Delfield NZ123 Service Manual

Nordic Zone™ Cold Food Bars

CAUTIO

N

Service, Installation and Care Manual

Please read this manual completely before attempting to install or operate this equipment! Notify carrier of

damage! Inspect all components immediately. See page 2.

IMPORTANT INFORMATION

READ BEFORE USE

PLEASE SAVE THESE INSTRUCTIONS!

August 2003

Nordic Zone Salad Bar Service and Installation Manual

Nordic Zone Salad Bar Service and Installation Manual

3

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

CONTENTS

RECEIVING AND INSPECTING UNIT ................................................. 2

INSTALLATION.................................................................................. 3

ROUTINE MAINTENANCE ................................................................. 3

OPERATION ...................................................................................... 4

WIRING DIAGRAM............................................................................ 5

REPLACEMENT PARTS LIST............................................................. 5

FULL VIEW........................................................................................ 6

UNIT DETAILS................................................................................... 7

WALL MOUNT INSTALLATION.......................................................... 8

STANDARD WARRANTIES........................................................... 9-10

AUTHORIZED PARTS DEPOTS........................................................ 12

©2003 The Deleld Company. All rights reserved. Reproduction without written permission is prohibited. “Deleld” is a registered trademark of The Deleld Company.

SERIAL NUMBER LOCATION

The serial number on Nordic Zone series is located behind the hinge

doors afxed to the interior stainless side. On the two section model,

it will be the two interior sides in the center of the assembly.

Always have the serial number of your unit available when calling for

parts or service. A complete list of authorized Deleld parts depots is

shown on the back cover of this manual.

Refrigeration system is set up as a R-404a refrigerant.

Mechanical Data (dimensions for RT00012 (left side) and RT00013 (right side) combined

MODEL PRODUCT #OF # OF REMOTE REMOTE SHIP WEIGHT

NUMBER LENGTH HOLDING AREA DOORS LIGHT BULBS AMP HP BTU LBS.

NZ123 123.5” (313.69cm) 24” x 80.5” (60.69cm X 204.47cm) 4 (4) 48” 6 1.5 10,030 951

NZ207 207” (525.78cm) 24” x 124” (60.69 x 410 cm) 8 (8) 48” (2) 6 (2) 1 1/2 20,060 1600

RECEIVING AND INSPECTING THE EQUIPMENT

Units are shipped blanket wrapped.

Care should be taken during unloading so the equipment is not

damaged while being moved into the building.

1. Visually inspect the unit. Any damage should be noted and

reported to the delivering carrier immediately.

2. If damaged, open and inspect the unit with the carrier.

3. In the event that the unit is not damaged, yet upon opening,

there is concealed damage to the equipment notify the carrier.

Notification should be made verbally as well as in written

form.

4. Request an inspection by the shipping company of the

5. Also open the mechanical compartment housing and visually

6. Freight carriers can supply the necessary damage forms upon

damaged equipment. This should be done within 10 days

from receipt of the equipment.

inspect the control package. Be sure lines are secure and

base is still intact.

request.

2

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

INSTALLATION

Nordic Zone Salad Bar Service and Installation Manual

In most instances, the salad bar units will arrive at the job site

uncrated, and caution must be taken not to damage any exterior

surfaces when moving into position. All internal components

including glass and mirrors will be shipped intact within the unit.

The area where the salad bar is to be located must be clean and the

oor level to assure a satisfactory installation.

In the appropriate location, units must be leveled with the nished

work height top of Corian® to be approximately 34” above nished

oor. Make sure units are level left to right as well as front to back.

The units are mounted on 6” high legs which can be adjusted up to 1”.

Corian® adhesive (supplied) is to be applied between Corian®

surfaces where they adjoin at center for proper moisture sealing.

Once the Corian® adhesive has been applied the units are ready to

be connected together where noted “spline here.” The locations are

directly behind the front nosing, below the upper front air diffuser,

and at the rear of the unit. Fasteners will be pre-installed within the

spline locations. Clean the units. Remove any excess silicone or

adhesive that may have squeezed out after splining units together.

With sufcient help (4-5) individuals, slowly push the connected units

“evenly” back to the wall at the rear. Make sure that all stubbed out

electrical, refrigeration lines, and plumbing lines clear the cabinet

structure. If not, make any necessary adjustments to clear these

components. Once the units are secure against the wall at the rear,

double check for level.

Locate and install Corian® rear and side splashes using adhesive

supplied. It may be necessary to trim pieces slightly to t.

REFRIGERATION INSTALLATION

If the condensing units are to be set on the roof of the building, it

must be mounted on beams supplied by the roong contractor or the

refrigeration contractor.

The condensing units must be a minimum of three feet apart to assure

proper air ow. Before the salad bar units arrive the refrigeration lines

must be installed from the condensing units down through the ceiling

and the rear wall and stubbed out per the drawing supplied to the

installer. The suction line should be 5/8 inch and the liquid line should

be 3/8 inch for most installations. The pipe insulation should be 1/2

inch wall thickness. A “p” trap must be installed at the lowest point

of the refrigeration lines. The electrical power supply must also be

stubbed through the rear wall.

The liquid line should be insulated if exposed to sunlight on roof

installations. All refrigeration lines must be secured to prevent

excessive vibrating or kinking of the copper tubing. Drain lines must

be installed to the drain stub on the bottom of the evaporator housing.

The drain must have proper slope to insure good drainage from the

evaporator pan. A minimum vacuum of 200 microns must be reached

before charging the units with R-404A refrigerant. The system must

be charged under a heat load with R-404A until the sight glass is clear.

Normal installations will require approximately 9lbs. of refrigerant for

each system.

All panels and covers must be installed in the proper locations and

the defrost timer must be set for the proper time. Defrost time for

normal installations should be 15 minutes every three hours and the

thermostat setting should be for 37º degrees box temperature.

NOTE: do not change setting of defrost timer or

thermostat. See page #4 for complete operation

instructions.

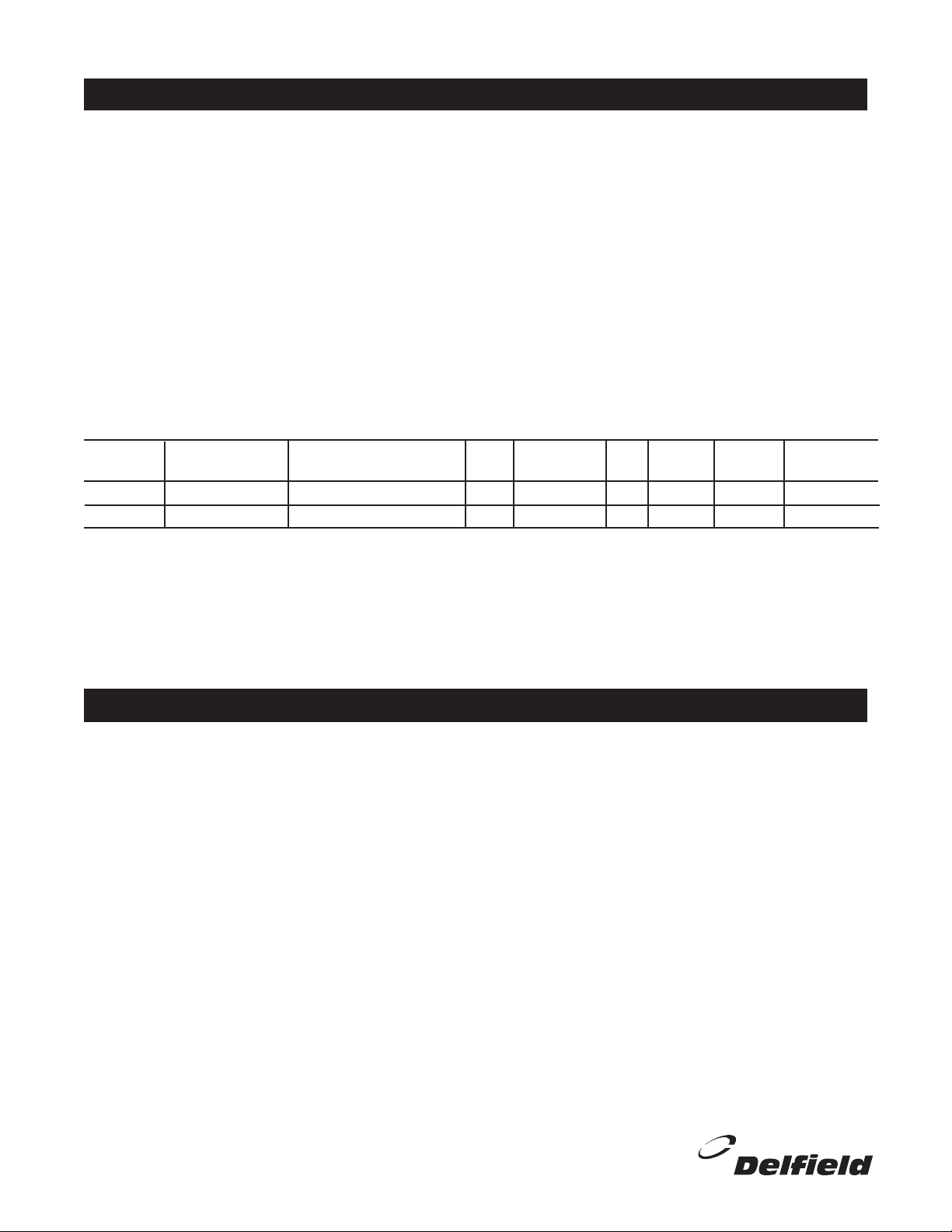

On/Off Switch located

behind the center

panel.

Thermostat located

behind the On/Off

switch panel.

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

3

Nordic Zone Salad Bar Service and Installation Manual

Nordic Zone Salad Bar Service and Installation Manual

5

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

CAUTION

CLEANING INSTRUCTIONS

Daily cleaning of the interior and exterior of the unit is recommended.

All food must be removed from the interior before cleaning. Always

wear gloves and eye protection when handling cleaning solutions and

cleaning the salad bar.

GLASS: Use the mildest cleaning product available to clean glass

mirrors on the salad bar. Typically, soap and water, or ammonia will

clean the glass sufciently. If stronger solutions are required, be

sure to use products designed for use on glass. Cleaning products

designed for other materials will leave residue that is not removable.

DISINFECTING: If the interior surface requires disinfecting, use a

product that contains Alkyl Ammonium Chloride to kill germs.

GREASE REMOVAL: Your regular daily cleaner may not remove

grease, ngerprints or other oily deposits found on glass. In this

case, use a stronger degreasing cleaner with butoxyethanol. Apply

this cleaner with sponge or cloth. Remove with a squeegee. Reclean

as necessary if streaks appear from degreaser.

DEGREASERS CAN HARM YOU. ALWAYS WEAR PROTECTIVE

GLOVES AND EYE PROTECTION WHEN USING THESE MATERIALS.

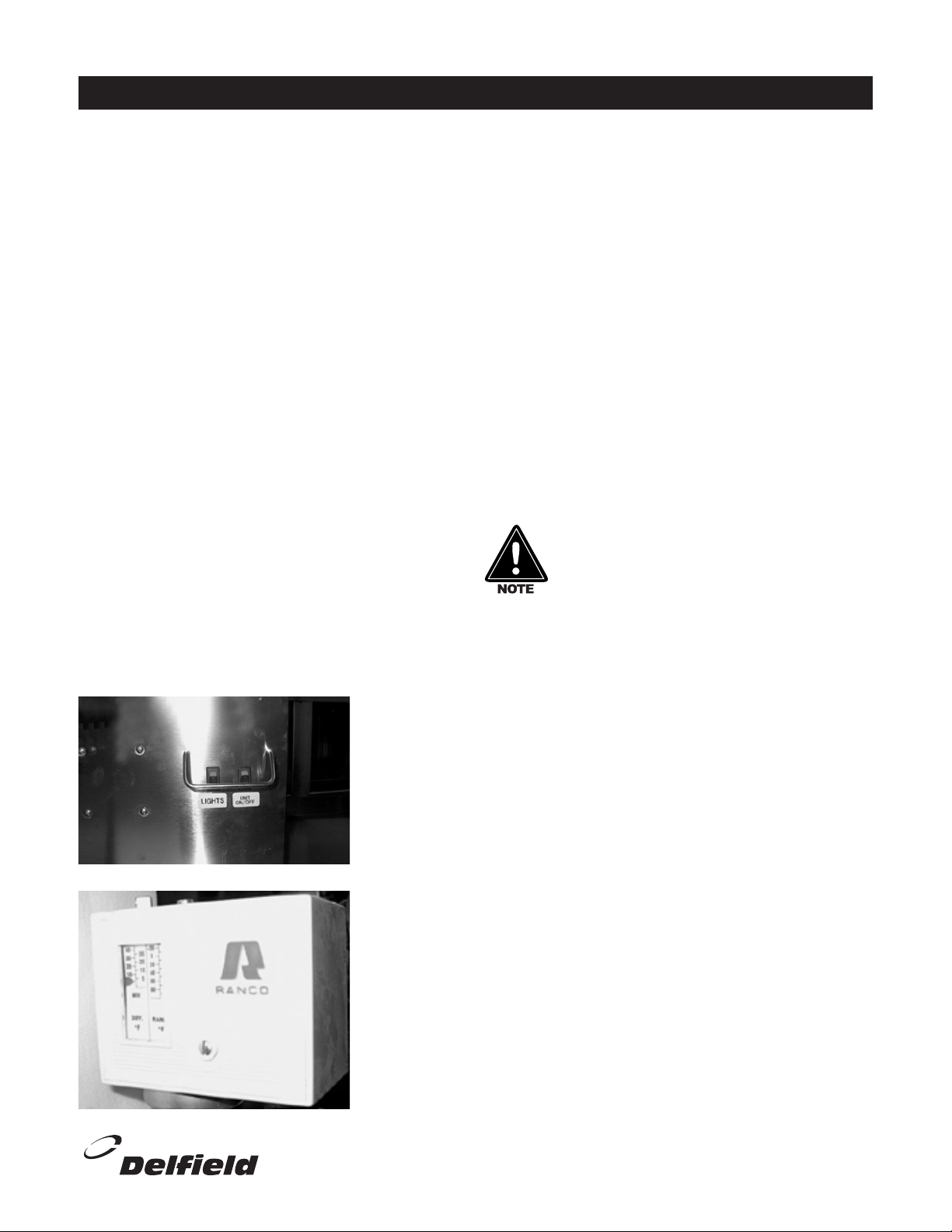

CLEANING REFRIGERATED PLATFORM: After removing all food

product and containers, lift the platform by grasping the front edge

and pulling up.

When lifting front edge take caution to ensure palms are down as

to not pinch ngers. See Figure-1 and Figure-2.

PLASTIC LAMINATE

In most cases, you only need to use a clean, damp nonabrasive

cotton cloth and a mild liquid detergent or household cleaner. Rinse

with clean water, using a clean, nonabrasive cotton cloth. Do not

ood the laminate, especially near seams since water can penetrate

and cause the substrate to swell. Dry the surface with a soft, clean,

non-abrasive cotton cloth.

DO NOT use abrasive cleaners, powders, steel wool, sandpaper,

or Scotch-Brite™ scouring pads. Use a trivet, insulated hot pad or

other protective device beneath all hot cookware, heat generating

appliances, or other heated objects.

®

CORIAN

There are three types of countertop nishes: matte,

semigloss and gloss. All Corian® sinks and bowls

have the matte nish. Soapy water or ammonia-based

cleaners will remove most dirt and stains from all

types of nishes. However, slightly different techniques must be

used to remove difcult stains, depending on the nish.

Preventing Heat Damage: to prevent heat damage, always use a hot

pad or a trivet with rubber feet to protect your Corian.

The platform is mounted on two pistons, located at

each end of the platform. Once raised, clean food debris

from the area, paying attention not to force food down

the drain of this area. This drain is easily clogged and

difcult to clean. Once food debris is cleaned out of the

area, use soap and water to wash the area and rinse. This will ow

down the drain. When cleaning is done, pull the platform down.

CABINET WOOD

To clean, gently wipe liquid spills up with a damp towel. If necessary

use with mild detergent.

Figure-1 Figure-2

4

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

OPERATION

Nordic Zone Salad Bar Service and Installation Manual

Start Up Procedures

1) Turn main power toggle switch to the ON position

2) Turn the toggle switch labeled lights to the ON position

3) Allow the case to reach refrigerator temperatures before lling

with product.

Display area must be in down position for fans to run.

Shut Down Procedures

1) Turn the toggle switch labeled LIGHTS to the OFF position.

2) Turn the toggle switch labeled MAIN to the OFF position.

3) Remove product from the case and clean.

COPIES OF THIS INFORMATION ARE ATTACHED TO THE INSIDE CENTER DOORS ON THE SALAD BAR.

TO INSURE THE PROPER OPERATION OF THIS AIR SCREEN SALAD BAR, PLEASE OBSERVE THE FOLLOWING.

The master back door light switch controls the power to the salad bar. When turned on, the process of circulating cold air and cooling down the

cold plates will start. This must be done one hour prior to stocking the salad bar with any food items. (At pre-determined times throughout the

day, the unit will cycle itself into a defrost mode.) Turn on the overhead display lights and you are ready to go.

Listed below are some important steps that must be followed

to insure that the air screen salad bar unit is set up correctly.

Do not install plastic wrap on any areas except the solid surface

portion of the cooling plates. Be careful not to block the return

air vents at the front or extreme ends of the cooling plates.

The mirrored panels along the rear of the unit must be securely

in place with no air leaks between mirror panels or at the outside

ends.

Control Knobs and Switches: All control and switches are

labeled accordingly.

1. Never attempt to change the setting of the defrost timer

or thermostat. Adjustments are to be made by qualied

service technicians only. Defrost cycles are factory preset and should not require eld adjustments. In the event of a power loss to this unit,

timers will NOT need to be reset.

2. The toggle switch labeled lights are for the overhead display lights and can be operated as necessary. A master on/off switch is located in the

base area.

3. If the units are not keeping acceptable temperatures or performing properly an authorized service agent MUST BE contacted. Contact local

service company or Deleld Service direct at 800-733-8829.

4. When lifting front edge take caution to ensure palms are down as to not pinch ngers

- see photo to the right.

5. Cleaning under display area can be done by lifting front edge of display area - see photo above.

Consult service/maintenance manual for additional information.

PRIORITY:

All refrigerated Salad Bar items must

be at or below 40˚F prior to being

Do not allow the pewter bowls or kale garnish to block the airow from the louvered

areas at the inside back of the cooling plates. There must be a minimum of 3 inches

between the louvered panels and the pewter. Do not allow the pewter bowls or kale

garnish to block the return air vents at the front or extreme ends of the cooling plates.

placed onto the salad bar. Do not stack

the salad bar with warm product.

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

5

Nordic Zone Salad Bar Service and Installation Manual

Nordic Zone Salad Bar Service and Installation Manual

7

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

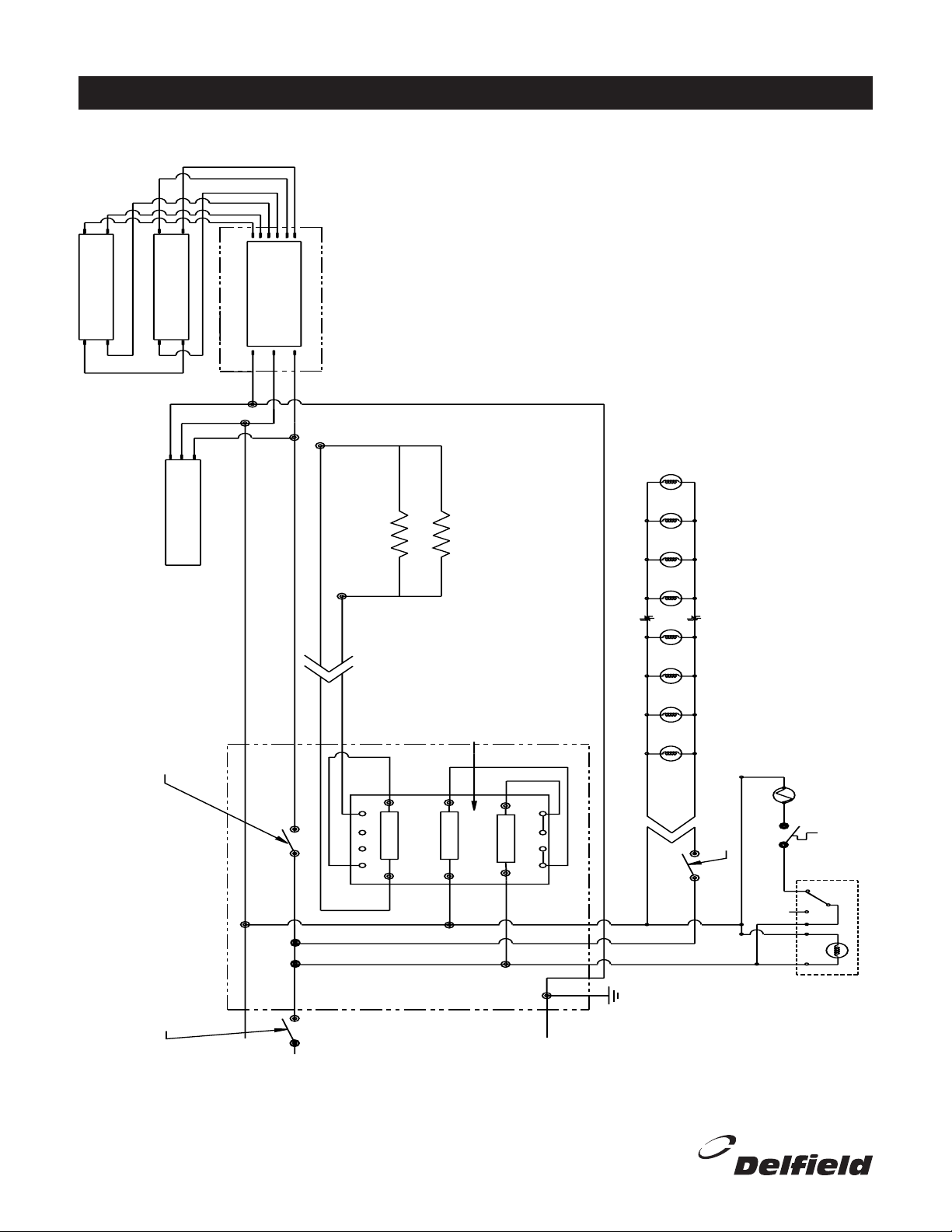

WIRING DIAGRAM 207”

NOTE: each 1/2 section of the

salad bar requires separate elec-

R

R

LAMP 1

Y

B

B

LAMP 2

Y

GREEN

WHITE

END LAMP

BLACK

Y

R

R

BALLAST, 120v INPUT, 227v OUTPUT

WHITE

GREEN

trical connections. This wiring

BBY

diagram represents a 1/2 section.

BLACK

RAIL FAN

HEATING ELEMENTS

RAIL FAN RAIL FANRAIL FAN RAIL FAN

(4) TO (8) FAN MOTORS

LIGHT ON/OFF SWITCH

WHITE

STAINLESS STEEL ENCLOSURE

MAIN ON/OFF SWITCH

NEUTRAL

BLACK

L1

BLUE

BLUE

RED

RED

X1 X2

BLUE

FUSE OFNM-15

XF

WHITE

RED

BLACK

120v TO 24v TRANSFORMER

BLACK

FUSE IKTK-R-5

WHITE

BLACK

FUSE IKTK-R-5

H4 H2 H3 H1

HF

H1

BLACK

GND

WHITE

WHITE

RAIL FAN RAIL FAN

BLACK

RAIL FAN

SOLENOID

THERMOSTAT

RED

5

4

1 2 3

FAN MOTOR

6

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

Loading...

Loading...