Page 1

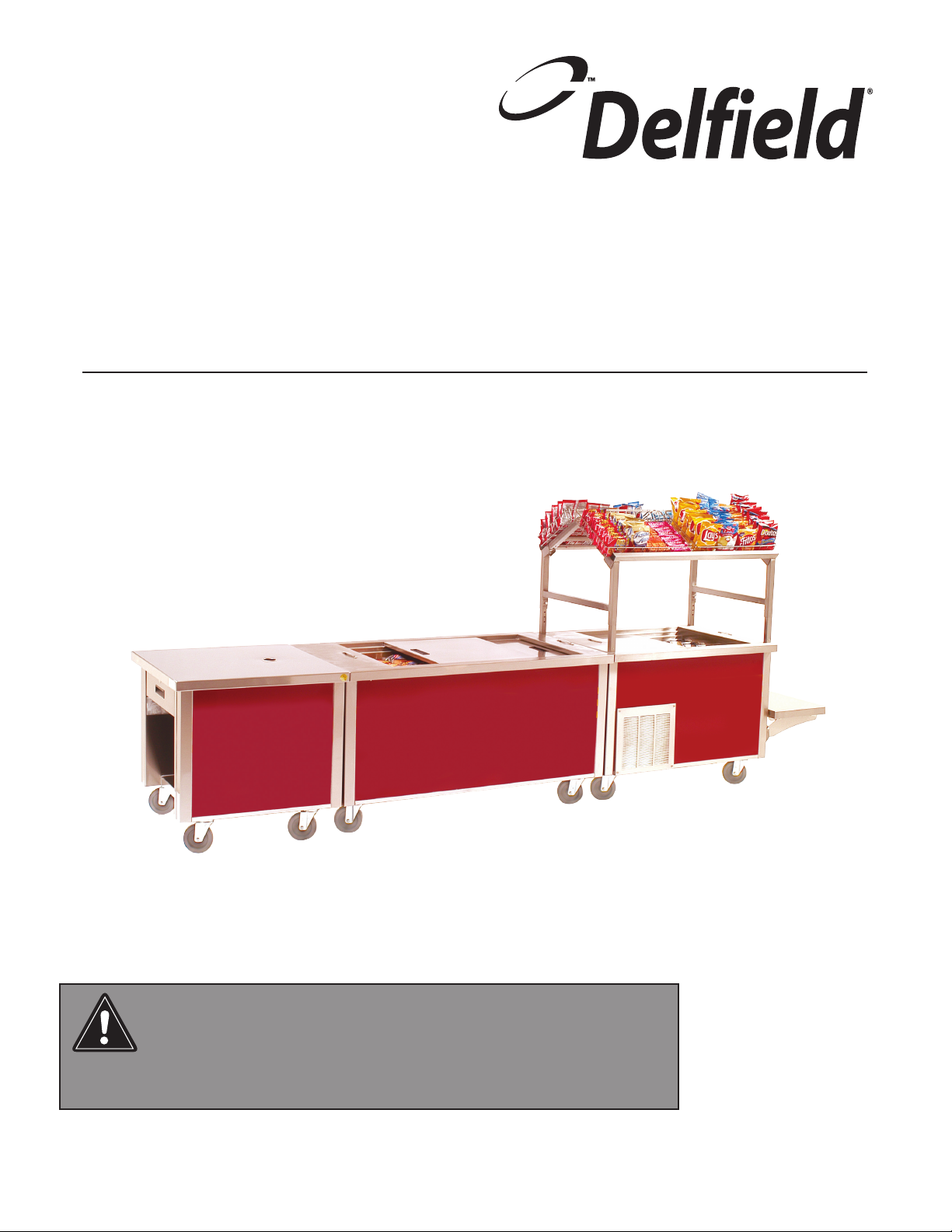

Shelleyspeed™

Service and Installation Manual

Please read this manual completely before attempting to install or operate this equipment!

Notify carrier of damage! Inspect all components immediately.

CAUTION

Refrigerated, Heated and Non-Electrical Units

Important Information

Read Before Use

Please Save These Instructions!

February 2013

Page 2

Shelleyspeed™ Service and Installation Manual

Important Warning And Safety Information

WARNING Read This Manual Thoroughly Before Operating, Installing, Or Performing Maintenance On The Equipment.

WARNING Failure To Follow Instructions In This Manual Can Cause Property Damage, Injury Or Death.

WARNING Do Not Store Or Use Gasoline Or Other Flammable Vapors Or Liquids In The Vicinity Of This Or Any Other

Appliance.

WARNING Unless All Cover And Access Panels Are In Place And Properly Secured, Do Not Operate This Equipment.

WARNING This Appliance Is Not Intended For Use By Persons Who Lack Experience Or Knowledge, Unless They Have

Been Given Supervision Or Instruction Concerning Use Of The Appliance By A Person Responsible For Their

Safety.

WARNING This Appliance Is Not To Be Played With.

WARNING Do Not Clean With Water Jet.

WARNING Do Not Use Electrical Appliances Inside The Food Storage Compartment Of This Appliance.

CAUTION Observe the following:

• Minimum clearances must be maintained from all walls and combustible materials.

• Keep the equipment area free and clear of combustible material.

• Allow adequate clearance for air openings.

• Operate equipment only on the type of electricity indicated on the specification plate.

• Unplug the unit before making any repairs.

• Retain this manual for future reference.

2

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

Page 3

CONTENTS

Receiving & Inspecting Equipment ...........................................3

Serial Number Information ........................................................ 4

Warranty Information ................................................................. 4

Regulatory Certifications ............................................................ 4

Specifications ..........................................................................5-6

Heated Unit Info .....................................................................7-8

Heated Merchandiser Info .......................................................... 9

Refrigerator/Freezer Unit Info .............................................10-12

Wiring Diagrams .................................................................13-15

Replacement Parts List ............................................................ 16

Standard Labor Guidelines ......................................................17

Notes ...................................................................................18-19

Shelleyspeed™ Service and Installation Manual

RECEIVING AND INSPECTING THE EQUIPMENT

Even though most equipment is shipped crated, care should

be taken during unloading so the equipment is not damaged

while being moved into the building.

1. Visually inspect the exterior of the package and skid or

container. Any damage should be noted and reported to

the delivering carrier immediately.

2. If damaged, open and inspect the contents with the

carrier.

3. In the event that the exterior is not damaged, yet upon

opening, there is concealed damage to the equipment

notify the carrier. Notification should be made verbally

as well as in written form.

4. Request an inspection by the shipping company of the

damaged equipment. This should be done within 10

days from receipt of the equipment.

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

5. Check the lower portion of the unit to be sure legs or

casters are not bent.

6. Also open the compressor compartment housing and

visually inspect the refrigeration package. Be sure lines

are secure and base is still intact.

7. Freight carriers can supply the necessary damage forms

upon request.

8. Retain all crating material until an inspection has been

made or waived.

Uncrating the Equipment

First cut and remove the banding from around the crate.

Remove the front of the crate material. If the unit is on legs,

remove the top of the crate as well and lift the unit off the

skid. If the unit is on casters, it can be rolled off the skid.

3

Page 4

Shelleyspeed™ Service and Installation Manual

SERIAL NUMBER INFORMATION

Always have the serial number of your unit available when

calling for parts or service.

Serial number is located beside the power switch. (Power

switch is located on upper right hand corner of operator

side.)

This manual covers standard units only. If you have a

custom unit, consult the customer service department at the

number listed below.

©2013 The Delfield Company. All rights reserved. Reproduction without

written permission is prohibited.

“Delfield” is a registered trademark of The Delfield Company.

Warranty Information

Visit http://www.delfield.com/minisite/service/warranty_info to:

• Register your product for warranty.

• Verify warranty information.

• View and download a copy of your warranty.

Regulatory Certifications

All Models are certified by:

National Sanitation Foundation (NSF)

Electical models are also certified by:

Underwriters Laboratories (UL)

Underwriters Laboratories of Canada (ULC)

4

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

Page 5

Shelleyspeed™ Service and Installation Manual

SPECIFICATIONS, 30” DEPTH MODULES

This manual covers standard units only. If you have a custom unit, consult the customer service department at the number listed below.

Model Length Width Height Basket Capacity Voltage Nema Amp H.P. Refrigerant BTU

Number

Refrigerated Module (134A)

SPR-40 40 30 34 12 6 115 5-15P 5.0 1/5 16oz. 1470

SPR-40E 40 30 30 8 4 115 5-15P 5.0 1/5 16oz. 1470

SPR-50 50 30 34 18 9 115 5-15P 7.0 1/4 16oz. 2280

SPR-50E 50 30 30 12 6 115 5-15P 7.0 1/4 16oz. 2280

SPR-64 64 30 34 24 12 115 5-15P 7.0 1/4 16oz. 2280

SPR-64E 64 30 30 16 8 115 5-15P 7.0 1/4 16oz. 2280

Freezer Module (404A)

SPF-42 42 30 34 10 5 115 5-15P 8.0 1/3 24oz. 1440

SPF-42E 42 30 30 8 4 115 5-15P 8.0 1/3 24oz. 1440

SPF-52 52 30 34 15 7 115 5-15P 8.0 1/3 24oz. 1440

SPF-52E 52 30 30 12 6 115 5-15P 8.0 1/3 24oz. 1440

SPF-66 66 30 34 20 10 115 5-15P 8.0 1/3 24oz. 1440

SPF-66E 66 30 30 16 8 115 5-15P 8.0 1/3 24oz. 1440

Refrigerator/Freezer Module(134A & 404A)

SPRF-68 68 30 34 12 6 120 5-20P 15.0 1/5, 1/3 16oz./24oz. 1440/1470

SPRF-68E 68 30 30 16 8 120 5-20P 15.0 1/5, 1/3 16oz./24oz. 1440/1470

Refrigerator/Heater Module (134A)

SPRH-68 68 30 34 12 6 120 5-30P 18.5 1/5 16oz. 1470

SPRH-68E 68 30 30 8 4 120 5-30P 18.5 1/5 16oz. 1470

Heated Module

SPH-40 40 30 34 12 6 120 5-30P 17.0 NA NA NA

SPH-40E 40 30 30 8 4 120 5-30P 17.0 NA NA NA

SPH-50 50 30 34 18 9 120 5-30P 17.0 NA NA NA

SPH-50E 50 30 30 12 6 120 5-30P 17.0 NA NA NA

SPH-64 64 30 34 24 12 120 5-30P 17.0 NA NA NA

SPH-64E 64 30 30 16 8 120 5-30P 17.0 NA NA NA

Utility (Merchandising) Module

SPM-28 28 30 34 NA NA NA NA NA NA NA NA

SPM-28E 28 30 30 NA NA NA NA NA NA NA NA

SPM-36 36 30 34 NA NA NA NA NA NA NA NA

SPM-36E 36 30 30 NA NA NA NA NA NA NA NA

SPM-50 50 30 34 NA NA NA NA NA NA NA NA

SPM-50E 50 30 30 NA NA NA NA NA NA NA NA

SPM-60 60 30 34 NA NA NA NA NA NA NA NA

SPM-60E 60 30 30 NA NA NA NA NA NA NA NA

SPM-74 74 30 34 NA NA NA NA NA NA NA NA

SPM-74E 74 30 30 NA NA NA NA NA NA NA NA

Heated / Merchandising Module

SPHM-50 50 30 34 6 3 120 5-20P 14.75 NA NA NA

SPHM-50E 50 30 30 6 3 120 5-20P 14.75 NA NA NA

SPHM-64 64 30 34 8 4 120 5-20P 16.3 NA NA NA

SPHM-64E 64 30 30 8 4 120 5-20P 16.3 NA NA NA

Cashier Stand

SPCS-30 30 30 34 NA NA NA NA NA NA NA NA

SPCS-30E 30 30 30 NA NA NA NA NA NA NA NA

Refrigerated Display Case Module (134A)

SPRD36P-36N 36 30 76 NA NA 115 5-15P 12.0 1/2 32oz. 4450

SPRD36P-50N 50 30 76 NA NA 115 5-15P 12.0 1/2 32oz. 4450

SPRD48P-50N 50 30 76 NA NA 115 5-15P 12.0 1/2 32oz. 4450

SPRD48P-60N 60 30 76 NA NA 115 5-15P 12.0 1/2 32oz. 4450

SPRD60P-60N 60 30 76 NA NA 115 5-20P 16.0 3/4 48oz. 7470

SPRD60P-74N 74 30 76 NA NA 115 5-20P 16.0 3/4 48oz. 7470

SPRD72P-74N 74 30 76 NA NA 115 5-20P 16.0 3/4 48oz. 7470

SPRD36P-36NE 36 30 76 NA NA 115 5-15P 12.0 1/2 32oz. 4450

SPRD36P-50NE 50 30 76 NA NA 115 5-15P 12.0 1/2 32oz. 4450

SPRD48P-50NE 50 30 76 NA NA 115 5-15P 12.0 1/2 32oz. 4450

SPRD48P-60NE 60 30 76 NA NA 115 5-15P 12.0 1/2 32oz. 4450

SPRD60P-60NE 60 30 76 NA NA 115 5-20P 16.0 3/4 48oz. 7470

SPRD60P-74NE 74 30 76 NA NA 115 5-20P 16.0 3/4 48oz. 7470

SPRD72P-74NE 74 30 76 NA NA 115 5-20P 16.0 3/4 48oz. 7470

20.5x13.25x2.5” 20.5x13.25x4.75” Plug

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

5

Page 6

Shelleyspeed™ Service and Installation Manual

SPECIFICATIONS, 35” DEPTH MODULES

This manual covers standard units only. If you have a custom unit, consult the customer service department at the number listed below.

Model Length Width Height Basket Capacity Voltage Nema Amp H.P. Refrigerant BTU

Number 20.5x13.25x2.5 20.5x13.25x4.75 Plug

Refrigerated Module (134A)

SPR-40W 40 35 34 12 6 115 5-15P 5.0 1/5 16oz. 1470

SPR-40EW 40 35 30 8 4 115 5-15P 5.0 1/5 16oz. 1470

SPR-50W 50 35 34 18 9 115 5-15P 7.0 1/4 16oz. 2280

SPR-50EW 50 35 30 12 6 115 5-15P 7.0 1/4 16oz. 2280

SPR-64W 64 35 34 24 12 115 5-15P 7.0 1/4 16oz. 2280

SPR-64EW 64 35 30 16 8 115 5-15P 7.0 1/4 16oz. 2280

Freezer Module (404A)

SPF-42W 42 35 34 12 6 115 5-15P 8.0 1/3 24oz. 1440

SPF-42EW 42 35 30 8 4 115 5-15P 8.0 1/3 24oz. 1440

SPF-52W 52 35 34 18 9 115 5-15P 8.0 1/3 24oz. 1440

SPF-52EW 52 35 30 12 6 115 5-15P 8.0 1/3 24oz. 1440

SPF-66W 66 35 34 24 12 115 5-15P 8.0 1/3 24oz. 1440

SPF-66EW 66 35 30 16 8 115 5-15P 8.0 1/3 24oz. 1440

Refrigerator/Freezer Module (134A & 404A)

SPRF-68W 68 35 34 24 12 120 5-20P 15.0 1/5, 1/3 16oz./24oz. 1440/1470

SPRF-68EW 68 35 30 8 4 120 5-20P 15.0 1/5, 1/3 16oz./24oz. 1440/1470

Refrigerator/Heater Module (134A)

SPRH-68W 68 35 34 12 6 120 5-30P 18.5 1/5 16oz. 1470

SPRH-68EW 68 35 30 8 4 120 5-30P 18.5 1/5 16oz. 1470

Heated Module

SPH-40W 40 35 34 12 6 120 5-30P 17.0 NA NA NA

SPH-40EW 40 35 30 8 4 120 5-30P 17.0 NA NA NA

SPH-50W 50 35 34 18 9 120 5-30P 17.0 NA NA NA

SPH-50EW 50 35 30 12 6 120 5-30P 17.0 NA NA NA

SPH-64W 64 35 34 24 12 120 5-30P 17.0 NA NA NA

SPH-64EW 64 35 30 16 8 120 5-30P 17.0 NA NA NA

Utility (Merchandising) Module

SPM-28W 28 35 34 NA NA NA NA NA NA NA NA

SPM-28EW 28 35 30 NA NA NA NA NA NA NA NA

SPM-36W 36 35 34 NA NA NA NA NA NA NA NA

SPM-36EW 36 35 30 NA NA NA NA NA NA NA NA

SPM-50W 50 35 34 NA NA NA NA NA NA NA NA

SPM-50EW 50 35 30 NA NA NA NA NA NA NA NA

SPM-60W 60 35 34 NA NA NA NA NA NA NA NA

SPM-60EW 60 35 30 NA NA NA NA NA NA NA NA

SPM-74W 74 35 34 NA NA NA NA NA NA NA NA

SPM-74EW 74 35 30 NA NA NA NA NA NA NA NA

Heated/Merchandising Module

SPHM-50W 50 35 34 6 3 120 5-20P 14.75 NA NA NA

SPHM-50EW 50 35 30 6 3 120 5-20P 14.75 NA NA NA

SPHM-64W 64 35 34 8 4 120 5-20P 16.3 NA NA NA

SPHM-64EW 64 35 30 8 4 120 5-20P 16.3 NA NA NA

Cashier Stand

SPCS-30W 30 35 34 NA NA NA NA NA NA NA NA

SPCS-30EW 30 35 30 NA NA NA NA NA NA NA NA

Refrigerated Display Case Module (134A)

SPRD36P-36DW 36 35 76 NA NA 115 5-15P 12.0 1/2 32oz. 4450

SPRD36P-50DW 50 35 76 NA NA 115 5-15P 12.0 1/2 32oz. 4450

SPRD48P-50DW 50 35 76 NA NA 115 5-15P 12.0 1/2 32oz. 4450

SPRD48P-60DW 60 35 76 NA NA 115 5-15P 12.0 1/2 32oz. 4450

SPRD60P-60DW 60 35 76 NA NA 115 5-20P 16.0 3/4 48oz. 7470

SPRD60P-74DW 74 35 76 NA NA 115 5-20P 16.0 3/4 48oz. 7470

SPRD72P-74DW 74 35 76 NA NA 115 5-20P 16.0 3/4 48oz. 7470

SPRD36P-36DEW 36 35 76 NA NA 115 5-15P 12.0 1/2 32oz. 4450

SPRD36P-50DEW 50 35 76 NA NA 115 5-15P 12.0 1/2 32oz. 4450

SPRD48P-50DEW 50 35 76 NA NA 115 5-15P 12.0 1/2 32oz. 4450

SPRD48P-60DEW 60 35 76 NA NA 115 5-15P 12.0 1/2 32oz. 4450

SPRD60P-60DEW 60 35 76 NA NA 115 5-20P 16.0 3/4 48oz. 7470

SPRD60P-74DEW 74 35 76 NA NA 115 5-20P 16.0 3/4 48oz. 7470

SPRD72P-74DEW 74 35 76 NA NA 115 5-20P 16.0 3/4 48oz. 7470

6

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

Page 7

INSTALLATION: HEATED UNITS

Shelleyspeed™ Service and Installation Manual

Location

Do not install the unit near combustible objects or surfaces

affected by heat or moisture. Units are intended for indoor

use only.

Leveling

The unit must be level, both front and back and left to

right.

Stabilizing

Most models are supplied on casters for your convenience.

The unit must be installed in a stable condition

with the front wheels locked. Locking the front

casters after installation is the operator’s

responsibility.

OPERATION: HEATED UNITS

After the unit is plugged into the proper power source, you

will need to turn on the main power switch. The main power

switch is located behind the hinged panel located at the

bottom center of the operators side of the equipment. If the

unit fails to operate at this point, check the night switch to

ensure it is in the ON position. (The night switch is located

on the top right of the operator’s side of the equipment

behind spring hinged cover.)

The purpose of the night switch is to allow the unit to remain

connected to the power source with the main power switch

in the ON position and turn the unit off at night or when not

in operation. The night switch will terminate power to the

unit with the exception of the fans. The fans will continue to

operate for a duration of 3 minutes to allow the elements to

cool and prevent overheating.

Electrical Connections

Connections must be made in accordance with

all applicable local codes and/or the National

Electrical Code. Refer to the amperage data on

the specification pages or the wiring diagrams. A

standard unit is provided with a power cord and

grounded plug. All units should be plugged into a

grounded receptacle with its own circuit protection

that matches the amperage of the plug.

The unit is designed with a stay cool surface technology,

the top of the heated serving counter should remain at

approximately 80˚F. This will allow for the safe removal of

product from the baskets.

This unit is designed for DRY OPERATION ONLY!

Water is not required and should NEVER be used while the

unit is in operation or during the cleaning. Beneath the

false bottom on the interior of the equipment are the heating

elements, controls and wiring.

Operating with water or cleaning with water can

cause serious injury.

After usage DO NOT disconnect power from the

plug or from the main power switch as the fans

will not operate and a hi-limit may be tripped.

There is also a thermostat control located behind the

hinged panel at the bottom center of the operator’s side of

the equipment. This will allow the customer to adjust the

temperature for their desired requirements. The thermostat

has a three color range setting: YELLOW, GREEN and RED

with GREEN being the optimum range. This should allow the

unit to operate at temperatures that vary between 160˚ and

180˚ Fahrenheit. The desired product temperature at this

same setting is 140˚ to 160˚ Fahrenheit.

Due to the high temperatures, the inside of the

heated storage area is very hot and may cause

serious injury!

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

Proper air flow is critical to the operation of this equipment.

(Be sure to only use Delfield approved wire baskets for

storage of product). Other loading methods may cause air

flow restrictions and improper operation.

7

Page 8

Shelleyspeed™ Service and Installation Manual

OPERATION: HEATED UNITS CONTINUED

Product that is being stored in the Shellyspeed heated serving

counters are required to be properly heated prior to loading.

After rethermalizing product to desired temperature, it can

be placed in the wire baskets and loaded into the preheated

Shellyspeed heated unit. Preheating of equipment takes

approximately 1 hour. Hold time is 4 hours. The Shellyspeed

line is not designed for long-term storage of product. The

unit must be shut off properly with the night switch when not

in use.

MAINTENANCE: HEATED UNITS

Maintenance

Wipe unit clean with a damp cloth. Never pour water or

cleaning solution directly into the Shellyspeed heated unit.

For tougher cleaning requirements a mild abrasive and damp

cloth may be used.

Never use flammable oil soaked cloths or

combustible cleaning solutions, for cleaning.

Wipe casters down with food safe cleaner and fresh water.

If it becomes necessary to inspect or replace components

on the Shellyspeed heated unit, the elements and hi-limit

can be accessed by removing the bottom panel from the

interior of the unit. Most other components can be accessed

through the hinged panel located at the bottom center of the

operator’s side.

8

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

Page 9

OPERATION: HEATED MERCHANDISERS

Shelleyspeed™ Service and Installation Manual

After the unit is plugged into the proper power source, turn

on the main power switch. The main power switch is located

on the top right of the operator’s side of the equipment and is

located behind the spring hinge cover.

The merchandiser is heated by a 120-volt food warmer

mounted under the center shelf. The food warmer is

sufficient to heat both the lower and upper work surfaces.

The temperature control (infinite switch) for the food warmer

is located behind the right hand hinged door of the operator

side. The control can be set between 1 and 10 to maintain

proper temperatures.

There is a circulating fan for the lower work surface, which

allows for even temperatures across the lower area. The

circulating fan is located at the right end of the operator’s side

and can be accessed from the louver also located at the right.

The circulating fan assembly incorporates a 700 watt 120

volt heating element. The heating element is controlled by a

temperature control located at the bottom of the circulating

assembly. The control is set for “E”, this is the maximum

temperature control setting and has a variable setting of A

thru E. Any adjustments must be made by a qualified service

technician. The circulating fan will draw air in from the

intake at the right and discharge the heated air out the left air

diffuser.

There is a 120-volt incandescent light located in the top of the

overstructure. The incandescent light is controlled by the unit

power switch.

The merchandiser is designed to hold product above 140˚F.

Product must be properly heated prior to storage in the

merchandiser.

MAINTENANCE: HEATED MERCHANDISERS

Maintenance

Wipe unit clean with a damp cloth. Never pour water or

cleaning solution directly into the Shelleyspeed heated unit.

For tougher cleaning requirements a mild abrasive and damp

cloth may be used.

Never use flammable oil soaked cloths or

combustible cleaning solutions for cleaning.

Merchandisers are standard with Plexiglas® ends and

also sliding Plexiglas® doors. The doors are removable by

lifting the door into the upper track and pulling the bottom

of the Plexiglas® out of the lower track, lower the Plexiglas®

and remove. Once removed, the lower sanilite track can

be removed and cleaned following the standard cleaning

procedures. There is also a cleanout located at the ends

of the track holder to remove any food product or debris.

Simply reverse the order to reinstall tracks and Plexiglas®.

With a wet a clean cloth with lukewarm water and

dishwashing liquid. Apply only light pressure, rinse with clear

water and blot dry with a damp chamois. For excessively

dirty surfaces, rinse surface dirt off before washing.

Fine scratches will disappear when you polish by hand with a

plastic cleaner polish.

Wipe casters down with food safe cleaner and fresh water.

Failure to follow these guidelines can result in cracked or

broken Plexiglas®.

Note: Never use window sprays, kitchen scouring

compounds or solvents such as acetone, gasoline,

benzene, alcohol, carbon tetrachloride, or lacquer

thinner.

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

9

Page 10

Shelleyspeed™ Service and Installation Manual

INSTALLATION: REFRIGERATED/FREEZER UNITS

Location

Be sure the location chosen has a floor strong enough

to support the total weight of the cabinet and contents,

approximately 1,000 pounds. Reinforce the floor as necessary

to provide for maximum loading. Units are intended for indoor

use only.

Leveling

The unit must be level, both front and back and left to

right.

Stabilizing

Most models are supplied on casters for your convenience.

The unit must be installed in a stable condition

with the front wheels locked. Locking the front

casters after installation is the operator’s

responsibility.

Electrical connection

A standard refrigerated unit is provided with a power cord

and 3-prong grounded plug.

The unit should be plugged into a receptacle with its own

circuit protection that matches the amperage of the plug.

Connections must be made in accordance with

all applicable local codes and/or the National

Electrical Code. Refer to the amperage data on

the specification pages or the wiring diagrams. A

standard unit is provided with a power cord and

grounded plug. All units should be plugged into a

grounded receptacle with its own circuit protection

that matches the amperage of the plug.

On cord-connected units, an ON/OFF switch is

located on the operator side upper right hand

corner. The switch must be turned to its OFF

position and power supply disconnected whenever

doing the following:

1. Performing maintenance functions.

2. Cleaning the refrigerated cabinet area.

3. Performing service or repair functions.

Under no circumstances should the unit be

operated without the louvered panel in place.

OPERATION: REFRIGERATED UNITS

Inside cabinet: Do not pack unit so full that air cannot

circulate (only use Delfield approved wire baskets to store

product). See diagram to right.

Outside cabinet: Be sure the unit has access to ample air;

avoid hot corners and locations near stoves and ovens.

After the unit is plugged into the proper power source,

you will need to turn on the main power switch. The main

power switch is located on the top right of the operator’s

side of the equipment behind the spring hinged cover. If

the unit fails to operate, check the thermostat position

to make sure it is not in the OFF position. The optimum

setting for the temperature control is “5”. The temperature

control can be accessed through the removable louver

panel for the machine compartment located at the end of

the unit.

The unit will require approximately one hour of pre-chill

time prior to loading product. It is important the product

being stored in the refrigerated compartment is at or below

the desired holding temperature. The unit is designed to

store product, not to cool warm food product.

NOTE: Ice or water should never be used with this

equipment.

The Shelleyspeed refrigerator is also equipped with a defrost

timer. This allows for continuous operation throughout the

day. The timer is preset at the factory to defrost every four

hours for 15 minutes. The timer comes standard with a

lithium battery and will keep time for up to seven days in the

event of a power failure or if the unit is disconnected from the

power source. Even though the unit is set to defrost, it is still

recommended that all product be removed at night and the unit

shut off when not in use.

10

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

Page 11

Shelleyspeed™ Service and Installation Manual

REFRIGERATOR TEMPERATURE CONTROL SETTINGS AND DEFROST TIMER

Defrost timer: every 4 hours for 15 minutes.

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

11

Page 12

Shelleyspeed™ Service and Installation Manual

OPERATION: FREEZER UNITS

If it is necessary to adjust the temperature, the control is

located behind the louver on right end of unit. Turn the

knob clockwise as indicated on the control for desired

temperature. Adjustments should be made gradually.

Several small adjustments will be more effective than one

large adjustment. It may take an hour or longer to realize

the temperature change depending on the application and

location of the unit.

These units are not designed to freeze cold food products.

Items should be placed in the unit at the desired holding

temperature.

MAINTENANCE: REFRIGERATOR AND FREEZER UNITS

Defrosting

Freezer units should be defrosted daily using the ON/OFF

switch located on operator side upper right hand corner.

It is recommended that product be removed at night and the

unit shut off when not in use.

Never use sharp objects or tools to clean or

scrape ice/frost build up. A puncture to the

freezer could cause unrepairable damage to the

refrigeration system.

Casters

Casters can be lubricated with penetrating type oil.

Recommended maintenance schedule

Daily: Wipe and/or wash food wells, unit surface and door

gaskets.

Monthly: Remove louvers and clean condensing coil with a

soft brush, a fin comb or vacuum cleaner brush attachment.

Remove dust and debris from fins without bending them.

Overshelves and other items mounted to the top of the

counters should never be installed in the field due to the

potential damage to the refrigeration system.

Cleaning the unit

For stainless steel parts, use a mild, non-abrasive soap

or detergent and warm water. This may be followed by an

application of stainless steel cleaner or polish which will

eliminate water spotting and fingerprints.

Check casters for any debris that could be binding the

wheels, such as, strings from mops or bits of paper.

If it becomes necessary to inspect or repair components on

the Shelleyspeed refrigerated units, the fans and coils can be

accessed by removing the bottom panel from the interior of

the unit. Most other components can be located at the end

of the unit behind the removable louver panel.

12

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

Page 13

Shelleyspeed™ Service and Installation Manual

WIRING DIAGRAM

L1

ON/OFF SWITCH

TEMPERATURE CONTROL

— 115V REFRIGERATED UNITS

N G

CONDENSING UNIT

DEFROST TIMER

EVAPORATOR FAN

WIRING DIAGRAM

L1

ON/OFF SWITCH

TEMPERATURE CONTROL

— 115V FREEZER UNITS

N G

CONDENSING UNIT

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

13

Page 14

Shelleyspeed™ Service and Installation Manual

WIRING DIAGRAM

N

MAIN SWITCH

L1

G

— 120V HEATED UNITS

NIGHT SWITCH

1

2

3

MIN.

MAX.

5

FAN

6 7

TEMP.

CONTROL

54

HEATER ELEMENTS

HI-LIMIT

SAFETY

WIRING DIAGRAM

MAIN SWITCH

L1

N

L2

G

— 120/208V HEATED UNITS (OPTIONAL)

NIGHT SWITCH

FAN

1

2

3

MIN.

MAX.

5

6 7

TEMP.

CONTROL

53

HI-LIMIT

SAFETY

HEATER ELEMENTS

14

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

Page 15

Shelleyspeed™ Service and Installation Manual

WIRING DIAGRAM

INFINITE CNTRL

N

MAIN SWITCH

L1

— 120V MERCHANDISER HEATED UNITS

LIGHT

HEATLAMP

T-STAT

(SET ON E=205˚)

FAN

G

HI-LIMIT

SAFETY

HEATER ELEMENT

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

15

Page 16

Shelleyspeed™ Service and Installation Manual

PARTS LIST

HEATED UNITS

120V UNIT

2162516 BLOWER, HI TEMP

2183390 CORD, 10/3, TYPE SO/STO/SJO, 105C

2190154 SWITCH, ROCKER, 20A

2194216 TERMINAL, RING, 12-10 GA., 1/4” STUD

2194279 GRIP, STRAIN RELIEF, 90, 10/3, CORD

2194297 PLUG, 30A-125V, NEMA 5-30P

2194325 BOX, ELECTRIC, 4.68 SQ. 56.7 KO

2194326 COVER, 4.6875 SQ., BLANK

2194370 SENSOR, TEMPERATURE, HEATED

2194372 THERMOSTAT, HEATED CABINET

2194377 KNOB, CONTROL, THERMOSTAT

2194409 SWITCH, ROCKER, 20A, SNAP-IN

2194589 THERMOSTAT, HI-LIMIT, SAFETY, 300

2194618 RELAY, TIMER, 120V, 1HP, SUP/MER HTD

2194694 ELEMENT, HEATING, FIN, 120V/900W

3234067 HINGE, FLAG, SHELLEYGLAS

3234156 CATCH, MAGNETIC DOOR

3234669 INTERLOCK ASSY, TOP

3234783 CASTER, 5”, PLT, SWVL. BRK, POLYURE

3234888 SPRING HINGE, MCMASTER CARR 15205A42

3516390 THERMOMETER, DIAL, 40-240 F

000-B9X-0031 ASSY, LID, BTM, SLDG, 64X35 UNIT

000-B9X-0030 ASSY, LID, TOP, SLDG, 64X35 UNIT

208V UNIT

2183422 CORD, 10/4, TYPE SO/STO/SJO, 105C

2194410 PLUG, 30A-125/208V, NEMA 14-30P

2194605 ELEMENT, HEATING, FIN, 208V/900W

TBP60137 SWITCH, ROCKER, 20A

REFRIGERATED COLD UNIT

2162515 FAN, EFFICIENCY

2190154 SWITCH, ROCKER 20A/125V, 15A/250V

2194345 TIMER, 24 HOUR, CLOCK FACE

3234783 CASTER, 5”, PLT, SWVL, BRK, POLYURETHANE

3234888 SPRING HINGE, MCMASTER CARR #15205A42

3516056 CONTROL, TEMP, -35 TO 100

3516062 VALVE, EXPANSION, 1/4 TON, R134A

3516101 DRYER, FILTER, 1/4 ODF, SPORLAN

3516135 THERMOMETER, HANGING, 4

3516335 COIL, EVAPORATOR, 32.83” LG, SPECIAL

3526976 COND UNIT, 1/4 MED, 115/60, R134A COPELAND

000-B9X-0030 ASSY, LID, TOP, SLDG, 64X35 UNIT

000-B9X-0031 ASSY, LID, BTM, SLIDING, 64X35 UNIT

000-B02-0039 ASSY, LOCK, LID, BAR, SPR-64

HEATED MERCHANDISER UNIT

2190154 SWITCH, ROCKER, 20A

2194107 CONTROL, INFINITE, 120V/13A

2194190 LIGHT, PILOT, 125V, RED

2194557 HEATLAMP, MERCO, NWM-48X-120V-W

3234009 BEARING, SLIDING DOOR

3234783 CASTER, 5”, PLT, SWVL, BRK, POLYURETHANE

3234283 BEARING, SLIDING DOOR

3234557 KNOB, INFINITE CONTROL

3234669 INTERLOCK ASSY, TOP

6160007 BLADE, FAN, 4” DIA, ALUM.

6160024 MOTOR, 120V/50-60HZ, DIS

6190180 SWITCH, HIGH LIMIT, 245DEG F

6190181 THERMOSTAT, A RESET, 165-205D

6190269 ELEMENT, HEATING, 700W/120V

9321079 BUMPER, DRAWER

000-A0l-0033 ASSY, SLIDING DOOR, 24 X 48

221-411-0001 PANEL, SHELLEY LOUVER, END

Heated Unit Shown

FREEZER UNIT

2190154 SWITCH, ROCKER, 20A

3234783 CASTER, 5”, PLT, SWVL, BRK, POLYURETHANE

3234888 SPRING HINGE, MCMASTER CARR #15205A42

2193927 CONTROL, PRESSURE

3516101 DRYER, FILTER, 1/4 ODF, SPORLAN

3516135 THERMOMETER, HANING, 4

3516225 VALVE, EXPANSION, 1/4, LOW, R134A

3526710 COND UNIT, 1/3 ,LOW, 115/60, R404A S-SPEED

000-B9X-0030 ASSY, LID, TOP, SLDG, 64X35 UNIT

000-B9X-0031 ASSY, LID, BTM, SLIDING, 64X35 UNIT

16

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

Page 17

Shelleyspeed™ Service and Installation Manual

STANDARD LABOR GUIDELINES TO REPAIR OR REPLACE PARTS ON DELFIELD EQUIPMENT

Advice and recommendations given by Delfield Service Technicians do not constitute or guarantee any special coverage.

•Amaximumof1-hourisallowedtodiagnose a defective component.

•Amaximumof1-hourisallowedforretrieval of parts not in stock.

•Amaximumtravel distance of 200 miles round trip and 2-hours will be reimbursed.

•Overtime,installation/start-up,normalcontroladjustments,generalmaintenance,glassbreakage,freightdamage,and/or

correcting and end-user installation error will not be reimbursed under warranty unless pre-approved with a Service Work

Authorization from Delfield. You must submit the number with the service claim.

LABOR OF 1-HOUR IS ALLOWED TO REPLACE:

•Thermostat • Contactor/Relay

•InfiniteSwitch • Evaporator/CondenserFanMotorandBlade

•SolenoidCoil • CirculatingFanMotorandBlade

•Hi-limit/ThermalProtectorSwitch • CompressorStartComponentsandOverloadProtector

•DefrostTimer

•Thermometer

LABOR OF 2 HOURS TO REPLACE:

•PressureControl • HeatingElement

•SolenoidValve • Locate/RepairLeak

LABOR OF 3 HOURS TO REPLACE:

•CondenserorEvaporatorCoil

•ExpansionValve • CondensateElement

LABOR OF 4 HOURS TO REPLACE

•Compressor

This includes recovery of refrigerant and leak check.

$35.00 maximum reimbursement for refrigerant recovery (includes recovery machine, pump, torch, oil, flux, minor fittings,

solder, brazing rod, nitrogen, or similar fees.)

REFRIGERANTS

•R22Amaximumof$4.00/lb.or25¢/oz.willbereimbursed.

•R134AAmaximumof$5.00/lb.or31¢/oz.willbereimbursed.

•R404AAmaximumof$12.00/lb.or75¢/oz.willbereimbursed.

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

17

Page 18

Shelleyspeed™ Service and Installation Manual

NOTES:

18

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

Page 19

NOTES:

Shelleyspeed™ Service and Installation Manual

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

19

Page 20

Mt. Pleasant, MI

Covington, TN

Thank you for choosing Delfield!

Help is a phone call away. Help our team of professional, courteous customer

service reps by having your model number and serial number available at the time

of your call (800) 733-8829.

Model: _______________________ S/N: ______________________

Installation Date: _______________

For a list of Delfield’s authorized parts depots,

visit our website at www.delfield.com

Register your Deleld warranty

online. Go to www.deleld.com

under the service tab to complete.

™

®

Delfield

Delfield reserves the right to make changes in design or specifications without prior notice. ©2013 The Delfield Company. All rights reserved. Printed in the U.S.A.

980S.IsabellaRd.,Mt.Pleasant,MI48858,U.S.A.•(989)773-7981or(800)733-8829•Fax(989)773-3210•www.deleld.com

DMSSPEED 02/13

9291496

Loading...

Loading...