Page 1

Dell™ PowerVault™ LTO-2-024 Tape Drive User's

Guide

Introduction Troubleshooting

Installation Internal Drive Getting Help

Installation External Drive Contacting Dell

Specifications Glossary

Operation

Notes, Notices, and Cautions

Note: A note indicates important information that helps you make better use of your computer.

Notice: A notice indicates either potential damage to hardware or loss of data and tells you how to avoid the

problem.

CAUTION: A CAUTION indicates a potential for property damage, personal injury, or death.

Information in this document is subject to change without notice.

© 2006-2007 Dell Inc. All rights reserved.

Trademarks used in this text: the Dell logo, Dimension, OptiPlex, Precision, Latitude, Inspiron, DellNet, PowerEdge,

PowerConnect, and PowerVault, are trademarks of Dell Inc. Microsoft Windows, and Windows Server are registered

trademarks of Microsoft Corporation; Novell and NetWare are registered trademarks of Novell, Inc.; UNIX is a registered

trademark of The Open Group in the United States and other countries; Red Hat is a registered trademark of Red Hat,

Inc.; TapeWare is a registered trademark of Yosemite Technologies, Inc.; VERITAS is a registered trademark and Backup

Exec is a trademark of VERITAS Software Corporation in the USA and/or other countries. CommVault is a registered

trademark of CommVault Systems, Inc.; LEGATO is a registered trademark of LEGATO Software.

Other trademarks and trade names may be used in this document to refer to either the entities claiming the marks and

names or their products. Dell Inc. disclaims any proprietary interest in trademarks and trade names other than its own.

All other trademarks are registered marks of their respective owners.

Initial release: May 2007

Page 2

Introduction

Overview

Features

Capacity and Transfer Rates

SCSI Bus Interface

Tape Backup Software

Data Compression

Front Panel LEDs

Overview

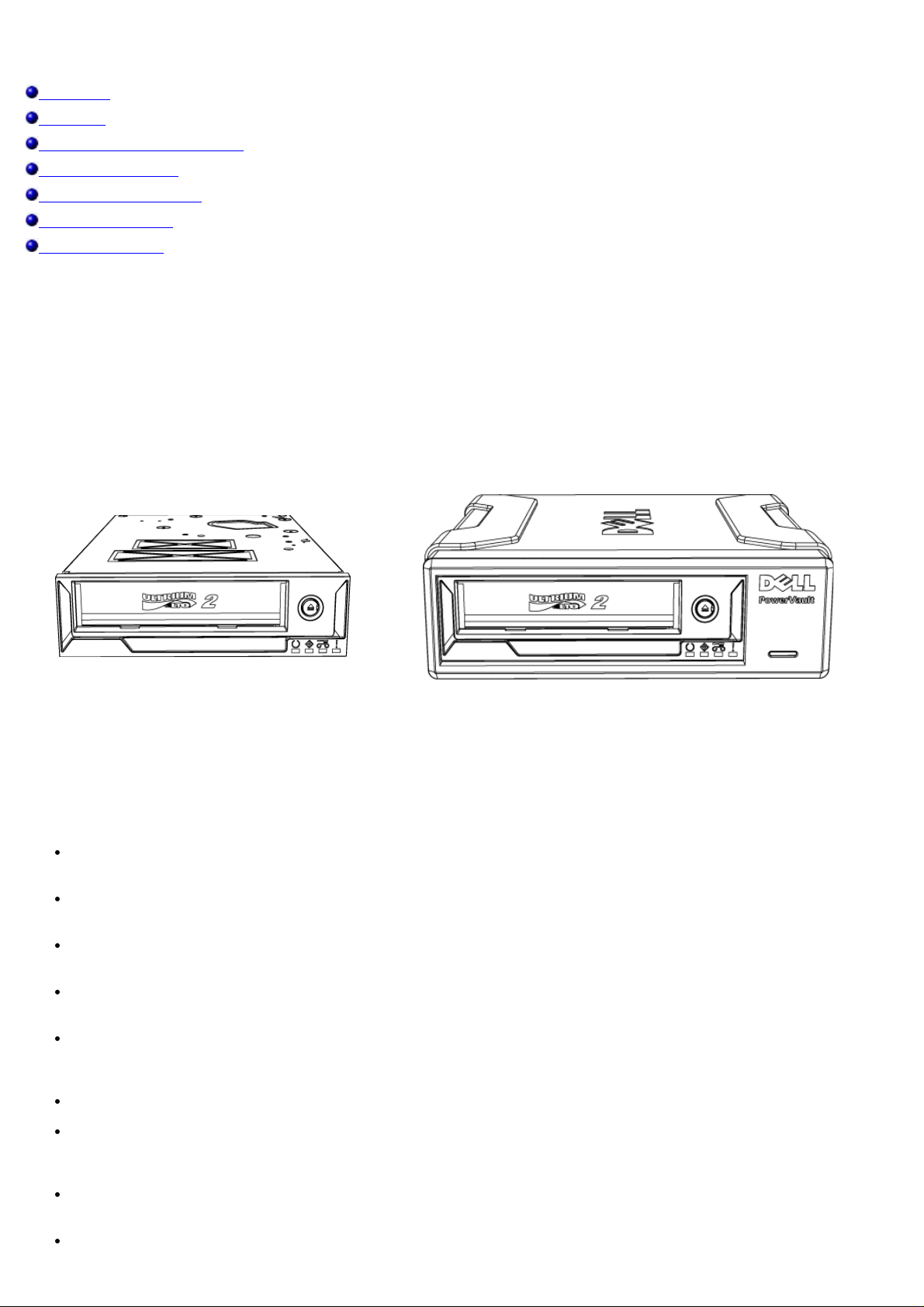

Thie Dell™ PowerVault™ LTO-2-024 is a third generation LTO tape drive designed for high performance, high capacity,

and high reliability data storage in a small form factor. Due to the low power consumption, low heat dissipation, and

multiple mounting holes, the PowerVault LTO-2-024 can easily be integrated into desktop workstations and servers, as

well as in a table-top version connected externally to the server. Using advanced technologies, this drive offers twice the

capacity and data transfer rates of the preceding generation but needs only half the space.

The external table-top version has a rugged design that allows for an easy connection to the host system.

Figure 1: The PowerVault LTO-2-024 Tape Drive

Internal drive External drive

Features

The tape drive has the following features:

Ultra160 SCSI interface

Provides excellent performance.

High speed back-up.

Provides 24 MByte/sec native transfer rate

Backward compatible for investment protection

Read/write compatible with LTO2 and LTO1 media.

Embedded quality monitoring and test features

Provides preventive maintenance information for reduced down time.

Small footprint

5.25 inch half-height form factor with several mounting capabilities for easy and trouble free integration into

servers and workstations.

Rugged external table-top version.

Media Management

Keeps track of Read/Write performance and detects when the drive needs cleaning, if there is a defective or worn

media, or the tape drive head has degraded.

Stand Alone Diagnostics

Provides self-diagnostic routines independent of the host to troubleshoot the drive.

Intelligent Head Cleaning

Page 3

Determines and initiates a head brush cleaning when needed as well as indicating the need for a cleaning cartridge

when required.

Intelligent Thermal Guard

Provides drive and media protection by monitoring the internal temperature. The drive will slow down or even stop

an operation if needed to avoid destruction of critical drive components or the media.

Smart Gripper

Catches and holds the tape pin firmly avoiding "lost leader" problems

Variable Speed

Provides host transfer rate matching by dynamically selecting between five different transfer rates (12 - 24

MB/sec).

TM

Capacity and Transfer Rates

Characteristic Value

Tape length (m) 609

Native capacity (GB) 200

Compressed capacity (GB) assuming 2:1 compression 400

Native transfer rate (MB/sec) 24

Variable speed transfer rates (MB/sec) 12, 15, 18, 21, 24

SCSI Bus Interface

The PowerVault LTO-2-024 tape drive is designed to operate with a burst transfer rate up to 160 MB/sec, and may be

attached to an Ultra160 or Ultra 320 low voltage differential (LVD) SCSI bus.

The tape drive features a high density 68-pin (HD-68) connector for attachment to the server or to the interface

connector in an external tabletop device.

Note: Dell recommends that you attach the tape drive to SCSI controllers that support the SCSI LVD interface only.

Attaching the tape drive to a non-LVD SCSI controller or an 8-bit narrow SCSI controller will degrade the

performance of your tape drive and backup operations. Performance will also be degraded if you attach non-LVD

SCSI devices on the same bus cable as your LVD connection. If you install an adapter, it is recommended that you

purchase a SCSI LVD controller kit that includes the SCSI cable and terminator.

Do not connect the tape drive to a disk RAID controller (disk RAID controllers are not supported). If, however, your

system is a Dell server with an embedded RAID solution that can be configured for RAID/SCSI operation, the tape

drive can be connected to the SCSI channel.

Tape Backup Software

You will need tape backup software that supports the Dell PowerVault™ tape drive. Note that native backup applications

(for example, the UNIX® .tar command) generally do not provide the required data streaming rate to get the full

performance out of your tape drive. (However, if for some reason you need to use the Microsoft® Windows® native

backup software, the drivers for your tape drive under Windows 2003 are included on the CD that came with the drive.)

Dell recommends using a backup application that provides improved memory management as well as other useful

features, such as TapeAlert.

See the User's Operating Guide supplied with your Tape Backup application. For the latest supported software versions, go

to the Dell Support website at www.

support.dell.com or visit the support site of your backup software vendor.

Data Compression

Data Compression is a way to increase capacity on a storage device. Compression ratios are normally specified to be 2:1,

assuming that it is possible to store twice as much data on the tape as without data compression. However, the

compression rate is dependant on the type of data (i.e. ordinary text files can be compressed in a much higher rate than

program, media, and picture files).

There are two ways to compress data, hardware compression and software compression. Hardware compression means

that the data compression is done by the electronics in the storage device. Software compression means that an

Page 4

application program in the host computer is compressing the data before it is sent to the storage device. Hardware

compression is much more efficient and works much faster than software compression.

The PowerVault LTO-2-024 tape drive uses SLDC hardware compression to compress data. This feature is enabled per

default but the user may turn off data compression through the application software.

Note: If the data is compressed by software in the host computer, and then sent to a device that does hardware

compression, the data have a tendency to expand instead of being compressed because the control data used on the

tape.

Be sure to turn the software data compression off if using the PowerVault LTO-2-024 - which has embedded

hardware compression.

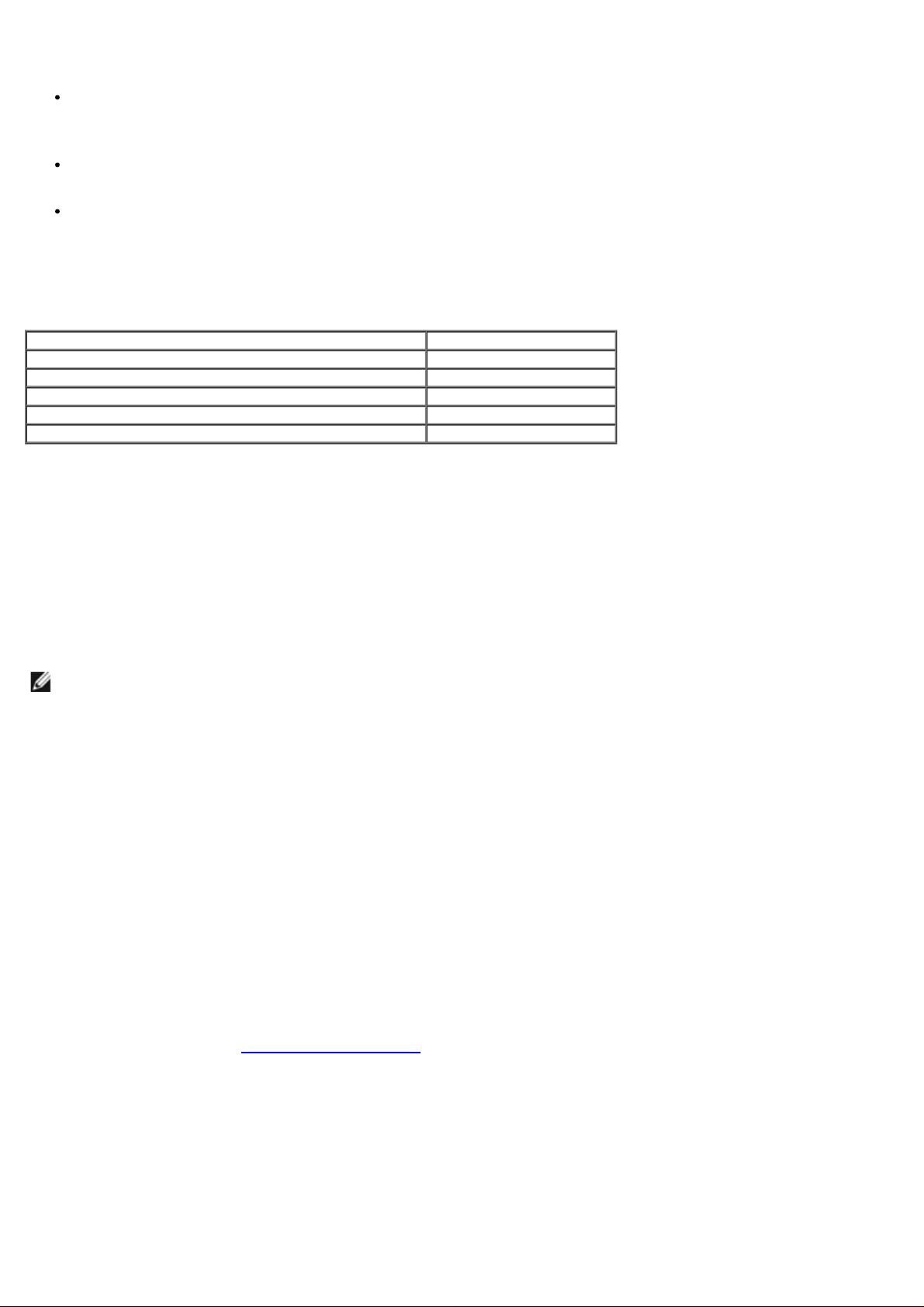

Front Panel LEDs

Figure 2: Status indicators (LEDs) on the front panel

Table 1: Front-Panel LEDs

READY LED

(Green)

Activity LED

(Green)

CLEAN LED

(Amber)

FAULT LED

(Amber)

For complete information including failure conditions and FW loading see Front LED Indicators.

Page 5

Troubleshooting

Hardware

Software

Verifying Recent Changes

Standalone Diagnostics

Media Management Reporting

Problem Situations

In case of problems with the operation of your PowerVault LTO-2-024 tape drive and before contacting the Customer

Services Group, ensure that you check the following:

Hardware Troubleshooting

1. Check that the system recognizes the tape drive during the boot process.

Check that the SCSI host adapter recognizes the tape drive during its initialization.

2.

Check the tape drive front panel LED status.

3.

Check that the SCSI ID of the drive is not conflicting on the SCSI bus.

4.

Check that the power cable is inserted correctly.

5.

Check that the SCSI cable connections including termination are made correctly.

6.

Software Troubleshooting

1. Check that the operating system does not report a problem during the boot.

Check that the driver for the SCSI host adapter is present and loaded properly.

2.

Check that the correct tape device driver has been installed properly - if applicable.

3.

Check that the backup software does not report any error messages when loading.

4.

If any problem occurs, reinstall the backup application software and check that the PowerVault LTO-2-024 is

5.

recognized.

Verifying Recent Changes

If the PowerVault LTO-2-024 has been installed previously and operating correctly but is now incurring a problem, verify

any recent changes to the system to ensure that these changes are not causing the problem. Try the following:

If the system configuration has changed:

1.

Remove the change to see if it affected the tape drive.

If an operating system corrective patch has been installed:

2.

Remove it to see if it affected the tape drive.

If a SCSI device has been added:

3.

Check for SCSI ID conflicts.

If a SCSI device has been added:

4.

Check the SCSI termination.

Standalone Diagnostics

The main objective of Standalone Diagnostics test is to test the complete drive as comprehensively and quickly as possible

without any drive configuration or host support. The tool can also be used to verify tapes.

Starting the Test

Page 6

A Standalone Diagnostic test requires a tape that is not write-protected. The media type can be any media type that

supports a tape format that can be written by the drive.

Notice: Since the test involves write operations, the existing tape contents will be destroyed.

Note: If the Clean LED is On, it will remain On after a test is run. To clear the Clean LED, run a cleaning cartridge.

1. Ensure that no cartridge is loaded. If a cartridge is loaded it can be ejected by double-clicking the eject button.

Enter Service Mode by keeping the Eject button pressed for at least 6 seconds.

2.

The Ready LED (on the left) starts flashing quickly (indicating the drive is in Service Mode and that Service entry

number 1 is active).

Insert the tape cartridge into the drive within 15 seconds.

3.

The drive loads the cartridge and the Ready LED starts flashing indicating that Standalone Diagnostics has started.

The eject button has now returned to normal mode. During the Standalone Diagnostics test, it is possible to abort

the test and eject the cartridge by clicking the eject button. The drive indicates the detection of the abort request

by flashing both the Ready and Activity LEDs. Depending on which stage the test is aborted, it may take a while

before the drive starts the eject operation. When the cartridge has been ejected, all LEDs are turned off. The

Clean LED may still be On.

The Ready LED will continuously flash during the entire testing process. The Activity LED will flash as the tape is in

motion during testing.

If no cartridge has been inserted after 15 seconds, the LEDs revert back to their initial state and the eject button

must be pressed for 6 seconds again to get back to Service Mode.

Test Sequence

The Standalone Diagnostics test will perform the following operations:

Collect Information: Reads and stores drive and media information:

Firmware and drive ID

Tape type and format

Cartridge serial number

Error History Log and Log page 0x33 from EEPROM

Run-time counters from EEPROM

Mainboard Test. Tests the mainboard hardware.

Cartridge Manipulation Test: The Cartridge Manipulation Test performs the same mechanical movement operations as

those performed during Cartridge Load and Eject.

Read/Write Test: This test involves actual reading and writing on the tape medium. A write pass and a read pass are

executed.

When the test has completed without errors the tape cartridge is ejected. No LEDs will be lit. The Clean LED may be On.

Failure Indication

When a failure has been detected the tape is not ejected and the Failure LED will be flashing.

Note for programmers:

Detailed test results are available through the Receive Diagnostics SCSI command. To use this command, Support-only

tools are required.

If a write protected, unsupported, or damaged tape cartridge is inserted prior to starting the Standalone Diagnostics test,

it will be ejected by the drive and the Failure and Activity LEDs will be flashing while the Ready LED is off. The two

flashing LEDs can be turned off by clicking the eject button.

Media Management Reporting

Media Management (MM) is a feature embedded in the PowerVault LTO-2-024 tape drive’s firmware that monitors the

read and write performance of the tape drive and media. Write performance information is written on the media header

every time the media is rewound, and before the media is unloaded.

Page 7

Cleaning is Required

If the write performance falls below a set re-write threshold, the PowerVault LTO-2-024 reports that cleaning is required

by setting the Clean LED to a steady amber. If you are using a backup application that supports TapeAlert then the

application will also report that the drive requires cleaning. See Cleaning Procedure

for instructions on how to clean.

Degraded Media

If the write performance is still below the re-write threshold after cleaning, MM illuminates the Clean LED (set to steady

amber) and reports to the backup application software that the media is degraded.

The degraded media warning means that the cartridge should not be used; it may become worn to the point where drive

cannot write or read successfully using this cartridge.

Problem Situations

Dead on Arrival

1. Check LED activity at power up.

All four LEDs should flash for two seconds at power up and the Ready LED flashes for several seconds while the

power-on self test is running.

Make sure that the power supply used is working:

2.

Measure with an external voltmeter or use a verified supply.

Perform “drive dead test” when supply is verified.

3.

Push the eject button for at least 6 seconds to enter the “drive dead test”. The Activity LED should keep flashing

for approximately 15 seconds.

If the drive still looks dead try to remove all cables except power and rerun the “drive dead test.” A defective cable or

SCSI host bus adapter may affect the drive.

Drive Not Detected by the Operating System

1. Check LED activity at Power Up.

All four LEDs should flash for two seconds at power up and the Ready LED flashes for several seconds while the

power-on self test is running.

Check the SCSI ID.

2.

Each device on the SCSI bus needs a unique SCSI ID. The SCSI ID is set with jumpers on the back of the drive.

See SCSI Configuration

Check SCSI termination.

3.

The SCSI bus should be terminated at the end of the cable. A defective terminator may affect the drive.

.

Will Not Insert/Hold Media or Media is Not Recognized

1. Check the cartridge type.

The PowerVault LTO-2-024 will only accept LTO-3, LTO-2 or LTO-1 type data or cleaning cartridges.

If a wrong type of cartridge is inserted, the drive will eject the media with the Activity LED and Fault LED flashing.

Check media orientation.

2.

The arrow on the cartridge must point into the tape drive facing up when the tape drive is mounted horizontally

with the LEDs on the right.

Media can be inserted only one way and there are mechanical blocks to prevent improper insertion.

Try using a new cartridge.

3.

If it loads correctly, check the failing cartridge for damage.

Check failing media for pin damage (buckling pin).

4.

Hold the cartridge in your hand with the write protect switch to your left and orientation arrow pointing from you.

On the right side, all the way towards the front is a small door that can be opened by sliding the door towards

you. Inside the cartridge you should see a metal pin that is held tightly in place and has media attached to it. If

the pin is missing, loose or damaged the tape will be rejected from the drive.

Page 8

Noisy Tape Drive

There are no fans in the PowerVault LTO-2-024 tape drive and any noise should be very low in idle mode. When the tape

is in motion, noise can come from the media and motors when loading or reading/writing data. The sound should be

steady when streaming but may be intermittent if the host is not delivering data at the data rate of the drive.

Check if the noise comes from the cartridge.

1.

Insert new media – first check this media for any damage.

Check that the PowerVault LTO-2-024 is mounted correctly.

2.

If the PowerVault LTO-2-024 is mounted incorrectly, it can produce abnormal noise when the tape moves.

Cartridge is Stuck Inside the Drive

1. Try to eject the cartridge by pushing the Eject button

Do a drive reset using the Service mode.

2.

Service mode is entered by keeping the eject button pressed for at least six seconds. The Activity LED starts

flashing.

To reset the drive, push the eject button once more to make the Activity LED flash. While

flashing, double-click the eject button. This should invoke a reset of the drive.

If the button is not pushed for 15 seconds, the eject button reverts back to its original cartridge eject function.

3. Power cycle the drive (switch power on/off, if possible).

Fault LED Flashes Amber and the Activity LED is Off

The tape drive reports that it has a failure.

Do a Drive reset using the Service mode.

1.

Service mode is entered by keeping the Eject button pressed for at least six seconds. The Ready LED will start

flashing.

To reset the drive, push the eject button once more to make the Activity LED flash. While this LED is flashing,

double-click the eject button. This should make the drive do a reset.

If the button is not pushed for 15 seconds, the eject button reverts back to its original cartridge eject function.

Power cycle the drive (switch power on/off, if possible).

2.

Fault LED Flashes Amber and the Activity LED is Flashing

The drive signals Media Error.

the Activity LED is

To eject media, press the Eject button.

Ensure the media is the correct type and compatible.

1.

Check the write protection switch position.

2.

Check if the media is damaged (see Will Not Insert/Hold Media or Media is Not Recognized).

3.

Check if an expired cleaning cartridge was used (Clean LED is On).

4.

Clean LED is On

The Clean LED will be lit 100 hours after the last cleaning operation or after an unrecoverable read or write error. These

errors are often caused by debris on the head indicating the drive should be cleaned. See Cleaning Procedure

instruction.

for cleaning

Incorrect Data Compression

1. Check if data is already compressed

Data may have been compressed by software in the host computer.

Page 9

In some cases data will actually expand when subjected to both the hardware and software compression. This can

occur when sending data already compressed at the software application level to the drive and the compression

option is enabled. If this is the case the drive may try to turn compression on and off to optimize the data storage

having the negative unintended result of data expansion.

Note: The PowerVault LTO-2-024 has compression On by default. The compression can be turned Off by

using the SCSI Mode Select command.

2. Turn Off any software compression in use.

The compression is already being accomplished at the hardware level of the PowerVault LTO-2-024 drive.

Therefore any other compression software in the host or on the host bus adapter should be turned off.

The data is compressed using the SLDC (Streaming Lossless Data Compression) algorithm that is based on ALDC

(Adaptive Lossless Data Compression). The SLDC format is defined in the ECMA-321 standard. Two enhancements

are introduced:

o Two methods to reduce expansion of uncompressible data.

o Embedded code word.

Slow Performance

Check that the software driver used for the PowerVault LTO-2-024 is the latest version.

Check the SCSI ID

Each device on the SCSI bus needs a unique SCSI ID. The SCSI ID is set with jumpers on the back of the drive.

Check SCSI termination

The SCSI bus should be terminated at the end of the cable. A defective terminator may affect the drive.

Clean the tape drive.

Perform a Drive Diagnostics test.

Intermittent Failures

If the drive fails intermittently:

Clean the tape drive.

1.

Check the SCSI termination on the SCSI bus.

2.

Check the operating system logs for any errors.

3.

If the problem occurs in the middle of an operation:

Use a different data cartridge.

1.

If the error occurs when the software scans for the files to be backed up, please operate a SCANDISK (or similar)

2.

operation to check the state of the File Systems(s) and hard disk.

If the error consistently occurs on the same file or directory:

Try to remove the file or directory from the backup operation to see if that corrects the problem.

1.

Use a different data cartridge before the drive is sent for service.

2.

If the issue is still not resolved, contact technical support.

3.

Page 10

Installation - Internal drive

Pre-Installed Drives

Installing the Drive

Installing the Drive: SCSI Configuration and Connection

Installing the Drive: Mechanical Installation

Installing Tape Backup Software

Installing Software Device Drivers

Verifying Tape Drive Operation

CAUTION: Before performing any of the procedures in this section, read and follow the safety

instructions located in your tape drive's Product Information Guide.

Pre-Installed Drives

Dell™ installs and configures drives that are shipped as part of the system. However, the tape backup software is not

installed by Dell. Installation instructions are provided with the software.

Store the tape backup software CD/diskette that ships with your system in a safe place in case you ever need to reinstall

the software.

Installing the Drive

If your tape drive is not pre-installed, the installation instructions are in the following sections.

Installing the Drive: Prerequisites

You need the following items to install your internal tape drive:

Ensure that the SCSI host bus adapter is one of the supported types. For a list of the supported SCSI adapters, go

to the Dell Support website at www.

5.25-inch half-height bay.

Internal SCSI-cable with an LVD terminator attached.

Backup application software that supports the internal tape drive.

Phillips screwdriver, if your system uses Phillips screws.

Flat-bladed screwdriver, if your system uses flathead screws.

TORX screwdriver, if your system uses TORX screws.

System documentation, which you can refer to during the installation.

Mounting Bay and Hardware

You need one industry standard, 5 1/4-inch, half-height bay to install the PowerVault LTO-2-024 drive.

CAUTION: The computer must provide forced cooling and be capable of drawing 6 cfm (0.17 cubic

meters/minute or 10.08 cubic meters/hour) of air through the tape drive.

support.dell.com.

See your system documentation to ensure that your system meets these requirements. Also, the documentation specifies

if any special mounting brackets are needed. Next, ensure that all fans in your system are in place and operational and

that empty bays have the appropriate blanking plates so that airflow is maintained.

Installing the Drive: SCSI Configuration and Connection

The PowerVault LTO-2-024 tape drive is designed to operate on an Ultra160 or Ultra320 low voltage differential (LVD)

SCSI bus with an LVD SCSI terminator.

SCSI Configuration

All devices on a SCSI bus need their own unique identification, called the SCSI ID. If a SCSI ID conflict exists, some of the

SCSI devices will not be recognized by your system. Normally the SCSI Host Adaptor (HBA) uses SCSI ID 7 and the

Page 11

default for the drive is SCSI ID 6. The SCSI ID is set with Jumpers as shown below.

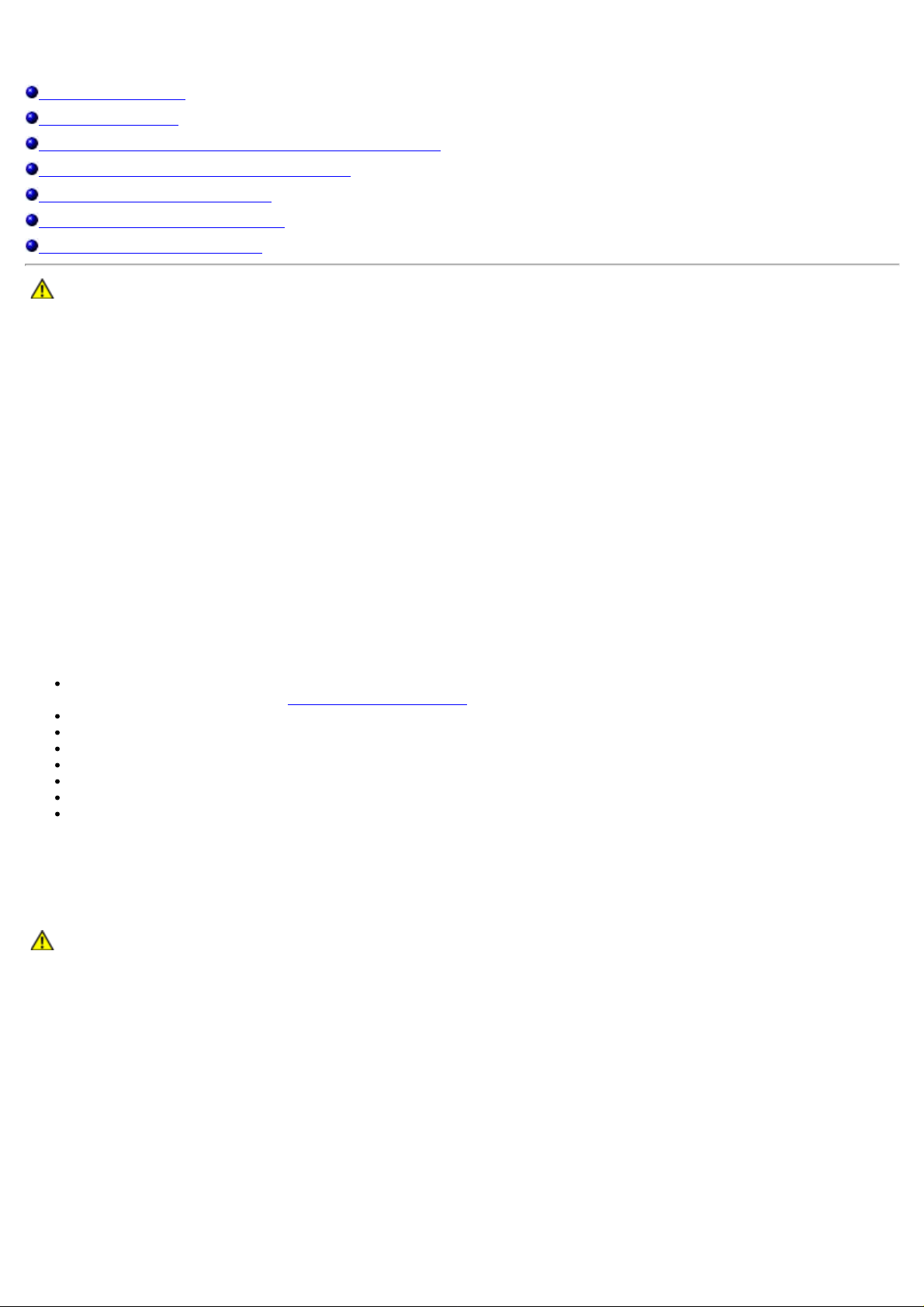

Figure 1: Drive connectors, internal model

termination of the SCSI bus system is a part of the SCSI-cable and not a part of the SCSI-device.

A = Power Connector

B = Service Connector (the right-most 4 strap pin pairs of the complete connector)

C = SCSI connector

Table 1: Service Connector strap settings for SCSI ID (Dark = Strap mounted)

If the tape drive is going to share the SCSI bus with other devices, check the SCSI ID numbers used by the other devices,

then set the drive’s SCSI ID to a number that is not being used.

Note: Notice that the SCSI host adapter uses ID 7.

For optimal performance Dell recommends that the tape drive be the only device on the SCSI bus.

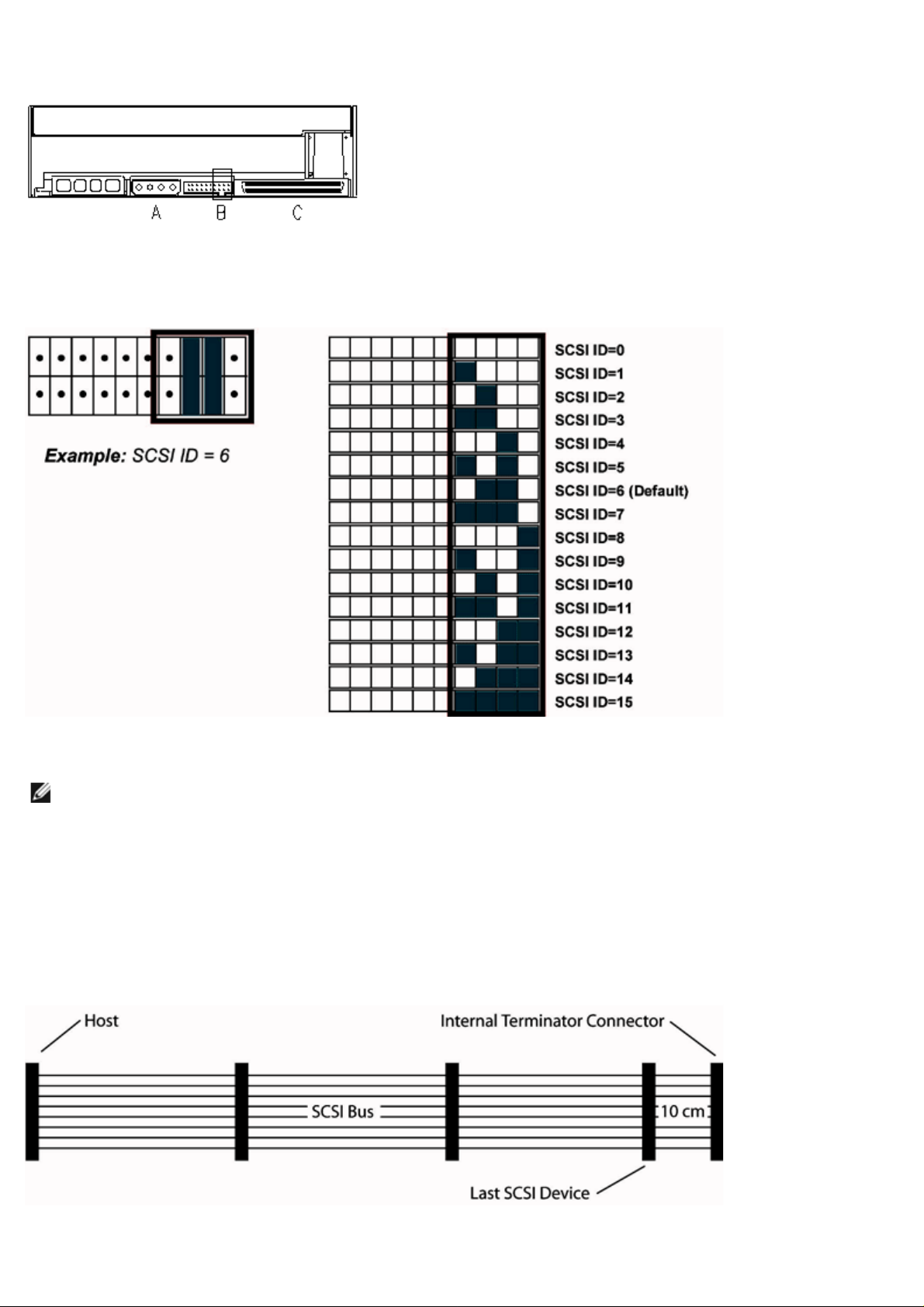

SCSI Termination

A SCSI bus must be terminated at both ends. The SCSI Host Adaptor provides the termination for one end but the tape

drive does not provide termination for the other. Therefore, if the tape drive is the last device on the bus, a cable with

proper LVD termination is required within 10 cm of the drive as illustrated below.

Figure 2: SCSI cable

PowerVault LTO-2-024 has a combined SCSI-LVD/SE interface embedded. The PC-98 Specification specifies that the

Page 12

For internal devices, a SCSI-cable with an integrated terminator or a separate terminator applied to the end connector of

the cable, 10 cm from the last device must be used.

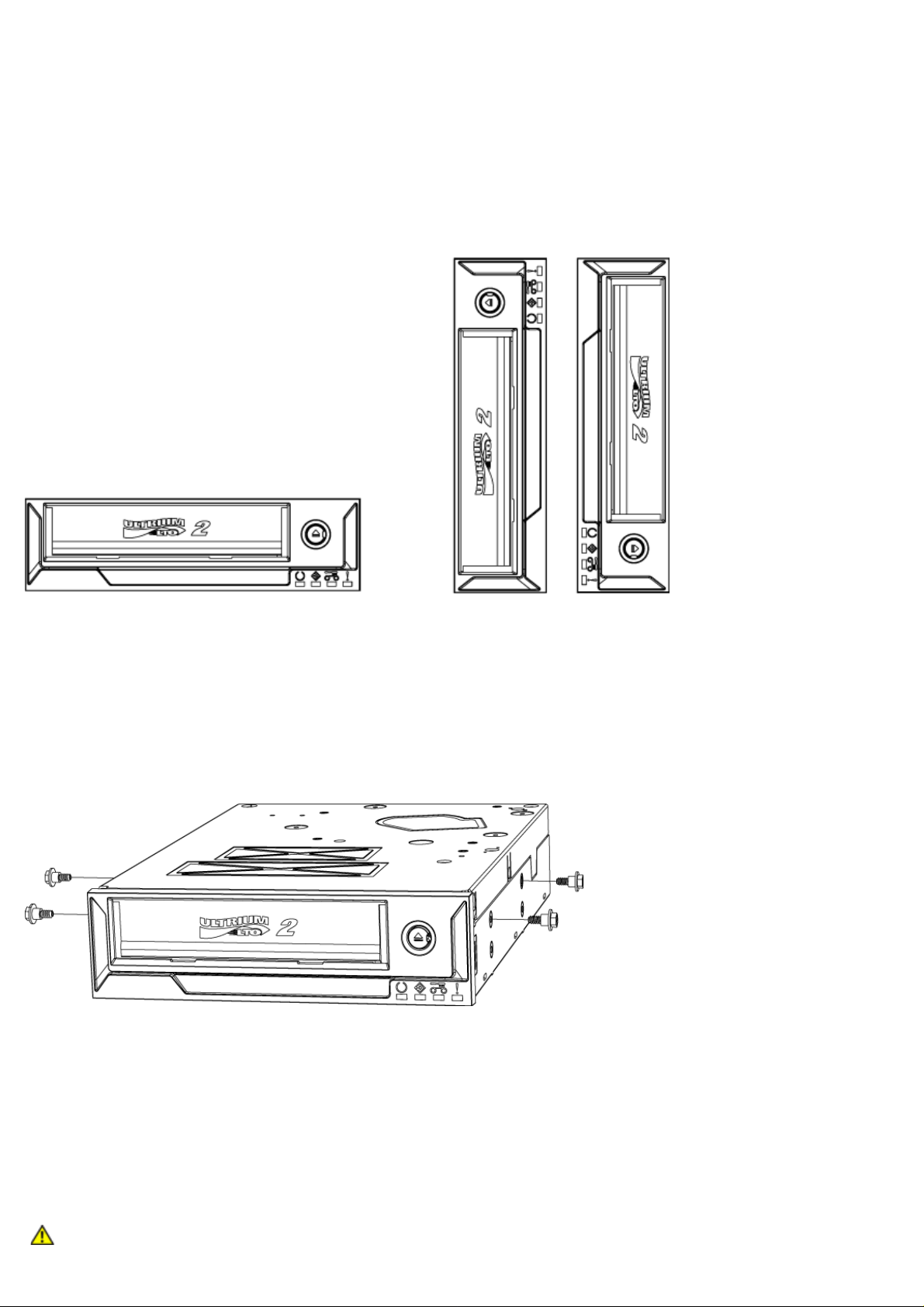

Installing the Drive: Mechanical Installation

Mechanical mounting specifications are specified in the illustration below.

Figure 3: Allowed mounting orientations

Mounting Screw Requirements

The tape drive occupies a half-height 5.25" slot within your system.

Depending on the server design, the tape drive may be supplied with shoulder screws or flat screws, provided in a

separate bag.

Figure 4: Mounting specifications, shoulder screws

The shoulder screws shall be mounted in the four upper mounting holes of the drive. Fix the screws firmly without using

excess force. Slide the drive with the shoulder screws attached into the mounting slot of the server.

If the server is designed for flat screws, it shall be mounted in a carrier sled using mounting brackets:

1. Place drive in carrier and align screw mounting holes in the drive near front of screw hole slots in the carrier (For

best fit, the drive screw holes should be as close to the front of the carrier screw slots as possible.)

2. Using the M3x3mm screws, attach drive to carrier sled through the exposed mounting holes.

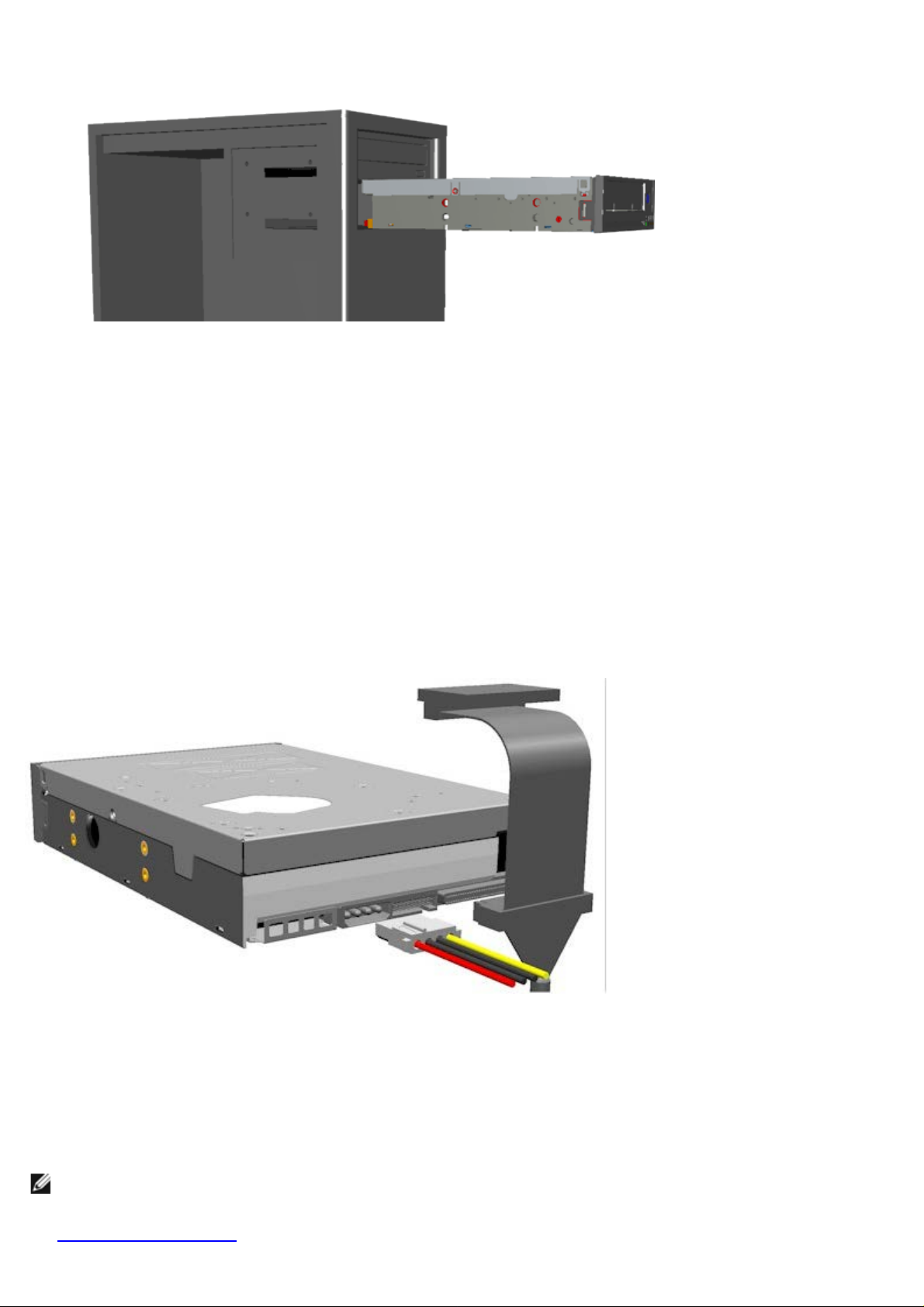

Tape Drive Installation

CAUTION: To avoid personal injury or damage to the computer or tape drive, ensure that the system is

Page 13

disconnected from the main power source while you install the drive.

Figure 5: Installing the internal tape drive

1. Gather the necessary tools and materials.

Shut down the system and turn off any connected peripherals.

2.

Remove the side cover, front panel (if necessary), and filler panel from a 5.25-inch bay of your system as detailed

3.

in the system’s documentation.

Orient the drive as shown in figure 6.

4.

Secure the tape drive to the bay.

5.

NOTE:

If shoulder screws are already attached to the drive then slide the drive in the system until it is secure.

If screws are provided in a separate bag install shoulder screws as shown in figure 4.

If the screws provided are flat screws, install the mounting rails as given by the server documentation.

Connect the power and SCSI cable, as shown in figure 6. Be careful to connect the cables in the right orientation.

6.

Before powering on the server, check the SCSI settings as detailed in the next section.

Figure 6: Connecting the cables to the tape drive

Installing Tape Backup Software

Install your backup program as specified in the software’s documentation.

Installing Software Device Drivers

Note: Most backup applications provide all the necessary device driver support for your drive. However, if you intend

to use the drive with the Microsoft® Windows® native backup software you will need the drivers included with the

Dell PowerVault LTO-2-024 Tape Drive Documentation and Drivers CD. The latest drivers can be downloaded from

support.dell.com.

www.

Page 14

Windows Server 2003

Windows Tape Driver Installation

1. Right-click My Computer.

Select Manage, you should see the tape drive under "Other devices" with a "?".

2.

Select the device, right click and select Properties.

3.

Select the appropriate driver location.

4.

Follow the instructions on the screen.

5.

Backup Utility for Windows

The Backup application is included in the Windows Operating System.

Before running the application, make sure the tape driver for your PowerVault LTO-2-024 tape drive is properly installed.

To start the application, click Start Programs Accessories System Tools Backup.

Linux

SCSI Host Adapter

Linux contains a driver for most SCSI host adapters. For more information, see the documentation provided with the SCSI

host adapter.

If the driver cannot be found, see the documentation provided with the SCSI host adapter.

Linux System Command

TAR, CPIO and DD allow simple backup, verify or restore operations to be performed.

Two different device drivers can be used:

A Non Rewind device driver (used to perform append backup)

A Rewind device driver (used only to perform overwrite backup)

Tar command examples:

tar cvf /dev/st0 /etc performs the backup of the /etc directory

tar tvf /dev/st0 reads the data on the tape

tar xvf /dev/st0 restores the data from the tape to the current directory tree

Note: For a complete explanation on how to use the system commands, please refer to the Linux documentation, or

the online help. (MAN command).

Verifying Tape Drive Operation

Once you have installed the PowerVault LTO-2-024 tape drive, verify that it is functioning properly before you attempt to

store data.

Switch on the host computer.

1.

The PowerVault LTO-2-024 tape drive starts a power on self test (POST) that exercises most of its functionality.

2.

All four LEDs light up for 2 seconds during power-up (see Front LED Indicators).

3.

The Activity LED flashes during POST.

4.

When complete only the Ready LED will remain on.

5.

If there is an error, the tape drive will flash the Fault LED. Please refer to Troubleshooting

if this happens.

Page 15

6.

Firmly push the cartridge to its end stop, then release the cartridge.

The Activity LED will start flashing.

The cartridge will move back a short section.

The cartridge will then be lowered into the drive.

The tape will be loaded. The sound of the gears may be heard.

When the tape is fully loaded, the Activity LED will stop blinking, and the Ready LED will remain on.

Page 16

Getting Help

Technical Assistance

Dell Enterprise Training and Certification

Problems With Your Order

Product Information

Returning Items for Warranty Repair or Credit

Before You Call

Technical Assistance

If you need assistance with a technical problem, perform the following steps:

1. Complete the procedures in "Troubleshooting Your System."

2. Run the system diagnostics and record any information provided.

3. Make a copy of the Diagnostics Checklist

4. Use Dell's extensive suite of online services available at Dell Support at www.support.dell.com

installation and troubleshooting procedures.

For more information, see "Online Services."

5. If the preceding steps have not resolved the problem, call Dell for technical assistance.

NOTE: Call technical support from a phone near or at the system so that technical support can assist you with any

necessary procedures.

NOTE: Dell's Express Service Code system may not be available in all countries.

When prompted by Dell's automated telephone system, enter your Express Service Code to route the call directly to

the proper support personnel. If you do not have an Express Service Code, open the Dell Accessories folder,

double-click the Express Service Code icon, and follow the directions.

For instructions on using the technical support service, see "Technical Support Service

NOTE: Some of the following services are not always available in all locations outside the continental U.S. Call your local

Dell representative for information on availability.

, and fill it out.

for help with

" and "Before You Call."

Online Services

You can access Dell Support at support.dell.com. Select your region on the WELCOME TO DELL SUPPORT page, and

fill in the requested details to access help tools and information.

You can contact Dell electronically using the following addresses:

World Wide Web

www.dell.com

www.dell.com/ap (Asian/Pacific countries only)

www.dell.com.cn

www.dell.com/jp

www.euro.dell.com

(China only)

(Japan only)

(Europe only)

Page 17

www.dell.com/la (Latin American countries)

www.dell.ca

Anonymous file transfer protocol (FTP)

ftp.dell.com/

Log in as user:anonymous, and use your e-mail address as your password.

Electronic Support Service

support@us.dell.com

apsupport@dell.com (Asian/Pacific countries only)

cn_support@dell.com (China only)

support.jp.dell.com (Japan only)

support.euro.dell.com(Europe only)

Electronic Quote Service

(Canada only)

sales@dell.com

apmarketing@dell.com (Asian/Pacific countries only)

sales_canada@dell.com (Canada only)

Electronic Information Service

info@dell.com

AutoTech Service

Dell's automated technical support service—AutoTech—provides recorded answers to the questions most frequently asked

by Dell customers about their portable and desktop computer systems.

When you call AutoTech, use your touch-tone telephone to select the subjects that correspond to your questions.

The AutoTech service is available 24 hours a day, 7 days a week. You can also access this service through the technical

support service. See the contact information for your region.

Automated Order-Status Service

To check on the status of any Dell™ products that you have ordered, you can go to www.support.dell.com, or you can

call the automated order-status service. A recording prompts you for the information needed to locate and report on your

order. See the contact information for your region.

Technical Support Service

Page 18

Dell's technical support service is available 24 hours a day, 7 days a week, to answer your questions about Dell hardware.

Our technical support staff use computer-based diagnostics to provide fast, accurate answers.

To contact Dell's technical support service, see "Before You Call

" and then see the contact information for your region.

Dell Enterprise Training and Certification

Dell Enterprise Training and Certification is available; see www.dell.com/training for more information. This service

may not be offered in all locations.

Problems With Your Order

If you have a problem with your order, such as missing parts, wrong parts, or incorrect billing, contact Dell for customer

assistance. Have your invoice or packing slip available when you call. See the contact information for your region.

Product Information

If you need information about additional products available from Dell, or if you would like to place an order, visit the Dell

website at www.dell.com

for your region.

. For the telephone number to call to speak to a sales specialist, see the contact information

Returning Items for Warranty Repair or Credit

Prepare all items being returned, whether for repair or credit, as follows:

1. Call Dell to obtain a Return Material Authorization Number, and write it clearly and prominently on the outside of

the box.

For the telephone number to call, see the contact information for your region.

2. Include a copy of the invoice and a letter describing the reason for the return.

3. Include a copy of any diagnostic information (including the Diagnostics Checklist) indicating the tests you have run

and any error messages reported by the system diagnostics.

4. Include any accessories that belong with the item(s) being returned (such as power cables, media such as CDs and

diskettes, and guides) if the return is for credit.

5. Pack the equipment to be returned in the original (or equivalent) packing materials.

You are responsible for paying shipping expenses. You are also responsible for insuring any product returned, and

you assume the risk of loss during shipment to Dell. Collect-on-delivery (C.O.D.) packages are not accepted.

Returns that are missing any of the preceding requirements will be refused at our receiving dock and returned to you.

Before You Call

NOTE: Have your Express Service Code ready when you call. The code helps Dell's automated-support telephone system

direct your call more efficiently.

Page 19

Remember to fill out the Diagnostics Checklist. If possible, turn on your system before you call Dell for technical

assistance and call from a telephone at or near the computer. You may be asked to type some commands at the

keyboard, relay detailed information during operations, or try other troubleshooting steps possible only at the computer

system itself. Ensure that the system documentation is available.

CAUTION: Before servicing any components inside your computer, see your System Information Guide

for important safety information.

Diagnostics Checklist

Name:

Date:

Address:

Phone number:

Service Tag (bar code on the back of the computer):

Express Service Code:

Return Material Authorization Number (if provided by Dell support technician):

Operating system and version:

Peripherals:

Expansion cards:

Are you connected to a network? Yes No

Network, version, and network card:

Programs and versions:

See your operating system documentation to determine the contents of the system's start-up files. If possible, print

each file. Otherwise, record the contents of each file before calling Dell.

Error message, beep code, or diagnostic code:

Description of problem and troubleshooting procedures you performed:

Back to Contents Page

Page 20

Installation External Drive

Accessories

A

Check that the

Store the tape backup software CD/diskette that came with your system in a safe place in case you ever need to reinstall the software.

Installing the Drive

The installation instructions are in the following sections.

Installing the Drive: Prerequisites

Before installing the external tape drive, ensure that

Drive orientation

The external drive should be mounted in a horizontal position.

Figure

External Tape Drive Installation

Figure

A= ON/OFF Switch

B = Power Connector

C = SCSI Interface and Terminator Connectors

D = SCSI-ID Switch

Installing the Drive: SCSI Configuration and Connection

The

SCSI Configuration

All devices on a SCSI bus need their own unique identification, called the SCSI ID. If a SCSI ID conflict exists, some of the SCSI devices will not be recognized by your system. Normally the SCSI Host Adapter uses SCSI ID 7 and the default for the external drive is SCSI ID 6.

For the external drives, you will find the SCSI-ID setting switch on the rear end of the unit box:

Figure 3.

If the tape drive is going to share the SCSI bus with other devices, check the SCSI ID numbers used by the other devices,

SCSI-bus Termination

For optimal performance, Dell recommends

Figure 4: Termination of external SCSI devices

A = Terminator

B = External SCSI cable

If other external devices are present, the PowerVault LTO-2-024 tape drive can be installed in any position on the SCSI-bus. The PowerVault LTO-2-024 tape drive must be terminated if installed at the end of the SCSI-bus.

Installing Tape Backup Software

To install the tape

Installing

Windows Server 2003

Windows Tape Driver

Backup

The Backup application is included in the Windows Operating System.

Before running the application,

To start

Linux

Linux System Command

TAR

Two different device drivers can be used:

Tar command examples:

tar

tar

tar

Verifying Tape Drive Operation

Once you have installed the PowerVault LTO-2-024 tape drive, verify that it is functioning properly before you attempt to store data.

Installing the Drive

Drive orientation

External Tape Drive Installation

Installing the Drive: SCSI Configuration and Connection

Installing Tape Backup Software

Installing Software Device Drivers

Verifying Tape Drive Operation

CAUTION: Before performing any of the procedures in this section, read and follow the safety instructions located in your tape drive's Product Information Guide.

ccessories

following accessories are delivered with the External drive:

External PowerVault LTO-2-024 tape drive

Power cable

SCSI cable

Terminator

Cleaning cartridge

Documentation and drivers CD

Placemat

Product Information Guide

SCSI Adapter (HBA) (optional)

Tape backup software (optional)

the following items are available:

Ensure that the SCSI host bus adapter is one of the supported types. For a list of the supported SCSI adapters, go to the Dell Support website at www.support.dell.com

External SCSI cable and an LVD terminator

Power cable

Backup application software that supports the tape drive

System documentation

1: Recommended mounting orientation

CAUTION: Do not apply or insert power cord until all connections have been made.

Turn off the power on your server/PC system.

1.

Open your system and install the SCSI controller card in the appropriate slot. When complete, close your system. Connect the tape drive to your Server/PC with the SCSI cable provided to any of the two available SCSI connectors. Remember to place the termination on the free connector on the back of the tape drive.

2.

Connect the power cable provided to the power connector on the tape drive and to the power outlet.

3.

Turn on the power to the tape drive with the ON/OFF switch.

4.

Turn on the power to your server/PC and check that all your SCSI devices are recognized by the SCSI controller board.

5.

2 Drive connectors, external tabletop model

PowerVault LTO-2-024 tape drive is designed to operate on an Ultra160 and Ultra320 low voltage differential (LVD) SCSI bus with an LVD SCSI terminator.

SCSI-ID Thumb-wheel

Note: The SCSI host adapter normally uses ID 7.

Note: Make certain the terminator is connected to the second SCSI connector.

backup software, see the documentation that ships with the software.

Software Device Drivers

Note: Most backup applications provide all the necessary device driver support for your drive. However, if you intend to use the drive with the Microsoft® Windows® native backup software you will need the drivers included with the Dell PowerVault LTO-2-024 Documentation and Drivers CD. For the latest drivers go to the Dell Support website at www.support.dell.com.

Installation

1. Right-click My Computer.

Select Manage, you should see the tape drive under "Other devices" with a "?".

2.

Select the device, right click and select Properties.

3.

Select the appropriate driver location.

4.

Follow the instructions on the screen.

5.

Utility for Windows

ensure that the tape driver for your PowerVault LTO-2-024 tape drive is properly installed.

the application, click Start Programs Accessories System Tools Backup.

, CPIO and DD allow simple Backup, Verify or Restore operations to be performed.

A Non Rewind device driver (used to perform append backup)

A Rewind device driver (used only to perform overwrite backup)

cvf /dev/st0 /etc performs the backup of the /etc directory

tvf /dev/st0 reads the data on the tape

xvf /dev/st0 restores the data from the tape to the current directory tree

Note: For any questions related to this operating system or its embedded backup applet, see the documentation provided on the Linux CD- ROM.

1. Switch on the external PowerVault LTO-2-024 (The LEDs may be flickering until the host computer is switched on)

Switch on the host computer.

2.

The PowerVault LTO-2-024 tape drive starts a power on self test (POST) that exercises most of its functionality.

3.

All four LEDs light up for 2 seconds during power-up (see Front LED Indicators).

4.

The Activity LED flashes during POST.

5.

All LED's will turn off except for the Ready LED.

6.

If there was an error, the tape drive will flash the Fault LED. Please refer to Troubleshooting if this happens.

Firmly push the cartridge in until the loading mechanism is activated, then release the cartridge.

7.

· The Activity LED will start flashing.

· The cartridge will move back a short section.

· The cartridge will then be lowered into the drive.

· The tape will be loaded. The sound of the gears may be heard.

· When the tape is fully loaded, the Activity LED will stop blinking, and the Ready LED will be on.

then set the drive’s SCSI ID to a number that is not being used.

— External Tape Drives

that the PowerVault LTO-2-024 is the only device on the external SCSI-bus. In that case it must be terminated using the external SCSI termination installed in the second SCSI connector position.

Page 21

Contacting Dell

To contact Dell electronically, you can access the following websites:

www.dell.com

www.support.dell.com (support)

For specific web addresses for your country, find the appropriate country section in the table below.

NOTE: Toll-free numbers are for use within the country for which they are listed.

NOTE: In certain countries, support specific to Dell™ XPS™ computers is available at a separate telephone

number listed for participating countries. If you do not see a telephone number listed that is specific for XPS

computers, you may contact Dell through the support number listed and your call will be routed

appropriately.

When you need to contact Dell, use the electronic addresses, telephone numbers, and codes provided in the

following table. If you need assistance in determining which codes to use, contact a local or an international

operator.

NOTE: The contact information provided was deemed correct at the time that this document went to print

and is subject to change.

Country (City)

International Access

Code Country Code

City Code

Anguilla General Support toll-free: 800-335-0031

Antigua and

Barbuda

Argentina (Buenos

Aires)

International Access

Code: 00

Country Code: 54

General Support 1-800-805-5924

Website: dell.com.ar

E-mail: us_latin_services@dell.com

E-mail for desktop and portable computers:

la-techsupport@dell.com

E-mail for servers and EMC® storage products:

la_enterprise@dell.com

Customer Care toll-free: 0-800-444-0730

Department Name or Service Area,

Website and E-Mail Address

Local Numbers, and

Toll-Free Numbers

Area Codes,

City Code: 11

Aruba General Support toll-free: 800-1578

Australia (Sydney)

International Access

Code: 0011

Technical Support toll-free: 0-800-444-0733

Technical Support Services toll-free: 0-800-444-0724

Sales 0-810-444-3355

Website: support.ap.dell.com

E-mail: support.ap.dell.com/contactus

Page 22

Country Code: 61

City Code: 2

General Support 13DELL-133355

Austria (Vienna)

Website: support.euro.dell.com

E-mail: tech_support_central_europe@dell.com

Home/Small Business Sales 0820 240 530 00

Home/Small Business Fax 0820 240 530 49

International Access

Code: 900

Country Code: 43

City Code: 1

Bahamas General Support toll-free: 1-866-278-6818

Barbados General Support 1-800-534-3066

Belgium (Brussels)

International Access

Code: 00

Country Code: 32

City Code: 2

Home/Small Business Customer Care 0820 240 530 14

Preferred Accounts/Corporate Customer Care 0820 240 530 16

Support for XPS 0820 240 530 81

Home/Small Business Support for all other Dell

computers

Preferred Accounts/Corporate Support 0660 8779

Switchboard 0820 240 530 00

Website: support.euro.dell.com

Tech Support for XPS 02 481 92 96

Tech Support for all other Dell computers 02 481 92 88

Tech Support Fax 02 481 92 95

Customer Care 02 713 15 65

Corporate Sales 02 481 91 00

0820 240 530 17

Bermuda General Support 1-800-342-0671

Bolivia General Support toll-free: 800-10-0238

Brazil

International Access

Code: 00

Country Code: 55

City Code: 51

British Virgin

Islands

Brunei

Country Code: 673

Fax 02 481 92 99

Switchboard 02 481 91 00

Website: dell.com/br

Customer Support, Tech Support

0800 90 3355

Technical Support Fax 51 481 5470

Customer Care Fax 51 481 5480

Sales 0800 90 3390

General Support toll-free: 1-866-278-6820

Technical Support (Penang, Malaysia) 604 633 4966

Customer Care (Penang, Malaysia) 604 633 4888

Transaction Sales (Penang, Malaysia) 604 633 4955

Online Order Status: dell.ca/ostatus

Page 23

AutoTech (automated Hardware and Warranty

Support)

Customer Service (Home Sales/Small Business) toll-free: 1-800-847-4096

Customer Service (med./large business, government) toll-free: 1-800-326-9463

toll-free: 1-800-247-9362

Customer Service (printers, projectors, televisions,

Canada (North York,

Ontario)

International Access

Code: 011

Cayman Islands General Support 1-800-805-7541

Chile (Santiago)

Country Code: 56

City Code: 2

handhelds, digital jukebox, and wireless)

Hardware Warranty Support (Home Sales/Small

Business)

Hardware Warranty Support (med./large bus.,

government)

Hardware Warranty Support (printers, projectors,

televisions, handhelds, digital jukebox, and wireless)

Sales (Home Sales/Small Business) toll-free: 1-800-387-5752

Sales (med./large bus., government) toll-free: 1-800-387-5755

Spare Parts Sales & Extended Service Sales 1 866 440 3355

Sales and Customer Support toll-free: 1230-020-4823

toll-free: 1-800-847-4096

toll-free: 1-800-906-3355

toll-free: 1-800-387-5757

1-877-335-5767

China (Xiamen)

Country Code: 86

City Code: 592

Technical Support website: support.dell.com.cn

Technical Support E-mail: cn_support@dell.com

Customer Care E-mail: customer_cn@dell.com

Technical Support Fax 592 818 1350

Technical Support (Dell™ Dimension™ and Inspiron) toll-free: 800 858 2968

Technical Support (OptiPlex™, Latitude™, and Dell

Precision™)

Technical Support (servers and storage) toll-free: 800 858 0960

Technical Support (projectors, PDAs, switches,

routers, and so on)

Technical Support (printers) toll-free: 800 858 2311

Customer Care toll-free: 800 858 2060

Customer Care Fax 592 818 1308

Home and Small Business toll-free: 800 858 2222

Preferred Accounts Division toll-free: 800 858 2557

toll-free: 800 858 0950

toll-free: 800 858 2920

Large Corporate Accounts GCP toll-free: 800 858 2055

Large Corporate Accounts Key Accounts toll-free: 800 858 2628

Large Corporate Accounts North toll-free: 800 858 2999

Large Corporate Accounts North Government and

Education

toll-free: 800 858 2955

Page 24

Large Corporate Accounts East toll-free: 800 858 2020

Large Corporate Accounts East Government and

Education

Large Corporate Accounts Queue Team toll-free: 800 858 2572

Large Corporate Accounts South toll-free: 800 858 2355

Large Corporate Accounts West toll-free: 800 858 2811

Large Corporate Accounts Spare Parts toll-free: 800 858 2621

Colombia General Support 980-9-15-3978

Costa Rica General Support 0800-012-0435

toll-free: 800 858 2669

Czech Republic

(Prague)

International Access

Code: 00

Country Code: 420

Denmark

(Copenhagen)

International Access

Code: 00

Country Code: 45

Website: support.euro.dell.com

E-mail: czech_dell@dell.com

Technical Support 22537 2727

Customer Care 22537 2707

Fax 22537 2714

Technical Fax 22537 2728

Switchboard 22537 2711

Website: support.euro.dell.com

Technical Support for XPS 7010 0074

Technical Support for all other Dell computers 7023 0182

Customer Care (Relational) 7023 0184

Home/Small Business Customer Care 3287 5505

Switchboard (Relational) 3287 1200

Switchboard Fax (Relational) 3287 1201

Switchboard (Home/Small Business) 3287 5000

Switchboard Fax (Home/Small Business) 3287 5001

Dominica General Support toll-free: 1-866-278-6821

Dominican Republic General Support 1-800-148-0530

Ecuador General Support toll-free: 999-119

El Salvador General Support 01-899-753-0777

Website: support.euro.dell.com

E-mail: fi_support@dell.com

Finland (Helsinki)

International Access

Code: 990

Country Code: 358

City Code: 9

Technical Support 0207 533 555

Customer Care 0207 533 538

Switchboard 0207 533 533

Sales under 500 employees 0207 533 540

Fax 0207 533 530

Sales over 500 employees 0207 533 533

Page 25

Fax 0207 533 530

Website: support.euro.dell.com

Home and Small Business

Technical Support for XPS 0825 387 129

Technical Support for all other Dell computers 0825 387 270

Customer Care 0825 823 833

France (Paris)

(Montpellier)

International Access

Code: 00

Country Code: 33

City Codes: (1) (4)

Germany (Langen)

International Access

Code: 00

Country Code: 49

City Code: 6103

Switchboard 0825 004 700

Switchboard (calls from outside of France) 04 99 75 40 00

Sales 0825 004 700

Fax 0825 004 701

Fax (calls from outside of France) 04 99 75 40 01

Corporate

Technical Support 0825 004 719

Customer Care 0825 338 339

Switchboard 01 55 94 71 00

Sales 01 55 94 71 00

Fax 01 55 94 71 01

Website: support.euro.dell.com

E-mail: tech_support_central_europe@dell.com

Technical Support for XPS 069 9792 7222

Technical Support for all other Dell computers 069 9792-7200

Home/Small Business Customer Care 0180-5-224400

Global Segment Customer Care 06103 766-9570

Preferred Accounts Customer Care 06103 766-9420

Large Accounts Customer Care 06103 766-9560

Public Accounts Customer Care 06103 766-9555

Switchboard 06103 766-7000

Website: support.euro.dell.com

Greece

International Access

Code: 00

Country Code: 30

Grenada General Support toll-free: 1-866-540-3355

Guatemala General Support 1-800-999-0136

Guyana General Support toll-free: 1-877-270-4609

Technical Support 00800-44 14 95 18

Gold Service Technical Support 00800-44 14 00 83

Switchboard 2108129810

Gold Service Switchboard 2108129811

Sales 2108129800

Fax 2108129812

Page 26

Website: support.ap.dell.com

Technical Support E-mail: HK_support@Dell.com

Technical Support (Dimension and Inspiron) 2969 3188

Hong Kong

International Access

Code: 001

Country Code: 852

India

Technical Support (OptiPlex, Latitude, and Dell

Precision)

Technical Support (PowerApp™, PowerEdge™,

PowerConnect™, and PowerVault™)

Customer Care 3416 0910

Large Corporate Accounts 3416 0907

Global Customer Programs 3416 0908

Medium Business Division 3416 0912

Home and Small Business Division 2969 3105

E-mail: india_support_desktop@dell.com

india_support_notebook@dell.com

india_support_Server@dell.com

Technical Support

and 1600448046

Sales (Large Corporate Accounts) 1600 33 8044

Sales (Home and Small Business) 1600 33 8046

2969 3191

2969 3196

1600338045

Ireland

(Cherrywood)

International Access

Code: 00

Country Code: 353

City Code: 1

Website: support.euro.dell.com

E-mail: dell_direct_support@dell.com

Sales

Ireland Sales 01 204 4444

Dell Outlet 1850 200 778

Online Ordering HelpDesk 1850 200 778

Customer Care

Home User Customer Care 01 204 4014

Small Business Customer Care 01 204 4014

Corporate Customer Care 1850 200 982

Technical Support

Technical Support for XPS 1850 200 722

Technical Support for all other Dell computers 1850 543 543

At-Home-Service — Technical Support Queries 1850 200 889

General

Fax/Sales Fax 01 204 0103

Switchboard 01 204 4444

U.K. Technical Support (dial within U.K. only) 0870 353 0800

U.K. Customer Care (dial within U.K. only) 0870 353 0202

Page 27

Corporate Customer Care (dial within U.K. only) 0870 353 0240

U.K. Sales (dial within U.K. only) 0870 353 4000

Korea (Seoul)

Website: support.euro.dell.com

Home and Small Business

Technical Support 02 577 826 90

Italy (Milan)

International Access

Code: 00

Country Code: 39

City Code: 02

Jamaica General Support (dial from within Jamaica only) 1-800-682-3639

Customer Care 02 696 821 14

Fax 02 696 821 13

Switchboard 02 696 821 12

Corporate

Technical Support 02 577 826 90

Customer Care 02 577 825 55

Fax 02 575 035 30

Switchboard 02 577 821

Website: support.jp.dell.com

Technical Support (servers) toll-free: 0120-198-498

Technical Support outside of Japan (servers) 81-44-556-4162

Technical Support (Dimension and Inspiron) toll-free: 0120-198-226

Technical Support outside of Japan (Dimension and

Inspiron)

81-44-520-1435

Japan (Kawasaki)

International Access

Code: 001

Country Code: 81

City Code: 44

Technical Support (Dell Precision, OptiPlex, and

Latitude)

Technical Support outside of Japan (Dell Precision,

OptiPlex, and Latitude)

Technical Support (PDAs, projectors, printers, routers) toll-free: 0120-981-690

Technical Support outside of Japan (PDAs, projectors,

printers, routers)

Faxbox Service 044-556-3490

24-Hour Automated Order Status Service 044-556-3801

Customer Care 044-556-4240

Business Sales Division (up to 400 employees) 044-556-1465

Preferred Accounts Division Sales (over 400

employees)

Public Sales (government agencies, educational

institutions, and medical institutions)

Global Segment Japan 044-556-3469

toll-free:0120-198-433

81-44-556-3894

81-44-556-3468

044-556-3433

044-556-5963

Individual User 044-556-1760

Switchboard 044-556-4300

E-mail: krsupport@dell.com

Page 28

International Access

Support toll-free: 080-200-3800

Country Code: 52

Code: 001

Support (Dimension, PDA, Electronics and

Accessories)

toll-free: 080-200-3801

Country Code: 82

City Code: 2

Latin America

Luxembourg

International Access

Code: 00

Sales toll-free: 080-200-3600

Fax 2194-6202

Switchboard 2194-6000

Customer Technical Support (Austin, Texas, U.S.A.) 512 728-4093

Customer Service (Austin, Texas, U.S.A.) 512 728-3619

Fax (Technical Support and Customer Service)

(Austin, Texas, U.S.A.)

Sales (Austin, Texas, U.S.A.) 512 728-4397

SalesFax (Austin, Texas, U.S.A.)

Website: support.euro.dell.com

Support 342 08 08 075

Home/Small Business Sales +32 (0)2 713 15 96

Corporate Sales 26 25 77 81

512 728-3883

512 728-4600

or 512 728-3772

Country Code: 352

Macao

Country Code: 853

Malaysia (Penang)

International Access

Code: 00

Country Code: 60

City Code: 4

Customer Care +32 (0)2 481 91 19

Fax 26 25 77 82

Technical Support toll-free: 0800 105

Customer Service (Xiamen, China) 34 160 910

Transaction Sales (Xiamen, China) 29 693 115

Website: support.ap.dell.com

Technical Support (Dell Precision, OptiPlex, and

Latitude)

Technical Support (Dimension, Inspiron, and

Electronics and Accessories)

Technical Support (PowerApp, PowerEdge,

PowerConnect, and PowerVault)

Customer Care

Transaction Sales toll-free: 1 800 888 202

Corporate Sales toll-free: 1 800 888 213

toll-free: 1 800 880 193

toll-free: 1 800 881 306

toll-free: 1800 881 386

toll-free: 1800 881 306

(option 6)

Mexico

International Access

Code: 00

001-877-384-8979

Customer Technical Support

or 001-877-269-3383

50-81-8800

Sales

or 01-800-888-3355

001-877-384-8979

Customer Service

Page 29

or 001-877-269-3383

50-81-8800

Main

Montserrat General Support toll-free: 1-866-278-6822

Netherlands Antilles General Support 001-800-882-1519

or 01-800-888-3355

Netherlands

(Amsterdam)

International Access

Code: 00

Country Code: 31

City Code: 20

New Zealand

International Access

Code: 00

Country Code: 64

Website: support.euro.dell.com

Technical Support for XPS 020 674 45 94

Technical Support for all other Dell computers 020 674 45 00

Technical Support Fax 020 674 47 66

Home/Small Business Customer Care 020 674 42 00

Relational Customer Care 020 674 4325

Home/Small Business Sales 020 674 55 00

Relational Sales 020 674 50 00

Home/Small Business Sales Fax 020 674 47 75

Relational Sales Fax 020 674 47 50

Switchboard 020 674 50 00

Switchboard Fax 020 674 47 50

Website: support.ap.dell.com

E-mail: support.ap.dell.com/contactus

General Support 0800 441 567

Nicaragua General Support 001-800-220-1006

Website: support.euro.dell.com

Norway (Lysaker)

International Access

Code: 00

Country Code: 47

Panama General Support 001-800-507-0962

Peru General Support 0800-50-669

Poland (Warsaw)

International Access

Code: 011

Country Code: 48

Technical Support for XPS 815 35 043

Technical Support for all other Dell products 671 16882

Relational Customer Care 671 17575

Home/Small Business Customer Care 23162298

Switchboard 671 16800

Fax Switchboard 671 16865

Website: support.euro.dell.com

E-mail: pl_support_tech@dell.com

Customer Service Phone 57 95 700

Customer Care 57 95 999

Sales 57 95 999

Customer Service Fax 57 95 806

Page 30

City Code: 22

Reception Desk Fax 57 95 998

09/091

Portugal

International Access

Code: 00

Country Code: 351

Puerto Rico General Support 1-800-805-7545

St. Kitts and Nevis General Support toll-free: 1-877-441-4731

St. Lucia General Support 1-800-882-1521

St. Vincent and the

Grenadines

Switchboard 57 95 999

Website: support.euro.dell.com

Technical Support 707200149

Customer Care 800 300 413

Sales

Fax 21 424 01 12

General Support toll-free: 1-877-270-4609

NOTE: The phone numbers in this section should be

called from within Singapore or Malaysia only.

800 300 410 or 800 300 411 or

800 300 412 or 21 422 07 10

Singapore

(Singapore)

International Access

Code: 005

Country Code: 65

Slovakia (Prague)

International Access

Code: 00

Country Code: 421

Website: support.euro.dell.com

Technical Support (Dimension, Inspiron, and

Electronics and Accessories)

Technical Support (OptiPlex, Latitude, and Dell

Precision)

Technical Support (PowerApp, PowerEdge,

PowerConnect, and PowerVault)

Customer Care

Transaction Sales toll-free: 1 800 394 7412

Corporate Sales toll-free: 1 800 394 7419

Website: support.euro.dell.com

E-mail: czech_dell@dell.com

Technical Support 02 5441 5727

Customer Care 420 22537 2707

Fax 02 5441 8328

Tech Fax 02 5441 8328

toll-free: 1 800 394 7430

toll-free: 1 800 394 7488

toll-free: 1 800 394 7478

toll-free: 1 800 394 7430

(option 6)

South Africa

(Johannesburg)

International Access

Code:

Switchboard (Sales) 02 5441 7585

Website: support.euro.dell.com

E-mail: dell_za_support@dell.com

Gold Queue 011 709 7713

Technical Support 011 709 7710

Customer Care 011 709 7707

Page 31

Country Code: 27

Technical Support (OptiPlex, Latitude, Inspiron,

City Code: 11

Sales 011 709 7700

Fax 011 706 0495

Switchboard 011 709 7700

Southeast Asian and

Pacific Countries

Spain (Madrid)

International Access

Code: 00

Country Code: 34

City Code: 91

Technical Support, Customer Service, and Sales

(Penang, Malaysia)

Website: support.euro.dell.com

Home and Small Business

Technical Support 902 100 130

Customer Care 902 118 540

Sales 902 118 541

Switchboard 902 118 541

Fax 902 118 539

Corporate

Technical Support 902 100 130

Customer Care 902 115 236

Switchboard 91 722 92 00

Fax 91 722 95 83

Website: support.euro.dell.com

604 633 4810

Sweden (Upplands

Vasby)

International Access

Code: 00

Country Code: 46

City Code: 8

Switzerland (Geneva)

International Access

Code: 00

Country Code: 41

City Code: 22

Technical Support for XPS 0771 340 340

Technical Support for all other Dell products 08 590 05 199

Relational Customer Care 08 590 05 642

Home/Small Business Customer Care 08 587 70 527

Employee Purchase Program (EPP) Support 020 140 14 44

Technical Support Fax 08 590 05 594

Sales 08 590 05 185

Website: support.euro.dell.com

E-mail: Tech_support_central_Europe@dell.com

Technical Support for XPS 0848 33 88 57

Technical Support (Home and Small Business) for all

other Dell products

Technical Support (Corporate) 0844 822 844

Customer Care (Home and Small Business) 0848 802 202

Customer Care (Corporate) 0848 821 721

0844 811 411

Taiwan

Fax 022 799 01 90

Switchboard 022 799 01 01

Website: support.ap.dell.com

E-mail: ap_support@dell.com

Page 32

International Access

toll-free: 00801 86 1011

Code: 002

Country Code: 886

Dimension, and Electronics and Accessories)

Technical Support (PowerApp, PowerEdge,

PowerConnect, and PowerVault)

Customer Care

Transaction Sales toll-free: 00801 65 1228

Corporate Sales toll-free: 00801 651 227

toll-free: 00801 60 1256

toll-free: 00801 60 1250

(option 5)

Website: support.ap.dell.com

Technical Support (OptiPlex, Latitude, and Dell

Thailand

International Access

Code: 001

Country Code: 66

Trinidad/Tobago General Support 1-800-805-8035

Turks and Caicos

Islands

Precision)

Technical Support (PowerApp, PowerEdge,

PowerConnect, and PowerVault)

Customer Care

Corporate Sales toll-free: 1800 006 009

Transaction Sales toll-free: 1800 006 006

General Support toll-free: 1-866-540-3355

Website: support.euro.dell.com

E-mail: dell_direct_support@dell.com

Customer Care website:

support.euro.dell.com/uk/en/ECare/form/home.asp

toll-free: 1800 0060 07

toll-free: 1800 0600 09

toll-free: 1800 006 007

(option 7)

U.K. (Bracknell)

International Access

Code: 00

Country Code: 44

City Code: 1344

Sales

Home and Small Business Sales 0870 907 4000

Corporate/Public Sector Sales 01344 860 456

Customer Care

Home and Small Business Customer Care 0870 906 0010

Corporate Customer Care 01344 373 185

Preferred Accounts (500–5000 employees) Customer

Care

Global Accounts Customer Care 01344 373 186

Central Government Customer Care 01344 373 193

Local Government & Education Customer Care 01344 373 199

Health Customer Care 01344 373 194

Technical Support

Technical Support for XPS 0870 366 4180

Technical Support (Corporate/Preferred

Accounts/PAD [1000+ employees])

0870 906 0010

0870 908 0500

General

Page 33

Technical Support for all other products 0870 908 0800

Home and Small Business Fax 0870 907 4006

Uruguay General Support toll-free: 000-413-598-2521

Automated Order-Status Service toll-free: 1-800-433-9014

AutoTech (portable and desktop computers) toll-free: 1-800-247-9362

U.S.A. (Austin,

Texas)

International Access

Code: 011

Country Code: 1

Hardware and Warranty Support (Dell TV, Printers,

and Projectors) for Relationship customers

Americas Consumer XPS Support toll-free: 1-800-232-8544

Consumer (Home and Home Office) Support for all

other Dell products

Customer Service toll-free: 1-800-624-9897

Employee Purchase Program (EPP) Customers toll-free: 1-800-695-8133

Financial Services website:

www.dellfinancialservices.com

Financial Services (lease/loans) toll-free: 1-877-577-3355

Financial Services (Dell Preferred Accounts [DPA]) toll-free: 1-800-283-2210

Business

Customer Service and Support toll-free: 1-800-456-3355

Employee Purchase Program (EPP) Customers toll-free: 1-800-695-8133

Support for printers, projectors, PDAs, and MP3

players

toll-free: 1-877-459-7298

toll-free: 1-800-624-9896

toll-free: 1-877-459-7298

Public (government, education, and healthcare)

Customer Service and Support toll-free: 1-800-456-3355

Employee Purchase Program (EPP) Customers toll-free: 1-800-695-8133

toll-free: 1-800-289-3355

Dell Sales

or toll-free: 1-800-879-3355

Dell Outlet Store (Dell refurbished computers) toll-free: 1-888-798-7561

Software and Peripherals Sales toll-free: 1-800-671-3355

Spare Parts Sales toll-free: 1-800-357-3355

Extended Service and Warranty Sales toll-free: 1-800-247-4618

Fax toll-free: 1-800-727-8320

Dell Services for the Deaf, Hard-of-Hearing, or

Speech-Impaired

U.S. Virgin Islands General Support 1-877-673-3355

Venezuela General Support 8001-3605

toll-free: 1-877-DELLTTY

(1-877-335-5889)

Back to Contents Page

Page 34

Page 35

Specifications

Tape Drive Capacity and Performance

Media Specifications and Compatibility

Mechanical Specifications

Power Specifications

Environmental Specifications

Tape Drive Capacity and Performance

Drive Model Tape Format

PowerVault LTO-2-024

*) Capacity and transfer rate given in native/compressed (assuming 2:1 compression)

Ultrium Gen. 2

Ultrium Gen. 1

Capacity

200/400 GB

100/200 GB

*)

Sustained Transfer Rate

24/48 MB/sec

16/32 MB/sec

*)

Interface Type

Ultra160

Ultra160

Media Specifications and Compatibility

Drive Model Media Name Tape Length

PowerVault LTO-2-024

LTO Ultrium Generation 2 (Read/Write compatible) 609 m 200 GB/ 400 GB

LTO Ultrium Generation 1 (Read/Write compatible) 609 m 100 GB/ 200 GB

(Native/compressed)

Mechanical Specifications

Standard drive mounting, internal drive:

Fits in 5.25-inch half-height standard drive bay. Standard mounting holes for a half-height drive.

Height/width/depth Weight

Internal drive: 41.3/146.0/214 mm (1.63/5.75/8.43 inch) 1.4 kg (3.2 lbs)

External drive: 65/205/259 mm (2.56/8.1/10.2 inch) 3.0 kg (6.6 lbs)

Capacity

Power Specifications

Internal drive:

External drive: AC input, 50-60 Hz: 100 VAC / 0.6 A or 240 VAC / 0.3 A

Operating: 18 W

Sleep mode with cartridge inserted: 9 W

Environmental Specifications

0

Operating +10 to +40 20 to 80

Storage -30 to +60 5 to 90

Transport -40 to +60 5 to 95

Temperature (

Rel. Humidity (%)

C)

Page 36

Glossary

Active

Termination

ALDC Adaptive Lossless Data Compression. A hardware data compression method.

ASPI

Auto

sensing

EEPROM

GUI Graphical User Interface. Software which interacts with the user.

ID See SCSI ID.

LVD

RWW

SCSI

SCSI ID

SLDC™

HBA Host Board Adapter. The SCSI interface board located in the server/PC

Enhanced SCSI termination that provides better stability and noise immunity of the electrical signals on the

SCSI bus lines.

Advanced SCSI Programming Interface. Standard SCSI software that acts as a liaison between host

adapters and SCSI device drivers. ASPI enables host adapters and device drivers to share a single SCSI

hardware interface.

PowerVault LTO-2-024 feature that allows detection of the best transfer rate to use for optimizing

performance on the SCSI bus.

Electrically Erasable Programmable Read Only Memory. An integrated circuit typically used to store

configuration information.

Low Voltage Differential. A SCSI interface that provides better stability and noise immunity of the electrical

signals on the SCSI bus. LVD also allows longer SCSI bus length and improved data rates.

Read While Write. All Tandberg tape drives automatically and internally read the data just being written to

the tape to avoid writing to bad block.

Small Computer Signaling Interface. The PowerVault LTO-2-024 utilizes the SCSI Ultra160 interface which

allows for a transfer rate of up to 160 MB/sec on the bus.

A unique identifier assigned to SCSI devices that enables them to communicate with a computer when they

are attached to a host adapter via the SCSI bus. Each SCSI host adapter board has eight available SCSI