Page 1

TECHNICAL INFORMATION

STEAM IRON

January '94 - Ironing systems PRO50 - PRO420 - PRO460

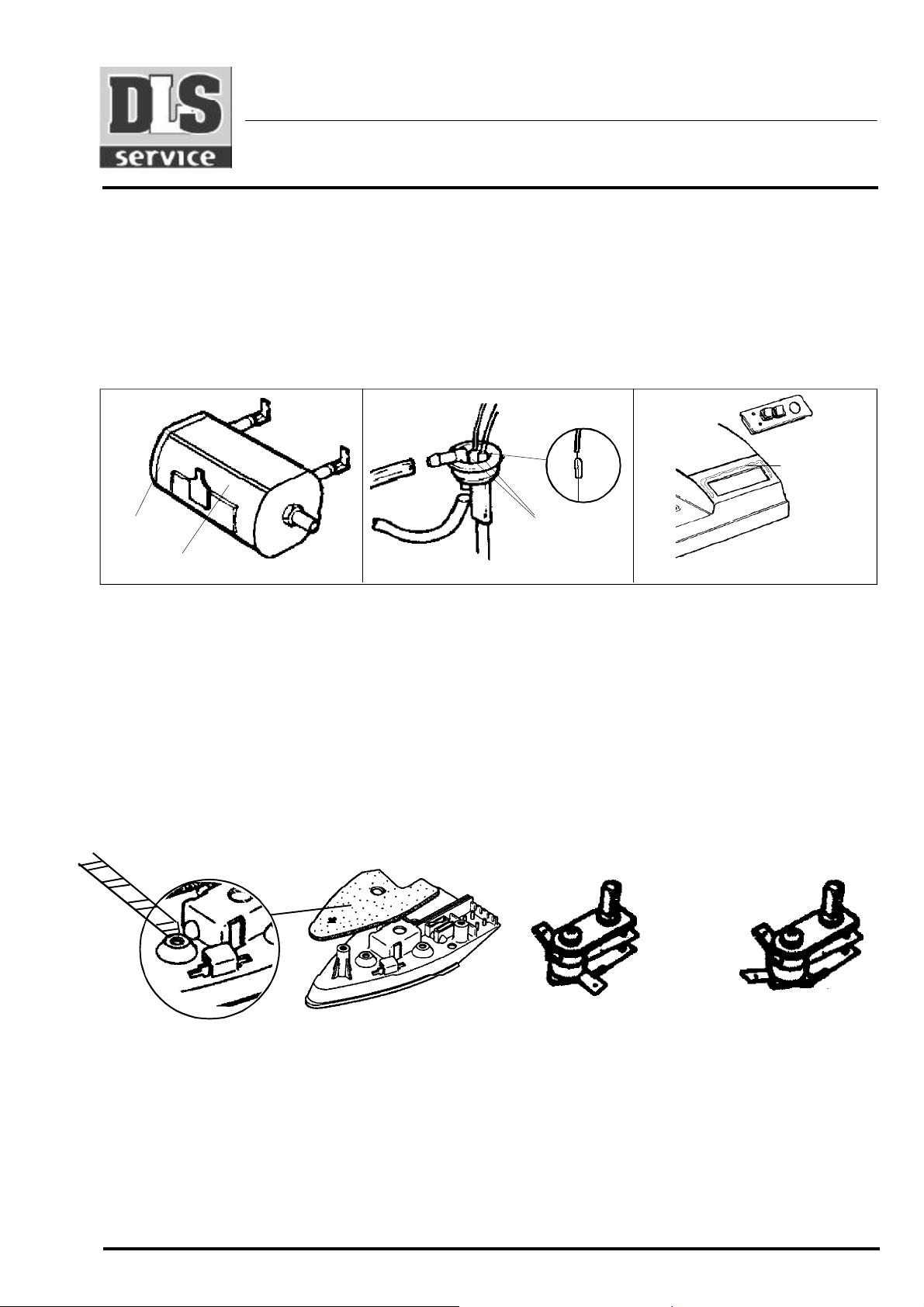

Eventual traces of humidity or calcium found in the central unit can come from a bad sealing of the steam generator gasket

(Fig. 1) or from a inadequate sealing of the water probe wires (Fig. 2) which start from the water reservoir and go to the

electronic board.

In the first case replace the old gasket with the red O-Ring code VT105061.

In the second case seal the water probe wires at the connection with the probe.

Eventual water spilt during filling of the reservoir can get inside the central unit by the control panel. In this case seal the

panel with some silicon (Fig. 3).

Fig. 1 Fig. 2 Fig. 3

wire

ç

clamp

probe

zone to seal

Gasket

Steam generator

April '94 - Ironing systems: - DE'LONGHI models PRO50 - PRO420 - PRO460

- VETRELLa and ATLANTIC model STIRAMAGIC NEW

In order to avoid the problems of failure of the electronic board, due to flooding of water into the central unit, starting from

serial nr. 94 10 onwards, in the above models can now be installed a protection which covers the board itself.

It is suggestable to install it, after any reparation. The code of the protection is: VT205507.

Wire to seal with

silicon

April '96 - Steam iron VVX 50

We inform you, that the thermostat with code no. 521285 is not available anymore. Instead of

thermostat code nr. 521285 you will receive from now on thermostat code no. 512298. Together with the

modified heat separator with code no. 733900 the new thermostat is interchangeable with the old one.

In case that the new heat separator is not available, you can easely adapt the old heat seperator to the new

thermostat, drilling a 12mm hole into the separator as shown in the figure below.

Hole in the heat separator

Old thermostat

521285

New thermostat

512298

September '96 - Ironing system VV10 - VV10B - VVX20B

To avoid in some cases the blockage of the pump shaft the resistor in series with the pump (with code no.

512141) has been modified.

The resistor has been reduced from 900W (7W) to 450W (7W).

You receive this value by connecting another resistor of the same type in paralel to the existing one.

September '96 - Ironing system PRO 880

In some appliances from the first production there has been noted a parcial melting of the bottom plastic cover

with code nr. VT515400. The cause has been a missing spacer in the center of the plastic cover which keeps the correct

distance between cover and water boiler.

In the case of a replacement of the plastic cover it is absolutely necessary to add a spacer (with code no. 535524)

in the center between cover and water boiler to avoid that the problem repeats itself.

Pag. 1

Page 2

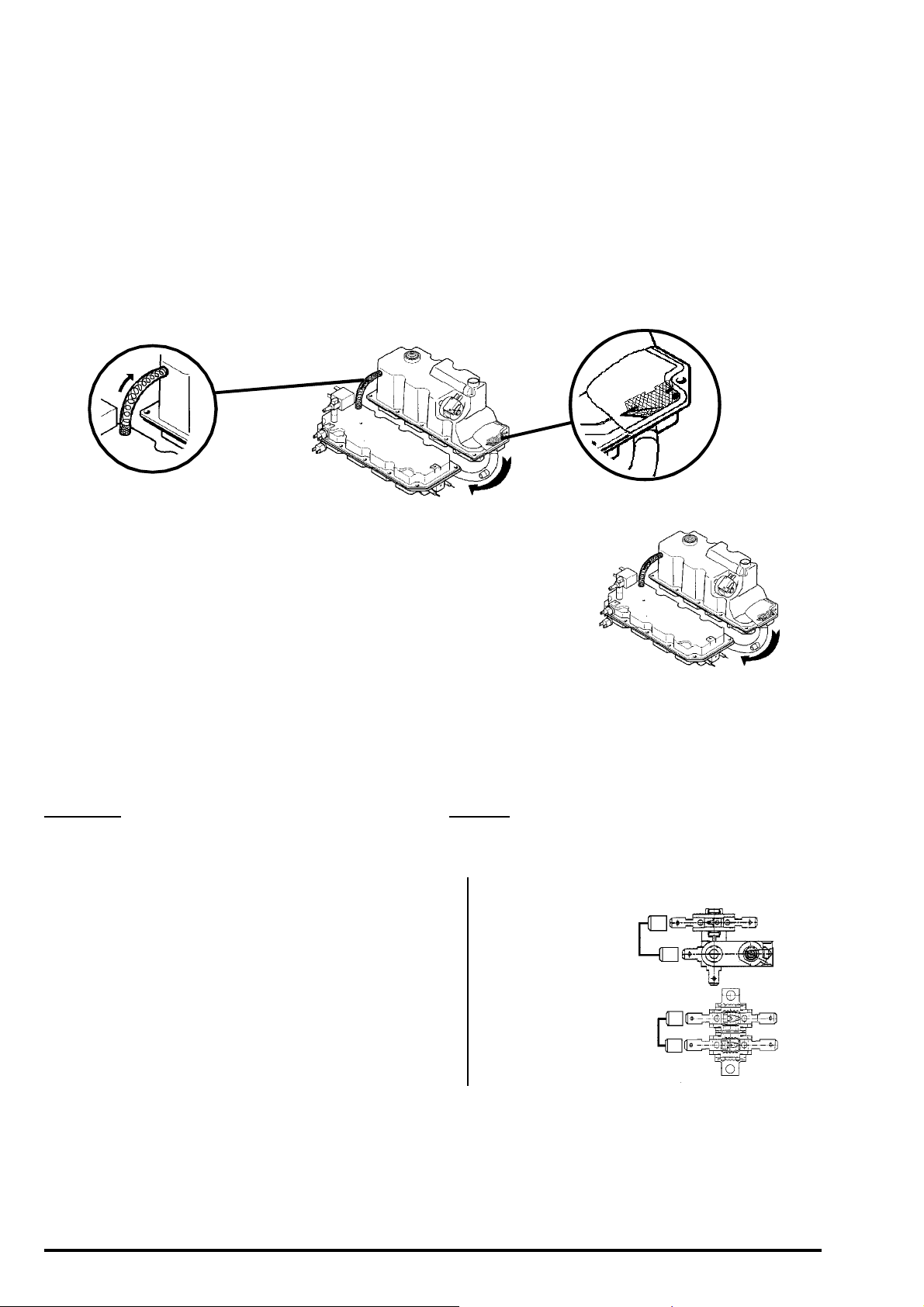

September '96 - All ironig systems with double boiler (e.g. PRO 880; VVX880; PRO750; VVX750)

We inform you, that in all ironing Systems with double boiler has been carried out a serie of modifications

in order to improve quality. The modifications are as follows:

- From N° serie 9622.. onwards, all boiler parts receive a protective painting on their inside to avoid oxidation

which resulted sometimes into blocking the lower connection between the two boiler with the no return valve in it.

As the painted boilers are perfectly interchangeable with the old ones their spare code no. remained unchanged.

Our stock warehouse will provide you automatically with the improved spare part.

- From N° serie 9622.. onwards, the diameter of the hole in the electrovalve, where steam passes through,

has been reduced from 2mm to 1.8mm in order to avoid water spills at the ironing plate.

As the new eletrovalve is perfectly interchangeable with the old one its code no. remained unchanged.

Our stock warehouse will provide you automatically with the improved spare part.

- From series N° 9626.. onwards, the bigger (right) boiler received a protective net with code no. 622351 in front

of the water outlet, hindering any dirt to get into the connection tube between the boilers blocking the valve.

- From Serial N° 9629.. onwards, inside of the upper conection tube (code no. 535526) between the two

boilers has been inserted a small spring with code no. 612019 in order to avoid strong bends and consequently the

blockage of the needed connection between the two boilers.

November '96 - All ironig systems with double boiler (e.g. PRO 880; VVX880; PRO750; VVX750)

We inform you that in order to semplify the intervention on these

machines, when there is the need to replace both boilers, is now available

a group with cod. VT515155 including the two boilers and the related

connection tubes.

March '97 - Ironig systems: PRO 880; PRO750; PRO460

We inform you that for technical and aesthetical reasons, on the iron of the above listed ironing systems, the

plastic-made handle cod. VT505535 will be replaced with a cork-made one cod.VT505526. This means that after the

exhaustion of the stock of the plastic-made handles, we will automatically send the cork-made ones.

June '97 - Ironig systems Mod. PRO 110, PRO 110A, VVT 110, VVX 110.

We inform you that from serial nr. 9608, on these models the electric diagram has changed. In particular

has changed the Thermostat +TCO (thermofuse), which is now with 4 contacts (thermostat and TCO

separated), instead of 2 contacts (thermostat and TCO bridged). This is valid for both the thermostat on the

Iron and on the Boiler.

The new thermostats are interchangeable with the old ones, as long as you bridge two of the side contacts

(see figures).

Old Code (with two contacts) New Code (with four contacts)

(Thermostat+TCO) Iron SSC40023 SSC40043

(Thermostat+TCO) Boiler SSC40021 SSC40042

This modification will apply also on the Irons type VV_ , which are available as optional on some Floor

Steam-Cleaner machines.

October '97 - Ironing systems type PRO 420 and PRO 460.

We inforrm you that, if the descaling filters of these Ironing systems remain for a long time unused, they will loose

their descaling capacity with the result that the pilot lamp will remain always on, even with a brand new filter.

In order to reactivate those filter, is enough to immerge them in water for at least 15±20 min.

PAG. 2

Page 3

TECHNICAL INFORMATION

STEAM IRON

January '98 - Irons for Ironing Systems type: PRO 110, VVT110, VVX 110,750,880.

We inform you that on the iron-plate of these irons, has been changed the connection

between the tube coming from the boiler and the iron-plate itself.

On the new iron-plate, that mantains the same code (code SSB40024),

CLAMPS

has been eliminated the brass connector to the tube, that was screwed

into the plate.

So, from now on,in case of replacement of the iron-plate, as is not

IRON-PLATE

STEAM-TUBE

(from the boiler)

BRASS CONNECTOR

(SSD20573)

PIECE OF

SILICONIC TUBE

possible to connect directly the tube to the plate (this in order

to prevent too high temperature on the tube), you will have to interpose a brass connector (our code SSD20573

or a piece of brass-made small tube instead) connected with a short piece of siliconic tube (about 4cm.), between

the tube coming from the boiler and the iron-plate (as shown on the drawing).

June '98 - Ironing Systems Micromax/SIMAC mod.315-320-321-325-330-335-408-425-903 and De' Longhi

mod. PRO 90 AS.

We inform you that from October '97, on this model we have modified the bracket that fixes the thermostats to

the bottom of the boiler (now there is a single bracket that fixes the 2 thermostats with only one screw in the

middle) and consequently we have also changed the 2 thermostats and the bottom of the boiler.

As the new parts are not interchangeable with the old ones, and, on top of this, the old parts (bottom boiler with

code SC29990082 and complete boiler with code SC33021005), are not available anymore, if you order these

codes we will automatically send you instead the new modified parts ( bottom boiler code SC29990086 and

complete boiler code SC33021006). In case you have to replace either the complete boiler or only the bottom of

it, for systems produced before the modification, you will have to replace also the thermostats and the bracket,

with the new ones (128°C with code SC1771508, of 165°C code SC1771509 and the bracket with code SC5804200

(this one will be screwed into the bottom of the boiler only with one M3x10 self-threding screw.

This means that you will have to order as well the new thermostats as the new bracket.

September '98 - Ironing Systems and Steam Cleaners with double boiler (es. PRO880, PRO750, Green

vap etc.).

We inform you that, for the tap of these appliances,is now available, other than the complete tap

(comprehensive of the "OR" gasket) also the single "OR" gasket, with code number 536465.

February '99 - Steam Irons mod. JX 1800 e JXL 1810.

code 536465

We inform you that, on the very first production of these irons (with serial number 84306 and 84406), there might

be some difficulty on the actioning of the pumps. To solve the problem is enough to replace the original OR gasket

on the pump itself with a modified OR (made of sylicon gum) with code 535692.

April '99 - Ironing Systems MICROMAX/SIMAC models 315-320-321-325-330-335-408-409-415-903 etc.,

and De' Longhi models PRO 90 AS, VVX90 etc.

With reference to the previous information (see June '98), we inform you that for a more precise intervention,

these ironing systems are now produced with two new thermostats with code VT105662 (128°C) and code

VT105663 (165°C), and also with a new fixing bracket with code 606683.

You can easily recognise the thermostats by their shape. Considering that the old

thermostats are not availavle anymore, for all request we will automatically send the

NEW OLD

correspondent new thermostat. As the old bracket is not interchangeable with the new one,

in case you have to replace an old thermostat, it will be necessary to order both and the new bracket as well.

November 2000 - Ironing Systems De' Longhi series VVX and PRO models 110/120/200.

In case you have to replace in these appliances either the heating element or the boiler, in order to improve the

heat-conduction between these two parts, is now available a special gasket with high heat-conductivity.

The codes are:

SSD80007 the 9 holes gasket for PRO/VVX 110 and 120,

SSD80009 the 10 holes gasket used on PRO/VVX 200.

The use of this gasket avoids the use of any heat-conductivity paste.

Pag. 3

Loading...

Loading...