Delkron Space-N-Time User Manual

SPACE- -TIME TOOL MASTER KIT I STRUCTIO S

PART # D7020MK

CO GRATULATIO S! You have just purchased the most innovative and practical tool available for 1970 to 1999 “Big Twin” single cam HARLEY-DAVIDSO * style engines. This DELKRO tool is all you will need to professionally setup everything in the cam chest of your engine. By simply following these step by step instructions, you can build a more durable and powerful engine in a lot less time than other methods by eliminating the “Guess Work” and building an engine with true confidence and peace of mind.

CAMSHAFT E D-PLAY

The recommended camshaft end-play for a high performance application is .005” to

.015” with .010” being the nominal target. The following method will allow you to check your camshaft end-play.

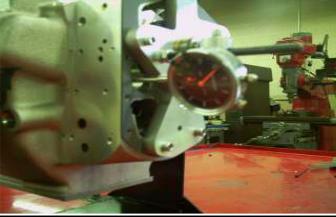

DIAL I DICATOR METHOD – With your camshaft installed, using O LY the thrust washer, install your DELKRO Space-N-Time tool, along with your cam cover gasket in place of your cam cover and torque the tool to the crankcase (use OEM torque spec.)

Mount the dial indicator to the outer face of the tool so that the indicator shaft is in line and contacting the camshaft end protruding through the tool. Push the camshaft back

1

towards the inboard cam bearing in the crankcase and zero the indicator dial … now push the camshaft outwards towards the tool and take your reading. This reading will be your TOTAL CAMSHAFT E D-PLAY … now subtract .010” from this reading and this will be the amount that you will need to shim your camshaft to achieve a PREFERED OMI AL E D-PLAY … Example – TCEP = .075” - .010” = .065” camshaft shim needed.

SETTI G CAMSHAFT E D PLAY

BREATHER GEAR E D-PLAY

The recommended breather gear end-play for a high performance application is .003” to .006”. The following method will allow you to correctly check your breather gear endplay.

DIAL I DICATOR METHOD – With your breather gear and breather gear spacer installed in the breather port of the crankcase, install the cam cover gasket and the DELKRO Space-N-Time tool in place of your cam cover and torque it to OEM specifications. Mount the dial indicator to the face of the tool with the indicator shaft in line and touching the face of the breather gear. Push the breather towards the crankcase and zero the indicator dial … now push the breather gear outward towards the tool. This reading will be your TOTAL BREATHER GEAR E D-PLAY. Make any necessary adjustments by increasing or decreasing the thickness of the breather

2

gear spacer in relation to the dial indicator reading to achieve an end-play of .003” to

.005”

SETTI G BREATHER GEAR E D PLAY

BREATHER GEAR TIMI G

The recommended breather gear timing in a high performance application is for the opening event to occur no sooner than 10 degrees BTDC and no later than 10 degrees ATDC, with the closing event occurring no sooner than 55 degrees ABDC and no later than 75 degrees ABDC on the FRO T cylinder.

To check the opening and closing event of the breather gear, install the camshaft, pinion gear, and breather gear, being sure that all timing marks on the gears are in alignment. Install the DELKRO Space-N-Time tool with the cam cover gasket to the crankcase and torque to OEM specifications. Determine TDC of the front cylinder and install the degree wheel of the DELKRO Space-N-Time tool to the pinion shaft using the aluminum pinion shaft adapter and ½” allen head bolt and washer supplied with the tool.

Set the degree wheel to zero at TDC and rotate flywheel assembly counter clockwise to 10 degrees BTDC, note position of breather gear window, it should be closed. Now rotate flywheel assembly clockwise to 10degrees ATDC, the breather gear should start to open between these two areas, make note of the degree that the window starts its opening event. Continue rotating the flywheel assembly clockwise until 55 degrees ABDC, noting the position of the breather gear window, it should still be open. Continue rotating the flywheel assembly clockwise to 75 degrees ABDC, the breather window should start its closing event between these two areas.

If the opening and closing events of the breather gear do not fall within the specified areas, then either the window in the breather port of the crankcase will need modification or the breather gear will need to be modified. The window in the breather port of the

3

Loading...

Loading...