Page 1

Dell 5110cn

Service Manual

12 Nov 2007

Page 2

Information in this document is subject to change without notice.

2010 Dell Inc. All rights reserved.

Reproduction in any manner whatsoever without the written permission of Dell Inc.is strictly forbidden.

Trademarks used in this text: Dell and the DELL logo are trademarks of Dell Inc.

Other trademarks and trade names may be used in this document to refer to the entities claiming the marks and

names of their products. Dell Inc. disclaims any proprietary interest in trademarks and trade names other than

its own.

Page 3

Cautions for operation

Contents of this document may be subjected to modification without previous notice.

Dell Inc. will not assume responsibility for accidental or incidental damages resulting from technical

or editorial errors or omissions in this manual, the issue of this manual, the execution of descriptions

in this manual, or

the use of this manual.

This document is protected by copyright.

any form without written permission from Dell Inc.

Do not photocopy or duplicate any part of this document in

Intro-1

Page 4

1. About this manual

This manual is a standard service manual of

of this laser printer (standard specifications).

Dell Inc.

containing information

reTuired for maintenance

2. Marks giving caution

Maintenance operations requiring special cautions or additional information to descriptions of this

manual are presented as "Warning", "Caution", or "Note", according to their nature.

If instructions are not observed, death or serious injury may be caused.

If instructions are not observed, injuries of workers or physical damages to assets

(including this laser printer) may result.

Particularly important essentials for procedures, steps, rules, and others.

Reference Incidental information to descriptions.

3. Related documents

T Instruction manuals (standard manuals)

Describe operation and handling of this laser printer.

T Performance specifications

Describe in detail various specifications of this laser printer.

(In the event of discrepancy between this manual and the performance specifications, the performance

specifications shall take preference.)

T Video interface specifications

Detailed video interface specifications for this laser printer

T Spare parts list

Information on maintenance parts (spare parts) for this laser printer

Intro-2

Page 5

4. Safety

To prevent possible accidents during maintenance operation, you should observe strictly the "Warning"

and "Caution" information in this manual.

Dangerous operations and operations out of range of this manual should be absolutely avoided.

Generally various processes not covered by this manual may be required in actual operation, which

should be performed carefully always giving attention to safety.

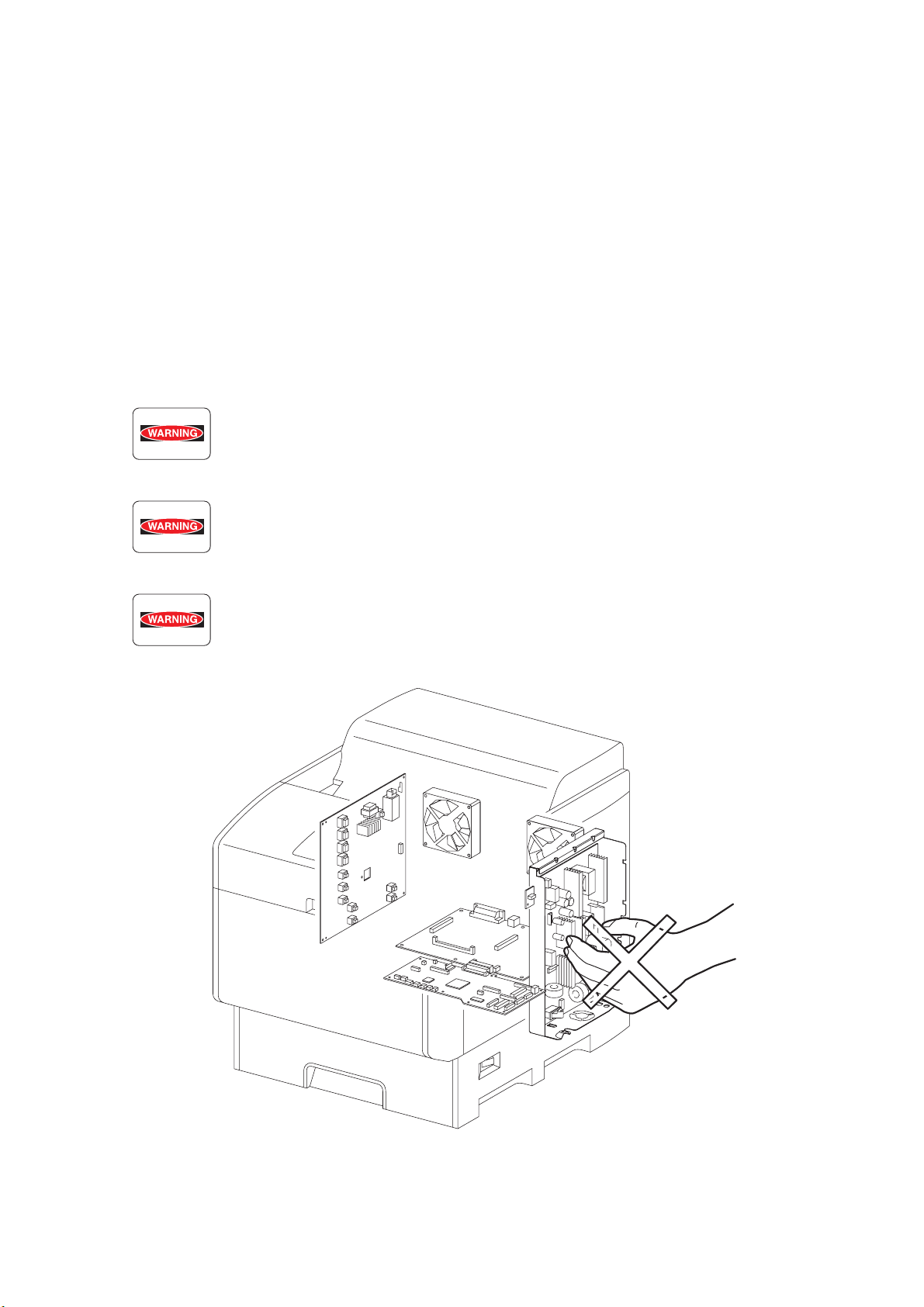

4.1 Power source

Keep the power supply off during maintenance operation to prevent electric shock, burns and other

damages. Keep the power plug disconnected during the maintenance operation.

If the power supply should be kept connected for measurement of voltage or other similar reasons,

sufficient care should be given to prevent electric shock, by following the procedures of this manual.

While the printer is ON, never touch live parts if not required absolutely.

Power is supplied to the power unit (Low Voltage Power Supply ASSY) even while

the printer is off. Never touch its live components.

Do not touch live parts unless otherwise specified.

Intro-3

Ten00002KA

Page 6

4.2 Driving units

When servicing gears or other driving units, be sure to turn them OFF and plug off. Drive them

manually when required.

Never touch the gears or other driving units while the printer is running.

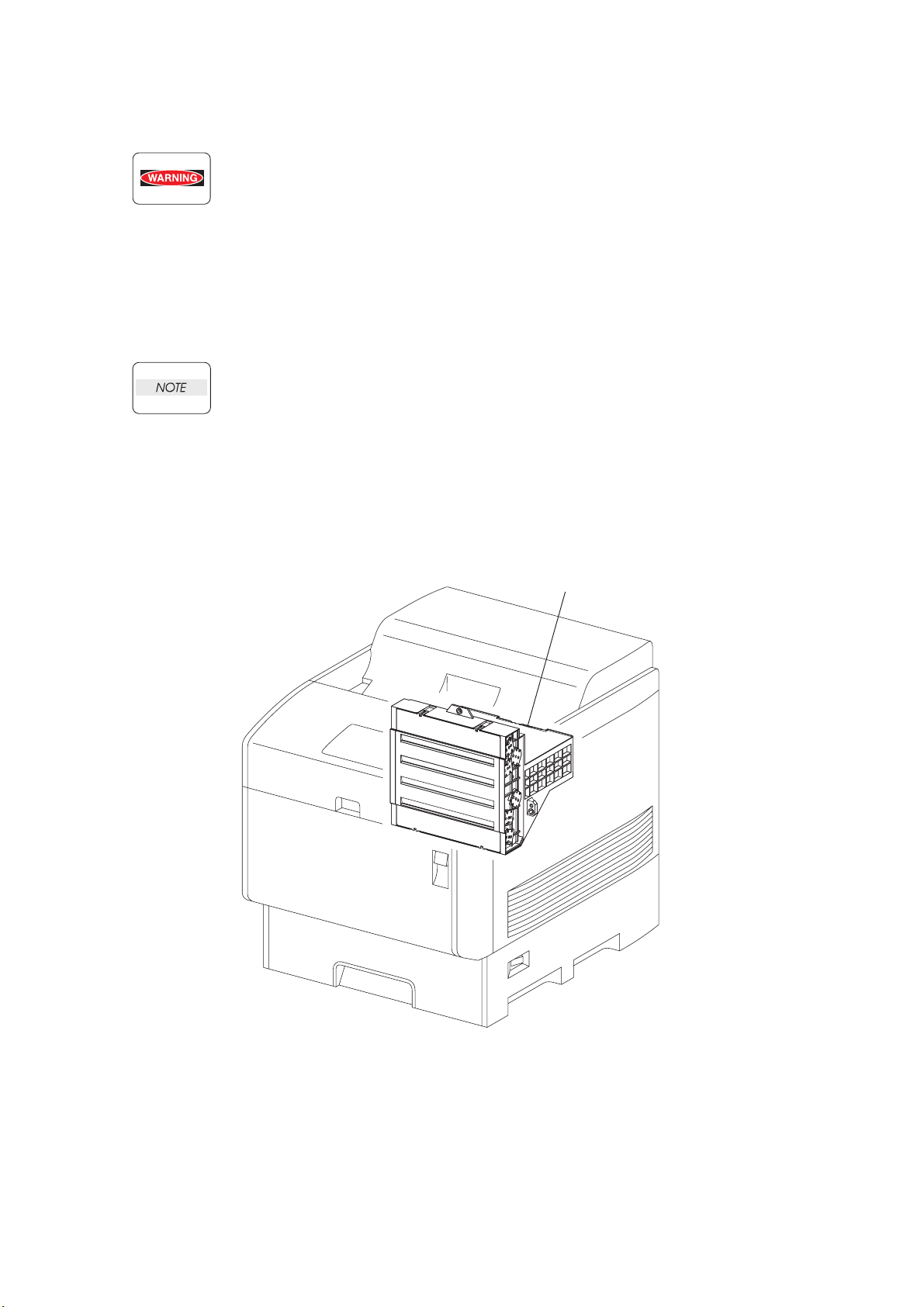

4.3 High-temperature units

When servicing high-temperature units (securing unit, etc.), be sure to turn them OFF to prevent burns,

injuries and other troubles, remove the power plug and start service processes after they have cooled

down enough.

Immediately after completion of operation, they are still hot. Start services after

more than 40 minutes.

Intro-4

Page 7

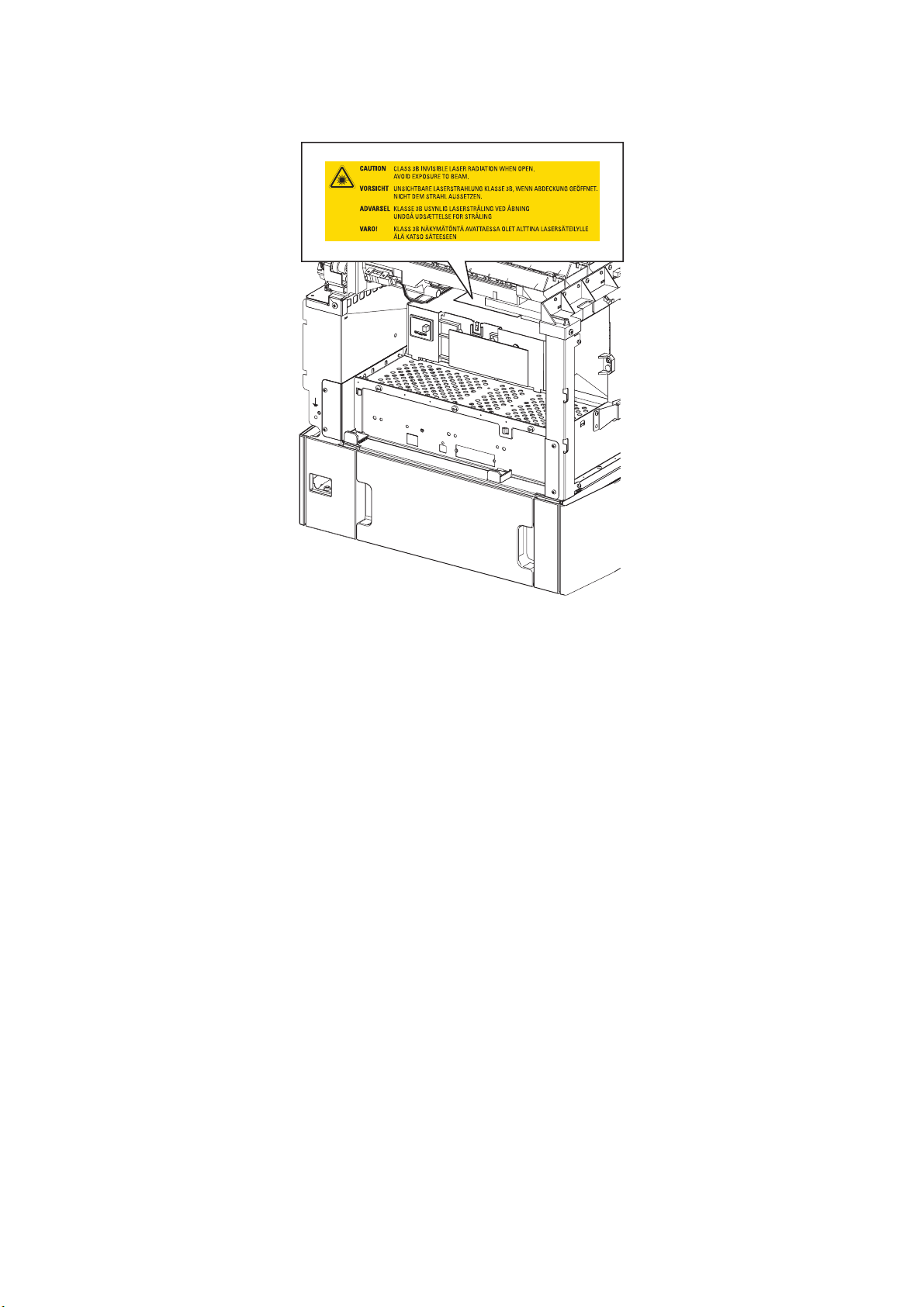

4.4 Laser beams

• If your eyes are exposed to laser beams, you may lose your eyesight.

• Never open the cover if warning label for laser beams is attached there.

• Before disassembling and reassembling this laser printer, be sure to turn it OFF.

• When servicing this laser printer while it is running, be sure to follow the

procedures specified in this manual.

• You should understand the features of the laser beams which are capable of

having an injurious action on the human body, not to extend the danger over the

workers as well as other people around the printer.

Laser beams have features as follows:

• Frequencies are smaller in width than other beams (sun and electric bulbs) and

phases are uniform so that high monochromatic and convergence performance

can be obtained and thin beams of light can reach places at a long distance.

• Due to the high convergence, beams are concentrated in high density and high

temperature, which is dangerous to human body.

Reference: Laser beams of this laser printer is invisible rays which you cannot see.

PRINT HEAD

Ten00003KA

Intro-5

Page 8

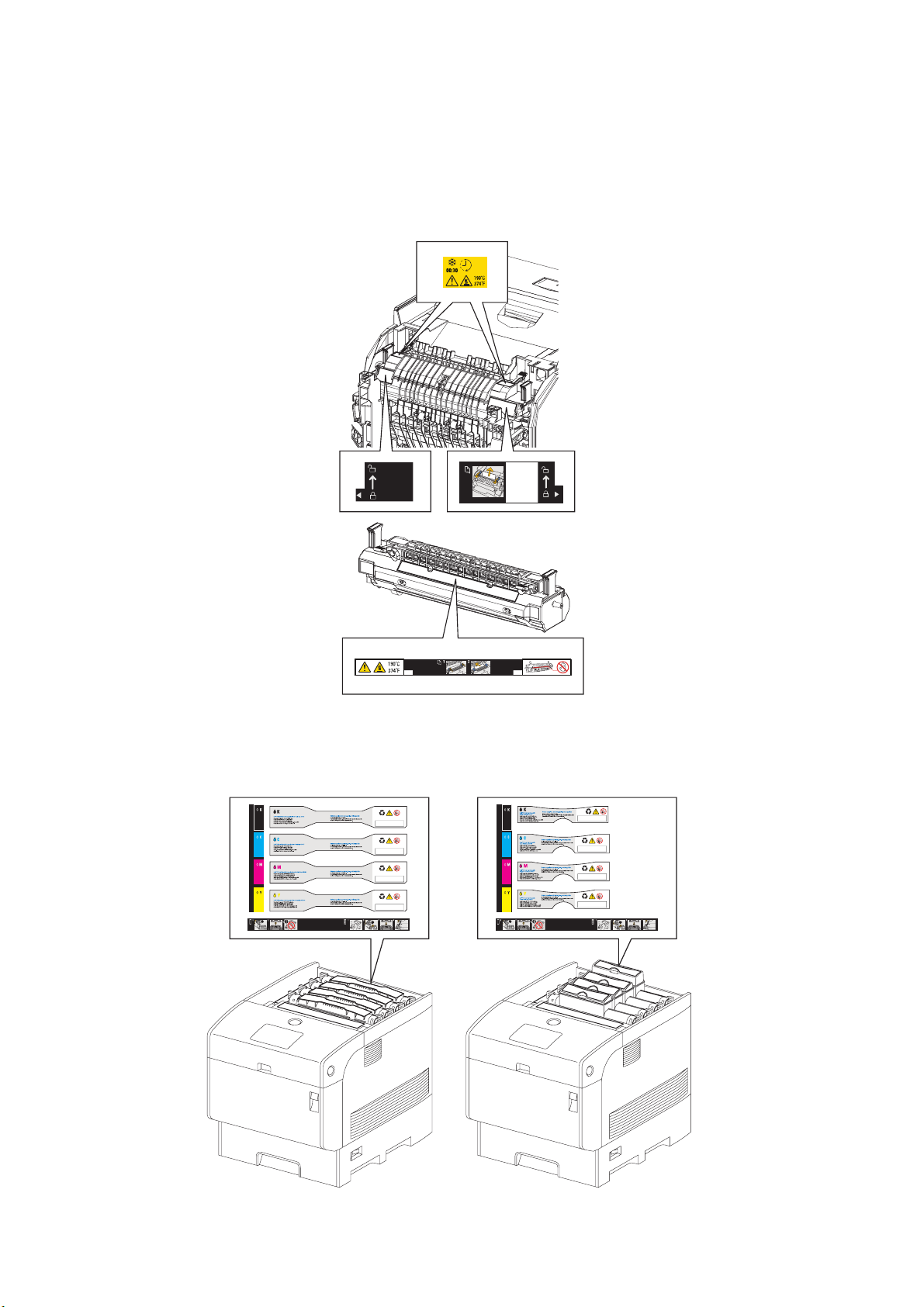

4.5 Warning/caution labels

Warning labels and caution labels are attached to this laser printer to prevent accidents Check those

labels for their peeling or stain when servicing the printer.

4.5.1 Caution label for high-temperature units

4.5.2 Caution label regarding toner cartridge

Ida_Sec00_010FA

Intro-6

Ten00004KA

Page 9

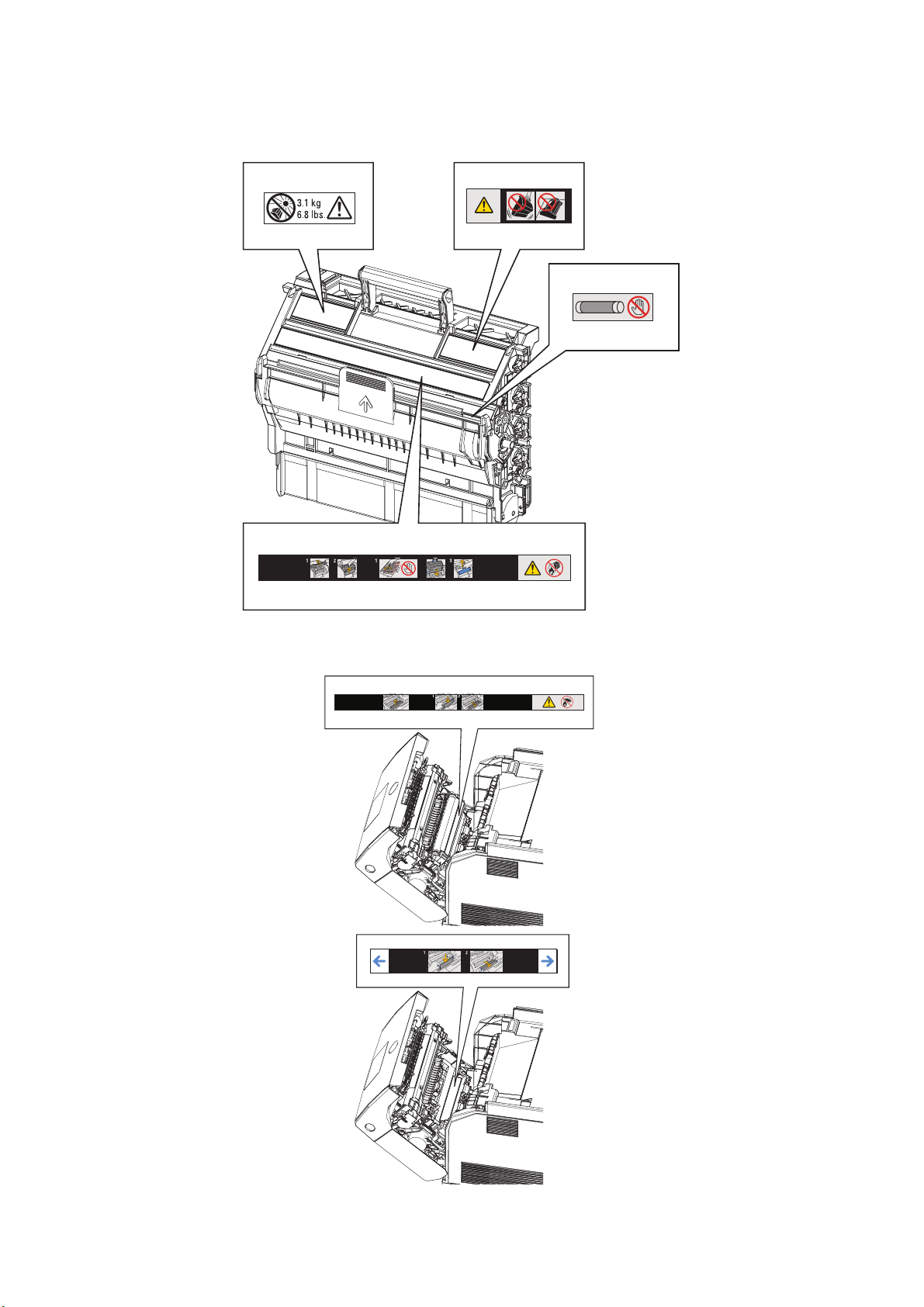

4.5.3 Caution label regarding Imaging Drum and Transfer Roller

Ida_Sec00_005FA

Intro-7

Ida_Sec00_009FA

Page 10

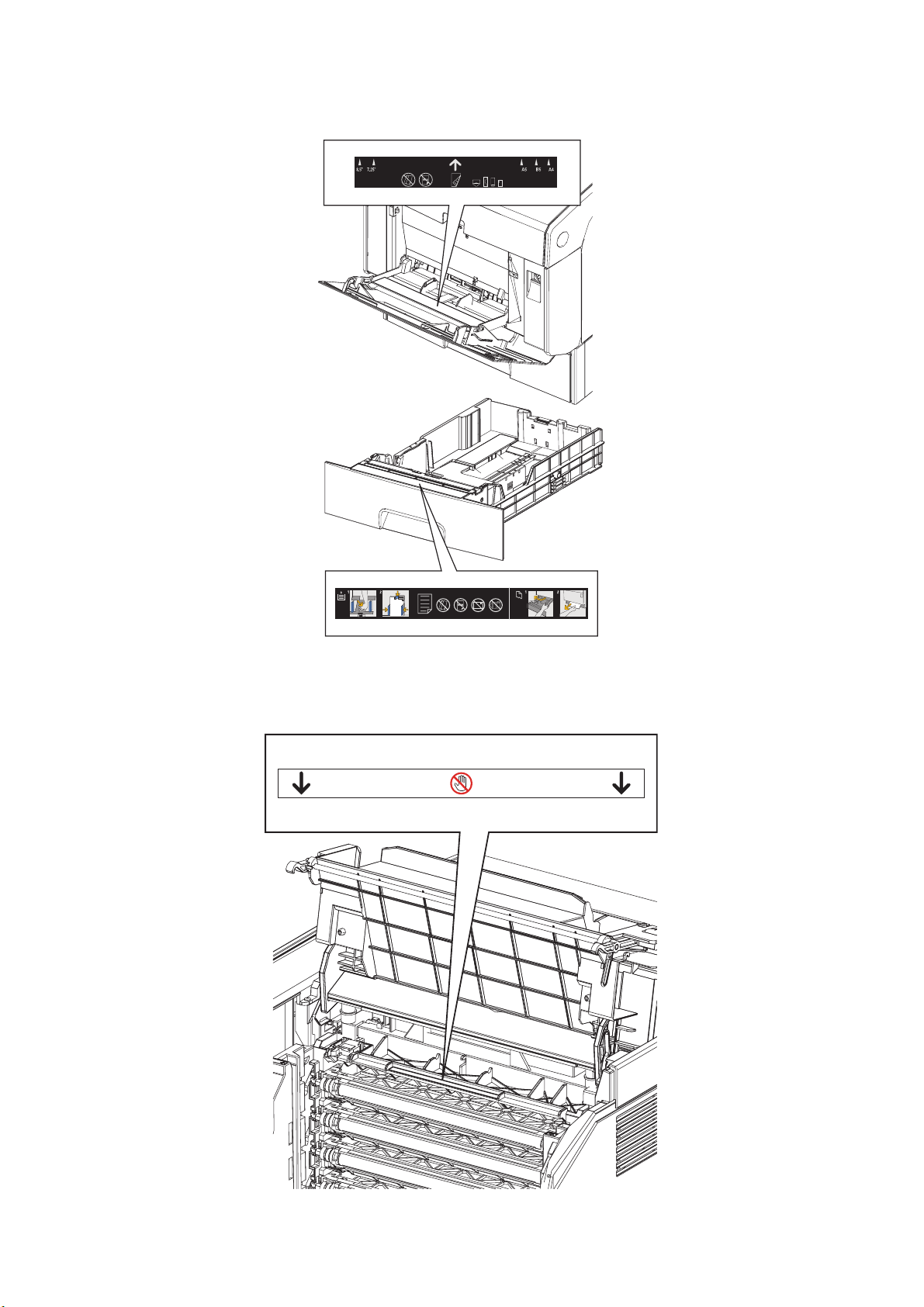

4.5.4 Caution label regarding MPF and paper tray

4.5.5 Caution label regarding Developer Frame

Ida_Sec00_006FA

Intro-8

Ida_Sec00_007FA

Page 11

4.5.6 Caution label regarding Print Head

Ida_Sec00_008FA

Intro-9

Page 12

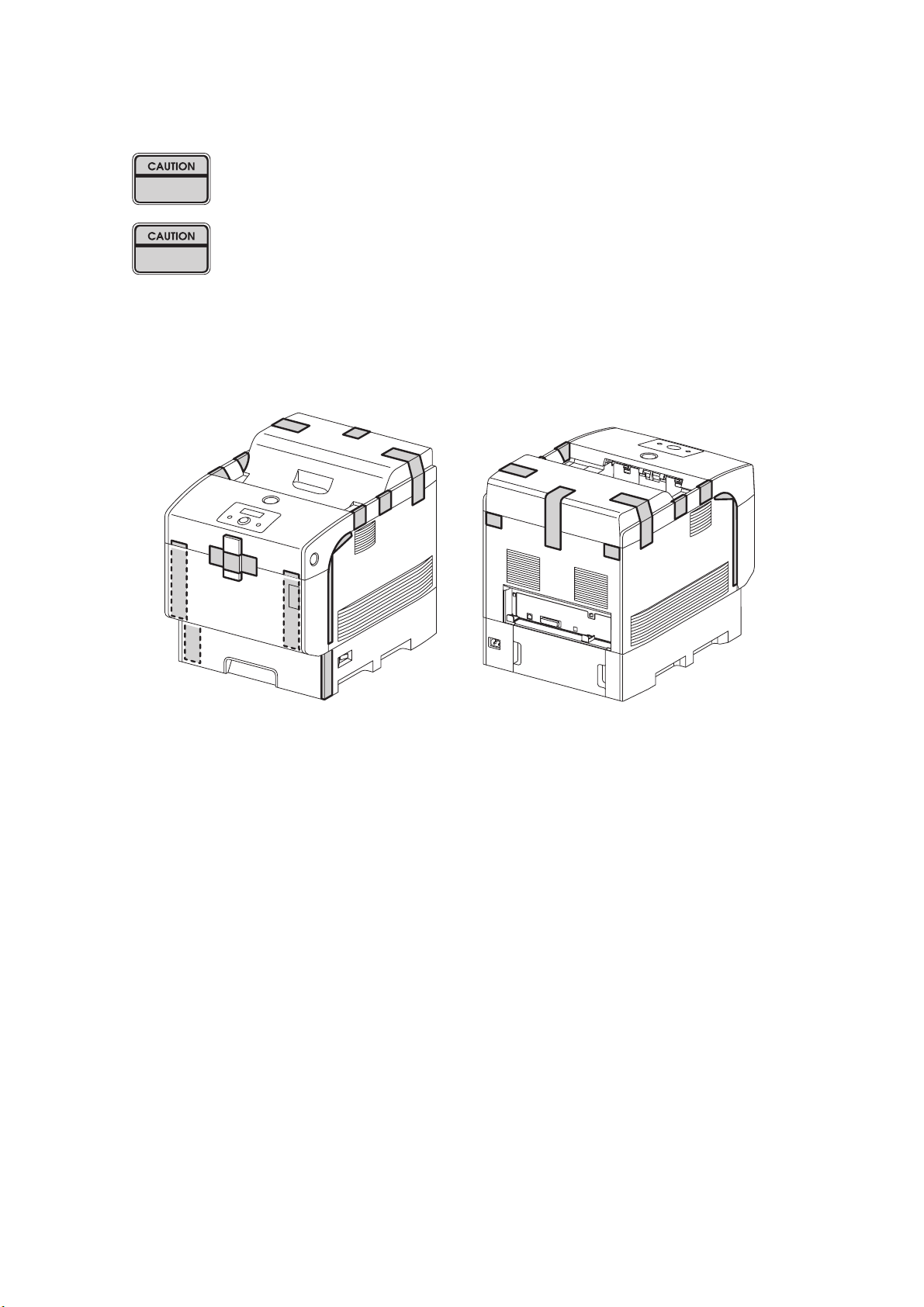

Unpacking the Printer

The printer must be carried horizontally with two or more persons.

Extreme care must be taken to avoid personal injuries.

Ch

eck the printer visually for evidence of any damage.

Peel all tapes off the printer.

Ten00011KA

Intro-10

Page 13

TABLE OF CONTENTS

Cautions for operation ................................................................................................. Intro-1

1. About this manual.....................................................................................................Intro-2

2. Marks giving caution.................................................................................................Intro-2

3. Related documents...................................................................................................Intro-2

4. Safety .......................................................................................................................Intro-3

4.1 Power source..........................................................................................................Intro-3

4.2 Driving unit..............................................................................................................Intro-4

4.3 High-temperature units...........................................................................................Intro-4

4.4 Laser beams...........................................................................................................Intro-5

4.5 Warning/caution labels ...........................................................................................Intro-6

4.5.1 Caution label for high-temperature units .............................................................Intro-6

4.5.2 Caution label regarding toner cartridge ...............................................................Intro-6

4.5.3 Caution label regarding PHD ASSY and BTR ASSY ..........................................Intro-7

4.5.4 Caution label regarding MSI and paper tray........................................................Intro-8

4.5.5 Caution label regarding FRAME ASSY DEVE ....................................................Intro-8

4.5.6 Caution label regarding ROS ASSY....................................................................Intro-9

Unpacking the Printer.................................................................................................Intro-10

Chapter 1 Troubleshooting .............................................................................................1 - 1

Chapter 2 Operation of Diagnostic .................................................................................2 - 1

Chapter 3 Removal and Replacement Procedures ........................................................3 - 1

Chapter 4 Plug/Jack(P/J) Connector Locations..............................................................4 - 1

Chapter 5 Parts List........................................................................................................5 - 1

Chapter 6 Principles of Operation ..................................................................................6 - 1

Chapter 7 Wiring Diagrams and Signal Information .......................................................7 - 1

Chapter 8 Printer Specifications.....................................................................................8 - 1

Intro-11

Page 14

Chapter 1 Troubleshooting

Chapter 1 Troubleshooting CONTENTS

1. Progressing with the Troubleshooting .........................................................................1 - 1

1.1 Flow of Troubleshooting.................................................................................................................... 1 - 1

1.2 Preparatory Requirements................................................................................................................ 1 - 2

1.3 Cautions for Service Operations ....................................................................................................... 1 - 3

1.4 Cautions for FIP Use......................................................................................................................... 1 - 4

2. Level 1 FIP ..................................................................................................................1 - 6

2.1 Level 1 FIP........................................................................................................................................ 1 - 6

2.2 Flow of Level 1 FIP ........................................................................................................................... 1 - 6

3. Level 2 FIP ..................................................................................................................1 - 8

3.1 Level 2 FIP........................................................................................................................................ 1 - 8

3.2 Status Code List................................................................................................................................ 1 - 9

3.3 LCD Display .................................................................................................................................... 1 - 15

3.4 Error Code FIP................................................................................................................................ 1 - 25

FIP-1 001-360/001-363/001-364/001-366 Restart Printer ................................................................... 1 - 25

FIP-2 001-361/001-363/001-365/001-366 Restart Printer ................................................................... 1 - 26

FIP-3 001-362/001-364/001-365/001-366 Restart Printer ................................................................... 1 - 27

FIP-4 003-340/003-341/003-342/003-344/003-345/003-346/003-347/003-348/003-349/

003-350/003-351 Restart Printer ............................................................................................. 1 - 28

FIP-5 003-343 Restart Printer.............................................................................................................. 1 - 29

FIP-6 003-356 Restart Printer.............................................................................................................. 1 - 31

FIP-7 004-310 Restart Printer.............................................................................................................. 1 - 34

FIP-8 006-370/006-371/006-372/006-373/006-374/006-375/006-376/006-377/006-378/

006-379/006-380/006-381/006-382/006-383/006-384 Restart Printer..................................... 1 - 35

FIP-9 007-342/007-345/007-346/007-348 Restart Printer ................................................................... 1 - 36

FIP-10 007-343/007-345/007-347/007-348 Restart Printer ................................................................. 1 - 37

FIP-11 007-344/007-346/007-347/007-348 Restart Printer ................................................................. 1 - 38

FIP-12 009-340/009-341 Restart Printer.............................................................................................. 1 - 39

FIP-13 009-360/009-361/009-362/009-363 Restart Printer ................................................................. 1 - 40

FIP-14 010-354 Restart Printer............................................................................................................ 1 - 41

FIP-15 010-378/010-379/010-380/010-381/010-382/010-383/010-384/010-385/010-386/

010-387/010-388/010-389/010-390/010-391/010-392/010-393/010-394/010-395/

010-396/010-397 Restart Printer ............................................................................................. 1 - 42

FIP-16 016-300/016-301/016-302/016-310/016-311/016-313/016-315/016-317/016-323/

016-324/016-327/016-340/016-344/016-345/016-346 Restart Printer/

Erase Flash Err. 016-392/Write Flash Err. 016-393/Verify Error 016-394 ............................... 1 - 43

FIP-17 016-312 Restart Printer............................................................................................................ 1 - 44

FIP-18 016-316/016-318 Restart Printer.............................................................................................. 1 - 45

FIP-19 016-330/016-331/016-332/016-333/016-334/016-335/016-336/016-337

Restart Printer .......................................................................................................................... 1 - 46

FIP-20 016-338 Restart Printer............................................................................................................ 1 - 48

FIP-21 016-350 Restart Printer............................................................................................................ 1 - 49

FIP-22 016-360/016-361 Restart Printer.............................................................................................. 1 - 50

FIP-23 016-370 Restart Printer............................................................................................................ 1 - 51

FIP-24 Paper Jam 077-902.................................................................................................................. 1 - 52

FIP-25 Paper Jam 077-900.................................................................................................................. 1 - 53

Page 15

Chapter 1 Troubleshooting

Chapter 1 Troubleshooting CONTENTS

FIP-26 Paper Jam 071-101.................................................................................................................. 1 - 54

FIP-27 Paper Jam 077-907.................................................................................................................. 1 - 60

FIP-28 Load Tray N 024-910/024-911/024-912/024-913/024-914 ....................................................... 1 - 61

FIP-29 Exit Tray Full 024-920 .............................................................................................................. 1 - 62

FIP-30 Load MPF 024-969/Load Tray N 024-965/024-966/024-967/024-968/024-969....................... 1 - 63

FIP-31 Tape On XXX Toner 093-919/093-920/093-921/093-922........................................................ 1 - 66

FIP-32 Insert TonerCart 093-970......................................................................................................... 1 - 67

FIP-33 Insert TonerCart 093-971......................................................................................................... 1 - 68

FIP-34 Insert TonerCart 093-972......................................................................................................... 1 - 69

FIP-35 Insert TonerCart 093-973......................................................................................................... 1 - 70

FIP-36 Replace Toner 093-930 ........................................................................................................... 1 - 71

FIP-37 Replace Toner 093-931 ........................................................................................................... 1 - 72

FIP-38 Replace Toner 093-932 ........................................................................................................... 1 - 73

FIP-39 Replace Toner 093-933 ........................................................................................................... 1 - 74

FIP-40 Ready to Print 093-423 ............................................................................................................ 1 - 75

FIP-41 Ready to Print 093-424 ............................................................................................................ 1 - 76

FIP-42 Ready to Print 093-425 ............................................................................................................ 1 - 77

FIP-43 Ready to Print 093-426 ............................................................................................................ 1 - 78

FIP-44 Toner Type 093-980/093-981/093-982/093-983/CRUM ID 093-960/093-961/

093-962/093-963...................................................................................................................... 1 - 79

FIP-45 Insert Drum 091-972 ................................................................................................................ 1 - 81

FIP-46 Imaging Drum 091-935 ............................................................................................................ 1 - 82

FIP-47 Ready to Print 094-402 ............................................................................................................ 1 - 83

FIP-48 Imaging Drum 091-912/CRUM ID 093-965 .............................................................................. 1 - 84

FIP-49 Replace Fuser 010-351............................................................................................................ 1 - 85

FIP-50 Insert Fuser 010-317................................................................................................................ 1 - 86

FIP-51 Ready to Print 010-421 ............................................................................................................ 1 - 87

FIP-52 Fuser Type 010-358/CRUM ID 093-964 .................................................................................. 1 - 88

FIP-53 Transfer Roller 094-911 ........................................................................................................... 1 - 89

FIP-54 Ready to Print 094-422 ............................................................................................................ 1 - 90

FIP-55 BTR Not Detected 094-910...................................................................................................... 1 - 91

FIP-56 Load Tray N 077-912/077-913/077-914/Tray Detached 024-945/024-946/024-947/

024-948/024-949...................................................................................................................... 1 - 92

FIP-57 Close Front Door 077-300........................................................................................................ 1 - 93

FIP-58 CTD Sensor Dirty 092-310/Ready to Print 092-910 ................................................................. 1 - 95

FIP-59 Out of Memory 016-700 ........................................................................................................... 1 - 97

FIP-60 Disk Full 016-980 ..................................................................................................................... 1 - 98

FIP-61 PCL Request 016-720............................................................................................................ 1 - 100

FIP-62 Invalid Job 016-799................................................................................................................ 1 - 101

FIP-63 Ready to Print 193-700 .......................................................................................................... 1 - 102

FIP-64 Invalid ID 016-383/Range Chk Error 016-384/Header Error 016-385/

Check Sum Error 016-386/Format Error 016-387.................................................................. 1 - 103

FIP-65 MPC Error 016-388/MPC Detached 016-389/MPC Com. Failed 016-390 ............................. 1 - 104

FIP-66 Invalid User 016-757/Disabled Func 016-758/Reached Limits 016-759 ................................ 1 - 106

3.5 Image Quality Troubleshooting ..................................................................................................... 1 - 107

3.5.1 Image Quality Specifications................................................................................................. 1 - 109

Page 16

Chapter 1 Troubleshooting

Chapter 1 Troubleshooting CONTENTS

P1 "Light (Undertoned) Prints" ........................................................................................................... 1 - 113

P2 "Blank Prints"................................................................................................................................ 1 - 116

P3 "Solid Prints"................................................................................................................................. 1 - 118

P4 "Vertical deletion or blank line" ..................................................................................................... 1 - 119

P5 "Horizontal deletion or blank line" ................................................................................................. 1 - 122

P6 "Black (color) spots" ..................................................................................................................... 1 - 125

P7 "Background or Foggy Print" ........................................................................................................ 1 - 128

P8 "Skewed paper" ............................................................................................................................ 1 - 130

P9 "Paper Damage"........................................................................................................................... 1 - 134

P10 "Unfused Image or Image Easily Rubs off of Page" ................................................................... 1 - 139

P11 "Vertical Dark Line"..................................................................................................................... 1 - 140

P12 "Afterimage (Ghost)"................................................................................................................... 1 - 141

P13 "Partial Deletion"......................................................................................................................... 1 - 142

P14 "Horizontal Line (Periodical)" ...................................................................................................... 1 - 143

P15 "Fade Horizontal/Vertical"........................................................................................................... 1 - 145

P16 "Color Registration (Color Shift)" ................................................................................................ 1 - 147

3.6 Other FIP ...................................................................................................................................... 1 - 150

FIP-No Power ..................................................................................................................................... 1 - 150

FIP-Multiple Feed................................................................................................................................ 1 - 151

4. Abnormal Noise Trouble..........................................................................................1 - 152

4.1 Entry Chart for Abnormal Noise Troubleshooting ......................................................................... 1 - 152

4.2 Operation Mode Table .................................................................................................................. 1 - 153

FIP-1.N1 When Power is Turned On ................................................................................................. 1 - 153

FIP-1.N2 During Standby................................................................................................................... 1 - 154

FIP-1.N3 During Printing.................................................................................................................... 1 - 155

Page 17

Chapter 1 Troubleshooting CONTENTS

Chapter 1 Troubleshooting

Page 18

Chapter 1 Troubleshooting

Troubleshooting in this manual assumes use of Diag. tools (maintenance tools).

However, the troubleshooting allows for the case where the Diag tools are not

used. You can correct troubles according to these troubleshooting procedures

after understanding them well.

1. Progressing with the Troubleshooting

After making sure of actual condition of a trouble, proceed with the troubleshooting process efficiently

making use of the Fault Isolation Procedure (FIP), Operation of Diag. tools (Chapter 2), Wire

connecting diagram (Chapter 7), and Principle of operation (Chapter 6).

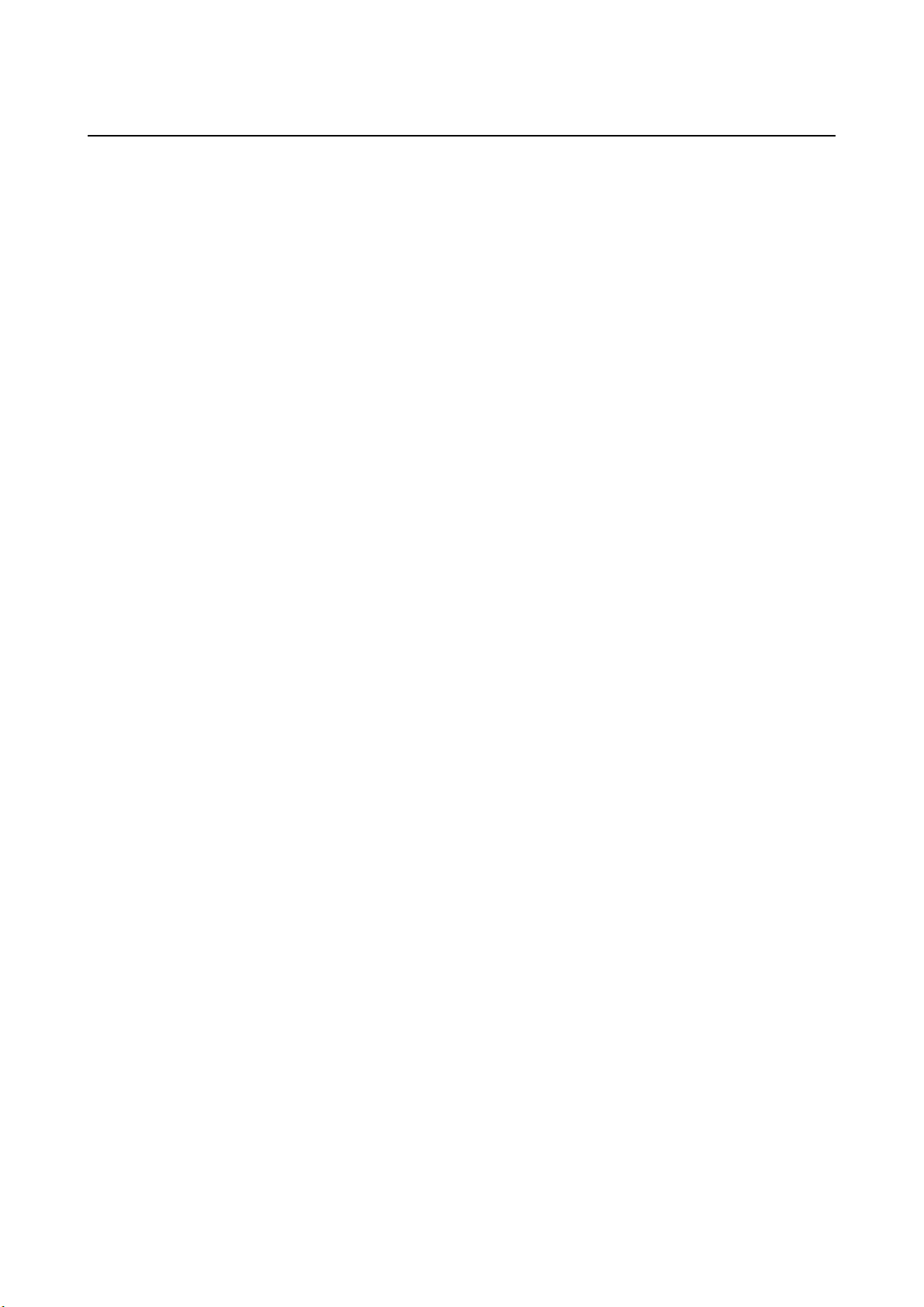

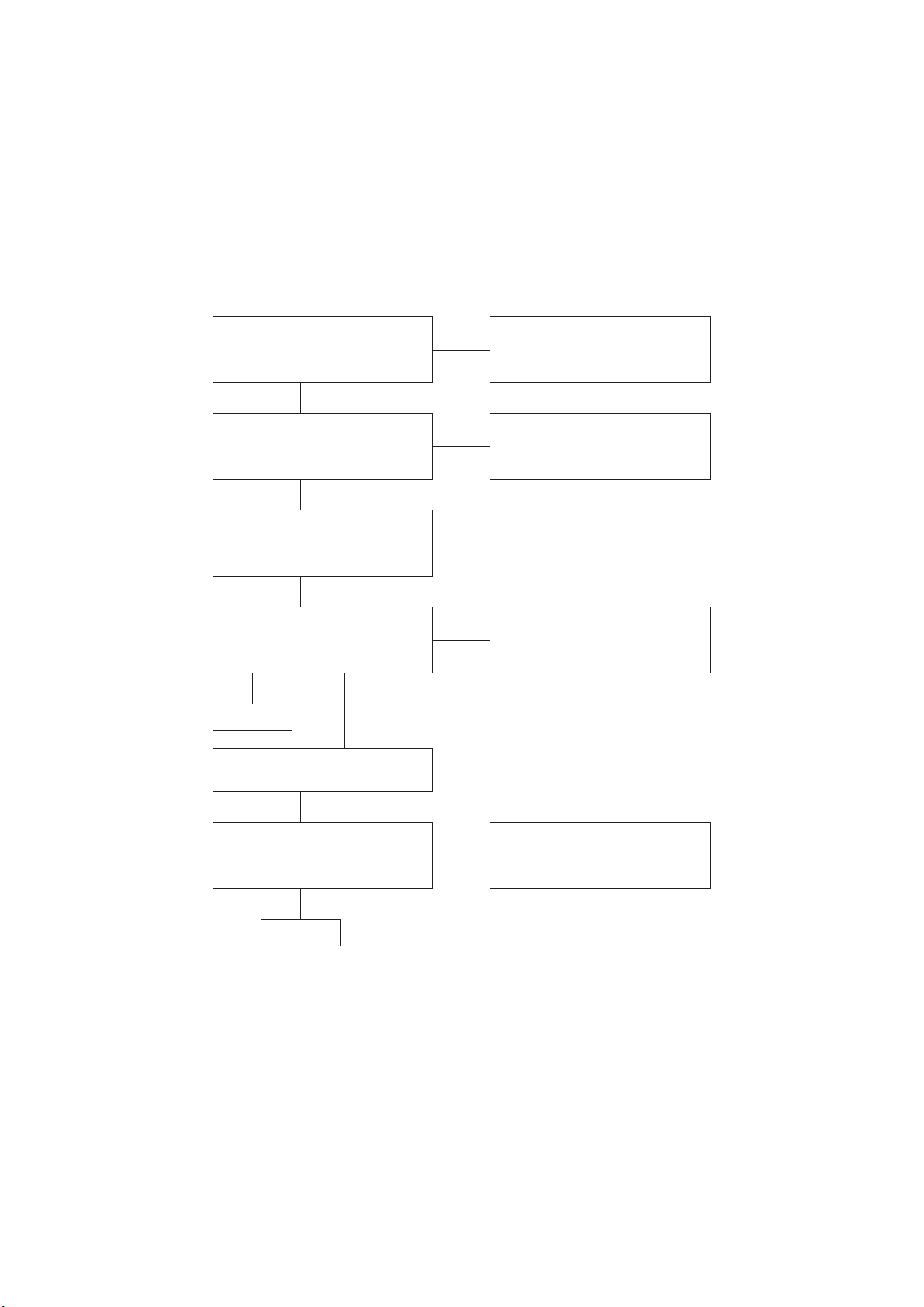

1.1 Flow of Troubleshooting

Flow of the troubleshooting is as follows:

Installation status check

Trouble status check

Execute FIP

Trouble recovery check

End

Operation of Diagnostic

Principles of Operation

Wiring Diagrams

Reference

information

When a problem can not be settle

Send back printer or parts to

the factory, check it the engineer.

1 – 1

Page 19

Chapter 1 Troubleshooting

1.2 Preparatory Requirements

Be sure to check the following items before starting the troubleshooting procedures:

1) Voltage of the power supply is within the specifications (measure the voltage at the electric outlet).

2) Power cord is free from breakage, short-circuit, disconnected wire, or incorrect connection in the

power cord.

3) The laser printer is properly grounded.

4) The laser printer is not installed at a place subjected to too high temperature, too high humidity, too

low temperature, too low humidity or rapid change of temperature.

5) The laser printer is not installed close to water service, humidifier, heat generating unit, or fire, in

very dusty place, or a place exposed to air flow from the air conditioning system.

6) The laser printer is not installed in a place where volatile gas or inflammable gas is generated.

7) The laser printer is not installed under direct sunbeams.

8) The laser printer is installed in a well-ventilated place.

9) The laser printer is installed on a stout and stable plane.

10) Paper used meets specifications (standard paper is recommendable).

11) The laser printer is handled properly.

12) Parts which should be periodically replaced are replaced each time when specified number of

sheets have been printed.

13) Make the PHD ASSY and the FRAME ASSY DEVE reseated, and try some printing using the

papers out of a newly opened package.

1 – 2

Page 20

Chapter 1 Troubleshooting

1.3 Cautions for Service Operations

1) Be sure to remove the power cord except when it is specifically required.

If the printer is kept ON, never touch the conductive parts while it is not specifically

required.

The power switch/inlet of LVPS is live even while the power supply is cut off. Never

touch the live parts.

2) When checking some parts with covers removed and with the interlock and safety and power

switches ON, remove the connector (P/J151) on the ROS ASSY except when it is specifically

required.

When checking some parts with covers removed and with the interlock and safety

and power switches ON, laser beams may be irradiated from the ROS ASSY. Since

it is dangerous, be sure to remove the connector (P/J151) while it is not required.

3) When checking some parts with the left cover removed and power ON, be sure to remove the

connector (P/J141) on the HVPS while it is not required.

When checking some parts with the left cover removed and power ON, high voltage

may be applied by the HVPS. Be sure to remove the connector (P/J141) on the

HVPS.

When connecting the connector (P/J141) on the HVPS according to the instructions

of the FIP, never touch the HVPS and parts of high voltage.

4) When using Diag. tools or other tools of high voltage, be sure to keep them covered except when

otherwise specified.

When using Diag.Tool or other tools of high voltage, never touch parts of high

voltage.

When using Diag.Tool or other tools of high voltage, be sure to follow the

procedure of this manual.

5) When operating the driving units using the Diag or other tools, be sure to keep them covered

unless otherwise specified.

When operating the driving units using the Diag or other tools, never touch the

driving units. When operating the driving units using Diag or other tools, be sure

to observe the procedures in this manual.

6) When touching hot parts, be careful not to get burnt.

7) Workers should wear a wrist band or the like to remove static electricity from their body , grounding

their body while working.

1 – 3

Page 21

Chapter 1 Troubleshooting

1.4 Cautions for FIP Use

1) It is assumed in the FIP that the printer controller (CONTROLLER PWB) is normally functioning. If

any trouble cannot be corrected by troubleshooting, replace the printer controller with a normal one

and check for proper operation again.

If the trouble is not still corrected, replace the major parts and then related parts in succession and

confirm according to the procedure of the "Initial check" and "Major check parts".

2) When troubleshooting according to the FIP, normal MCU PWB, PHD ASSY or other parts may be

necessary for isolation of failed parts. Prepare them in advance.

3) In the initial check according to the FIP, check only items which can be simply checked.

4) In the initial check according to the FIP, check the constitutive parts of the major check parts and

related parts, as well as major check parts.

5) When working with the printer, Be sure to remove the power cord except when required specifi-

cally. Never touch live parts if not required, while the power cord is connected.

6) Connector condition is denoted as follows:

[P/J12] → Connector (P/J12) is connected.

[P12] → Plug side with the connector (P/J12) removed (except when attached directly to the

board).

[J12] → Jack side with the connector (P/J12) removed (except when attached directly to the

board).

7) [P/J1-2PIN <=> P/J3-4PIN] in the FIP means measurement with the plus side of the measuring

instrument connected to [P/J1] and the minus side to [4PIN] of [P/J3].

8) [P/J<=>P/12] in the FIP means measurement for all terminals corresponding between [P/J1] and

[P/J2] referring to "Wire connecting diagram".

9) In [P/J1-2PIN <=> P/J3-4PIN] in the FIP where voltage is measured, [P/J3-4PIN] on the rear minus

side is always at the AG (analog ground), SG (signal ground), or RTN (return).

Therefore, after checking of proper conduction between AGs, SGs, or RTNs respectively, the rear

minus side can be connected to the PIN of AG, SG or RTN instead of [P/J3-4PIN].

However, care should be taken not to mistake since [AG], [SG], and [RTN] are not on the same

level.

10) Measure the voltage of small connectors with the special tool. Handle the tool with care, as the

leading edge of the tool is pointed.

11) When measuring the voltage, set the PDH ASSY, FUSER ASSY, BRT ASSY and paper tray, close

the FRONT COVER ASSY and power ON if not required specifically.

12) Numerical values in the FIP are only for standard. If numerical values are approximate, they

should be considered permissible.

1 – 4

Page 22

Chapter 1 Troubleshooting

13) Parts which are always removed to check as indicated in the FIP and procedures for that purpose

are not specifically referred to here. They should be handled carefully.

14) "Replacement" in the FIP indicates replacement of parts which are considered to be the source of

trouble to be checked after replacing those parts, assemblies containing them, or parts (HIGH

ASSY).

15) In the FIP, the paper pick-up unit by means of the paper tray at the lower part of the printer is

referred to as "try 1", the first level of the paper pick-up unit feeder unit as "try 2", and the second

level as the "tray3".

16) In the FIP, existence and non-existence of Diag tools (maintenance tools,) are distinguished in

some cases. Correct troubles according to the instructions in the FIP.

17) In the FIP, procedures are differentiated depending on specifications. Correct troubles according

to the instructions in the FIP.

18) For optional parts, some troubleshooting procedure may follow the manual for those options, of

which you should take note.

Keep those manuals for the optional parts when required.

1 – 5

Page 23

Chapter 1 Troubleshooting

2. Level 1 FIP

2.1 Level 1 FIP

The level 1 FIP is the first step for trouble diagnosis. The level 1 FIP isolates the presence of various

troubles including error codes, and the level 2 FIP provides a guide for proceeding of the

troubleshooting.

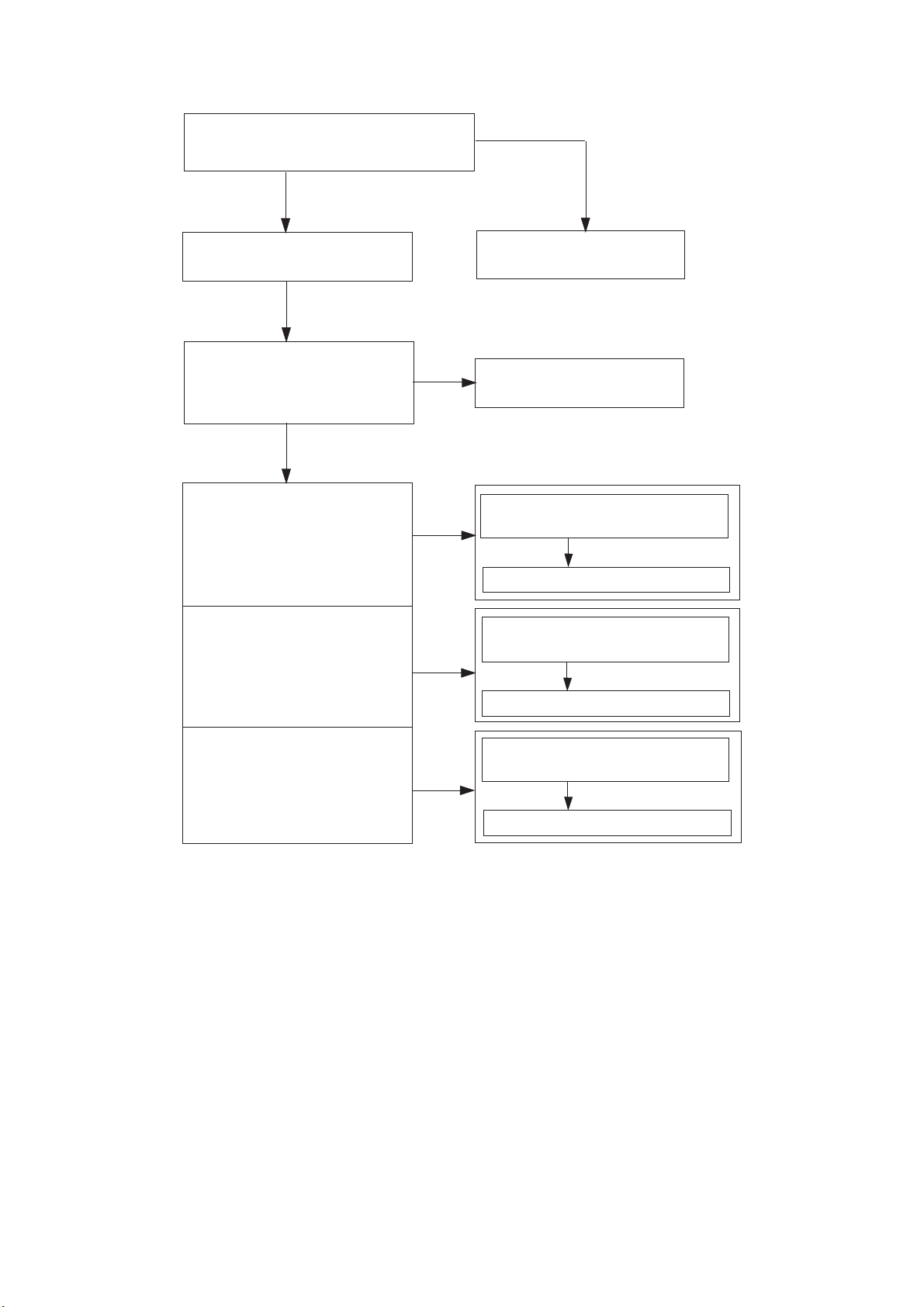

2.2 Flow of Level 1 FIP

Before commencing Troubleshooting, verify or fix the following general matters first.

Verify the type and size of the

print media installed meet the

specifications.

Yes

Verify that the settings of the

printer for the type and size of

the print media are correct.

Yes

Reinstall the Fuser Assy, BTR

Assy, PHD Assy and four

TONER Cartridges to the printer.

Yes

Inspect there is no damage on

the tabs for safety interlock of

the Covers and Doors.

Yes When a paper

is jammed

Go to FIP.

Remove the paper jams from

the printer.

Yes

If not

If not

If not

Reinstall the print media fall

within the print media guidelines.

Reset the printer settings.

Replace the damaged parts.

Verify the scraps of paper,

staples, paper-clips and so on

are not remained in the printer.

Yes

Go to FIP.

If not

Remove the remaining obstacles.

1 – 6

Page 24

Chapter 1 Troubleshooting

Ask the operator about trouble status.

Is operator’s operating method correct?

Y

Turn off and turn on the Power.

Does error still occur when print

is done by the problem mode?

Y

When status code or LCD

display is displayed:

N

Instruct how to operate

N

End of work

Refer to "3.2 Status Code List."

Refer to "3.3 LCD Display."

When image quality trouble

is occurred:

When abnormal noise

is occurred:

Refer to "3.4 Error Code FIP."

Refer to "3.5 Entry Chart for Image

Quality Troubleshooting."

Refer to "3.5 Image Quality FIP."

Refer to "4.1 Entry Chart for

Abnormal Noise Troubleshooting."

Refer to "4.2 Operation Mode Table."

1 – 7

Page 25

Chapter 1 Troubleshooting

3. Level 2 FIP

3.1 Level 2 FIP

The Level 2 FIP is the trouble diagnostic procedure to sort various troubles in addition to the error

codes. In the troubleshooting, executing the steps given in the FIP or checking procedure allows you to

find out a cause of trouble in a short time.

1 – 8

Page 26

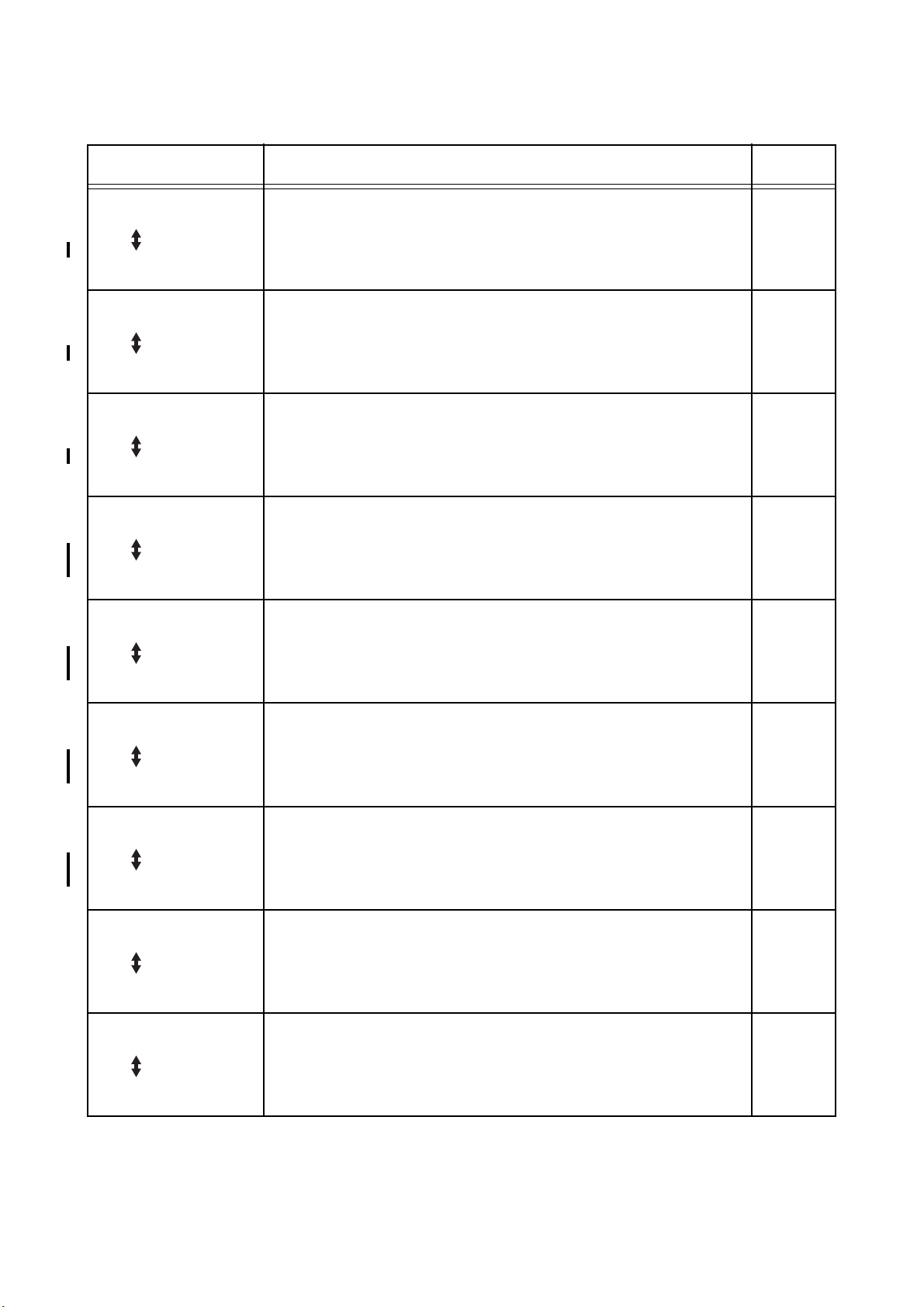

3.2 Status Code List

Chapter 1 Troubleshooting

Error Message Error Contents

001-360

Restart Printer

Flip

Contact Support

IfMessageReturns

001-361

Restart Printer

Flip

Contact Support

IfMessageReturns

001-362

Restart Printer

Flip

Contact Support

IfMessageReturns

001-363

Restart Printer

Flip

Contact Support

IfMessageReturns

001-364

Restart Printer

Flip

Contact Support

IfMessageReturns

001-365

Restart Printer

Flip

Contact Support

IfMessageReturns

001-366

Restart Printer

Flip

Contact Support

IfMessageReturns

003-340 to 003-342

Restart Printer

Flip

Contact Support

IfMessageReturns

003-343

Restart Printer

Flip

Contact Support

IfMessageReturns

<IOT Fan Motor 1 Failure>

MCU detects an error upon receiving error signal from the Rear Fan.

<IOT Fan Motor 2 Failure>

MCU detects an error upon receiving error signal from the Front Fan.

<IOT Fan Motor 3 Failure>

MCU detects an error upon receiving error signal from the LV Fan.

<IOT Fan Motor 4 Failure>

MCU detects an error upon receiving error signals from the Rear and

Front Fans.

<IOT Fan Motor 5 Failure>

MCU detects an error upon receiving error signals from the Rear and

LV Fans.

<IOT Fan Motor 6 Failure>

MCU detects an error upon receiving error signals from the Front and

LV Fans.

<IOT Fan Motor 6 Failure>

MCU detects an error upon receiving error signals from the Front,

Rear and LV Fans.

<IOT Firmware Error>

Firmware Error is detected.

<IOT Firmware Error>

CRUM communication error is detected.

FIP to be

referred

FIP-1

FIP-2

FIP-3

FIP-1

FIP-2

FIP-1

FIP-3

FIP-2

FIP-3

FIP-1

FIP-2

FIP-3

FIP-4

FIP-5

1 – 9

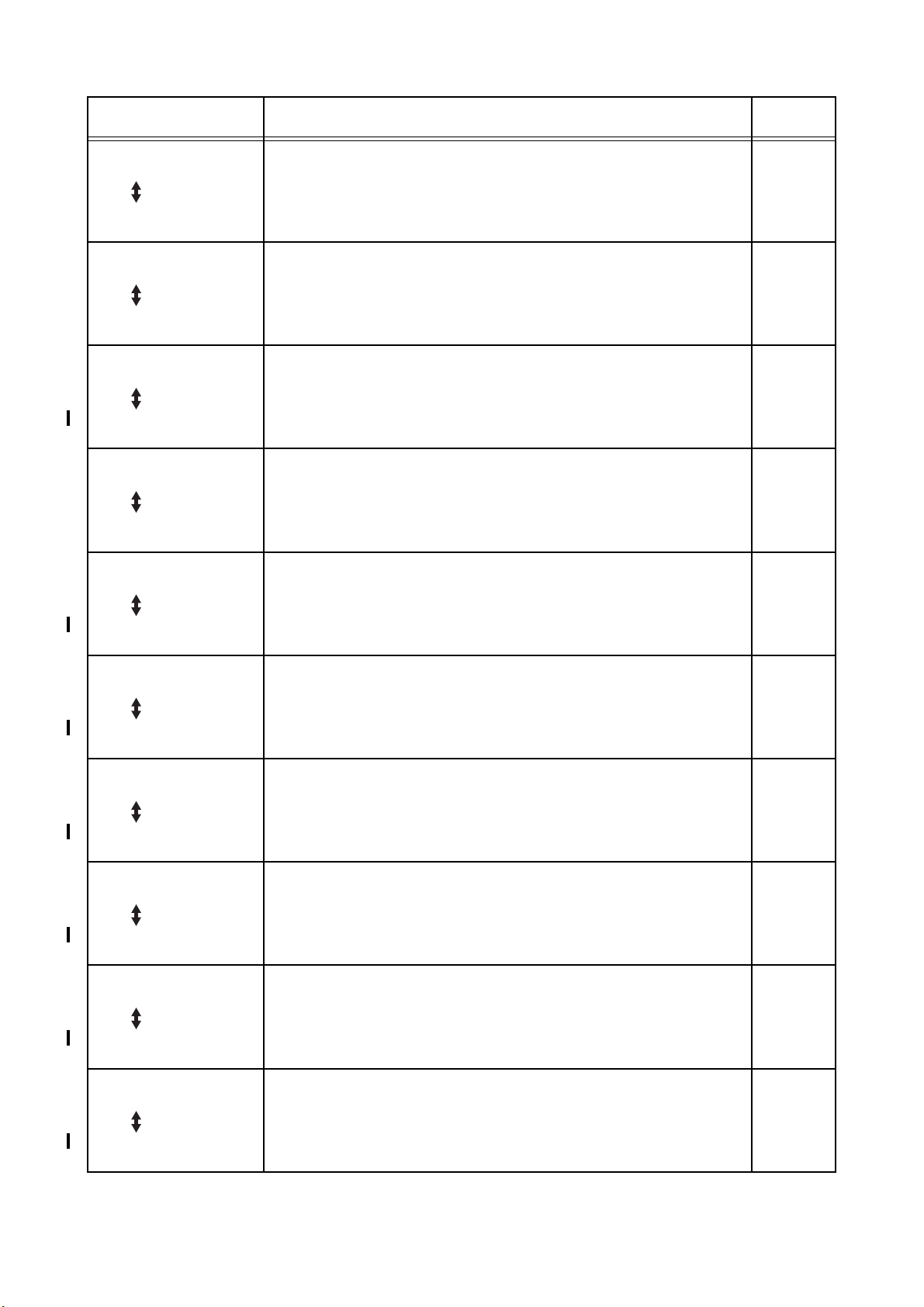

Page 27

Chapter 1 Troubleshooting

Error Message Error Contents

003-344 to 003-351

Restart Printer

Flip

Contact Support

IfMessageReturns

003-356

Restart Printer

Flip

Contact Support

IfMessageReturns

004-310

Restart Printer

Flip

Reseat Feeder

Contact Support

006-370 to 006-384

Restart Printer

Flip

Contact Support

IfMessageReturns

007-342

Restart Printer

Flip

Contact Support

IfMessageReturns

007-343

Restart Printer

Flip

Contact Support

IfMessageReturns

007-344

Restart Printer

Flip

Contact Support

IfMessageReturns

007-345

Restart Printer

Flip

Contact Support

IfMessageReturns

007-346

Restart Printer

Flip

Contact Support

IfMessageReturns

007-347

Restart Printer

Flip

Contact Support

IfMessageReturns

<IOT Firmware Error>

Firmware Error is detected.

<IOT NVRAM Error>

NVRAM and CRUM errors are detected.

<IOT Option Feeder Communication Error>

Option Feeder Communication Error is detected.

Communication error between the Option Feeder and the printer.

<IOT ROS Motor Failure>

The SOS signal does not come from the ROS ASSY.

<IOT Motor Failure>

Main Motor fail is detected.

MCU detects an error upon receiving error signal from the Motor.

<IOT Motor Failure>

Deve Motor fail is detected.

MCU detects an error upon receiving error signal from the Motor.

<IOT Motor Failure>

Fuser Motor fail is detected.

MCU detects an error upon receiving error signal from the Motor.

<IOT Motor Failure>

Main and Deve Motor fails are detected.

MCU detects an error upon receiving error signal from the Motors.

<IOT Motor Failure>

Main and Fuser Motor fails are detected.

MCU detects an error upon receiving error signal from the Motors.

<IOT Motor Failure>

Deve and Fuser Motor fails are detected.

MCU detects an error upon receiving error signal from the Motors.

FIP to be

referred

FIP-4

FIP-6

FIP-7

FIP-8

FIP-9

FIP-10

FIP-11

FIP-9

FIP-10

FIP-9

FIP-11

FIP-10

FIP-11

1 – 10

Page 28

Chapter 1 Troubleshooting

Error Message Error Contents

007-348

Restart Printer

Flip

Contact Support

IfMessageReturns

009-340/009-341

Restart Printer

Flip

Clean CTD

Contact Support

009-360

Restart Printer

Flip

Reseat Y Toner

Contact Support

009-361

Restart Printer

Flip

Reseat M Toner

Contact Support

009-362

Restart Printer

Flip

Reseat C Toner

Contact Support

009-363

Restart Printer

Flip

Reseat K Toner

Contact Support

010-354

Restart Printer

Flip

Contact Support

IfMessageReturns

010-378 to 010-397

Restart Printer

Flip

Reseat Fuser

Contact Support

016-300

Restart Printer

Flip

Contact Support

IfMessageReturns

016-301

Restart Printer

Flip

Contact Support

IfMessageReturns

<IOT Motor Failure>

Main, Deve and Fuser Motor fails are detected.

MCU detects an error upon receiving error signal from the Motors.

<IOT CTD Sensor Error>

CTD (ADC) Sensor Error is detected.

CTD (ADC) Sensor error at calibrating.

<IOT (Y) Toner CRUM Error>

Yellow Toner CRUM Communication Error is detected.

Printer can not read the CRUM data of the yellow toner cartridge.

<IOT (M) Toner CRUM Error>

Magenta Toner CRUM Communication Error is detected.

Printer can not read the CRUM data of the magenta toner cartridge.

<IOT (C) Toner CRUM Error>

Cyan Toner CRUM Communication Error is detected.

Printer can not read the CRUM data of the cyan toner cartridge.

<IOT (K) Toner CRUM Error>

Black Toner CRUM Communication Error is detected.

Printer can not read the CRUM data of the black toner cartridge.

<IOT Environment Sensor Error>

Temperature Sensor Error is detected.

Temperature Sensor detected abnormal temperature.

<IOT Fuser Fail>

Fuser Error is detected.

<ESS Data Cache Error>

CPU data cache error

<ESS Instruction Cache Error>

CPU instruction cache error

FIP to be

referred

FIP-9

FIP-10

FIP-11

FIP-12

FIP-13

FIP-13

FIP-13

FIP-13

FIP-14

FIP-15

FIP-16

FIP-16

1 – 11

Page 29

Chapter 1 Troubleshooting

Error Message Error Contents

016-302

Restart Printer

Flip

Contact Support

IfMessageReturns

016-310

Restart Printer

Flip

Contact Support

IfMessageReturns

016-311

Restart Printer

Flip

Contact Support

IfMessageReturns

016-312

Restart Printer

Flip

Contact Support

IfMessageReturns

016-313

Restart Printer

Flip

Contact Support

IfMessageReturns

016-315

Restart Printer

Flip

Contact Support

IfMessageReturns

016-316

Restart Printer

Flip

Reseat Memory

Contact Support

016-317

Restart Printer

Flip

Contact Support

IfMessageReturns

016-318

Restart Printer

Flip

Contact Support

IfMessageReturns

016-323

Restart Printer

Flip

Contact Support

IfMessageReturns

<ESS Illegal Exception>

CPU illegal exception

<ESS FontROM SumCheckError (Main)>

Checksum error in the built-in font ROM

<ESS FontROM SumCheckErrorOption>

Checksum error in the option font ROM

<ESS HDD Error>

The error is detected by HDD error.

<ASIC Error>

The error is detected by ASIC error.

<ESS On Board RAM W/R Check Error>

The error is detected by On board RAM W/R check during

initialization.

<ESS DIMM Slot RAM W/R Check Error>

The error is detected by DIMM slot RAM W/R check during

initialization.

<ESS ROM Check (Main) Error>

Checksum error in the main program ROM

<ESS DIMM Slot RAM Error>

DIMM slot RAM (option) error occurs during the initialization.

<ESS NVRAM1 W/R Check Error>

The error is detected by master NVRAM W/R check.

FIP to be

referred

FIP-16

FIP-16

FIP-16

FIP-17

FIP-16

FIP-16

FIP-18

FIP-16

FIP-18

FIP-16

1 – 12

Page 30

Chapter 1 Troubleshooting

Error Message Error Contents

016-324

Restart Printer

Flip

Contact Support

IfMessageReturns

016-327

Restart Printer

Flip

Contact Support

IfMessageReturns

016-330

Restart Printer

Flip

Contact Support

IfMessageReturns

016-331

Restart Printer

Flip

Reseat MPC

Contact Support

016-332

Restart Printer

Flip

Reseat MPC

Contact Support

016-333

Restart Printer

Flip

Reseat MPC

Contact Support

016-334

Restart Printer

Flip

Reseat MPC

Contact Support

016-335

Restart Printer

Flip

Reseat MPC

Contact Support

016-336

Restart Printer

Flip

Reseat MPC

Contact Support

016-337

Restart printer

Flip

Reseat MPC

Contact Support

<ESS NVRAM2 W/R Check Error>

The error is detected by master NVRAM2 W/R check.

<ESS NVRAM1 SIZE And ID Check Error>

The error is detected by consistency check between the NVRAM size

required by the system and its actual size, and by consistency check

of the ID recorded when turning ON the power first.

<MPC-ESS Communication Fail>

Communication fail between MPC and ESS

<MPC Flash ROM Boot Module Checksum Error>

Checksum error in the Flash ROM

<MPC RAM R/W Test Error>

The error is detected by MPC RAM W/R check.

<MPC Flash ROM Application Module Checksum Error>

Checksum error in the MPC Flash ROM

<MPC MAC Address Checksum Error>

Checksum error in the MPC MAC address

<MPC Ethernet BIST Parity/RAM R/W Error>

The error is detected by MPC Ethernet BIST parity RAM R/W check.

<MPC Internal Loopback Error>

The error is detected by Loopback test.

<MPC Fatal Error>

The fatal error is detected by MPC check.

FIP to be

referred

FIP-16

FIP-16

FIP-19

FIP-19

FIP-19

FIP-19

FIP-19

FIP-19

FIP-19

FIP-19

1 – 13

Page 31

Chapter 1 Troubleshooting

Error Message Error Contents

016-338

Restart Printer

Flip

Reseat Wireless

Contact Support

016-340

Restart Printer

Flip

Contact Support

IfMessageReturns

016-344

Restart Printer

Flip

Contact Support

IfMessageReturns

016-345

Restart Printer

Flip

Contact Support

IfMessageReturns

016-346

Restart Printer

Flip

Contact Support

IfMessageReturns

016-350

Restart Printer

Flip

Reseat Parallel

Contact Support

016-360

Restart Printer

Flip

Reseat MPC

Contact Support

016-361

Restart Printer

Flip

Reseat HDD

Contact Support

016-370

Restart Printer

Flip

Reseat Parallel

Contact Support

<Wireless Option Error>

The error is detected by Wireless Option check.

<ESS Network Communication Error>

Communication error between CPU network and ESS firmware

<ESS Network MAC Address Checksum Error>

Checksum error in the Network MAC address

<ESS Network Ethernet BIST parity/RAM R/W Error>

The fail is detected by Network Ethernet parity RAM R/W check.

<ESS Network Internal Loopback Error>

The error is detected by On Board Network Internal Loopback check.

<IEEE1284 Data Error>

The error is detected by IEEE1284 controller.

<PCI Option#0 (MPC I/F Connector) Fail>

Detection error of PCI option 0

<PCI Option#1 (HDD I/F Connector) Fail>

Detection error of PCI option 1

<MCU-ESS Communication Fail>

Communication fail between MCU and ESS

FIP to be

referred

FIP-20

FIP-16

FIP-16

FIP-16

FIP-16

FIP-21

FIP-22

FIP-22

FIP-23

1 – 14

Page 32

3.3 LCD Display

Chapter 1 Troubleshooting

Problem Error Message Error Contents

Paper Jam

Paper Jam

077-902

Flip

Open Front Latch

Remove Paper

Paper Jam

077-900

Flip

Open Front Latch

Remove Paper

Paper Jam

071-101

Flip

Open Tray

Remove Paper

Flip

Open & close

Front Latch

Paper Jam

077-907

Flip

Push Side Button

Remove Paper

<IOT Fuser Jam>

1. The exit sensor cannot detect passage of paper

within specified time.

2. The exit sensor detected a paper while power is

on or interlock is closed.

<IOT Registration Jam>

1. The regi sensor cannot detect passage of paper

within specified time.

2. The regi sensor detected a paper while power is

on or interlock is closed.

<IOT Feed Jam>

The regi sensor cannot detect paper within specified

time.

<IOT Duplex Jam>

1. The duplex jam sensor cannot detect passage of

paper within specified time.

2. The duplex jam sensor detected a paper while

power is on or interlock is closed.

FIP to be

referred

FIP-24

FIP-25

FIP-26

FIP-27

1 – 15

Page 33

Chapter 1 Troubleshooting

Problem Error Message Error Contents

Load Tray N

024-910, 024-911, 024912, 024-913, 024-914

Flip

Load Tray N

XXX

Flip

Load Tray N

YYY

NOTE:

N: Tray number

XXX: Paper size

YYY: Media type

024-910: Tray 1

024-911: Tray 2

024-912: Tray 3

024-913: Tray 4

024-914: MPF

Exit Tray Full

024-920

Flip

Empty Exit Tray

Load MPF

024-969

<IOT Paper Size Mismatch>

The paper size mismatch is detected.

<IOT Standard Stacker Full>

The Exit tray full is detected.

Printed paper on the Exit Tray exceeds the 250

sheets.

Flip

Paper Setting

Load MPF

XXX

Flip

Load MPF

YYY

NOTE:

XXX: Paper size

YYY: Media type

Load Tray N

024-965, 024-966, 024967, 024-968, 024-969

Flip

Load Tray N

XXX

Flip

Load Tray N

YYY

NOTE:

N: Tray number

XXX: Paper size

YYY: Media type

024-965: Tray 1

024-966: Tray 2

024-967: Tray 3

024-968: Tray 4

024-969: MPF

<Specified Tray Empty>

When a tray is specified, the tray is empty.

<No Suitable Paper>

1. When the printer is waiting for a job or APS is

specified, all the trays (including MPF) installed

on the printer are empty. (All Tray Empty)

2. When APS is specified, a size of paper in all trays

(including MPF) is mismatched. (All Tray Size

Mismatch)

3. When a tray is specified, a size of paper in the

specified tray (including MPF) is mismatched.

(Specified Tray Size Mismatch)

FIP to be

referred

FIP-28

FIP-29

FIP-30

1 – 16

Page 34

Chapter 1 Troubleshooting

Problem Error Message Error Contents

Tape On XXX Toner

093-919, 093-920, 093921, 093-922

Flip

<IOT Toner Tape Staying>

The toner tape staying is detected.

When a new toner cartridge installed, the MCU does

not detect the toner cartridge.

<IOT Toner Detached>

The yellow, magenta, cyan or black toner cartridge

detached is detected.

Toner Cartridge Sensor on the BOX ASSY CRUM

READER can not detect the toner cartridge.

<IOT Toner Empty>

The toner empty is detected.

The value of the Toner Cartridge counter has

reached the replacement time.

The No Toner Sensor on the DISPENSER ASSY HI

detected the no toner.

To ne r

Remove Tape

From XXX Toner

NOTE:

XXX: Toner color

093-919: Yellow

093-920: Magenta

093-921: Cyan

093-922: Black

Insert TonerCart

093-970, 093-971, 093972, 093-973

Flip

Insert

XXX Toner

NOTE:

XXX: Toner color

093-970: Yellow

093-971: Magenta

093-972: Cyan

093-973: Black

Replace Toner

093-930, 093-931, 093932, 093-933

Flip

Replace

XXX Toner

NOTE:

XXX: Toner color

093-930: Yellow

093-931: Magenta

093-932: Cyan

093-933: Black

Ready to Print

093-423, 093-424, 093425, 093-426

Flip

XXX Toner

Is Low

NOTE:

XXX: Toner color

093-423: Yellow

093-424: Magenta

093-425: Cyan

093-426: Black

<IOT Toner Near Empty>

Toner near empty is detected.

The value of the Toner Cartridge counter is going to

reach the replacement time.

FIP to be

referred

FIP-31

FIP-32 (Y)

FIP-33 (M)

FIP-34 (C)

FIP-35 (K)

FIP-36 (Y)

FIP-37 (M)

FIP-38 (C)

FIP-39 (K)

FIP-40 (Y)

FIP-41 (M)

FIP-42 (C)

FIP-43 (K)

1 – 17

Page 35

Chapter 1 Troubleshooting

Problem Error Message Error Contents

Toner Type

093-980, 093-981, 093982, 093-983

Flip

<IOT Toner Type Error>

The toner type error is detected.

The CRUM data the CRUM Sensor read was the

type of the other company.

To ne r

Reseat

XXX Toner

NOTE:

XXX: Toner color

093-980: Yellow

093-981: Magenta

093-982: Cyan

093-983: Black

CRUM ID

093-960, 093-961, 093962, 093-963

Flip

<IOT CRUM ID Error (Toner)>

The toner CRUM ID error is detected.

The toner cartridge CRUM ID read by the sensor is

different from the one that was recorded.

<IOT PHD Detached>

The PHD detached is detected.

<IOT PHD Life Over>

The PHD life over is detected.

<PHD Life Warning>

The PHD life warning is detected.

The value of the PHD counter has reached the

replacement time.

<IOT PHD Type Error>

The PHD type error is detected.

The CRUM data the MCU read was the type of the

other company.

<IOT CRUM ID Error>

The imaging drum CRUM ID error is detected.

The toner cartridge CRUM ID read by the MCU is

different from the one that was recorded.

PHD ASSY

Reseat

XXX Toner

NOTE:

XXX: Toner color

093-960: Yellow

093-961: Magenta

093-962: Cyan

093-963: Black

Insert Drum

091-972

Flip

Insert/Reseat

Imaging Drum

Imaging Drum

091-935

Flip

Replace

Imaging Drum

Ready to Print

094-402

Flip

Imaging Drum

Replace Soon

Imaging Drum

091-912

Flip

Reseat

Imaging Drum

CRUM ID

093-965

Flip

Reseat

Imaging Drum

FIP to be

referred

FIP-44

FIP-44

FIP-45

FIP-46

FIP-47

FIP-48

FIP-48

1 – 18

Page 36

Chapter 1 Troubleshooting

Problem Error Message Error Contents

Fuser

BTR

Replace Fuser

010-351

Flip

Replace

Fuser

Insert Fuser

010-317

Flip

Reseat Fuser

Ready to Print

010-421

Flip

Replace Fuser

Soon

Fuser Type

010-358

Flip

Reseat

Fuser

CRUM ID

093-964

Flip

Reseat

Fuser

Transfer Roller

094-911

Flip

Replace

Transfer Roller

Ready to Print

094-422

Flip

Replace Transfer

Roller Soon

BTR Not Detected

094-910

Flip

Insert/Reseat

Transfer Roller

<IOT Fuser Life Over 2>

The fuser life over is detected.

The value of the Fuser counter has reached the

replacement time.

<IOT Fuser Detached>

The fuser detached is detected.

<Fuser Life Warning>

The fuser life warning is detected.

The value of the Fuser counter is going to reach the

replacement time.

<IOT Fuser Type Error>

The fuser type error is detected.

The CRUM data the MCU read was the type of the

other company.

<IOT CRUM ID Error>

The fuser CRUM ID error is detected.

The Fuser CRUM ID read by the MCU is different

from the one that was recorded.

<IOT BTR Life Over>

The BTR life over is detected.

The value of the BTR counter has reached the

replacement time.

<BTR Life Warning>

The BTR life warning is detected.

The value of the BTR counter is going to reach the

replacement time.

<IOT BTR Detached>

The BTR detached is detected.

The CTD (ADC) Sensor detected the BTR

detached.

FIP to be

referred

FIP-49

FIP-50

FIP-51

FIP-52

FIP-52

FIP-53

FIP-54

FIP-55

1 – 19

Page 37

Chapter 1 Troubleshooting

Problem Error Message Error Contents

Load Tray N

077-912, 077-913, 077-

Tray

914

Flip

Push In

Tray N

NOTE:

N: Tray number

077-912: Tray 1

077-913: Tray 2

077-914: Tray 3

Tray Detached

024-945

Flip

Push in

Tray

Tray Detached

024-946, 024-947, 024948, 024-949

Flip

Push in

Tray N

NOTE:

N: Tray number

024-946: Tray 1

024-947: Tray 2

024-948: Tray 3

024-949: Tray 4

<Upper Cassette Detached>

1. When APS is specified, any trays located above

the feedeable tray are open.

2. When a tray is specified, any trays located above

the specified tray are open.

The Tray Size Switch detected the no tray.

<Tray Detached>

When the printer is waiting for a job or APS is

specified, all the trays are detached. (All Tray

Detached)

The Tray Size Switch detected the no tray.

<Tray Detached>

When a tray is specified, the tray is detached.

(Specified Tray Detached)

The Tray Size Switch detected the no tray.

FIP to be

referred

FIP-56

1 – 20

Page 38

Chapter 1 Troubleshooting

Problem Error Message Error Contents

Load Tray N

024-965, 024-966, 024967, 024-968

Flip

Load Tray N

XXX

Flip

Load Tray N

Tray

YYY

NOTE:

N: Tray number

XXX: Paper size

YYY: Media type

024-965: Tray 1

024-966: Tray 2

024-967: Tray 3

024-968: Tray 4

Load MPF

024-969

Flip

Load MPF

XXX

<No Suitable Paper>

1. When the printer is waiting for a job or APS is

specified, all the trays (including MPF) installed

on the printer are empty. (All Tray Empty)

2. When APS is specified, a size of paper in all trays

(including MPF) is mismatched. (All Tray Size

Mismatch)

3. When a tray specified, the tray is empty.

(Specified Tray Empty)

4. When a tray is specified, a size of paper in the

specified tray (including MPF) is mismatched.

(Specified Tray Size Mismatch)

Flip

Load MPF

YYY

NOTE:

XXX: Paper size

YYY: Media type

Close Front Door

Cover Open

077-300

Flip

Front Door

Is Open

<IOT Cover Front Open>

The front cover is open.

FIP to be

referred

FIP-30

FIP-57

1 – 21

Page 39

Chapter 1 Troubleshooting

Problem Error Message Error Contents

Other

CTD Sensor Dirty

092-310

Flip

Clean

CTD Sensor

Ready to Print

092-910

Flip

Clean

CTD Sensor

Out of Memory

016-700

Flip

Job too Large

Press Set

Disk Full

016-980

Flip

Job too Large

Press Set

PCL Request

016-720

Flip

Data Violation

Press Set

Invalid Job

016-799

Flip

Data Violation

Press Set

Ready to Print

193-700

Flip

non-Dell Toner

Installed

Invalid ID

016-383

Flip

Data Violation

Press set

Range Chk Error

016-384

Flip

Data Violation

Press Set

Header Error

016-385

Flip

Data Violation

Press Set

<IOT CTD Sensor Dustiness>

The CTD (ADC) sensor dustiness is detected.

The output signal of the CTD (ADC) sensor does not

reach the specified value at sensing the toner patch

on the BTR ASSY.

<IOT CTD Sensor Dustiness>

The CTD (ADC) sensor dustiness is detected.

The output signal of the CTD (ADC) sensor does not

reach the specified value at sensing the toner patch

on the BTR ASSY.

<Out of Memory>

Exceeds the memory capacity.

The print data size exceeded the memory capacity

of the printer.

<HDD full>

Exceeds the memory or the Hard Disk capacity.

The print data size exceeded the memory or the

hard disk capacity of the printer.

<PDL Error>

PCL error occurs.

The print data cannot be processed by PCL.

<Job Environment Violation>

Detects violation data for the print condition.

The print data specifies paper type/size not

available for the printer.

<Custom Toner Mode>

The printer is in Custom Toner Mode.

<Download Error>

The ID of the downloaded file is invalid.

<Download Error>

The address of the write destination is invalid.

<Download Error>

The header information is invalid.

FIP to be

referred

FIP-58

FIP-58

FIP-59

FIP-60

FIP-61

FIP-62

FIP-63

FIP-64

FIP-64

FIP-64

1 – 22

Page 40

Chapter 1 Troubleshooting

Problem Error Message Error Contents

Check Sum Error

Other

016-386

Flip

Data Violation

Press Set

Format Error

016-387

Flip

Data Violation

Press Set

MPC Error

016-388

Flip

Reseat MPC

Press Set

MPC Detached

016-389

Flip

Reseat MPC

Press Set

MPC Com. Failed

016-390

Flip

Reseat MPC

Press Set

Erase Flash Err.

016-392

Flip

Contact Support

IfMessageReturns

Write Flash Err.

016-393

Flip

Contact Support

IfMessageReturns

Verify Error

016-394

Flip

Contact Support

IfMessageReturns

Invalid User

016-757

Flip

Account Denied

Press Set

Disabled Func

016-758

Flip

Denied Col print

Press Set

<Download Error>

The checksum is invalid.

<Download Error>

The format is invalid.

<MPC Download Error>

Failed to start MPC download mode at MPC

download.

<MPC Download Error>

MPC Download was attempted without MPC

mounted.

<MPC Download Error>

Communication error occurred between MPC and

ESS during download.

<Download Error>

An error occurred erasing the Flash.

<Download Error>

An error occurred writing to the Flash.

<Download Error>

An error occurred verifying the Flash.

<Auditron Error>

The user is not registered to any account.

<Auditron Error>

An invalid account was detected.

FIP to be

referred

FIP-64

FIP-64

FIP-65

FIP-65

FIP-65

FIP-16

FIP-16

FIP-16

FIP-66

FIP-66

1 – 23

Page 41

Chapter 1 Troubleshooting

Problem Error Message Error Contents

Reached Limits

Other

016-759

Flip

Over your limits

Press Set

<Auditron Error>

The number of registered users exceeded its upper

limit.

FIP to be

referred

FIP-66

1 – 24

Page 42

3.4 Error Code FIP

FIP-1 001-360/001-363/001-364/001-366 Restart Printer

Possible causative parts:FAN REAR (PL1.1.19)

LVPS (PL9.1.6)

PWBA MCU (PL9.1.16)

Checking the FAN REAR

Chapter 1 Troubleshooting

Replace the PWBA MCU.

(RRP9.7)

Does the FAN REAR function

normally?

Checked by [Digital Output] - [DO-3f]

in [IOT Diagnosis].

In the test, close the INTERLOCK

SWITCH.

Checking after replacing

the PWBA MCU

Replace the PWBA MCU.

(RRP9.7)

NoYes

Checking after replacing

the FAN REAR

Replace the FAN REAR.

(RRP1.6)

Does the error still

occur when turning

on the power?

NoYes

END

Replace the LVPS.

(RRP9.3)

Does the error still

occur when turning

on the power?

1 – 25

NoYes

END

Page 43

FIP-2 001-361/001-363/001-365/001-366 Restart Printer

Possible causative parts:FAN FRONT (PL5.3.31)

PWBA MCU (PL9.1.16)

Checking the FAN FRONT

Chapter 1 Troubleshooting

Replace the PWBA

MCU. (RRP9.7)

Does the FAN FRONT function

normally?

Checked by [Digital Output] - [DO-45]

in [IOT Diagnosis].

In the test, close the INTERLOCK

SWITCH.

Checked by [Digital Output] - [DO-45]

In the test, close the INTERLOCK

END

NoYes

Reseat the

FAN FRONT.

Does the FAN FRONT function

normally?

in [IOT Diagnosis].

SWITCH.

NoYes

Replace the

FAN FRONT.

1 – 26

Page 44

FIP-3 001-362/001-364/001-365/001-366 Restart Printer

Possible causative parts:FAN LV (PL1.1.33)

LVPS (PL9.1.6)

PWBA MCU (PL9.1.16)

Checking the FAN LV

Does the FAN LV function normally?

Checked by [Digital Output] - [DO-42]

in [IOT Diagnosis].

In the test, close the INTERLOCK

SWITCH.

Chapter 1 Troubleshooting

NoYes

Replace the PWBA MCU.

(RRP9.7)

Checking after replacing

the PWBA MCU

Replace the PWBA MCU.

(RRP9.7)

Checking after replacing

the FAN LV

Replace the FAN LV.

(RRP1.13)

Does the error still

occur when turning

on the power?

Reseat the FAN LV.

(RRP1.13)

Does the error still

occur when turning

on the power?

NoYes

END

NoYes

END

Replace the LVPS.

(RRP9.3)

Does the error still

occur when turning

on the power?

NoYes

END

1 – 27

Page 45

Chapter 1 Troubleshooting

FIP-4 003-340/003-341/003-342/003-344/003-345/003-346/003-347/003-348/003-349/

003-350/003-351 Restart Printer

If the error occurred after replacing the PWBA MCU, transfer the internal data of the

old PWBA to the new PWBA.

Possible causative parts:PWBA MCU (PL9.1.16)

PWBA HVPS (9.1.21)

Checking the connector connection

Reseat the following connectors.

-P/J16 and P/J191 on the PWBA MCU

-P/J141 on the PWBA HVPS

-P/J144 on the PWBA EEPROM STD

Replace the PWBA

MCU. (RRP9.7)

Checking after replacing

the PWBA HVPS

Replace the PWBA HVPS.

(RRP9.9)

Yes

Does the error still

occur when turning on

the power?

Yes

Does the error still

occur when turning on

the power?

No

No

END

END

1 – 28

Page 46

FIP-5 003-343 Restart Printer

Possible causative parts:FUSER ASSY (PL5.1.1)

Chapter 1 Troubleshooting

PHD ASSY (PL6.1.1)

CRUM (PL7.1.4)

PWBA EEPROM STD (PL9.1.12)

PWBA MCU (PL9.1.16)

PWBA HVPS (PL9.1.21)

Checking the FUSER ASSY

installation

Reseat the FUSER ASSY.

Checking the PWBA MCU

installation

Reseat the PWBA MCU.

(RRP9.7)

Yes

Does the error still

occur when turning on

the power?

Checking the PHD ASSY

installation

Reseat the PHD ASSY and

check the CRUM

connector.

Yes

Does the error still

occur when turning on

the power?

No

Yes

Does the error still

occur when turning on

the power?

No

No

END

END

Checking the PWBA HVPS

installation

Reseat the PWBA HVPS.

(RRP9.9)

Yes

A

Does the error still

occur when turning on

the power?

No

END

END

1 – 29

Page 47

Chapter 1 Troubleshooting

A

Checking the PWBA

EEPROM STD installation

Reseat the PWBA EEPROM

STD. (RRP9.6

Checking after replacing the

FUSER ASSY

Replace the FUSER ASSY.

Yes

Does the error still

occur when turning on

the power?

Checking after replacing

the PHD ASSY

Replace the PHD ASSY.

Yes

Does the error still

occur when turning on

the power?

No

Yes

Does the error still

occur when turning on

the power?

No

No

END

END

Checking after replacing

the PWBA HVPS

Replace the PWBA HVPS.

(RRP9.9)

Replace the PWBA

MCU. (RRP97)

Yes

Does the error still

occur when turning on

the power?

END

No

END

1 – 30

Page 48

FIP-6 003-356 Restart Printer

Possible causative parts:FUSER ASSY (PL5.1.1)

Chapter 1 Troubleshooting

PHD ASSY (PL6.1.1)

CRUM (PL7.1.4)

PWBA EEPROM STD (PL9.1.12)

PWBA MCU (PL9.1.16)

PWBA HVPS (PL9.1.21)

Checking the failure parts.

Press the "S", "T" and "3" keys

after 003-356 error occurred

Replace the PWBA

EEPROM

Reseat the PWBA

EEPROM.

Does the error still

occur when turning

on the power?

Is the "ADDR: 38∗∗"

displayed?

NoYes

NoYes

Is the "ADDR: 34∗∗"

displayed?

NoYes

A

END

Reseat the FUSER

ASSY

Replace the FUSER

ASSY

1 – 31

Does the error still

occur when turning

on the power?

NoYes

END

Page 49

Chapter 1 Troubleshooting

A

Check the PHD

connector

Reseat the PHD ASSY

Does the error still

occur when turning

on the power?

Are there any

damages on the PHD

ASSY connector?

Is the "ADDR: 30∗∗"

displayed?

NoYes

END

NoYes

NoYes

B

Replace the PHD ASSY

Replace the PWBA

MCU. (RRP9.7)

Replace the PHD ASSY

Does the error still

occur when turning

on the power?

NoYes

END

1 – 32

Page 50

Chapter 1 Troubleshooting

B

Replace the PWBA

HVPS (RRP9.9)

Reseat the PWBA

HVPS

Does the error still

occur when turning

on the power?

Is the "ADDR: 4∗∗∗"

displayed?

NoYes

END

NoYes

Reseat the PWBA MCU

Does the error still

occur when turning

on the power?

NoYes

Replace the PWBA

MCU (RRP9.7)

END

1 – 33

Page 51

FIP-7 004-310 Restart Printer

Possible causative parts:PWBA MCU (PL9.1.16)

Chapter 1 Troubleshooting

1 TRAY OPTION FEEDER ASSY (PL11.1.1)

2 TRAY OPTION FEEDER ASSY (PL12.1.1)

Checking the Optional Tray

installing

Reseat the Optional Tray.

Yes

Replace the PWBA

MCU. (RRP9.7)

Checking after replacing

the Optional Tray

Replace the Optional Tray.

Does the error still

occur when turning

on the power?

Does the error still

occur when turning

on the power?

No

END

NoYes

END

1 – 34

Page 52

Chapter 1 Troubleshooting

FIP-8 006-370/006-371/006-372/006-373/006-374/006-375/006-376/006-377/006-378/

006-379/006-380/006-381/006-382/006-383/006-384 Restart Printer

Possible causative parts:ROS ASSY (PL6.1.2)

PWBA MCU (PL9.1.16)

Checking after replacing

the ROS ASSY

Replace the ROS ASSY.

(RRP6.1)

Replace the PWBA

MCU. (RRP9.7)

Yes

Does the error still

occur when turning on

the power?

No

END

1 – 35

Page 53

FIP-9 007-342/007-345/007-346/007-348 Restart Printer

Possible causative parts:DRIVE ASSY MAIN (PL8.1.2)

PWBA MCU (PL9.1.16)

Checking the printer installation

Chapter 1 Troubleshooting

Yes

Replace the PWBA

MCU. (RRP9.7)

Is the printer on the

Checking the DRIVE

ASSY MAIN

Does the DRIVE ASSY MAIN

function normally?

Checked by [Digital Output] - [DO-

00] in [IOT Diagnosis].

In the test, close the INTERLOCK

SWITCH.

Yes

Checked by [Digital Output] - [DO-

END

NoYes

flat surface?

Reseat the printer to

the flat surface.

No

Reseat the DRIVE

ASSY MAIN. (RRP8.2)

Does the DRIVE ASSY MAIN

function normally?

00] in [IOT Diagnosis].

In the test, close the INTERLOCK

SWITCH.

No

Replace the DRIVE

ASSY MAIN. (RRP8.2)

1 – 36

Page 54

FIP-10 007-343/007-345/007-347/007-348 Restart Printer

Possible causative parts:DRIVE ASSY DEVE (PL8.1.1)

PWBA MCU (PL9.1.16)

Checking the printer installation

Chapter 1 Troubleshooting

Yes

Replace the PWBA

MCU. (RRP9.7)

Is the printer on the

Checking the DRIVE

ASSY DEVE

Does the DRIVE ASSY DEVE

function normally?

Checked by [Digital Output] - [DO-

16] in [IOT Diagnosis].

In the test, close the INTERLOCK

SWITCH.

Yes

Checked by [Digital Output] - [DO-

END

NoYes

flat surface?

Reseat the printer to

the flat surface.

No

Reseat the DRIVE

ASSY DEVE. (RRP8.1)

Does the DRIVE ASSY DEVE

function normally?

16] in [IOT Diagnosis].

In the test, close the INTERLOCK

SWITCH.

No

Replace the DRIVE

ASSY DEVE. (RRP8.1)

1 – 37

Page 55

FIP-11 007-344/007-346/007-347/007-348 Restart Printer

Possible causative parts:DRIVE ASSY FUSER (PL5.2.25)

PWBA MCU (PL9.1.16)

Checking the printer installation

Chapter 1 Troubleshooting

Yes

Replace the PWBA

MCU. (RRP9.7)

Is the printer on the

Checking the MOTOR

ASSY FUSER

Does the MOTOR ASSY

FUSER function normally?

Checked by [Digital Output] - [DO-1f]

in [IOT Diagnosis].

In the test, close the INTERLOCK

SWITCH.

Yes

Checked by [Digital Output] - [DO-1f]

In the test, close the INTERLOCK

END

NoYes

flat surface?

Reseat the printer to

the flat surface.

No

Reseat the DRIVE ASSY

FUSER. (RRP5.5)