and clean for best and safest

performance. Follow instructions for lubricating and changing

accessories. Poorly maintained tools and machines can further

damage the tool or machine and/or cause injury.

6. CHECK FOR DAMAGED PARTS. Before using the machine,

check for any damaged parts. Check for alignment of moving

parts, binding of moving parts, breakage of parts, and any

other conditions that may affect its operation. A guard or any

other part that is damaged should be properly repaired or

replaced with Delta or factory authorized replacement

parts. Damaged parts can cause further damage to the

machine and/or injury.

7. KEEP THE WORK AREA CLEAN. Cluttered areas and benches

invite accidents.

8. KEEP CHILDREN AND VISITORS AWAY. Your shop is a

potentially dangerous environment. Children and visitors can be

injured.

9. REDUCE THE RISK OF UNINTENTIONAL STARTING. Make

sure that the switch is in the “OFF” position before plugging

in the power cord. In the event of a power failure, move the

switch to the “OFF” position. An accidental start-up can cause

injury. Do not touch the plug’s metal prongs when unplugging

or plugging in the cord.

10. USE THE GUARDS. Check to see that all guards are in place,

secured, and working correctly to prevent injury.

11. REMOVE ADJUSTING KEYS AND WRENCHES BEFORE

STARTING THE MACHINE. Tools, scrap pieces, and other

debris can be thrown at high speed, causing injury.

12. USE THE RIGHT MACHINE. Don’t force a machine or an

attachment to do a job for which it was not designed. Damage

to the machine and/or injury may result.

13. USE RECOMMENDED ACCESSORIES. The use of

accessories and attachments not recommended by Delta

may cause damage to the machine or injury to the user.

14. USE THE PROPER EXTENSION CORD. Make sure your

extension cord is in good condition. When using an extension

cord, be sure to use one heavy enough to carry the current

your product will draw. An undersized cord will cause a drop

in line voltage, resulting in loss of power and overheating. See

the Extension Cord Chart for the correct size depending on

the cord length and nameplate ampere rating. If in doubt, use

the next heavier gauge. The smaller the gauge number, the

heavier the cord.

15. SECURE THE WORKPIECE. Use clamps or a vise to hold the

workpiece when practical. Loss of control of a workpiece can

cause injury.

16. FEED THE WORKPIECE AGAINST THE DIRECTION OF

THE ROTATION OF THE BLADE, CUTTER, OR ABRASIVE

SURFACE. Feeding it from the other direction will cause the

workpiece to be thrown out at high speed.

17. DON’T FORCE THE WORKPIECE ON THE MACHINE.

Damage to the machine and/or injury may result.

18. DON’T OVERREACH. Loss of balance can make you fall into

a working machine, causing injury.

19. NEVER STAND ON THE MACHINE. Injury could occur if the tool

tips, or if you accidentally contact the cutting tool.

20. NEVER LEAVE THE MACHINE RUNNING UNATTENDED.

TURN THE POWER OFF. Don’t leave the machine until it comes

to a complete stop. A child or visitor could be injured.

21. TURN THE MACHINE “OFF”, AND DISCONNECT THE

MACHINE FROM THE POWER SOURCE before installing or

removing accessories, changing cutters, adjusting or changing

set-ups. When making repairs, be sure to lock the start switch

in the “OFF” position. An accidental start-up can cause injury.

22. MAKE YOUR WORKSHOP CHILDPROOF WITH

PADLOCKS, MASTER SWITCHES, OR BY REMOVING

STARTER KEYS. The accidental start-up of a machine by a

child or visitor could cause injury.

23. STAY ALERT, WATCH WHAT YOU ARE DOING, AND USE

COMMON SENSE. DO NOT USE THE MACHINE WHEN

YOU ARE TIRED OR UNDER THE INFLUENCE OF DRUGS,

ALCOHOL, OR MEDICATION. A moment of inattention while

operating power tools may result in injury.

24.

AND DISBURSE DUST OR OTHER AIRBORNE

PARTICLES, INCLUDING WOOD DUST, CRYSTALLINE

SILICA DUST AND ASBESTOS DUST. Direct particles away

from face and body. Always operate tool in well ventilated

area and provide for proper dust removal. Use dust collection

system wherever possible. Exposure to the dust may cause

serious and permanent respiratory or other injury, including

silicosis (a serious lung disease), cancer, and death. Avoid

breathing the dust, and avoid prolonged contact with dust.

Allowing dust to get into your mouth or eyes, or lay on your

skin may promote absorption of harmful material. Always use

properly fitting NIOSH/OSHA approved respiratory protection

appropriate for the dust exposure, and wash exposed areas

with soap and water.

USE OF THIS TOOL CAN GENERATE

SAVE THESE INSTRUCTIONS.

Refer to them often and use them to instruct others.

3 - English

Page 4

ADDITIONAL SPECIFIC SAFETY RULES

Failure to follow these rules may result in serious personal injury.

1. DO NOT OPERATE THIS MACHINE until it is completely

assembled and installed according to the instructions. A

machine incorrectly assembled can cause serious injury.

2. OBTAIN ADVICE from your supervisor, instructor, or

another qualified person if you are not thoroughly

familiar with the operation of this machine. Knowledge

is safety.

3. FOLLOW ALL WIRING CODES and recommended electrical

connections to prevent shock or electrocution.

4. SECURE THE MACHINE TO A SUPPORTING SURFACE.

Vibration can cause the machine to slide, walk, or tip over.

5. NEVER START THE MACHINE BEFORE CLEARING

THE TABLE OF ALL OBJECTS (tools, scrap pieces,

etc.). Debris can be thrown at high speed.

6. NEVER START THE MACHINE with the drill bit or

cutting tool against the workpiece. Loss of control of the

workpiece can cause serious injury.

7. PROPERLY LOCK THE DRILL BIT OR CUTTING TOOL IN

THE UNIT before operating this machine.

8. ADJUST the depth stop to avoid drilling into the table.

9. DO NOT attempt to mortise material that does not have

a flat surface, unless a suitable support is used.

10. USE ONLY DRILL BITS, CUTTING TOOLS, OR OTHER

ACCESSORIES with shank size recommended in your

instruction manual. The wrong size accessory can cause

damage to the machine and/or serious injury.

11. USE ONLY DRILL BITS OR CUTTING TOOLS that are

not damaged. Damaged items can cause malfunctions

that lead to injuries.

12. USE RECOMMENDED SPEEDS for all operations. Other

speeds may cause the machine to malfunction causing

damage to the machine and/or serious injury.

13. AVOID AWKWARD OPERATIONS AND HAND

POSITIONS. A sudden slip could cause a hand to move

into the bit.

14. KEEP ARMS, HANDS, AND FINGERS away from the

bit. Serious injury to the hand can occur.

15. ALWAYS position the holddown directly over the

workpiece to prevent the workpiece from lifting during

operation. Loss of control of the workpiece can cause

serious injury.

16. TURN THE MACHINE “OFF” AND WAIT FOR THE DRILL

BIT, CUTTING TOOL, OR SANDING DRUM TO STOP

TURNING prior to cleaning the work area, removing

debris, removing or securing work-piece, or changing

the angle of the table. A moving drill bit or cutting tool

can cause serious injury.

17. PROPERLY SUPPORT LONG OR WIDE work-pieces.

Loss of control of the workpiece can cause severe

injury.

18. NEVER PERFORM LAYOUT, ASSEMBLY OR SET-UP

WORK on the table/work area when the machine is

running. Serious injury can result.

19. TURN THE MACHINE “OFF”, disconnect the machine

from the power source, and clean the table/work area

before leaving the machine. LOCK THE SWITCH IN

THE “OFF” POSITION to prevent unauthorized use.

Someone else might accidentally start the machine and

cause serious injury to themselves.

20. ADDITIONAL INFORMATION regarding the safe

and proper operation of power tools (i.e. a safety

video) is available from the Power Tool Institute, 1300

Sumner Avenue, Cleveland, OH 44115-2851 (www.

powertoolinstitute.com). Information is also available

from the National Safety Council, 1121 Spring Lake

Drive, Itasca, IL 60143-3201. Please refer to the

American National Standards Institute ANSI 01.1 Safety

Requirements for Woodworking Machines and the U.S.

Department of Labor OSHA 1910.213 Regulations.

SAVE THESE INSTRUCTIONS.

Refer to them often and use them to instruct others.

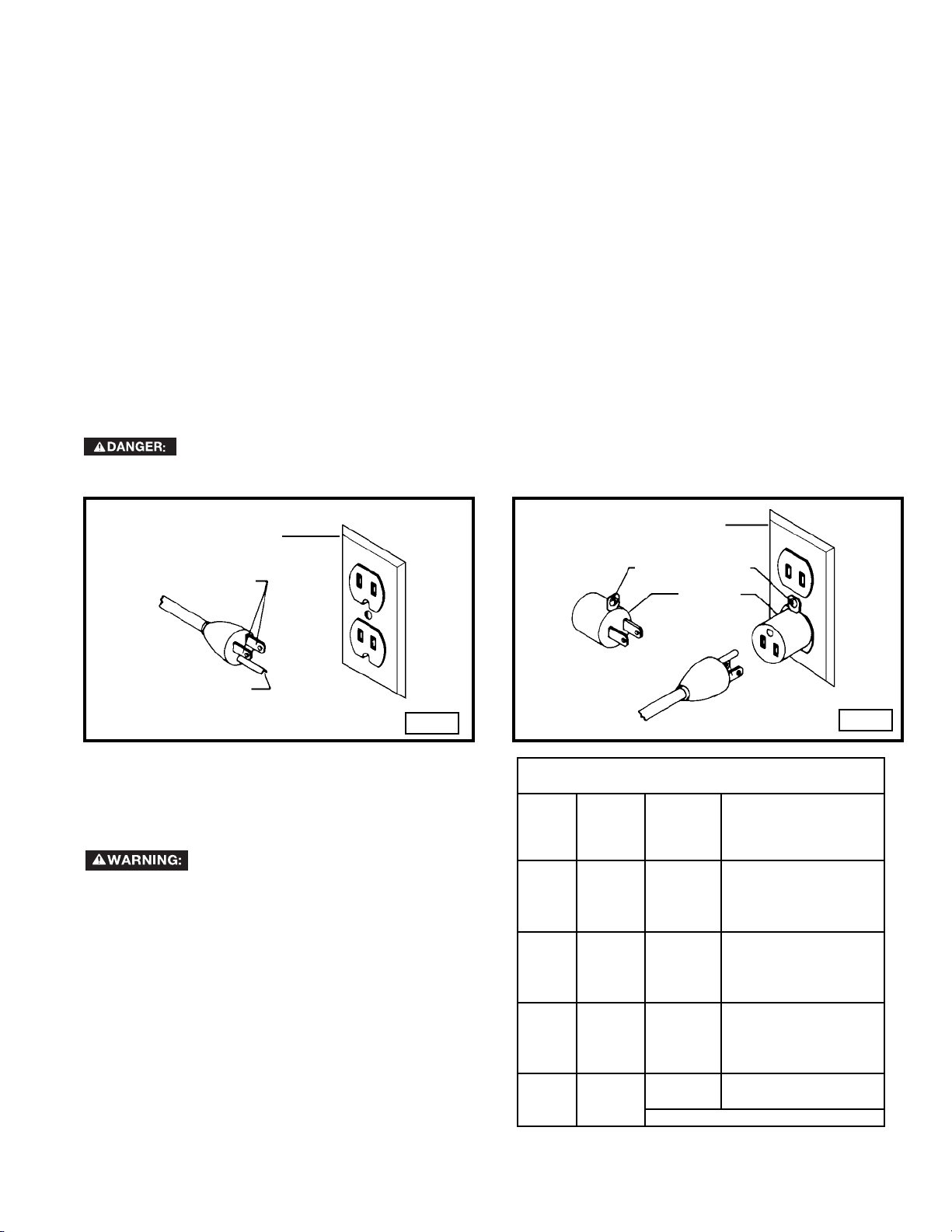

POWER CONNECTIONS

A separate electrical circuit should be used for your machines. This circuit should not be less than #12 wire and should

be protected with a 20 Amp time lag fuse. If an extension cord is used, use only 3-wire extension cords which have

3-prong grounding type plugs and matching receptacle which will accept the machine’s plug. Before connecting the

machine to the power line, make sure the switch (s) is in the “OFF” position and be sure that the electric current is of

the same characteristics as indicated on the machine. All line connections should make good contact. Running on low

voltage will damage the machine.

Do not expose the machine to rain or operate the machine in damp locations.

MOTOR SPECIFICATIONS

Your machine is wired for 120 Volt, 60 HZ alternating current. Before connecting the machine to the power source, make

sure the switch is in the “OFF” position.

GROUNDING INSTRUCTIONS

This machine must be grounded while in use to protect the operator from electric shock.

4 - English

Page 5

1. All grounded, cord-connected machines:

In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current to reduce

the risk of electric shock. This machine is equipped with an electric cord having an equipment-grounding conductor and

a grounding plug. The plug must be plugged into a matching outlet that is properly installed and grounded in accordance

with all local codes and ordinances.

Do not modify the plug provided - if it will not fit the outlet, have the proper outlet installed by a qualified electrician.

Improper connection of the equipment-grounding conductor can result in risk of electric shock.The conductor with

insulation having an outer surface that is green with or without yellow stripes is the equipment-grounding conductor. If

repair or replacement of the electric cord or plug is necessary, do not connect the equipment-grounding conductor to a live

terminal.

Check with a qualified electrician or service personnel if the grounding instructions are not completely understood, or if in

doubt as to whether the machine is properly grounded.

Use only 3-wire extension cords that have 3-prong grounding type plugs and matching 3-conductor receptacles that

accept the machine’s plug, as shown in Fig. A.

Repair or replace damaged or worn cord immediately.

2.

Grounded, cord-connected machines intended for use on a supply circuit having a nominal rating less than 150 volts:

If the machine is intended for use on a circuit that has an outlet that looks like the one illustrated in Fig. A, the machine

will have a grounding plug that looks like the plug illustrated in Fig. A. A temporary adapter, which looks like the adapter

illustrated in Fig. B, may be used to connect this plug to a matching 2-conductor receptacle as shown in Fig. B if a

properly grounded outlet is not available. The temporary adapter should be used only until a properly grounded outlet can

be installed by a qualified electrician. The green-colored rigid ear, lug, and the like, extending from the adapter must be

connected to a permanent ground such as a properly grounded outlet box. Whenever the adapter is used, it must be held

in place with a metal screw.

NOTE: In Canada, the use of a temporary adapter is not permitted by the Canadian Electric Code.

qualified electrician check the receptacle.

In all cases, make certain that the receptacle in question is properly grounded. If you are not sure, have a

GROUNDED OUTLET BOX

CURRENT

CARRYING

PRONGS

GROUNDING BLADE

IS LONGEST OF THE 3 BLADES

Fig. A

Fig. A

EXTENSION CORDS

your extension cord is in good condition and is a 3-wire

extension cord which has a 3-prong grounding type

plug and matching receptacle which will accept the

machine’s plug. When using an extension cord, be sure

to use one heavy enough to carry the current of the

machine. An undersized cord will cause a drop in line

voltage, resulting in loss of power and overheating. Fig.

D-1 shows the correct gauge to use depending on the

cord length. If in doubt, use the next heavier gauge. The

smaller the gauge number, the heavier the cord.

Use proper extension cords. Make sure

GROUNDED OUTLET BOX

GROUNDING MEANS

ADAPTER

MINIMUM GAUGE EXTENSION CORD

RECOMMENDED SIZES FOR USE WITH STATIONARY ELECTRIC MACHINES

Total

Ampere

Rating Volts

0-6 120

0-6 120 25-50 16 AWG

0-6 120 50-100 16 AWG

0-6 120 100-150 14 AWG

6-10 120

6-10 120 25-50 16 AWG

6-10 120 50-100 14 AWG

6-10 120 100-150 12 AWG

10-12 120

10-12 120 25-50 16 AWG

10-12 120 50-100 14 AWG

10-12 120 100-150 12 AWG

12-16 120

12-16 120 25-50 12 AWG

12-16 120

Length of

Cord in

Feet

up to

25 18 AWG

up to

25 18 AWG

up to

25 16 AWG

up to

GREATER THAN 50 FEET NOT RECOMMENDED

Fig. D-1

Gauge of Extension

Cord

25 14 AWG

Fig. B

5 - English

Page 6

FUNCTIONAL DESCRIPTION

FOREWORD

The Delta Model 14-651 is easier to operate than a conventional drill press equipped with a mortising attachment. The

model 14-651 is made of cast-iron and steel for rigidity and stability, and comes with a standard 3-jaw type chuck for

positive gripping of mortising bits.

NOTICE: The photo on the manual cover illustrates the current production model. All other illustrations contained in the

manual are representative only and may not depict the actual labeling or accessories included. These are intended to

illustrate technique only.

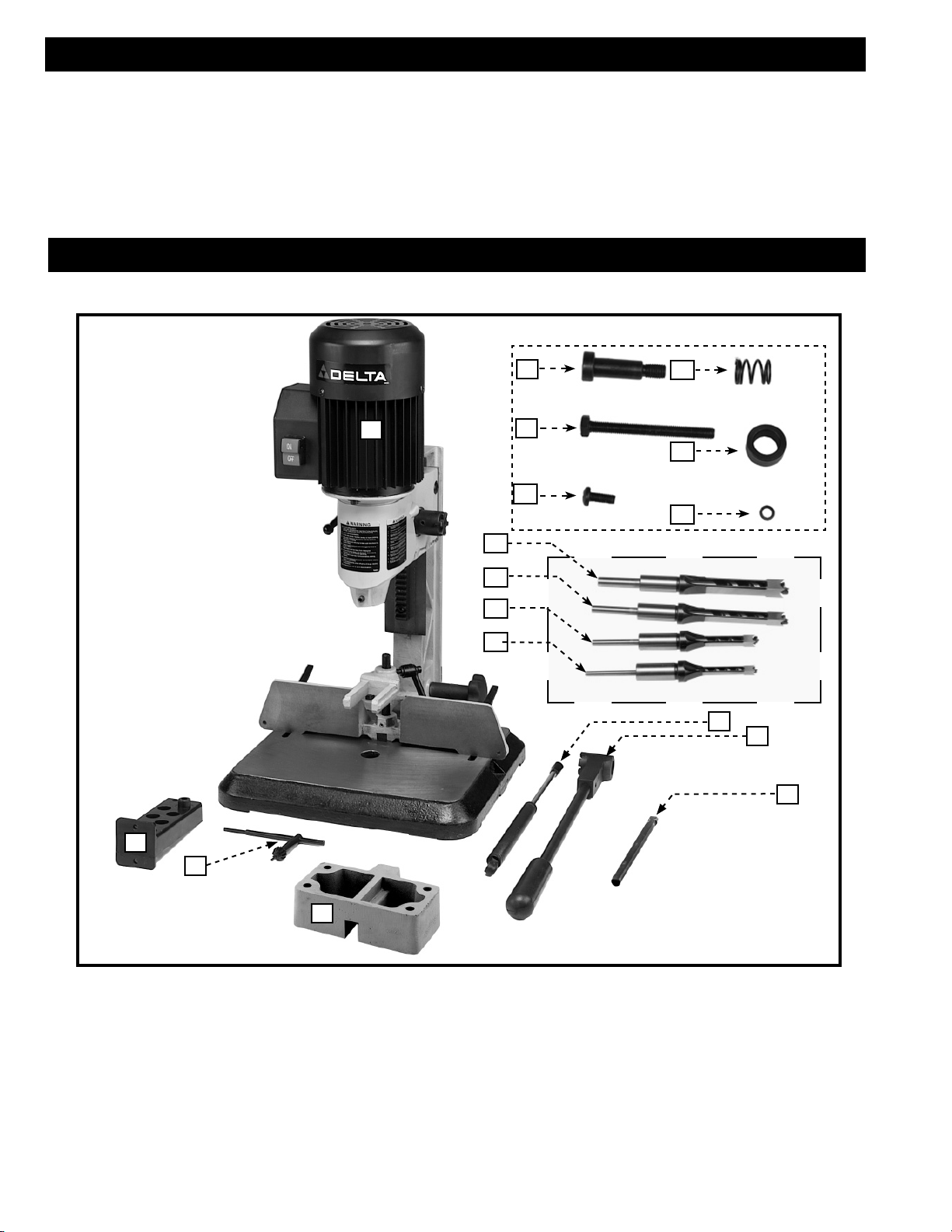

CARTON CONTENTS

8

1

9

11

12

10

13

14

15

16

17

5

6

7

2

3

4

1. Mortiser

2. Tool and Chisel Holder

3. Chuck Key / Wrench

4. Column Extension

5. Hydraulic Cylinder

6. Handle

7. Extended hold-down rod (use with column extension)

8. Special Screw (for raising and lowering handle)

9. M8 x 1.25 x 80mm Head Screw (4) (for attaching column

extension to base)

10. M6 x 1 x 25mm Pan Head Screws (2) (for attaching tool and

chisel holder)

11. Spring

12. Bushing (for use with extra long chisels)

13. M6 Lockwashers (2) (for assembling tool and chisel

holder)

14. 1/2" Mortising Chisel and Bit

15. 3/8" Mortising Chisel and Bit

16. 5/16" Mortising Chisel and Bit

17. 1/4" Mortising Chisel and Bit

6 - English

Page 7

ASSEMBLY

For your own safety, do not connect the machine to the power source until the machine is

completely assembled and you read and understand the entire instruction manual.

ASSEMBLY TOOLS REQUIRED

Chuck Key/Wrench (Supplied)

ASSEMBLY TIME ESTIMATE

Assembly for this machine takes less than 30 minutes.

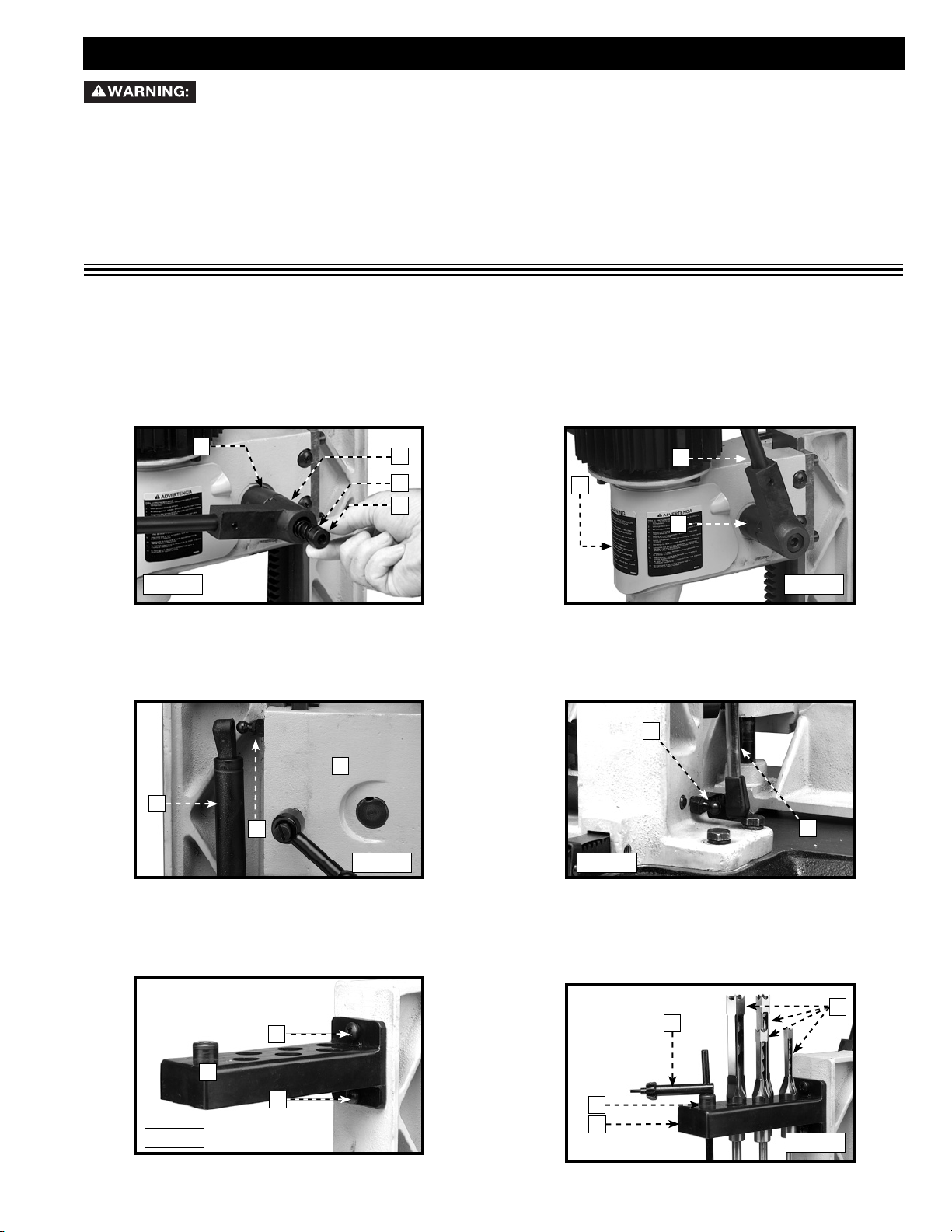

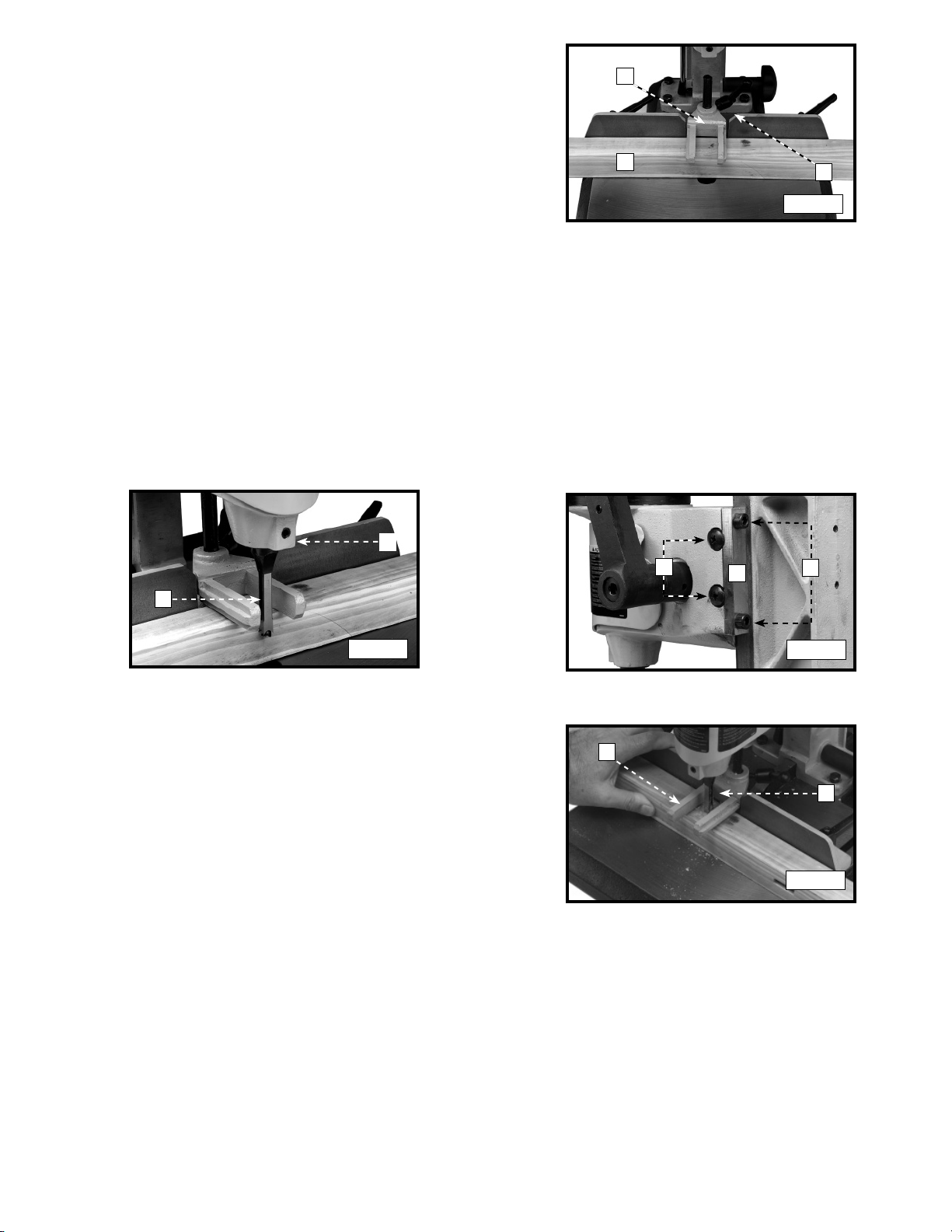

RAISING AND LOWERING THE HANDLE

1. Attach the hub of the handle assembly (A) Fig. 1 to the end of the pinion shaft (B). Fasten the handle to the pinion

shaft using the special screw (C) and spring (D).

2. Raise the mortising machine head (E) Fig. 2 to the "up" position by turning the handle (A) clockwise.

NOTE: The handle (A) is spring-loaded. Reposition it by pulling it out and moving it on pinion shaft (B).

B

Fig. 1

A

D

C

E

A

B

Fig. 2

ATTACHING THE HYDRAULIC CYLINDER

Place the head (A) Fig. 3 in the “up” position. Attach the hydraulic cylinder (B) to the two fittings, one located on the

back of the head (C) Fig. 3, and the other on the column (D) Fig. 4. Push each end of the hydraulic cylinder on its fitting

to secure the cylinder.

D

A

B

C

Fig. 3

Fig. 4

B

ATTACHING THE TOOL AND CHISEL HOLDER

1. Attach the tool and chisel holder (A) Fig. 5 to the back of the column, using the two M6x1x25mm screws (B) and

M6 lockwashers.

2. Fig. 6 illustrates the stored chuck key/wrench (C), bushing (F) for use with extra long chisels, and chisels and bits (E).

E

C

Fig. 6

Fig. 5

B

A

B

7 - English

F

A

Page 8

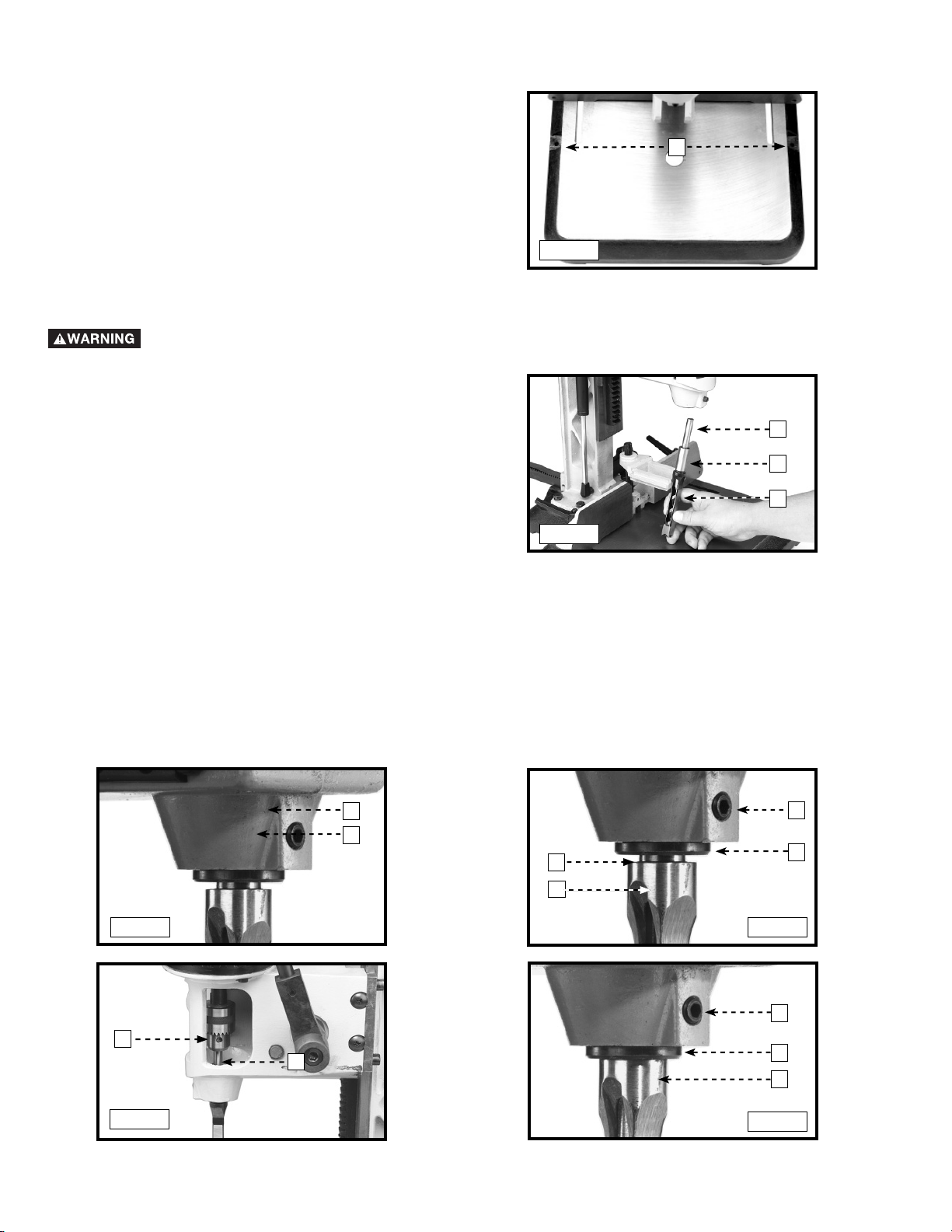

FASTENING THE MACHINE TO A SUPPORTING SURFACE

If the machine has any tendency to tip over, slide,

or walk on the supporting surface, you must secure

the base of the machine to a supporting surface with

fasteners (not supplied) through the two holes (A) Fig. 7,

located in the mortiser base.

Fig. 7

A

ATTACHING THE CHISEL AND BIT

Disconnect the machine from the power source!

1. Insert the bit (A) Fig. 8 in the chisel (B).

A

NOTE: The opening (C) on the side of the chisel (that

allows chips to escape) should always face the side never the front or rear.

Fig. 8

2. Loosen the screw (D) Fig. 9, and push the chisel (B) up through the hole in the head as far as possible. Lower the

chisel (B) 1/16" to 3/16" and tighten the set screw (D).

IMPORTANT: When inserting the chisel (B) Fig. 10 into the head, leave a space of 1/16" to 3/16" clearance (F) between

the bushing (E) and the shoulder of the chisel (B).

3. Push the bit (A) Fig. 11 up through the chisel and into the chuck (G) as far as it will go. Lock the bit in the chuck

using the supplied chuck key.

4. Loosen the set screw (D) Fig. 12, and push the chisel (B) against the bottom of the bushing (E), and tighten the set screw

(D) to provide the proper distance between the cutting lips of the bit and the points of the chisel.

B

C

Fig. 9

G

Fig. 11

D

B

F

B

A

8 - English

D

E

Fig. 10

D

E

B

Fig. 12

Page 9

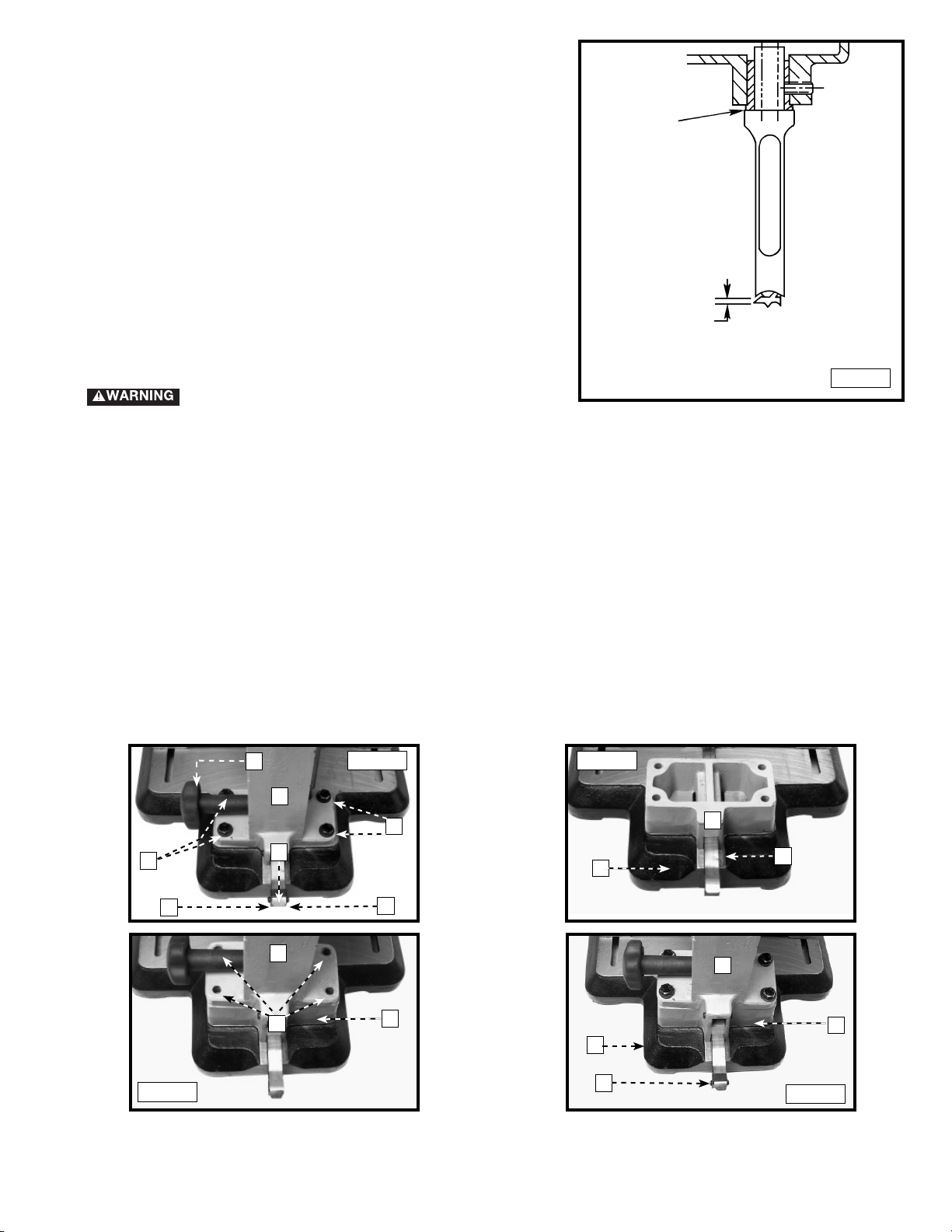

PUSH THE

CHISEL AGAINST

5. Adjust the flat portion of the bit to a minimum of

THE BUSHING

1/16" below the bottom of the chisel. Certain types

of wood may require an increase in this gap up to a

maximum of 3/16".

ADJUST THE BIT IN

THE CHUCK TO GIVE

CLEARANCE

ATTACHING THE COLUMN EXTENSION

1/16" to 3/16"

You can extend the column to mortis taller workpieces.

To extend the column:

Disconnect the machine from the power source!

1. Take out the two screws (B) Fig. 14 and remove the rack cover bracket (D).

2. Remove the four screws and flat washers (A) Fig. 14.

3. Rotate handle (E) until the column assembly (C) Fig. 14 moves off the back of the rack and base.

4. Place the column extension (A) Fig. 15 on top of the rack (B). Align the four holes in the column extension (A) Fig. 15

with the four holes in the base (C).

5. Place the column assembly (C) Fig. 16 on top of the column extension (A) and align the four holes (B) in the column

assembly with the four holes in the column extension (A).

6. Place a flat washer that was removed in STEP 2 on an M8x1.25x80mm hex head screw.

7. Insert the screw through the hole in the column assembly (C) Fig. 17 and the column extension (A). Thread it into the

base (B). Repeat this process for the three remaining holes.

8. Replace the rack cover bracket (D) Fig. 17 that was removed in STEP 1.

9. Loosen the holddown knob (B) Fig. 18 and remove the hold-down. Loosen the set screw (C) and remove the holddown

rod (A) and replace with the extended hold-down rod. Tighten the set screw (C). Place the hold-down (B) on the holddown rod and tighten the hold-down handle (B).

CLEARANCE DEPENDING ON

THE TYPE OF WOOD

Fig. 13

A

B

Fig. 16

E

Fig. 14

Fig. 15

C

A

D

C

A

B

B

C

B

A

C

A

B

D

Fig. 17

9 - English

Page 10

NOTE: Reverse the procedure to remove the column

extension.

To prevent damage to the unit, place the rack

cover over the gear. This action will prevent the cover from

being trapped between the rack and the gear.

A

C

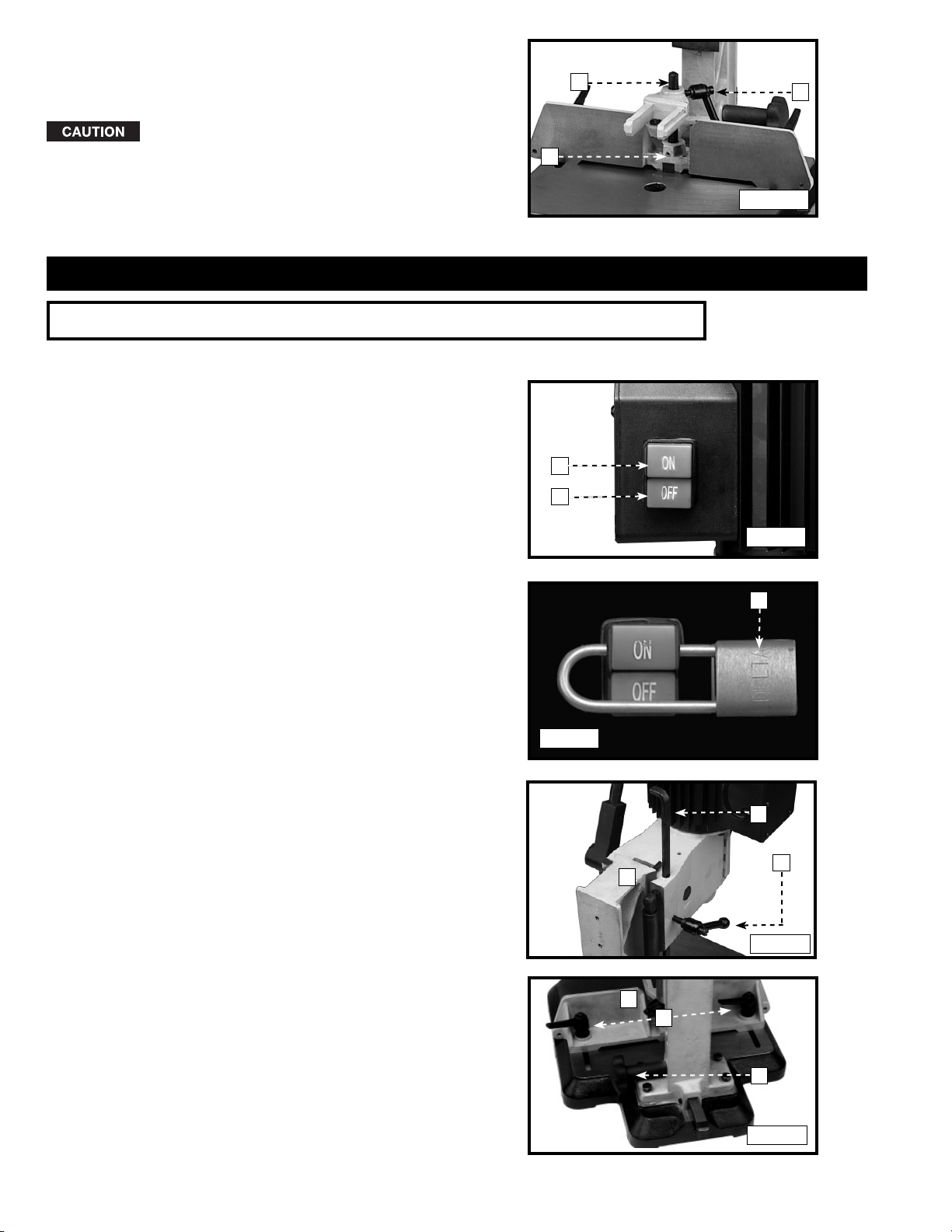

OPERATION

OPERATIONAL CONTROLS AND ADJUSTMENTS

STARTING AND STOPPING THE MACHINE

The power switch is located on the left side of the mortiser.

To turn the mortiser “ON”, press the green start button (A) Fig.

19. To stop the mortiser, push the red button (B).

A

B

B

Fig. 18

LOCKING SWITCH IN THE “OFF” POSITION

IMPORTANT: When the machine is not in use, the switch

should be locked in the "OFF" position to prevent unauthorized

using a padlock (A) Fig. 20 with a 3/16" diameter shackle.

use,

ADJUSTING THE DEPTH STOP ROD

The depth stop rod (A) Fig. 21 limits the depth of the chisel.

To adjust the depth stop rod (A), loosen the lever (C) and

lower the head. When the head is at the desired location,

lower the depth stop rod (A) until it contacts the top of the

column (D) and tighten the lever (C).

ADJUSTING THE FENCE

Fig. 19

A

Fig. 20

A

C

D

Fig. 21

You can move the fence (A) Fig. 22 in or out by loosening

the lock handles (B), and rotating the fence rack handle (C).

Tighten the handles (B) after the move.

NOTE: The levers (B) are spring-loaded and can be repositioned.

Pull out on the lever and reposition it on the serrated nut

located underneath the lever.

10 - English

A

B

C

Fig. 22

Page 11

ADJUSTING THE HOLD-DOWN

The hold-down (C) Fig. 23 prevents the workpiece (E)

from lifting as the chisel rises out of the hole. To adjust

the hold-down, loosen the handle (F), position the holddown so that it just touches the top of the workpiece (E),

then tighten the handle. You can turn the hold-down (C)

upside down to accommodate thicker workpieces.

C

E

F

Fig. 23

ADJUSTING THE CHISEL PARALLEL TO THE WORKPIECE

You can adjust the chisel (A) Fig. 24 parallel to the workpiece by loosening the screw (B) and rotating the chisel until

the back surface of the chisel is touching the workpiece. Tighten the screw (B).

ADJUSTING THE SLIDING FIT BETWEEN THE HEAD AND THE COLUMN

A dovetail gib (A) Fig. 25 ensures a good sliding fit between the head and the column. Make the adjustment by

loosening the two screws (B) and turning the adjusting screws (C). Tighten the two screws (B).

NOTE: The adjustment is correct when no side movement between the gib and the column is evident. Adjust the gib

so that is is not so tight as to restrict the sliding movement or so loose that it affects accuracy.

B

C

A

Fig. 24

1. Keep chisels and bits sharp.

2. A typical mortis operation is illustrated in Fig. 26. Note

that the opening (A) in the chisel is to the right. Move your

workpiece from left to right for subsequent cuts to allow

chips to escape freely.

3. Hold the workpiece firmly against the fence. Ensure that

the hold-down (B) Fig. 28 is properly adjusted. The rate of

penetration of the chisel must be fast enough to prevent

burning at the tip of the bit, but not too fast as to stall

the motor. You may encounter smoke from the bit or the

workpiece. Smoke is a natural operating occurrence, caused by friction and burning of resins. Bluing of the chisel

after initial use is not indicative of a dull chisel, but rather is a combination of friction and built-up resin on the

cutting face of the chisel. You can detect a dull chisel by the amount of excess force required to complete a cut.

4. When performing a through mortise, place a thin piece of wood between the workpiece and the table to prevent

“chip-out” at the bottom of the mortise.

B

A

B

Fig. 25

A

Fig. 26

11 - English

Page 12

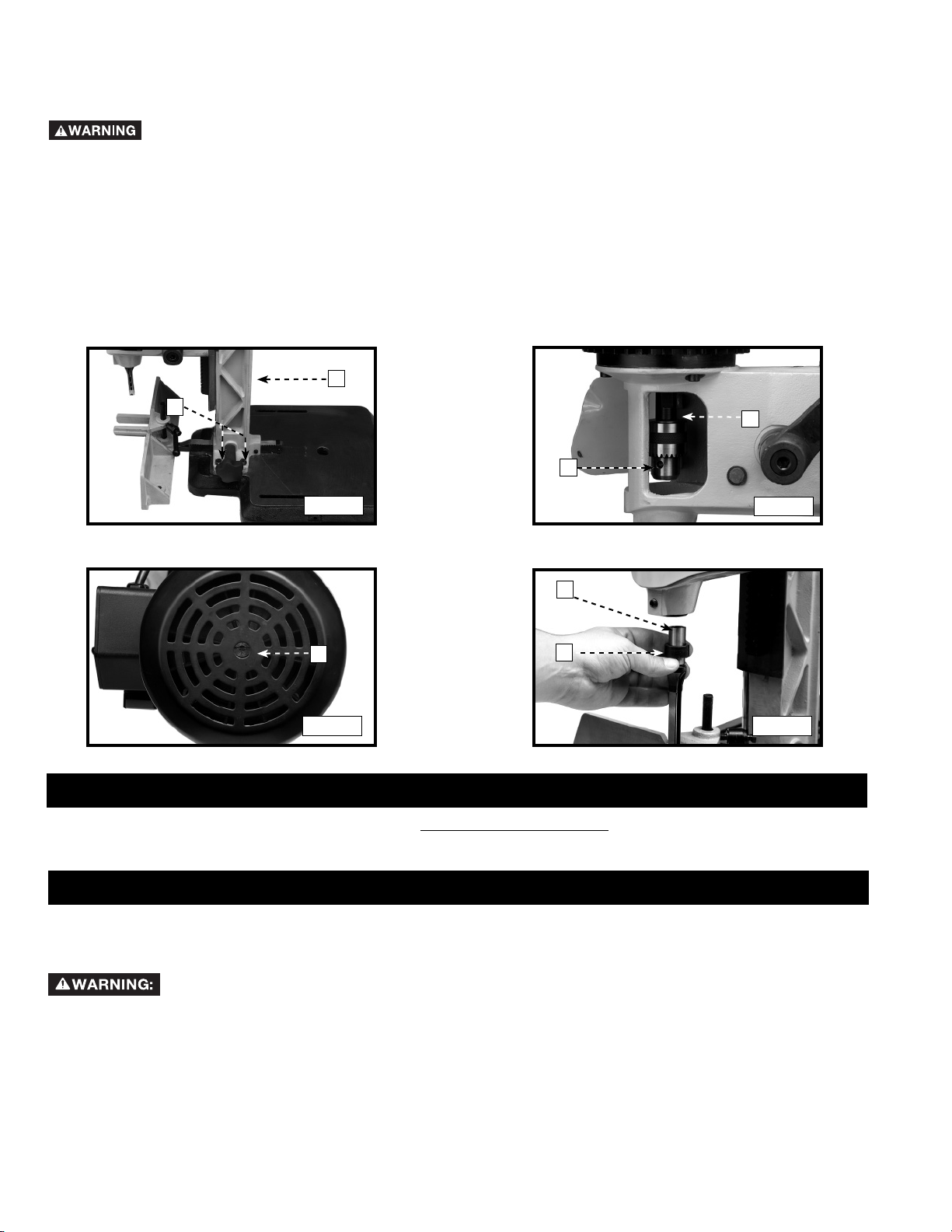

ROTATING THE COLUMN 180 DEGREES

The column (A) Fig. 27 can be rotated 180 degrees for special cuts. To rotate the column, remove the four screws, two

of which are shown at (B), rotate the column (A) 180 degrees, and replace the four screws (B).

You must secure the base to a supporting surface.

USING BITS WITH EXTRA LONG SHANKS

When using bits with extra long shanks, remove the extension (A) Fig. 28. Insert a screwdriver into the slot (B) Fig. 29 in

the end of the armature shaft on top of the motor. Use a chuck key to unscrew and remove the chuck (C) Fig. 28 and

extension (A). Remove the extension (A) from the chuck (C) and replace the chuck (C). You can also use the chisel

spacer. Place the chisel spacer (D) Fig. 30 on the chisel shank (F) and insert the chisel into the chisel holder. Tighten

the chisel holder securely.

A

B

C

Fig. 27

F

B

Fig. 29 Fig. 30

D

A

Fig. 28

TROUBLESHOOTING

For assistance with your machine, visit our website at www.deltamachinery.com for a list of service centers or call the

DELTA Machinery help line at 1-800-223-7278 (In Canada call 1-800-463-3582).

MAINTENANCE

KEEP MACHINE CLEAN

Periodically blow out all air passages with dry compressed air. All plastic parts should be cleaned with a soft damp

cloth. NEVER use solvents to clean plastic parts. They could possibly dissolve or otherwise damage the material.

Wear certified safety equipment for eye, hearing and respiratory protection while using compressed air.

FAILURE TO START

Should your machine fail to start, check to make sure the prongs on the cord plug are making good contact in the

outlet. Also, check for blown fuses or open circuit breakers in the line.

LUBRICATION & RUST PROTECTION

Apply household floor paste wax to the machine table, extension table or other work surface weekly. Or use a commercially

available protective product designed for this purpose. Follow the manufacturer’s instructions for use and safety.

To clean cast iron tables of rust, you will need the following materials: a sheet of medium Scotch-Brite™ Blending Hand

Pad, a can of WD-40® and a can of degreaser. Apply the WD-40 and polish the table surface with the Scotch-Brite pad.

Degrease the table, then apply the protective product as described above.

12 - English

Page 13

SERVICE

REPLACEMENT PARTS

Use only identical replacement parts. For a parts list or to order parts, visit our website at

You can also order parts from your nearest factory-owned branch, or by calling our Customer Care Center at 1-800-223-7278 to

receive personalized support from highly-trained technicians.

FREE WARNING LABEL REPLACEMENT

If your warning labels become illegible or are missing, call

1-800-223-7278

for a free replacement.

servicenet.deltamachinery.com.

SERVICE AND REPAIRS

All quality tools will eventually require servicing and/or replacement of parts. For information about Delta Machinery, its factoryowned branches, or an Authorized Warranty Service Center, visit our website at www.deltamachinery.com or call our Customer

Care Center at 1-800-223-7278. All repairs made by our service centers are fully guaranteed against defective material and

workmanship. We cannot guarantee repairs made or attempted by others.

You can also write to us for information at Delta Machinery, 4825 Highway 45 North, Jackson, Tennessee 38305 - Attention:

Product Service. Be sure to include all of the information shown on the nameplate of your tool (model number, type, serial number,

etc.)

ACCESSORIES

A complete line of accessories is available from your Delta Supplier, Porter-Cable • Delta Factory Service Centers, and

Delta Authorized Service Stations. Please visit our Web Site www.deltamachinery.com for a catalog or for the name of

your nearest supplier.

Since accessories other than those offered by Delta have not been tested with this product, use

of such accessories could be hazardous. For safest operation, only Delta recommended accessories should be

used with this product.

13 - English

Page 14

WARRANTY

To register your tool for warranty service visit our website at www.deltamachinery.com.

Two Year Limited New Product Warranty

Delta will repair or replace, at its expense and at its option, any new Delta machine, machine part, or machine accessory which in normal

use has proven to be defective in workmanship or material, provided that the customer returns the product prepaid to a Delta factory service

center or authorized service station with proof of purchase of the product within two years and provides Delta with reasonable opportunity

to verify the alleged defect by inspection. For all refurbished Delta product, the warranty period is 180 days. Delta may require that electric

motors be returned prepaid to a motor manufacturer’s authorized station for inspection and repair or replacement. Delta will not be responsible

for any asserted defect which has resulted from normal wear, misuse, abuse or repair or alteration made or specifically authorized by anyone

other than an authorized Delta service facility or representative. Under no circumstances will Delta be liable for incidental or consequential

damages resulting from defective products. This warranty is Delta’s sole warranty and sets forth the customer’s exclusive remedy, with respect

to defective products; all other warranties, express or implied, whether of merchantability, fitness for purpose, or otherwise, are expressly

disclaimed by Delta.

14 - English

Page 15

LES INSTRUCTIONS IMPORTANTES DE SURETE

n'importe quel outil ou n'importe quel équipement. En utilisant les outils ou l'équipement, les précautions de sûreté

fondamentales toujours devraient être suivies pour réduire le risque de blessure personnelle. L'opération déplacée,

l'entretien ou la modification d'outils ou d'équipement ont pour résultat la blessure sérieux et les dommages

de propriété. Il y a de certaines applications pour lequel outils et l'équipement sont conçus. La Delta Machinery

recommande avec force que ce produit n'ait pas modifié et/ou utilisé pour l'application autrement que pour lequel il

a été conçu.

Si vous avez n'importe quelles questions relatives à son application n'utilisent pas le produit jusqu'à ce que vous avez écrit

Porter-Cable et nous vous avons conseillé.

Information en ce qui concerne l'opération sûre et correcte de cet outil est disponible des sources suivantes:

American National Standards Institute, 25 West 43rd Street, 4 floor, New York, NY 10036 www.ansi.org ANSI 01.1Safety

Requirements for Woodworking Machines, and the U.S. Department of Labor regulations www.osha.gov

Lire et comprendre toutes instructions d'avertissements et opération avant d'utiliser

La forme en ligne de contact à www.deltamachinery.com

Courrier Postal: Technical Service Manager

Delta Machinery

4825 Highway 45 North

Jackson, TN 38305

Power Tool Institute

1300 Sumner Avenue, Cleveland, OH 44115-2851

www.powertoolinstitute.org

National Safety Council

1121 Spring Lake Drive, Itasca, IL 60143-3201

MESURES DE SÉCURITÉ - DÉFINITIONS

Ce guide contient des renseignements importants que vous deviez bien saisir. Cette information porte sur VOTRE

SÉCURITÉ et sur LA PRÉVENTION DE PROBLÈMES D’ÉQUIPEMENT. Afin de vous aider à identifier cette

information, nous avons utilisé les symboles ci-dessous. Veuillez lire attentivement ce guide en portant une attention

particulière à ces sections.

Indique un danger imminent qui, s'il n'est pas évité, causera de graves blessures ou la mort.

Indique la possibilité d’un danger qui, s’il n’est pas évité, pourrait causer de graves blessures ou

la mort

Indique la possibilité d’un danger qui, s’il n’est pas évité, peut causer des dommages à la

propriété.

S

dommages; mineures ou moyennes.

LA PROPOSITION DE CALIFORNIE 65

activités de construction peut contenir des produits chimiques qui sont reconnus, par l'état de la Californie, de causer

le cancer, les anomalies congénitales ou autres maux de reproduction. Ces produits chimiques comprennent, entre

autres :

• le plomb provenant des peintures à base de plomb;

• la silice cristalline provenant de briques, de béton ou d'autres produits de maçonnerie

• l'arsenic et le chrome provenant du bois de charpente traité chimiquement

Le risque d'exposition à ces produits dépend de la fréquence d'exécution de ce genre de travaux. Afin de réduire l'exposition

à ces produits chimiques, travaillez dans un endroit bien aéré et utilisez de l'équipement de sécurité approuvé,

un masque facial ou respirateur homologué MSHA/NIOSH bien ajusté lorsque vous utilisez de tels outils.

.

ans le symbole d’alerte.

La poussière produite par le ponçage électrique le sciage, le meulage, le perçage et autres

Indique la possibilité d'un danger qui, s'il n'est pas évité,

peut causer des

portez toujours

CONSERVEZ CES INSTRUCTIONS!

15 - French

Page 16

RÈGLES DE SÉCURITÉ GÉNÉRALES

L’inobservation de ces règles peut conduire à des blessures graves.

1. POUR SA SÉCURITÉ PERSONNELLE, LIRE LA NOTICE

D’UTILISATION, AVANT DE METTRE LA MACHINE EN

MARCHE, et pour aussi apprendre l’application et les limites

de la machine ainsi que les risques qui lui sont particuliers ainsi,

les possibilités d’accident et de blessures seront beaucoup

réduites.

2. PORTEZ DES DISPOSITIFS DE PROTECTION DES YEUX

ET DE L'OUÏE. UTILISEZ TOUJOURS DES LUNETTES DE

SÉCURITÉ. Des lunettes ordinaires ne constituent PAS des

lunettes de sécurité. UTILISEZ DES ÉQUIPEMENTS DE

SÛRETÉ HOMOLOGUÉS. Les dispositifs de protection des

yeux doivent être conformes aux normes ANSI Z87.1. Les

dispositifs de protection de l'ouïe doivent être conformes aux

normes ANSI S3.19.

3. PORTER UNE TENUE APPROPRIÉE. Pas de cravates, de

gants, ni de vêtements amples. Enlever montre, bagues et

autres bijoux. Rouler les manches. Les vêtements ou les bijoux

qui se trouvent pris dans les pièces mobiles peuvent entraîner

des blessures.

4. NE PAS UTILISER LA MACHINE DANS UN

ENVIRONNEMENT DANGEREUX. L’utilisation d’outils

électriques dans des endroits humides ou sous la pluie peut

entraîner des décharges électriques ou une électrocution.

Garder la zone de travail bien éclairée pour éviter de trébucher

ou d’exposer les doigts, les mains ou les bras à une situation

dangereuse.

5. GARDER LES OUTILS ET LES MACHINES EN PARFAIT

ÉTAT. Garder les outils affûtés et propres afin d’obtenir le

meilleur et le plus sûr rendement. Suivre les instructions pour

lubrifier et changer les accessoires. Les outils et les machines

mal entretenus peuvent se dégrader davantage, et/ou entraîner

des blessures.

6. INSPECTER LES PIÈCES POUR DÉCELER TOUT

DOMMAGE. Avant d’utiliser la machine, la vérifier pour voir s’il

n’y a pas de pièces endommagées. Vérifier l’alignement des

pièces mobiles et si ces pièces ne se coincent pas, la rupture

de pièces, ou toute autre condition pouvant en affecter le

fonctionnement. Toute pièce ou protecteur endommagé doit

être réparé ou remplacé. Les pièces endommagées peuvent

dégrader davantage la machine et/ou entraîner des blessures.

7. GARDER L’AIRE DE TRAVAIL PROPRE. Les zones et établis

encombrés favorisent les accidents.

8. GARDER LES ENFANTS ET LES VISITEURS À DISTANCE.

L’atelier est un lieu potentiellement dangereux. Les enfants et

les visiteurs peuvent se blesser.

9. ÉVITER LE DÉMARRAGE ACCIDENTEL. S’assurer que

l’interrupteur est sur « OFF » (ARRÊT) avant de brancher le

cordon. En cas de coupure de courant, placer l’interrupteur

à la position « OFF » (ARRÊT). Un démarrage accidentel peut

entraîner des blessures.

10. UTILISER LES DISPOSITIFS PROTECTEURS. Vérifier que tous

les dispositifs protecteurs sont bien en place, bien fixés et en

bon état de marche pour éviter les blessures.

11. ENLEVER LES CLÉS DE RÉGLAGE ET CELLES DE SERRAGE

AVANT DE METTRE LA MACHINE EN MARCHE. Les outils,

les chutes et les autres débris peuvent être projetés violemment

et blesser.

12. UTILISER LA BONNE MACHINE. Ne pas forcer la machine ou

l’accessoire à faire un travail pour lequel il n’a pas été conçu.

Des dommages à la machine et/ou des blessures pourraient

s’ensuivre.

13. UTILISER LES ACCESSOIRES RECOMMANDÉS. L’utilisation

d’accessoires non recommandés par Delta peut endommager

la machine et blesser l’utilisateur.

14. UTILISER LE CORDON PROLONGATEUR APPROPRIÉ.

S’assurer que le cordon prolongateur est en bon état. Lorsqu’un

cordon prolongateur est utilisé, s’assurer que celui-ci est d’un

calibre suffisant pour l’alimentation nécessaire à la machine. Un

cordon d’un calibre insuffisant entraînera une perte de tension

d’où une perte de puissance et surchauffe. Voir le tableau sur

les cordons prolongateurs pour obtenir le calibre approprié

selon la longueur du cordon et l’ampérage de la machine. S’il

y a un doute, utiliser un cordon d’un calibre supérieur. Plus le

chiffre est petit, plus le fil est gros.

15. FIXER LA PIÈCE. Utilisez les brides ou l'étau quand vous ne

pouvez pas fixer l'objet sur la table et contre la barrière à la

main ou quand votre main sera dangereusement près de la

lame (à moins de 6").

16. AVANCER LA PIÈCE DANS LE SENS CONTRAIRE À

LA ROTATION DE LA LAME, DE LA FRAISE OU DE LA

SURFACE ABRASIVE. L’alimentation dans l’autre sens peut

entraîner une projection violente de la pièce.

17. NE PAS FORCER LA MACHINE EN AVANÇANT LA PIÈCE

TROP VITE. Des dommages et/ou des blessures peuvent

s’ensuivre.

18. NE PAS SE PENCHER AU-DESSUS DE LA MACHINE. Une

perte de l’équilibre peut entraîner une chute sur la machine en

marche et causer des blessures.

19. NE JAMAIS MONTER SUR LA MACHINE. On peut se

blesser gravement si la machine bascule ou si l’on touche

accidentellement son outil tranchant.

20. NE JAMAIS LAISSER LA MACHINE EN MARCHE SANS

SURVEILLANCE. COUPER LE COURANT. Ne pas quitter la

machine tant qu’elle n’est pas complètement arrêtée. Un enfant

ou un visiteur pourrait se blesser.

21. METTRE LA MACHINE À L’ARRÊT « OFF » ET LA

DÉBRANCHER avant d’installer ou d’enlever des accessoires,

d’ajuster ou de changer des montages, ou lors des réparations.

Un démarrage accidentel peut entraîner des blessures.

22. METTRE L’ATELIER À L’ABRI DES ENFANTS AU MOYEN

DE CADENAS, D’INTERRUPTEURS PRINCIPAUX OU EN

ENLEVANT LES BOUTONS DES DISPOSITIFS DE MISE

EN MARCHE. Le démarrage accidentel de la machine par un

enfant ou un visiteur peut entraîner des blessures.

23. RESTER VIGILANT, ATTENTIF, ET FAIRE PREUVE DE BON

SENS. NE PAS UTILISER LA MACHINE LORSQUE L’ON

EST FATIGUÉ OU SOUS L’INFLUENCE DE DROGUES,

D’ALCOOL OU DE MÉDICAMENTS. Un instant d’inattention

lors de l’utilisation d’outils électriques peut entraîner des

blessures graves.

24. L'UTILISATION DE CET OUTIL

PEUT PRODUIRE ET DISPERSER DE LA POUSSIÈRE OU

D'AUTRES PARTICULES EN SUSPENSION DANS L'AIR,

TELLES QUE LA SCIURE DE BOIS, LA POUSSIÈRE DE

SILICIUM CRISTALLIN ET LA POUSSIÈRE D'AMIANTE.

Dirigez les particules loin du visage et du corps. Faites

toujours fonctionner l'outil dans un espace bien ventilé et

prévoyez l'évacuation de la poussière. Utilisez un système

de dépoussiérage chaque fois que possible. L'exposition à

la poussière peut causer des problèmes de santé graves et

permanents, respiratoires ou autres, tels que la silicose (une

maladie pulmonaire grave) et le cancer, et même le décès

de la personne affectée. Évitez de respirer de la poussière

et de rester en contact prolongé avec celle-ci. En laissant la

poussière pénétrer dans vos yeux ou votre bouche, ou en la

laissant reposer sur votre peau, vous risquez de promouvoir

l'absorption de substances toxiques. Portez toujours des

dispositifs de protection respiratoire homologués par NIOSH/

OSHA, appropriés à l'exposition à la poussière et de taille

appropriée, et lavez à l'eau et au savon les surfaces de votre

corps qui ont été exposées.

16 - French

Page 17

RÈGLES SPÉCIFIQUES ADDITIONNELLES DE SÛRETÉ

L’inobservation de ces règles peut conduire à des blessures graves.

1. DO NOT OPERATE THIS MACHINE until it is completely

assembled and installed according to the instructions. A

machine incorrectly assembled can cause serious injury.

2. OBTAIN ADVICE from your supervisor, instructor, or

another qualified person if you are not thoroughly

familiar with the operation of this machine. Knowledge

is safety.

3. FOLLOW ALL WIRING CODES and recommended electrical

connections to prevent shock or electrocution.

4. SECURE THE MACHINE TO A SUPPORTING SURFACE.

Vibration can cause the machine to slide, walk, or tip over.

5. NEVER START THE MACHINE BEFORE CLEARING

THE TABLE OF ALL OBJECTS (tools, scrap pieces,

etc.). Debris can be thrown at high speed.

6. NEVER START THE MACHINE with the drill bit or

cutting tool against the workpiece. Loss of control of the

workpiece can cause serious injury.

7. PROPERLY LOCK THE DRILL BIT OR CUTTING TOOL IN

THE UNIT before operating this machine.

8. ADJUST the depth stop to avoid drilling into the table.

9. DO NOT attempt to mortise material that does not have

a flat surface, unless a suitable support is used.

10. USE ONLY DRILL BITS, CUTTING TOOLS, OR OTHER

ACCESSORIES with shank size recommended in your

instruction manual. The wrong size accessory can cause

damage to the machine and/or serious injury.

11. USE ONLY DRILL BITS OR CUTTING TOOLS that are

not damaged. Damaged items can cause malfunctions

that lead to injuries.

12. USE RECOMMENDED SPEEDS for all operations. Other

speeds may cause the machine to malfunction causing

damage to the machine and/or serious injury.

13. AVOID AWKWARD OPERATIONS AND HAND

POSITIONS. A sudden slip could cause a hand to move

into the bit.

14. KEEP ARMS, HANDS, AND FINGERS away from the

bit. Serious injury to the hand can occur.

15. ALWAYS position the holddown directly over the

workpiece to prevent the workpiece from lifting during

operation. Loss of control of the workpiece can cause

serious injury.

16. TURN THE MACHINE “OFF” AND WAIT FOR THE DRILL

BIT, CUTTING TOOL, OR SANDING DRUM TO STOP

TURNING prior to cleaning the work area, removing

debris, removing or securing work-piece, or changing

the angle of the table. A moving drill bit or cutting tool

can cause serious injury.

17. PROPERLY SUPPORT LONG OR WIDE work-pieces.

Loss of control of the workpiece can cause severe

injury.

18. NEVER PERFORM LAYOUT, ASSEMBLY OR SET-UP

WORK on the table/work area when the machine is

running. Serious injury can result.

19. TURN THE MACHINE “OFF”, disconnect the machine

from the power source, and clean the table/work area

before leaving the machine. LOCK THE SWITCH IN

THE “OFF” POSITION to prevent unauthorized use.

Someone else might accidentally start the machine and

cause serious injury to themselves.

20. ADDITIONAL INFORMATION regarding the safe

and proper operation of power tools (i.e. a safety

video) is available from the Power Tool Institute, 1300

Sumner Avenue, Cleveland, OH 44115-2851 (www.

powertoolinstitute.com). Information is also available

from the National Safety Council, 1121 Spring Lake

Drive, Itasca, IL 60143-3201. Please refer to the

American National Standards Institute ANSI 01.1 Safety

Requirements for Woodworking Machines and the U.S.

Department of Labor OSHA 1910.213 Regulations.

CONSERVER CES DIRECTIVES.

Les consulter souvent et les utiliser pour donner des directives aux autres.

RACCORDEMENTS ÉLECTRIQUES

Un circuit électrique séparé doit être utilisé pour les machines. Les fils de ce circuit doivent être au moins de calibre 12. Ce circuitdoit

être protégé par un fusible temporisé de 20 A. Si on utilise un cordon prolongateur, ce cordon doit être à trois fils, avoir unefiche à trois

broches et une prise de courant à trois cavités, mise à la terre qui correspond à la fiche de la machine. Avant debrancher la machine,

s’assurer que l’interrupteur (les interrupteurs) se trouve(nt) en position « OFF » (ARRÊT) et que le courantélectrique présente les

mêmes caractéristiques que celles qui sont inscrites sur la machine. Toutes les connexions électriquesdoivent établir un bon contact.

Le fonctionnement sur une basse tension endommagera la machine.

Ne pas exposer la machine à la pluie, et ne pas l’utiliser dans des endroits humides.

SPÉCIFICATIONS DU MOTEUR

Cette machine est câblée pour un fonctionnement sur un courant alternatif de 120 volts 60 Hz. Avant de brancher la machine,

s’assurer que l’interrupteur se trouve à la position « OFF » (ARRÊT).

INSTRUCTIONS DE MISE À LA TERRE

électriques.

Cette machine doit être mise à la terre pendant son emploi, afin de protégerl’utilisateur des décharges

17 - French

Page 18

1. Toutes les machines avec cordon mis à la terre: Dans l’éventualité d’un mauvais fonctionnement ou d’unepanne, la mise à

la terre fournit un trajet de moindre résistance permettant de réduire le risque de décharge électrique. Cette machine est dotée

d’un cordon électrique possédant unconducteur de mise à la terre de l’équipement ainsi que d’unefiche mise à la terre. La fiche

doit être branchée dans une prisede courant correspondante, installée de façon adéquate etmise à la terre conformément à tous

les codes et règlements locaux.

Ne pas modifier la fiche fournie - si elle ne s’adapte pas à laprise de courant, il faut faire installer une prise de courant convenable

par un électricien compétent.

Un mauvais raccordement du conducteur de mise à la terrede l’équipement peut entraîner un risque de décharge électrique. Le

conducteur possédant un isolant avec surface extérieure de couleur verte, avec ou sans rayures jaunes, estle conducteur de

mise à la terre de l’équipement. Si uneréparation ou un remplacement du cordon électrique s’avère nécessaire, ne pas brancher

le conducteur de mise à la terrede l’équipement à une borne sous tension.

Consulter un électricien compétent ou le personnel de service après-vente si on ne comprend pas entièrement les instructions

de mise à la terre, ou si l’on doute que la machines oit correctement mise à la terre.

Utiliser seulement des cordons prolongateurs à trois fils dotésd’une fiche mise à la terre, à trois broches, et de prises à

troiscavités convenant à la fiche de la machine, comme l’illustre lafigure A.

Réparer ou remplacer sans délai tout cordon endommagé ouusé.

2. Machines avec cordon mis à la terre prévues pour uneutilisation sur une alimentation nominale inférieure à150volts

:

Si cette machine est prévue pour être utilisée sur un circuit quicomporte une prise semblable à celle illustrée à la figure A, la

machine devra comporter une fiche mise à la terre semblableà celle illustrée à la figure A. Un adaptateur temporaire semblable

à celui illustré à la figure B, peut être utilisé pour raccorder cette fiche à une prise à deux cavités comme celle illustrée à la figure

B, si une prise correctement mise à la terren’est pas disponible. L’adaptateur temporaire ne doit êtreutilisé que jusqu’au moment

où une prise correctement miseà la terre est installée par un électricien compétent. L’oreillerigide ou autre dispositif semblable de

couleur verte, sur ledessus de l’adaptateur, doit être connecté sur une mise à laterre permanente comme, par exemple une boîte

à prisescorrectement mise à la terre. Quand un adaptateur est utilisé,celui-ci doit être retenu en place par une vis en métal.

REMARQUE: Au Canada, le Code canadien de l’électriciténe permet pas l’emploi d’un adaptateur temporaire.

électricien compétentde vérifier la prise.

Dans tous les cas, s'assurer quela prise en question est bien mise à la terre. Dans le doute, demander à un

BOÎTE À PRISES MISE À LA TERRE

BROCHES

CONDUCTRICESDE

COURANT

LA BROCHE DE MISE

ÀLA TERRE EST LA PLUS

LONGUEDES TROIS

Fig. A

CORDON DE RALLONGE

Employez les cordes appropriées de prolongation. S'assurent votre corde de

prolongation est en bon état. En utilisant une corde

de prolongation, soyez sûr d'employer un assez lourd

pour porter le courant de la machine. Une corde trop

petite causera une baisse dans la tension secteur, ayant

pour résultat la perte de puissance et de surchauffe.

Fig. D-1 expositions la mesure correcte à employer

selon la longueur de corde. En cas de doute, utilisez

la prochaine mesure plus lourde. Plus le nombre de

mesure est petit, plus la corde est lourde.

BOÎTE À PRISES MISE À LA TERRE

OREILLE DE MISEÀ LA

TERRE

ADAPTATEUR

Fig. B

MESUR MINIMUM DE CORDE D’EXTENSION

TAILLES RECOMMANDÉES POUR L'CUSAGE AVEC STATIONNAIRES ÉLECTRIQUES LES OUTILS

Longueur

Estimation

pere Volts

0-6 120

Totale De

Corde En

Pieds

up to

Mesure De Corde D’Am

25 18 AWG

D’Extension

0-6 120 25-50 16 AWG

0-6 120 50-100 16 AWG

0-6 120 100-150 14 AWG

6-10 120

up to

25 18 AWG

6-10 120 25-50 16 AWG

6-10 120 50-100 14 AWG

6-10 120 100-150 12 AWG

10-12 120

up to

25 16 AWG

10-12 120 25-50 16 AWG

10-12 120 50-100 14 AWG

10-12 120 100-150 12 AWG

12-16 120

up to

25 14 AWG

12-16 120 25-50 12 AWG

12-16 120

50 PI PLUS GRANDS QUE NON RECOMMANDES

18 - French

Page 19

DESCRIPTION FONCTIONNELLE

AVANT-PROPOS

Le modèle 14-651 de Delta est plus facile à utiliser qu’une perceuse à colonne traditionnelle dotée d’un accessoire pour

mortaise. Pour plus de rigidité et de stabilité, l’outil est fabriqué en fonte et en acier et livré avec un mandrin standard à trois

mâchoires pour la fixation solide des bédanes.

REMARQUE : La photo de la couverture du mode d’emploi illustre le modèle de production actuel. Les autres illustrations de

ce mode d’emploi ne sont présentes qu’à titre indicatif et il est possible que les étiquettes et accessoires actuels diffèrent des

caractéristiques réelles de ce modèle. Ces illustrations ont uniquement pour but d’illustrer la technique.

DÉSEMBALLAGE ET NETTOYAGE

Désemballer soigneusement la machine et toutes les pièces de ou des emballage(s) d’expédition. Retirer l’huile anticorrosion

des surfaces non peintes à l’aide d’un chiffon doux humidifié avec de l’alcool, du diluant à peinture ou de l’alcool dénaturé.

pour nettoyer. Après nettoyage, couvrir les surfaces non peintes d’une cire à parquets d’usage domestique de bonne

qualité.

N’utiliser pas de solvants hautement volatils tel l’essence, le naphte, l’acétone ou du diluant à laque

CONTENUS DE BOITE

8

11

9

1

12

10

13

14

15

16

17

5

6

7

2

3

4

1. Mortaiseuse

2. Porte-outil et porte-bédane

3. Clé de mandrin/Clé

4. Rallonge de colonne

5. Vérin hydraulique

6. Poignée

7. Longue tige de retenue (pour utilisation avec la rallonge

de colonne)

8. Vis spéciale (pour relever et abaisser la poignée)

9. (4) vis de M8 x 1,25 x 80 mm (pour fixer la rallonge de

colonne à la base)

10. (2) vis à tête cylindrique à dépouille de M6 x 1 x 25 mm

(pour fixer le porte-outil et le porte-bédane)

11. Ressort

12. Bague (pour utilisation avec bédanes extra longs)

13. (2) rondelles de blocage M6 (pour fixer le porte-outil et le

porte-bédane)

14. Bédane et mèche de 12,7 mm (1/2 po)

15. Bédane et mèche de 9,5 mm (3/8 po)

16. Bédane et mèche de 7,9 mm (5/16 po)

17. Bédane et mèche de 6,4 mm (1/4 po)

19 - French

Page 20

ASSEMBLAGE

For your own safety, do not connect the machine to the power source until the machine is

completely assembled and you read and understand the entire instruction manual.

OUTILS NÉCESSAIRES POUR L’ASSEMBLEE

Clé de mandrin/Clé (fourni)

L'ESTIMATION DE TEMPS D'ASSEMBLEE

L’Assemblée pour cette machine prend moins de 30 minutes.

ABAISSEMENT ET RELÈVEMENT DE LA POIGNÉE

1. Fixer le moyeu du module de la poignée (A), fig. 1, sur l’extrémité de l’arbre pignon (B). Utiliser la vis spéciale (C) et le

ressort (D) pour fixer la poignée à l’arbre pignon.

2. Tourner la poignée (A) dans le sens horaire pour relever la tête de la mortaiseuse en position « haute » (E), fig. 2.

REMARQUE : la poignée (A) est à ressort. La repositionner en tirant dessus et en la déplaçant sur l’arbre pignon (B).

B

Fig. 1

A

D

C

E

A

B

Fig. 2

FIXATION DU VÉRIN HYDRAULIQUE

Placer la tête de la mortaiseuse en position « haute » (A), fig. 3. Fixer le vérin hydraulique (B) aux deux raccords, un situé au

dos de la tête (C), fig. 3, et l’autre sur la colonne (D), fig. 4. Enfoncer chaque extrémité du vérin hydraulique dans les raccords

pour fixer correctement le vérin.

D

A

B

C

Fig. 3

Fig. 4

B

FIXATION DU PORTE-OUTIL ET PORTE-BÉDANE

1. Fixer le porte-outil et porte-bédane (A), fig. 5, au dos de la colonne avec les deux vis de M6 x 1 x 25 mm (B) et les

rondelles de blocage M6.

2. La figure 6 illustre la clé de mandrin/clé (C), la bague (F) pour utilisation avec les bédanes extra longs et les bédanes et

mèches (E).

Fig. 5

E

B

A

B

20 - French

F

A

C

Fig. 6

Page 21

FIXATION DE LA MACHINE SUR UNE SURFACE DE SUPPORT

Si la machine tend à basculer, à glisser ou à se déplacer

sur la surface portante, fixer solidement la base de la

machine à celle-ci en insérant des attaches (non fournies)

dans les deux trous (A), fig. 7, situés dans la base de la

mortaiseuse.

INSTALLATION DU BÉDANE ET DE LA MÈCHE

Débrancher la machine de la source de pouvoir !

1. Insérer la mèche (A), fig. 8, dans le bédane (B).

REMARQUE : l’ouverture (C) sur le côté du bédane (pour

l’évacuation des copeaux) doit toujours faire face au côté.

Ne jamais l’orienter vers l’avant ou l’arrière.

A

Fig. 7

A

B

C

Fig. 8

2. Desserrer la vis (D), fig. 9, et insérer le bédane (B) dans le trou de la tête de la machine aussi loin que possible, puis

l’abaisser (B) de 1,6 à 4,8 mm (1/16 à 3/16 po). Serrer la vis de calage (D).

IMPORTANT : lors de l’insertion du bédane (B), fig. 10, dans la tête de la machine, laisser un dégagement de 1,6 à 4,8 mm

(1/16 à 3/16 po) (F) entre la bague (E) et la saillie du bédane (B).

3. Insérer la mèche (A), fig. 11, dans le bédane puis dans le mandrin (G) aussi loin que possible. Verrouiller la mèche dans

le mandrin avec la clé de mandrin fournie.

4. Desserrer la vis de calage (D), fig. 12, et pousser le bédane (B) contre la base inférieure de la bague (E), puis serrer la vis

de calage (D). On obtient ainsi la distance correcte entre les pointes de la mèche et le bord tranchant du bédane.

D

D

B

F

E

B

Fig. 9

Fig. 10

D

G

A

E

B

Fig. 11

Fig. 12

21 - French

Page 22

APPUYER LE

BÉDANE CONTRE LA

5. La portion plane de la mèche doit dépasser la partie

BAGUE

inférieure du bédane d’au moins 1,6 mm (1/16 po).

Certains types de bois exigent un accroissement de

cet écart jusqu’à un maximum de 4,8 mm (3/16 po).

DÉPLACER LA MÈCHE

DANS LE MANDRIN

POUR OBTENIR UN

DÉGAGEMENT

INSTALLATION DE LA RALLONGE DE COLONNE

LE DÉGAGEMENT DE 1,6 À 4,8

Il est possible de prolonger la colonne pour mortaiser

des pièces plus épaisses. Pour installer la rallonge :

Débrancher la machine de la source de pouvoir !

1. Retirer les deux vis (B), fig. 14, puis retirer le support du couvercle de la crémaillère (D).

2. Retirer les quatre vis et les rondelles plates (A), fig. 14.

3. Faire pivoter la poignée (E) jusqu’à ce que le module de la colonne (C), fig. 14, s’éloigne du dos de la crémaillère et de la

base.

4. Déposer la rallonge de colonne (A), fig. 15, sur le dessus de la crémaillère (B). Aligner les quatre trous de la rallonge de

colonne (A), fig. 15, avec les quatre trous de la base (C).

5. Installer le module de la colonne (C), fig. 16, sur le dessus de la rallonge de colonne (A) et aligner les quatre trous (B) du

module de la colonne avec les quatre trous de la rallonge (A).

6. Enfiler une rondelle plate retirée auparavant à l’ÉTAPE 2 sur la vis à tête hexagonale de M8 x 1,25 x 80 mm.

7. Insérer la vis dans le trou du module de la colonne (C), fig. 17, et de la rallonge de colonne (A). La visser dans la base (B).

Répéter l’assemblage pour les trois autres trous.

8. Remettre en place le support du couvercle de la crémaillère (D), fig. 17, retiré plus tôt à l’ÉTAPE 1.

9. Desserrer le bouton de retenue (B), fig. 18, et retirer la pièce. Desserrer la vis de calage (C) et retirer la tige de retenue (A).

La remplacer par la longue tige de retenue. Serrer la vis de calage (C). Placer la pièce de retenue (B) sur la tige de retenue

et serrer la poignée de retenue (B).

MM (1/16 À 3/16 PO)

VARIE SELON LE TYPE DE BOIS

Fig. 13

A

B

Fig. 16

E

Fig. 14

Fig. 15

C

A

D

C

A

B

B

C

B

A

C

A

B

D

Fig. 17

22 - French

Page 23

REMARQUE : inverser la procédure pour retirer la rallonge de

colonne.

A

B

le couvercle de la crémaillère sur le système d’engrenages.

Ainsi, le couvercle ne se coincera pas entre la crémaillère et les

engrenages.

Pour éviter d’endommager l’appareil, installer

C

FONCTIONNEMENT

L'OPERATION CONTROLE DE LE ET LES AJUSTEMENTS

DÉMARRAGE ET ARRÊT DE MACHINE

L’interrupteur est situé sur le côté gauche de la mortaiseuse.

Pour mettre la mortaiseuse en marche, enfoncer le bouton de

démarrage vert (A), fig. 19. Pour arrêter la mortaiseuse, enfoncer

le bouton rouge (B).

VERROUILLAGE DE L’INTERRUPTEUR EN POSITION D’ARRÊT

A

B

Fig. 18

Fig. 19

IMPORTANT : Lorsque la machine n’est pas utilisée, l’interrupteur

doit être verrouillé en position d’arrêt (OFF) pour empêcher toute

utilisation non autorisée en utilisant un cadenas (A) fig. 49 avec une

boucle de 4,76 mm (3/16 po).

RÉGLAGE DE LA TIGE DE LIMITATION DE LA PROFONDEUR

La tige de limitation de la profondeur (A), fig. 21, restreint la

profondeur de pénétration du bédane. Pour régler la tige de

limitation de la profondeur (A), desserrer le levier (C) et abaisser

la tête du bédane. Une fois en position, abaisser la tige de

limitation de la profondeur (A) jusqu’à ce qu’elle touche le haut

de la colonne (D), puis serrer le levier (C).

RÉGLAGE DU GUIDE

Il est possible de déplacer le guide (A), fig. 22, vers l’intérieur

ou l’extérieur en desserrant les poignées de verrouillage (B) et

en tournant la poignée de guide de la crémaillère (C). Serrer les

poignées (B) une fois le guide en position.

REMARQUE : les leviers (B) sont à ressort et peuvent être

repositionnés. Pour ce faire, tirer sur le levier et le repositionner

sur l’écrou cannelé situé sous le levier.

A

Fig. 20

A

C

D

Fig. 21

A

B

C

Fig. 22

23 - French

Page 24

RÉGLAGE DE LA PIÈCE DE RETENUE

La pièce de retenue (C), fig. 23, empêche la pièce (E) de se

soulever lorsque le bédane sort du trou. Pour régler la pièce

de retenue, desserrer la poignée (F), positionner la pièce de

retenue de sorte qu’elle touche la partie supérieure de la

pièce de bois (E), puis resserrer la poignée. Il est possible

d’inverser l’orientation de la pièce de retenue (C) pour

l’adapter à des pièces de bois plus épaisses.

C

E

F

Fig. 23

RÉGLAGE DU PARALLÉLISME DU BÉDANE À LA PIÈCE DE BOIS

Régler le bédane (A), fig. 24, parallèle à la pièce de bois. Desserrer la vis (B) et tourner le bédane jusqu’à ce que le dos du

bédane s’appuie sur la pièce de bois. Serrer la vis (B).

RÉGLAGE DU MONTANT COULISSANT ENTRE LA TÊTE DU BÉDANE ET LA COLONNE

Une clavette à queues d’arondes (A), fig. 25, garantit un glissement serré entre la tête du bédane et la colonne. Effectuer le

réglage en desserrant les deux vis (B) et en tournant les vis de réglage (C). Resserrer les deux vis (B).

REMARQUE : le réglage est correct en l’absence de mouvement évident entre la clavette et la colonne. Régler la clavette de

sorte qu’elle soit suffisamment serrée pour maintenir sa précision sans toutefois nuire au mouvement coulissant.

B

C

A

A

B

Fig. 24

1. Maintenir les bédanes et les mèches affûtés.

2. Une opération courante de mortaise est illustrée à la figure

26. Remarquer que l’ouverture (A) du bédane est à droite.

Déplacer la pièce de bois de la gauche vers la droite pour

les coupes subséquentes tout en permettant une évacuation

correcte des copeaux.

3. Tenir fermement la pièce de bois contre le guide. S’assurer

que la pièce de retenue (B), fig. 28, soit correctement réglée.

Le rythme de pénétration du bédane doit être assez rapide

pour prévenir toute marque de brûlure à la pointe de la

mèche, mais à une vitesse qui ne bloque pas le moteur. Il

est possible que de la fumée s’échappe de la mèche ou de

la pièce de bois. La fumée est une conséquence naturelle du fonctionnement de l’outil et est provoquée par la friction

et le brûlement des résines. Une combinaison de la friction et de l’accumulation de résine sur la surface de coupe du

bédane fait bleuir celui-ci, mais n’indique toutefois pas que le bédane soit émoussé. Un bédane émoussé se décèle

lorsqu’une force excessive est nécessaire pour terminer une coupe.

4. Lors de l’exécution d’une mortaise de bord en bord, insérer une fine pièce de bois entre la pièce à découper et la table

pour empêcher la formation d’éclats au bas de la mortaise.

B

Fig. 25

A

Fig. 26

ROTATION DE LA COLONNE SUR 180 DEGRÉS

Pour certaines coupes spéciales, faire pivoter la colonne (A), fig. 27, de 180 degrés. Pour ce faire, retirer les quatre vis, dont

deux sont illustrées en (B), faire pivoter la colonne (A) sur 180 degrés et réinsérer les quatre vis (B).

La base de l’appareil doit être fixée à une surface portante.

24 - French

Page 25

L’UTILISATION DE MÈCHES AVEC QUEUES EXTRA LONGUES

Lors de l’utilisation de mèches avec queues extra longues, enlever la rallonge (A), fig. 28. Insérer un tournevis dans la rainure (B),

fig. 29, à l’extrémité de l’arbre d’induit sur le dessus du moteur. Utiliser une clé de mandrin pour dévisser et retirer le mandrin (C),

fig. 28, et la rallonge (A). Retirer la rallonge (A) du mandrin (C), puis remettre celui-ci (C) en place. Utiliser également la cale du

bédane. Insérer la cale du bédane (D), fig. 30, dans la queue du bédane (F), puis insérer le bédane dans le porte-bédane. Serrer

solidement le porte-bédane.

A

B

C

Fig. 27

F

B

Fig. 29 Fig. 30

D

A

Fig. 28

DEPANNAGE

Pour l'assistance avec votre outil, visiter notre site web à www.deltamachinery.com pour une liste de centres de maintenance

ou appeler la ligne d'aide de Delta Machinery à 1-800-223-7278. (Canada: 1-800-463-3582).

ENTRETIEN

GARDER LA MACHINE PROPRE

Dégager régulièrement toutes les conduites d’air avec de l’air comprimé sec. Toutes les pièces en plastique doivent être nettoyées

à l’aide d’un chiffon doux humide. NE JAMAIS utiliser de solvants pour nettoyer les pièces en plastique. Les solvants peuvent dissoudre ou endommager le matériel.

Porter des protections oculaire et auditive homologuées et utiliser un appareil respiratoire lors de

l’utilisation d’air comprimé.

DÉMARRAGE IMPOSSIBLE

Si la machine ne démarre pas, s’assurer que les lames de la fiche du cordon d’alimentation sont bien enfoncées dans la prise de

courant. Vérifier également que les fusibles ne sont pas grillés ou que le disjoncteur ne s’est pas déclenché.

LUBRIFICATION ET PROTECTION CONTRE LA ROUILLE

Appliquer chaque semaine une cire à parquets d’usage domestique sur la table de la machine, sur la rallonge de table ou toute autre

surface de travail. Ou utiliser un produit protecteur commercial conçu à cet effet. Suivre les directives du fabricant pour l’utilisation

et la sécurité.

Pour nettoyer les tables en fonte contre la rouille, utiliser le matériel suivant : une feuille de papier à poncer Scotch-Brite™ medium,

une boîte de WD-40® et une boîte de dégraissant. Appliquer le WD-40 et polir la surface de la table avec le papier à poncer ScotchBrite. Dégraisser la table puis appliquer le produit protecteur comme décrit ci-dessus.

SERVICE

PIÈCES DE RECHANGE

Utiliser seulement des pièces de rechange identiques. Pour obtenir une liste des pièces de rechange ou pour en commander,

consulter notre site Web au servicenet.deltamachinery.com. Commander aussi des pièces auprès d’une succursale d’usine

ou composer le 1-800-223-7278 pour le service à la clientèle et recevoir ainsi une assistance personnalisée de techniciens

bien formés.

25 - French

Page 26

REMPLACEMENT GRATUIT DE L'ÉTIQUETTE

Si vos étiquettes d'avertissement deviennent illisibles ou sont manquantes, composez le 1-800-223-7278 pour obtenir

une étiquette de remplacement gratuite.

ENTRETIEN ET RÉPARATION

Tous les outils de qualité finissent par demander un entretien ou un changement de pièce. Pour de plus amples renseignements

à propos de Delta Machinery, ses succursales d’usine ou un centre de réparation sous garantie autorisé, consulter notre site

Web au www.deltamachinery.com ou composer le 1-800-223-7278 pour le service à la clientèle. Toutes les réparations

effectuées dans nos centres de réparation sont entièrement garanties contre les défauts de matériaux et de main-d’oeuvre.

Nous ne pouvons garantir les réparations effectuées en partie ou totalement par d’autres.

Pour de plus amples renseignements par courrier, écrire à Delta Machinery, 4825 Highway 45 North, Jackson, Tennessee

38305, É.-U. – à l’attention de : Product Service. S’assurer d’indiquer toutes les informations figurant sur la plaque signalétique

de l’outil (numéro du modèle, type, numéro de série, etc.).

ACCESSOIRIES

Une ligne complète des accessoires est fournie des centres commerciaux d'usine de par votre de Porter-Cable•Delta

fournisseur, de Porter-Cable•Delta, et des stations service autorisées par Porter-Cable. Veuillez visiter notre site Web

www.deltamachinery.com pour un catalogue ou pour le nom de votre fournisseur plus proche.

avec ce produit, utilisation de tels accessoires a pu être dangereux. Pour l'exploitation sûre, seulement PorterCable•Delta a recommandé des accessoires devrait être utilisé avec ce produit.

Depuis des accessoires autre que ceux offertspar Porter-Cable•Delta n'ont pas été testés

GARANTIE

Pour enregistrer votre outil pour la garantie service la visite notre site Web à www.deltamachinery.com.

Garantie limitée de deux ans

Delta réparera ou remplacera, à ses frais et à sa discrétion, toute nouvelle machine Delta, pièce de rechange ou tout accessoire qui,

dans des circonstances d'utilisation normale, s'est avéré défectueux en raison de défauts de matériau ou de fabrication, à condition

que le client retourne le produit (transport payé d'avance) au centre de réparation de l'usine Delta ou à un centre de réparation autorisé

accompagné d'une preuve d'achat et dans les deux ans de la date d'achat du produit, et fournisse à Delta une opportunité raisonnable de

vérifier le défaut présumé par une inspection. La période de garantie des produits Delta réusinés est de 180 jours. Delta peut demander

que les moteurs électriques soient retournés (transport payé d'avance) à un centre de réparation autorisé du fabricant du moteur en vue

d'une inspection, d'une réparation ou d'un remplacement. Delta ne peut être tenu pour responsable des défauts résultants de l'usure

normale, de la mauvaise utilisation, de l'abus, de la réparation ou de la modification du produit, sauf en cas d'autorisation spécifique

d'un centre de réparation ou d'un représentant Delta autorisé. En aucune circonstance Delta ne peut être tenu pour responsable des

dommages accidentels ou indirects résultant d'un produit défectueux. Cette garantie constitue la seule garantie de Delta et le recours

exclusif des clients en ce qui concerne les produits défectueux ; toutes les autres garanties, expresses ou implicites, de qualité

marchande, d'adéquation à un usage particulier, ou autre, sont expressément déclinées par Delta.

26 - French

Page 27

INSTRUCCIONES DE SEGURIDAD IMPORTANTES

Lea y entienda todas advertencias y las instrucciones operadoras antes de utilizar cualquier

instrumento o el equipo. Cuando se usa instrumentos o equipo, las precauciones básicas de la seguridad

siempre se deben seguir para reducir el riesgo de la herida personal. La operación impropia, la conservación o la

modificación de instrumentos o equipo podrían tener como resultado el daño grave de la herida y la propiedad.

Hay ciertas aplicaciones para que equipaas con herramienta y el equipo se diseña. La Delta Machinery