Page 1

Dell™P o werVault™LTO Tape User's Guide

User's Guide

Page 2

Note!

Before using this information and the product it supports, be sure to read the general information under Notices in the Dell

PowerVault LTO Tape Drive User's Guide.

NOTE indicates important information that helps you make better use of your system.

NOTICE indicates either potential damage to hardware or loss of data and tells you how to avoid the problem.

CAUTION indicates a potential for property damage, personal injury, or death.

Information in this document is subject to change without notice.

© 2012 Dell Inc. All rights reserved.

© International Business Machines Corporation, 2012. All rights reserved.

Trademarks used in this text: Dell, the DELL logo, and PowerVault, are trademarks of Dell Inc. Microsoft and Windows

are registered trademarks of Microsoft Corporation.

Other trademarks and trade names may be used in this document to refer to either the entities claiming the marks

and names or their products. Dell Inc. disclaims any proprietary interest in trademarks and trade names other than

its own.

v Internal Drive Model Numbers: LTO Ultrium 6-H, LTO Ultrium 5-H, LTO Ultrium 4-H, LTO Ultrium 3-H

v External Drive Model Numbers: CSEH 001, LTO4-EH1, LTO3-EH1

v Rack Mount Model Number: 2U Storage Rack A

Initial release: November 2012

Page 3

Contents

Figures ...............v

Tables ...............vii

Chapter 1. Introduction .......1-1

Overview ...............1-1

Encryption ..............1-2

Specifications and Features .........1-3

Tape Backup Software ..........1-4

Front Panel ..............1-4

Rear Panel ..............1-6

Chapter 2. Setting Up the Tape Drive 2-1

Pre-installed Internal Drives ........2-1

Installing Internal Drives .........2-1

Installing the Internal Drive - Step-By-Step

Instructions .............2-1

Installing External and Rack Mount Drives . . . 2-5

Installing the External Drive - Step-By-Step

Instructions .............2-5

Verifying Drive Operation ........2-7

Loading Device Drivers .........2-7

Ethernet Service Port Procedures ......2-8

Chapter 3. Using the Tape Drive . . . 3-1

Operating the Drive ...........3-1

Loading, Unloading, and Write-Protecting

Cartridges ..............3-2

Caring for Tape Cartridges .........3-5

Cleaning the Tape Mechanism ........3-7

Obtaining Drivers and Firmware Upgrades . . . 5-1

Selecting a Diagnostic or Maintenance Function . . 5-1

General Guidelines ...........5-8

Methods of Receiving Errors and Messages . . . 5-9

Descriptions and Corrective Actions .....5-10

Drive Status .............5-13

Drive Maintenance ...........5-14

Fixing SAS Connectivity Problems ......5-15

Resolving Media-Related Problems ......5-16

Removing an Internal SAS Tape Drive .....5-16

TapeAlert ..............5-17

Recovering a Tape Cartridge ........5-20

Chapter 6. Specifications ......6-1

General Specifications ...........6-1

Internal Drive .............6-1

External Drive .............6-2

Rack Mount Drive ............6-3

Chapter 7. Getting Help .......7-1

Technical Assistance ...........7-1

Dell Enterprise Training and Certification ....7-3

Problems with Your Order .........7-3

Product Information ...........7-3

Returning Items for Warranty Repair or Credit . . 7-3

Before You Call .............7-3

Chapter 8. Contacting Dell ......8-1

Appendix. Regulatory Information . . A-1

Chapter 4. Using the Tape Backup

Software..............4-1

Chapter 5. Troubleshooting .....5-1

Glossary .............B-1

Index ...............X-1

iii

Page 4

iv Dell PowerVault LTO Tape Drive User's Guide

Page 5

Figures

1-1. PowerVault Internal Model ......1-1

1-2. PowerVault External Model ......1-2

1-3. PowerVault Rack Mount Model .....1-2

1-4. Front Panel............1-4

1-5. Rear Panel of Internal SAS Tape Drive 1-6

1-6. Rear Panel of External SAS Tape Drive 1-6

1-7. Rear Panel of the Rack Mount Tape Drive 1-7

2-1. Air Intake Area ..........2-2

2-2. Install the Drive ..........2-3

2-3. Mounting Holes on Tape Drive .....2-4

2-4. Attaching SAS Cable ........2-4

2-5. Secure the Drive ..........2-5

2-6. Connecting the SAS cable .......2-6

2-7. Connecting two SAS Hosts to one Tape

Drive..............2-7

3-1. Turning on the External Drive .....3-1

3-2. Turning on the Rack Mount Drive 3-1

3-3. Resetting the Drive .........3-2

3-4. LTO Ultrium Data Cartridge ......3-3

3-5. Loading .............3-4

3-6. Setting the Write-Protect Switch .....3-5

5-1. Drive Status page .........5-14

5-2. Drive Status page - details ......5-14

5-3. Drive Maintenance page .......5-15

v

Page 6

vi Dell PowerVault LTO Tape Drive User's Guide

Page 7

Tables

1-1. LTO Generation Specifications .....1-3

1-2. SCD, Ready/Activity LED, and Fault LED

Descriptions ...........1-5

3-1. Supported Functions of Compatible Media

Types..............3-2

3-2. Environmental Specifications ......3-6

5-1. Diagnostic and Maintenance Function Codes

and Descriptions ..........5-2

5-2. General Troubleshooting .......5-8

5-3. Methods of Receiving Errors and Messages 5-10

5-4. Descriptions and Corrective Actions 5-10

5-5. TapeAlert Flags and Descriptions 5-17

6-1. General specifications ........6-1

6-2. Internal Drive specifications ......6-1

6-3. External Drive specifications ......6-3

6-4. Rack Mount drive specifications.....6-3

7-1. Diagnostics Checklist ........7-4

vii

Page 8

viii Dell PowerVault LTO Tape Drive User's Guide

Page 9

Chapter 1. Introduction

v “Overview”

– “Serial Attached SCSI (SAS) Interface” on page 1-2

v “Encryption” on page 1-2

v “Specifications and Features” on page 1-3

v “Tape Backup Software” on page 1-4

v “Front Panel” on page 1-4

v “Rear Panel” on page 1-6

Overview

The LTO PowerVault tape drive is a high-performance, high-capacity tape storage

device that is designed to back up and restore data and archive and retrieve files

in an Open Systems environment. The drive can be integrated into a system

(internal model) or can be provided as a separately packaged desktop unit

(external model). There are six generations of the Dell PowerVault tape drives in

the LTO series of products.

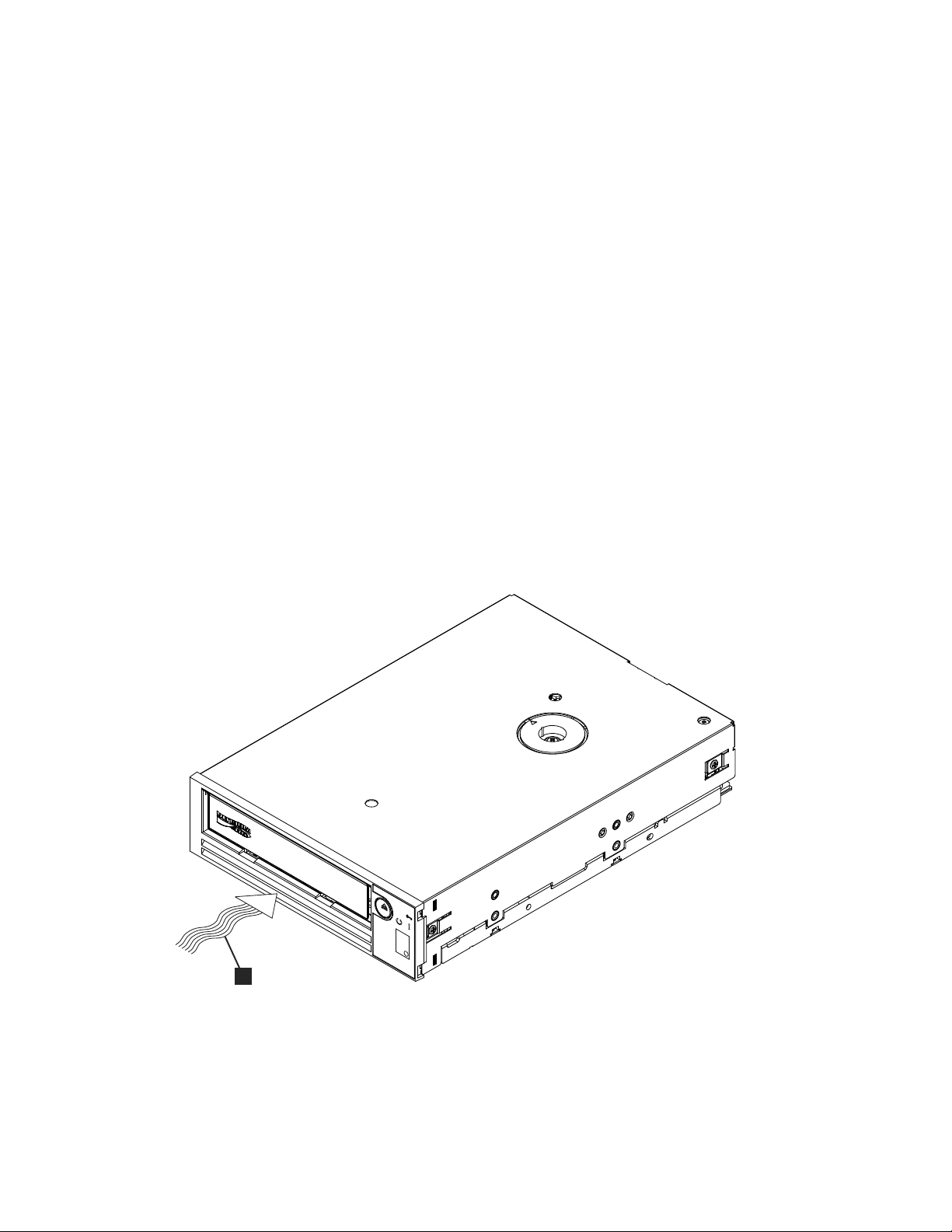

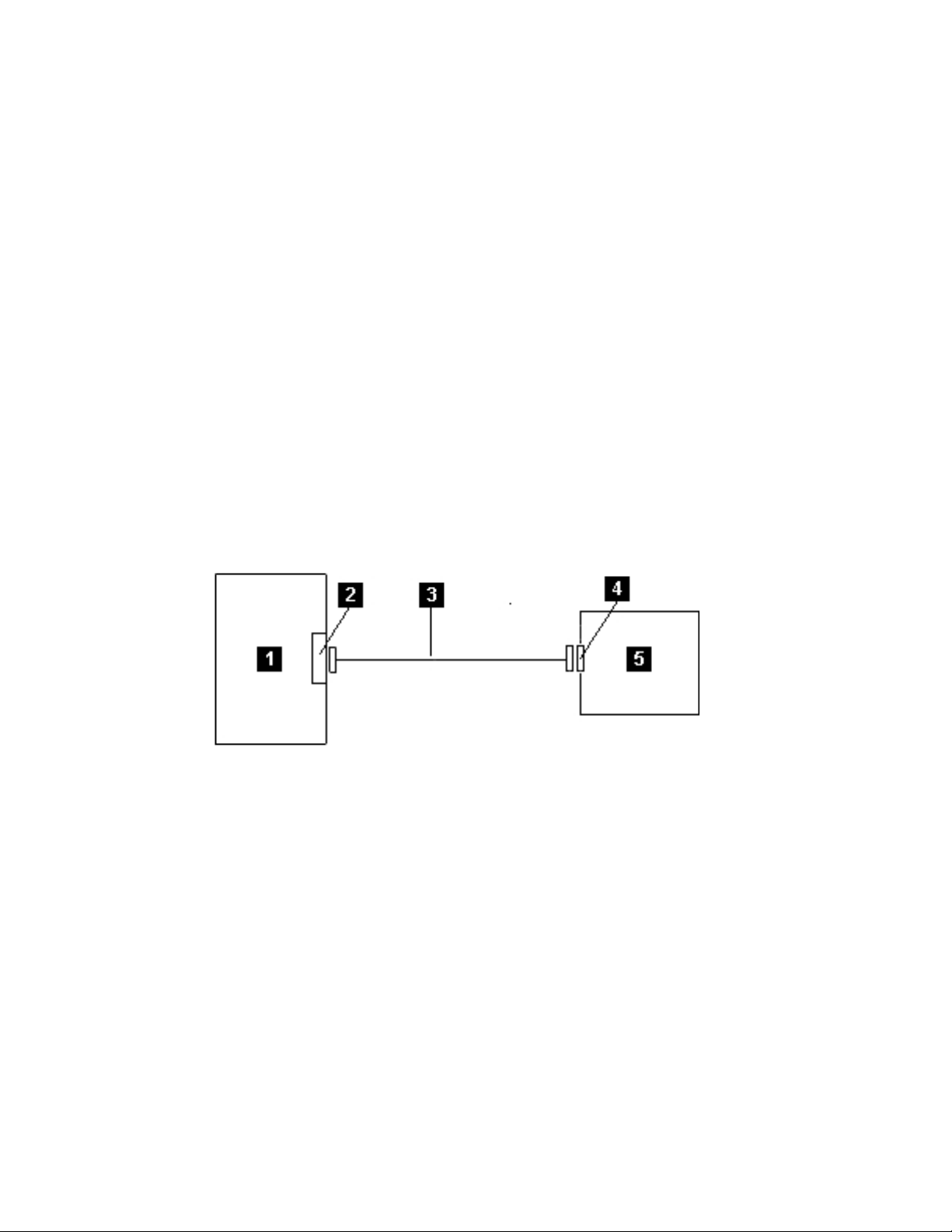

Figure 1-1 shows the internal model of the tape drive. Figure 1-2 on page 1-2

shows the separately purchased external model of the tape drive. Figure 1-3 on

page 1-2 shows the rack mount model.

Figure 1-1. PowerVault Internal Model

a80hd004

1-1

Page 10

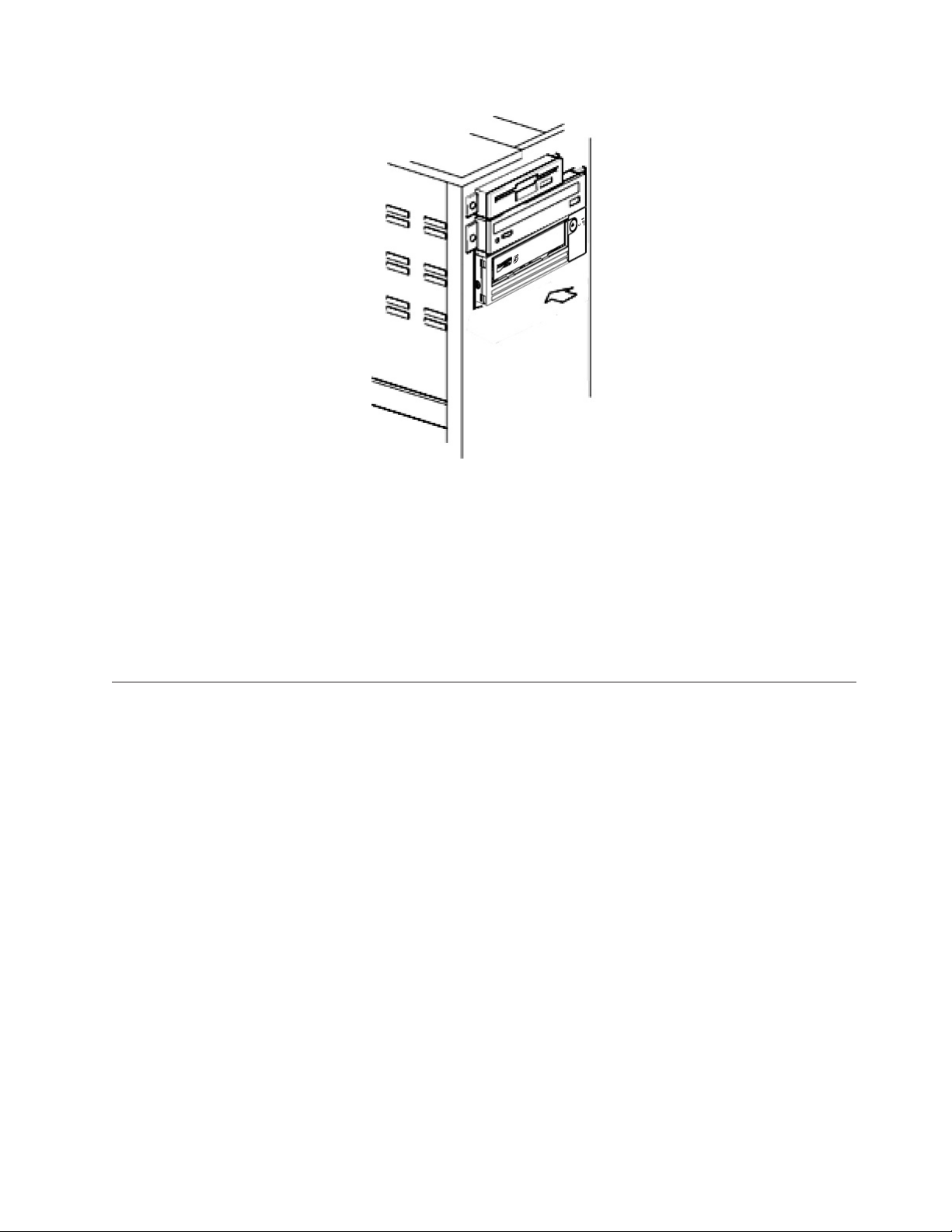

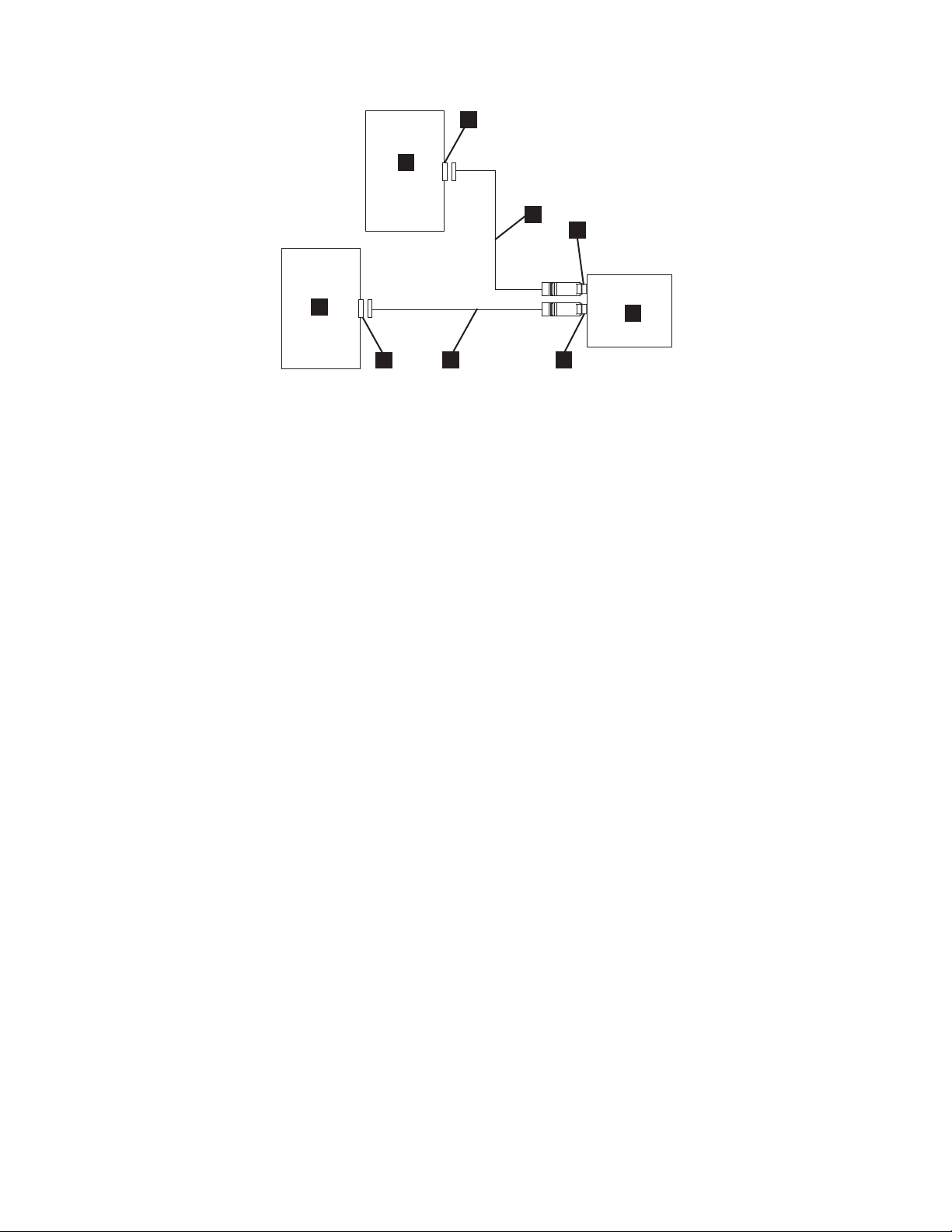

Figure 1-2. PowerVault External Model

Figure 1-3. PowerVault Rack Mount Model

Serial Attached SCSI (SAS) Interface

A drive with a SAS (Serial Attached SCSI) interface can be linked directly to

controllers. The SAS interface offers the following advantages over the traditional

SCSI interface:

v SAS enables multiple devices (up to 128) of different sizes and types to be

connected simultaneously with thinner and longer cables.

v Its full-duplex signal transmission supports up to 6.0 Gb/s.

v SAS drives can be hot-plugged.

1

a80hd00

a77ug279

Encryption

The Tape Drive has Application Managed Encryption (AME) functionality. You

must have an application that supports encryption to use the drive's encryption

capability. For more details, consult your application support documentation.

1-2 Dell PowerVault LTO Tape Drive User's Guide

Page 11

Specifications and Features

Specifications

Table 1-1. LTO Generation Specifications

Specification LTO6 LTO5-140 LTO4-120 LTO3-80

Native Capacity 2500 GB 1500 GB 800 GB 400 GB

2.5:1

Compressed

Capacity

2:1 Compressed

Capacity

Maximum

Native Data

Transfer

Compressed

Maximum Data

Transfer*

Media

Partitioning**

Data Safe

Mode**

Encryption

Status LED

PowerVault Generation

6250 GB NA NA NA

5000 GB 3000 GB 1600 GB 800 GB

160 MB/s 140 MB/s 120 MB/s 80 MB/s

400 MB/s 280 MB/s 240 MB/s 160 MB/s

X X NA NA

X X NA NA

X X NA NA

* Assumes compression. The capacity and transfer rate you realize in practice

depends on the data set, which affects the actual compression ratio. LTO6 supports

2.5:1 compression. LTO5-140 and below support 2:1 compression.

** This feature must be supported by your tape backup software.

Features

The tape drive has the following features:

v Built-in read-after-write verification for a high level of data integrity

v Burst data transfer rate of 600 MB per second

v 512 MB of read/write cache memory

v Intelligent LTO-DC dual-mode compression algorithm

v Failsafe leader capture mechanism with pin pick error recovery

v Reads cartridge memory in LTO cartridges

v TapeAlert support for improved diagnostic and troubleshooting

v Two 6 Gb Serial Attached SCSI interface

v Speed matching (The drive can slow down to match the system data rate.)

v Sleep mode for energy conservation

v Backward read and write compatibility dependent on generation

v Compatible with all cartridges dependent on generation that bears the official

Ultrium LTO logo. See Table 1-1 for more information.

Chapter 1. Introduction 1-3

Page 12

v Will interchange tapes with other LTO tape drives that bear the official Ultrium

LTO logo

v Support for WORM (Write Once Read Many) using WORM media

v Data encryption capability using LTO Ultrium 4, 5 and 6 media

v Ethernet interface for transferring drive firmware and dumps only (not an iSCSI

interface)

v Diagnostics of the drive over the ethernet service port (not an iSCSI interface)

Tape Backup Software

You need backup software that supports the Dell PowerVault tape drive. As a

general rule, native backup applications (such as NTBackup and tar) do not

provide the required data streaming rate to get the full performance of your tape

drive. It is recommend that you use a backup application that provides better

memory management as well as other useful features, such as TapeAlert. For the

latest supported software versions, go to the Dell support website at

http://support.dell.com or visit the support site of your backup software vendor.

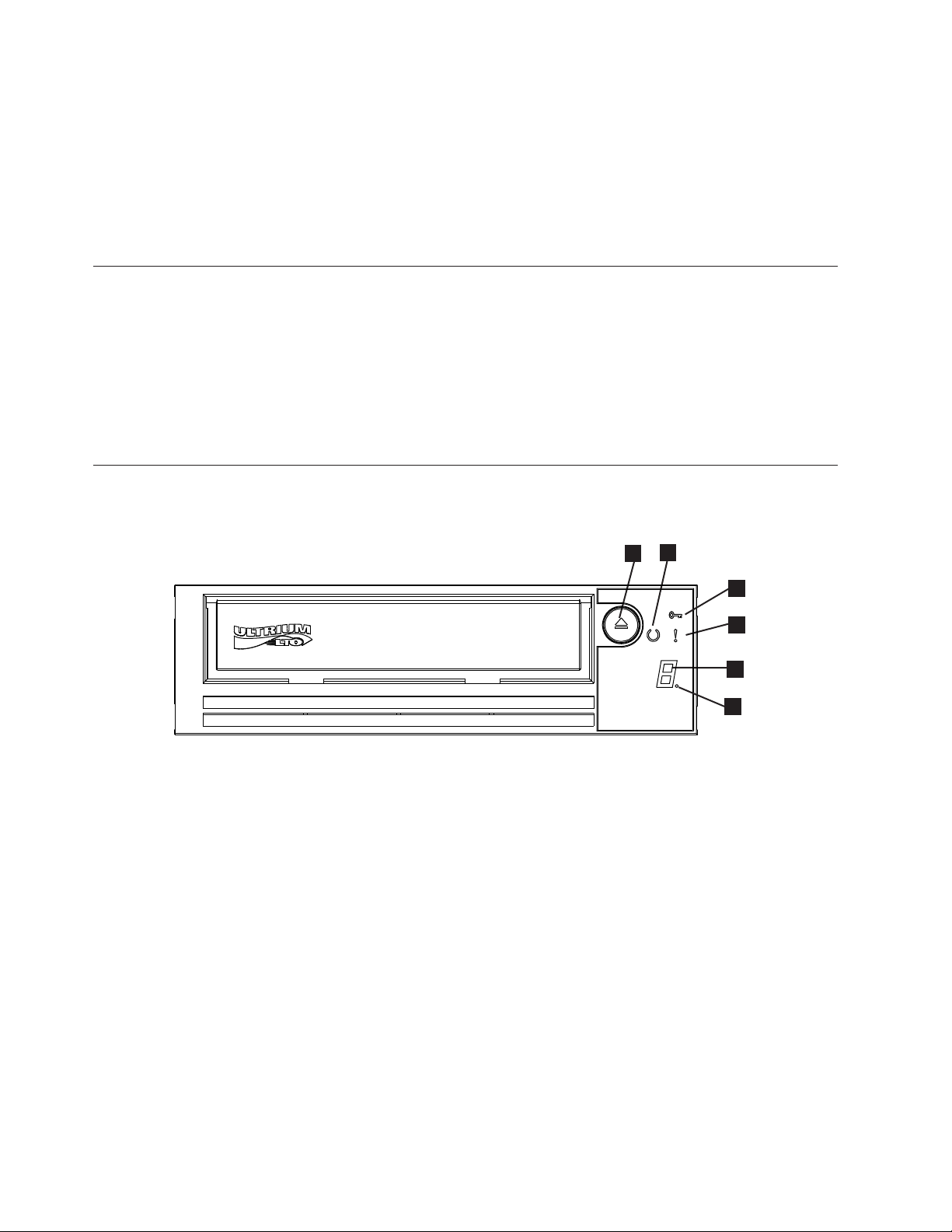

Front Panel

2

1

Figure 1-4. Front Panel

6

3

4

3

5

a80hd00

1 Eject button 4 Single-character display (SCD)

2 Ready/Activity LED 5 Single dot

3 Fault LED 6 Encryption Status LED

1. Eject button. The eject button enables you to perform several functions. These

functions are described in detail in Chapter 3, “Using the Tape Drive,” on page

3-1.

2. Ready/Activity LED. The front panel of your Dell PowerVault LTO tape drive

has a green Ready/Activity LED providing information about the state of the

tape drive. The LED can be solid on or flashing when lit. See Table 1-2 on page

1-5 for more descriptions.

3. Fault LED. The front panel of your Dell PowerVault LTO tape drive has an

amber fault LED indicating the drive has encountered an error, is not in a

normal operational status, or needs cleaning. See Table 1-2 on page 1-5 for more

detailed description.

1-4 Dell PowerVault LTO Tape Drive User's Guide

Page 13

4. Single-character display (SCD). This LED presents a single-character code for

C

C

C

diagnostic/maintenance functions, error conditions, and informational

messages.

5. Single dot. This single-character display is blank during normal operation.

When a single dot illuminates and flashes on the display, the drive has created

a dump of vital technical data to drive memory.

6. Encryption status LED. This white LED indicates all data (except for the label

information) on the cartridge is encrypted. (LTO5 and LTO6 cartridges only).

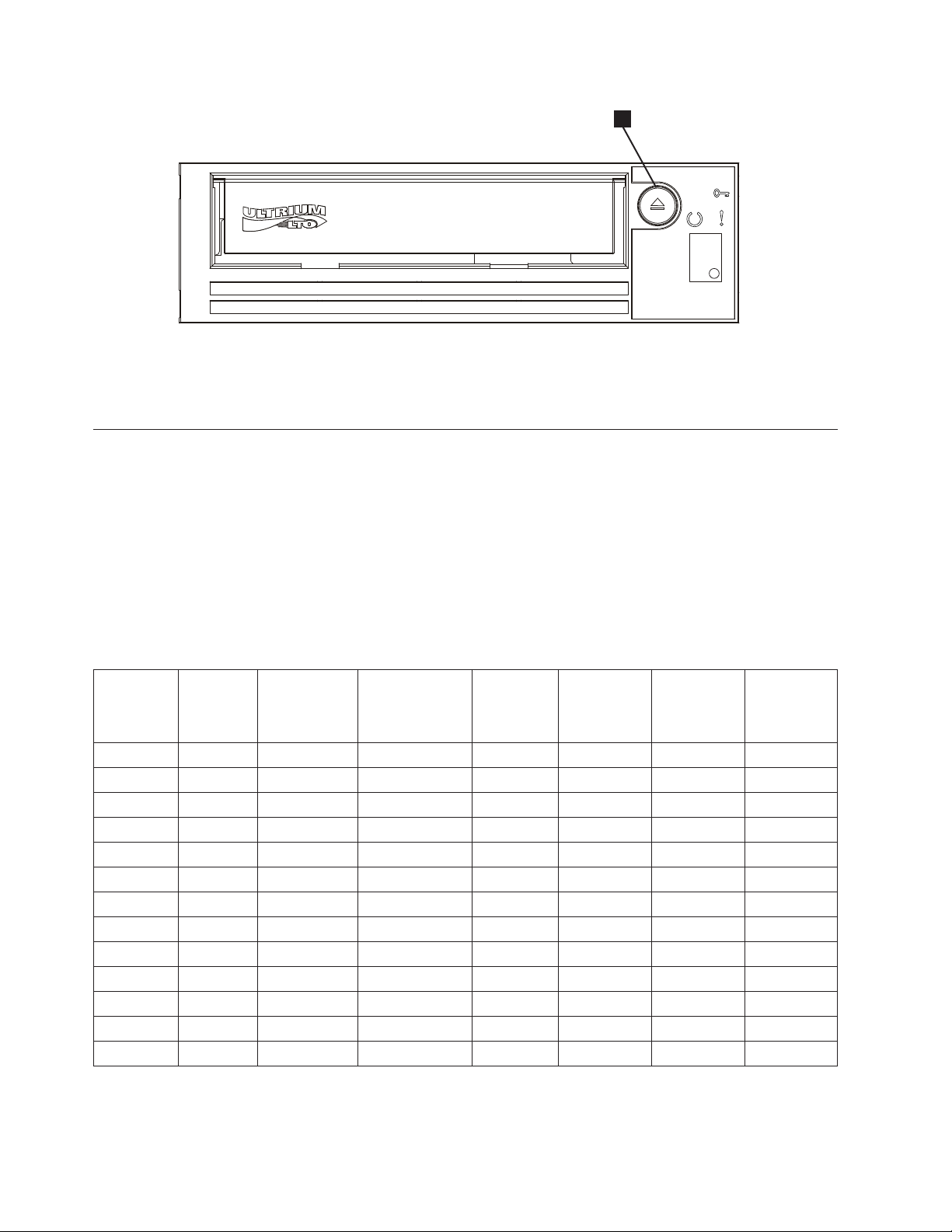

Table 1-2. SCD, Ready/Activity LED, and Fault LED Descriptions

Condition of

green

Ready/

Activity LED

Off Off Off Off Off The tape drive has no power or is

On Solid Off Off

Flashing once

per second

Off On/Solid Off On Solid On/Off The tape drive is in maintenance mode

Off On Solid Off Flashing once

Off Flashing

Condition

of amber

Fault LED

Off On or Off Off Off The tape drive is reading from the

once per

second

Condition

of white

encryption

LED

Off On Solid Off An error occurred and the tape drive

Condition of

the SCD Panel

Off or

per second

Condition of

the SCD Dot

Off The tape drive is powered on or (if a

On/Off Executing the selected option while in

Meaning of LEDs and SCD Panel and

SCD Dot

powered off.

solid

character display) needs cleaning.

tape, writing to the tape, rewinding the

tape, locating data on the tape, loading

the tape, or unloading the tape. The

Encryption LED will be On if all the

data on the cartridge is encrypted

during these drive operations. The

Ready/Activity LED also flashes green

if the tape drive contains a cartridge

during the power on cycle. In this case,

the drive completes POST and slowly

rewinds the tape (this process may take

approximately 13 minutes). The

Ready/Activity LED stops blinking

when the drive completes the recovery

and is ready for a read or write

operation. To eject the cartridge, press

the unload button.

or is displaying an error code on the

SCD in maintenance mode option 9.

maintenance mode.

or media may require service or drive

may require cleaning.

displays in the single

Note the code on the single character

display, and then go to the error code

table in the troubleshooting section to

determine the meaning of the error

codes.

If a

cleaning cartridge must be loaded.

appears on the SCD, a

Chapter 1. Introduction 1-5

Page 14

Table 1-2. SCD, Ready/Activity LED, and Fault LED Descriptions (continued)

Condition of

green

Ready/

Activity LED

Condition

of amber

Fault LED

Off Flashing

Condition

of white

encryption

LED

Condition of

the SCD Panel

Condition of

the SCD Dot

Off Off Off The drive is updating firmware.

twice per

second

Off Flashing

Off Off Off The drive detected an error and is

once every

2 seconds

Rear Panel

Meaning of LEDs and SCD Panel and

SCD Dot

performing a firmware recovery. It will

reset automatically.

2

1

4

3

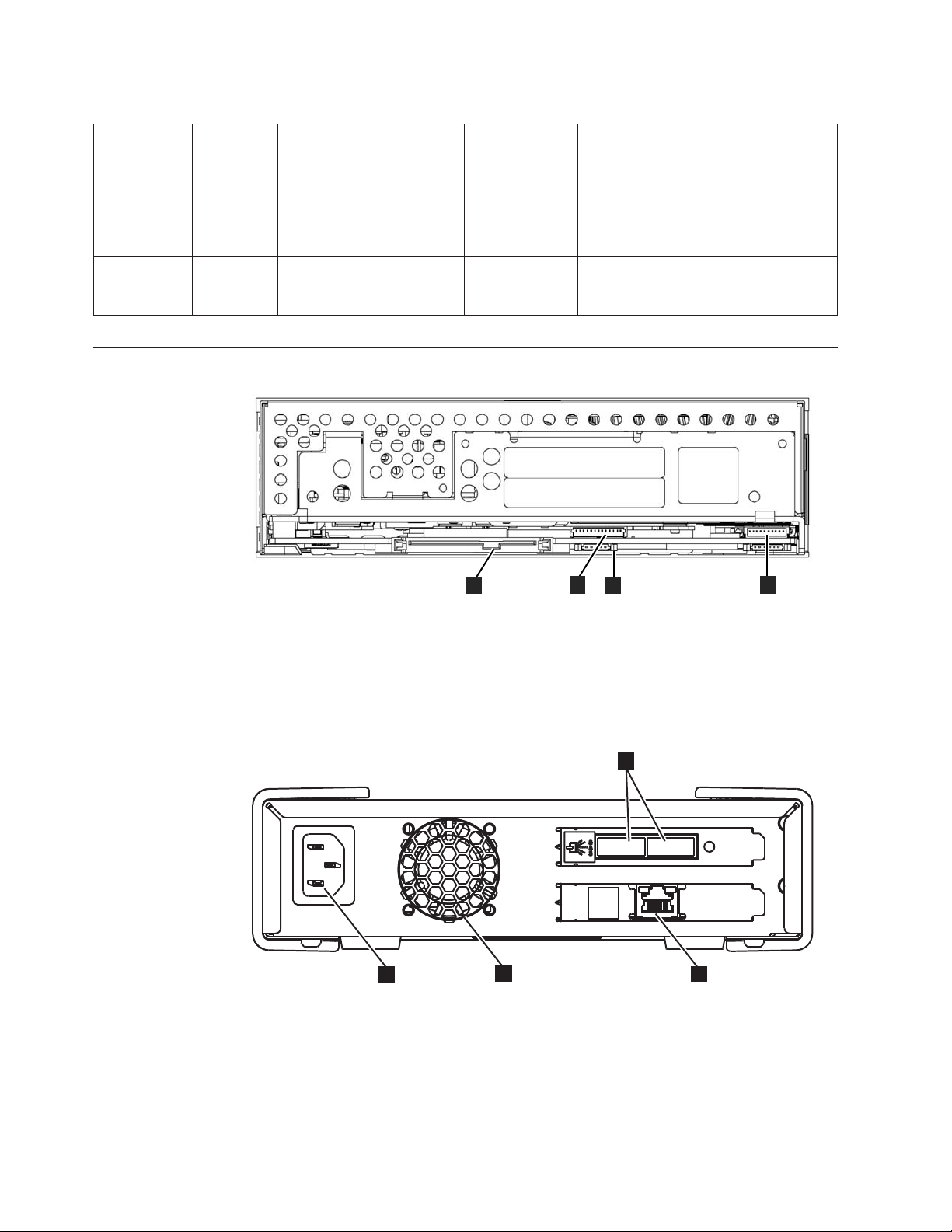

Figure 1-5. Rear Panel of Internal SAS Tape Drive

1 SAS connector 3 Library interface

2 Ethernet - not iSCSI - for

4 LED controls for library drive sled

transferring firmware

and dumps only

3

1

2

4

Figure 1-6. Rear Panel of External SAS Tape Drive

1 Power connector 3 SAS connectors

2 Fan enclosure 4 Ethernet - not iSCSI - for transferring

firmware and dumps only

a80hh095

12

a80hh0

1-6 Dell PowerVault LTO Tape Drive User's Guide

Page 15

33

4

1

4

2

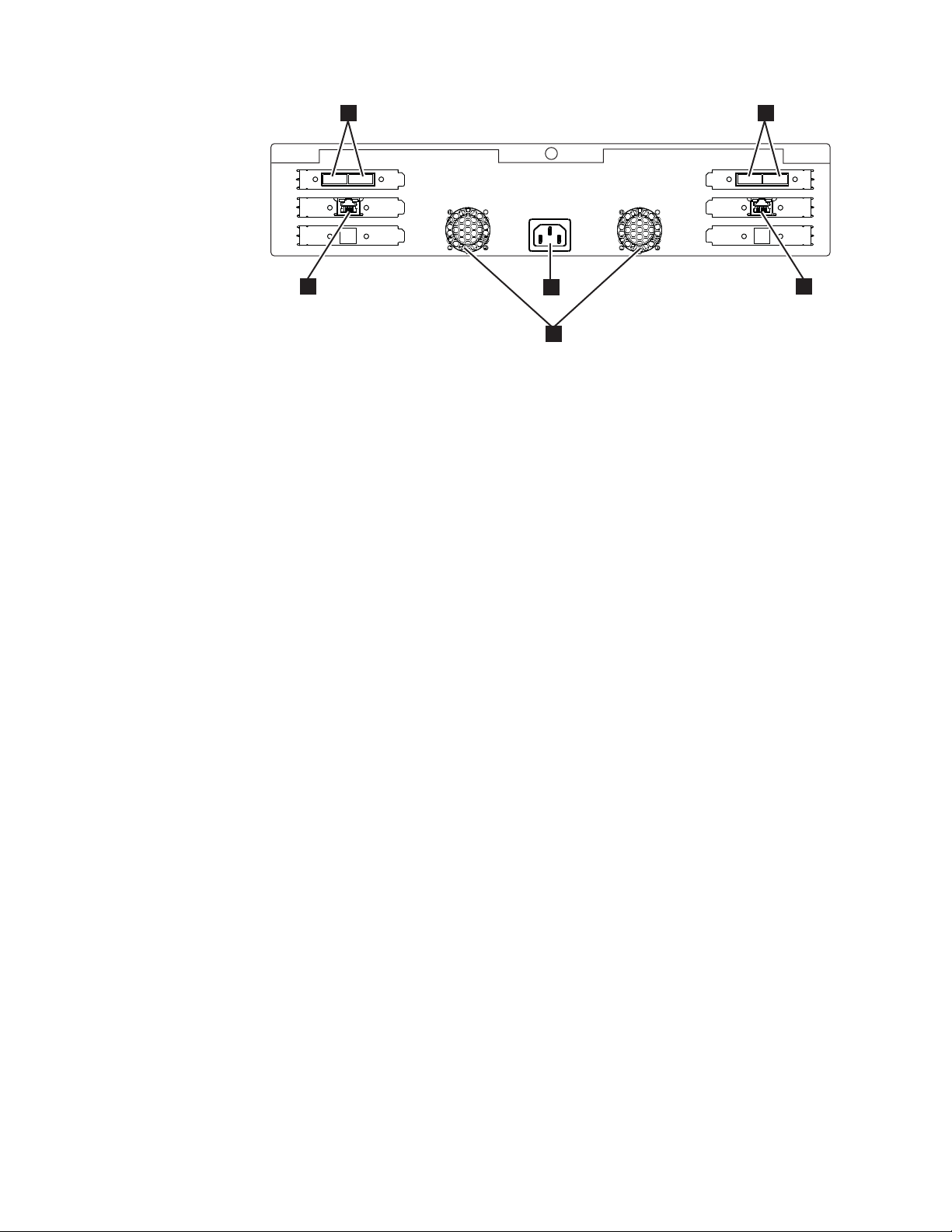

Figure 1-7. Rear Panel of the Rack Mount Tape Drive

1 Power connector 3 SAS connectors

2 Fan enclosure 4 Ethernet - not iSCSI - for transferring

firmware and dumps only

a80hh089

Chapter 1. Introduction 1-7

Page 16

1-8 Dell PowerVault LTO Tape Drive User's Guide

Page 17

Chapter 2. Setting Up the Tape Drive

v “Pre-installed Internal Drives”

v “Installing Internal Drives”

– “Installing the Internal Drive - Step-By-Step Instructions”

v “Installing External and Rack Mount Drives” on page 2-5

– “Installing the External Drive - Step-By-Step Instructions” on page 2-5

v “Verifying Drive Operation” on page 2-7

v “Loading Device Drivers” on page 2-7

v “Ethernet Service Port Procedures” on page 2-8

Pre-installed Internal Drives

Dell performs the installation and setup of internal tape drives that are shipped as

part of a system. If tape backup software is included in your system, refer to the

installation instructions included with the software.

For the latest supported software versions, go to the Dell support website

http://support.dell.com or visit the support site of your backup software vendor.

Installing Internal Drives

If your internal tape drive is not pre-installed, the installation instructions are

described in the following sections:

Installing the Drive — Prerequisites

The Dell PowerVault tape drive isa6GbSASdevice with a burst transfer rate of

600 MB per second. It is recommended that you use a dedicated SAS host bus

adapter for this tape drive.

Mounting Bay

You need one industry-standard, 5 1/4 inch, half-height bay in which to install the

PowerVault tape drive. The only supported mounting configurations are

horizontally with the base of the drive parallel to the ground, or vertically with

either the left or right side of the drive parallel to the ground.

Install and configure the drive according to the instructions provided in the Dell

documentation for your system.

Mounting Hardware

Most systems use trays or rails to mount the tape drive. If the mounting hardware

is pre-installed, you can simply slide the drive into the mounting bay. Some

systems do not use slides or rails and drives must be fixed in place with screws.

Installing the Internal Drive - Step-By-Step Instructions

Procedure

1. Unpacking the Drive

2-1

Page 18

Unpack the tape drive and store the packaging. You may need the packaging if

you return the unit for service.

A period of time is required if the temperature of the drive when unpacked is

different than the temperature of its operating environment (measured at the

front of the bezel near the air intake area; see 1 in Figure 2-1). The

recommended time is 4 hours after the drive has been unpacked or 1 hour after

any condensation that you can see has evaporated, whichever is greater. To

allow the drive to adjust to its new environment, apply the following measures:

v If the drive is colder than its operating environment and the air contains

sufficient humidity, condensation may occur in the drive and damage it.

When the drive has warmed to the operating temperature range (greater

than 10 degrees C or 50 degrees F) and no danger of condensation is present

(the air is dry), warm the drive more quickly by powering it on for 30

minutes. Use a scratch tape to test the drive before inserting a tape that

contains data.

v If the drive is hotter than its operating environment, the tape can stick to the

drive head. When the drive has cooled to the operating temperature range

(less than 40 degrees C or 104 degrees F), cool the drive more quickly by

applying airflow for 30 minutes. Power on the drive and use a scratch tape

to test it before inserting a tape that contains data.

If you are uncertain about whether the temperature of the drive is within the

recommended operating range or the humidity is sufficient to cause

condensation, allow the drive to adjust to its new environment for the full 4

hours.

1

Figure 2-1. Air Intake Area

1 Air Intake Area

2. Removing Power from the System

a. Power-off the system.

b. Disconnect the power cord from both the electrical outlet and the system.

2-2 Dell PowerVault LTO Tape Drive User's Guide

a80hd002

Page 19

3. Preparing the Mounting Bay in Your System

CAUTION:

To avoid personal injury or damage to the system or tape drive, ensure that

the system power cord is disconnected before you install the drive.

Refer to your system's documentation for instructions on how to prepare the

mounting bay to receive the tape drive.

4. Attaching Mounting Hardware

If your system requires special rails or other hardware to install the tape drive,

mount them on the tape drive in this step.

If your system does not require special mounting hardware, proceed to step 5.

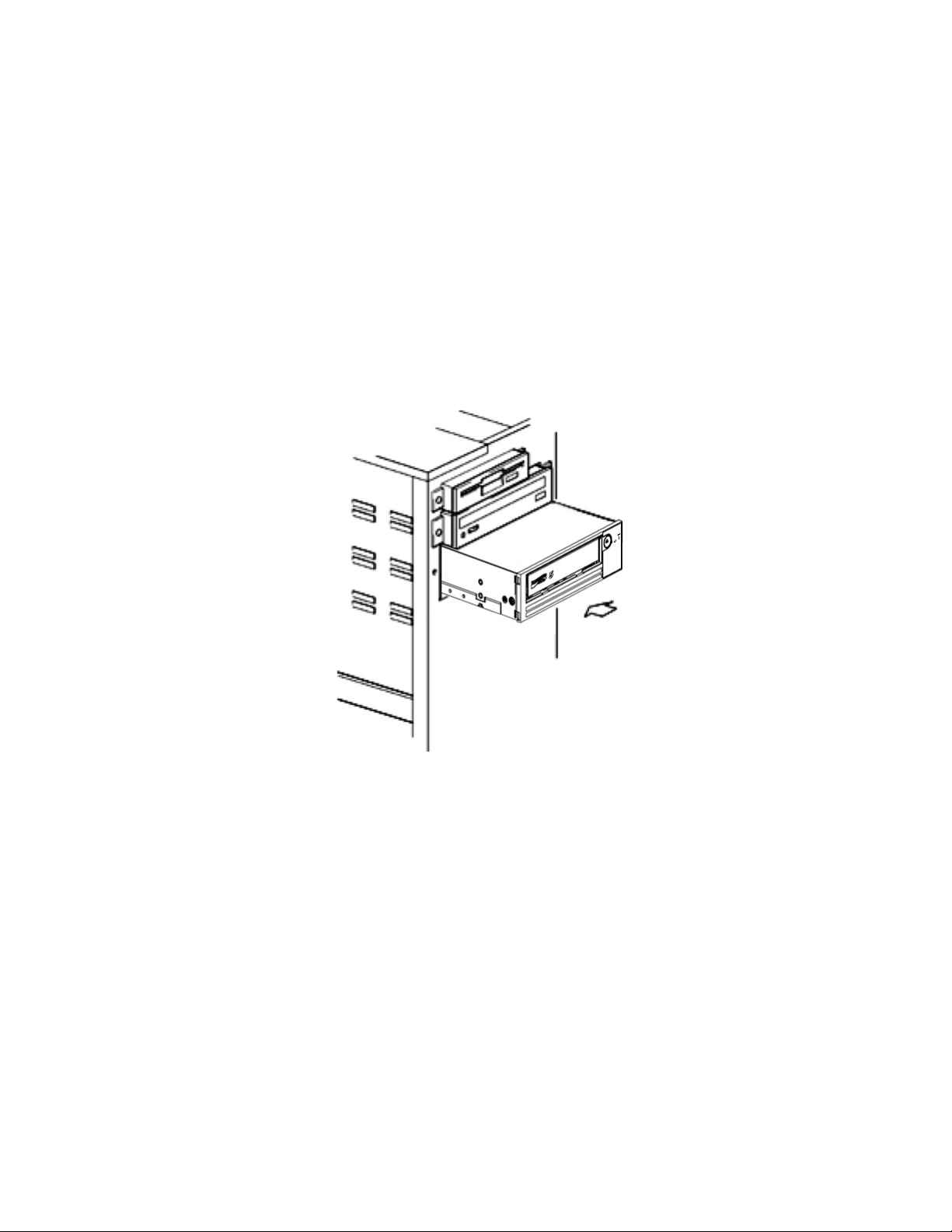

5. Installing the Drive

Slide the tape drive into the open bay, aligning the tray or rails with the slots in

the bay, as shown in Figure 2-2.

Figure 2-2. Install the Drive

6

a80hd00

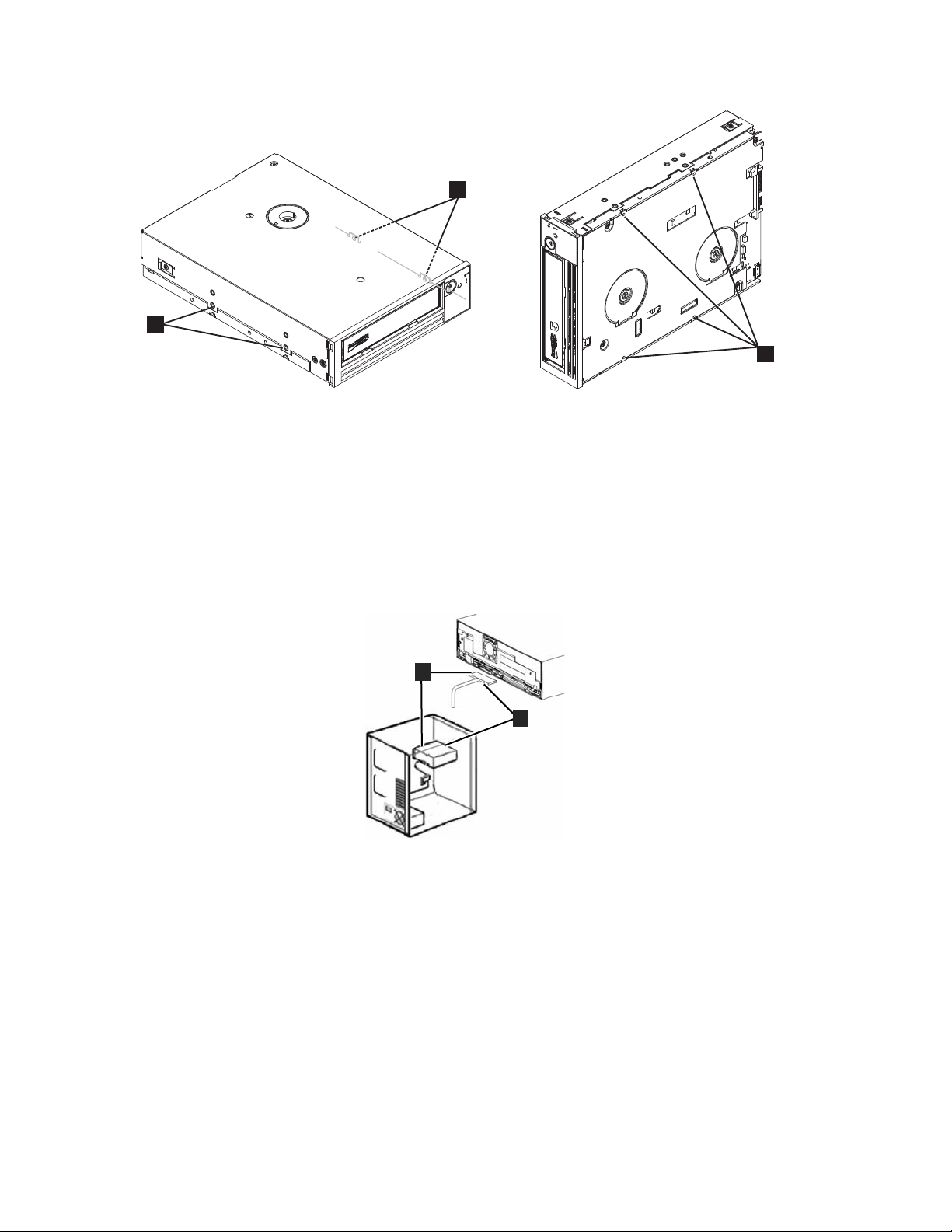

If your system does not use mounting hardware, check that the holes in the

chassis are aligned with the holes in the side of the tape drive (see Figure 2-3

on page 2-4).

Chapter 2. Setting Up the Tape Drive 2-3

Page 20

1

Figure 2-3. Mounting Holes on Tape Drive

1 M-3 mounting screw holes

Do not secure the drive with screws at this point because you may have to

move the drive to get the cables in place.

6. Attaching SAS Cable

Attach the system SAS cable to the drive SAS connector, as shown in

Figure 2-4.

1

10

1

a80hh0

Figure 2-4. Attaching SAS Cable

1 SAS cable

2 Power cable

7. Securing the Drive

The tape drive can now be secured to the system as shown in Figure 2-5 on

page 2-5. There are several ways to secure the drive. If the drive is on rails or

in a sled, then push it in place. Some systems require the drive to be inserted

into a media bay and attached directly to the system with screws.

1

2

a80hh094

2-4 Dell PowerVault LTO Tape Drive User's Guide

Page 21

Figure 2-5. Secure the Drive

8. Connecting Host System Power and Testing Power to the Tape Drive

Connect the power cord to the system and to the electrical outlet. To ensure

that the drive is receiving power, watch for the following indicators while

turning on the power to the system:

a. The single-character display presents a series of random characters.

b. The single-character display becomes blank (not lit).

c. The Fault LED briefly turns on, then the ready/activity LED turns on solid.

Installing External and Rack Mount Drives

Installing the Drive — Prerequisites

The SAS tape drive has a burst transfer rate of 600 MB per second. It is

recommended that a dedicated host bus adapter is used for the tape drive.

Your system must have a properly installed and configured SAS host adapter or a

SAS controller on the motherboard (if available) with driver software that supports

the tape drive. Do not connect to a RAID controller channel; RAID controller

channels are for disk drives only.

a80hd007

Installing the External Drive - Step-By-Step Instructions

Procedure

1. Positioning the Tape Drive

Position the tape drive convenient to the system. The only restrictions are the

length of the power cord and the length of the SAS cable. The following

locations are recommended:

v Away from high-traffic areas, especially if the floor is carpeted.

v Out of copy rooms to avoid toner and paper dust. Do not store paper

supplies next to any unit.

v Away from moving air, such as doorways, open windows, fans, and air

conditioners.

Chapter 2. Setting Up the Tape Drive 2-5

Page 22

v Off the floor.

v Where the tape cartridge can easily be inserted.

Only the following mounting positions are supported:

v In a horizontal or vertical position for external drives.

v In a horizontal position for rack mounted drives.

Notice: The external tape drive should not be stacked. Do not place anything

on top of the unit.

2. Connecting Power

An external Dell PowerVault Tape Drive will operate using any voltage in the

range 100–240 volts (50–60 Hz). No adjustment is needed. To connect your

drive to the power supply, proceed as follows:

a. Plug the power cable securely into the socket on the rear panel of the drive.

b. Plug the other end of the power cable into a grounded power outlet.

c. Power on the tape drive by pressing the power on/off button. The tape

drive runs the POST, which checks all hardware except the drive head.

3. Connecting the SAS Cable

Attach one end of the SAS cable to the SAS host adapter card installed in the

system. Attach the other end of the SAS cable to the SAS connector on the rear

panel of the tape drive. The cable can be up to 5 m (16.4 ft) long. This

configuration is shown in Figure 2-6.

Figure 2-6. Connecting the SAS cable

1 System 4 Drive SAS connector

2 SAS host adapter card 5 Tape Drive

3 SAS cable

To connect a second system to the tape drive, attach one end of the second SAS

cable to the SAS host adaptor installed in the second system. Attach the other

end of the second SAS cable to the other SAS port on the rear panel of the tape

drive. This configuration is shown in Figure 2-7 on page 2-7.

2-6 Dell PowerVault LTO Tape Drive User's Guide

ltog2028

Page 23

4

5

3

2

5

4

Figure 2-7. Connecting two SAS Hosts to one Tape Drive

1 Tape Drive 4 SAS host adapter card

2 Drive shaft connector 5 System

3 SAS cable

3

Note: Unlike SCSI, the SAS architecture does not support daisy changing.

4. Configuring the Tape Drive to the Host

Power on the tape drive. Refer to your system and application software

manuals to configure the tape drive for use.

Verifying Drive Operation

After you install the drive hardware, verify that it is functioning properly before

you store your valuable data. Turn on the system. For external drives, turn on the

drive before you turn on the system.

The tape drive will run its Power-On Self Test (POST), which checks all hardware

except for the drive head. The single-character display will present a series of

random characters, and then become blank (not lit). The fault LED will flash once,

then the Ready/Activity LED will turn on solid.

1

2

a67ru043

Verify that the tape drive installation was successful. Following the instructions

given with your Tape Backup Software application, write test data to a tape, read

the test data from the tape, and compare the data read from the tape with the

original data on disk.

Loading Device Drivers

Microsoft Windows Server

This section describes how to install the Microsoft®Windows Server®Device

Drivers for the tape drive.

Notice: Some backup software applications do not require device drivers to be

loaded and, in some cases, installing device drivers could interfere with

proper functioning of the application. See the documentation for the

respective application prior to loading these drivers. The latest drivers are

available at http://support.dell.com.

Chapter 2. Setting Up the Tape Drive 2-7

Page 24

Ethernet Service Port Procedures

To update the drive’s firmware using the ethernet interface:

Note: The drive uses a limited version of FTP protocol to communicate on the

ethernet interface. It is recommended to use a simple, command line FTP

session, such as the DOS command prompt, when communicating with the

drive. This product is not intended to be connected directly or indirectly by

any means whatsoever to interfaces of public telecommunications networks.

When the IP address has been changed to the customer LAN or DHCP has

obtained a new address, the default address of the tape drive will still be

available. This does not create a LAN conflict as the customer LAN address

takes operational preference. The default address will not conflict with other

drives having the default address. When the drive comes online the drive

checks if the default address is on the LAN and will not become active

while another drive is active. This is acceptable operation and at times a

multi-drive LAN may see different drives with accessible default address.

1. Obtain the latest drive firmware from the web. Go to http://support.dell.com.

2. Connect an ethernet patch cable to the drive’s ethernet interface and to a

computer. In order to meet electromagnetic immunity requirements, a shielded

ethernet cable is required.

3. Create an FTP session between the drive and the computer. The drive’s default

IP address: 169.254.0.3.

4. At the user prompt, type guest and press Enter.

5. At the password prompt, press Enter. No response is needed.

6. Type bin to set the communication mode to binary.

7. Type put firmware name to transfer the firmware to the drive. Replace firmware

name with the actual firmware file name. The drive will reset automatically

when the transfer is complete and the FTP session will be lost. Type quit to end

the FTP session.

8. After the drive resets, the new firmware will be loaded on the drive.

9. Remove the ethernet patch cable from the drive’s ethernet interface.

Capturing a drive dump using the ethernet interface

Another way to capture a drive dump is using the ethernet port. To capture a

dump on the drive using the ethernet interface follow the steps below.

Note: The drive uses a limited version of FTP protocol to communicate on the

ethernet interface. It is recommended to use a simple, command line FTP

session, such as the DOS command prompt, when communicating with the

drive. This product is not intended to be connected directly or indirectly by

any means whatsoever to interfaces of public telecommunications networks.

1. Connect an ethernet patch cable to the drive’s ethernet interface and to a

computer. In order to meet electromagnetic immunity requirements, a shielded

ethernet cable is required.

2. Create an FTP session between the drive and the computer. The drive’s default

IP address: 169.254.0.3.

3. At the user prompt, type guest and press Enter.

4. At the password prompt, press Enter. No response is needed.

5. Type bin to set the communication mode to binary.

6. Type mget *.dmp to transfer a drive dump to the computer. If a dump already

exists, the drive will show you the dump name and ask if you want to transfer

2-8 Dell PowerVault LTO Tape Drive User's Guide

Page 25

it to the computer. Type y to transfer the existing dump or n to skip this dump

file. Then the drive will ask if you want a forced dump. Type y to force a dump

and to transfer the forced dump to the computer, or type n to skip forcing a

dump.

7. Type quit to end the FTP session.

8. Remove the ethernet patch cable from the drive’s ethernet interface.

Chapter 2. Setting Up the Tape Drive 2-9

Page 26

2-10 Dell PowerVault LTO Tape Drive User's Guide

Page 27

Chapter 3. Using the Tape Drive

v “Operating the Drive”

v “Loading, Unloading, and Write-Protecting Cartridges” on page 3-2

v “Caring for Tape Cartridges” on page 3-5

v “Cleaning the Tape Mechanism” on page 3-7

Operating the Drive

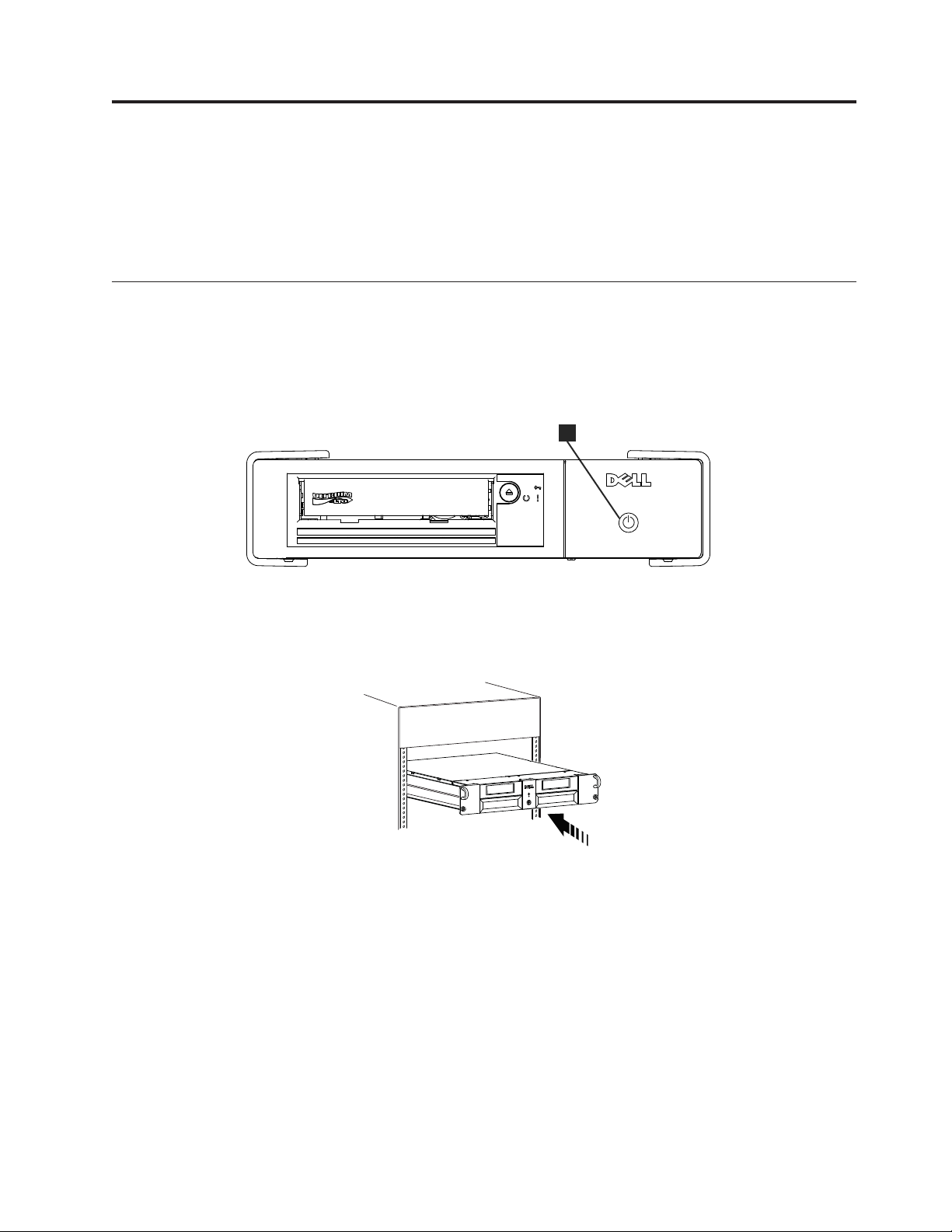

Turn on the external drive by pushing the power on/off button on the front panel

(Figure 3-1). Turn on the rack mount drive by pushing the power on/off button on

the front panel (Figure 3-2).The tape drive runs its Power-On Self-Test (POST). At

the end of the hardware self-test, the ready/activity LED must be solid green.

Figure 3-1. Turning on the External Drive

1

30

a80hd0

1 Power On/Off Button

Figure 3-2. Turning on the Rack Mount Drive

Resetting the Drive

You can reset the drive without powering off the drive and system. This may be

necessary if the drive stops responding. To do this, press and hold the eject button

on the front panel of the tape drive for 10 seconds (Figure 3-3 on page 3-2). The

drive forces a dump of vital technical data to drive memory and overwrites the

existing dump. The drive then reboots to allow communication.

3-1

Page 28

1

Figure 3-3. Resetting the Drive

1 Eject Button

Loading, Unloading, and Write-Protecting Cartridges

Use only LTO Ultrium format cartridges with your drive, as specified in the LTO

Ultrium standard. Ensure that only one label is stuck to the label area of the

cartridge. Do not use nonstandard labels, and do not stick anything to the

cartridge other than in the label area.

a80hd008

The Dell PowerVault LTO Tape Drive is compatible (see Supported Functions of

Compatible Media Types) with the cartridges of its predecessors. Below is a

description of the functions that are supported on the different compatible media

types:

Table 3-1. Supported Functions of Compatible Media Types

LTO

Cartridge

Generation

6 846 2500 6250 Yes No No No

6 WORM 846 2500 6250 Yes No No No

5 846 1500 3000 Yes Yes No No

5 WORM 846 1500 3000 Yes Yes No No

4 820 800 1600 RO Yes Yes No

4 WORM 820 800 1600 RO Yes Yes No

3 680 400 800 No RO Yes Yes

3 WORM 680 400 800 No RO Yes Yes

2 609 200 400 No No RO Yes

1 609 100 200 No No No RO

1 319 50 100 No No No RO

1 203 30 60 No No No RO

1 97 10 20 No No No RO

Tape

Length

(nominal)

(m)

Data Capacity

(native) (GB

Data Capacity

(compressed

1

)

(GB

1

)

PowerVault

2

Generation

)

LTO 6

PowerVault

Generation

LTO 5

PowerVault

Generation

LTO 4

PowerVault

Generation

LTO 3

3-2 Dell PowerVault LTO Tape Drive User's Guide

Page 29

1

1 GB = 1 000 000 000 bytes.

2

Compression Ratio

v 2.5:1 = LTO6

v 2:1 = LTO5, LTO4, and LTO3

3

RO = Read Only

Figure 3-4 shows the LTO Ultrium Data Cartridge and its components.

4

6

2

3

5

Figure 3-4. LTO Ultrium Data Cartridge

1 LTO cartridge memory 4 Insertion guide

2 Label area 5 Cartridge door

3 Write-protect switch 6 Leader pin

Loading a Tape Cartridge

1. Ensure that the tape drive is powered on. (The ready/activity LED is solid

green.)

2. Ensure that the write-protect switch (see 3 in Ultrium LTO Data Cartridge)is

properly set. (See “Setting the Write-Protect Switch on Tape Cartridges” on

page 3-4.)

3. Grasp the cartridge so that the write-protect switch faces you.

4. Slide the cartridge into the tape load compartment (see Figure 3-5 on page 3-4).

The tape drive automatically loads the cartridge.

v If the cartridge is already in the ejected position and you want to reinsert it,

remove the cartridge and then insert it again.

v If the cartridge is already loaded and you cycle the power (turn it off, then

on), the cartridge does not automatically eject. When the drive powers back

on, the cartridge is brought back to the loaded position.

1

Chapter 3. Using the Tape Drive 3-3

Page 30

Figure 3-5. Loading

a80hd009

1 Write-Protect Switch

Unloading a Tape Cartridge

1. Ensure that the tape drive is powered on. (The ready/activity LED is solid

green.)

2. Press the eject button (see 1 in Figure 3-3 on page 3-2). The drive rewinds the

tape and ejects the cartridge. The ready/activity LED flashes green while the

tape rewinds, then goes out before the cartridge ejects.

3. After the cartridge ejects, grasp the cartridge and remove it.

Whenever you unload a tape cartridge, the tape drive writes any pertinent

information to the cartridge memory.

Notice: Do not remove a tape cartridge while the drive activity indicator is on.

Setting the Write-Protect Switch on Tape Cartridges

Notice: Write-protection will not prevent a cartridge from being erased by

bulk-erasure or degaussing. Do not bulk-erase Ultrium format cartridges.

This will destroy prerecorded servo information and render the cartridge

unusable. Always use the long or quick erase command in your backup

software to erase cartridges.

The position of the write-protect switch (Figure 3-6 on page 3-5) on the tape

cartridge determines whether you can write to the tape:

v If the switch is set to locked (locked padlock), data cannot be written to the tape.

v If the switch is set to unlocked (unlocked padlock or black void), data can be

written to the tape.

3-4 Dell PowerVault LTO Tape Drive User's Guide

Page 31

Figure 3-6. Setting the Write-Protect Switch

1 Write-Protect Switch

To set the switch, slide it left or right to the desired position.

Notice: Always set the write protection tab prior to loading the cartridge into the

drive. Sliding the tab after loading will cause unpredictable results and

could result in drive errors or backup failure.

Caring for Tape Cartridges

Notice: Do not insert a damaged tape cartridge into your tape drive. A damaged

cartridge can interfere with the reliability of the drive and may void the

warranties of the drive and the cartridge. Before inserting a tape cartridge,

inspect the cartridge case, cartridge door, and write-protect switch for

breaks.

Incorrect handling or an incorrect environment can damage the LTO Ultrium Tape

Cartridge or its magnetic tape. To avoid damage to your tape cartridges and to

ensure the continued high reliability of your tape drive, use the following

guidelines.

Provide Training

v Post procedures that describe proper media handling in places where people

gather.

v Ensure that anyone who handles tape has been properly trained in handling and

shipping procedures. This includes operators, users, programmers, archival

services, and shipping personnel.

v Ensure that any service or contract personnel who perform archiving are

properly trained in media-handling procedures.

v Include media-handling procedures as part of any services contract.

v Define and make personnel aware of data recovery procedures.

Ensure Proper Packaging

v When you ship a cartridge, ship it in its original or similar packaging.

v Always ship or store a cartridge in a jewel case.

v Use only a recommended shipping container that securely holds the cartridge in

its jewel case during transportation.

Chapter 3. Using the Tape Drive 3-5

Page 32

v Never ship a cartridge in a commercial shipping envelope. Always place it in a

box or package.

v If you ship the cartridge in a cardboard box or a box of a sturdy material, ensure

the following:

– Place the cartridge in polyethylene plastic wrap or bags to protect it from

dust, moisture, and other contaminants.

– Pack the cartridge snugly; do not allow it to move around.

– Double-box the cartridge (place it inside a box, then place that box inside the

shipping box) and add padding between the two boxes.

Provide Proper Acclimation and Environmental Conditions

v Before you use a cartridge, let it acclimate to the normal operating environment

for 1 hour. If you see condensation on the cartridge, wait an additional hour.

v Ensure that all surfaces of a cartridge are dry before inserting it.

v Do not expose the cartridge to moisture or direct sunlight.

v Do not expose recorded or blank cartridges to stray magnetic fields of greater

than 100 oersteds (for example, terminals, motors, video equipment, X-ray

equipment, or fields that exist near high-current cables or power supplies). Such

exposure can cause the loss of recorded data or make the blank cartridge

unusable.

v Maintain the following environmental conditions outlined in Table 3-2.

Table 3-2. Environmental Specifications

Environmental

Factor

Temperature 10° to 45°C

Relative

humidity

(noncondensing)

Wet bulb

temperature

1

Operational storage equals less than 1 year.

2

Archival storage equals 1 to 10 years.

Operating Operational

Storage

16° to 35°C

(50° to 113°F)

10% to 80% 20% to 80% 20% to 50% 5% to 80%

26°C (79°F) 26°C (79°F) 26°C (79°F) 26°C (79°F)

(61° to 95°F)

1

Archival

Storage

16° to 25°C

(61° to 77°F)

2

Shipping

-23° to 49°C

(-9° to 120°F)

Perform a Thorough Inspection

v Inspect the cartridge's packaging to determine potential rough handling.

v When inspecting a cartridge, open only the cartridge door. Do not open any

other part of the cartridge case. The upper and lower parts of the case are held

together with screws; separating them destroys the usefulness of the cartridge.

v Inspect the cartridge for damage before using or storing it.

v Inspect the rear of the cartridge (the part that you load first into the tape load

compartment) and ensure that there are no gaps in the seam of the cartridge

case. If there are gaps in the seam, the leader pin may be dislodged.

v Check that the leader pin is properly seated.

v If you suspect that the cartridge has been mishandled but it appears useable,

copy any data onto a good cartridge immediately for possible data recovery.

Discard the mishandled cartridge.

v Review handling and shipping procedures.

3-6 Dell PowerVault LTO Tape Drive User's Guide

Page 33

Handle the Cartridge Carefully

C

C

7

7

v Do not drop the cartridge. If the cartridge drops, slide the cartridge door back

and ensure that the leader pin is properly seated in the pin-retaining spring

clips.

v Do not handle tape that is outside the cartridge. Handling the tape can damage

the tape's surface or edges, which may interfere with read or write reliability.

Pulling on tape that is outside the cartridge can damage the tape and the brake

mechanism in the cartridge.

v Do not stack more than six cartridges.

v Do not degauss a cartridge that you intend to reuse. Degaussing makes the tape

unusable.

Cleaning the Tape Mechanism

Dell PowerVault drives have been developed to have a minimal cleaning

requirement. The tape drive will display a

the fault LED will flash amber when the drive needs cleaning. Only insert a

cleaning cartridge into the tape drive when the

Notice: Only use LTO cleaning cartridges that are labeled "universal." The tape

drive is only compatible with the LTO Ultrium universal cleaning

cartridges. Use of any other type of cleaning cartridge or method can

damage the read/write head in your drive. If you load any other type of

cleaning cartridge, the tape drive displays a

the cartridge until it is ejected manually by pressing the Eject button.

An LTO Ultrium universal cleaning cartridge is supplied with each tape drive. Do

not use swabs or other means of cleaning the heads. The cleaning cartridge uses a

special tape to clean the tape heads.

Though the number may vary according to the manufacturer, the universal

cleaning cartridge is generally valid for 50 separate cleaning operations. If you try

to use the cleaning cartridge beyond 50 separate cleaning operations, an error code

of

one.

To use the LTO Ultrium universal cleaning cartridge:

1. Insert a cleaning cartridge into the tape drive. The tape drive performs the

2. Remove the cleaning cartridge from the drive.

will be displayed. Eject the cleaning cartridge and replace it with a new

cleaning automatically. When the cleaning is finished, the drive ejects the

cartridge.

on the single-character display and

is displayed.

in the SCD and retains

Chapter 3. Using the Tape Drive 3-7

Page 34

3-8 Dell PowerVault LTO Tape Drive User's Guide

Page 35

Chapter 4. Using the Tape Backup Software

See the User's Operating Guide supplied with your Tape Backup application for

more information about using the Tape Backup software. For the latest supported

software versions, go to the Dell support website at http://support.dell.com or

visit the support site of your backup software vendor.

4-1

Page 36

4-2 Dell PowerVault LTO Tape Drive User's Guide

Page 37

Chapter 5. Troubleshooting

v “Obtaining Drivers and Firmware Upgrades”

v “Selecting a Diagnostic or Maintenance Function”

v “General Guidelines” on page 5-8

v “Methods of Receiving Errors and Messages” on page 5-9

v “Descriptions and Corrective Actions” on page 5-10

v “Drive Status” on page 5-13

v “Drive Maintenance” on page 5-14

v “Fixing SAS Connectivity Problems” on page 5-15

v “Resolving Media-Related Problems” on page 5-16

v “Removing an Internal SAS Tape Drive” on page 5-16

v “TapeAlert” on page 5-17

v “Recovering a Tape Cartridge” on page 5-20

Obtaining Drivers and Firmware Upgrades

Notice: When updating firmware, do not power off the tape drive until the update

is complete, or the firmware may be lost.

For information on the latest versions of firmware, see the Dell support website at

http://support.dell.com.

Selecting a Diagnostic or Maintenance Function

The tape drive can run diagnostics, test write and read functions, test a suspect

tape cartridge, and perform other diagnostic and maintenance functions. The drive

must be in maintenance mode to perform these functions. To place the drive in

maintenance mode and select a diagnostic or maintenance function, see the

Diagnostic and Maintenance Function Codes and Descriptions table.

Note: The host interface on this tape drive is Serial Attached SCSI (SAS). This

interface presents SCSI protocol to the tape drive. In this User's Guide,

references to SCSI relate to SCSI protocol, not the serial interface that it is

transmitted over.

Note: You cannot perform maintenance functions concurrently with read or write

operations. While in maintenance mode, the tape drive does not accept SCSI

commands from the system. Close all tape drive applications before entering

maintenance mode.

5-1

Page 38

Table 5-1. Diagnostic and Maintenance Function Codes and Descriptions

1

1

C

C

P

1

0

F

Function Code1-RunTapeDrive Diagnostics

Causes the tape drive to run self tests.

Attention: Insert only a scratch data cartridge for this test. Data on the cartridge will be overwritten.

1. Ensure that there is no cartridge in the drive.

2. Press the eject button three times within an interval of 2 seconds. The fault LED becomes solid amber, which

means that the drive is in maintenance mode.

3. Press the eject button once per second until

continue to press the eject button until it reappears.

4. To select the function, press and hold the eject button for 3 seconds. After you select the function,

the drive runs diagnostics for approximately 90 seconds, then

waiting for a cartridge.

5. Within 60 seconds, insert a scratch data cartridge that is not write-protected.

Note: If you wait longer than 60 seconds to load a cartridge, the drive automatically exits maintenance mode. If

you insert a write-protected cartridge, the tape drive displays a

ejected. When the cartridge is ejected and removed, the tape drive exits maintenance mode.

After you insert the cartridge,

v The diagnostic test takes approximately 5 minutes to run. The tape drive will unload and load the cartridge

during the test. Do not try to remove the cartridge when it unloads the first time. Wait for the test to

complete.

v If the diagnostic completes successfully, the cartridge ejects, the single-character display flashes a

goes blank, and the drive exits maintenance mode. If the diagnostic fails, the fault LED flashes and an error

code displays. When the cartridge is manually ejected and removed, the tape drive automatically exits

maintenance mode.

v To halt the diagnostic and terminate the test, press the eject button twice anytime during the test. The drive

flashes and the test begins.

appears in the single-character display. If you cycle past1,

flashes,

flashes. When

and retains the cartridge until it is manually

flashes, the drive is

, then

acknowledges the request by slowing the flash rate of the

second to once per second. The tape drive rewinds and unloads the cartridge and then exits maintenance

mode.

Function Code 2 — RESERVED (Service Function)

Function Code 3 — RESERVED (Service Function)

on the single-character display from twice per

5-2 Dell PowerVault LTO Tape Drive User's Guide

Page 39

Table 5-1. Diagnostic and Maintenance Function Codes and Descriptions (continued)

8

8

0

9

0

0

Function Code 4 — Force a Dump of Vital Data to Tape Drive Memory

Causes the tape drive to perform a collection (or dump) of vital technical data and save it to drive memory. (A

drive dump is also known as a save of the firmware trace.)

Notice: When an error code is displayed in maintenance mode, the tape drive also displays a dot to remind you

that a dump already exists. If you perform Function Code 4, it will overwrite the dump and cause the error

information to be lost.

1. Ensure that there is no cartridge in the drive.

2. Press the eject button three times within an interval of 2 seconds. The fault LED becomes solid amber, which

means that the drive is in maintenance mode.

3. Press the eject button once per second until

continue to press the eject button until it reappears.

4. To select the function, press and hold the eject button for 3 seconds. After you select the function,

followed by

You can also perform this operation when the tape drive is in normal operating mode. Simply press and hold the

eject button for 10 seconds.

Function Code5-RESERVED (Service Function)

Function Code6-RESERVED (Service Function)

Function Code7-RESERVED (Service Function)

Function Code8-RESERVED (Service Function)

Function Code9-Display Error Code Log

Causes the tape drive to display the last ten error codes, one at a time. (The codes are ordered; the most recent is

presented first and the oldest (tenth) is presented last.)

To view the drive error log:

1. Ensure that there is no cartridge is in the drive.

2. Within a 2 second interval press the eject button three times. The fault LED becomes solid amber, which means

that the drive is in maintenance mode.

3. Press the eject button once per second until

4. Press and hold the eject button for 3 seconds to view the most recent error code.

5. Refer to “Descriptions and Corrective Actions” on page 5-10 to determine the meaning of the code and the

action to take.

6. Press the eject button to view the next error code. (The codes are ordered; the most recent is presented first and

the oldest (tenth) is presented last.)

. The single-character display then goes blank, and the tape drive exits maintenance mode.

appears in the single-character display. If you cycle past8,

displays,

appears in the single-character display.

7. Continue to press the eject button until

been encountered or the log has just been cleared, a

maintenance mode. A maximum of ten error codes are stored.

To redisplay the error codes, repeat steps 1 through 7.

appears, indicating that no more error codes exist. If no errors have

will appear immediately and the drive will exit

Chapter 5. Troubleshooting 5-3

Page 40

Table 5-1. Diagnostic and Maintenance Function Codes and Descriptions (continued)

A

0

6or7

E

C

C

E

6or7

Function Code A - Clear Error Code Log

Causes the tape drive to erase the contents of the error code log.

1. Ensure that there is no cartridge in the drive.

2. Press the eject button three times within an interval of 2 seconds. The fault LED becomes solid amber, which

means that the drive is in maintenance mode.

3. Press the eject button once per second until

continue to press the eject button until it reappears.

4. To select the function, press and hold the eject button for 3 seconds. After you select the function, the tape drive

erases all errors from the error code log, displays

Function Code C - Insert Cartridge Into Tape Drive

This function cannot be selected by itself. It relates to other maintenance functions (such as Run Tape Drive

Diagnostics) that require a scratch tape cartridge that is not write protected.

Function CodeE-TestCartridge & Media

Causes the tape drive to perform a Write/Read test (on the edge bands) to ensure that a suspect cartridge and its

magnetic tape are acceptable. The tape drive takes approximately 15 minutes to run one loop of the test. The test

loops ten times before completing.

v If no error is detected, the test begins again and runs for a maximum of ten times. After the tenth loop, the test

stops and the drive automatically exits maintenance mode.

v If an error is detected, the tape drive displays

manually ejected and removed, the tape drive exits maintenance mode.

v To halt the diagnostic at the end of the current 15 minute test loop, press the eject button once. The drive

acknowledges the request by slowing the length of time that the currently displayed character flashes on the

single-character display (from twice per second to once per second). The diagnostic continues to the end of its

loop and then stops. The tape drive then rewinds, unloads the cartridge, and exits maintenance mode.

v To halt the diagnostic immediately and terminate the test that is running, press the eject button twice. The tape

drive rewinds, unloads the cartridge, and exits maintenance mode.

appears in the single-character display. If you cycle pastA,

, then exits maintenance mode.

in the single-character display. Once the cartridge is

Attention: Data on the suspect tape will be overwritten.

1. Ensure that there is no cartridge in the drive.

2. Press the eject button three times within an interval of 2 seconds. The fault LED becomes solid amber, which

means that the drive is in maintenance mode.

3. Press the eject button once per second until

continue to press the eject button until it reappears.

4. To select the function, press and hold the eject button for 3 seconds. After you select the function,

When

the tape drive exits maintenance mode). After you insert the cartridge,

v If no error is detected, the test begins again and runs for a maximum of ten times. After the tenth loop, the

test stops and the drive automatically exits maintenance mode. To halt the test, press the eject button. The

tape drive then rewinds and unloads the cartridge, displays0, and exits maintenance mode.

v If an error is detected, the tape drive displays

removed, the tape drive exits maintenance mode.

flashes, the drive is waiting for a cartridge. Within 60 seconds, insert the suspect data cartridge (or

appears in the single-character display. If you cycle pastE,

flashes.

flashes and the test begins.

. Once the cartridge is manually ejected and

5-4 Dell PowerVault LTO Tape Drive User's Guide

Page 41

Table 5-1. Diagnostic and Maintenance Function Codes and Descriptions (continued)

F

C

C

F

Function CodeF-Write Performance Test

Causes the tape drive to perform tests to ensure that the drive can read from and write to tape. This diagnostic

performs fewer tests than the Run Tape Drive Diagnostics test (Function Code 1). The tape drive takes

approximately 3 minutes to run the test. The Fast Read/Write Test is not as comprehensive a test and is not

recommended for isolating errors between the drive and the media.

Attention: Data on the suspect tape will be overwritten.

1. Ensure that there is no cartridge in the drive.

2. Press the eject button three times within an interval of 2 seconds. The fault LED becomes solid amber, which

means that the drive is in maintenance mode.

3. Press the eject button once per second until

continue to press the eject button until it reappears.

4. To select the function, press and hold the eject button for 3 seconds. After you select the function,

When

the tape drive exits maintenance mode). After you insert the cartridge,

v If no error is detected, the test begins again and runs for a maximum of ten times. Each loop takes

approximately 3 minutes to run. After the tenth loop, the test stops and the drive automatically exits

maintenance mode.

v If an error is detected, the tape drive displays an error code. Once the cartridge is manually ejected and

removed, the tape drive exits maintenance mode.

v To halt the diagnostic at the end of the current 3 minute test loop, press the eject button once. The drive

acknowledges the request by slowing the length of time that the currently displayed character flashes on the

single-character display (from twice per second to once per second.) The diagnostic continues to the end of its

loop and then stops. The tape drive then rewinds, unloads the cartridge, and exits maintenance mode.

v To halt the diagnostic immediately and terminate the test that is running, press the eject button twice. The

tape drive rewinds, unloads the cartridge, and exits maintenance mode.

flashes, the drive is waiting for a cartridge. Within 60 seconds, insert the suspect data cartridge (or

appears in the single-character display. If you cycle pastF,

flashes and the test begins.

flashes.

Chapter 5. Troubleshooting 5-5

Page 42

Table 5-1. Diagnostic and Maintenance Function Codes and Descriptions (continued)

H

C

C

H

5

Function Code H - Test Head

Causes the tape drive to perform the Head Resistance Measurements test and a Write/Read test (on the center of

the tape). The drive runs these tests to ensure that the tape drive's head and tape-carriage mechanics are working

correctly. The tape drive takes approximately 10 minutes to run the test.

1. Ensure that there is no cartridge in the drive.

2. Press the eject button three times within an interval of 2 seconds. The fault LED becomes solid amber, which

means that the drive is in maintenance mode.

3. Press the eject button once per second until

continue to press the eject button until it reappears.

4. To select the function, press and hold the eject button for 3 seconds. After you select the function,

When

tape drive exits maintenance mode). After you insert the cartridge,

v If no error is detected, the test begins again and runs for a maximum of ten times. Each loop takes

approximately 10 minutes to run. After the tenth loop, the test stops and the drive automatically exits

maintenance mode.

v If an error is detected, the tape drive displays

v To halt the diagnostic at the end of the current 10 minute test loop, press the eject button once. The drive

acknowledges the request by slowing the length of time that the currently displayed character flashes on the

single-character display (from twice per second to once per second). The diagnostic continues to the end of its

loop and then stops. The tape drive then rewinds, unloads the cartridge, and exits maintenance mode.

v To halt the diagnostic immediately and terminate the test that is running, press the eject button twice. The

tape drive then rewinds, unloads the cartridge, and exits maintenance mode.

flashes, the drive is waiting for a cartridge. Within 60 seconds, insert a scratch data cartridge (or the

appears in the single-character display. If you cycle pastH,

flashes and the test begins.

, unloads the tape cartridge, and exits maintenance mode.

flashes.

5-6 Dell PowerVault LTO Tape Drive User's Guide

Page 43

Table 5-1. Diagnostic and Maintenance Function Codes and Descriptions (continued)

P

7

Function Code J - Fast Read/Write Test

Approximate Run Time=5minutes

Total Number of Loops = 10

J

Function Code

The diagnostic loops ten times. Press the eject button to stop the diagnostic and exit maintenance mode. Pressing

the eject button once will abort the test at the end of the current test loop. Pressing the eject button twice will abort

the test immediately.

Attention: For this test, insert only a scratch (blank) data cartridge or a cartridge that may be overwritten. During

the test, the drive overwrites the data on the cartridge.

1. Ensure that there is no cartridge in the drive.

2. Press the eject button three times within an interval of 2 seconds. The fault LED becomes solid amber, which

means that the drive is in maintenance mode.

3. Press the eject button once per second until

continue to press the eject button until it reappears.

4. Press and hold the eject button for three or more seconds, then release it to select the function. The

single-character display changes to a flashingC.

5. Within 60 seconds, insert a scratch data cartridge that is not write-protected.

Note: If you wait longer than 60 seconds to load a cartridge, the drive will automatically exit maintenance

performs tests to ensure that the drive can read from and write to tape.

J

appears in the single-character display. If you cycle pastJ,

mode. If you insert a write-protected cartridge, the tape drive will display a

is manually ejected. Once the cartridge is ejected and removed, the tape drive will exit maintenance mode.

After you insert the cartridge, the single-character display changes to a flashing

tests.

Note: If you inserted an invalid cartridge, error code

retains the cartridge until it is manually ejected. Once ejected, the tape drive exits maintenance mode.

v If no error is detected, the test will loop and begin again. To stop the loop, press the eject button for one second

and release. When the loop ends, the drive rewinds, unloads the tape, and exits maintenance mode.

v If an error is detected, the fault LED flashes amber, then the tape drive posts an error code to the single-character

display. To determine the error, locate the code in “Descriptions and Corrective Actions” on page 5-10. Once the

cartridge is manually ejected and removed, the tape drive exits maintenance mode.

appears in the single-character display. The tape drive

and retain the cartridge until it

J

, and the tape drive runs the

Chapter 5. Troubleshooting 5-7

Page 44

Table 5-1. Diagnostic and Maintenance Function Codes and Descriptions (continued)

L

L

P

L

0

7

7

Function Code L - Load/Unload Test

Approximate Run Time = 15 seconds per loop

Total Number of Loops = 10

Function Code

The diagnostic loops ten times. To stop the diagnostic and exit maintenance mode, press the eject button once to

abort the test.

Attention: The diagnostic loops ten times. To stop the diagnostic and exit maintenance mode, press the eject

button once to abort the test.

1. Ensure that there is no cartridge in the drive.

2. Press the eject button three times within an interval of 2 seconds. The fault LED becomes solid amber, which

means that the drive is in maintenance mode.

3. Press the eject button once per second until

continue to press the eject button until it reappears.

4. Press and hold the eject button for three or more seconds, then release it to select the function. The

single-character display changes to a flashingC.

5. Within 60 seconds, insert a scratch data cartridge that is not write-protected.

Note: If you wait longer than 60 seconds to load a cartridge, the drive will automatically exit maintenance

mode. If you insert a write-protected cartridge, the tape drive will display a

is manually ejected. Once the cartridge is ejected and removed, the tape drive will exit maintenance mode.

After you insert the cartridge, the single-character display changes to a flashing

v If no error is detected, the test will loop and begin again. To stop the loop, press the eject button for one second

tests the drive's ability to load and unload a tape cartridge.

appears in the single-character display. If you cycle pastL,

and retain the cartridge until it

. The tape drive runs the tests.

and release. When the loop ends,

tape and unloads the cartridge. The drive then exits maintenance mode.

v If an error is detected the test stops,

in “Descriptions and Corrective Actions” on page 5-10. The drive unloads the tape cartridge and exits

maintenance mode. To clear the error, turn the tape drive power off, then on again.

Function Code P or U - RESERVED (Service Function)

temporarily appears in the single-character display. The drive rewinds the

appears in the single-character display. To determine the error, locate

General Guidelines

If you encounter problems when running the Dell PowerVault Tape Drive, refer to

Table 5-2 for common problems. If the problem is not identified, refer to “Methods

of Receiving Errors and Messages” on page 5-9. The color and condition of the

LEDs may also indicate a problem.

Table 5-2. General Troubleshooting

If the problem is this... Do this...

A code displays on the single-character display and the

fault LED flashes amber.

The tape drive detected an error or is directing you to an

informational message. See “Methods of Receiving Errors

and Messages” on page 5-9.

5-8 Dell PowerVault LTO Tape Drive User's Guide

Page 45

Table 5-2. General Troubleshooting (continued)

If the problem is this... Do this...

The ready/activity LED or single-character display never

turns on.

The tape drive does not load a tape cartridge. One of the following has occurred:

The tape drive does not unload the tape cartridge. The tape cartridge is stuck or is broken. Press the eject

The system received TapeAlert flags. See Table 5-5 on page 5-17.

The system reported system problems (such as selection

or command time-outs, or parity errors).

Codes display on the single-character display, but the

ready/activity LED does not turn on.

The tape drive does not respond to system commands. Press and hold the eject button on the drive for 10

The tape drive has no power. Check the power at the

power source. Connect power to the tape drive. If the

problem persists, contact Dell technical support.

v A tape cartridge is already loaded. To remove the

cartridge, press the eject button. If the cartridge does

not eject, turn off the power to the tape drive, then

turn it back on. After the ready/activity LED becomes

solid green, press the eject button to eject the cartridge.

v The cartridge tray may not be in the correct position.

Press the eject button to return the tray to the correct

position.

v The tape cartridge was loaded incorrectly. To properly

load a cartridge, see the Loading section in “Loading,

Unloading, and Write-Protecting Cartridges” on page

3-2.

v The tape cartridge may be defective. Load another

tape cartridge. If the problem exists for multiple

cartridges, the tape drive is defective. Contact Dell

technical support.

v The tape drive has no power. Connect power to the

tape drive.

button. If the cartridge does not eject, turn off the power

to the tape drive, and then turn it back on. (Note that the

mid-tape recovery could take up to 10 minutes to

complete.) If the cartridge still does not eject, manually

remove it (see “Recovering a Tape Cartridge” on page

5-20).

See “Fixing SAS Connectivity Problems” on page 5-15.

The tape drive is defective. Contact Dell technical

support.

seconds to force a drive dump. The drive will save the

dump and then reboot to allow communication to the

drive to occur. Do not cycle power, as this will erase the

contents of the dump.

Methods of Receiving Errors and Messages

Use Table 5-3 on page 5-10 as a guide for identifying error codes and message

codes reported by the tape drive, its computer (if applicable), or the system.

Note: The codes on the single-character display have different meanings,

depending on whether they display during normal operations or while the

drive is in maintenance mode. Codes that occur during normal operations

are defined in “Descriptions and Corrective Actions” on page 5-10. Codes

that occur while in maintenance mode are defined in “Selecting a Diagnostic

or Maintenance Function” on page 5-1

Chapter 5. Troubleshooting 5-9

Page 46

Table 5-3. Methods of Receiving Errors and Messages

0

0

1

If the error or message was presented by... Do this...

The system's display (if the tape drive is enclosed in a

library or autoloader)

The tape drive's single-character display and the fault

LED flashes amber

The tape drive's single-character display and the fault

LED is solid amber

SCSI log sense data (such as TapeAlert flags) or SCSI

drive sense data

The tape drive's error log See “Descriptions and Corrective Actions.”

Refer to the documentation for the system.

See “Descriptions and Corrective Actions.” To determine

the meaning of the LED, see the “Front Panel” on page

1-4 section in the Introduction.

See “Selecting a Diagnostic or Maintenance Function” on

page 5-1. To determine the meaning of the fault LED

activity, see the “Front Panel” on page 1-4 section in the

Introduction.

See Table 5-5 on page 5-17 or “Descriptions and

Corrective Actions.”

Descriptions and Corrective Actions

Table 5-4 gives descriptions of the errors and messages that pertain to the tape

drive, and tells what to do when you receive them.

Notice: If the tape drive detects a permanent error and displays an error code

other than

, it automatically performs a dump of vital data to drive

memory. If you force a dump, the existing dump will be overwritten and

data will be lost. After you force a dump, do not turn off the power to the

tape drive or you may lose the dump data.

Table 5-4. Descriptions and Corrective Actions

The single-character display clears if you power-off the drive.

Code Cause and Action

No error occurred and no action is required. This code displays:

v When power is cycled (turned off, then on) to the tape drive

v When diagnostics have finished running and no error occurred

Note: The single-character display is blank during normal operation of the tape drive.

Cooling problem. The tape drive detected that the recommended operating temperature was

exceeded. Perform the following action:

1. If a fan is present in the system, ensure that it is rotating and is quiet. If not, replace the

fan. (For instructions about replacing the fan, see your system's documentation.)

2. Remove any blockage that prevents air from flowing freely through the tape drive.

3. Ensure that the operating temperature and airflow is within the specified range (see

Chapter 6, “Specifications,” on page 6-1).

4. If the proper voltages are being applied but the problem persists, contact Dell technical

support.

The error code clears when you power-off the tape drive or place it in maintenance mode.

5-10 Dell PowerVault LTO Tape Drive User's Guide

Page 47

Table 5-4. Descriptions and Corrective Actions (continued)

8

3

8

5

6

Power problem. The tape drive detected that the externally supplied power is either

approaching the specified voltage limits (the drive is still operating) or is outside the

specified voltage limits (the drive is not operating). Perform the following action:

1. Ensure that the power connector is properly seated.

2. Ensure that the proper DC voltages are being applied within the tolerances allowed (see

Chapter 6, “Specifications,” on page 6-1).

3. If the proper voltages are being applied but the problem persists, contact Dell technical

support.

The error code clears when you power-off the tape drive or place it in maintenance mode.

Firmware problem. The tape drive determined that a firmware error occurred. Perform the

following action:

1. Power the tape drive off and on, then retry the operation that produced the error. The

error code clears when you power-off the tape drive or place it in maintenance mode.

2. If the problem persists, download the latest firmware and retry the operation.

Firmware or tape drive problem. The tape drive determined that a firmware or tape drive

hardware failure occurred. Perform the following action:

1. Power the tape drive off and on, then retry the operation that produced the error. The

error code clears when you power-off the tape drive or place it in maintenance mode.

2. If the problem persists, download the latest firmware and retry the operation; if new

firmware is not available, contact Dell technical support.

Tape drive hardware problem. The drive determined that a tape path or read/write error

occurred. To prevent damage to the drive or tape, the drive will not allow you to insert a

cartridge if the current cartridge was successfully ejected. The error code may clear when you

cycle power to the tape drive or place it in maintenance mode. If the problem persists,

contact Dell technical support.

Tape drive or media error. The drive determined that an error occurred, but it cannot isolate

the error to faulty hardware or to the tape cartridge. Perform the appropriate action, as

described below.

v If the operation succeeds, the original cartridge was defective. Copy data from the

defective cartridge and discard it.

v If the operation fails and another drive is available, insert the cartridge into the other drive

and retry the operation.

– If the operation fails, discard the defective cartridge.

– If the operation succeeds, insert a scratch cartridge into the first drive and run the tape

drive diagnostics (see Function Code 1 in “Selecting a Diagnostic or Maintenance

Function” on page 5-1).

- If the diagnostics fail, contact Dell technical support.

- If the diagnostics succeed, the error was temporary.

v If the operation fails and another drive is not available, insert a scratch cartridge into the

drive and run the tape drive diagnostics (see Function Code 1 in “Selecting a Diagnostic or

Maintenance Function” on page 5-1).

– If the diagnostics fail, contact Dell technical support.

– If the diagnostics succeed, discard the cartridge.

Chapter 5. Troubleshooting 5-11

Page 48

Table 5-4. Descriptions and Corrective Actions (continued)

6

7

For Problems with Writing Data:

, continued

If the problem occurred while the drive was writing data to the tape, and if you know the

volume serial number (located on the cartridge label) of the tape cartridge loaded in the drive

when the problem occurred, retry the operation with a different cartridge:

If the problem occurs with multiple tape cartridges or if you do not know the tape cartridge's

volume serial number, run the tape drive diagnostics (see Function Code 1 in “Selecting a

Diagnostic or Maintenance Function” on page 5-1):

v If the diagnostics fail, contact Dell technical support.

v If the diagnostics succeed, run the Test Head diagnostic (see Function Code H in “Selecting

a Diagnostic or Maintenance Function” on page 5-1).

– If the Test Head diagnostic fails, contact Dell technical support.