Page 1

™

Delfield

Installation, Use And Care Manual

Please read this manual completely before attempting to install or operate this equipment!

Notify carrier of damage! Inspect all components immediately.

®

Important Information

Read Before Use

Please Save These Instructions!

November 2011

Page 2

Mobile Kiosks Installation, Use And Care Manual

Delfield

Contents

Serial Number Information ........................................................ 2

Receiving And Inspecting Equipment ........................................ 2

Specifications ............................................................................. 3

Important Caution Notes ............................................................3

Initial Setup ................................................................................ 4

Closing the Gullwing .................................................................. 5

Gullwing Component Guide ....................................................... 6

Sink Operation ..........................................................................10

Sink Wiring Diagram ................................................................ 11

Wiring Diagrams ...................................................................... 12

Energy Management Unit ........................................................12

Plumbing .................................................................................. 13

Safety Strut Locks Installation & Usage .................................. 14

Winterizing ...............................................................................16

Maintenance ............................................................................. 18

Serial Number Information

The serial number is on the identification plate that also includes

the model number. The identification plate is located on the left

inside wall of the mechanical section.

Always have the serial number of your unit available when calling

for parts or service.

©2011 The Delfield Company. All rights reserved. Reproduction without

written permission is prohibited. “Delfield” is a registered trademarks of The

Delfield Company.

Trouble Shooting ...................................................................... 20

Replacement Parts ................................................................... 21

Standard Labor Guidelines ......................................................22

Standard Warranty ................................................................... 23

Receiving And Inspecting The Equipment

Even though most equipment is shipped packaged, care

should be taken during unloading so the equipment is not

damaged while being moved into the building.

1. Visually inspect the exterior of the package and skid or

container. Any damage should be noted and reported to

the delivering carrier immediately.

2. If damaged, open and inspect the contents with the

carrier.

3. In the event that the exterior is not damaged, yet upon

opening, there is concealed damage to the equipment

notify the carrier. Notification should be made verbally as

well as in written form.

4. Request an inspection by the shipping company of the

5. Visually inspect the heating package.

6. Freight carriers can supply the necessary damage forms

7. Retain all crating material until an inspection has been

damaged equipment. This should be done within 10 days

from receipt of the equipment.

upon request.

made or waived.

2

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.delfield.com

™

®

Page 3

Mobile Kiosks Installation, Use And Care Manual

Delfield

Specifications

Model V/Hz/Ph Power (Watts) Amps Nema Plug Ship Weight

lbs (kg)

GULL316 120/240V-60Hz-1Ph 9,600 40.0 14-50P 1279 (580)

NF316 120/240V-60Hz-1Ph 9,600 40.0 14-50P 1346 (611)

MINI316 120/60/1 1,440 12.0 5-15P 505 (229)

MINICOF316 120/60/1 1,440 12.0 5-15P 539 (244)

Model Sink

Capacity

WASH1-316 25 gal 5 gal (1) 13 gal 120/60/1 1,440 12.0 5-15P 556 (252)

WASH2-316 (2) 15 gal 5 gal (1) 13 gal 120/60/1 1,440 12.0 5-15P 578 (262)

WASH3-316 (3) 8.5 gal 5 gal (2) 13 gal 120/60/1 1,440 12.0 5-15P 590 (268)

Water Tank

Capacity

Waste

Water Tank

Capacity

V/Hz/Ph Power

(Watts)

Amps Nema Plug Ship Weight

lbs (kg)

Important Caution Notes

•Ensure that the mobile kiosk is only moved and operated on a hard level surface.

•Use the mobile kiosk for its intended purposes only.

•The mobile kiosk is designed to be used both indoors and outdoors.

•If the mobile kiosk is fitted with a water pump, be aware that pressure in water lines can vary.

•When moving the mobile kiosk, use the handles provided at either end.

•Be careful when moving the mobile kiosk.

•Never stand on the unit or its counter extensions. Doing so may result in bodily injury.

•Ensure all doors are closed and in the locked position before moving the mobile kiosk.

•Be cautious of moving parts to avoid injury.

•Failure to follow instructions in this manual can cause property damage, injury and void warranty.

™

®

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.delfield.com

3

Page 4

Mobile Kiosks Installation, Use And Care Manual

Delfield

Initial Set Up

It Is Essential That The Mobile Kiosk Is Only Moved And

Operated On A Hard Level Surface

When opening the mobile kiosk for the first time please take

time to follow these steps.

1. Remove the black night cover, to expose the locked/closed

Gullwing.

2. Confirm unit is on a hard level surface. Lock all casters.

3. Using the keys attached to the main handle, unlock the two

main bolt locks and slide open the bolt.

6. Reach over the main service bench to locate and unlock

the 2 bolt locks on the inside of the customer side door.

With care raise the customer side door. Swing safety strut

lock up onto strut.

7. Fold down the customer service shelf.

8. Using the second set of keys provided, unlock the right

or left counter extension door. Hold the door and release

the lock, the door will spring release. While holding the

counter extension door:

a. Pull out the extension support slides. Warning – Fully

Extend Slides Before Lowering Counter Extensions

b. Lower the counter extension into position.

c. Counter extensions can support a maximum of 220lbs

(100kg).

4. Note: Do not allow the Gullwing doors to open

uncontrolled as damage to the mechanism may occur.

Using the main handle, raise the door. Note the door is

installed using gas struts. Once initiated allow the struts

to open the door automatically, keep control of the door

while raising.

5. Swing safety strut lock up onto strut. The lock’s top should

be under the bottom of the strut’s upper section keeping

it from closing. (1) Safety strut lock is required per door.

4

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.delfield.com

™

®

Page 5

Mobile Kiosks Installation, Use And Care Manual

Delfield

Initial Set Up, continued Closing The Gullwing

9. Repeat Step 8 for the opposite end.

10. Locate and open the two compartment sink using the

recessed handle. Rotate the disk on the backsplash to lock

the sink in the open position.

1. Turn off all appliances, light switches, radio/CD and,

unless refrigeration is required overnight, disconnect the

power source.

2. Allow hot equipment to cool.

3. Empty and clean the waste container.

4. Clean as required.

5. Rotate the disk on the sink backsplash and close the sink.

6. Close and lock the counter extensions.

7. Raise the customer service shelf.

8. Swing safety strut lock down to unlock. Close and lock the

customer side door.

9. Ensure the doors to undercounter modules are closed.

10. Swing safety strut lock down to unlock. Close and lock the

operator’s side door.

11. Clean the exterior.

12. If required, cover the Gullwing.

11. To access the water, drainage and mechanical section

open the left end door.

12. Provide power and water to the unit.

™

®

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.delfield.com

5

Page 6

Mobile Kiosks Installation, Use And Care Manual

Delfield

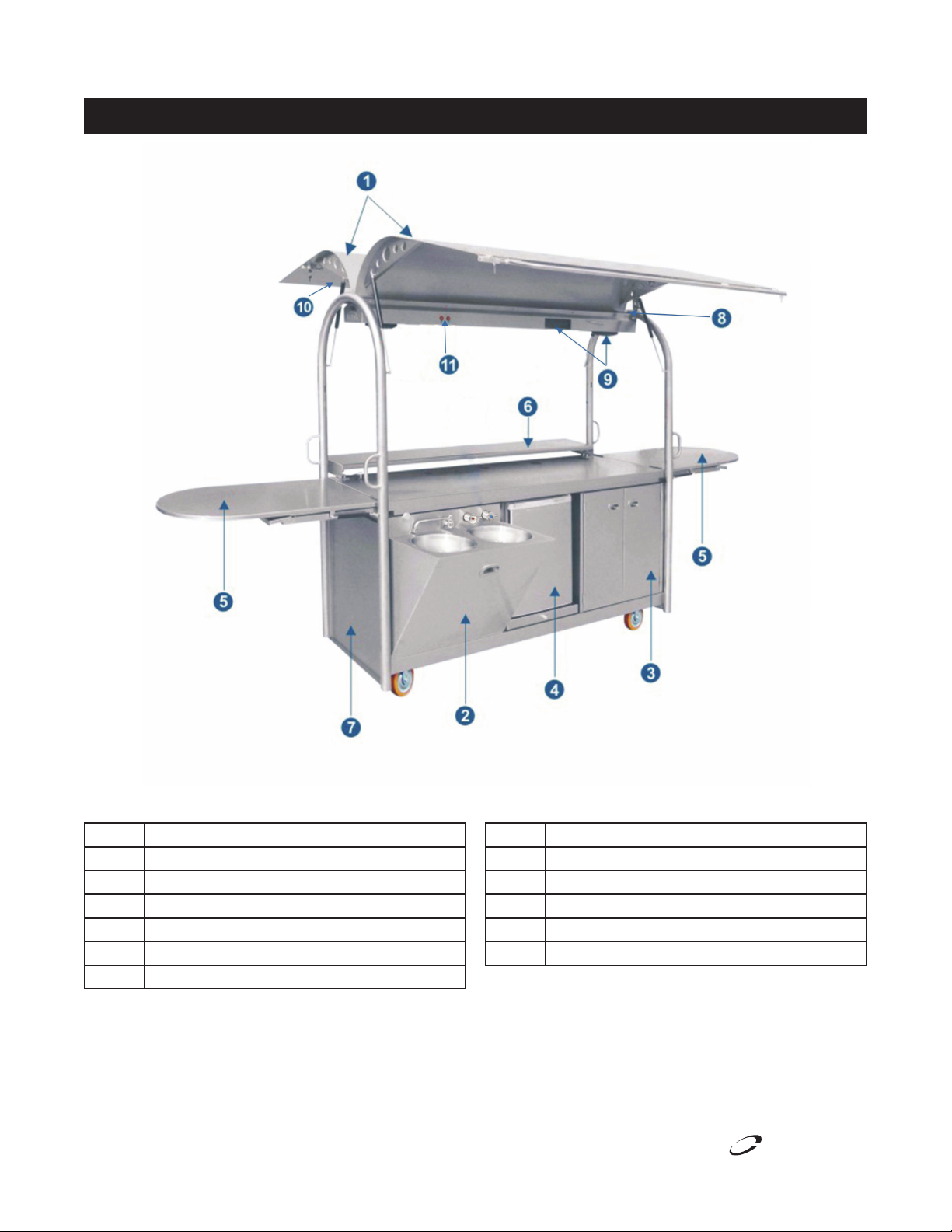

Gullwing Component Guide

Key Description

1 Gullwings

2 Two Compartment Sink

3 Dry Storage Cupboard

4 Refrigerator

5 Counter Extensions

6 Customer Service Shelf

6

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.delfield.com

Key Description

7 Access Door

8 Internal Drainage and Gutter System

9 CD Player and Speakers

10 Menu Board Display

11 Lighting – On/Off Switches

™

®

Page 7

Delfield

Gullwing Component Guide, continued

Mobile Kiosks Installation, Use And Care Manual

Service Module

The Service Module is an enclosed area that is located

immediately behind the sinks and is accessed through a door

at the left lower end of the Gullwing.

The Service Module is equipped to accommodate the following

components:

1. Energy management unit

2. Fresh water tank

3. Waste water tank

4. Water filtration

5. Hot water system

6. Water pump

Energy Management Unit

The Energy Management Unit is located in the Service Module .

Fresh Water Tank

The Gullwing comes supplied with a standard water tank. The

water tank can simply be refilled or replaced. To remove or

replace, pull the hose out. Be sure to replace and secure the top

cap and hose firmly before operation.

Please note the water tank can be bypassed and plumbed direct

to a water supply.

Waste Water Tank

The Gullwing has been fitted with a waste water tank for your

convenience.

Check that all plugs are correctly connected. The EMU has

spare plugs available for additional equipment to be added on

site.

Identify a suitable power outlet to connect the Energy

Management Unit. North American power requirements for

standard configuration is 120/240V-60Hz-1Ph 40A.

The main power should be supplied to the Mobile Kiosk and can

be channelled to the Energy Management Unit via the cutout in

the base of the service module.

One cannot operate electrical appliances on a Mobile Kiosk

if power is not available. The Energy Management Unit isn’t

designed to provide power, but rather distribute it, power must

be available at the site.

This bracket is for hanging the energy management unit.

™

®

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.delfield.com

Please note the waste water tank can be bypassed and plumbed

direct to main drainage.

7

Page 8

Mobile Kiosks Installation, Use And Care Manual

Delfield

Gullwing Component Guide, continued

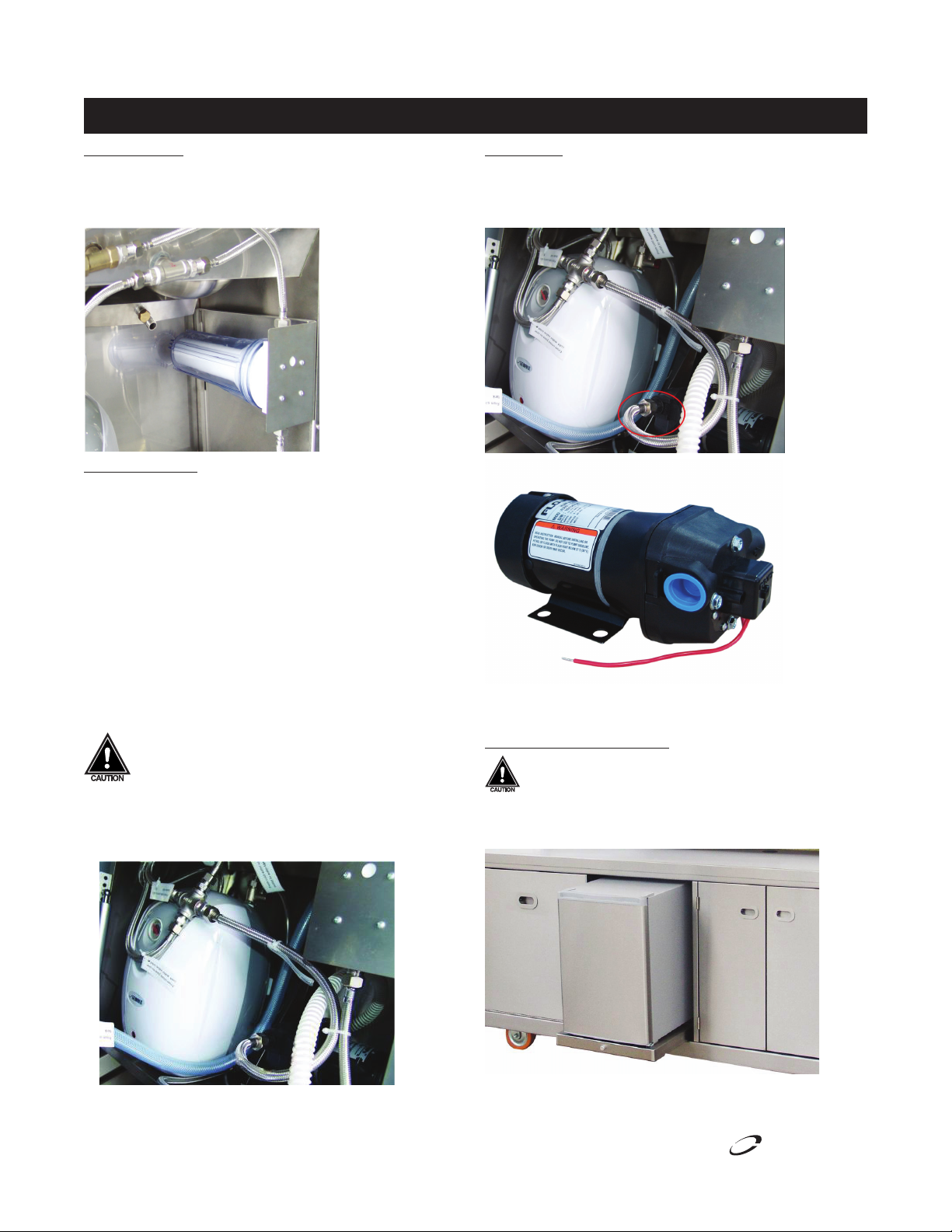

Water Filtration

The Gullwing is fitted with a water filter, located in the service

module in the right corner of the food vending unit. Check that

the waste water tank hose is connected and without kinks.

Hot Water System

The Gullwing has been fitted with a hot water heater. It is

installed at the factory and plumbed to the internal water

system/filter/pump and also connected to the electrical supply.

Please ensure these connections have not been effected during

transit and that all hoses connections are free of kinks.

Double check water and waste connections for:

•Hot water system

•Water filter

•12volt water pump

Turn on the water heater and allow water to flow until air has

escaped the plumbing system and the flow is constant.

Allow approximately twenty minutes to heat the hot

water system and then open each tap on the food

vending unit to check water flow. This will release

any air in the system. Do not let the water heater run

without water. This will damage the unit and void

warranty.

Water Pump

The Gullwing has a water pump installed to control the water

system within the unit. Additional pumps may need to be added

for items such as coffee machines.

When plumbing directly to main water, please unscrew the inlet

pipe at the end of water pump and connect it to main water.

Optional Central Refrigerator

This refrigerator/freezer option is intended for indoor

use only.

Centrally located on the operator side, the refrigerator is

installed on a slide for ease of cleaning.

8

Note: The refrigerator can be replaced with a freezer for your

required application.

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.delfield.com

™

®

Page 9

Delfield

Gullwing Component Guide, continued

Mobile Kiosks Installation, Use And Care Manual

Dry Storage Cupboard

The dry storage cupboard is located on the right third of the

Gullwing. The dry storage cupboard is equipped with a locking

cash drawer and data cable.

Food Vending Unit

The Food Vending Unit is one of the key features on the

Gullwing, providing the following:

•Two sinks

•Fresh water tank

•Waste water tank

•Water filtration

•Hot water system

•Water pumps

•Manifolds for controlling waste water

The equipment in the food vending unit can be accessed via the

Service Module.

Opening Food Vending Unit

1. Standing in front of the Food Vending Unit, pull it out using

the centrally located handle.

2. Rotate the disc on the backsplash to lock the unit in the

open position.

3. Check that the waste water tank is empty and the drain

hose is properly connected.

4. Check the fresh water tank is full

5. Check that the power supply is connected and sufficient

time has elapsed to heat the hot water system.

6. Turn the cold tap for cold water (right tap) Turn the hot tap

for hot water (left tap)

Closing Food Vending Unit

1. Hold the centrally located handle with one hand

2. Rotate the disc on the backsplash to unlock the Food

Vending Unit

3. Allow it to slowly close

4. Caution must be taken not to trap hands or fingers between

the Food Vending Unit and the sink backsplash

Lighting

The Gullwing is equipment with 3 sections of lighting. Located

in the operator side of the bulk head are 2 light switches which

control the following:

•Down lights – in the main bulk head, focus onto the main

bench surface

•Point of Purchase lighting – located under the customer

service shelf, focused on the bottom front panel.

•Point of Sale lights – located in the bulk head on the

customer side, focused on the menu board

Entertainment System

The Gullwing is equipped with an integrated CD radio and

speakers (MP3 play back capable). Speakers for the system are

located under the main bulk head. The system is wired to the

main energy management unit, and once power is supplied to

the main Gullwing, the system can be turned on. The CD player

has a detachable face plate which is normally stored in the dry

storage cupboard cash drawer when not in use.

If the above steps have been followed and all systems are

working; the mobile kiosk is ready for use.

™

®

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.delfield.com

9

Page 10

Mobile Kiosks Installation, Use And Care Manual

Delfield

Sink Operations

Sink Fully Open Closed

Height 42.00” (1070mm) 52.00” (1327mm)

Length 98.00” (2486mm) 41.50” (1051mm)

Width 34.50” (875mm) 27.50” (700mm)

2. Lift the counter extension until it is level with the counter.

3. Slide out counter extension support under the counter

extension, and gently lower the counter extension on the

support.

CAUTION

•Use the sink for its intended purposes only

•If the sink is fitted with a water pump, be aware that

pressure in water lines can vary

•Be careful when moving the sink.

Setting Up The Sink For The First Time

When opening the sink for the first time please take time to

follow these steps.

1. Open the package of sink and remove packing materials.

4. Lower the customer service shelf with both hands. The

unit is open and ready for use.

5. Identify a suitable power outlet to connect the power cord.

Then put the plug fitted for the appliance into the socket.

Power requirement for standard configuration is 120V,

60Hz, 1ph, 12A.

6. If required make sure plumbing meets all local code

requirements.

7. If the above steps have been followed and all systems are

working; the sink is ready for use.

10

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.delfield.com

™

®

Page 11

Mobile Kiosks Installation, Use And Care Manual

Delfield

Sink Operations Sink Wiring Diagram

Components – Sink

The core of all sinks comprises:

•Solid stainless steel frame

•Stainless steel cladding

•Solid wheels; two that rotate at one end

•Optional: one sink, two sinks or three sinks

Water Filter

The water filter cartridge is shipped loose and will need to

be installed during initial setup. The water filter cartridge will

need regular replacement. The frequency of replacement will

depend on the use of a coffee machine and/or other appliances.

However, the maximum interval should not exceed 6 months.

120V 15A Plug

L1

Water Heater 120V

10.5A (max)

N

G

Water Pump

120V 1.5A

™

®

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.delfield.com

11

Page 12

Mobile Kiosks Installation, Use And Care Manual

Delfield

Mobile Kiosk Wiring Diagram

Energy Management Unit

Circuit breaker

5A Fuse

12VAC Lighting

Circuit breaker

12

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.delfield.com

20A single

15A single

15A double, all the rest

are also 15A double

8’ cord with a

14-50 plug

™

®

Page 13

Delfield

Plumbing

Mobile Kiosks Installation, Use And Care Manual

To empty the waster water tank, connect waste water tank

outlet valve, the end is open. See location 10.

When using the water in an additional appliance, connect it to

the additional appliance water connection, the end is screwed

with choke plug. See location 11.

11

™

®

Key Plumbing Description

1 From water bottle to pump

2 From pump to cross joint

3 From cross joint to water filter

4 From cross joint to water heater inlet

5 From cross joint to one cold water valve inlet

6 From water heater outlet to hot water valve inlet

7 From cold water valve outlet to water tap

8 From hot water valve outlet to water tap

9 From sinks outlet to waste water tank

10 Waste water tank outlet valve

11 Additional appliance water connection

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.delfield.com

13

Page 14

Mobile Kiosks Installation, Use And Care Manual

Delfield

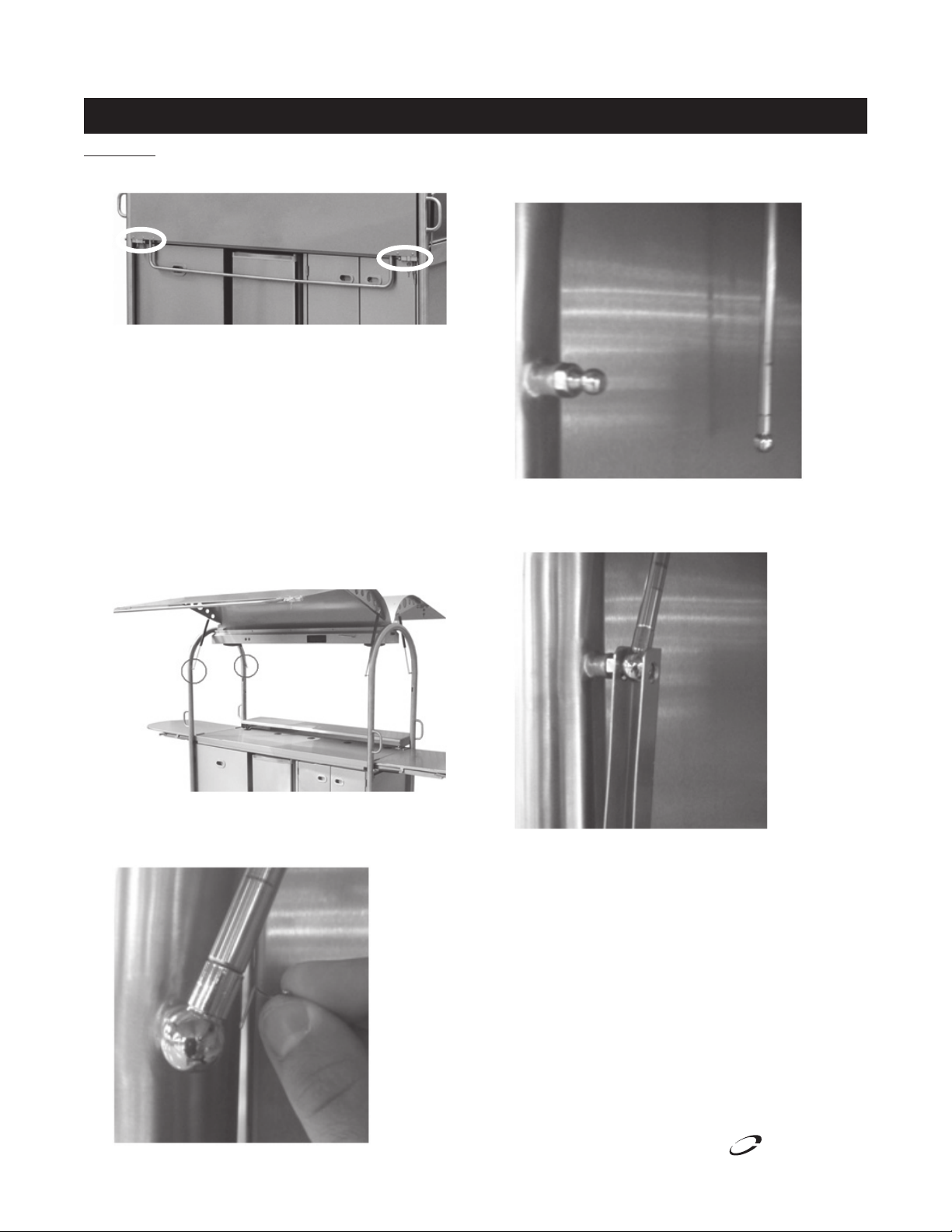

Safety Strut Locks Installation & Usage

Installation

1. Unlock gullwing locks and open lock slides.

2. Open operator side gullwing.

3. Unlock locks on the interior of customer side gullwing

and open lock slides.

4. Open customer side gullwing.

5. Have a second person hold the gullwings in the open

position while first person mounts the safety strut locks.

NOTE: During safety strut lock installation, the gullwings

will close if not supported!

6. Locate the points where the gullwing struts connect to

the vertical s/s tubing.

8. While second person holds gullwing, pull gently on the

strut to disconnect the bottom of it from strut mounting

ball.

9. Slide the end of the safety strut lock channel with the

holes over the bottom ball on strut and slide both back

onto strut mounting ball.

7. Locate small spring clip that holds the bottom end of the

strut to the vertical s/s tubing. Remove the clip by rotating it 180 degrees and pulling it up.

14

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.delfield.com

™

®

Page 15

Mobile Kiosks Installation, Use And Care Manual

Delfield

Safety Strut Locks Installation & Usage, continued

10. Push spring pin back into strut and rotate 180 degrees to

lock it into place.

Usage

1. Swing safety strut lock up onto strut. The top edge of the

channel should be under the bottom edge of the upper

larger diameter of the strut’s cylinder keeping it from

closing.

2. Repeat same steps on customer side gullwing. NOTE:

Only (1) safety strut lock is required per wing.

3. To close gullwings, simply swing safety strut locks back

down and let them hang in place.

™

®

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.delfield.com

15

Page 16

Mobile Kiosks Installation, Use And Care Manual

Delfield

Winterizing

Failure to perform the winterizing process will void the

warranties.

For Conditions Where Unit Is Stored Above 40°F

1. Drain fresh water tank.

2. Drain waste water tank and re-install.

3. Remove water filter and reinstall water filter container

without the water filter.

4. Cover unit with the provided black cover.

For Conditions Where Unit Is Stored Below 40°F

Option 1

1. Drain fresh water tank.

2. Drain waste water tank and re-install.

3. Remove water filter and reinstall water filter container

without the water filter.

4. Remove fresh water inlet from fresh water tank.

5. Insert fresh water inlet into RV antifreeze (NEVER USE

AUTOMOTIVE ANTIFREEZE) .

6. Turn on hot water at faucet to circulate RV antifreeze

(NEVER USE AUTOMOTIVE ANTIFREEZE) through hot

water system.

7. Turn off hot water at faucet.

8. Turn on cold water at faucet to circulate RV antifreeze

(NEVER USE AUTOMOTIVE ANTIFREEZE) through cold

water system.

9. Turn off cold water at faucet

10. Drain waste water tank and re-install.

5. Disconnect discharge line from water pump at bottom of

cross joint fitting.

6. Unplug water pump, remove the (4) mounting bolts and

remove water pump from the mobile kiosk. Drain all

water from inside pump and supply and discharge lines.

7. Disconnect supply line from inline filter from right side of

cross joint fitting.

For Conditions Where Unit Is Stored Below 40°F

Option 2

1. Disconnect unit power

2. Open up sink compartment and lock in place and open up

end access door.

3. Remove hose from top of fresh water tank and then

remove and empty tank.

4. Disconnect the hose from top of waste water tank and

then remove and empty tank.

16

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.delfield.com

™

®

Page 17

Delfield

Winterizing, continued

Mobile Kiosks Installation, Use And Care Manual

8. Remove the (4) mounting screws that hold the inline filter

in place and remove it from the mobile kiosk unit. Open

cover, remove filter and drain filter and lines completely.

9. Insert new dry filter and screw cover back on filter and

remount in unit with same (4) screws

10. Disconnect (2) lines from top of water heater.

13. Disconnect both supply lines going to tap.

14. Open both faucet handles to drain any remaining water

from lines.

15. Dry off any residual water left in the mobile kiosk base.

16. Reconnect both supply lines to tap.

17. Replace water heater on hanger bracket and reconnect

lines.

18. Reconnect supply line to inline filter at right side of cross

joint fitting.

19. Remount water pump with (4) bolts and reconnect line to

bottom side of cross joint fitting.

20. Remount waste water tank and reconnect drain line from

sink.

21. Remount fresh water tank and reconnect supply line to

water pump.

11. Raise water heater up 1” off hanger bracket and remove

from the mobile kiosk.

12. Carefully turn upside down and drain completely of all

water.

™

®

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.delfield.com

Flushing The RV Antifreeze From Your Mobile Kiosk Water

System (After Winterizing)

1. Fill the fresh water tank.

2. Turn on hot water at faucet to circulate fresh water through

hot water system to purge all RV antifreeze.

3. Turn off hot water at faucet.

4. Turn on cold water at faucet to circulate fresh water

through cold water system to purge all RV antifreeze.

5. Turn off cold water at faucet.

6. Install a new water filter.

7. Drain waste water tank and re-install.

17

Page 18

Mobile Kiosks Installation, Use And Care Manual

Delfield

Maintenance

Door Gasket Maintenance

Door gaskets require regular cleaning to prevent mold and

mildew build up and also to retain the elasticity of the gasket.

Gasket cleaning can be done with the use of warm soapy water.

Avoid full strength cleaning products on gaskets as this can

cause them to become brittle and crack. Never use sharp tools

or knives to scrape or clean the gasket.

Caster Maintenance

Wipe casters with a damp cloth monthly to prevent corrosion.

The power switch must be turned to OFF and the

unit disconnected from the power source whenever

moving, replacing the lamp, performing service,

maintenance functions or cleaning.

Heated Display

Care must be taken to allow the Heated Display to cool down

before cleaning. The interior and exterior can be cleaned using

soap and warm water. If this isn’t sufficient, try ammonia

and water or a nonabrasive liquid cleaner. When cleaning

the exterior, always rub with the “grain” of the stainless steel

to avoid marring the finish. Do not use an abrasive cleaner

because it will scratch the stainless steel and can damage the

breaker strips and gaskets.

of stainless steel can be done with soap and water. Extreme

stains or grease should be cleaned with a non-abrasive cleaner

and plastic scrub pad. Always rub with the grain of the steel.

There are stainless steel cleaners available which can restore

and preserve the finish of the steels protective layer. Early signs

of stainless steel breakdown are small pits and cracks. If this

has begun, clean thoroughly and start to apply stainless steel

cleaners in attempt to restore the passivity of the steel.

Never use an acid based cleaning solution! Many

food products have an acidic content, which can

deteriorate the finish. Common items include,

tomatoes, peppers and other vegetables. Be sure

to clean the stainless steel surfaces under ALL food

products.

Doors/Hinges

Dry storage cupboard doors can be removed for easy cleaning.

Over time and with heavy use doors the hinges may become

loose. If this happens tighten the screws that mount the hinge

brackets to the frame of the unit. Loose or sagging doors can

cause the hinges to pull out of the frame, which may damage

both the doors and the hinges. In some cases this may require

qualified service agents or maintenance personnel to perform

repairs.

Stainless Steel Care and Cleaning

To prevent discoloration or rust on stainless steel several

important steps need to be taken. First, we need to understand

the properties of stainless steel. Stainless steel contains 7080% iron, which will rust. It also contains 12-30% chromium,

which forms an invisible passive film over the steel’s surface,

which acts as a shield against corrosion. As long as the

protective layer is intact, the metal is still stainless. If the film

is broken or contaminated, outside elements can begin to

breakdown the steel and begin to form discoloration or rust.

Proper cleaning of stainless steel requires soft cloths or plastic

scouring pads.

Never use a high pressure water wash for this

cleaning procedure as water can damage the

components.

NEVER USE STEEL PADS, WIRE BRUSHES OR

SCRAPERS!

Cleaning solutions need to be alkaline based or non-chloride

cleaners. Any cleaner containing chlorides will damage

the protective film of the stainless steel. Chlorides are also

commonly found in hard water, salts, and household and

industrial cleaners. If cleaners containing chlorides are used be

sure to rinse repeatedly and dry thoroughly. Routine cleaning

Racks

If necessary, remove the racks for cleaning. Use soft and wet

cloth and non irritating cleaning agent to clean the racks.

Do not place hot pans on/against the blue ABS liner.

Do not throw items into the storage area. Failure

to follow these recommendations could result in

damage to the interior of the cabinet. Overloading

the storage area, restricting the airflow, and

continuous opening and closing of the doors and

drawers will hamper the units ability to maintain

operational temperature.

Cleaning the Condenser Coil

In order to maintain proper refrigeration performance, the

condenser fins must be cleaned of dust, dirt and grease

regularly. It is recommended that this be done at least every

three months. If conditions are such that the condenser is totally

blocked in three months, the frequency of cleaning should be

increased. Clean the condenser with a vacuum cleaner or stiff

brush. If extremely dirty, a commercially available condenser

cleaner may be required.

Failure to maintain a clean condenser coil can initially cause high

temperatures and excessive run times. Continuous operation

with a dirty or clogged condenser coil can result in compressor

18

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.delfield.com

™

®

Page 19

Delfield

Maintenance, continued

Mobile Kiosks Installation, Use And Care Manual

failure. Neglecting the condenser coil cleaning procedures will

void any warranties associated with the compressor and cost

to replace the compressor.

Never use a high-pressure water wash for this cleaning

procedure as water can damage the electrical

components located near or at the condenser coil.

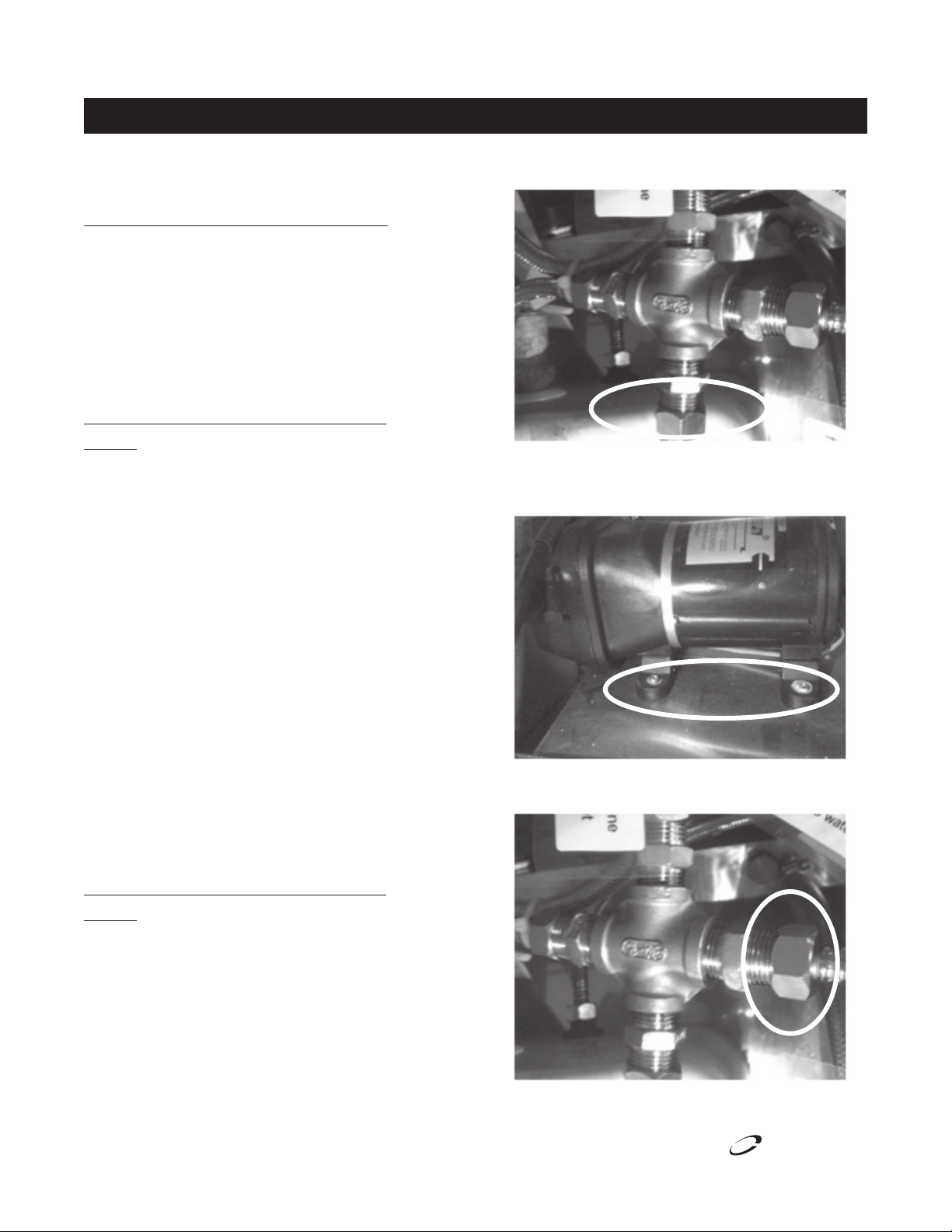

Waste Water Tank

It is recommended the waste water tank is removed and

thoroughly cleaned periodically based on the amount of use.

To drain the waste water tank, locate the hose and drain

valve. Direct the drain hose into the mains drain or secondary

container and turn on the valve to drain.

To remove the waste water tank for thorough cleaning, release

the stainless steel strap holding the water bottle and waste

water tank in position. Remove the water bottle.

Remove the waste water tank from inside of the unit. Using the

disconnect fitting (see below image), twist the fitting to remove

the main drain hose from the waste water tank. Your waste

water tank can be removed for cleaning. To access the main

vessel of the waste water tank, the top lid can be removed.

When reinstalling, please be sure to secure the main lid,

reconnect the main drain fitting, and slide back into position.

Place the water bottle in position and secure the stainless steel

strap.

Water Filter

The water filter is located on the right hand side of the service

module. The water filter cartridge will need regular replacement.

The frequency of replacement will depend on the use of a coffee

machine and/or other appliances. However, the maximum

interval should not exceed 6 months.

To change the cartridge in the water filter:

1. After turning off all appliances, drain residual water from

the filter.

2. Unscrew the filter from the mounting plate.

3. Unscrew the transparent filter cover.

4. Exchange old cartridge for new.

5. Replace securely when finished.

™

®

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.delfield.com

19

Page 20

Mobile Kiosks Installation, Use And Care Manual

Delfield

Trouble Shooting

The below chart is a guide to possible problems and causes. Please read through these and double check any problems you

may be having. The steps below will allow you to trouble shoot before placing a service call.

Problem Possible Causes Solution

Water is not hot Power not connected for sufficient time Allow 20 minutes to preheat

Water Heater is not turned on Locate power, and turn on

Water tank is empty Refill tank

Hot water unit faulty Unit can not run dry

Water does not come out of tap Power not connected Connect to power

Fresh water tank empty Refill

Pump faulty Call a qualified service technician

Inlet Pipe is Broken Call a qualified service technician

Water is not draining from sink Drain hose is blocked or kinked Remove obstruction

Waste water tank is full Empty waste water tank

Mobile kiosk is not level Level mobile kiosk

Refrigerator not cold Refrigerator not plugged in Plug in refrigerator, allow time to cool

Power not connected Connect to power

Circuit breaker on EMU tripped Reset breaker

Faulty refrigerator Call a qualified service technician

No water Water supply not connected Connect water supply

Inlet valve is open or not Open inlet valve

Water is blocked at any connection spot Call a qualified service technician

Drip from relief valve outlet Excessive water pressure Install pressure reducing valve at point of

connection with water inlet line

Water Pump Broken Call customer service

Can’t switch on the machine No power supply Locate power

Defective component(s) Call customer service

20

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.delfield.com

™

®

Page 21

Delfield

Replacement Parts

Mobile Kiosks Installation, Use And Care Manual

Dry Storage Module Replacement Parts

Part Number Description

GCP00060 Skirt

Mobile Kiosk Replacement Parts

Part Number Description

GCP00037 120V Water Heater

GCP00005 Cash Drawer

GCP00061 CD Player 2250

GCP00033 Down Lights

GCP00025 Feet

GCP00023 Filter

GCP00002 Gas Strut - Counter Extension

GCP00001 Gas Strut - Customer Service Shelf

GCP00003 Gas Strut

GCP00065 Key, Cash Drawer

GCP00064 Key, End Panel Locks

GCP00063 Key, Gullwing Locks

GCP00066 Key, Module Handle

GCP00022 Latch, Service Module (Male &

Female Set)

GCP00006 Lock - Counter Extension

GCP00011 Lock

GCP00049 Skirt

GCP00062 Speaker

GCP00034 Stereo Antenna

GCP00027 Switch (Round 12A)

GCP00026 Switch (Round 6A 250V)

GCP00008 Tap Set - Tap And Handles

GCP00007 Universal Castor - Lockable

GCP00045 Vinyl Cover 86.61”x32.87”x77.95”

GCP00038 Water Pump

Mini Replacement Parts

Part Number Description

GCP00024 Feet

GCP00009 Latch

GCP00043 Vinyl Cover

GCP00036 Water Pump

Sink Replacement Parts

Part Number Description

GCP00015 Retractable Spout

GCP00010 Round Stainless Steel Plug

GCP00042 Vinyl Cover

™

®

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.delfield.com

21

Page 22

Mobile Kiosks Installation, Use And Care Manual

Delfield

Standard Labor Guidelines To Repair Or Replace Parts On Delfield Equipment

Advice and recommendations given by Delfield Service Technicians do not constitute or guarantee any special coverage.

•Amaximumof1-hourisallowedtodiagnose a defective component.

•Amaximumof1-hourisallowedforretrieval of parts not in stock.

•Amaximumtravel distance of 100 miles round trip and 2-hours will be reimbursed.

•Overtime,installation/start-up,normalcontroladjustments,generalmaintenance,glassbreakage,freightdamage,and/or

correcting and end-user installation error will not be reimbursed under warranty unless pre-approved with a Service Work

Authorization from Delfield. You must submit the number with the service claim.

Labor Of 1-Hour Is Allowed To Replace:

•Thermostat•Contactor/Relay

•Evaporator/CondenserFanMotorandBlade• Hi-limit/ThermalProtectorSwitch

•SolenoidCoil•CirculatingFanMotorandBlade

•FanDelay/DefrostTerminationSwitch•Springs/Lowerator/Struts

•CompressorStartComponentsandOverloadProtector• DoorHinges,Locks,andGaskets

•DefrostTimer•Thermometer

Labor Of 2 Hours To Replace:

•DrawerTracks/Cartridges•DefrostElement

•PressureControl•HeatingElement

•SolenoidValve•Locate/RepairLeak

Labor Of 3 Hours To Replace:

•EPRorCPRValve•CondenserorEvaporatorCoil

•CapillaryTube

Labor Of 4 Hours To Replace:

•Compressor

This includes recovery of refrigerant and leak check.

$55.00 maximum reimbursement for refrigerant recovery (includes recovery machine, pump, torch, oil, flux, minor fittings,

solder, brazing rod, nitrogen, or similar fees.)

Refrigerants:

•R22Amaximumof$4.00/lb.or25¢/oz.willbereimbursed.

•R134AAmaximumof$5.00/lb.or31¢/oz.willbereimbursed.

•R404AAmaximumof$16.00/lb.or$1.00/oz.willbereimbursed.

22

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.delfield.com

™

®

Page 23

Mobile Kiosks Installation, Use And Care Manual

Delfield

Standard One Limited Year Warranty (One Year Parts And Labor.)

Delfield warrants to the Original Purchaser of the Delfield product

(herein called the “Unit”) that such Unit, and all parts thereof,

will be free from defects in material and workmanship under

normal use and service for a period of one (1) year from the

date of shipment of the Unit to the Original Purchaser or, if the

Original Purchaser returns the warranty card completely filled

out including the date of installation within thirty (30) days of

receipt of the Unit, one (1) year from the date of installation.

During this one year warranty period, Delfield will pay labor,

crating and freight incurred in the removal of the Unit or defective

component and shipment to Delfield. Reimbursement is subject

to the following limitations: A maximum of 1-hour is allowed

to diagnose a defective component; A maximum of 1-hour is

allowed for retrieval of parts not in stock; A maximum travel

distance of 100 miles round trip and 2-hours will be reimbursed.

Overtime, installation/start-up, normal control adjustments,

general maintenance, glass breakage, freight damage, and/or

correcting an end-user installation error will not be reimbursed

under warranty unless pre-approved with a Service Work

Authorization from Delfield. Delfield will pay the return costs if

the Unit or part thereof was defective.

The term “Original Purchaser” as used herein means that person,

firm, association, or corporation for whom the Unit was originally

installed.

This warranty does not apply to any Unit or part thereof that has

been subjected to misuse, neglect, alteration, or accident, such

as accidental damage to the exterior finish, operated contrary to

the recommendations specified by Delfield; or repaired or altered

by anyone other than Delfield in any way so as to, in Delfield’s

sole judgement, affect its quality or efficiency. This warranty

does not apply to any Unit that has been moved from the location

where it was originally installed. This warranty also does not

cover the refrigerator drier or the light bulbs used in the Unit.

The warranty is subject to the user’s normal maintenance and

care responsibility as set forth in the Service and Installation

Manual, such as cleaning the condenser coil, and is in lieu of

all other obligations of Delfield. Delfield neither assumes, nor

authorizes any other person to assume for Delfield, any other

liability in connection with Delfield’s products.

Removal or defacement of the original Serial Number or Model

Number from any Unit shall be deemed to release Delfield from

all obligations hereunder or any other obligations, express or

implied.

Parts furnished by suppliers to Delfield are guaranteed by Delfield

only to the extent of the original manufacturer’s express warranty

to Delfield. Failure of the Original Purchaser to receive such

manufacturers warranty shall in no way create any warranty,

expressed or implied, or any other obligation or liability on

Delfield’s part in respect thereof.

If shipment of a replacement part is requested prior to the arrival

in the Delfield factory of the part claimed to be defective, the

Original Purchaser must accept delivery of the replacement part

on a C.O.D. basis, with credit being issued after the part has

been received and inspected at Delfield’s plant and determined

by Delfield to be within this warranty.

Under no condition does this warranty give the Original Purchaser

the right to replace the defective Unit with a complete Unit of the

same manufacturer or of another make. Unless authorized by

Delfield in writing, this warranty does not permit the replacement

of any part, including the motor-compressor, to be made with the

part of another make or manufacturer.

No claims can be made under this warranty for spoilage of any

products for any reason, including system failure.

The installation contractor shall be responsible for building

access, entrance and field conditions to insure sufficient

clearance to allow any hood(s), vent(s), or Unit(s) if necessary,

to be brought into the building. Delfield will not be responsible

for structural changes or damages incurred during installation of

the Unit or any exhaust system.

Delfield shall not be liable in any manner for any default or delay

in performance hereunder caused by or resulting from any

contingency beyond Delfield’s control, including, but not limited

to, war, governmental restrictions or restraints, strike, lockouts,

injunctions, fire, flood, acts of nature, short or reduced supply of

raw materials, or discontinuance of the parts by the original part

manufacturer.

Except as provided in any Additional Four Year Protection

Plan, if applicable, and the Service Labor Contract, if

applicable, the foregoing is exclusive and in lieu of all other

warranties, whether written or oral, express or implied. This

warranty supersedes and excludes any prior oral or written

representations or warranties. Delfield expressly disclaims

any implied warranties of merchantability, fitness for a

particular purpose or compliance with any law, treaty, rule

or regulation relating to the discharge of substances into the

environment. The sole and exclusive remedies of any person

relating to the Unit, and the full liability of Delfield for any

breach of this warranty, will be as provided in this warranty.

Other than this Delfield Standard One Year Limited Warranty,

any applicable Delfield Additional Four Year Protection Plan or

applicable Delfield Service Labor Contract, the Original Purchaser

agrees and acknowledges that no other warranties are offered

or provided in connection with or for the Unit or any other part

thereof.

In no event will Delfield be liable for special, incidental or

consequential damages, or for damages in the nature of penalties.

™

®

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.delfield.com

23

Page 24

™

®

Delfield

Mt. Pleasant, MI Covington, TN

Thank you for choosing Delfield!

Help is a phone call away. Help our team of professional, courteous customer

service reps by having your model number and serial number available at the time

of your call (800) 733-8829.

Model: _______________________ S/N: ______________________

Installation Date: _______________

For a list of Delfield’s authorized parts depots,

visit our website at www.delfield.com.

™

®

Delfield

980S.IsabellaRd.,Mt.Pleasant,MI48858,U.S.A.•(989)773-7981or(800)733-8829•Fax(989)773-3210•www.deleld.com

Delfield reserves the right to make changes in design or specifications without prior notice. ©2011 The Delfield Company. All rights reserved. Printed in the U.S.A.

DMGCMK 11/11

Loading...

Loading...