Page 1

F2800

Remote Low-Prole Refrigerated Equipment Stands

Models

F2852 52.25” Re mote low-prof ile s tand

•

F2856 56.25” Re mote low-prof ile s tand

•

F2862 62.25” Re mote low-prof ile s tand

•

F2875 75.25” Re mote low-prof ile s tand

•

F2880 80.25” Re mote low-prof ile s tand

•

F2887 87.25” Re mote low-prof ile s tand

•

F2899 99.25” Re mote low-prof ile s tand

•

F28110 110.25 ” R emote low-prof il e stand

•

Project ___ ____________________ ___________

Item _________________ ___________________

Quantity _________________ _______________

CSI Sec tion 11400

Approved ____________ ___________________

Date ____ _____________________ ___________

F2800: Remote Low-Prole Refrigerated Equipment Stands

F287 5

Specifications

Ext erio r t op is 18-g auge st ainl ess ste el with st anda rd m arin e e dges on a ll

fou r sid es. Co rner s are full y wel ded w ith s moot h rad ii co rners for e asy

cle an out. Int erio r s ub-t op made o f 2 2-ga uge 2BF s tainl ess ste el is mad e

int egral wi th t he top by inje ctin g 2. 00” o f h igh dens ity poly uret hane foa m

bet ween the ext erio r an d in teri or t ops.

Ref rige rated ba se i nter ior bac k an d b ottom ar e co nstr ucte d o f a 22- gaug e

2BF sta inle ss steel . Exte rior sid es, bott om and back are ma de o f 2 2-ga uge

gal vani zed steel . Both le ft a nd right in terio r s ides are for med of ABS

pla stic. T he base is inj ecte d w ith 2.00 ” of hig h de nsit y p olyu retha ne foam

bet ween t he ex terio r and i nter ior. Re frig erate d base front s are m ade of

.09 5” thic k ABS t herm oform ed pl astic and b acked up by r idge d poly ure-

tha ne wate r b lown i njec tion mo lded fr ames . The f rames a re an exce llen t

the rmo- brea k a nd supe rior str uctu ral mat eria l f or fast ening do ors and

dra wers. Ex teri or mach ine co mpar tmen t side is c onst ruct ed of 18- gaug e

gal vani zed steel .

Fini shed s tain less st eel en ds are st andar d. Louve r, coil pa nel an d d rawe r

fac es a re all stan dard wi th s tain less ste el cons truc tion. Unit s ar e s uppl ied

wit h wall -mou nted b racke t and t hrea ded ro d to all ow ins tall atio n of the

uni t ag ains t a soli d su rfa ce.

Full Ex tens ion Plus dr awer sys tem is a co mple te drawe r s ystem , w hich can

ope rate ind epen dent of the uni t i t’s insta lled in . D rawer sys tem is size d t o

hol d 12” x 20” x 4“ d eep ho tel pan s and s malle r frac tion al pan s. Draw er

sys tem is al l stain less s teel co nstr ucti on for ma ximu m durab ilit y. D rawer

tra ck roll ers ar e made o f Delr in and do not r equir e grea se for o perat ion.

Standard Features

Top is heavy duty stain less steel, with integral front

•

marine ed ge

Standard st ainless steel end s

•

Exterior drawer fronts are s tainless steel

•

High densi ty enviro nmentally fr iendly, Kyo to

•

Protocol Compl iant, Non ODP (Ozone Depleti on

Potential), Non GWP (Global Warming Potential)

polyurethane foam insulation throughout unit

Snap-in drawer gaskets for easy removal

•

Standard on legs

•

Base interior cabinet is cooled with mullion style

•

coated blower co il(s) mou nted betwe en each

door/drawer section for even air and temperature

control

Electric condensate evaporator s are standard

•

Inter ior refri gerated ba se cabin et s ection t o

•

maintain 3 6° to 40° meeti ng NSF7

Digital th ermometer

•

Wall-mounted b racket to prevent tipping

•

Full Extension Plus Drawer sy stem is a complete

•

drawer system. Drawer system is s ized to hold

12” x 20” x 4” deep hote l pans (by othe rs). The

drawer system is all stainle ss steel construc tion for

Int erme diat e track s are re mova ble wit hout t ools a nd hou se Del fiel d’s

“ant i-fr icti on bina ry rol ler sys tem”. Dr awer bo xes are de sign ed with “eas y

pan gr ip flan ges”. Trac ks are des igne d w ith a stay s hut feat ure tha t h olds

the draw er g asket tig ht to the base fro nt on une ven f loor s. E xter ior drawe r

fro nts are made of stai nles s st eel; and an int erior ma de o f AB S p lasti c w ith

for med in cha nnel s to hous e t he sna p-in da rt sty le sant opre ne gask et. A

gal vani zed bra ce is fo amed i n plac e to be an i ntegr al par t of th e drawe r

fro nt ass embl y. Each drawe r fron t is in ject ed wi th 1.8 7” of hi gh den sity

pol yuret hane foam betw een t he ex teri or an d int erio r. Han dles are r ecess ed

bla ck p last ic a nd h eld in w ith a p osit ive lock syst em.

Uni t is su ppor ted with two 14 -gau ge l eg rails th at r un t he entir e l ength of

the un it. L eg rail s a re weld ed to the bot tom sid e o f t he unit an d a re tied

tog ether wit h two 12-g auge brac es ru nnin g fro nt to back . Ca ster/ leg b oxes

are we lded in side th e leg rai l a nd 6.1 2” ad just able st ainl ess ste el leg s a re

mou nted as stan dard with (4 ) 5/ 16” bo lts.

Ref rig erat ion syst em co mpo nent s are HFC -404 A. I nter ior cabi net i s

coo led w ith mulli on s tyle blow er co ils (coat ed) mount ed b etwee n ea ch

doo r/dra wer sec tion fo r very ev en air and t emper atur e c ontro l. E lect rica l

con nect ions are 115 V-60H -1PH .

A t herm omet er i s in stall ed i n th e re mova ble acces s pa nel, ele ctri c co nden -

sat e evap orato r, sole noid a nd the rmos tat. R emote m odel s must b e hard -

wir ed a t th e in stal lati on s ite.

•

•

•

•

Options &

Accessories

•

•

•

•

•

•

•

•

maximum du rability

When o rdering, specify make, mod el and

depth of cooking eq uipment sitting on

the equipm ent stand

Height of surface for setti ng e quipment

is 25.50”

Envi ronmen tally fri endly HFC- 404A

refrigerant

One year parts and 90 day labor stan dard

warranty

Drawer locks

230V, 50Hz e lectrical system

Stainless steel back

Mechanical housing left s ide

Doors in lieu of drawers (except 32”)

Plastic la minate end

Plastic la minate back

Plastic la minate front

980 S. I sabella Rd.

Mt. Pleasa nt, Michigan 4885 8

Phone: 800 -733-8948 or 989 -773-7981

Fax: 800-669-0 619

www.delfield.co m

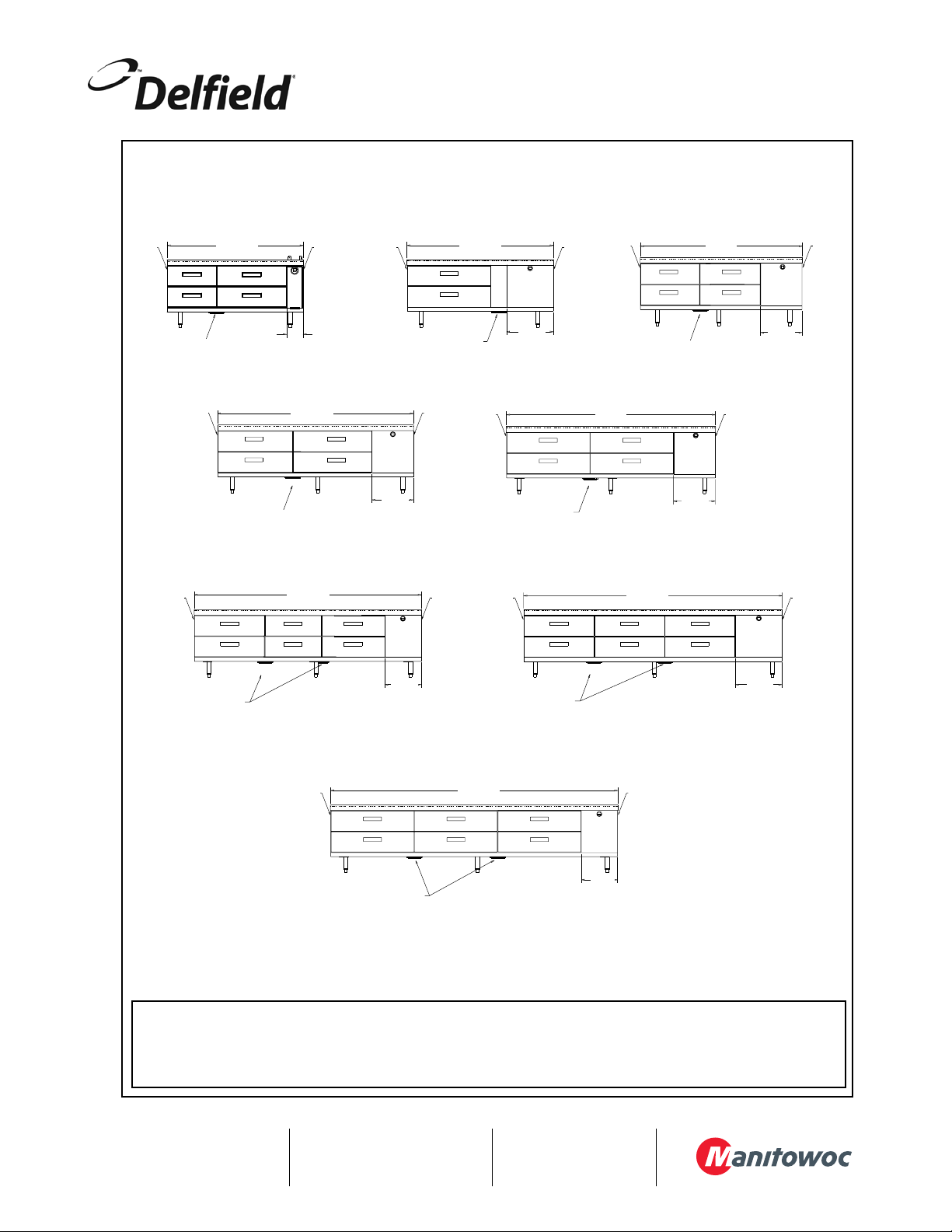

Page 2

S/S End

Elevation View

F2852 F2856

52.25"

132.7cm

S/S End S/S End

56.25"

142.9cm

S/S End

S/S End

F2862

62.25"

158.1cm

S/S End

S/S End

19" Ref

19" Ref

Elec. Cond. Evap

S/S End

Elec. Cond. Evap

27" Ref

27" Ref

27" Ref

27" Ref

27" Ref

27" Ref

32" Ref

32" Ref

6.00"

15.2cm

Elec. Cond. Evap

18.00"

45.7cm

F2875 F2880

75.25"

191.1cm

32" Ref

32" Ref

16.00"

40.6cm

S/S End

S/S End

32" Ref

32" Ref

Elec. Cond. EvapElec. Cond. Evap

F2887

19" Ref

19" Ref

87.25"

221.6cm

27" Ref

27" Ref

14.00"

35.6cm

S/S End

S/S End

Elec. Cond. Evap

27" Ref

27" Ref

80.25"

203.8cm

32" Ref

32" Ref

F2899

27" Ref

27" Ref

19" Ref

19" Ref

Elec. Cond. Evap

99.25"

252.1cm

16.00"

40.6cm

27" Ref

27" Ref

27" Ref

27" Ref

S/S End

18.00

45.7cm

16.00"

40.6cm

S/S End

F28110

32" Ref

32" Ref

110.25"

280.0cm

S/S End

32" Ref

32" Ref

Elec. Cond. Evap

Remote Low-Pro fil e Refrigerated Equipment Stands

Warning

To assure proper operation a 2” airspace must be maintained between the bottom of any cooking equipment and the

top of this unit. Cooking equipment must have a barrier (i.e. bottom, drip pan) between its heat source and the top of the

equipment stand. Failure to comply with this could severely damage the equipment stand and void all warranties.

F2800

Deleld reserves the right to make changes to the design or specications without prior notice.

980 S. I sabella Rd.

Mt. Pleasa nt, Michigan 4885 8

Phone: 800 -733-8948 or 989 -773-7981

Fax: 800-669-0 619

www.delfield.co m

32" Ref

32" Ref

14.00"

35.6cm

S/S End

Page 3

Length

Nominal Length + .25"

W/ Marine Edge Top

30.93"

78.6cm

Plan View

Remote Low-Pro fil e Refrigerated Equipment Stands

F2800

Deleld reserves the right to make changes to the design or specications without prior notice.

25.08" (63.7cm)

28.18" (71.6cm)

27" Drawers

7.63"

(19.4cm)

6.13”

(15.6cm)

31.00"

(78.7cm)

25.50"

(64.8cm)

26.00"

(66.0cm)

Right End View

Specications

Remote Models # Of 12x20 Pans V/Hz/Ph Amps Ship Weight BTU Load Evap Cap

BTU/TD

F2852 4 115/60/1 3.0 278lbs (126kg) 461 120/14°F

F2856 4 115/60/1 3.0 299lbs (136kg) 461 120/14°F

F2862 6 115/60/1 3.0 331lbs (150kg) 518 120/14°F

F2875 8 115/60/1 3.0 401lbs (182kg) 717 120/14°F

F2880 8 115/60/1 3.0 428lbs (194kg) 726 240/15°F

F2887 10 115/60/1 6.0 466lbs (211kg) 859 240/15°F

F2899 12 115/60/1 6.0 530lbs (240kg) 973 240/15°F

F28110 12 115/60/1 6.0 588lbs (267kg) 1143 240/15°F

980 S. I sabella Rd.

Mt. Pleasa nt, Michigan 4885 8

Phone: 800 -733-8948 or 989 -773-7981

Fax: 800-669-0 619

www.delfield.co m

Page 4

Remote Low-Pro fil e Refrigerated Equipment Stands

F2800

980 S. I sabella Rd.

Mt. Pleasa nt, Michigan 4885 8

Phone: 800 -733-8948 or 989 -773-7981

Fax: 800-669-0 619

www.delfield.co m

Printed in the U.S.A.

DSF2800

12/08

Loading...

Loading...