Delfield GAF1P-S, GADBR1P-SH, GADTR1P-SH, GADFL2P-S, GAF2P-S Original Instructions Service Manual

...Page 1

Specification Line®

GA Series

Original Instructions

Service Manual

This manual is updated as new information and models are released. Visit our website for the latest manual.

Part Number GA_SM 08/18

Page 2

Safety Notices

Warning

n

Read this manual thoroughly before operating, installing

or performing maintenance on the equipment. Failure

to follow instructions in this manual can cause property

damage, injury or death.

DANGER

Do not install or operate equipment that has been

misused, abused, neglected, damaged, or altered/

modified from that of original manufactured

specifications.

DANGER

Use appropriate safety equipment during installation

and servicing.

Warning

n

Do not use electrical appliances inside the food storage

compartments of the appliance, unless they are of the

type recommended by the manufacturer.

Warning

n

Use caution when handling metal surface edges of all

equipment.

Warning

n

This appliance is not intended for use by persons

(including children) with reduced physical, sensory

or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision

concerning use of the appliance by a person responsible

for their safety. Do not allow children to play with this

appliance.

DANGER

All utility connections and fixtures must be maintained

in accordance with Local and national codes.

Warning

n

Do not damage the refrigeration circuit when installing,

maintaining or servicing the unit.

Warning

n

Authorized Service Representatives are obligated to

follow industry standard safety procedures, including,

but not limited to, local/national regulations for

disconnection / lock out / tag out procedures for all

utilities including electric, gas, water and steam.

Warning

n

Do not store or use gasoline or other flammable vapors

or liquids in the vicinity of this or any other appliance.

Never use flammable oil soaked cloths or combustible

cleaning solutions, for cleaning.

Warning

n

This product contains chemicals known to the State

of California to cause cancer and/or birth defects or

other reproductive harm. Operation, installation, and

servicing of this product could expose you to airborne

particles of glasswool or ceramic fibers, crystalline

silica, and/or carbon monoxide. Inhalation of airborne

particles of glasswool or ceramic fibers is known to the

State of California to cause cancer. Inhalation of carbon

monoxide is known to the State of California to cause

birth defects or other reproductive harm.

Caution

,

Use caution handling, moving and use of the R290

refrigerators to avoid either damaging the refrigerant

tubing or increasing the risk of a leak. Components

shall be replaced with like components. Servicing shall

be done by a factory authorized service personnel to

minimize the risk of possible ignition due to incorrect

parts or improper service.

Notice

Proper installation, care and maintenance are

essential for maximum performance and trouble-free

operation of your equipment. Visit our website www.

wbtkitchencare.com for manual updates, translations,

or contact information for service agents in your area.

Notice

Warranty may be deemed invalid if other than

authorized OEM (original equipment manufacture)

replacement parts are used in Delfield equipment.

Page 3

Table of Contents

Section 1

General Information

Model Numbers .......................................................... 5

Serial Number Information ........................................ 5

Warranty Information ................................................ 5

Regulatory Certifications ........................................... 5

Section 2

Installation

Location ....................................................................... 7

Clearance Requirements ............................................ 7

Drain Connections ...................................................... 7

Floor Drain Required .......................................................... 7

Weight, Capacity & Dimensions of Equipment ........ 8

Electrical Service ......................................................... 9

Ground Fault Circuit Interrupter .................................... 9

Electrical Specification Chart .......................................... 9

Energy Use ...........................................................................10

Leg & Caster Installation .......................................... 11

Level & Stable ............................................................12

Shelf Installation ....................................................... 12

Reversible Door Instructions ................................... 12

Applicable to Full Door Models ...................................12

Roll-In & Roll-Thru Installation ................................ 13

New Hinge Cartridge Installation ............................ 14

Accessory Interior Drawer Installation ...................14

T-1 Tray Slide Installation ......................................... 15

T-2 Tray Slide Installation ......................................... 16

T-3 Tray Slide Installation ......................................... 17

T-4 Rack Slide Installation ........................................ 18

Optional Foot Pedal Installation Instructions ........ 19

Section 3

Operation

Refrigerator & Freezer Operation ............................ 21

Refrigerator & Freezer Start Up ............................... 21

Evaporator Fan Operation .............................................22

Heated Cabinet Operation ....................................... 22

Heated Cabinet Start Up ......................................... 22

Fan Operation .....................................................................22

High Temperature Safety Device .................................23

Power Down ..............................................................23

Home Screen ............................................................. 23

TouchScreen Password .............................................24

Configuration Screen ...............................................25

Settings Screen ......................................................... 25

Units ........................................................................... 26

Defrost Type (Refrigerator & Freezer) ..................... 26

Set Box Temperature ................................................ 27

Alarm Management .................................................. 28

Network Connection ................................................28

Interior Light ............................................................. 29

Time / Date ................................................................30

Language ................................................................... 30

LCD Brightness .......................................................... 31

Manual Defrost ......................................................... 31

Web Application .......................................................31

KitchenConnect ................................................................. 31

Mobile Application ................................................... 31

Specification Line Connect ............................................ 31

Application Operation .............................................32

Equipment Management ...............................................32

Section 4

Maintenance

Part Number GA_SM 08/18 3

Responsibility ........................................................... 33

Interior Cleaning ....................................................... 34

Gaskets ..................................................................................34

Preventing Blower Coil Corrosion ............................... 34

Exterior Cleaning ...................................................... 34

Drain ......................................................................................34

Doors/Hinges .....................................................................34

Cleaning the Condenser Coil ...................................34

Section 5

Troubleshooting

Problem -> Cause -> Correction Chart ....................35

Page 4

Table of Contents (continued)

Section 6

Control

Service Screens ......................................................... 37

Frame Heater (Freezer Only) ......................................... 37

Rapid Pull Down (Refrigerator Only) ..........................37

Diagnostics ..........................................................................38

Relay Status .........................................................................38

Data History ........................................................................ 39

Energy Chart ....................................................................... 39

Temperature Chart ........................................................... 39

Temperature Probes .........................................................40

Relay Outputs ..................................................................... 40

Network Connection .......................................................41

Set Up Connection ...........................................................41

Complete Network Setup ..............................................42

Add A Network Screen ....................................................42

IP Address Setup Screen .................................................43

Password ..............................................................................43

Firmware Update ..............................................................44

Reset Factory Settings ..................................................... 45

Alarm History Screen ....................................................... 45

Alarm Screens .....................................................................46

Refrigerator & Freezer Alarms .......................................47

Section 7

Component Check Procedures

Evaporator Fan Access ..............................................49

Condenser Fan Access .............................................. 50

Unit Air Flow Design ................................................. 50

Frame Heater Routing .............................................. 51

Door Hinges .............................................................. 52

Temperature Probe Resistance ................................ 53

LED Light Replacement ............................................ 54

Door Gasket .............................................................. 55

Section 8

Refrigeration

R290

Charging Procedures ................................................ 57

System Contamination Clean-up ............................. 58

Mild System Contamination Clean-Up Procedure . 59

Severe Contamination Clean-Up Procedure ........... 59

Filter Driers................................................................60

Refrigerant Re-Use Policy ........................................ 60

Properties of R-290 (Propane) ................................. 61

Service Procedures ................................................... 62

Review .......................................................................63

Normal Operating Temperatures ............................ 64

1 Section Reach-In Refrigerator ................................... 64

2 Section Reach-In Refrigerator ................................... 67

3 Section Reach-In Refrigerator ................................... 70

1 Section Reach-In Freezer ............................................73

2 Section Reach-In Freezer ............................................76

3 Section Reach-In Freezer ............................................79

1 Section Pass-Thru Refrigerator .................................82

2 Section Pass-Thru Refrigerator .................................85

1 Section Pass-Thru Freezer ...........................................88

2 Section Pass-Thru Freezer ...........................................91

Section 9

Diagrams

Refrigerator Wiring Diagram ................................... 95

Freezers With One Compressor Wiring Diagram .... 96

Freezers With Two Compressors Wiring Diagram ..97

One Section Dual Temperature Wiring Diagram .... 98

Two Section Dual Temperature Wiring Diagram .... 99

One Section Heated Cabinet Wiring Diagram ...... 100

Two Section Heated Cabinet Wiring Diagram ......101

4 Part Number GA_SM 08/18

Page 5

Section 1

General Information

Model Numbers

This manual covers the following models:

One Door Section Two Door Section Three Door Section

Reach-In Dual Temperature

GADBR1P-SH

GADTR1P-SH

GAF1P-S(H) GAF2P-S(H) GAF3P-S(H)

GAFPT1P-S(H) GAFPT2P-S(H) -

GAFRI1P-S GAFRI2P-S -

GAH1-G(H) GAH2-G(H) -

GAH1-S(H) GAH2-S(H) -

GAHPT1-G(H) GAHPT2-G(H) -

GAHPT1-S(H) GAHPT2-S(H) -

GAHRI1-G GAHRI2-G -

GAHRI1-S GAHRI2-S -

GAHRT1-S GAHRT2-S -

Narrow Reach-In Refrigerator

GAR1NP-G(H) GAR2NP-G(H) -

GAR1NP-S(H) GAR2NP-S(H) -

GAR1P-G(H) GAR2P-G(H) GAR3P-G(H)

- GAR2P-GL -

GAR1P-S(H) GAR2P-S(H) GAR3P-S(H)

GARFF1P-D - -

GARPT1P-G(H) GARPT2P-G(H) -

GARPT1P-S(H) GARPT2P-S(H) -

GARRI1P-G GARRI2P-G -

GARRI1P-S GARRI2P-S -

GARRT1P-S GARRT2P-S -

GADFL2P-S

GADRL2P-S

Reach-In Freezer

Pass-Thru Freezer

Roll-In Freezer

Reach-In Heated

Pass-Thru Heated

Roll-In Heated

Roll-Thru Heated

Reach-In Refrigerator

Reach-In Fishfile

Pass-Thru Refrigerator

Roll-In Refrigerator

Roll-Thru Refrigerator

-

Serial Number Information

The model number and serial number are on the

identification plate. The identification plate is located near

the top front corner of the left interior wall.

Always have the serial number of your unit available

when calling for parts or service.

Warranty Information

Visit

http://www.delfield.com/warranty to:

• Register your product for warranty.

• Verify warranty information.

• View and download a copy of your warranty.

Regulatory Certifications

Models are certified by:

•

•

•

National Sanitation Foundation (NSF)

Underwriters Laboratories (UL)

Underwriters Laboratories of Canada (cUL)

Part Number GA_SM 08/18 5

Page 6

General Information Section 1

THIS PAGE INTENTIONALLY LEFT BLANK

6 Part Number GA_SM 08/18

Page 7

Section 2

Installation

DANGER

Installation must comply with all applicable fire and

health codes in your jurisdiction.

DANGER

Use appropriate safety equipment during installation and

servicing.

Location

Warning

n

This equipment must be positioned so that the plug is

accessible unless other means for disconnection from the

power supply (e.g., circuit breaker or disconnect switch)

is provided.

Warning

n

Adequate means must be provided to limit the movement

of this appliance without depending on or transmitting

stress to the electrical cord.

Warning

n

To avoid instability the installation area must be capable

of supporting the combined weight of the equipment

and product. Additionally the equipment must be level

side to side and front to back.

Warning

n

This equipment is intended for indoor use only. Do not

install or operate this equipment in outdoor areas.

• Recommended air temperature is 60° - 100°F

(16° - 38°C).

• Proper air supply for ventilation is REQUIRED AND

CRITICAL for safe and efficient operation. Refer to

Clearance Requirements chart on page 9.

• Do not obstruct the flow of ventilation air. Make sure the

air vents of the equipment are not blocked.

• Do not install the equipment where air vents are blowing

directly at it.

• Do not install the equipment directly over a drain. Steam

rising up out of the drain will adversely affect operation,

air circulation, and damage electrical / electronic

components.

Clearance Requirements

DANGER

Minimum clearance requirements are the same for

noncombustible locations as for combustible locations.

The flooring under the appliance must be made of a

noncombustible material.

DANGER

Risk of fire/shock. All minimum clearances must be

maintained. Do not obstruct vents or openings.

Top

12.00” (305mm)

• Keep the vents clean and free of obstruction.

• Casters or optional legs must be used and not removed.

Drain Connections

The location selected for the equipment must meet the

following criteria. If any of these criteria are not met, select

another location.

• Units are intended for indoor use only.

• The location MUST be level, stable and capable of

supporting the weight of the equipment.

• The location MUST be free from and clear of combustible

materials.

• Equipment MUST be level both front to back and side to

side.

• Position the equipment so it will not tip or slide.

• Front casters MUST be locked once positioned.

Part Number GA_SM 08/18 7

Warning

n

Moisture collecting from improper drainage can create a

slippery surface on the floor and a hazard to employees.

It is the owner’s responsibility to provide a container or

outlet for drainage.

FLOOR DRAIN REQUIRED

Dual Temperature Reach-In

Models GADBR1P-SH & GADTR1P-SH

Single section dual temperature reach-ins require plumbing

to a floor drain as they do not have hot gas condensate

removal.

Page 8

Installation Section 2

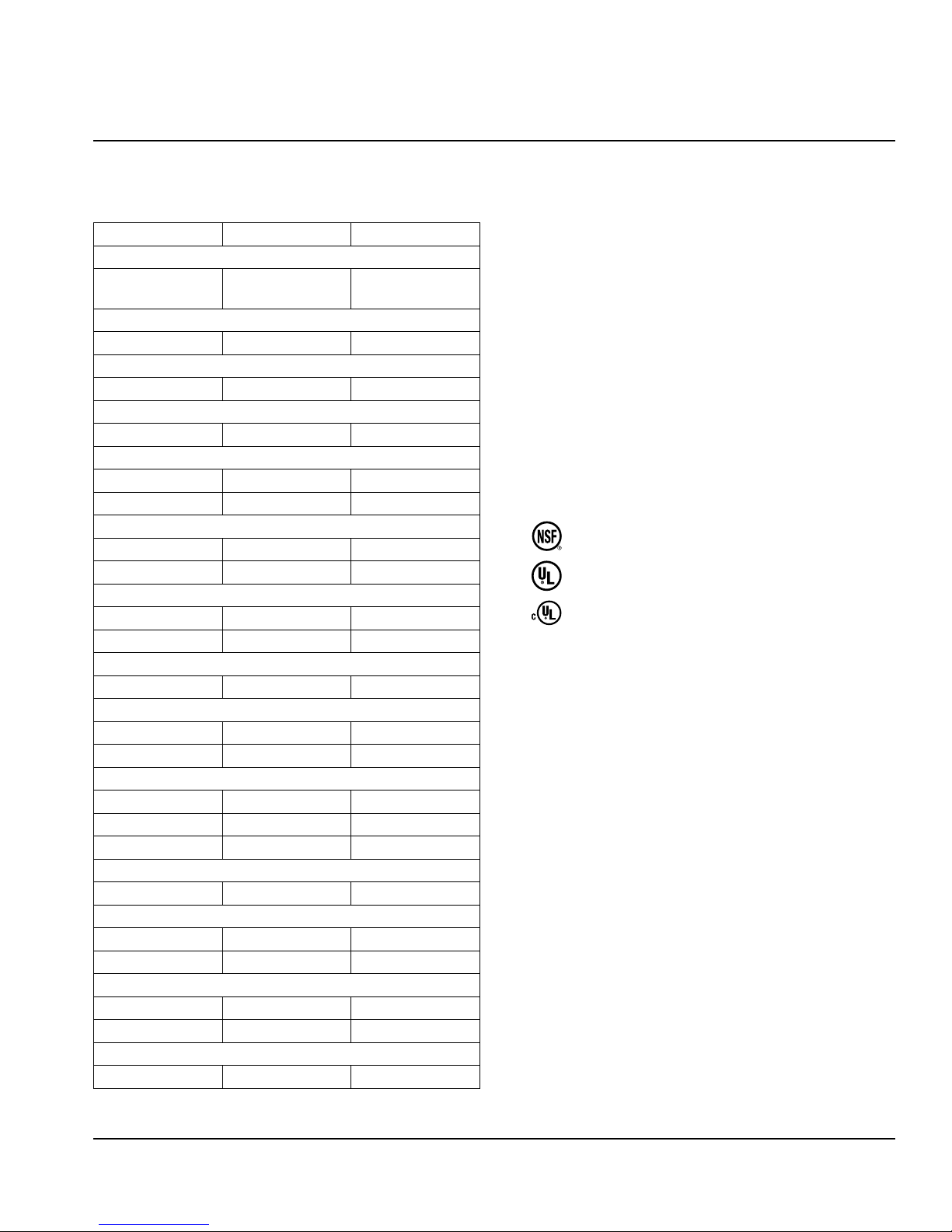

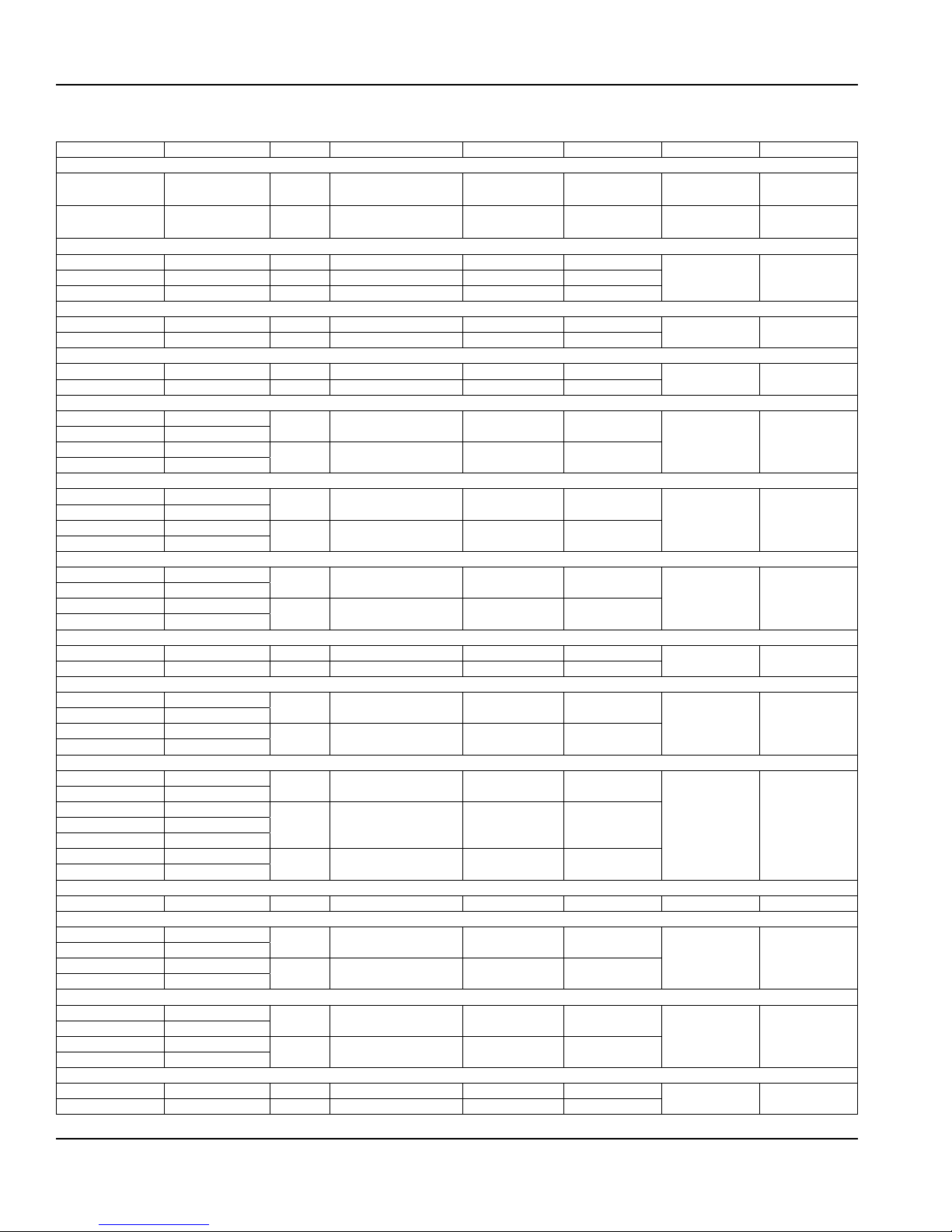

Weight, Capacity & Dimensions of Equipment

Model Weight Shelf Qty Shelf Area Volume Length Depth Height

Reach-In Dual Temperature

GADBR1P-SH

GADTR1P-SH

GADFL2P-S

GADRL2P-S

GAF1P-S(H) 354lbs (161kg) 3 11.5ft

GAF3P-S(H) 772lbs (350kg) 9 39ft2 (36232cm2) 71ft3 (2011L) 83.00” (211cm)

GAFPT1P-S(H) 452lbs (205kg) 3 12.12ft2 (11260cm2) 23ft3 (651L) 27.40” (70cm)

GAFPT2P-S(H) 682lbs (309kg) 6 26.5ft2 (24619cm2) 50ft3 (1416L) 55.22” (140cm)

GAFRI1P-S 466lbs (211kg) NA NA 37ft3 (1048L) 34.00” (86cm)

GAFRI2P-S 690lbs (313kg) NA NA 76.5ft3 (2166L) 66.00” (168cm)

GAH1-G(H) 361lbs (164kg)

GAH1-S(H) 333lbs (151kg)

GAH2-G(H) 640lbs (290kg)

GAH2-S(H) 630lbs (286kg)

GAHPT1-G(H) 361lbs (164kg)

GAHPT1-S(H) 333lbs (151kg)

GAHPT2-G(H) 640lbs (290kg)

GAHPT2-S(H) 630lbs (286kg)

GAHRI1-G 486lbs (220kg)

GAHRI1-S 446lbs (202kg)

GAHRI2-G 745lbs (338kg)

GAHRI2-S 715lbs (324kg)

GAHRT1-S 465lbs (211kg) NA NA 39ft3 (1104L) 34.00” (86cm)

GAHRT2-S 683lbs (310kg) NA NA 80.5ft3 (2280L) 66.00” (168cm)

GAR1NP-G(H) 391lbs (177kg)

GAR1NP-S(H) 361lbs (164kg)

GAR2NP-G(H) 652lbs (296kg)

GAR2NP-S(H) 632lbs (287kg)

GAR1P-G(H) 351lbs (159kg)

GAR1P-S(H) 236lbs (107kg)

GAR2P-G(H) 495lbs (225kg)

GAR2P-S(H) 322lbs (146kg)

GAR3P-G(H) 767lbs (348kg)

GAR3P-S(H) 485lbs (220kg)

GARFF1P-D 675lbs (306kg) NA NA 21ft3 (595L) 27.40” (70cm) 32.44” (82cm) 79.50” (202cm)

GARPT1P-G(H) 472lbs (214kg)

GARPT1P-S(H) 448lbs (203kg)

GARPT2P-G(H) 680lbs (308kg)

GARPT2P-S(H) 652lbs (296kg)

GARRI1P-G 486lbs (220kg)

GARRI1P-S 446lbs (202kg)

GARRI2P-G 745lbs (338kg)

GARRI2P-S 715lbs (324kg)

GARRT1P-S 486lbs (220kg) NA NA 39ft3 (1104L) 34.00” (86cm)

GARRT2P-S 683lbs (310kg) NA NA 80.5ft3 (2280L) 66.00” (168cm)

398lbs (181kg)

575lbs (261kg)

(2X)2 (2X)8ft

6 25.25ft

2

(7432cm2) (2X)8.6ft3 (244L) 27.40” (70cm) 32.44” (82cm) 79.50” (202cm)

2

(23458cm2) 42ft3 (1189L) 55.22” (140cm) 32.44” (82cm) 79.50” (202cm)

Reach-In Freezer

2

(10684cm2) 21ft3 (595L) 27.40” (70cm)

Pass-Thru Freezer

Roll-In Freezer

Reach-In Heated

3 11.5ft2 (10684cm2) 21ft3 (595L) 27.40” (70cm)

6 25.5ft2 (23690cm2) 46ft3 (1303L) 55.22” (140cm)

Pass-Thru Heated

3 11.5ft2 (10684cm2) 23ft3 (651L) 27.40” (70cm)

6 25.5ft2 (23690cm2) 50ft3 (1416L) 55.22” (140cm)

Roll-In Heated

NA NA 37ft3 (1048L) 34.00” (86cm)

NA NA 76.5ft3 (2166L) 66.00” (168cm)

Roll-Thru Heated

Narrow Reach-In Refrigerator

3 9.75ft2 (9058cm2) 18ft3 (510L) 24.00” (61cm)

6 21.75ft2 (20206cm2) 40ft3 (1133L) 48.42” (123cm)

Reach-In Refrigerator

3 11.5ft2 (10684cm2) 21ft3 (595L) 27.40” (70cm)

6 25.25ft2 (23458cm2) 46ft3 (1303L) 55.22” (140cm)GAR2P-GL 490lbs (222kg)

9 39ft2 (36232cm2) 71ft3 (2011L) 83.00” (211cm)

Reach-In Fishfile

Pass-Thru Refrigerator

3 12.12ft2 (11260cm2) 23ft3 (651L) 27.40” (70cm)

6 26.5ft2 (24619cm2) 50ft3 (1416L) 55.22” (140cm)

Roll-In Refrigerator

NA NA 37ft3 (1048L) 34.00” (86cm)

NA NA 76.5ft3 (2166L) 66.00” (168cm)

Roll-Thru Refrigerator

32.44” (82cm) 79.50” (202cm)GAF2P-S(H) 495lbs (225kg) 6 25.25ft2 (23458cm2) 46ft3 (1303L) 55.22” (140cm)

34.75” (88cm) 79.50” (202cm)

34.00” (86cm) 89.00” (226cm)

32.44” (82cm) 79.50” (202cm)

34.75” (88cm) 79.50” (202cm)

34.00” (86cm) 89.00” (226cm)

36.12” (92cm) 89.00” (226cm)

32.44” (82cm) 79.50” (202cm)

32.44” (82cm) 79.50” (202cm)

34.75” (88cm) 79.50” (202cm)

34.00” (86cm) 89.00” (226cm)

36.12” (92cm) 89.00” (226cm)

8 Part Number GA_SM 08/18

Page 9

Section 2 Installation

Electrical Service

DANGER

Check all wiring connections, including factory terminals,

before operation. Connections can become loose during

shipment and installation.

Warning

n

This appliance must be grounded and all field wiring must

conform to all applicable local and national codes. Refer

to rating plate for proper voltage. It is the responsibility of

the end user to provide the disconnect means to satisfy

the authority having jurisdiction.

• Plug units with R290 refrigerant into a receptacle that is a

minimum of 14” (36cm) above the floor.

• All electrical work, including wire routing and grounding,

must conform to local, state and national electrical codes.

• The equipment must be grounded.

• A separate fuse/circuit breaker must be provided for each

unit.

• The maximum allowable voltage variation is ±10% of the

rated voltage at equipment start-up (when the electrical

load is highest).

• Check all green ground screws, cables and wire

connections to verify they are tight before start-up.

GROUND FAULT CIRCUIT INTERRUPTER

Ground Fault Circuit Interrupter (GFCI/GFI) protection is a

system that shuts down the electric circuit (opens it) when it

senses an unexpected loss of power, presumably to ground.

Welbilt does not recommend the use of GFCI/GFI circuit

protection to energize our equipment. If code requires the

use of a GFCI/GFI then you must follow the local code. The

circuit must be dedicated, sized properly and there must

be a panel GFCI/GFI breaker. We do not recommend the

use of GFCI/GFI outlets to energize our equipment as they

are known for more intermittent nuisance trips than panel

breakers.

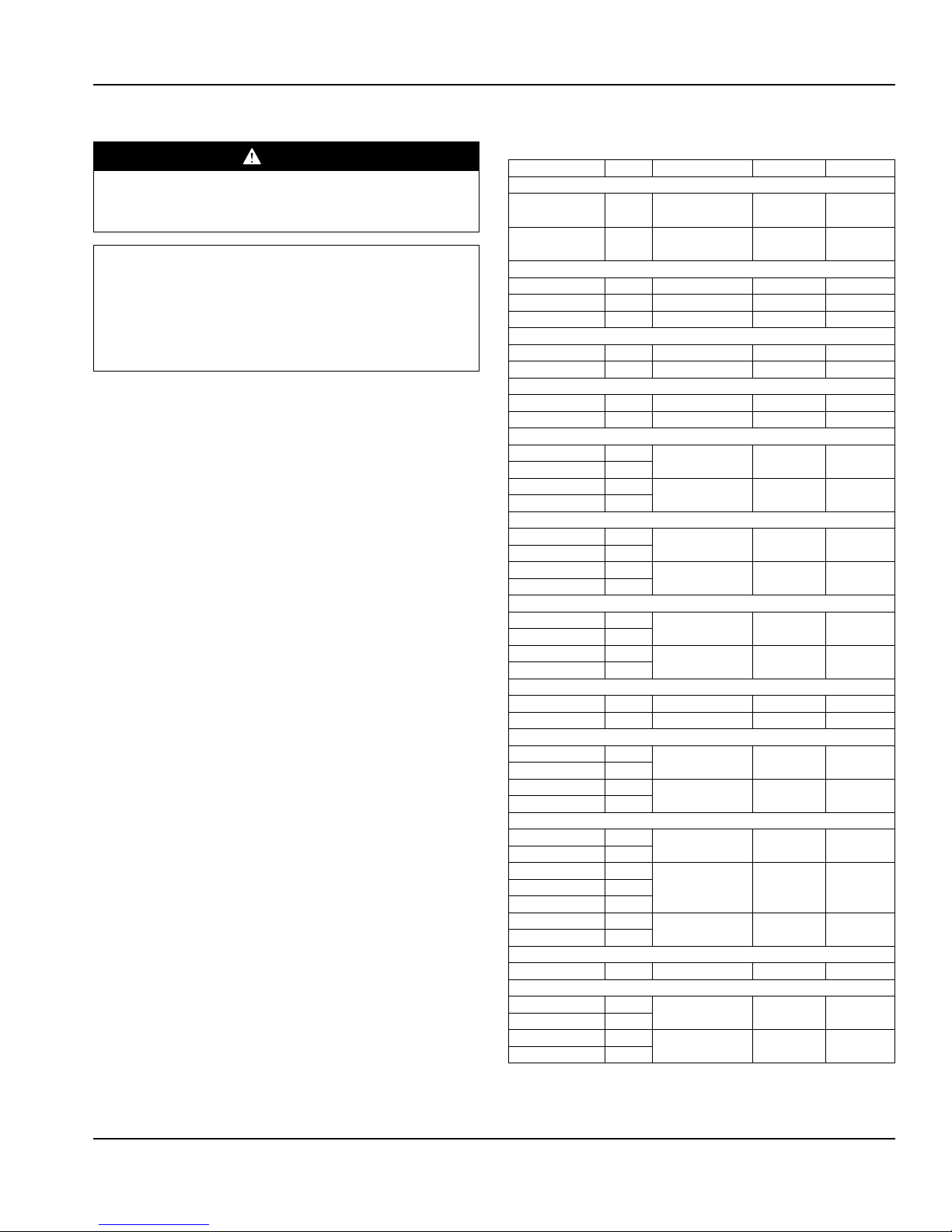

ELECTRICAL SPECIFICATION CHART

Maximum 10ft (3m) cord with plug.

Model Amps V, Hz, Ph H.P. Nema Plug

Reach-In Dual Temperature

GADBR1P-SH

GADTR1P-SH

GADFL2P-S

GADRL2P-S

GAF1P-S(H) 7.2 115, 60, 1 0.55 5-15P

GAF2P-S(H) 10.0 115, 60, 1 0.68 5-15P

GAF3P-S(H) 14.7 115, 60, 1 (2X)0.55 5-20P

GAFPT1P-S(H) 10.0 115, 60, 1 0.55 5-15P

GAFPT2P-S(H) 14.6 115, 60, 1 (2X)0.55 5-20P

GAFRI1P-S 10.0 115, 60, 1 0.68 5-15P

GAFRI2P-S 14.6 115, 60, 1 (2X)0.55 5-20P

GAH1-G(H) 6.0

GAH1-S(H) 6.0

GAH2-G(H) 10.5

GAH2-S(H) 10.5

GAHPT1-G(H) 6.0

GAHPT1-S(H) 6.0

GAHPT2-G(H) 10.5

GAHPT2-S(H) 10.5

GAHRI1-G 6.0

GAHRI1-S 6.0

GAHRI2-G 10.5

GAHRI2-S 10.5

GAHRT1-S 6.0 208-240, 60, 1 NA 6-20P

GAHRT2-S 10.5 208-240, 60, 1 NA 6-20P

GAR1NP-G(H) 4.2

GAR1NP-S(H) 4.2

GAR2NP-G(H) 6.0

GAR2NP-S(H) 6.0

GAR1P-G(H) 4.2

GAR1P-S(H) 4.2

GAR2P-G(H) 6.0

GAR2P-S(H) 6.0

GAR3P-G(H) 6.5

GAR3P-S(H) 6.5

GARFF1P-D 4.2 115, 60, 1 0.22 5-15P

GARPT1P-G(H) 4.5

GARPT1P-S(H) 4.5

GARPT2P-G(H) 6.2

GARPT2P-S(H) 6.2

5.8 115, 60, 1

11.4 115, 60, 1

Reach-In Freezer

Pass-Thru Freezer

Roll-In Freezer

Reach-In Heated

208-240, 60, 1 NA 6-20P

208-240, 60, 1 NA 6-20P

Pass-Thru Heated

208-240, 60, 1 NA 6-20P

208-240, 60, 1 NA 6-20P

Roll-In Heated

208-240, 60, 1 NA 6-20P

208-240, 60, 1 NA 6-20P

Roll-Thru Heated

Narrow Reach-In Refrigerator

115, 60, 1 0.22 5-15P

115, 60, 1 0.33 5-15P

Reach-In Refrigerator

115, 60, 1 0.22 5-15P

115, 60, 1 0.33 5-15PGAR2P-GL 6.0

115, 60, 1 0.355 5-15P

Reach-In Fishfile

Pass-Thru Refrigerator

115, 60, 1 0.22 5-15P

115, 60, 1 0.33 5-15P

Ref. 0.20

Frzr. 0.315

Ref. 0.22

Frzr. 0.55

5-15P

5-15P

Part Number GA_SM 08/18 9

Page 10

Installation Section 2

Model Amps V, Hz, Ph H.P. Nema Plug

Roll-In Refrigerator

GARRI1P-G 4.5

GARRI1P-S 4.5

GARRI2P-G 6.2

GARRI2P-S 6.2

GARRT1P-S 4.5 115, 60, 1 0.33 5-15P

GARRT2P-S 6.2 115, 60, 1 0.355 5-15P

115, 60, 1 0.33 5-15P

115, 60, 1 0.355 5-15P

Roll-Thru Refrigerator

ENERGY USE

Model Energy Use in kWh Energy Star® Certified

Reach-In Dual Temperature

GADBR1P-SH

GADTR1P-SH

GADFL2P-S

GADRL2P-S

GAF1P-S 5.863

GAF1P-SH 5.59

GAF2P-S 10.65

GAF2P-SH 9.69

GAF3P-S 10.50

GAF3P-SH 12.20

GAFPT1P-S 5.1112

GAFPT1P-SH 5.2623

GAFPT2P-S 9.337

GAFPT2P-SH 11.3327

GAFRI1P-S 7.6144

GAFRI2P-S 14.3393

GAH1-G 159.3144

GAH1-GH 183.6433

GAH1-S 141.1322

GAH1-SH 145.0789

GAH2-G 302.5585

GAH2-GH 299.055

GAH2-S 245.5875

GAH2-SH 233.8808

GAHPT1-G 228.636

GAHPT1-GH 234.906

GAHPT1-S 171.9222

GAHPT1-SH 192.0701

GAHPT2-G 421.2567

GAHPT2-GH 408.354

GAHPT2-S 290.2969

GAHPT2-SH 300.2424

GAHRI1-G 308.6124

GAHRI1-S 241.5638

GAHRI2-G 560.6883

GAHRI2-S 427.798

4.2576

4.87025

Reach-In Freezer

Pass-Thru Freezer

Roll-In Freezer

Reach-In Heated

Pass-Thru Heated

Roll-In Heated

Model Energy Use in kWh Energy Star® Certified

Roll-Thru Heated

GAHRT1-S 295.3889

GAHRT2-S 504.6286

Narrow Reach-In Refrigerator

GAR1NP-G 1.9248

GAR1NP-GH 1.9848

GAR1NP-S 1.8296

GAR1NP-SH 1.7665

GAR2NP-G 2.5934

GAR2NP-GH 2.3738

GAR2NP-S 2.1157

GAR2NP-SH 2.0552

Reach-In Refrigerator

GAR1P-G 2.08

GAR1P-GH 1.66

GAR1P-S 1.85

GAR1P-SH 1.70

GAR2P-G 3.18

GAR2P-GH 2.91

GAR2P-GL 3.18

GAR2P-S 2.71

GAR2P-SH 2.49

GAR3P-G 4.92

GAR3P-GH 4.55

GAR3P-S 3.59

GAR3P-SH 3.54

Reach-In Fishfile

GARFF1P-D

Pass-Thru Refrigerator

GARPT1P-G 2.4461

GARPT1P-GH 2.4620

GARPT1P-S 1.7873

GARPT1P-SH 1.9876

GARPT2P-G 3.6743

GARPT2P-GH 3.5395

GARPT2P-S 2.3019

GARPT2P-SH 2.4898

Roll-In Refrigerator

GARRI1P-G 2.7366

GARRI1P-S 2.2998

GARRI2P-G 5.1789

GARRI2P-S 5.1258

Roll-Thru Refrigerator

GARRT1P-S 2.4859

GARRT2P-S 4.6395

10 Part Number GA_SM 08/18

Page 11

Section 2 Installation

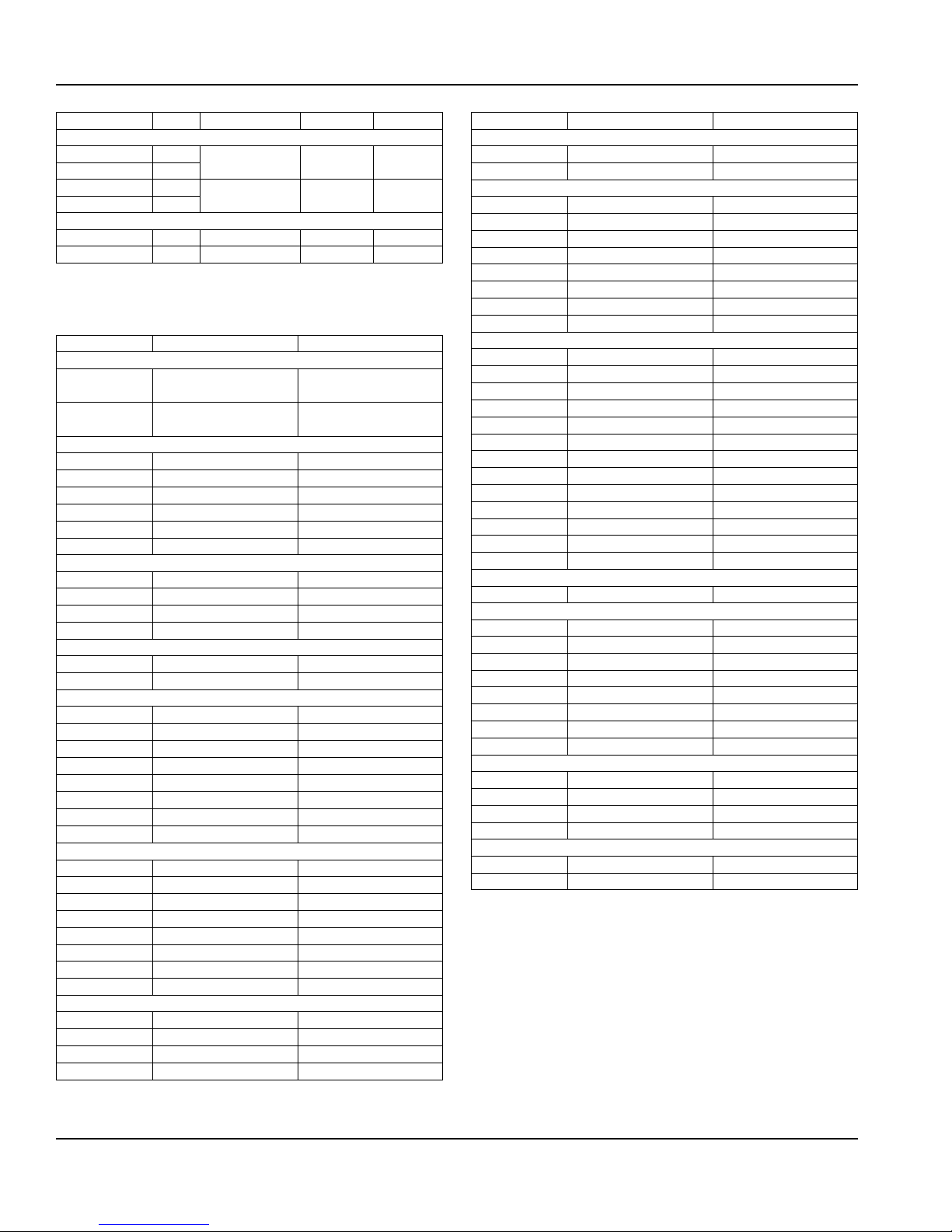

Refrigeration

Model Heat of

Rejection (BTU)

Reach-In Dual Temperature

GADBR1P-SH

GADTR1P-SH

GADFL2P-S

GADRL2P-S

GAF1P-S(H) 790 2035 93g

GAF2P-S(H) 1380 2485 109g

GAF3P-S(H) 1800 4070 (2X)110g

GAFPT1P-S(H) 930 2035 93g

GAFPT2P-S(H) 1630 4070 (2X)110g

GAFRI1P-S 1401 2261 109g

GAFRI2P-S 2458 4523 (2X)110g

GAR1NP-G(H) 540 1860 113g

GAR1NP-S(H) 390 1860 113g

GAR2NP-G(H) 890 2470 113g

GAR2NP-S(H) 590 2470 113g

GAR1P-G(H) 570 1920 113g

GAR1P-S(H) 420 1920 113g

GAR2P-G(H) 930 2540 113g

GAR2P-GL 1606 3370 113g

GAR2P-S(H) 620 2540 113g

GAR3P-G(H) 1400 3865 118g

GAR3P-S(H) 940 3865 118g

GARFF1P-D 570 1920 113g

GARPT1P-G(H) 690 1860 113g

GARPT1P-S(H) 460 1860 113g

GARPT2P-G(H) 1260 3760 113g

GARPT2P-S(H) 800 3760 113g

GARRI1P-G 800 2470 113g

GARRI1P-S 680 2470 113g

GARRI2P-G 1460 3760 118g

GARRI2P-S 1230 3760 118g

GARRT1P-S 830 2470 113g

GARRT2P-S 1530 3760 118g

Ref. 232

Frzr. 401

Ref. 420

Frzr. 790

Reach-In Freezer

Pass-Thru Freezer

Roll-In Freezer

Narrow Reach-In Refrigerator

Reach-In Refrigerator

Reach-In Fishfile

Pass-Thru Refrigerator

Roll-In Refrigerator

Roll-Thru Refrigerator

BTU/Hour

Capacity

Ref. 1431

Frzr. 1094

Ref. 1920

Frzr. 2035

R290

Charge

Ref. 78g

Frzr. 62g

Ref. 113g

Frzr. 93g

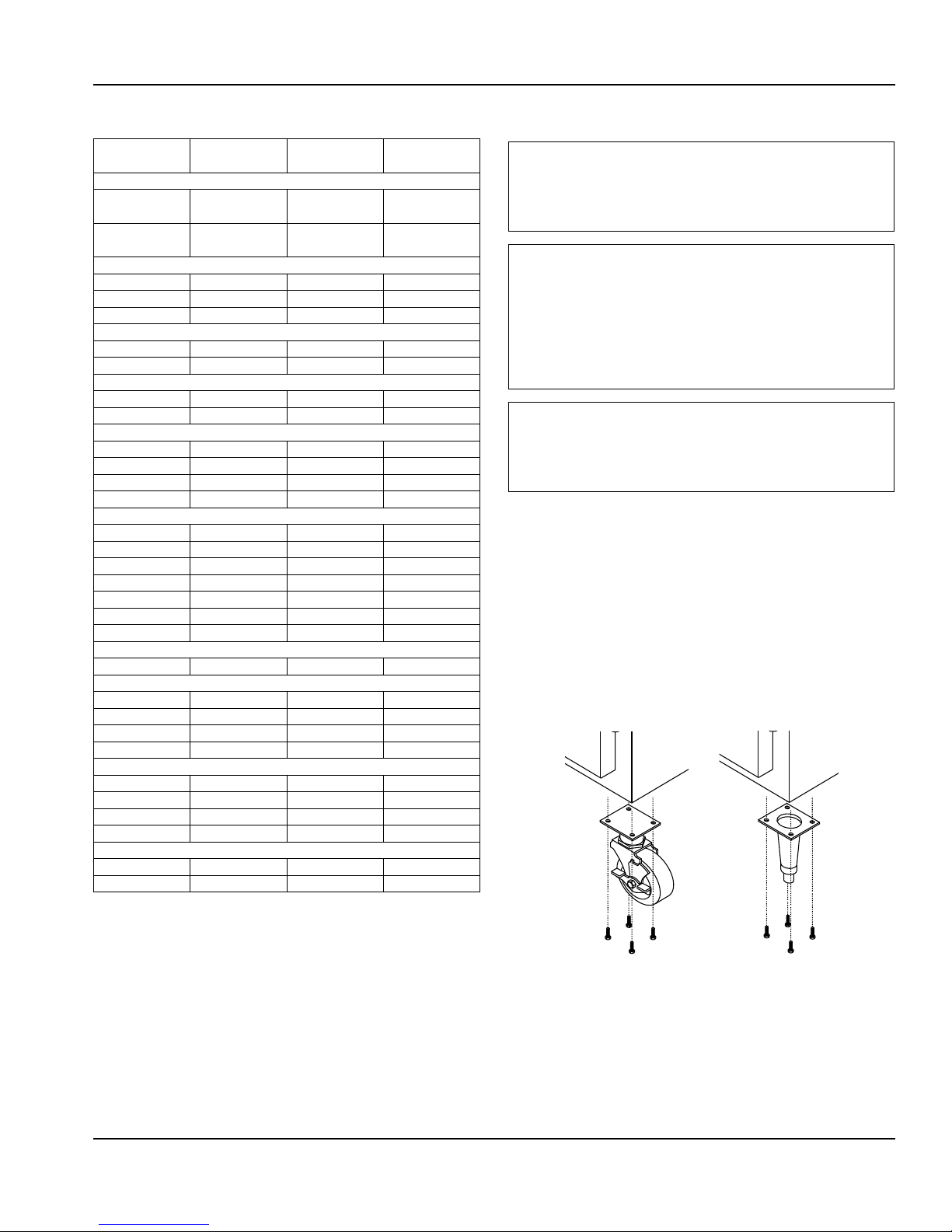

Leg & Caster Installation

Warning

n

The unit must be installed in a stable condition with

the front wheels locked. Locking the front casters after

installation is the owner’s and operator’s responsibility.

Warning

n

Use a jack to lift the refrigeration unit off the ground

just far enough to remove the leg/caster. Place blocking

underneath the unit. Do not work underneath a raised

unit without proper blocking. Do not lift the unit more

than necessary to remove the leg/caster. Lifting the unit

too far can make the unit unstable.

Caution

,

All single-section units require that the swivel casters be

mounted on the front and rigid casters be mounted on

the rear.

To install the legs or casters:

1. Remove unit from skid.

NOTE: The bolts used to hold the unit to the skid should

be re-used as the fourth hex head bolt for each caster or

leg plate installation. The bolt should not measure over

2” (5cm) in length.

2. Raise unit to access leg/caster mounting holes on

bottom of unit.

3. Attach the legs or casters to bottom of cabinet using hex

head bolts.

Part Number GA_SM 08/18 11

Page 12

Installation Section 2

Level & Stable

After the cabinet has been placed in the desired location,

cabinets must be leveled. Level units from front to back and

from side to side. Leveling will insure proper door operation

and removal of condensate.

• It is very important that all legs are properly adjusted to

keep the cabinet level, evenly distribute the weight and

to make sure the unit will not rock, lean or be unstable.

• Cabinets with casters must have the caster brake set so

the cabinet cannot move. Shim casters if necessary to

level unit.

• Roll-In and roll-thru units must also be level. Shim the

bottom of the unit if necessary. See Roll-In & Roll-Thru

Installation on page 13.

• Adjust doors and hinges until doors close properly.

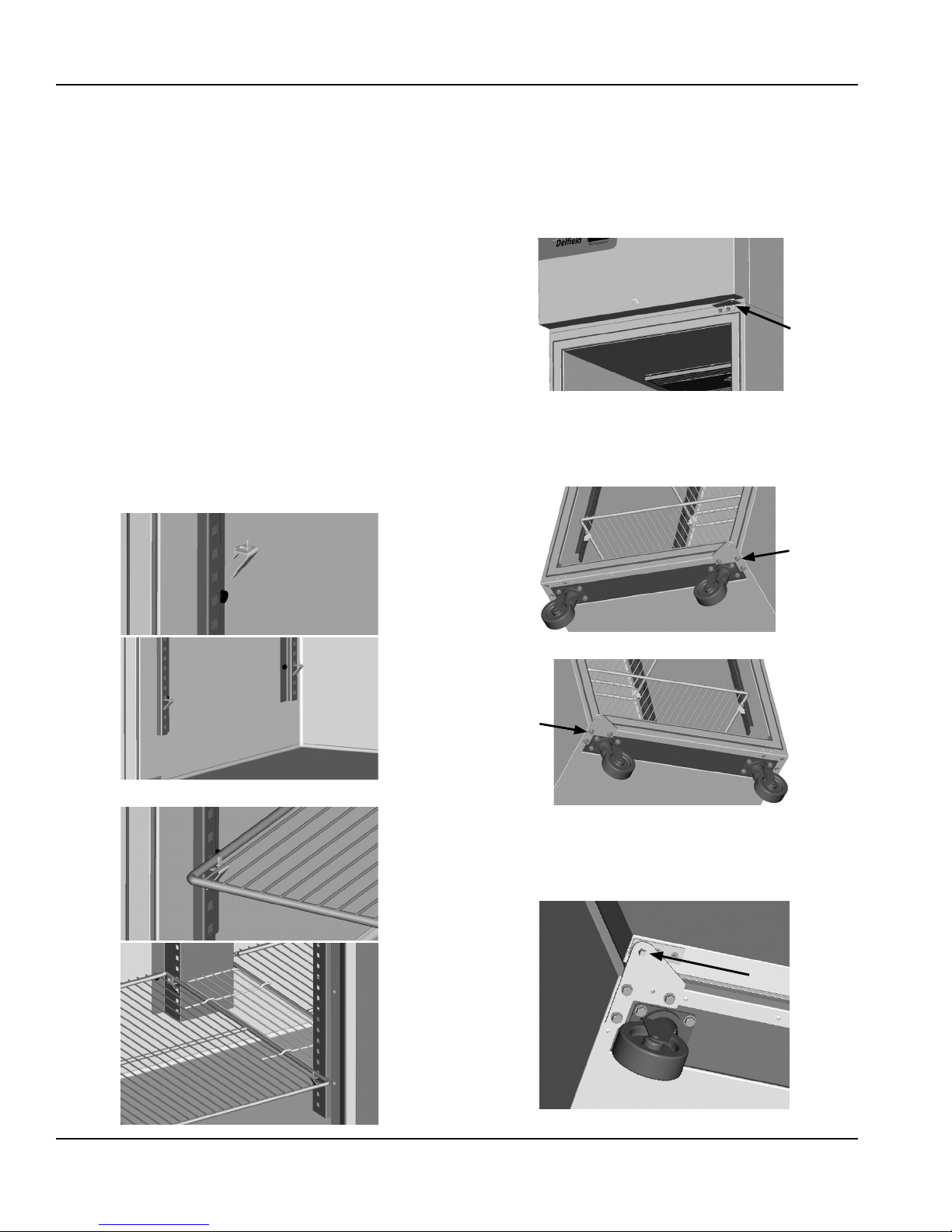

Shelf Installation

1. Insert the clips into the pilaster holes at the desired shelf

heights.

Reversible Door Instructions

APPLICABLE TO FULL DOOR MODELS

1. Open the door.

2. Remove two bolts securing the hinge bracket above the

door.

3. Lift the door up and out.

4. Save the hinge bracket.

5. Remove three bolts securing the hinge bracket to the

bottom of the unit.

2. Set the shelves on the clips.

6. Flip it over and install it on the opposite side.

7. Rotate the door 180°.

8. Move the white nylon washer from the top hinge pin to

the bottom hinge pin.

9. Insert the bottom hinge pin into the hinge bracket.

12 Part Number GA_SM 08/18

Page 13

Section 2 Installation

10. Locate the provided alternate top hinge bracket.

11. Place the hinge bracket over the top hinge pin.

12. Open the door.

13. Using the original screws install the hinge bracket on the

new side in the vacant lock holes.

14. Check for proper closure and gasket seal.

15. Adjust hinges as needed.

Roll-In & Roll-Thru Installation

NOTE: Local area codes may dictate other installation

requirements not mentioned.

1. Verify unit is level with 4’ Level. Shim as needed.

Depending on the height of the shims, stainless trim may

be needed to fill in a large gap between the unit and the

floor.

2. Remove door sweep before making door adjustments.

3. Adjust doors hinges so door closes by itself.

• A properly adjusted door will close and seal when the

door is held open 3” or less with no assistance.

4. Reinstall door sweep. It may need to be reinstalled in

new holes so that it does not interfere with the door

closing.

• If it is too tight to ramp it will hold door open.

• Make sure sweep is just touching ramp when closed.

Door

Sweep just touching

ramp

Ramp

Unit

5. Verify once again that the door will close and seal when

held open 3” or less.

6. If this is a multi-section unit make sure door stays shut

or closes by itself when other doors are shut.

7. Using silicone, seal the ramp to the floor; seal the unit to

the floor and walls. The silicone will make sure that no

water can get under the unit or ramps.

If shims and stainless trim are added they also need to

be sealed to the unit and the floor.

Part Number GA_SM 08/18 13

Page 14

Installation Section 2

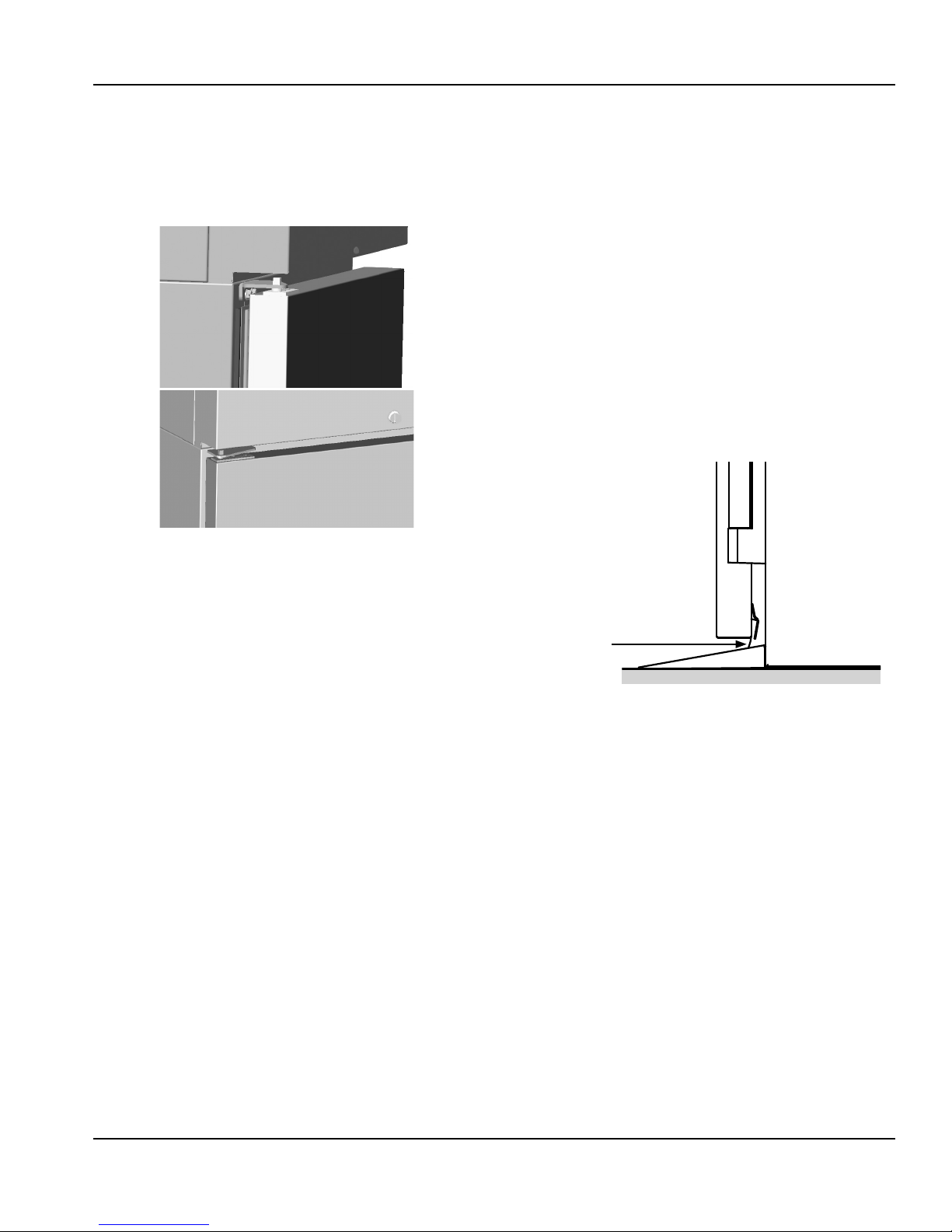

New Hinge Cartridge Installation

• Full doors have a cartridge hinge on both the bottom and

top of the door.

• Half doors only have one cartridge hinge, the bottom

hinge of the bottom half door and the top hinge of the

top half door.

1. Install the new cartridge into the door as received. The

new cartridge will be in the CLOSED position.

2. As you unload the hinge tension be careful to hold on

tight because you should feel the strong spring tension

as you rotate the hinge. Place the hinge bracket on the

square hinge pin and rotate it ½ turn to the outside of

the door.

Accessory Interior Drawer Installation

1. Accessory drawer installation requires two tracks and a

drawer.

2. Hang the drawer tracks on the pilaster strips across from

each other. Verify the tracks are lined up evenly.

3. After the hinge has been rotated, it will now be in the

OPEN position and NOT under spring tension.

4. Mount the door back onto the cabinet with the door

OPEN. The door should now close properly.

5. Begin closing the door, the door should finish closing

on it’s own. If the door stays open remove the door and

hinge bracket.

6. Using the hinge bracket rotate the square peg on the

cartridge until you feel tension and resistance if you

move the hinge in either direction. The hinge is now in

the CLOSED position. Repeat instructions starting with

step 2.

3. Slide the drawer box into the tracks slowly.

When the drawer box is half way in it will hit a STOP.

Lift the front of the drawer up slightly to continue.

14 Part Number GA_SM 08/18

Page 15

Section 2 Installation

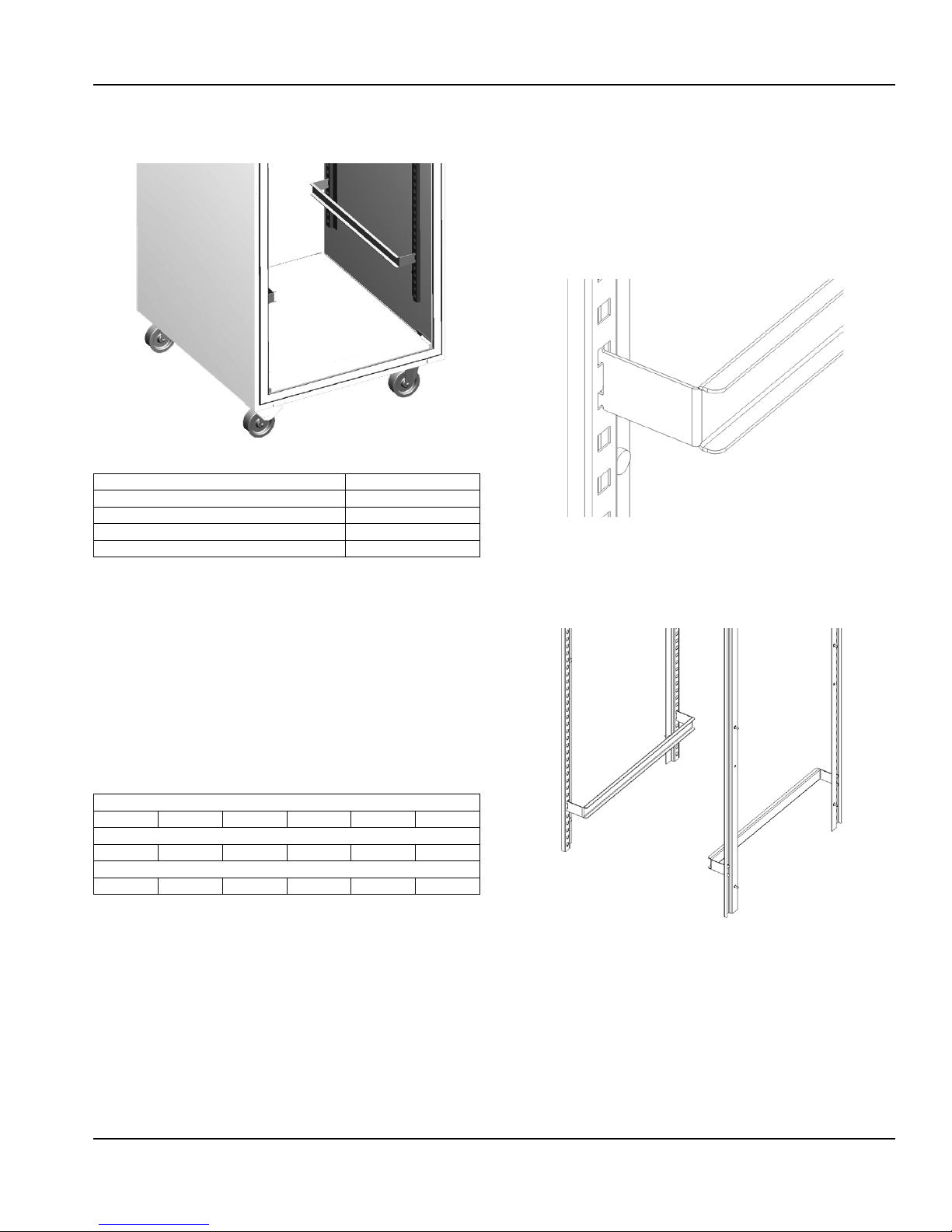

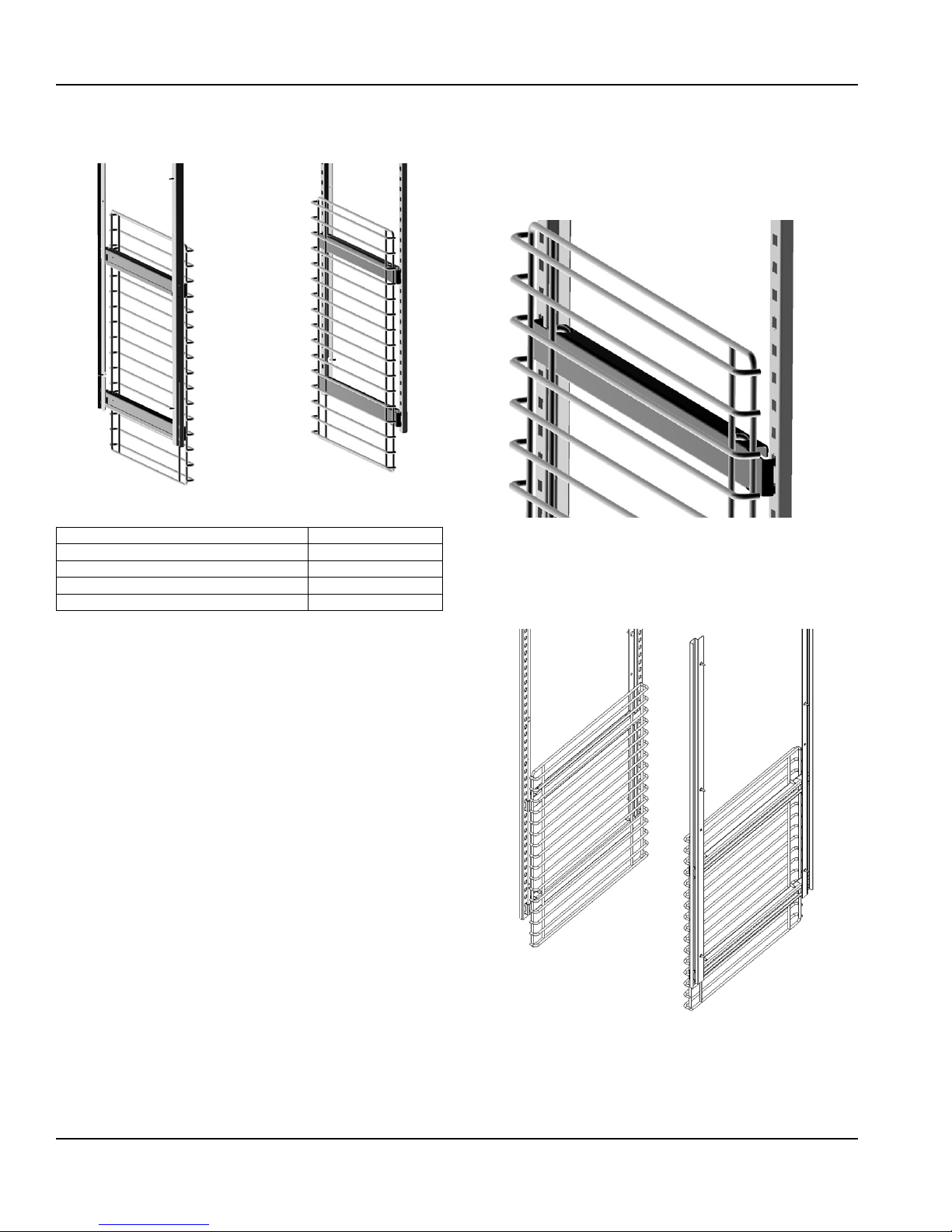

T-1 Tray Slide Installation

Edge Support for 18” x 26” pans

Installed T-1 Tray Slide for 18”x 26” Pans

System Name T-1

Slide Style Tray

Support Style Edge

Compatible with 12” x 20” Pans No

Compatible with 18” x 26” Pans Yes

• The T-1 tray slide system is designed to support 18” x 26”

pans by the edge of the pan.

• The slides are shaped as a C channel.

• Each set of tray slides is mounted at the same height

across a door section.

• For each pan, one set of two (2) tray slides is used. The

exception is 1.5” spacing.

• For 1.5” spacing, the tray slides are mounted every 3”

and the top and bottom of each tray slide is used to hold

a pan.

Centerline Spacing

1.5” 2.0” 3.0” 4.0” 5.0” 6.0”

Maximum Tray Slides for a Full Section

15 23 15 12 9 8

Maximum Tray Slides for a Half Section (Top or Bottom)

7 10 7 5 4 4

T-1 Installation Instructions

1. For each pan, mount a pair of tray slides; one on each

side of the door section at the same height. Mount the

tray slides onto the pilasters by sliding the tray slide

tabs down into the cutouts. Make sure that all tabs are

engaged securely to each pilaster.

NOTE: A dead-blow hammer is recommended to seat the tab

into the cutouts.

Pilaster

Slider

2. Verify that all tray slides are lined up evenly.

NOTE: An easy check to verify correct installation is to slide

an 18” x 26” pan onto each slide. If the pan is held securely,

and is level inside the door section, the installation has been

successful.

Part Number GA_SM 08/18 15

Page 16

Installation Section 2

T-2 Tray Slide Installation

Universal Bottom Support for 12” x 20” and 18” x 26” pans

T-2 Tray Slide System

T-2 Installation Instructions

1. For each pan, two (2) tray slides will be used. Each tray

slide must have another tray slide at the same height,

Installed T-2 tray slide with both size pans

System Name T-2

Slide Style Tray

Support Style Bottom

Compatible with 12” x 20” Pans Yes

Compatible with 18” x 26” Pans Yes

on the opposite side of the door section. Mount the tray

slides onto the pilasters by sliding the tabs down into

the pilaster cutouts. Make sure that all tabs are engaged

securely to each pilaster.

NOTE: A dead-blow hammer is recommended to seat the tab

into the cutouts.

• The T-2 (Universal) tray slide system is designed to

support both 12” x 20” and 18” x 26” pans by the

bottom.

• The tray slide is an L shaped piece of formed stainless

steel.

• Each set of tray slides is mounted at the same height

across a door section.

• For each pan, one set of two (2) tray slides is used.

Centerline Spacing

2.0” 3.0” 4.0” 5.0” 6.0”

Maximum Tray Slides for a Full Section

23 15 12 9 8

Maximum Tray Slides for a Half Section (Top or Bottom)

10 7 5 4 4

Pilaster

Slider

2. Verify that all tray slides are lined up evenly.

NOTE: An easy check to verify correct installation is to slide

a pan onto each slide. If the pan is held securely, and is level

inside the door section, the installation has been successful.

16 Part Number GA_SM 08/18

Page 17

Section 2 Installation

T-3 Tray Slide Installation

Edge Support for 12” x 20” pans

T-3 Tray Slide for 12”x 20” pans

System Name T-3

Slide Style Tray

Support Style Edge

Compatible with 12” x 20” Pans Yes

Compatible with 18” x 26” Pans No

• The T-3 tray slide system is designed to support 12” x 20”

pans by the edge of the pan.

• The slides are shaped as a C channel.

• Each set of tray slides is mounted at the same height

across a door section.

• For each pan, one set of two (2) tray slides is used.

Centerline Spacing

3.0” 4.0” 5.0” 6.0”

Maximum Tray Slides for a Full Section

17 12 9 7

Maximum Tray Slides for a Half Section (Top)

6 5 4 3

Maximum Tray Slides for a Half Section (Bottom)

8 6 5 4

T-3 Installation Instructions

1. For each pan, two (2) tray slides will be used. Each tray

slide must have another tray slide at the same height,

on the opposite side of the door section. Mount the tray

slides onto the pilasters by sliding the tabs down into

the pilaster cutouts. Make sure that all tabs are engaged

securely to each pilaster.

NOTE: A dead-blow hammer is recommended to seat the tab

into the cutouts.

Pilaster

Slider

2. Verify that all tray slides are lined up evenly.

NOTE: An easy check to verify correct installation is to slide a

pan of the appropriate size into each slide. If the pan is held

securely, and is level inside the door section, the installation

has been successful.

Part Number GA_SM 08/18 17

Page 18

Installation Section 2

T-4 Rack Slide Installation

Edge Support for 18” x 26” pans

Installed T-4 Tray Slide for 18”x 26” pan

System Name T-4

Slide Style Rack

Support Style Edge

Compatible with 12” x 20” Pans No

Compatible with 18” x 26” Pans Yes

3. Repeat steps 1-2 on the opposite side. Verify that all

mounting plates are lined up across the door section.

4. For a full section installation, repeat steps 1-3 for the

upper half.

5. Place each rack on two (2) mounting plates.

Pilaster

Rack

Mounting Plate

6. Verify that all tray slides are lined up evenly.

NOTE: An easy check to verify correct installation is to slide a

pan of the appropriate size into each slide. If the pan is held

securely, and is level inside the door section, the installation

has been successful.

• The T-4 rack slide system is designed to support 18” x 26”

pans by the edge of the pan.

• The T-4 rack slide system consists mounting plates for

each side, and a set of racks.

• The racks are formed of heavy gauge metal wire.

• Each set of rack slides is mounted at the same height

across a door section.

• Each rack uses two (2) mounting plates.

T-4 Installation Instructions

1. Start assembling the mounting plates at the bottom of

the door section. Place a bottom mounting plate so that

each set of tabs engages a cutout on the pilaster. Push

the mounting plate down to secure the plate to the

cutouts.

NOTE: A dead-blow hammer is recommended to seat the tab

into the cutouts.

2. On the same side place a top mounting plate with the

bottom edge 20” (51cm) above the top of the lower

mounting plate.

18 Part Number GA_SM 08/18

Page 19

Section 2 Installation

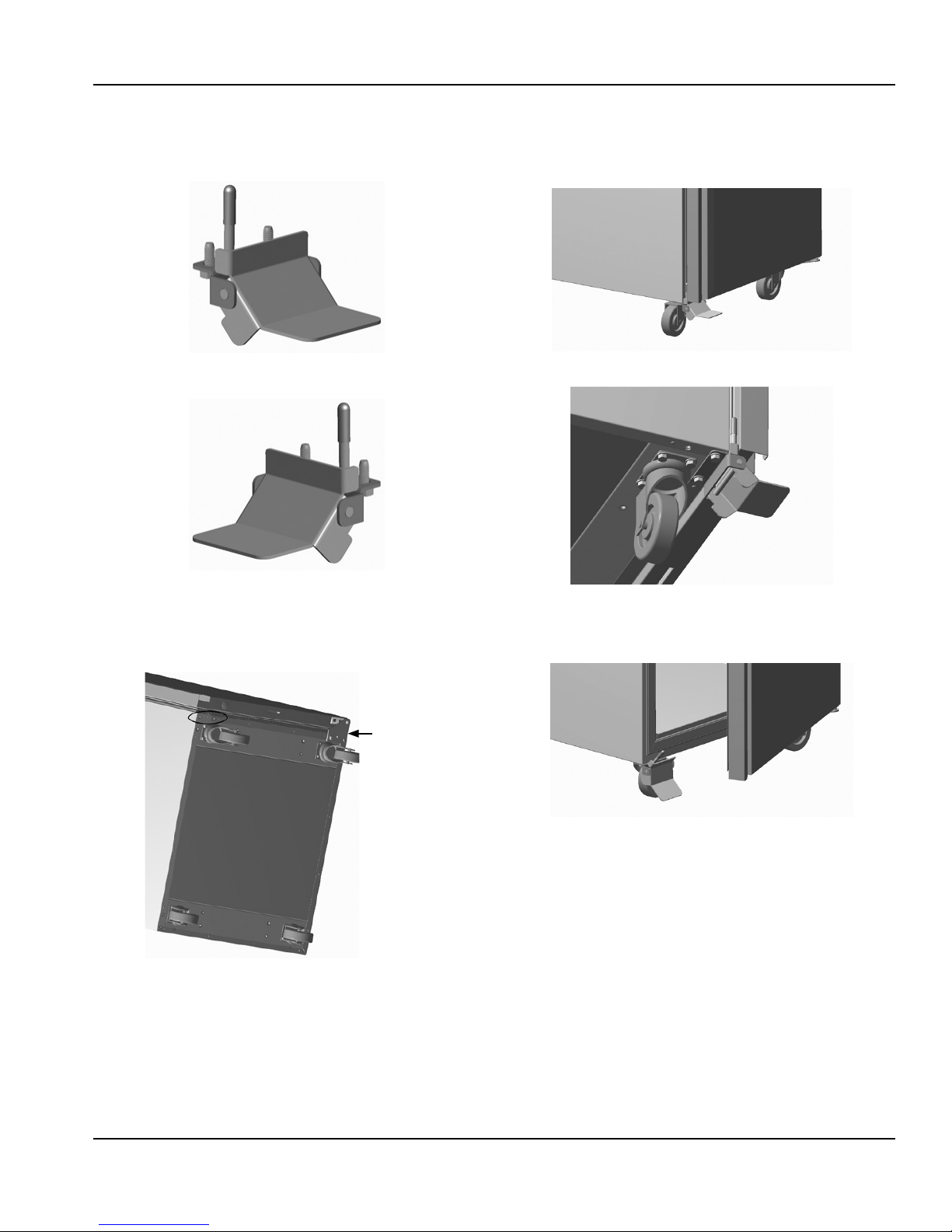

Optional Foot Pedal Installation Instructions

• If the optional foot pedal is ordered for a right hinged

door, ensure part # 000-D10-0031 is received.

• If the optional foot pedal is ordered for a left hinged

door, ensure part # 000-D10-0030 is received.

2. Mount foot pedal door assist with (2) 5/16-18 bolts that

are provided, use ½” socket or wrench. Foot pedal plate

should be facing forward and parallel to the floor when

door is closed.

Front View

1. Locate foot pedal placement. Placement is on the

bottom of the cabinet, opposite of the bottom flat door

hinge bracket.

Front of unit

Bottom flat

door hinge

bracket

Bottom Side View

3. Step down on top of foot pedal plate and door will swing

open.

Foot Pedal When Door Is Open

Part Number GA_SM 08/18 19

Page 20

Installation Section 2

THIS PAGE INTENTIONALLY LEFT BLANK

20 Part Number GA_SM 08/18

Page 21

!

!

!

°

F

32

!

Section 3

Operation

DANGER

The on-site supervisor is responsible for ensuring that

operators are made aware of the inherent dangers of

operating this equipment.

DANGER

Do not operate any appliance with a damaged cord or

plug. All repairs must be performed by a qualified service

company.

DANGER

Keep power cord AWAY from HEATED surfaces. DO NOT

immerse power cord in water. DO NOT let power cord

hang over edge of table or counter.

Warning

n

Do not contact moving parts.

Warning

n

All covers and access panels must be in place and properly

secured, before operating this equipment.

Refrigerator & Freezer Operation

• Delfield refrigerators are designed to maintain an

operational temperature of 36°F to 40°F (2°C to 4°C).

• Delfield freezers are designed to maintain an operational

temperature of 0°F (-18°C).

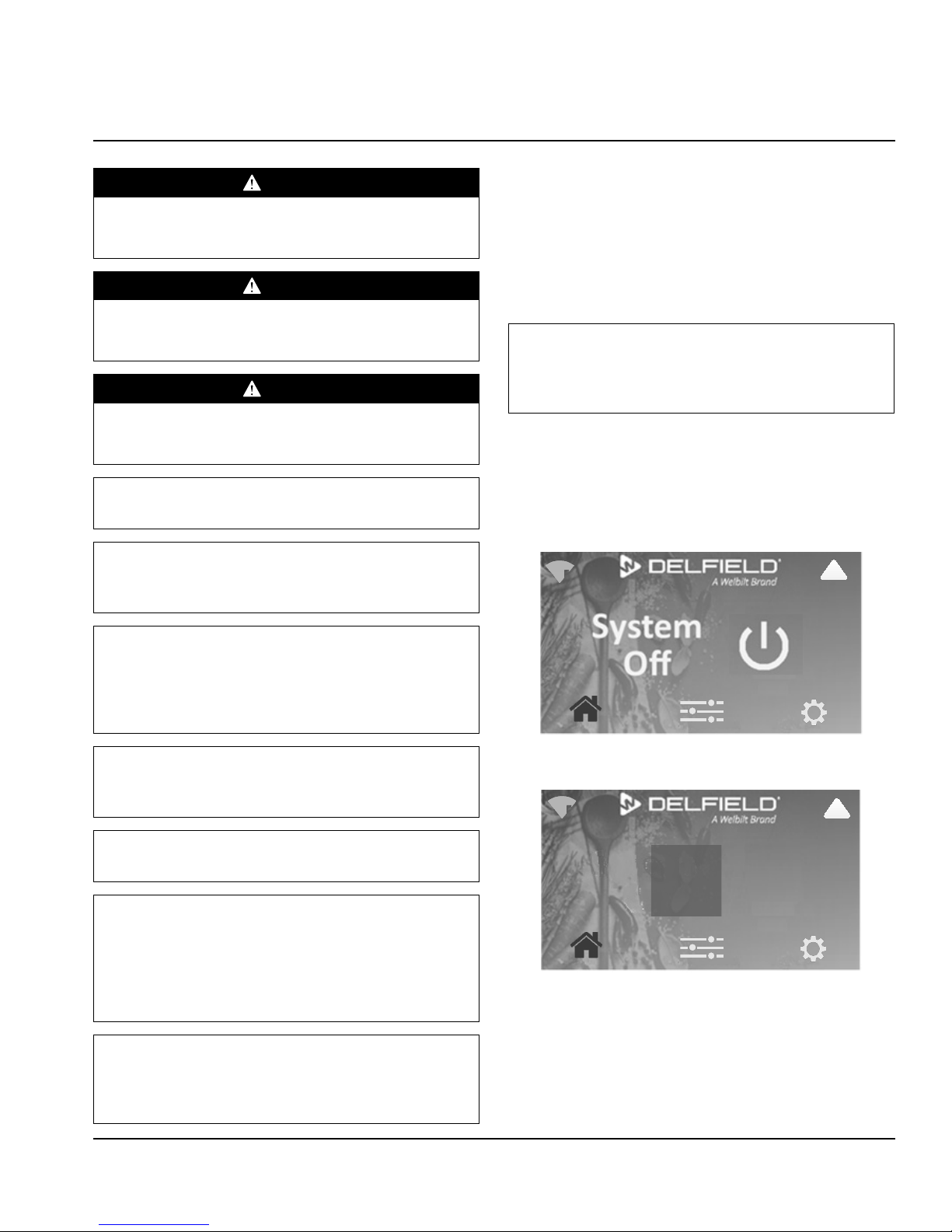

Refrigerator & Freezer Start Up

Note

Display responds to finger touch only. Do not use utensils

or other objects to operate the display. Use of these

objects could damage the display.

This also covers anytime power is disconnected then

reconnected.

1. Plug the unit in.

2. The screen will appear after a 30 second delay.

3. Select the power icon, located on the right of the screen.

Warning

n

The operator of this equipment is solely responsible

for ensuring safe holding temperature levels for all

food items. Failure to do so could result in unsafe food

products for customers.

Warning

n

Overloading shelves can damage equipment or cause

bodily injury.

Warning

n

Damp or wet hands may stick to cold surfaces.

Warning

n

Do not block the supply and return air grills or the air

space around the air grills. Keep plastic wrappings,

paper, labels, etc. from being airborne and lodging in

the grills. Failure to keep the air grills clear will result in

unsatisfactory operation of the system.

Caution

,

Do not throw items into the storage area. Failure to

heed this recommendation could result in damage to the

interior of the cabinet or to the blower coil.

4. The touchscreen will move through the following two

screens.

64

Part Number GA_SM 08/18 21

Page 22

Operation Section 3

!

!

!

°

F

32

!

!

!

!

°

F

32

!

Heated Cabinet Operation

DANGER

The unit surface is very hot! Avoid direct contact with

skin; use appropriate protective apparel, such as gloves.

Delfield heated cabinets are designed to maintain an

operational temperature of 165°F (73°C).

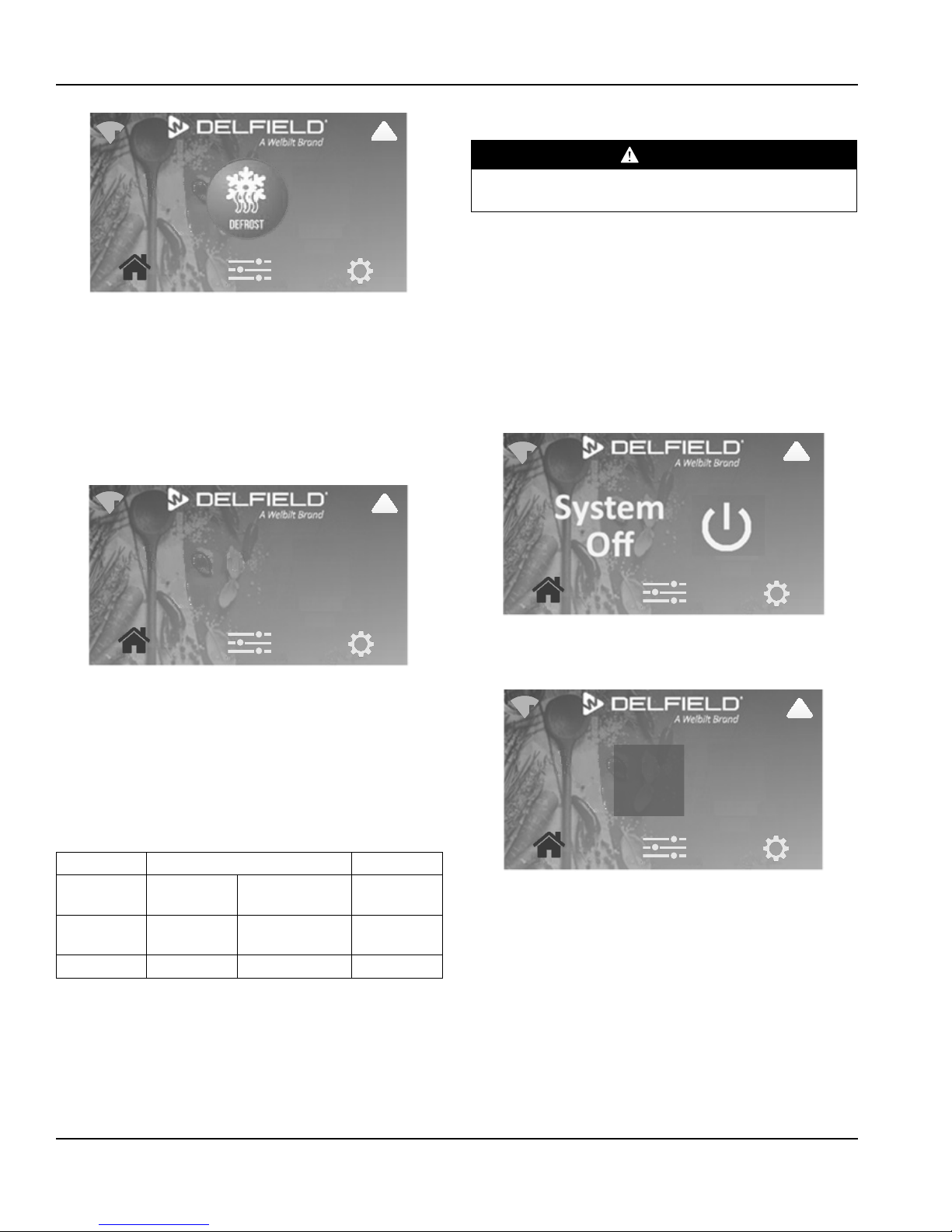

5. The unit will continue though the Defrost mode. The

compressor and condenser fan as well as the evaporator

fan will remain off until this initial defrost is complete.

This initial defrost cycle may take up to 35 minutes to

complete.

6. The defrost icon will continue on the display for an

additional 30 minutes while the cooling cycle cools the

box to the set temperature. Then the box temperature

will be displayed.

7. The temperature control will cycle the compressor,

evaporator fan motor and condenser fan motor to

maintain box temperature at the control setting.

Heated Cabinet Start Up

This also covers anytime power is disconnected then

reconnected.

1. Plug the unit in.

2. The screen will appear after a 30 second delay.

3. Select the power icon, located on the right of the screen.

4. The home screen will display. Allow unit to warm-up

before use. It may take up to two hours to reach the

desired temperature.

EVAPORATOR FAN OPERATION

During normal operation the evaporator fan may cycle and/

or pulse independently of the compressor. Consult Technical

Support at 1-844-724-CARE if you are unsure of the proper

function.

Cooling Cycle Defrost Cycle

Compressor OnCompressor Off Compressor

Off

Refrigerator Evap Fan On Cycles On 2-Min,

Off 2-Min

Freezer Evap Fan On Evap Fan Off Evap Fan Off

22 Part Number GA_SM 08/18

Evap Fan On

FAN OPERATION

When heating elements are ON, fan is ON.

When heating elements are OFF, fan cycles OFF for 2

minutes, then ON for 1 minute and repeating this cycle until

control turns heating elements back ON.

64

Page 23

Section 3 Operation

Unit Standby

Reset Factory Settings

Manual Defrost

Firmware Update

!

Unit Standby

Back

System Power

Setting system power to off will

shut down the cooling or heating

system only. Power will remain to

control.

ON

!

!

°

F

32

!

HIGH TEMPERATURE SAFETY DEVICE

An automatic reset type safety device is mounted above the

heater(s) behind the vertical air duct(s). This safety switch

will open if the temperature exceeds 220°F (105°C) in the

event of a fan failure or air duct obstruction. Whenever the

switch opens, power to the heaters is interrupted. Once

the safety switch cools sufficiently to automatically reset,

operation of the heaters will resume.

Power Down

1. From the settings screen, select Unit Standby.

2. Access to this page requires the manager password.

3. Slide over the System Power button to off.

4. Setting system power to off will shut down the cooling

or heating system only. Power will remain to control.

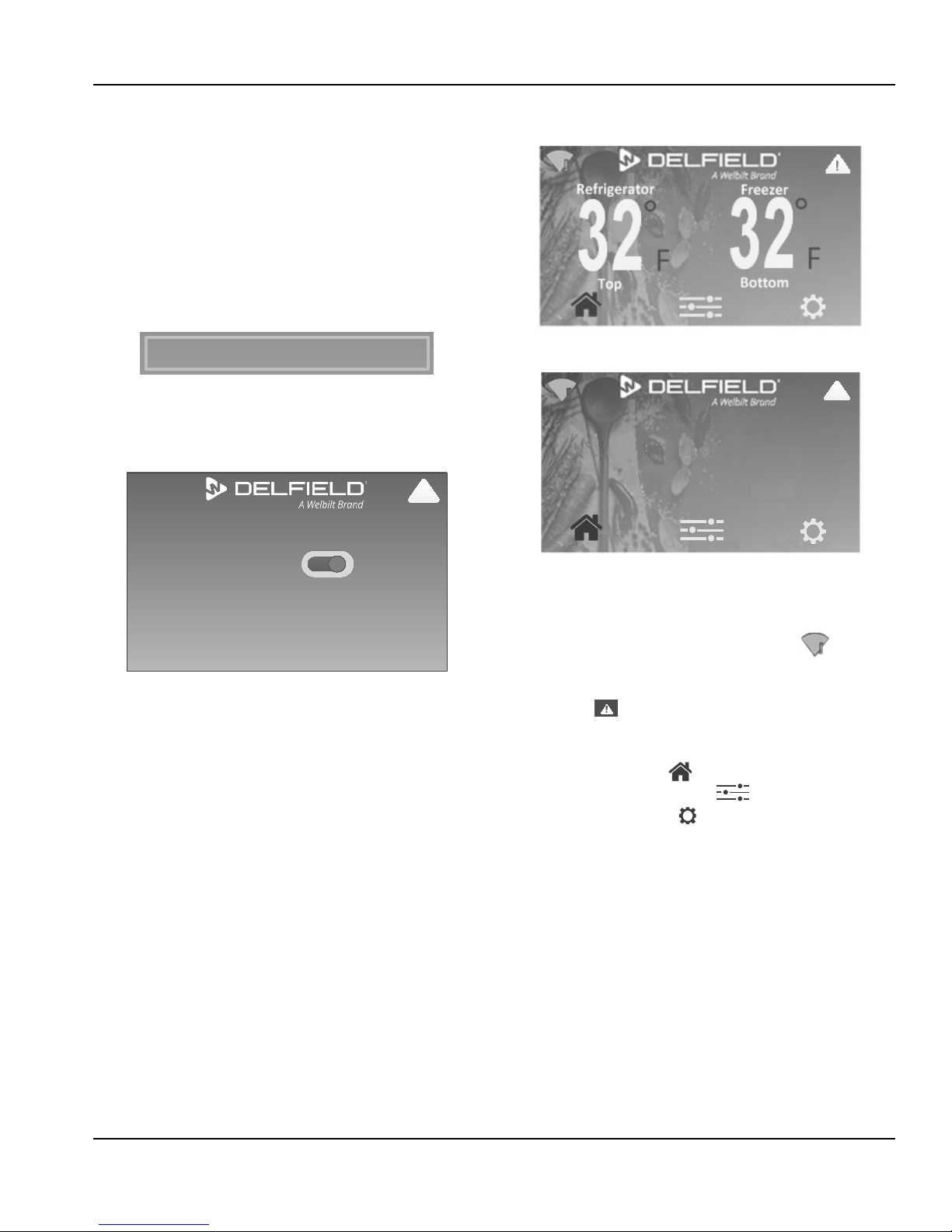

Home Screen

Dual Temperature Home Screen

Settings Screen\Unit Standby

5. If the unit is a heated cabinet, allow unit to cool down.

6. Clean equipment as discussed in the maintenance

section of this manual.

Standard Home Screen

• Home screens display:

₋ Cabinet temperature

₋ Top left features an internet status icon.

₋ Top right features an active alert icon. If there are

active alarms touching it will display the Alarm History

screen .

• At the bottom the active screen’s icon will be displayed in

blue.

₋ Home screen icon

₋ Configuration screen icon

₋ Settings screen icon

₋ Swipe to move between the screens or select the

desired screen icon

• Most function screens will timeout after 15 seconds of

inactivity and return to the home screen.

Part Number GA_SM 08/18 23

Page 24

Operation Section 3

!

!

!

---

!

!

!

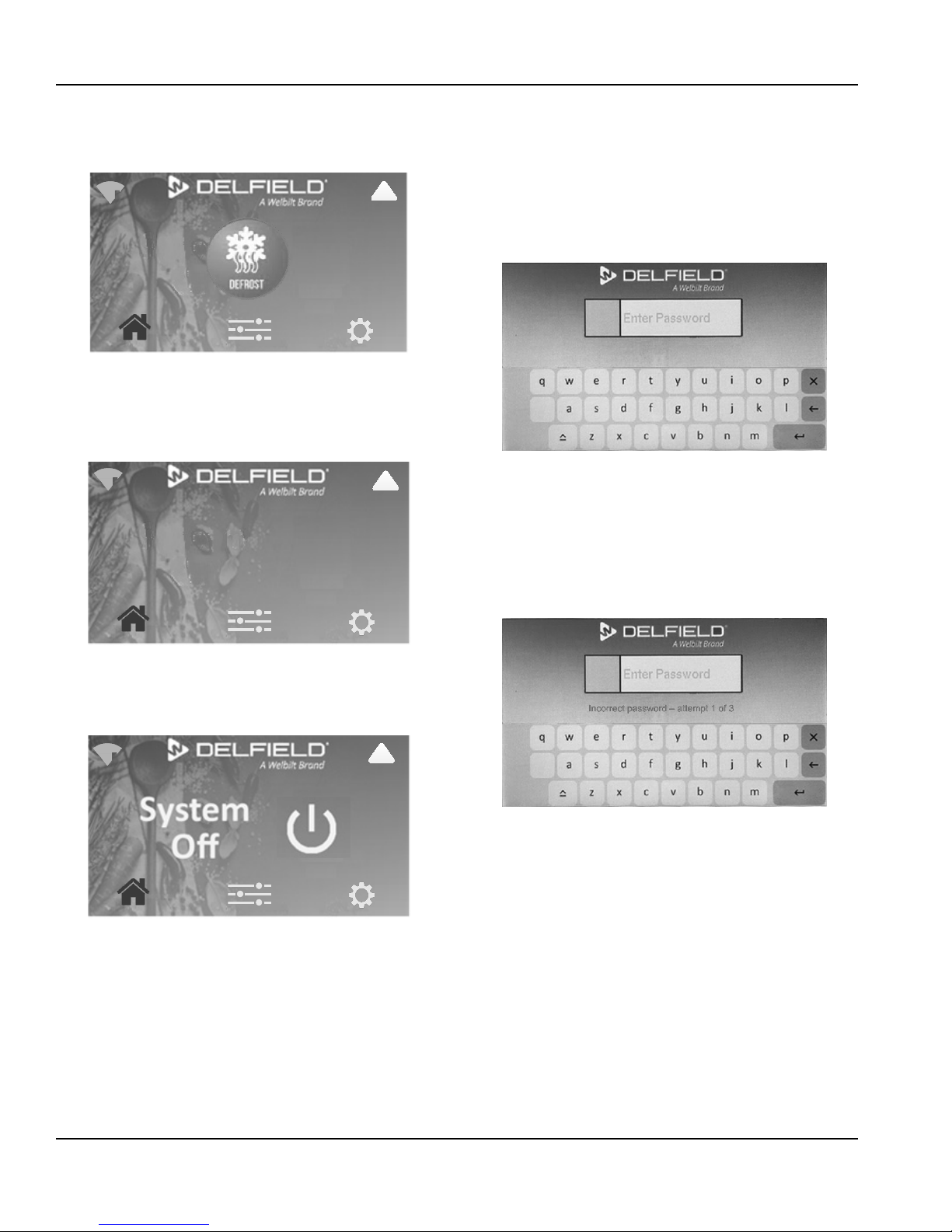

• If the unit is in defrost, the defrost icon replaces the

cabinet temperature. The defrost icon will be displayed

throughout the defrost process.

• If there is a cabinet temperature probe failure three

dashes will replace the cabinet temperature. The active

alert icon will also display. The three dashes will be

displayed as long as the temperature probe failure

continues.

TouchScreen Password

1. When a function is password protected, the password

enter screen will appear. Type in the either the manager

password or the service password.

₋ The icon ˄ in the bottom left will toggle the keyboard

between uppercase, lower case and numbers.

₋ The manager password is 211276.

2. After the correct password is entered, the display will

proceed to the password protected function.

₋ All features protected by the entered password will

remain active until the display is not active for 10

seconds. The display will return to the home screen

and the password accessed features will be locked.

3. Three attempts are allowed with incorrect passwords

then the touchscreen will return to the home screen.

• When the cabinet has been turned off and power is still

connected, the power icon will replace the temperature.

The display remains active for service functions and to

turn the cabinet back on.

24 Part Number GA_SM 08/18

Page 25

Section 3 Operation

Defrost Type

Rapid Pull DownSet Box Temperature

Units

Diagnostics

Alarm Managment

!

Interior Light

Language

Time / Date

LCD Brightness

Password

Unit Standby

Reset Factory Settings

Manual Defrost

Firmware Update

!

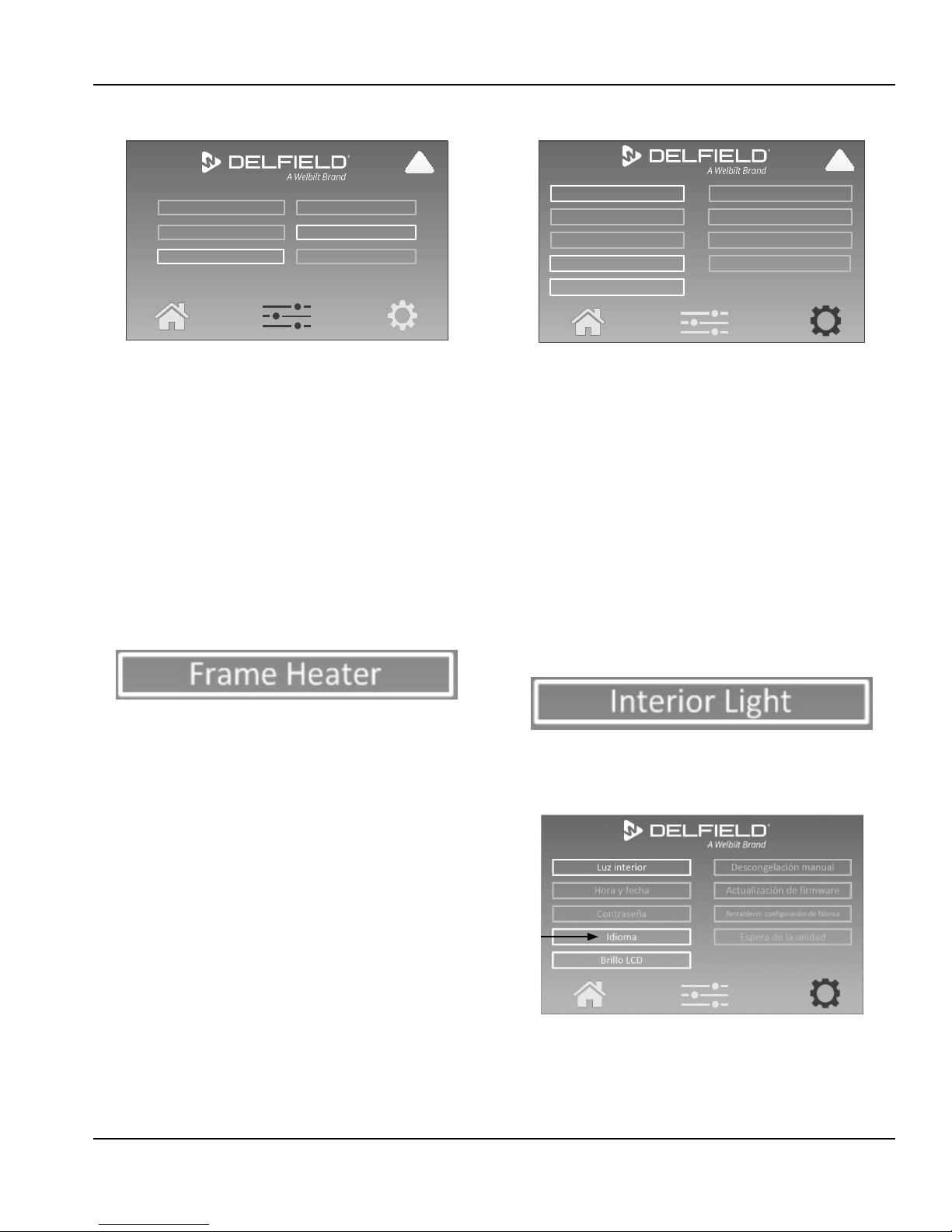

Configuration Screen

• The Configuration screen can be accessed by swiping

horizontally from the Home or any top level screen.

• From the Configuration Screen the following screens are

accessible:

₋ Frame Heater (freezer only)

₋ Rapid Pull Down (refrigerator only)

₋ Units

₋ Defrost Type (Refrigerator & Freezer)

₋ Set Box Temperature

₋ Alarm Management

₋ Diagnostics

₋ Network Connection

• Select the title frame to navigate there. The gray titles

require a password to access.

Settings Screen

• The Settings screen can be accessed by swiping

horizontally from the Home or any top level screen.

• From the Settings Screen the following screens are

accessible:

₋ Interior Light

₋ Time / Date

₋ Password

₋ Language

₋ LCD Brightness

₋ Manual Defrost (Refrigerator & Freezer)

₋ Firmware Update

₋ Reset Factory Settings

₋ Unit Standby

• Select the title frame to navigate there. The gray titles

require a password to access.

Part Number GA_SM 08/18 25

• From the settings screen, the language button remains

the fourth button down on the left regardless of

language.

Page 26

Operation Section 3

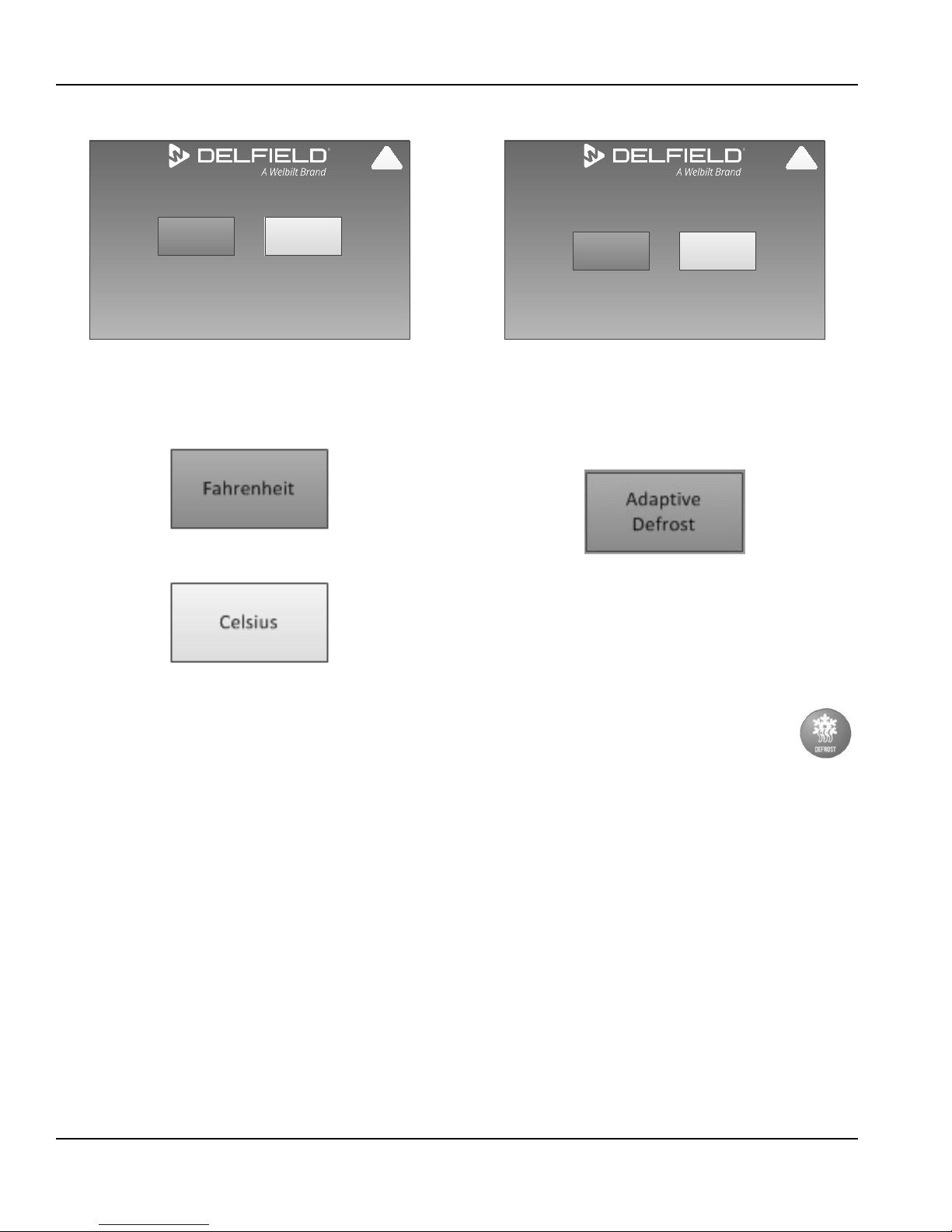

Fahrenheit/Celsius

Back

Celsius

Fahrenheit

!

Defrost Method

Back

Time of Day

Defrost

Adaptive

Defrost

!

Units

Configuration Screen\Units

• The selected mode/button will be gray.

• Selecting Fahrenheit sets the cabinet temperature units

to Fahrenheit. This is the factory default.

• Selecting Celsius sets the cabinet temperature units to

Celsius.

Defrost Type (Refrigerator & Freezer)

Configuration Screen\Defrost Type

• Access to this page requires the manager password.

• The selected mode/button will be gray.

• Selecting Adaptive Defrost activates this defrost mode.

This is the factory default.

Adaptive Defrost

The temperature control monitors the evaporator

temperature and will turn off the compressor and condenser

fan motor when needed to allow accumulated frost on the

evaporator to clear. Additionally the freezer evaporator fan

will turn off and the defrost heater will switch on to warm

the coil. During this defrost cycle, the control will display a

defrost icon. After the defrost cycle is complete,

the temperature control will return to a normal

cooling cycle, but the defrost icon will continue

on the display until the evaporator returns to

normal cooling temperatures (up to 30 minutes). The freezer

evaporator fan motor will not switch on until the evaporator

reaches -5°F (-21°C) or two minutes AFTER the compressor

and condenser fan motor have begun operating.

The temperature control monitors evaporator temperature

and compressor run time to determine the proper time for

a positive defrost cycle. A defrost cycle can occur as often as

every 60 minutes under extremely heavy usage. It can last

a minimum of 2 minutes in a refrigerator or 6 minutes in a

freezer. The compressor will remain off until the evaporator

coil temperature exceeds:

• 41°F (5°C) or the controller reaches a time limit of 75

minutes on a refrigerated unit.

• 55°F (13°C) or the controller reaches a time limit of 35

minutes on a freezer.

26 Part Number GA_SM 08/18

Page 27

Section 3 Operation

Back

Defrost Times

Hour Minutes AM/PM

4

r

s

AM

:

00

r

s

Hour Minutes AM/PM

6

r

s

PM

:

00

r

s

10

r

s

AM

:

00

r

s

10

r

s

PM

:

00

r

s

r

s

AM

:

r

s

2

r

s

PM

:

00

r

s

!

Set Box Temperature

Back

35.6

r

s

-1.4

r

s

Refrigerator Freezer

!

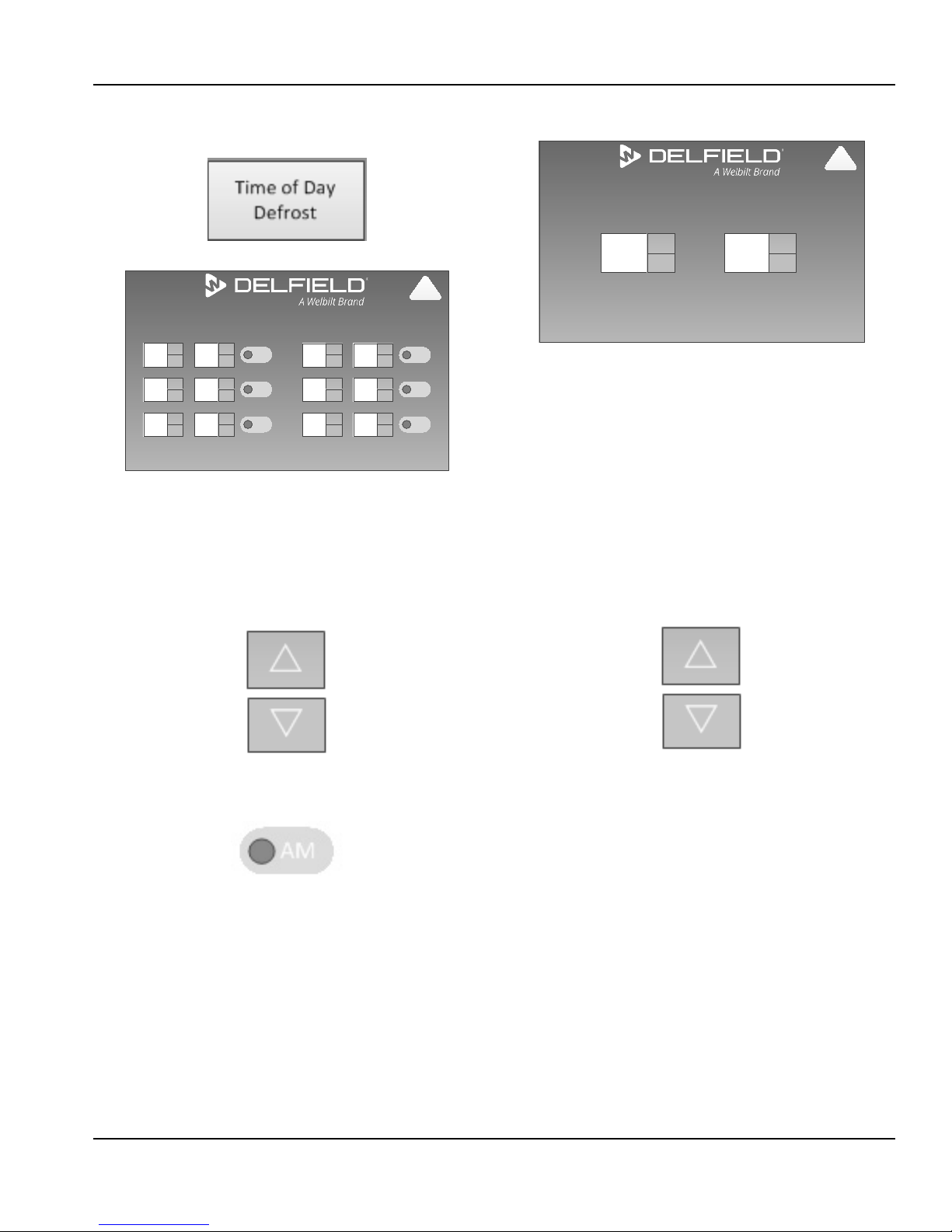

Time of Day Defrost

• Selecting Time of Day Defrost activates this defrost mode.

• Time of Day Defrost requires defrost times to be set up.

Configuration Screen\Defrost Type\Time of Day Defrost

• Six defrost times are allowed.

• A blank hour and minutes will be an inactive time.

• If no defrost times are assigned, no defrost will occur.

• Increase and decrease the defrost time settings using the

up and down arrows.

Set Box Temperature

Configuration Screen\Set Box Temperature

Screen For Dual Temperature Cabinet Shown

• Access to this page requires the manager password.

• Increase and decrease the cabinet temperature set point

using the up and down arrows.

• Set point can only be adjusted within the set point limits.

• Refrigeration factory setting is 35.6°F, set point limits are

30°F and 60°F.

• Freezer factory setting is -1.4°F, set point limits are -5°F

and 36°F.

• Heated cabinet factory setting is 165°F, set point limits

are 120°F and 200°F.

• Hours 1 through 12 will be available if a 12 hour clock

format has been selected on the Time/Date page. The

AM/PM icon will allow you to switch between the two.

• Hours 1 through 23 will be available if a 24 hour clock

format has been selected on the Time/Date page.

• Minutes can be set 00 through 59.

Part Number GA_SM 08/18 27

Page 28

Operation Section 3

Alarm Management

Back

!

Audible Alarm

ON

ON

Connected to:

Back Connection Setup

Ethernet: 10.214.25.62

WiFi: SSID: net_name

!

Back Add a Network

WBT_Enterprise

[WPA-PSK-TKIP=CCMP][WPA2-PSK-TKIP+CCMP][ESS]

Manage Networks

Freds_WiFi

[WPA-PSK-CCMP][WPA2-PSK-CCMP][WPS][ESS]

WBT_Guest

[WPA-PSK-TKIP=CCMP][WPA2-PSK-TKIP+CCMP][ESS]

Freds_WiFi

[WPA-PSK-TKIP=CCMP][WPA2-PSK-TKIP+CCMP][ESS]

!

Alarm Management

Configuration Screen\Alarm Management

• Access to this page requires the manager password.

• Selecting this Icon switches the audible alarm between

Off and On. On is the factory setting.

Audible Alarm is Off

Network Connection

Configuration Screen\Network Connection

• Ethernet: will display local area network name and icon if

it is connected.

• WiFi: will display the WiFi network name and signal

strength if it is connected.

• Ethernet and WiFi both offer access to a IP Address Setup

screen. Select the cog icon.

Audible Alarm is On

28 Part Number GA_SM 08/18

• Manage network connection by selecting Set Up

Connection.

Configuration Screen\Network Connection

\Set Up Connection

• Screen will list up to eight networks, their name, type of

security, and signal strength using an icon.

• Use the scroll bar on the right of the screen to see

additional networks.

Page 29

Section 3 Operation

Cancel Connect

Security

WPA2 PSK

WiFi_Name

Password:

!

• Select a listed network and the display will navigate to

the complete network setup.

Configuration Screen\Network Connection

\Set Up Connection\Network Name

• Selecting cancel navigates to the previously viewed

screen and cancels the network setup.

• Screen lists network name, type of security and empty

password box.

• Select the empty password box to bring up a keyboard.

Type in the password, each character will appear as an

asterisk. Connect will appear in the lower right corner.

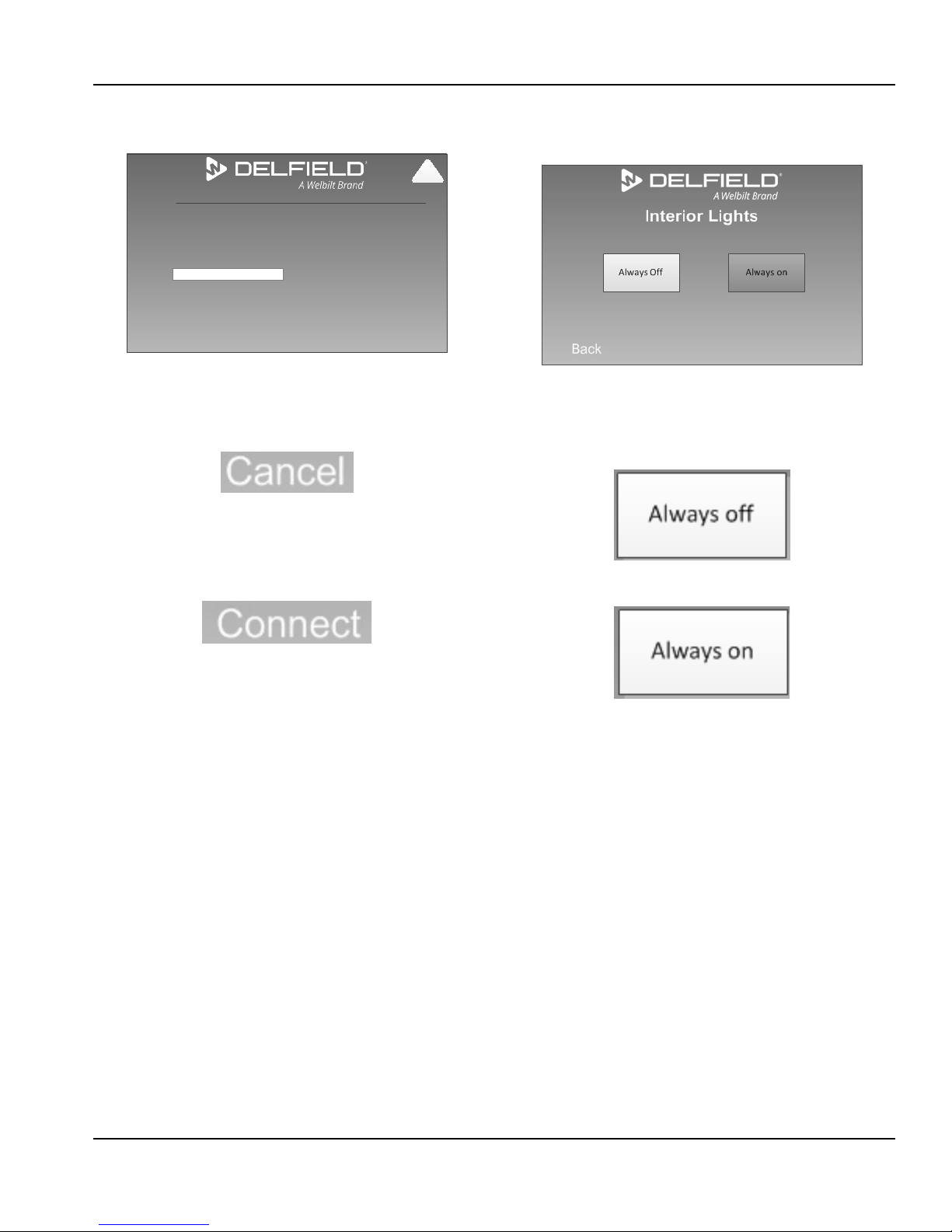

Interior Light

1. From the settings screen select Interior Lights.

Settings Screen\Interior Light

• The selected mode/button will be gray.

• Selecting Always Off switches the interior light to be off

at all times.

• Selecting Always On switches the interior light to be on at

times when the unit is on. This is the factory default.

• If the incorrect password is entered the entry will

disappear. Retry in the empty password box.

• If no password is required, security type will list None,

neither password nor empty box will display and connect

will appear in the lower right corner.

• Selecting Connect will complete the internet setup and

navigate back to the Network Connection screen.

Part Number GA_SM 08/18 29

Page 30

Operation Section 3

Back

Time Date Format

MM/DD/YR

DD/MM/YR

24 Hr Clock

12 Hr Clock

!

12

r

s

00

r

s

AM

:

Time Date Format

Hour Minutes AM/PM

!

Time Date Format

12

r

s

30

r

s

16

r

s

Month Day Year

!

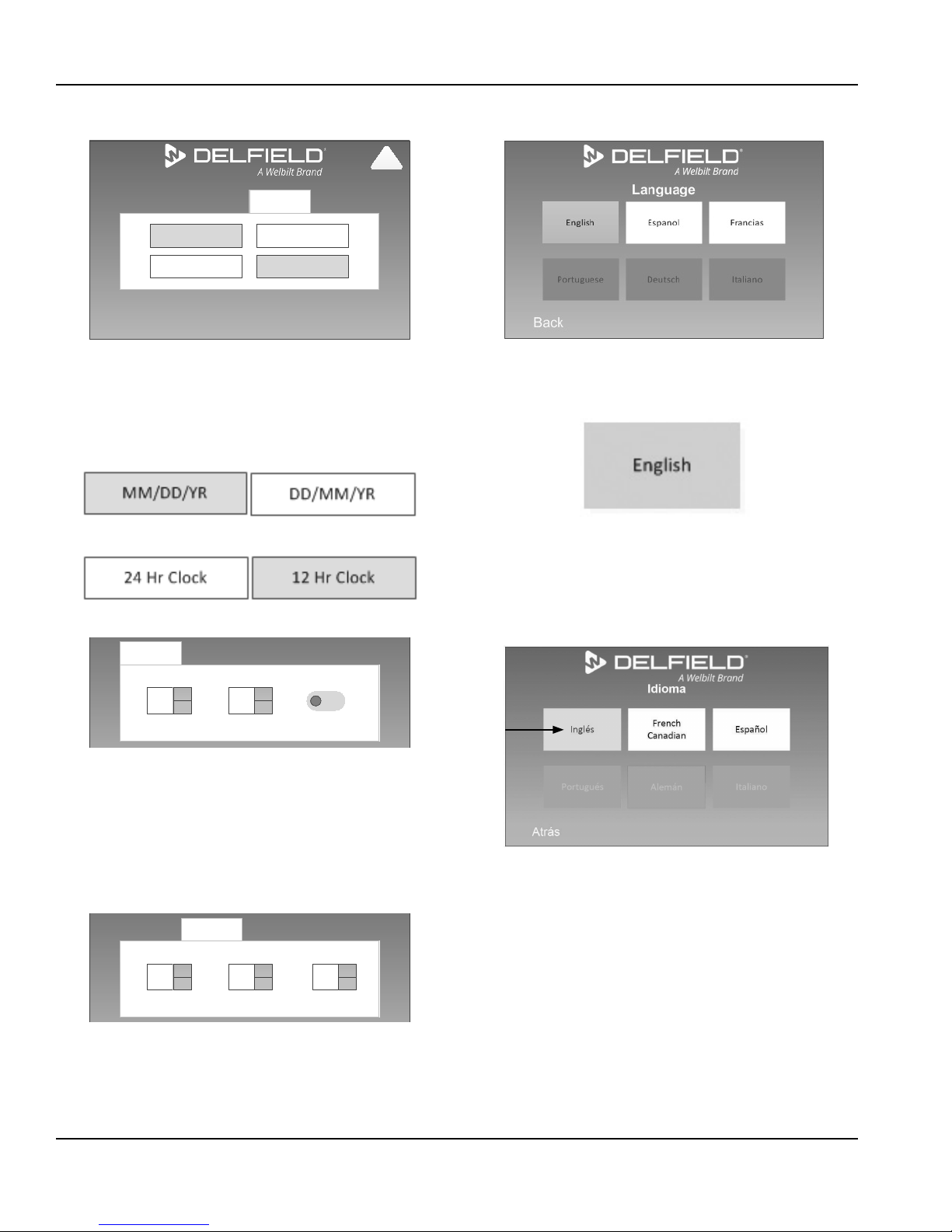

Time / Date

Settings Screen\Time׀Date\Format Tab

• The Format Tab has two date and two time choices.

• Select the desired date and time format. The active

choice will be gray.

• MM/DD/YR is the default. 12 Hr Clock is the default.

Date Format Choices

Time Format Choices

Language

Settings Screen\Language

• Language in the light gray box is current selection. English

is default.

Selected Language in Blue

• Select a language in a white box to change.

• Languages in dark gray boxes are not yet available.

• English remains the top left button regardless of

language.

Settings Screen\Time׀Date\Time Tab

• Increase and decrease the hour and minutes using the up

and down arrows.

• Based on the clock format chosen the hours can be set

through 12 or 24.

• Select the AM/PM icon to switch between the two. The

icon will not be available if the 24 Hr Clock is selected.

Settings Screen\Time׀Date\Date Tab

• Increase and decrease the Month, Day and Year using the

up and down arrows.

• 20 precedes the year setting.

30 Part Number GA_SM 08/18

Page 31

Section 3 Operation

LCD Brightness

Back

!

Manual Defrost

Back

Defrost

ON

!

ON

LCD Brightness

Settings Screen\LCD Brightness

• LCD default is 50%.

• Slide the small circle along the line to the right to

increase the brightness, left to decrease.

NOTE: Adjusting brightness to 60% or less will increase the

life of the display.

Manual Defrost

Web Application

KITCHENCONNECT

This online application is an equipment monitoring tool.

Register:

1. Navigate to https://www.welbiltdigital.com/

2. Select Register.

3. Enter Information in at least the required fields.

4. Select Submit.

5. Enter your email and password.

6. Select Login.

Mobile Application

SPECIFICATION LINE CONNECT

This mobile application is an equipment monitoring tool.

To Download The Mobile Application:

1. Open either Apple iTunes or Google PlayStore.

2. Search for Specification Line Connect.

3. Select and install.

4. Open the application. The Welbilt W logo is the

application icon.

Settings Screen\Manual Defrost

• Access to this page requires the manager password.

• Off is the factory setting.

• When On is selected the defrost will cycle once and

return to normal operation.

Part Number GA_SM 08/18 31

Page 32

Operation Section 3

Application Operation

Set Up A Site

1. Select + Add Site.

2. Fill in all site information. All fields are required.

₋ Site ID (Max 30 Characters)

₋ Site Name (Max 20 Characters)

₋ Site Manager Name (Max 20 Characters)

₋ Site Email ID (Max 50 Characters)

₋ Site Address (Max 50 Characters)

₋ Country (From a Menu)

₋ State (From a Menu

₋ City (Max 20 Characters)

₋ Postal Code (Max 10 Characters)

3. Select Choose Site Location to

put a pin on the map.

4. Select Submit.

5. The new site will be added to the home page.

Edit Or Delete Site

1. Select the menu icon next to

the site.

2. Edit and Delete Site are

available actions.

3. Edit will bring up the site

information page.

4. Delete will require confirmation.

Set Up Equipment

1. Select the menu icon next to the site.

2. Select View Equipments.

3. Select + Add.

4. Fill in all equipment information. All fields are required.

NOTE: Serial number entered must match equipment.

₋ Equipment Serial Number (Max 30 Characters)

₋ Equipment Name (Max 20 Characters)

₋ Equipment Type (From a Menu)

₋ Equipment Model (From a Menu)

5. Select Submit.

6. The new equipment will be connected to the site.

Edit Or Delete Equipment

1. Select the menu icon next to

the equipment.

2. Edit and Delete Equipment are

available actions.

3. Edit will bring up the

equipment information page.

4. Delete will require

confirmation.

EQUIPMENT MANAGEMENT

View Equipment Statistics

Tabs include:

• Summary tab includes the following statistics:

₋ Cavity1 Temp Max/Min

₋ Cavity2 Temp Max/Min

₋ Ambient Temp Max/Min

₋ Energy Used

₋ Network

₋ Signal Strength

• Latest Temperature Information

• Set Point Vs Cavity Vs Ambient Temperature

• Condenser Inlet Vs Outlet Temperature

• Evaporator Inlet Vs Outlet Temperature

• Energy Usage

Change the date range by clicking the calendar icon.

If the site has multiple pieces of equipment you can switch to

the other equipment from the equipment menu.

View Error Statistics

1. Select the menu icon next to the equipment.

2. View Error Statistics will bring up a list.

₋ Change to a graph view by selecting the graph

icon in the top right corner.

₋ Change the date range by clicking the calendar

icon.

₋ If the site has multiple pieces of equipment

you can switch to the other equipment from the

equipment menu.

32 Part Number GA_SM 08/18

Page 33

Section 4

Maintenance

DANGER

It is the responsibility of the equipment owner to perform

a Personal Protective Equipment Hazard Assessment

to ensure adequate protection during maintenance

procedures.

DANGER

Failure to disconnect the power at the main power supply

disconnect could result in serious injury or death. The

power switch DOES NOT disconnect all incoming power.

DANGER

Disconnect electric power at the main power disconnect

for all equipment being serviced. Observe correct polarity

of incoming line voltage. Incorrect polarity can lead to

erratic operation.

Warning

n

Never use sharp objects or tools to remove ice or frost. Do

not use mechanical devices or other means to accelerate

the defrosting process.

Warning

n

When using cleaning fluids or chemicals, rubber gloves

and eye protection (and/or face shield) must be worn.

Caution

,

Maintenance and servicing work other than cleaning as

described in this manual must be done by an authorized

service personnel.

Notice

Never use a high-pressure water jet for cleaning or hose

down or flood interior or exterior of units with water. Do

not use power cleaning equipment, steel wool, scrapers

or wire brushes on stainless steel or painted surfaces.

Responsibility

You are responsible for maintaining the equipment

in accordance with the instructions in this manual.

Maintenance procedures are not covered by the warranty.

Warning

n

When cleaning interior and exterior of unit, care should

be taken to avoid the front power switch and the rear

power cord. Keep water and/or cleaning solutions away

from these parts.

Maintenance Daily Weekly Monthly After Prolonged Shutdown At Start-Up

Interior X X X

Gasket X X X

Exterior X X X

Drain X X X

Condenser Coil X X X

Part Number GA_SM 08/18 33

Page 34

Maintenance Section 4

Interior Cleaning

The interior can be cleaned using soap and warm water. If

this isn’t sufficient, try ammonia and water or a nonabrasive

liquid cleaner.

GASKETS

Gaskets require regular cleaning to prevent mold and mildew

build up and also to retain the elasticity of the gasket. Clean

them with water and mild soap (not citrus based). Avoid full

strength cleaning products on gaskets as this can cause them

to become brittle and crack. Never use sharp tools or knives

to scrape or clean the gasket. Gaskets can be easily replaced

and do not require the use of tools or an authorized service

person. The gaskets are dart style and can be pulled out of

the groove in the door. Place gasket in warm water to make

the material more pliable for installation. Dry and press into

place.

PREVENTING BLOWER COIL CORROSION

To help prevent corrosion of the blower coil, store all acidic

items, such as pickles and tomatoes, in seal-able containers.

Immediately wipe up all spills.

Exterior Cleaning

Notice

Never use an acid based cleaning solution on exterior

panels! Many food products have an acidic content,

which can deteriorate the finish. Be sure to clean the

stainless steel surfaces of ALL food products.

Clean the area around the unit as often as necessary to

maintain cleanliness and efficient operation.

Wipe exterior surfaces with a damp cloth rinsed in water to

remove dust and dirt from the outside of the unit. Always

rub with the “grain” of the stainless steel to avoid marring

the finish. If a greasy residue persists, use a damp cloth

rinsed in a mild dish soap and water solution. Wipe dry with

a clean, soft cloth.

Never use steel wool or abrasive pads for cleaning. Never use

chlorinated, citrus based or abrasive cleaners.

Stainless steel exterior panels have a clear coating that

is stain resistant and easy to clean. Products containing

abrasives will damage the coating and scratch the panels.

Daily cleaning may be followed by an application of stainless

steel cleaner which will eliminate water spotting and

fingerprints. Early signs of stainless steel breakdown are

small pits and cracks. If this has begun, clean thoroughly and

start to apply stainless steel cleaners in attempt to restore

the steel.

Wipe casters with a damp cloth to prevent corrosion.

DRAIN

Each refrigerated unit has a drain located inside the unit

that removes the condensation from the evaporator coil and

routes it to an external condensate evaporator pan. Each

drain can become loose or disconnected during normal use.

If you notice water accumulation on the inside of the unit,

be sure the drain tube is connected to the evaporator drain

pan. If water is collecting underneath the unit, make sure the

end of the drain tube is in the condensate evaporator. The

leveling of the unit is important as the units are designed to

drain properly when level. Be sure all drain lines are free of

obstructions.

DOORS/HINGES

Over time and with heavy-use doors, the hinges may become

loose. If this happens, tighten the screws that mount the

hinge brackets to the frame of the unit. Loose or sagging

doors can cause the hinges to pull out of the frame, which

may damage both the doors and the hinges. In some cases

this may require qualified service agents or maintenance

personnel to perform repairs.

Cleaning the Condenser Coil

In order to maintain proper refrigeration performance, the

condenser fins must be cleaned of dust, dirt and grease

regularly. It is recommended that this be done monthly. If

conditions are such that the condenser is totally blocked

in a month, the frequency of cleaning should be increased.

Clean the condenser with a vacuum cleaner or stiff brush. If

extremely dirty, a commercially available condenser cleaner

may be required.

Failure to maintain a clean condenser coil can initially cause

high temperatures and excessive run times. Continuous

operation with a dirty or clogged condenser coil can result in

compressor failure. Neglecting the condenser coil cleaning

procedures will void any warranties associated with the

compressor and cost to replace the compressor.

34 Part Number GA_SM 08/18

Page 35

Section 5

Troubleshooting

Problem -> Cause -> Correction Chart

Problem Cause Correction

Cabinet not

running

Condensing

unit runs for

long periods or

continuously

Cabinet

temperature is too

high

Cabinet is noisy Loose part(s). Locate and tighten loose part(s).

Fuse blown or circuit breaker tripped. Replace fuse or reset circuit breaker.

Power cord unplugged. Plug in power cord.

Thermostat set too high. Set thermostat to lower temperature.

System is off. Turn system on.

Cabinet in defrost cycle.

(Refrigerator and Freezer models)

Excessive amount of warm product placed in

cabinet.

Prolonged door openings or door(s) ajar. Make sure door(s) are closed when not in use. Avoid

Door gasket(s) not sealing properly. Check gasket condition. Adjust door or replace gasket if

Dirty condenser coil. Clean the condenser coil.

Evaporator coil iced over. Turn unit off and allow coil to defrost.

Thermostat set too high. Set thermostat to lower temperature.

Poor air circulation in cabinet. Re-arrange product to allow proper air circulation.

Excessive amount of warm product placed in

cabinet.

Prolonged door openings or door(s) ajar. Make sure door(s) are closed when not in use.

Dirty condenser coil. Clean the condenser coil.

Evaporator coil iced over. Turn unit off and allow coil to defrost.

Allow adequate time for product to cool down.

Allow adequate time for product to cool down.

Wait for defrost cycle to finish.

prolonged door openings.

necessary.

Make sure thermostat is not set too cold.

Also, check gasket condition.

Avoid prolonged door openings.

Make sure thermostat is not set too cold.

Also, check gasket condition.

Refrigerator is

freezing product

Compressor will

not start

Thermostat is set too low. Set thermostat to higher temperature.

Dirty condenser coil. Clean the condenser coil.

Not enough cabinet clearance for proper

refrigeration system operation.

Low voltage to cabinet. Check and correct incoming voltage to cabinet.

Part Number GA_SM 08/18 35

Move cabinet or make other adjustments to gain proper

cabinet clearances.

Page 36

Troubleshooting Section 5

THIS PAGE INTENTIONALLY LEFT BLANK

36 Part Number GA_SM 08/18

Page 37

Frame Heater

Back

Always OffAlways on Power Save

!

Rapid Pull Down

Back

OFF

!

ON

Section 6

Control

Service Screens

Operator screens are covered in Section 3, Operation.

The manager password is 211276.

FRAME HEATER FREEZER ONLY

Configuration Screen\Frame Heater

• Access to this page requires the manager password.

• The selected mode/button will be gray.

• These buttons control the length of time that heat is

applied to the door perimeter.

• Selecting the Always On icon switches the frame heater