Page 1

GENERAL MANUAL

ELECTRONIC UNIT PUMP - YUCHAI ENGINE 4112 / 6112 / 6113 DDNX300(EN)

2006

Page 2

(D) Kommen Sie nicht mit dem Hochdruckstrahl in Verbindung! Besonders nicht, wenn

Druckrohrleitung oder Dichtung geprüft werden! Hochdruckflüssigkeiten können tödliche

Verletzungen verursachen! Im Falle einer Berührung mit der Haut, kontaktieren Sie

sofort einen Arzt. Bitte beachten Sie die Gesundheits-/und Sicherheitsunterlagen.

(E) Mantenga las manos y el cuerpo lejos del rociado del líquido, especialmente inyectores,

tuberías y juntas de alta presión con fugas. La inyección de alta presión puede perforar

la piel humana y producir una lesión fatal. En caso de que la inyección atraviese la piel,

consiga atención médica inmediatamente. Vea la hoja de Datos de Sanidad y

Seguridad.

(EN) Do not put your skin into the fuel jets under pressure, especially those due to pressure

pipe or seal leaks. High pressure liquids can cause deadly injuries. In case of an

injection under the skin, contact a doctor immediately. Please refer to the health and

security fuel documents.

(F) Ne pas approcher les mains ni le corps des jets de liquides, particulièrement ceux

provenant des fuites de tuyaux et des joint soumis a la haute pression. Le liquide sous

haute pression injecté sous la peau peut causer des blessures mortelles. En cas

d’injection sous la peau, consulter immédiatement un médecin. Se reporter a la fiche de

santé et de sécurité du gazole.

(IT) Non esporre le mani o altre parti del corpo a getti di gasolio ad alta pressione,

specialmente a quelli provenienti da tubi o paraolii. I getti di liquidi ad alta pressione

possono causare ferite anche mortali. In caso di iniezione sotto pelle contattare

immediatamente un medico. Fare riferimento alle schede di sicurezza del gasolio.

(NL) Zorg dat uw handen of andere lichaamsdelen niet in contact komen met vloeistofstralen

onder hoge druk, met name bij een lek aan een leiding of dichting. Als de vloeistof onder

hoge druk onder de huid terechtkomt, kan dit zelfs tot dodelijke verwondingen leiden. Als

de vloeistof onder de huid terechtkomt, onmiddellijk een arts raadplegen. Lees de

gezondheids- en veiligheidsfiche met betrekking tot de brandstof.

(P) Não exponha a pele a jactos de combustível sob pressão, especialmente os devidos a

fugas de tubos de pressão ou vedantes. Líquidos a alta pressão podem causar

ferimentos mortais. No caso de injecção subcutânea, consulte imediatamente um

médico. Consulte por favor a documentação respeitante a saúde e segurança de

combustíveis.

(D) Schutzbrille/Gesichtsschutz tragen.

(E) Úsese protección para los ojos/la cara.

(EN) Wear eye/face protection.

(F) Porter un appareil de protection des yeux / du visage.

(IT) Proteggersi gli occhi/la faccia.

(NL) Veiligheidsbril/-masker gebruiken.

(P) Use protecção da face/olhos.

(D) Von Zündquellen fernhalten - Nicht rauchen.

(E) Conservar alejado de toda llama o fuente de chispas -No fumar.

(EN) Keep away from sources of ignition - No smoking.

(F) Conserver à l'écart de toute flamme ou source d'étincelles - Ne pas fumer.

(IT) Conservare lontano da fiamme e scintille - Non fumare.

(NL) Ver van open vuur en ontstekingsbronnen houden – Niet roken.

(P) Mantenha afastado de fontes de ignição – Proibido fumar.

(D) Geeignete Schutzhandschuhe tragen.

(E) Usen guantes adecuados.

(EN) Wear suitable gloves.

(F) Porter des gants appropriés.

(IT) Usare guanti adatti.

(NL) Aangepaste veiligheidshandschoenen dragen.

(P) Use luvas apropriadas.

Page 3

SPECIAL FEATURES OF THE SYSTEM I

REMOVAL / REFITTING II

APPENDIX III

Produced and published by:

Delphi Diesel Systems Ltd

Delphi Diesel Aftermarket

Spartan Close

Warwick CV34 6AG Tel: +44 (0) 1926 472 900

Fax: +44 (0) 1926 472 901

© Delphi

TABLE OF CONTENTS

DDNX300(EN) - Issue 1 of 09/2006

i

Page 4

1. ENGINE CHARACTERISTICS - 4112

1.1 Engine Characteristics..................................................................................................................................................1-1

1.2 Power and Torque Values............................................................................................................................................1-1

2. ENGINE CHARACTERISTICS - 6112

2.1 Engine Characteristics..................................................................................................................................................2-3

2.2 Power and Torque Values............................................................................................................................................2-3

3. ENGINE CHARACTERISTICS - 6113

3.1 Engine Characteristics..................................................................................................................................................3-5

3.2 Power and Torque Values............................................................................................................................................3-5

4. PARTS SUPPLIED BY DELPHI

4.1 General...........................................................................................................................................................................4-7

4.2 Electronic Unit Pump....................................................................................................................................................4-7

4.3 Injectors and Inlet Connector.......................................................................................................................................4-8

4.4 Sensors..........................................................................................................................................................................4-8

4.4.1 Crankshaft sensor.........................................................................................................................................4-8

4.4.2 Camshaft sensor...........................................................................................................................................4-9

4.4.3 Boost pressure sensor.................................................................................................................................4-9

4.4.4 Boost temperature sensor...........................................................................................................................4-9

4.4.5 Coolant temperature sensor......................................................................................................................4-10

4.4.6 Fuel temperature sensor............................................................................................................................4-10

4.5 Engine Control Unit (ECU)..........................................................................................................................................4-11

I SP E CIA L FEA T URE S OF THE S YST E M

TABLE OF CONTENTS

ii

DDNX300(EN) - Issue 1 of 09/2006

Page 5

5. PRELIMINARY OPERATIONS

5.1 Preparation..................................................................................................................................................................5-13

6. HIGH PRESSURE PIPES

6.1 Removal Of A High Pressure Pipe.............................................................................................................................6-15

6.2 Refit Of A High Pressure Pipe.....................................................................................................................................6-15

7. INJECTOR

7.1 Removal Of An Injector...............................................................................................................................................7-17

7.2 Refit Of An Injector......................................................................................................................................................7-19

7.3 Bleeding The Low Pressure Fuel System..................................................................................................................7-20

8. SENSOR

8.1 Removal Of The Sensor..............................................................................................................................................8-21

8.2 Refit Of The Sensor.....................................................................................................................................................8-21

9. ELECTRONIC UNIT PUMP (EUP)

9.1 Removal Of The Electronic Unit Pump......................................................................................................................9-23

9.2 Refit Of The Electronic Unit Pump.............................................................................................................................9-24

9.3 Bleeding The Low Pressure Fuel System..................................................................................................................9-25

10. DIESEL CONTROL UNIT (DCU) OR ELECTRONIC ENGINE CONTROLLER (EEC)

10.1 Removal Of The Engine Control Unit......................................................................................................................10-27

10.2 Refit Of The Engine Control Unit.............................................................................................................................10-27

REM O VAL / RE F ITT I NG I I

TABLE OF CONTENTS

DDNX300(EN) - Issue 1 of 09/2006

iii

Page 6

11. MISCELLANEOUS

11.1 Tightening Torques...................................................................................................................................................11-29

11.2 Resistance Values......................................................................................................................................................11-30

11.3 Tools...........................................................................................................................................................................11-31

11.4 Wiring Diagrams.......................................................................................................................................................11-32

11.5 Abbreviations Used In This Manual........................................................................................................................11-34

III A PPEN DIX

TABLE OF CONTENTS

iv

DDNX300(EN) - Issue 1 of 09/2006

Page 7

1 ENGINE CHARACTERISTICS - 4112

1.1 Engine Characteristics

4112

Engine layout 4 or 6 cylinders in-line with direct injection

Engine capacity

5200 cm

3

Bore and stroke 112 x 132 mm

Compression ratio 17.8/1

Number of valves per cylinder 4

Drive Gear driven camshaft - overhead valve with push-rod actuation

1.2 Power and Torque Values

The 4112 engine is currently available in the following three specifications:

Specification Power Torque

4112 155kW @ 2200 erpm 820Nm @ 1500 erpm

4G220-30 132kW @ 2300 erpm 660Nm @ 1400 erpm

4G180-30 177 kW @ 2200 erpm 950Nm @ 1500 erpm

SPE C IAL F EAT U RES OF T H E S Y STEM I

ENGINE CHARACTERISTICS - 4112

DDNX300(EN) - Issue 1 of 09/2006

1-1

Page 8

Page 9

2 ENGINE CHARACTERISTICS - 6112

2.1 Engine Characteristics

6112

Engine layout 4 or 6 cylinders in-line with direct injection

Engine capacity

7800 cm

3

Bore and stroke 112 x 132 mm

Compression ratio 17.5/1

Number of valves per cylinder 2

Drive Gear driven camshaft - overhead valve with push-rod actuation

2.2 Power and Torque Values

The 6112 engine is currently available in the following three specifications:

Specification Power Torque

6112 199 kW @ 2200 erpm 1080Nm @ 1600 erpm

6G240-30 243 kW @ 2200 erpm 1280Nm @ 1400 erpm

6G270-30 228 kW @ 2200 erpm 1150Nm @ 1400 erpm

SPE C IAL F EAT U RES OF T H E S Y STEM I

ENGINE CHARACTERISTICS - 6112

DDNX300(EN) - Issue 1 of 09/2006

2-3

Page 10

Page 11

3 ENGINE CHARACTERISTICS - 6113

3.1 Engine Characteristics

6113

Engine layout 4 or 6 cylinders in-line with direct injection

Engine capacity

8424 cm

3

Bore and stroke 113 x 140 mm

Compression ratio 17.5/1

Number of valves per cylinder 4

Drive Gear driven camshaft - overhead valve with push-rod actuation

3.2 Power and Torque Values

The 6113 engine is currently available in the following four specifications:

Specification Power Torque

6113 206 kW @ 2200 erpm 1100Nm @ 1600 erpm

6L330-30

6L310-30

6L280-30

SPE C IAL F EAT U RES OF T H E S Y STEM I

ENGINE CHARACTERISTICS - 6113

DDNX300(EN) - Issue 1 of 09/2006

3-5

Page 12

Page 13

4 PARTS SUPPLIED BY DELPHI

4.1 General

DELPHI supplies the following original fitment parts:

• Electronic Unit Pump with tappet assembly

• Injector

• Inlet connector (4112 & 6113 engines only)

• Crankshaft sensor

• Camshaft sensor

• Boost Pressure sensor

• Boost Temperature sensor

• Coolant Temperature sensor

• Fuel Temperature sensor

• Engine Control Unit

4.2 Electronic Unit Pump

Specifications:

• Bore and stroke Ø11 x 16 mm

• Maximum Injection Pressure at Rated Speed : 2000

bar

• Fuel delivery (approx.):

-

190 mm

3

per stroke at Rated Speed

-

200 mm

3

per stroke at Peak Torque

• Operating condition and specification of solenoid :

- Electrical drive-EUP Nominal drive Voltage50

V

- Peak 10 A

- Hold 4.1-5.2 A (modulated)

• Tyco 2 pin harness plug connector

• Dot matrix trim code on connector

• External fuel filter

• Separate tappet assembly - location guide in

separate cambox

• EURO III & IV emissions capable

50V Electronic Unit Pump generates highly pressurised

fuel to achieve optimum injection consistency. On these

fuel systems it has proved beneficial to measure and

characterise individual assembly performance, to

communicate this data to the ECU and adjust the signal

outputs for each cylinder.

SPE C IAL F EAT U RES OF T H E S Y STEM I

PARTS SUPPLIED BY DELPHI

DDNX300(EN) - Issue 1 of 09/2006

4-7

Page 14

4.3 Injectors and Inlet Connector

Specifications:

• Bar type construction

• Single spring injectors with shim NOP adjustment

• Fuel back-leak drilling incorporated

• 4112 & 6113 engines:

- Side fuel entry via inlet connector with

incorporated edge filter

- Axial top clamp with combined radial

location

- NOP : 275 +10 /-0 bar

- Maximum pressure in normal operating

conditions upto 1600 Bar

- Maximum Nozzle flow upto 1.8 litres/min

flow rate

• 6112 engines

- Axial fuel entry via M1 x 1.5mm pipe

connection and incorporated edge filter

- Maximum pressure in normal operating

conditions upto 1600 Bar

- NOP : 270 +0 /-10 bar

- Maximum Nozzle flow upto 1.2 litres/min

flow rate

4.4 Sensors

4.4.1 Crankshaft sensor

Specifications:

• Variable Reluctance sensor

• Speed Range: 50 – 3000 eRPM

• Voltage Range: 1.0V peak to peak min at

(50eRPM) to 250V Peak to Peak max @ 25°C

• Input Impedance - 10kΩ @ DC

To provide accurate crankshaft position

information to the ECU, for engine speed sensing &

fuel timing & quantity scheduling

I SP E CIA L FEA T URE S OF THE S YST E M

PARTS SUPPLIED BY DELPHI

4-8

DDNX300(EN) - Issue 1 of 09/2006

Page 15

4.4.2 Camshaft sensor

• Variable Reluctance sensor

• Speed Range: 50 – 3000 eRPM

• Voltage Range: 500mV peak to peak min (at

50eRPM) to 100V Peak to Peak max @ 25 °C

• Input Impedance - 10kΩ @ DC

To identify the cylinder number for firing the

electronic unit pump. Extra tooth located before Cyl.

No.1 as firing cycle initiation

4.4.3 Boost pressure sensor

• Digital Sensor

• Voltage Range: 5V ± 0.25V DC

• Operating temperature -40°C to 125°C

• Operating pressure 50 to 300 kPa

Senses available boost pressure from

turbocharger. Is used by the ECU, along with boost

temperature to calculate air quantity available to

limit black smoke from excess fuelling quantity

4.4.4 Boost temperature sensor

• Thermistor Sensor

• Voltage Range: 5V ± 0.1V DC

• Operating temperature -40°C to 135°C

• Thermal time constant < 15 seconds

Senses boost temperature and is used by the ECU,

along with boost pressure, to calculate air quantity

available, to limit black smoke from excess fuelling

quantity

SPE C IAL F EAT U RES OF T H E S Y STEM I

PARTS SUPPLIED BY DELPHI

DDNX300(EN) - Issue 1 of 09/2006

4-9

Page 16

4.4.5 Coolant temperature sensor

• Thermistor Sensor

• Voltage Range: 5V ± 0.1V

• Operating temperature -40°C to 135°C

• Thermal time constant 8 seconds

The coolant temperature is used by ECU to

determine required engine cold-starting algorithm.

4.4.6 Fuel temperature sensor

• Thermistor Sensor

• Voltage Range: 5V ± 0.1V

• Operating temperature -40°C to 135°C

• Thermal time constant 8 seconds

The fuel temperature is used by ECU to calculate

required fuelling quantity offset according to

temperature of fuel in fuel manifold (due to fuel

density variation with temperature)

I SP E CIA L FEA T URE S OF THE S YST E M

PARTS SUPPLIED BY DELPHI

4-10

DDNX300(EN) - Issue 1 of 09/2006

Page 17

4.5 Engine Control Unit (ECU)

Specifications:

• Normal operating voltage: 9V - 31V

• 3 off 62 way Tyco cable connectors

The ECU controls the following functions:

• Injection fuelling and injection timing

• Voltage supply

• EGR (If applicable)

• System diagnostics

SPE C IAL F EAT U RES OF T H E S Y STEM I

PARTS SUPPLIED BY DELPHI

DDNX300(EN) - Issue 1 of 09/2006

4-11

Page 18

Page 19

5 PRELIMINARY OPERATIONS

The operations listed below will be required to gain access to the fuel injection system components, if any operations

are not appropriate it will be noted at the start of the relevant section.

5.1 Preparation

• Switch off the ignition and allow system to power down

• Prepare the tooling

• Prepare the plug kit

This operation is only required when removing/refitting the following components:

• High Pressure pipes

• Injectors

• Electronic Unit Pumps (EUP)

• Engine Control Unit (ECU)

• Electrical Sensors

REM O VAL / RE F ITT I NG I I

PRELIMINARY OPERATIONS

DDNX300(EN) - Issue 1 of 09/2006

5-13

Page 20

Page 21

6 HIGH PRESSURE PIPES

Important! Refer to the relevant cleanliness and safety instructions before starting work

6.1 Removal Of A High Pressure Pipe

Note: Carry out the preliminary operations - see section 1.1. Clean the high pressure pipe connector nuts using a solvent

(type CARECLEAN) applied using a clean brush. Clean the surrounding area to remove the dirt particles using a vacuum

cleaner (BLOVAC BV11 type)

Important! Immediately cap the injector and EUP high pressure pipe connections. Clean off any fuel to

prevent the risk of fire.

• Clean the connections with the pipe using the

solvent (type CARECLEAN) and vacuum any

contaminants from the high pressure junctions

using vacuum cleaner (BLOVAC BV11 type).

• Slacken the high pressure pipe nuts at both ends

whilst keeping the high pressure pipe in contact

with the injector and EUP. Ensuring the torque is

applied at the upper half of the nut to avoid

damaging it.

• Keeping the pipe nipple in contact with the injector

inlet with one hand, completely unscrew the nut

with the other, repeat operation for the pump

outlet.

• While maintaining the pipe nipple in contact with

either the pump or injector, vacuum any

contaminants from between the pipe and injector

or pump.

• Remove the high pressure pipe and discard.

• Once the pipe is removed, plug the exposed

orifices of the pump and injector to protect from

contamination.

Note: If a high pressure pipe has been removed, it MUST be replaced.

6.2 Refit Of A High Pressure Pipe

• Install the new high pressure pipe by placing the high pressure pipe nipples on to the injector and EUP.

• First tighten the high pressure pipe nuts by hand and then torque tighten them to a value of 28 Nm +/- 1 Nm. Torque

the injector connection first followed by the EUP connection.

Note: Apply the torque to the upper half of the high pressure pipe nut in order to avoid damaging it.

Note: The high pressure pipe MUST NOT be bent, as this could cause a leak.

REM O VAL / RE F ITT I NG I I

HIGH PRESSURE PIPES

DDNX300(EN) - Issue 1 of 09/2006

6-15

Page 22

Page 23

7 INJECTOR

Important! Refer to the relevant cleanliness and safety instructions before starting work

7.1 Removal Of An Injector

Important! Due to the possible presence of high pressure in the fuel tank, fuel may run into the cylinders

when removing the injectors. Therefore, when removing injectors always remove the fuel tank cap first.

Collect any fuel from the injectors. If it is necessary to remove an injector, it MUST be marked so that it

can be replaced in the same injector bore if it is to be reused and not replaced. It is recommended that all

dirt is removed from all the external parts before removal and refitting of engine components using the

Delphi special tool no. YDT205.

• Remove the rocker valve cover from the engine as

per the engine manufacturer instructions.

• Remove the valve rocker arms from the engine as

per the engine manufacturer instructions.

• Open the fuel tank cap to release the high pressure

of the fuel system.

• Remove the high pressure pipe as detailed in

section 2.1.

• Loosen and remove the injector inlet connector

(quill) securing nut from the side bore on the

engine.

• Remove the injector inlet connector (quill) from the

side of the cylinder head.

REM O VAL / RE F ITT I NG I I

INJECTOR

DDNX300(EN) - Issue 1 of 09/2006

7-17

Page 24

• Loosen and remove the injector clamp bolts and

remove the clamp.

• Screw a slide hammer into the injector removal

thread and carefully extract the injector ensuring

there is no side loading.

Note: 6112 engine: There may be a need to prize out the injector carefully and evenly under its clamping flange or

shoulder. Number injectors with its corresponding cylinder location.

• Carefully remove the copper sealing washer from the cylinder head, if washer is still in the bore or remove from

the injector.

• Clean the injector bore or all contaminants and then vacuum using a vacuum cleaner (BLOVAC BV11 type).

II R E MOV A L / R EFI T TIN G

INJECTOR

7-18

DDNX300(EN) - Issue 1 of 09/2006

Page 25

7.2 Refit Of An Injector

Important! New copper sealing washers and injector O rings MUST always be fitted when the injector is

refitted to the engine. New injectors are supplied complete with new copper sealing washers and O rings.

Take care not to add a second copper washer during installation.

Important! If during removal one or more copper sealing washers remain in the injector bore, the injector

would be reinstalled in a higher position. As a result fuel could be sprayed into the wrong part of the

combustion chamber which may lead to serious damage to the engine. Also there will be inadequate

sealing between the O-rings of the injector and the cylinder head. Fuel leaking from the injector could then

flow freely into the engine and dilute the lubricating oil. If an injector is showing signs of combustion due

to incorrect fitting do not reuse it.

• Please ensure cleanliness standards are met when

refitting the injector.

• Clean the injector well using tool YDT252. Position

the tool into the injector well and lowering the

centring device into the sleeve of the injector

holder. Turn the knob clockwise without pressing

on it. Remove and clean tool away from working

area.

• Clean the well and surrounding area of the cylinder

using the vacuum cleaner (YDT205) with the nozzle

attachment (YDT205).

• Remove the injector's protection caps.

• When refitting the old injector fit new O-rings (2)

and a copper sealing washer (1) to the injector.

Apply a little engine lubricating oil to both O-rings.

• Fit the injector back into the bore. Ensuring the

injector is correctly placed back into the bore,

making sure its located at the correct depth to allow

correct sealing.

Note: Injectors should always be fitted back into the same bore they were taken out from. If the inlet connector has

wear or damage on the sealing face it must be replaced.

• Refit the injector inlet connector (quill) into the bore in the side of the cylinder head by carefully aligning the ball

bearing on the top of the bore. Once in place, gently tap the end of the quill into the bore until it is securely located.

• Fit the injector clamp and tighten the bolt evenly and torque to a value of 23 Nm +/-1Nm.

• Tighten the injector inlet connector (quill) securing bolt to 40Nm +5Nm.

• Install the high pressure pipe (as detailed in

section 1.2) and torque tighten it to 28 Nm +/- 1 Nm.

• Refit the rocker cover and tighten to the specified torque as per the engine manufacturers manual.

• Refit the valve rocker arms to the engine and tighten to the specified torque as per the OEM workshop manual.

• Bleed the low-pressure fuel feed system (see

section 7.3).

REM O VAL / RE F ITT I NG I I

INJECTOR

DDNX300(EN) - Issue 1 of 09/2006

7-19

Page 26

7.3 Bleeding The Low Pressure Fuel System

• Using a hand primer (as supplied on the engine) bleed the low pressure fuel system by pumping the fuel.

• Collect the fuel from the highest part of the system using clear tubing.

• Continue to pump the primer until bubble-free fuel is seen at the fuel filter head and at the highest point in the lowpressure system.

II R E MOV A L / R EFI T TIN G

INJECTOR

7-20

DDNX300(EN) - Issue 1 of 09/2006

Page 27

8 SENSOR

Important! Refer to the relevant cleanliness and safety instructions before starting work

8.1 Removal Of The Sensor

Please refer to the vehicle's handbook and/or workshop manual for the location of each individual sensor

• Remove the connector from the sensor.

• Remove the sensor out of its location.

8.2 Refit Of The Sensor

• Refit the sensor into its location.

• Refit the connector onto the sensor.

• Tighten the sensor mounting bolts. Refer to

section 11.1 for torque settings.

REM O VAL / RE F ITT I NG I I

SENSOR

DDNX300(EN) - Issue 1 of 09/2006

8-21

Page 28

Page 29

9 ELECTRONIC UNIT PUMP (EUP)

Important! Refer to the relevant cleanliness and safety instructions before starting work

9.1 Removal Of The Electronic Unit Pump

Important! Perform the preliminary operations - see section 1.1. When removing the EUP, fuel will escape.

Collect this fuel to prevent the risk of fire. Dirt in the fuel system can lead to serious damage to the

electronic unit pumps and the pump housing.

Note: If it is necessary to remove an EUP, it MUST be marked so that it can be replaced in the same bore if it is to be

reused and not replaced. It is recommended that all dirt is removed from all external parts before removal/refit of engine

components using the Delphi special tool no. YDT205. To prevent dirt from entering the system, first clean the exterior

of the fuel tank around the filler cap.

• Open the fuel tank cap to release any pressure in

the fuel system.

• Disconnect the fuel supply and return pipes.

• If the fuel filter is high-mounted, unscrew the filter

cover a few turns to allow the fuel filter to empty,

collecting the fuel in a container.

• Open the connection to the pressure relief valve(s)

to allow the fuel to leave the fuel gallery.

• Remove the electrical connector from the EUP.

• Remove the high pressure pipe, as detailed in

section 2.1 and cap the EUP.

Note: The high pressure pipes may only be used once

and MUST be replaced after being removed.

• The two EUP securing bolts should initially be loosened evenly and only by a few threads, and NOT fully removed.

If necessary prize the pump lightly and evenly (from both sides) upwards from under the flange (using the recesses

provided), with a screwdriver or suitable tool. Once the bolts take up the spring load again, continue loosening the

bolts evenly until the spring load is fully released then remove the bolts fully.

Important! If the EUP's securing nuts are fully removed the pump can suddenly release itself, causing

damage to the housing bores and even fracturing the pumping plunger. The EUP may be under spring

tension, depending on the position of the camshaft. If the EUP spring is under tension the engine must be

rotated until this tension is relived.

REM O VAL / RE F ITT I NG I I

ELECTRONIC UNIT PUMP (EUP)

DDNX300(EN) - Issue 1 of 09/2006

9-23

Page 30

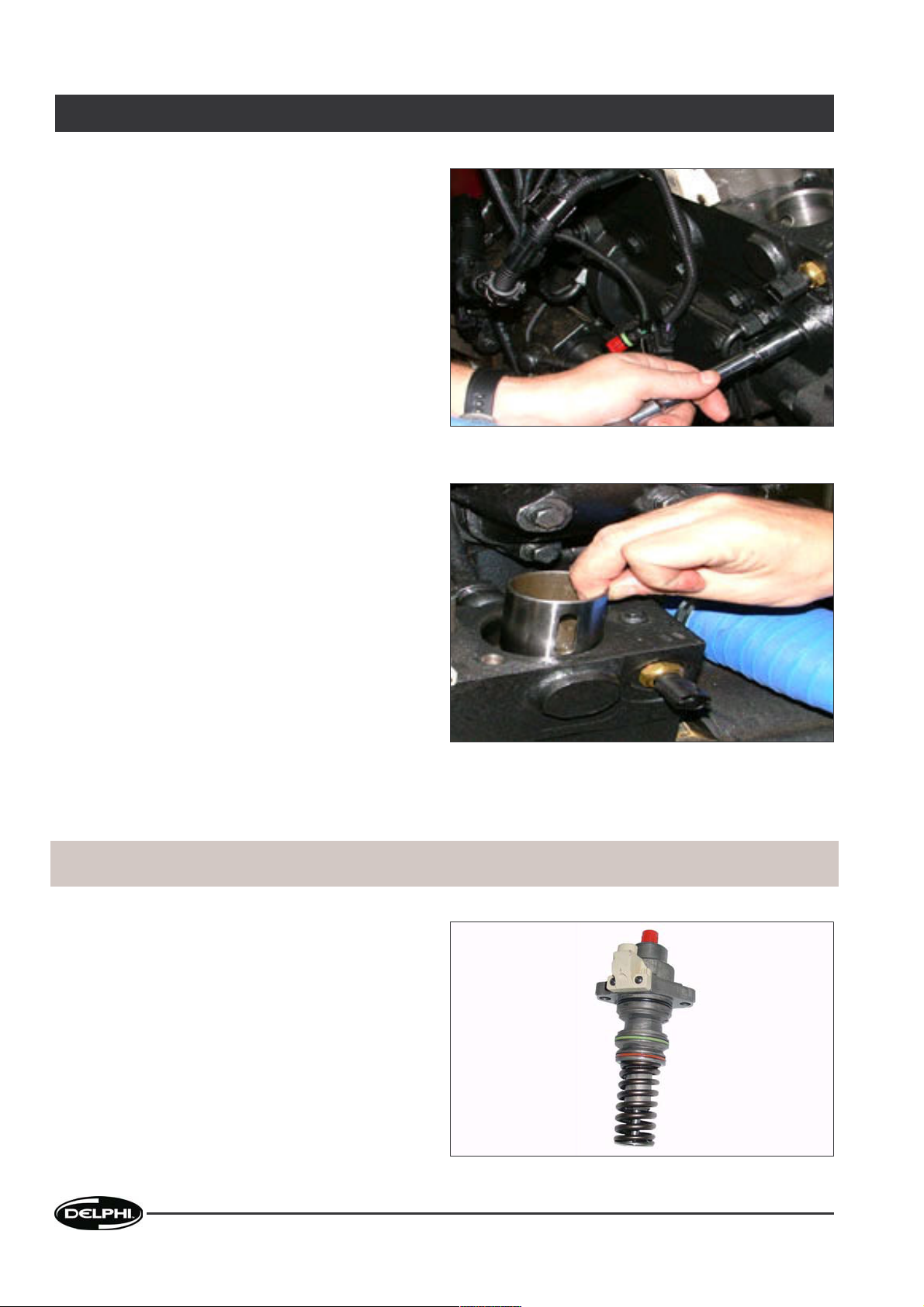

• Carefully extract the EUP from the bore by hand,

avoiding side loading which could damage the

bore.

• Wrap the pump in a plastic bag and place it

carefully in a protective box.

• Remove the locating bolt from the cam box to

release the EUP tappet.

• Carefully remove the tappet from the engine by

hand.

9.2 Refit Of The Electronic Unit Pump

Important! If a new EUP is fitted into the engine the Trim Code, which is found on the solenoid connection

of the EUP body, MUST be entered into the ECU using the DIAMAND diagnostic tool.

• Remove the pump from the plastic bag.

• If using a new pump record the trim values of the

pump so the systems can be calibrated correctly.

• Replace the EUP O-rings, if refitting the EUP.

Note:

Top O-ring = Black

Middle O-ring = Violet (Older EUP's may have light

green O-rings)

Bottom O-ring = Brown

II R E MOV A L / R EFI T TIN G

ELECTRONIC UNIT PUMP (EUP)

9-24

DDNX300(EN) - Issue 1 of 09/2006

Page 31

• Replace the EUP body filter (filter to be specified).

• Refit the tappet into the cambox bore by hand, making sure that it aligns with the locating bolt.

• Refit the locating bolt and tighten. Refer to

section 11.1 for torque settings.

Note: Before the EUP is fitted, a small amount of engine oil must be applied to the O-rings. Depending on the position

of the Cam lobe the pump may sit proud of where it is supposed to be located. If this is the case, slightly tighten the

bolts one at a time until both bolts are fully torqued.

• Fit the EUP into the bore, by feeding it past the O-ring seal lead-in chamfers by lightly turning the pump to and fro.

Note: Take care not to tilt the pump during insertion as this can damage the engine or cambox bores.

• Hand tighten the two securing bolts evenly before applying a torque value of 60 Nm +/- 1 Nm.

• Re-fit the electrical connector.

• Install the high pressure pipe and torque tighten it to 28 Nm +/- 1 Nm, as detailed in

section 11.1.

• Bleed the fuel system (see

section 9.3).

• Use the DIAMAND diagnostic tool to configure the ECU using the Trim code recorded from the new pump.

Important! Please ensure to change the Trim value against the correct cylinder.

• Start engine and allow engine speed to stabilise.

• Use DIAMAND to erase any fault codes raised during the remove and refit procedure.

• Stop Engine.

• Check Trim codes are correct for the relevant cylinders only if new EUP is fitted.

9.3 Bleeding The Low Pressure Fuel System

• Using a hand primer (as supplied on the engine) bleed the low pressure fuel system by pumping the fuel.

• Collect the fuel from the highest part of the system using clear tubing.

• Continue to pump the primer until bubble-free fuel is seen at the fuel filter head and at the highest point in the lowpressure system.

REM O VAL / RE F ITT I NG I I

ELECTRONIC UNIT PUMP (EUP)

DDNX300(EN) - Issue 1 of 09/2006

9-25

Page 32

Page 33

10 DIESEL CONTROL UNIT (DCU) OR ELECTRONIC ENGINE CONTROLLER (EEC)

Important! Refer to the relevant cleanliness and safety instructions before starting work

10.1 Removal Of The Engine Control Unit

Please refer to the vehicle's handbook and/or workshop manual for the location of where the ECU is fitted on the vehicle.

• Remove the wiring support bracket bolts from the ECU body.

• Remove the three electrical unit connectors on the ECU.

• Remove the four mounting bolts that secure the ECU to the vehicle.

10.2 Refit Of The Engine Control Unit

Please refer to the vehicle's handbook and/or workshop manual for the location of where the ECU is fitted on the vehicle.

• Mount the ECU in its correct position, making sure that the earth strap makes a good contact with the vehicles body.

• Tighten the ECU mounting bolts evenly to 20 Nm +/- 1 Nm.

• Refit the three electrical unit connectors onto the ECU.

• Tighten the wiring support bracket bolts into the ECU body, taking care as these are self-tapping screws.

Note: When fitting to a new ECU the correct data for the engine derivative must be downloaded from the Diamand

diagnostic tool into the ECU, otherwise the engine will not be able to start or run.

REM O VAL / RE F ITT I NG I I

DIESEL CONTROL UNIT (DCU) OR ELECTRONIC ENGINE CONTROLLER (EEC)

DDNX300(EN) - Issue 1 of 09/2006

10-27

Page 34

Page 35

11 MISCELLANEOUS

11.1 Tightening Torques

Components to tighten Torque

High Pressure Pipes 28 Nm +/- 1 Nm

Injector Clamp Securing Bolts 23 Nm +/-1 Nm

Electronic Unit Pump Securing Bolts 60 Nm +/- 1 Nm

ECU Mounting Bolts 20 Nm

Crankshaft Sensor 7 - 10 Nm

Camshaft Sensor 7 - 10 Nm

Boost Pressure Sensor 6 Nm

Boost Temperature Sensor 20 Nm

Boost Temperature Sensor 22 Nm

Coolant Temperature Sensor 22 Nm

Fuel Temperature Sensor 22 Nm

Fuel Temperature Sensor 20 Nm

APP E NDIX III

MISCELLANEOUS

DDNX300(EN) - Issue 1 of 09/2006

11-29

Page 36

11.2 Resistance Values

Important! It is impossible to measure resistance less than 1Ω using a conventional multimeter.

Components Terminals Resistance values

Sensor ECU

Boost Pressure Digital Sensor J1-28

J1-30

N/A

Boost Temperature Thermistor J1-41

J1-42

J1-45

J1-46

2 kOhms ± 120 Ohms @ 25°C

Camshaft Sensor Variable

Reluctance

J1-53

J1-54

825 Ohms ± 100 Ohms @ 25°C

Coolant Temperature Thermistor J2-25

J2-26

2 kOhms ± 120 Ohms @ 25°C

Crankshaft Sensor Variable

Reluctance

J1-49

J1-50

825 Ohms ± 100 Ohms @ 25°C

Electronic Unit Pump N/A J1 - 3

J1 - 4

J1 - 7

J1 - 12

J1 - 11

J1 - 20

J1 - 15

J1 - 8

J1 - 19

J1 - 16

J1 - 23

J1 - 24

1.53 Ohms ± 10% @ 20°C

Fuel Temperature Thermistor J1-41

J1-42

J1-45

J1-46

2.75 kOhms ± 155 Ohms @ 25°C

III A PPEN DIX

MISCELLANEOUS

11-30

DDNX300(EN) - Issue 1 of 09/2006

Page 37

11.3 Tools

Special tooling from Delphi Delphi Reference

CR Tool kit YDT200

CR Vacuum cleaner YDT205

Injector well cleaning tool YDT252

CR Vacuum nozzle YDT255

DIAMAND diagnostic tool YDT300

Standard tooling (sourced locally) Reference

12 Point socket Facom R.5,5E - R.14E (or from similar supplier)

12 Point socket (12 mm) Facom J.7 - J.24 (or from similar supplier)

12 Point socket (17 mm) Facom J.7 - J.24 (or from similar supplier)

1/4 ratchet Facom R.161 (or from similar supplier)

3/8 ratchet Facom J.161 (or from similar supplier)

8 - 19 mm combination wrench Facom 40.8 to 40.19 (or from similar supplier)

Crowfoot socket (19 mm) Facom 18.10 - 18.19 (or from similar supplier)

Extension Facom J.210 (or from similar supplier)

Extension Facom J.210RC (or from similar supplier)

Extension Facom R.210 (or from similar supplier)

Torque wrench, 5 - 25 Nm Facom R.208-25 (or from similar supplier)

Torque wrench, 10-50 Nm Facom J.305DA (or from similar supplier)

Torque wrench, 10-50 Nm Facom J.208-50 (or from similar supplier)

Slide hammer Facom U.49L (or from similar supplier)

Parts, consumables and cleaning kit Reference

Clean container and brush Use suitable item

Cleaning solution Careclean type

Plug kit

APP E NDIX III

MISCELLANEOUS

DDNX300(EN) - Issue 1 of 09/2006

11-31

Page 38

11.4 Wiring Diagrams

14v (vsen)

Internal

ECU Temperature sensor

(PCB mounted)

Boost pressure

Fuel Pressure (reserved)

Reserved 1

Accel Pedal Sensor

Reserved 2

Boost Temp

Fuel Temp

Coolant Temp

Reserved 3

VCC

CAN1H

CAN1L

Preheat Drive

Exhaust Brake

ECU Power Relay

Engine Speed

Cooling Fan Relay

Inj Mon SCV (for development only)

Vehicle speed (reserved)

Cam sensor

Crank sensor

Unit pump (feed) 1, 3, 5

Unit pump (feed) 2, 4, 6

5A

(10A

peak)

INPUTS

Power Supply(VBAT)

Analogue Inputs

Switch Inputs

PWM Outputs (Low side)

Communication

Frequency /PWM Inputs

Sensor Supplies

Low side drives

Unit Pump Drives

OUTPUTS

Power Ground

CAN1

2 A

4 A

Reserved 1

Reserved 2

Key Sw

Door Saftey Switch

Clutch (reserved)

Service Start Switch

Reserved 1

Foot Brake (reserved)

Parking Brake (reserved)

Reserved 2

Idle Validation

Idle Trim Enable

Idle Trim Increment

Idle Trim Decrement

Exhaust Brake Request

Starter Motor (Optional)

High side drives

Electronic Unit Pump System

CAN1H

CAN1L

Case Ground

Switched Battery

Vehicle

connector

Links select for internal bus termination

1.5A

1.5A

Reserved 1

Reserved 2

2 A

2 A

2 A

2 A

2 A

1 A

9 Inputs

14 Inputs

3 Inputs

5 Outputs

2A

6 Outputs

3 Outputs

Ambient pressure sensor

(PCB mounted)

J1-30

J1-45

J3-33

J1-34

J1-41

J2-25

J3-44

J3-47

J3-36

J3-41

J3-24

J3-20

J3-16

J3-51

J3-32

J3-8

J3-7

J3-11

J3-12

J1-29

J2-5

J2-45

J1-53

J1-49

J3-48

J3-57,58,59

J1-40

J1-44

J2-24

J2-8

J2-32

J2-28

J3-2

J3-1

J2-16

J3-10

J2-60,61,62

J3-60,61,62

J1-25

J3-15

J3-23

J 1-62, 2-40, 3-5

5V (1)

5V (2)

5V (2)

5V (1)

5V (3)

1 A

J3-22

J3-2

3 Resistive

6 Ratiometric

J1-36

1.5A

1.5A

J1-48

Preheat Lamp

Hi Temp Lamp

Red Stop Lamp

Reserved 1

Reserved 1

J1-31

J3-9

All the same output drive

Unit pump (return) 1 - 6

AC Sw

J3-4

Vref1,2,3 Monitors

Internal

VBATT supply Monitor

Internal

50V supply Monitor

Internal

SCV I_sense monitor

Internal

PROTECTION

VOLTAGE

REGULATOR

Vehicle

connector

Engine

connectors

III A PPEN DIX

MISCELLANEOUS

11-32

DDNX300(EN) - Issue 1 of 09/2006

Page 39

PWM

Outputs

LSD

VBATT

+

_

2A

Pre-Heat

2A

Exhaust Brake

2A

2A

2A

Reserved 1

Reserved 2

Coolant Fan

Reserved 2

Reserved 3

Coolant

Temperature

NTC

0v

Sw Batt

P Batt

INJECTORS

J2

J1

J2-32

J2-28

J2-24

J3- 9

J1-31

J2- 8

J2-16

J2-6 (+)

J2-5

J2-7 (0v)

J2-46 (+)

J2-45

J2-43 (0v)

J2-25

J2-26

J2-57,58,59

J2-60,61,62

J1- 3

SCV 1

J1- 4

SCV 2

SCV 3

SCV 4

SCV 5

SCV 6

J1-15

J1- 8

J1- 7

J1-12

J1-19

J1-16

J1-11

J1-20

J1-23

J1-24

J1-34 (T)

J1-28 (+)

J1-30 (P)

J1-27 (0v)

J1-41 (T)

J1-42 (+)

J1-45 (P)

J1-46 (0v)

Boost

Pressure /

Temp

Fuel Temp

Reserved 1

Cam Sensor

Crank Sensor

Twisted

Pair,

optional

screen

HSD

Outputs

Reserved 1

Reserved (HSD)

Reserved 2

Preheat

Lamp

Hi Temp

Lamp

J1-33 (+)

J1-29

J1-26 (0v)

J1-60

J1-53 (+)

J1-54 (-)

P Batt

J1-61

J1-36

J1-35

J1-25

J1-40

J1-44

J1-48

J1-47

0V

J3

J3-24

J3-20

J3-16

J3- 4

J3-16

J3-47

J3-36

J3-51

J3-32

J3- 8

J3- 7

J3-11

J3-22

J3-48

J3-10

J3-34

J3-33

J3-37

J3-38

J3-41

5V

100k

J3-15 (H)

J3-23 (L)

PEDAL

Idle Validation

0v (or sen ret)

Twisted pair, -

CAN

communication

LSD

Outputs

Engine speed

RPM

2k8

15k

J3-1

J3-10

J3-44

Inj Mon SCV

Development

use only

Key Switch

5A Fuse

VBA

TT

Emergency Stop

Switch

15A Fuse

P

Batt

24v

0v

Case

Ground

J3- 2

J3-60,61,62

J3-57,58,59

Keyswitch

to uP

Relay hold

from uP

10R

3n9

10R

3n9

10R

3n9

Inj Mon SCV

Vehicle Speed

in (Res)

Red

Stop

Lamp

Diode >5A

>100v

Reserved 1

Reserved 2

Service Start Request

Parking Brake (Res)

Foot Brake (Res)

Clutch (Res)

Door Safety Switch

Exhaust Brake Request

AC Sw

Idle Trim Dec

Idle Trim Enable

Idle Trim Inc

VBATT

APP E NDIX III

MISCELLANEOUS

DDNX300(EN) - Issue 1 of 09/2006

11-33

Page 40

11.5 Abbreviations Used In This Manual

cc Cubic Capacity

DC Direct Current

°C Degrees Celsius

ECU Engine Control Unit

eRPM Engine Revolutions per Minute

EUP Electronic Unit Pump

kΩ Kilo Ohms

kPa Kilo Pascals

kW Kilo Watts

mm Millimetres

Nm Newton Meters

OEM Original Equipment Manufacturer

Trim Individual Electronic Unit Pump Correction

V Volts

III A PPEN DIX

MISCELLANEOUS

11-34

DDNX300(EN) - Issue 1 of 09/2006

Page 41

Whilst every care has been taken in compiling the information in this publication, Delphi Diesel Systems Ltd. cannot accept legal liability for any inaccuracies.

Delphi Diesel Systems Ltd. has an intensive programme of design and development which may well alter product specification. Delphi Diesel Systems Ltd.

reserve the right to alter specifications without notice and whenever necessary to ensure optimum performance from its product range.

All Rights Reserved

No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form, or by any means, electronic, mechanical, photocopying,

recording or otherwise, without the prior permission of Delphi Diesel Systems Ltd.

Il a été apporté une attention particulière pour garantir l'exactitude des renseignements contenus dans cette publication par Delphi Diesel Systems Ltd, mais

la société décline toute responsabilité légale à cet égard. Delphi Diesel Systems Ltd poursuit un programme intensif de conception et de développement qui

peut entraîner la modification des spécifications des produits. Delphi Diesel Systems Ltd se réserve le droit de modifier les spécifications, sans préavis et si

cela est nécessaire, pour assurer les performances optimales de sa gamme de produits.

Tous droits réservés

Toute reproduction, mémorisation dans un système informatique ou transmission sous quelle que forme que ce soit, ou par

tout moyen électronique, mécanique, par photocopie, enregistrement ou autre de cette publication est interdit sans

l'autorisation préalable de Delphi Diesel Systems Ltd.

Bei der Zusammenstellung der in dieser Veröffentlichung enthaltenen Informationen wurde mit größtmöglicher Sorgfalt vorgegangen. Delphi Diesel Systems

Ltd. kann jedoch rechtlich nicht für etwaige Ungenauigkeiten zur Verantwortung gezogen werden. Delphi Diesel Systems Ltd. führt ein fortlaufendes Designund Entwicklungsprogramm durch, weshalb es möglich ist, daß sich Produktdaten ändern. Delphi Diesel Systems Ltd. behält sich das Recht vor, ohne

Vorankündigung Spezifikationen jederzeit zu ändern, um die optimale Leistung seiner Produkte sicherzustellen.

Alle Rechte vorbehalten.

Kein Teil dieser Veröffentlichung darf ohne vorherige Genehmigung durch Delphi Diesel Systems Ltd. abgedruckt, in einem Datenverarbeitungssystem

gespeichert oder auf irgendeine Art und Weise, sei es auf elektronischem oder mechanischem Wege, durch Fotokopieren, Aufzeichnen oder auf sonstige Art,

übertragen werden.

Anche se ogni cura è stata adottata nel compilare le informazioni di questa pubblicazione, Delphi Diesel Systems Ltd. Declina qualsiasi responsabilità per eventuali

imprecisioni.

Delphi Diesel Systems svolge un intenso programma di progettazione e sviluppo che potrebbe modificare le specifiche del prodotto. Delphi Diesel Systems si riserva

il diritto di modificare le specifiche senza preavviso e ogniqualvolta lo ritenga necessario ai fini di assicurare le prestazioni ottimali dalla sua gamma di prodotti.

Tutti i diritti riservati

Nessuna parte di questa pubblicazione può essere riprodotta, memorizzata in un sistema elettronico o trasmessa in qualsiasi forma o con qualsiasi mezzo, elettronico,

di fotocopiatura, di registrazione o altro, senza la preventiva autorizzazione di Delphi Diesel Sistems Ltd.

Aunque hemos tomado todas las precauciones necesarias al recopilar esta publicación, Delphi Diesel Systems Ltd no acepta ninguna responsabilidad legal

por inexactitudes que puedan aparecer en la misma. En Delphi Diesel Systems Ltd se sigue un programa intensivo de diseño e investigación el cual podría

en cualquier momento alterar la especificación de los productos. Delphi Diesel Systems Ltd se reserva el derecho de alterar las especificaciones sin

notificación previa y siempre que esto sea necesario para asegurar el mejor funcionamiento posible de sus productos.

Todos los Derechos Reservados

No se permite copiar, almacenar en sistema recuperable ni transmitir esta publicación de ninguna forma o medio electrónico, mecánico, de fotocopia,

grabación o cualquier otro, sin autorización previa de Delphi Diesel Systems Ltd.

Ainda que se tenha lido o máximo cuidado na compilação da informação contida nesta publicação, a Delphi Diesel Systems Ltd, não pode aceitar qualquer

responsabilidade legal por inexactidões. A Delphi Diesel Systems Ltd. tem um programa intensivo de projecto e desenvolvimento que pode porventura alterar

as especificações do produto. A Delphi Diesel Systems Ltd. reserva o direito de alterar especificações sem aviso e sempre que seja necessario para

assegurar um desempenho óptimo da sua linha de produtos.

Todos os direitos reservados.

Nenhuma parte desta publicação pode ser reproduzida, armazenada num sistema de onde possa ser recuperada ou transmitida de alguma forma, ou por

quaisquer meios, electrónico, mecânico, de fotocópia, gravação ou outros, sem autorização antecipada de Delphi Diesel Systems Ltd.

Loading...

Loading...