Page 1

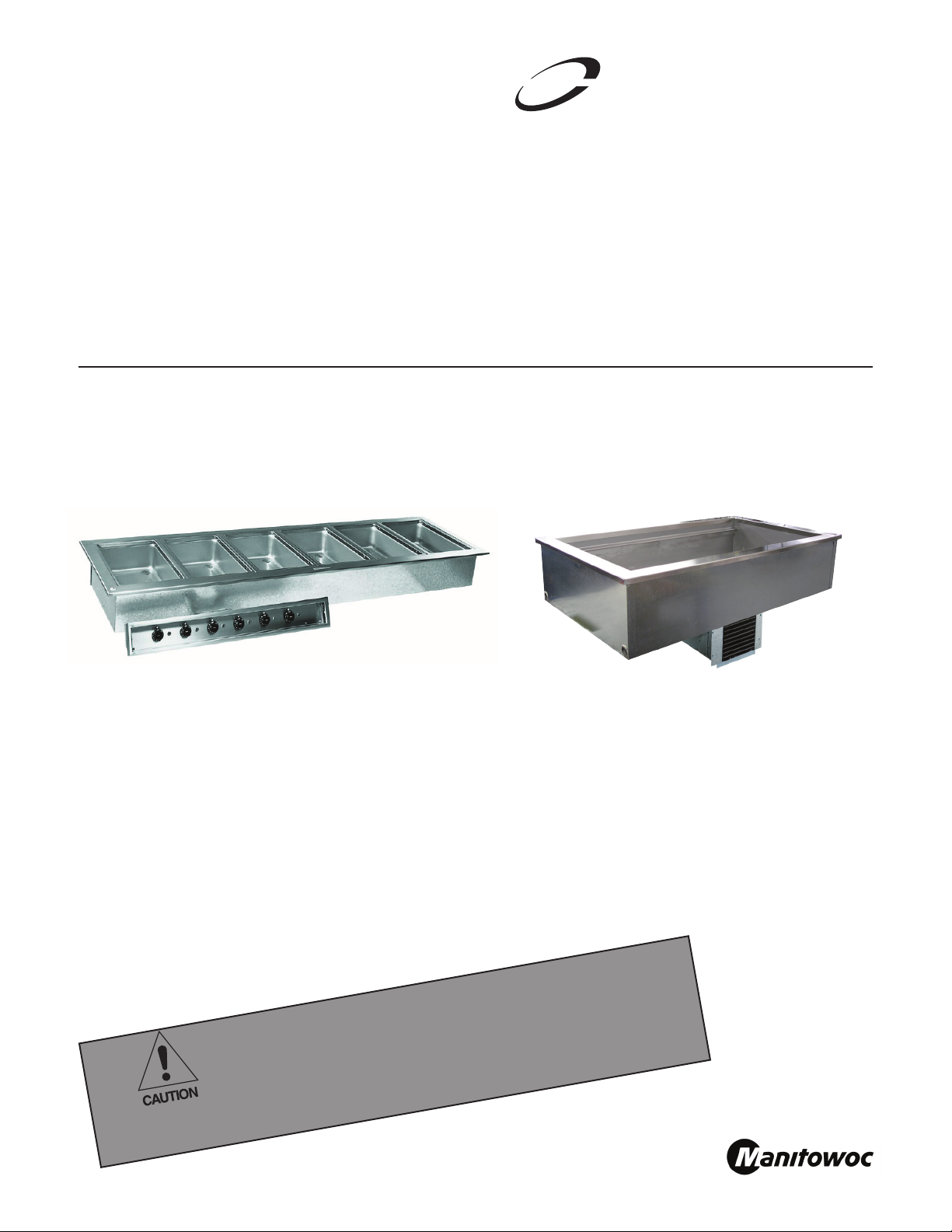

™

Delfield

N8000, N8000-R, N8100B, N8100-BR,

N8100-FA, 8100-EF, N8200, N8200G, N8600,

N8700-D, N8700-R, N8800 Drop Ins

Service, Installation and Care Manual

Please read this manual completely before attempting to install or operate this equipment! Notify

carrier of damage! Inspect all components immediately.

®

Hot Food Wells, Cold Pans, Granite Cold Slabs,

Frost Tops and Hot/Cold Food Wells

IMPORTANT INFORMATION

READ BEFORE USE

PLEASE SAVE THESE INSTRUCTIONS!

January 2012

Page 2

N8000 Series Drop-In Installation and Operation Manual

Delfield

Important Warning And Safety Information

WARNING Read This Manual Thoroughly Before Operating, Installing, Or Performing

Maintenance On The Equipment.

WARNING Failure To Follow Instructions In This Manual Can Cause Property Damage,

Injury Or Death.

WARNING Do Not Store Or Use Gasoline Or Other Flammable Vapors Or Liquids In The

Vicinity Of This Or Any Other Appliance.

WARNING Unless All Cover And Access Panels Are In Place And Properly Secured, Do

Not Operate This Equipment.

WARNING Do Not Clean With Water Jet.

CAUTION Observe the following:

• Minimum clearances must be maintained from all walls and combustible

materials.

• Keep the equipment area free and clear of combustible material.

• Adequate clearance for air openings.

• Operate equipment only on the type of electricity indicated on the

specification plate.

• Retain this manual for future reference.

2

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

™

®

Page 3

N8000 Series Drop-In Installation and Operation Manual

Delfield

Contents Serial Number Location

Receiving And Inspecting Unit .................................................... 3

Specifications ......................................................................... 4-7

Installation

Curved Drop-In Cutout Details .................................................. 8

N8000, N8000N, N8000-R, N8100B, N8100NB, N8100-BR, N8200,

N8200G, 8100-FA, 8100-EF Series ............................................ 9

N8600 Series ........................................................................... 9

N8700-D, N8700N, N8700-R & N8800 Series ........................... 10

Operation

N8100B, N8100NB, N8100-BR ................................................ 11

N8100-FA .............................................................................. 11

8100-EF ................................................................................ 12

N8200 & N8200G ................................................................... 12

N8600 ................................................................................... 13

N8700-D, N8700N, N8700-R & N8800 Series ........................... 14

Maintenance ............................................................................ 15

Unit Assembly N8100-FA .......................................................... 16

Wiring Diagram

N8100-FA .............................................................................. 16

N8100B, N8100NB & N8100-BR .............................................. 17

8100-EF & 8100-EFN .............................................................. 17

N8200 & N8200G ................................................................... 17

N8600 .............................................................................. 18-19

N8800 ................................................................................... 19

N8700-D, N8700N & N8700-R ................................................ 20

Louver Diagram ....................................................................... 21

Miscellaneous Replacement Parts ............................................. 21

N8100-FA Replacement Parts List ............................................. 22

Condensing Unit Assembly Parts List ................................... 23-26

Food Well Assembly Parts List ............................................. 27-28

Standard Labor Guidelines ........................................................ 29

Standard Warranties ........................................................... 30-31

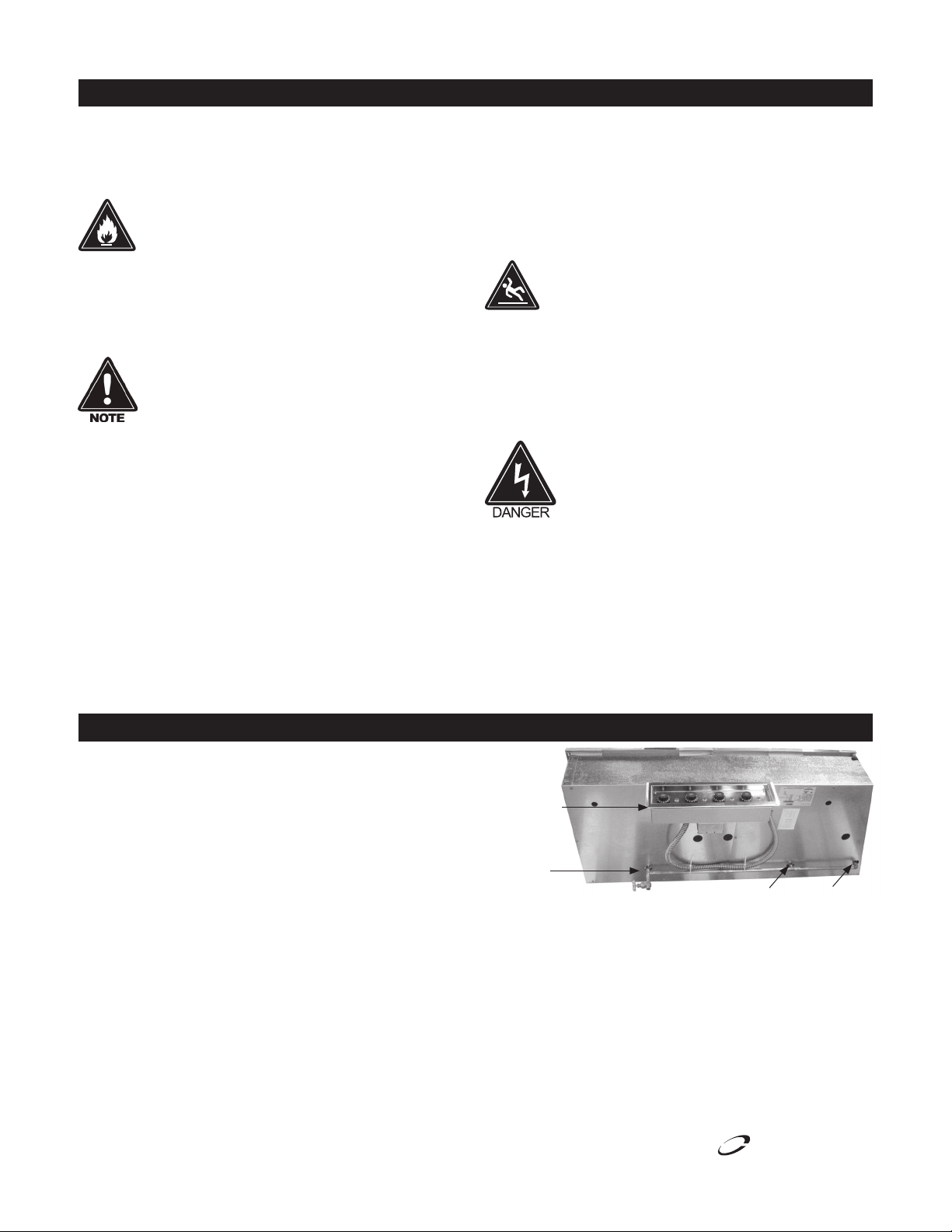

The serial number on self-contained refrigerated units is on the electrical

specications tag located near the condensing unit.

The serial number on remote refrigerated units is on the outside bottom

of the food well.

On hot food pans and hot/cold combination pans, the serial number tag

is located on the back of the control raceway or remote panel.

The serial number tag also lists the refrigerant used and the amount

of charge.

Always have the serial number of your unit available when calling for

parts or service.

This manual covers only standard 8000 series units. If you have a

custom designed unit, you should contact our parts/service department

at (800) 733-8829 for questions.

©2012 The Deleld Company. All rights reserved. Reproduction without written

permission is prohibited. “Deleld” is a registered trademark of The Deleld

Company.

Receiving And Inspecting The Equipment

Even though most equipment is shipped crated, care should

be taken during unloading so the equipment is not damaged

while being moved into the building.

1. Visually inspect the exterior of the package and skid or

container. Any damage should be noted and reported to

the delivering carrier immediately.

2. If damaged, open and inspect the contents with the carrier.

3. In the event that the exterior is not damaged, yet upon

opening, there is concealed damage to the equipment

notify the carrier. Notication should be made verbally as

well as in written form.

4. Request an inspection by the shipping company of the

damaged equipment. This should be done within 10 days

from receipt of the equipment.

™

®

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

5. Also open the compressor compartment housing and

visually inspect the refrigeration package. Be sure lines

are secure and base is still intact.

6. Freight carriers can supply the necessary damage forms

upon request.

7. Retain all crating material until an inspection has been

made or waived.

Uncrating The Equipment

First cut and remove the banding from around the crate.

Remove the front of the crate material, use of some tools will

be required.

3

Page 4

N8000 Series Drop-In Installation and Operation Manual

Delfield

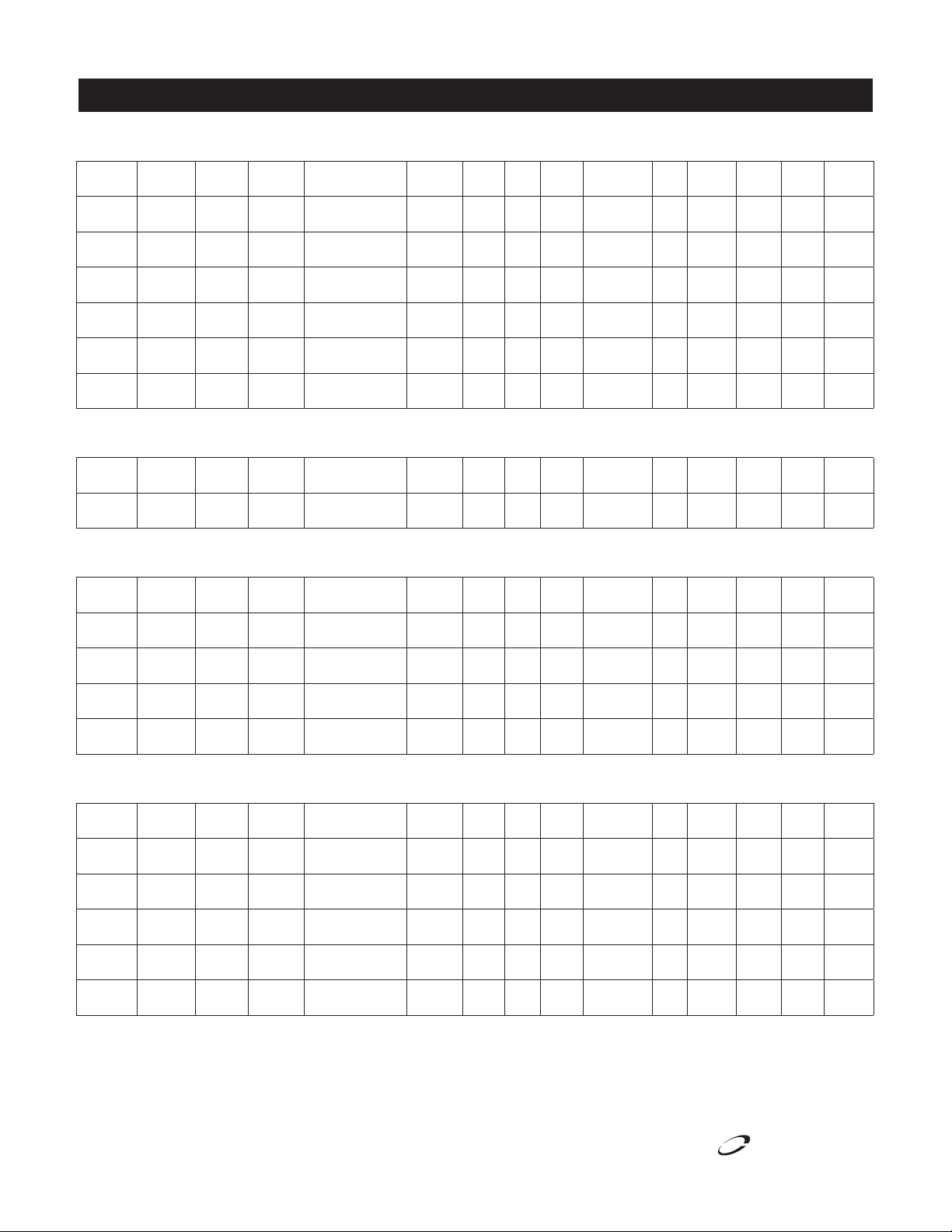

Specifications

N8100B Series Self-Contained Mechanically Cooled Pans - R134A

Model

N8118B

N8130B

N8143B

N8156B

N8169B

N8181B

L D H

18”

(45.7cm)

30.75”

(78.1cm)

43.5”

(110.5cm)

56.25”

(142.9cm)

69”

(175.3cm)

81.75”

(208cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

21.87”

(55.5cm)

21.87”

(55.5cm)

21.87”

(55.5cm)

21.87”

(55.5cm)

21.87”

(55.5cm)

21.87”

(55.5cm)

Counter Cutout

Dimensions V/Hz/Ph Amps H.P. BTU

17” X 25”

(43.2cm x 63.5cm)

29.75” x 25”

(75.6cm x 63.5cm)

42.50” X 25”

(108.6cm x 63.5cm)

55.25” x 25”

(140.3cm x 63.5cm)

68” X 25”

(172.7cm x 63.5cm)

80.75” x 25”

(205.1cm x 63.5cm)

115/60/1

115/60/1 4.0 1/5 379

115/60/1

115/60/1 7.0 1/4 758

115/60/1 7.0 1/4 948

115/60/1 8.0 1/3 1138

4.0 1/5 204

4.0 1/5 569

N8100NB Series Self-Contained Mechanically Cooled Pans Narrow Style - R134A

N8146NB

N8168NB

46.75”

(118.7cm)

67.5”

(171.5cm)

18”

(45.7cm)

18”

(45.7cm)

21.81”

(55.4cm)

21.81”

(55.4cm)

45.75” x 17”

(113.7cm x 43.2cm)

66.5” x 17”

(168.9cm x 43.2cm)

115/60/1 4.0 1/5 454 17/40º/-5º 680 175lbs

115/60/1 4.0 1/5 676 26/31º/4º 804 240lbs

Evap BTU/

TD/TEMP

19/38º/-3º

26/31º/4°

35/26º/9º

43/32º/3º

51/29º/6º

59/32º/3º

Sys

Cap

708 100lbs

812 140lbs

889 173lbs

1373 205lbs

1469 225lbs

1921 258lbs

Ship

Weight

(45kg)

(64kg)

(78kg)

(93kg)

(102kg)

(117kg)

(80kg)

(109kg)

Refrig.

NEMA

Charge

Plug

5-15P

8.0oz

8.0oz 5-15P 2

5-15P

8.0oz

16.0oz 5-15P 4

16.0oz 5-15P 5

11.5oz 5-15P 6

5-15P

8.0oz

8.0oz 5-15P 3

12”x20”

Pans

1

3

2

N8100BR Series Curved Self-Contained Mechanically Cooled Pans - R134A

Model

N8144-BR

N8159-BR

N8176-BR

N8194-BR

L D H

40.43”

(103cm)

57.22”

(145cm)

73.68”

(187cm)

89.86”

(228cm)

26.05”

(66cm)

26.05”

(66cm)

26.05”

(66cm)

26.05”

(66cm)

21.81”

(55cm)

21.81”

(55cm)

21.81”

(55cm)

21.81”

(55cm)

Counter Cutout

Dimensions V/Hz/Ph Amps H.P. BTU

see drawing on

page 8

see drawing on

page 8

see drawing on

page 8

see drawing on

page 8

115/60/1 4.0 1/5 379

115/60/1

115/60/1 7.0 1/4 758

115/60/1 7.0 1/4 948

4.0 1/5 569

Evap BTU/

TD/TEMP

26/31º/4°

35/26º/9º

43/32º/3º

51/29º/6º

N8100-FA Series Forced Air Drop-In Mechanically Cooled Cold Pans - R404A

Model L D H

N8131-FA

N8144-FA

N8157-FA

N8169-FA

N8182-FA

31.25”

(79.4cm)

44”

(111.8cm)

56.75”

(144.1cm)

69.5”

(176.5cm)

82.25”

(208.9cm)

26.67”

(67.7cm)

26.67”

(67.7cm)

26.67”

(67.7cm)

26.67”

(67.7cm)

26.67”

(67.7cm)

26.62”

(68cm)

26.62”

(68cm)

26.62”

(68cm)

28.62”

(72.7cm)

28.62”

(72.7cm)

Counter Cutout

Dimensions V/Hz/Ph Amps H.P. BTU

30.25” x 25.5”

(76.8cm x 64.8cm)

43” x 25.5”

109.2cm x 64.8cm)

55.75” x 25.5”

(141.6cm x 64.8cm)

68.5” x 25.5”

174.0cm x 64.8cm)

81.25” x 25.5”

206.4cm x 64.8cm)

115/60/1 7.8 1/4 1339 140/15º/20

115/60/1 9.2 1/2 2035 140/22º/13

115/60/1 9.2 1/2 2731 280/14º/21° 3806

115/60/1 14.8 3/4

115/60/1 14.8 3/4 4070 280/20º/15° 5545

Evap BTU/

TD/TEMP

º

º

3374 280/20º/15° 5545

Sys

Ship

Cap

Weight

812 161lbs

(72kg)

889 184lbs

(83kg)

1373 233lbs

(105kg)

1469 243lbs

(109kg)

Sys

Ship

Cap

Weight

168lbs

2154

(76kg)

175lbs

3142

(79kg)

225lbs

(102kg)

235lbs

(107kg)

406lbs

(184kg)

Refrig.

NEMA

Charge

Plug

8.0oz 5-15P 2

5-15P

8.0oz

16.0oz 5-15P 4

16.0oz 5-15P 5

Refrig.

NEMA

Charge

Plug

16.0oz 5-15P 2

32.0oz 5-15P 3

32.0oz 5-15P 4

48.0oz 5-20P 5

48.0oz 5-20P 6

12”x20”

Pans

3

12”x20”

Pans

4

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

™

®

Page 5

N8000 Series Drop-In Installation and Operation Manual

Delfield

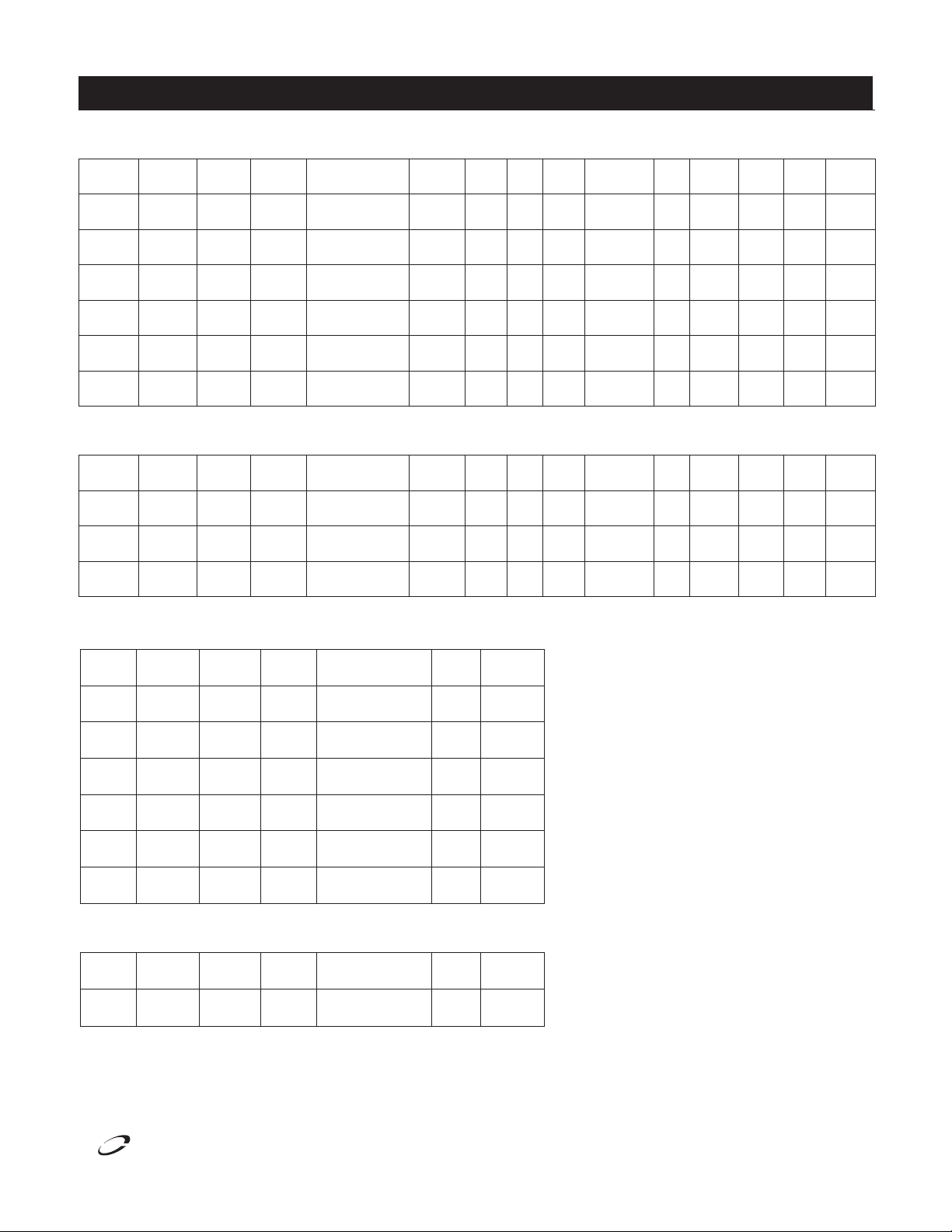

Specifications

8100-EF Series LiquiTec® Eutetic Fluid Refrigerated Cold Pans - R404A

Model L D H

8118-EF

8132-EF

8145-EF

8159-EF

8172-EF

8186-EF

18.20”

(46.2cm)

31.76”

(80.7cm)

45.32”

(115.1cm)

58.88”

(149.6cm)

72.44”

(184cm)

86”

(218.4cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

23.25”

(59.1cm)

23.25”

(59.1cm)

23.25”

(59.1cm)

23.25”

(59.1cm)

23.25”

(59.1cm)

23.25”

(59.1cm)

Counter Cutout

Dimensions V/Hz/Ph Amps H.P.

17” x 25”

(43.2cm x 63.5cm)

30.75” x 25”

(78.1cm x 63.5cm)

44.25” x 25”

(112.4cm x 63.5cm)

57.87” x 25”

(147cm x 63.5cm)

71.5” x 25”

(181.6cm x 63.5cm)

85” x 25”

(215.9cm x 63.5cm)

115/60/1 7.5 1/4 204 19/50º/-15° 928 169lbs

115/60/1 7.5 1/4 379 26/42º/-7° 1112 215lbs

115/60/1 7.5 1/4 569 35/36º/-1° 1259 265lbs

115/60/1 7.5 1/4 758 43/32º/3° 1373 285lbs

115/60/1 7.5 1/4 948 51/29º/6° 1469 295lbs

115/60/1 7.5 1/4 1138 59/26º/9° 1529 394lbs

8100-EFN Series LiquiTec® Slim Line Eutetic Fluid Refrigerated Cold Pans - R404A

Model L D H

8148-EFN

8169-EFN

8191-EFN

47.66”

(121.1cm)

69.22”

(175.8cm)

90.78”

(230.6cm)

18”

(45.7cm)

18”

(45.7cm)

18”

(45.7cm)

23.25”

(59.1cm)

23.25”

(59.1cm)

23.25”

(59.1cm)

Counter Cutout

Dimensions V/Hz/Ph Amps H.P.

46.88” x 17.25”

(119.1cm x 43.8cm)

68.5” x 17.25”

(174cm x 43.8cm)

90” x 17.25”

(228.6cm x 43.8cm)

115/60/1 7.5 1/4 379 26/42º/-7° 1112 235lbs

115/60/1 7.5 1/4 569 35/36º/-1° 1259 285lbs

115/60/1 7.5 1/4 758 43/32º/13° 1373 295lbs

BTU

Load

BTU

Load

Evap BTU/

TD/TEMP

Evap BTU/

TD/TEMP

Sys

Cap

Sys

Cap

Ship

Weight

(77kg)

(98kg)

(120kg)

(130kg)

(134kg)

(179kg)

Ship

Weight

(107kg)

(130kg)

(134kg)

Refrig.

NEMA

Charge

Plug

24.0oz 5-15P 1

24.0oz 5-15P 2

24.0oz 5-15P 3

24.0oz 5-15P 4

24.0oz 5-15P 5

24.0oz 5-15P 6

Refrig.

NEMA

Charge

Plug

24.0oz 5-15P 2

24.0oz 5-15P 3

24.0oz 5-15P 4

12x20

Pans

12x20

Pans

N8000 Series Ice Cooled Cold Pans

Model

N8018

N8030

N8043

N8056

N8069

N8081

L D H

18”

(45.7cm)

30.75”

(78.1cm)

43.5”

(110.5cm)

56.25”

(142.9cm)

69”

(175.3cm)

81.75”

(208cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

10.75”

(27.3cm)

10.75”

(27.3cm)

10.75”

(27.3cm)

10.75”

(27.3cm)

10.75”

(27.3cm)

10.75”

(27.3cm)

Counter Cutout

Dimensions

17” x 25”

(43.2cm x 63.5cm)

29.75” x 25”

(75.6cm x 63.5cm)

42.5” x 25”

(107.9cm x 63.5cm)

55.25” x 25”

(140.3cm x 63.5cm)

68” x 25”

(172.7cm x 63.5cm)

80.75” x 25”

(205.1cm x 63.5cm)

N8000N Series Narrow Ice Cooled Cold Pans

N8046N

N8068N

46.75”

(118.8cm)

67.5”

(171.5cm)

18”

(45.7cm)

18”

(45.7cm)

10.75”

(27.3cm)

10.75”

(27.3cm)

45.75” x 17”

(116.2cm x 43.2cm)

66.50” x 17”

(168.9cm x 43.2cm)

Ship

Weight

38lbs

(17kg)

84lbs

(38kg)

110lbs

(50kg)

139lbs

(63kg)

160lbs

(73kg)

197lbs

(89kg)

100lbs

(45kg)

120lbs

(55kg)

12”x20”

Pans Held

1

2

3

4

5

6

2

3

™

®

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

5

Page 6

N8000 Series Drop-In Installation and Operation Manual

Delfield

Specifications

N8000-R Series Curved Ice Cooled Cold Pans

Model

N8044-R

N8059-R

N8076-R

N8094-R

L D H

40.48”

(103cm)

57.22”

(145cm)

73.68”

(187cm)

89.89”

(228cm)

26.05”

(66cm)

26.05”

(66cm)

26.05”

(66cm)

26.05”

(66cm)

10.77”

(27cm)

10.77”

(27cm)

10.77”

(27cm)

10.77”

(27cm)

Counter Cutout

Dimensions

see drawing on page 8 100lbs

see drawing on page 8 118lbs

see drawing on page 8 145lbs

see drawing on page 8 164lbs

N8200 Series Self-Contained Frost Tops - R404A

Model

N8231

N8245

N8259

N8273

N8287

L D H

31.75"

(80.6cm)

45.63”

(115.9cm)

59.5”

(151.1cm)

73.38"

(186.4cm)

87.25"

(221.6cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

15.75”

(40cm)

15.75”

(40cm)

15.75”

(40cm)

15.75”

(40cm)

15.75”

(40cm)

Counter Cutout

Dimensions V/Hz/Ph Amps H.P. BTU

30.75” x 25"

(78.1cm x 63.5cm)

44.63” x 25”

(113.3cm x 63.5cm)

58.50” x 25”

(148.6cm x 63.5cm)

72.38” x 25”

(183.8cm x 63.5cm)

86.25" x 25"

(219.1cm x 63.5cm)

Ship

Weight

(45kg)

(53kg)

(65kg)

(74kg)

115/60/1 7.5 1/4

115/60/1 7.5 1/4

115/60/1 7.5 1/4

115/60/1 8.0 1/4

115/60/1 8.0 1/3

12”x20”

Pans Held

2

3

4

5

Evap BTU/

TD/TEMP

379 26/42º/-7° 1112

569 35/36º/-1° 1259

758 43/32º/3° 1373

948 51/29º/6° 1469

1138 59/30º/5° 1787

Sys

Cap Ship Weight

142lbs

(64kg)

168lbs

(76kg)

193lbs

(88kg)

209lbs

(95kg)

239lbs

(108kg)

Refrig.

Charge

24.0oz

24.0oz

24.0oz

24.0oz

24.0oz

NEMA

Plug

5-15P

5-15P

5-15P

5-15P

5-15P

N8200G Series Self-Contained Granite Cold Slabs

Model

N8231G

N8245G

N8259G

N8273G

L D H

31.75”

(80.6cm)

45.63”

(115.9cm)

59.5”

(151.1cm)

73.38”

(186.4cm)

25.87”

(65.7cm)

25.87”

(65.7cm)

25.87”

(65.7cm)

25.87”

(65.7cm)

19”

(48.3cm)

19”

(48.3cm)

19”

(48.3cm)

19”

(48.3cm)

Counter Cutout

Dimensions V/Hz/Ph Amps H.P. BTU

30.75” X 25”

(78.1cm x 63.5cm)

44.63” x 25”

(113.4cm x 63.5cm)

58.5” x 25”

(148.6cm x 63.5cm)

72.38” x 25”

(183.8cm x 63.5cm)

115/60/1 7.5 1/4

115/60/1 7.5 1/4

115/60/1 8.0 1/3

115/60/1 9.0 1/2

Evap BTU/

TD/TEMP

379 26/42º/-7° 1112

569 35/36º/-1° 1259

758 43/37º/-2° 1572

948 51/43º/-8° 2183

N8600 Series Self Contained Combination Hot/Cold Food Wells - R404A

Model

N8630

N8643

N8656

N8669

N8681

L D H

30.75”

(78.1cm)

43.5”

(110.5cm)

56.25”

(142.9cm)

69”

(175.3cm)

81.75”

(207.6cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

23.75”

(60.3cm)

23.75”

(60.3cm)

23.75”

(60.3cm)

23.75”

(60.3cm)

23.75”

(60.3cm)

Counter Cutout

Dimensions

29.75” X 25”

(75.5cm x 63.5cm)

42.50” x 25”

(107.9cm x 63.5cm)

55.25” x 25”

(140.3cm x 63.5cm)

68” x 25”

(172.7cm x 63.5cm)

80.75” x 25”

(205.1cm x 63.5cm)

Control Panel Cutout

Dimensions

12.25” x 4.25” x 7.00”

(31.1cm x 10.8cm x 17.8cm)

12.25” x 4.25” x 7.00”

(31.1cm x 10.8cm x 17.8cm)

12.25” x 4.25” x 7.00”

(31.1cm x 10.8cm x 17.8cm)

12.25” x 4.25” x 7.00”

(31.1cm x 10.8cm x 17.8cm)

12.25” x 4.25” x 7.00”

(31.1cm x 10.8cm x 17.8cm)

V/Hz/Ph Amps H.P. BTU

120/60/1 24.0 1/4

120/240

/60/1

120/240

/60/1

120/240

/60/1

120/240

/60/1

21.0 1/4

21.0 1/4

42.0 1/4

42.0 1/3

Sys

Cap Ship Weight

219lbs

(99kg)

284lbs

(129kg)

338lbs

(153kg)

425lbs

(193kg)

Evap BTU/TDSys

Cap

379 26/42º/-7° 1112

569 35/36º/-1° 1259

758 43/32º/3° 1373

948 51/29º/6° 1469

1138 59/30º/5° 1787

Refrig.

Charge

24.0oz

24.0oz

24.0oz

32.0oz

Ship

Weight

164lbs

(74kg)

198lbs

(90kg)

233lbs

(106kg)

266lbs

(121kg)

301lbs

(137kg)

NEMA

Plug

5-15P

5-15P

5-15P

5-15P

Refrig.

Charge

16.0oz 2

16.0oz 3

16.0oz 4

16.0oz 5

24.0oz 6

12”x20”

Pans

6

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

™

®

Page 7

N8000 Series Drop-In Installation and Operation Manual

Delfield

Specifications

N8700D Series Individually Controlled Heated Food Wells

Model

N8717-D

N8731-D

N8745-D

N8759-D

N8773-D

N8787-D

L D H

17.88”

(45.4cm)

31.75”

(80.6cm)

45.63”

(115.9cm)

59.5”

(151.1cm)

73.38”

(186.4cm)

87.25”

(221.4cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

9.5”

(24cm)*

9.5”

(24cm)*

9.5”

(24cm)*

9.5”

(24cm)*

9.5”

(24cm)*

9.5”

(24cm)*

Counter Cutout

Dimensions

16.88” X 25”

(42.8cm x 63.5cm)

30.75” x 25”

(78.1cm x 63.5cm)

44.62” x 25”

(113.3cm x 63.5cm)

58.5” x 25”

(148.6cm x 63.5cm)

72.37” x 25”

(183.8cm x 63.5cm)

86.25” x 25”

(219.1cm x 63.5cm)

*14” Overall height including drain connection

N8700-R Series Curved Individually Controlled Heated Food Wells

Model

N8744-R

N8759-R

N8776-R

N8794-R

L D H

40.48”

(103cm)

57.22”

(145cm)

73.68”

(187cm)

89.80”

(228cm)

26.05”

(66cm)

26.05”

(66cm)

26.00”

(66cm)

25.91”

(66cm)

9.5”

(24cm)*

9.5”

(24cm)*

9.5”

(24cm)*

9.5”

(24cm)*

*14” Overall height including drain connection

Counter Cutout

Dimensions

see drawing on page 8 10.31” x 4.62” x 7.00”

see drawing on page 8 14.5” x 4.62” x 7.00”

see drawing on page 8 18.69” x 4.62” x 7.00”

see drawing on page 8 22.88” x 4.62” x 7.00”

Control Panel Cutout

Dimensions

7.00” x 4.62” x 7.00”

(17.8cm x 11.7cm x 17.8cm)

10.31” x 4.62” x 7.00”

(26.2cm x 11.7cm x 17.8cm)

14.5” x 4.62” x 7.00”

(36.8cm x 11.7cm x 17.8cm)

18.69” x 4.62” x 7.00”

(47.5cm x 11.7cm x 17.8cm)

22.88” x 4.62” x 7.00”

(58.1cm x 11.7cm x 17.8cm)

27” x 4.62” x 7.00”

(68.6cm x 11.7cm x 17.8cm)

Control Panel Cutout

Dimensions

(26cm x 12cm x 18cm)

(37cm x 12cm x 18cm)

(47cm x 12cm x 18cm)

(58cm x 12cm x 18cm)

V/Hz/Ph Amps

120/60/1 8.3 41lbs

120/60/1 16.6 99lbs

208-230

/60/1

208-230

/60/1

208-230

/60/1

208-230

/60/1

V/Hz/Ph Amps

120/60/1 16.6 99lbs

208-230

/60/1

208-230

/60/1

208-230

/60/1

Ship

Weight

(19kg)

(45kg)

15.0/16.0 134lbs

(61kg)

20.0/22.0 166lbs

(75kg)

24.0/27.0 186lbs

(84kg)

29.0/32.0 236lbs

(107kg)

Ship

Weight

(45kg)

15.0/16.0 134lbs

(61kg)

20.0/22.0 166lbs

(75kg)

24.0/27.0 186lbs

(84kg)

12”x20”

Pans

1

2

3

4

5

6

12”x20”

Pans

2

3

4

5

N8700N Series Individually Controlled Heated Narrow Food Wells

Model

N8746N

N8746ND

N8768N

N8768ND

L D H

45.61”

(116cm)

67.48”

(172cm)

15.87”

(40cm)

15.87”

(40cm)

9.5”

(24cm)

9.5”

(24cm)

*ND Models are standard with drains

Counter Cutout

Dimensions

44.62” x 15.0”

(113.3cm x 38.1cm)

66.50” x 15.0”

(168.9cm x 38.1cm)

Control Panel Cutout Dimensions

10.31” x 4.62” x 7.00”

(26.2cm x 11.7cm x 17.8cm)

14.50” x 4.62” x 7.00”

(36.8cm x 11.7cm x 17.8cm)

V/Hz/Ph Amps

120/60/1 17.0 100lbs

208-230

/60/1

N8800 Series Single Tank Electric Hot Food Wells

Model

N8831

N8845

N8859

N8873

N8887

L D H

31.75”

(80.6cm)

45.63”

(115.9cm)

59.5”

(151.1cm)

73.38”

(186.4cm)

87.25”

(221.6cm)

™

26”

(66cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

®

11”

(27.9cm)

11”

(27.9cm)

11”

(27.9cm)

11”

(27.9cm)

11”

(27.9cm)

Counter Cutout

Dimensions

30.75” X 25”

(78.1cm x

63.5

44.63” x 25”

(113.4cm x

63.5

58.5” x 25”

(148.6cm x

63.5

72.38” x 25”

(183.8cm x

63.5

86.25” x 25”

(219.1cm x

63.5

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

Control Panel Cutout Dimensions

12.25” x 4.25” x 7.00”

cm)

(31.1cm x 10.8cm x 17.8cm)

12.25” x 4.25” x 7.00”

cm)

(31.1cm x 10.8cm x 17.8cm)

12.25” x 4.25” x 7.00”

cm)

(31.1cm x 10.8cm x 17.8cm)

12.25” x 4.25” x 7.00”

cm)

(31.1cm x 10.8cm x 17.8cm)

12.25” x 4.25” x 7.00”

cm)

(31.1cm x 10.8cm x 17.8cm)

V/Hz/Ph Amps

120/60/1 17.0 100lbs

208-230

/60/1

208-230

/60/1

208-230

/60/1

208-230

/60/1

Ship

Weight

(45kg)

15.0/16.0 130lbs

(59kg)

Ship

Weight

(45kg)

15.0/16.0 136lbs

(62kg)

20.0/22.0 158lbs

(72kg)

24.0/27.0 195lbs

(88kg)

29.0/32.0 224lbs

(102kg)

12”x20”

Pans

2

3

12”x20”

Pans

2

3

4

5

6

7

Page 8

N8000 Series Drop-In Installation and Operation Manual

Delfield

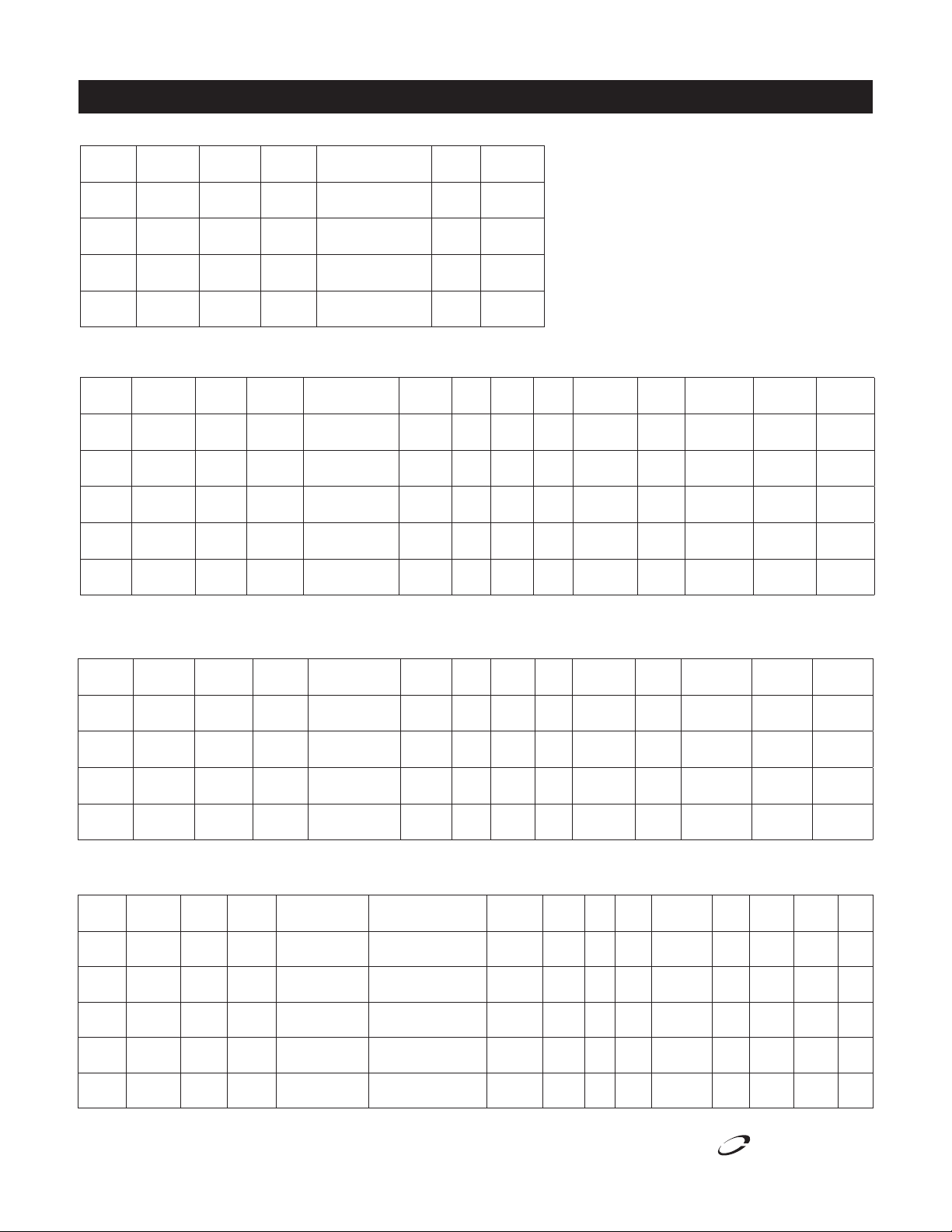

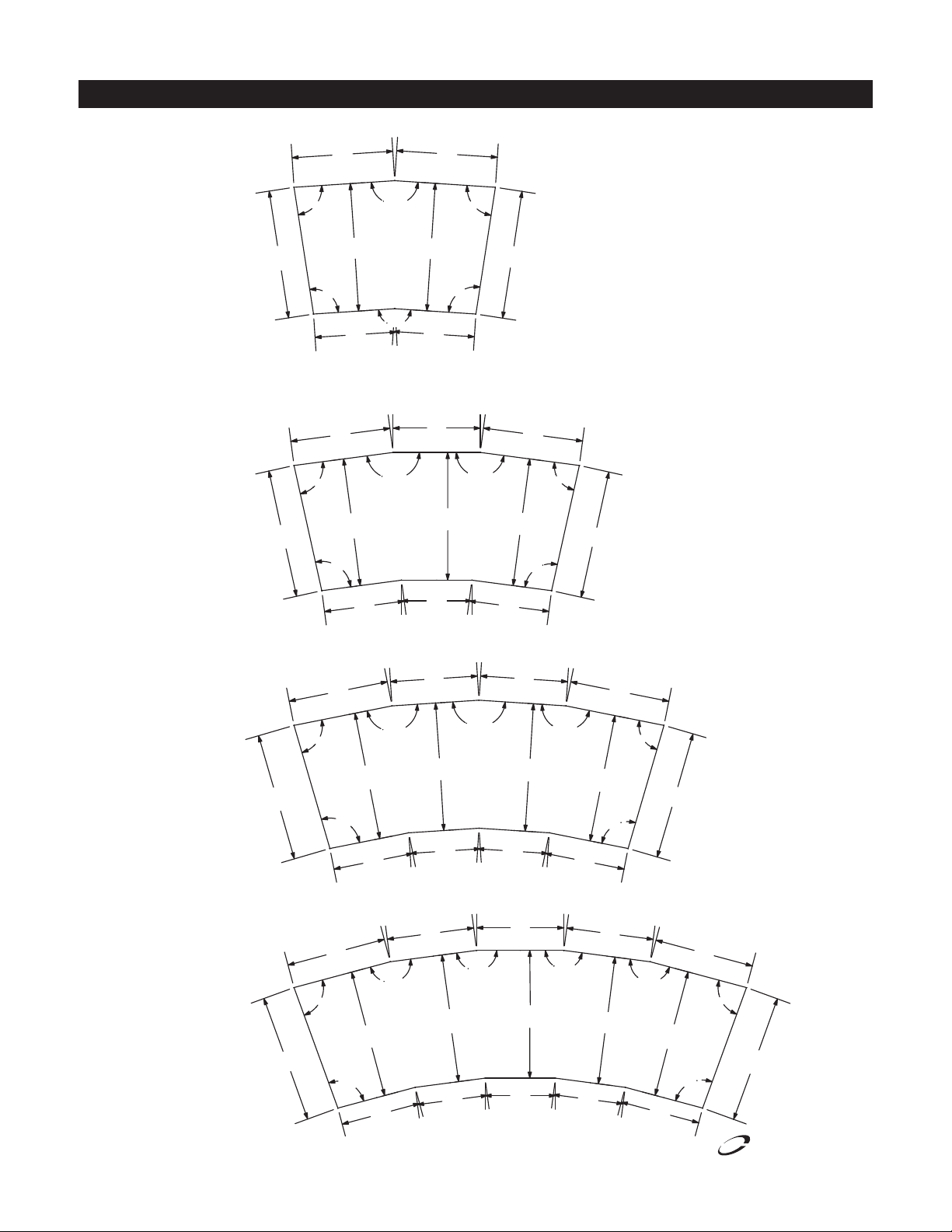

Curved Drop-In Cutout Details

2 pan standard curved drop-in cutout detail

Models:

• N8044-R

• N8144-BR

• N8744-R

85˚

19.75”

50cm

172.50˚

19.75”

50cm

85˚

25.10”

64cm

95˚

3 pan standard curved drop-in cutout detail

Models:

• N8059-R

• N8159-BR

• N8759-R

25.10”

64cm

85˚

4 pan standard curved drop-in cutout detail

Models:

• N8076-R

• N8176-BR

• N8776-R

25.10”

64cm

85˚

19.56”

50cm

19.56”

50cm

95˚

95˚

25.00”

64cm

15.92”

40cm

25.00”

64cm

15.73”

40cm

25.00”

64cm

15.73”

40cm

172.50˚

172.50˚

172.50˚

25.00”

64cm

15.92”

40cm

17.06”

43cm

13.78”

35cm

17.06”

43cm

25.00”

64cm

25.00”

64cm

13.78”

35cm

95˚

172.50˚

172.50˚

25.10”

64cm

15.73”

40cm

13.78”

35cm

25.00”

64cm

17.06”

43cm

25.00”

64cm

19.56”

50cm

95˚

85˚

172.50˚

25.10”

64cm

15.73”

40cm

25.00”

64cm

19.56”

50cm

95˚

85˚

25.10”

64cm

5 pan standard curved drop-in cutout detail

Models:

• N8094-R

• N8194-BR

• N8794-R

8

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

25.10”

64cm

172.50˚

17.06”

43cm

25.00”

64cm

13.78”

35cm

172.50˚

13.78”

35cm

17.06”

43cm

25.00”

64cm

172.50˚

15.67”

40cm

25.00”

64cm

95˚

19.50”

50cm

85˚

25.10”

64cm

™

®

17.06”

172.50˚

43cm

25.00”

64cm

13.78”

35cm

19.50”

50cm

85˚

25.00”

64cm

95˚

15.67”

40cm

Page 9

N8000 Series Drop-In Installation and Operation Manual

Delfield

CAUTION

DANGER

DANGER

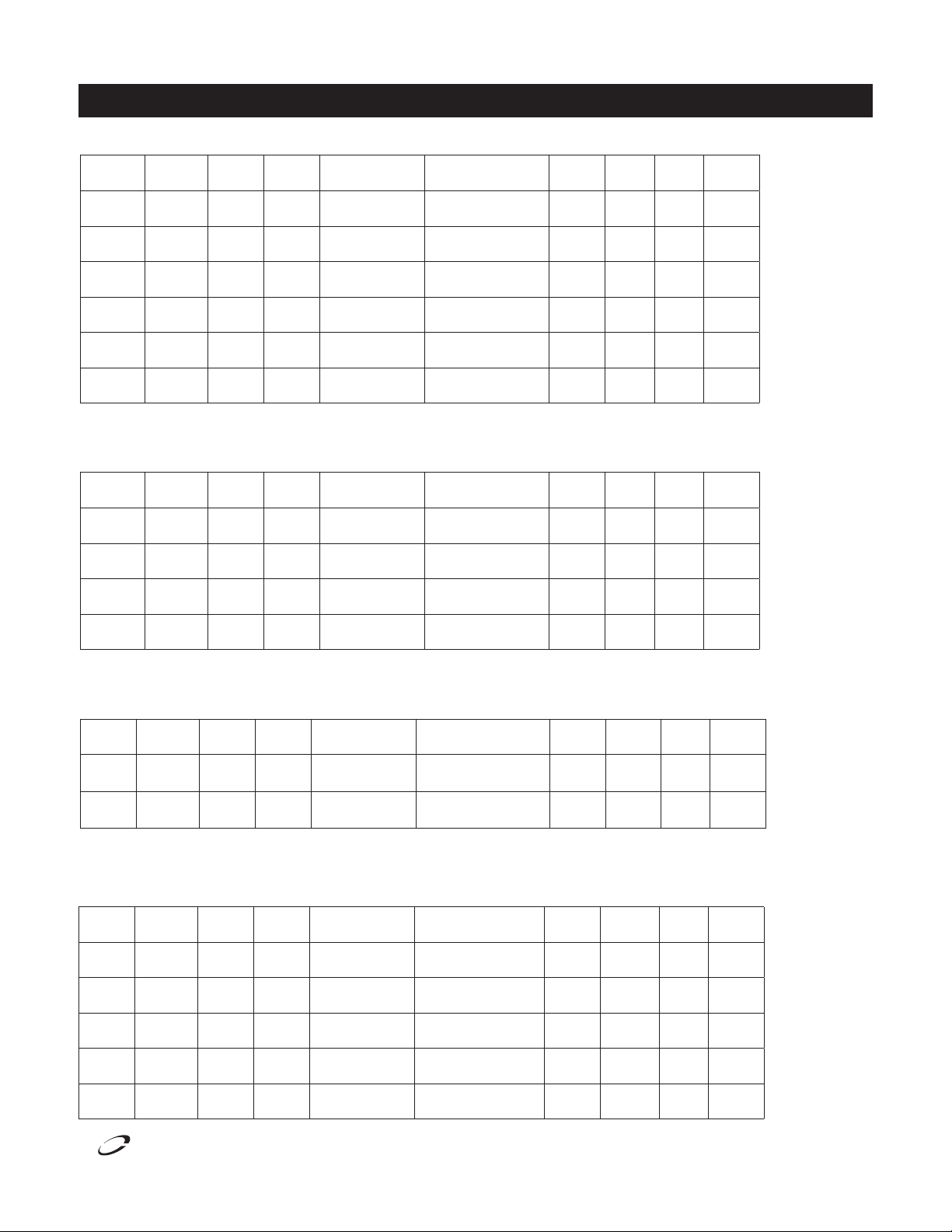

Installation N8000, N8000N, N8000-R, N8100B, N8100NB, N8100-BR, N8200, N8200G, N8100-FA & 8100-EF

These units are intended for indoor use only. A room

temperature of no more than 86°F (30°C) is recommended.

Be sure the location chosen has a counter strong enough to

support the total weight of the unit and contents. A fully loaded

model may weigh as much as 600 pounds! Reinforce the

counter as necessary to provide maximum loading.

Unit requires that the sides and bottom are not

any closer than 3” (7.6cm) to any combustible

material.

The counter cut-out sizes and power requirements are shown

on the specication pages. A gasket is installed in the ange

of each unit. The weight of the unit on the gasket forms a seal

preventing liquids from seeping into the cut-out opening.

Louvers

Self-contained refrigerated units (N8100, N8100NB, N8100-BR,

N8200 and N8200G Series) require airow to the compressor.

A 13” x 25” (33 cm x 63.5 cm) louver is provided by Deleld and

must be installed in the counter in front of the condenser. The

louver cutout dimension is 11” x 22” (27.9 cm x 55.9 cm). The

rear must have an opening to permit removal of heated air. The

opening must be at least 8” x 11”, a total of 88 square inches

(20.3 cm x 27.9 cm, a total of 566 square centimeters).

Plumbing

The units drain must have an outlet to an appropriate drainage

area or container. A drain trap must be installed. N8200 series

have 1/2” drain and N8200G series have 3/4” drain located on

end/center. The 1” diameter drain on N8000, N8000-R, N8100,

N8100NB, N8100-BR, N8100-FA and 8100-EF Series units

is shipped loose and must be connected during installation.

N8157-FA, N8169-FA, and N8182-FA have two drains.

Electrical connection

Refer to the amperage data on the specication pages, the

serial tag or your local code to be sure the unit is connected

to the proper power source. A protected circuit of the correct

voltage and amperage must be run for con nec tion of the line

cord.

Some units have an ON/OFF switch located behind the

louvered panel in the machine compartment. Simply turn the

switch to ON to begin operation.

Some units have an OFF position on the thermostat dial which is

located behind the louvered panel in the machine compartment.

Simply turn the dial to begin operation.

Moisture collecting from improper drainage

can create a slippery surface on the oor

and a hazard to employees. It is the owner’s

responsibility to provide a container or outlet

for drainage.

Some N8000, N8000N, N8000-R, N8100B,

N8100NB and N8100-BR may have

polyethylene insulation in the drain hole.

This can easily be cut out without any contact

or damage to the units interior insulation or

refrigeration lines.

The unit must be disconnected from the

power source whenever performing service

or maintenance functions.

Never operate the unit without the louvered

panel in place!

Installation N8600

These units are intended for indoor use only. A room temperature

of no more than 86°F (30°C) is recommended. Be sure the

location chosen has a counter strong enough to support the

total weight of the unit and contents. A fully loaded model

may weigh as much as 600 pounds! Reinforce the counter as

necessary to provide for maximum loading.

Unit requires that the sides and bottom are not

any closer than 3” (7.6cm) to any combustible

material.

The counter cut-out sizes and power requirements are shown

on the specication pages. A gasket is installed in the ange

of each unit. The weight of the unit on the gasket forms a seal

preventing liquids from seeping into the cut-out opening.

The cut-out dimensions for the control box on N8600 Series

units is 4.25” x 12.25” (10.8 cm x 31.1 cm).

Louvers

For proper refrigerated operation, N8600 Series units require

airow to the compressor. A 13” x 25” louver is (33.0 cm x 63.5

cm) is provided by Deleld and must be installed in the counter

in front of the condenser. The louver cutout dimension is 11”

™

®

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

x 22” (27.9 cm x 55.9 cm). The rear must have an opening to

permit removal of heated air. The opening must be at least 8” x

11”, a total of 88 square inches (20.3 cm x 27.9 cm, a total of 566

square centimeters).

Plumbing

The units 1” (2.54cm) drain must have an outlet to an appropriate

drainage area or container.

Moisture collecting from improper drainage

can create a slippery surface on the oor

and a hazard to employees. It is the owner’s

CAUTION

responsibility to provide a container or outlet

for drainage.

Electrical connection

Refer to the amperage data on the specication pages, the

serial tag or your local code to be sure the unit is connected to

the proper power source.

The unit must be disconnected from the

power source whenever performing service

or maintenance functions.

Never operate the unit without the louvered

panel in place!

9

Page 10

N8000 Series Drop-In Installation and Operation Manual

Delfield

CAUTION

DANGER

Installation N8700-D, N8700N, N8700-R & N8800 Series

These units are intended for indoor use only. Be sure the

location chosen has a counter strong enough to support the

total weight of the unit and contents. A fully loaded model

may weigh as much as 600 pounds! Reinforce the counter as

necessary to provide maximum loading.

Plumbing

N8700-D, N8700N-D and N8700-R Plumbing: Unit is equipped

with 1/2” (1.3cm) drains, (one per well located in right rear corner

1/2” (1.3cm) female N.P.T.) manifold and 1/2” (1.3cm) gate valve.

Unit requires that the sides and bottom are not

any closer than 3” (7.6cm) to any combustible

material.

The counter cut-out sizes and power requirements are shown

on the specication pages. A gasket is installed in the ange

of each unit. The weight of the unit on the gasket forms a seal

preventing liquids from seeping into the cut-out opening.

N8700 Series pans should be installed with the

drains at the back, away from the operator’s

sides.

The controls on N8700-D, N8700-R and N8800 series units

are mounted in a control panel, designed to be installed at a

“remote” location. The control panel should be installed so that

the indicator light for each control is to the right of the control.

N8700, N8700N and N8700-R series units have 48” (121.9cm)

of conduit and N8800 Series units have 24” (61.0cm) of conduit

between the pans and the remote control panel to facilitate this

installation.

N8800 Plumbing: Well is sloped to a 1.00” (2.5cm) male N.P.T.

stainless steel drain.

Moisture collecting from improper drainage

can create a slippery surface on the oor

and a hazard to employees. It is the owner’s

responsibility to provide a container or outlet

for drainage.

Electrical connection

Refer to the amperage data on the specication pages, the

serial tag or your local code to be sure the unit is connected to

the proper power source.

The unit must be disconnected from the

power source whenever performing service

or maintenance functions.

Control Panel Installation, N8700-D, N8700N & N8700-R Series

The control panel is designed to be installed on the side

opposite the drains.

If you choose to install the control panel on the same side as the

drains the control panel will either be upside down or the knobs

will control the opposite wells.

10

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

Control panel

installed

opposite drains

Drains

™

®

Page 11

Delfield

Operation N8100B, N8100NB & N8100-BR

Ruby Tuesday Salad Bar Service and Installation Manual

DEFROST TIMER

18648-BUC

. . . . . . . . . . . . . . . . . . . . . . .

16 oz.

18660-BUC

. . . . . . . . . . . . . . . . . . . . . . .

16 oz.

18672-BUC

16 oz.

18691-BUC

. . . . . . . . . . . . . . . . . . . . . . .

16 oz.

18699-BUC

24 oz.

186114-BUC

24 oz.

55# cut-in and 30# cut-out to maintain

82# cut-in and 57# cut-out to maintain

N8100 Series mechanically cooled cold pans are adjusted

at the factory to provide proper operation without any further

adjustments. However, if it is necessary to adjust the

temperature, the control is located in the machine compartment.

Turn the knob clockwise as indicated on the control. Settings

are from 1 thru 7 (7 being the coldest). Adjustments should

be made gradually. Several small adjustments will be more

effective than one large adjustment. It may take an hour or

longer to realize the temperature change depending on the

application and location of the unit.

These units are not designed to cool warm food products. Items

should be placed in the unit pre-cooled at least to the desired

holding temperature, if not slightly colder. In some applications,

a gradual warming of product may occur, particularly at the

exposed top of the product. Stirring or rotation of the product

may be necessary to maintain overall temperature.

N8000 Series Drop-In Installation and Operation Manual

Warming of food product can occur very quickly outside of the

unit. When loading or rotating product, avoid leaving food items

in a non-refrigerated location for any length of time to prevent

warming or spoilage.

The temperature control is used to turn the unit on and off as

well as control the temperature of the cold pan. The settings

range from 1 through 7 (7 being the coldest). To turn the cold

pan off, turn the knob to the OFF position.

If the cold pan is to be used with ice, it is recommended that

the optional perforated bottoms be used. These will allow ice

to melt properly.

The unit must be turned off when not in use or overnight for

defrosting and cleaning.

Operation N8100-FA

N8100-FA Series forced air mechanically cooled cold pans come

equipped with 115-volt, 60 Hertz, single phase refrigeration

units. The refrigeration valves are open and ready to operate

as soon as the power supply cord is plugged into the standard

115-volt, grounded electrical outlet.

Pressure Control

The temperature is controlled by an adjustable pressure control

located in the machine compartment and adjustable control has

the word COLDER near the knob, with an arrow to indicate the

adjustment direction. This control is eld adjustable and does

not require a service agent. If you have any questions, feel free

to contact the Deleld Service Department at (800) 733-8829.

In attempting to adjust the pressure control,

you can do damage to the unit by accidentally

adjusting the differential. Deleld is not

responsible for charges incurred while adjusting

the pressure control.

Food in the N8100-FA pans should not be loaded

in such a way as to interfere with the air curtain

owing over the cold pans.

Defrost Timer

Every 2 hours for 15 minutes.

30 psi (207 kPa) dierential

80 psi (552 kPa) cut-in

50 psi (345 kPa) cut-out

™

®

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

11

Page 12

N8000 Series Drop-In Installation and Operation Manual

Delfield

Operation 8100-EF Series

There is a switch on the compressor housing front to turn the

8100-EF units on and off. 8100-EF Series LiquiTec

uid cold pans are adjusted at the factory to provide proper

operation without any further adjustments. However, if it is

necessary to adjust the temperature, the control is located in the

machine compartment. Turn the knob clockwise as indicated

on the control to adjust it colder. Adjustments should be made

gradually. Several small adjustments will be more effective than

one large adjustment. It may take an hour or longer to realize

the temperature change depending on the application and

location of the unit.

These units are not designed to cool warm food products. Items

should be placed in the unit pre-cooled at least to the desired

holding temperature, if not slightly colder. In some applications,

a gradual warming of product may occur, particularly at the

exposed top of the product. Stirring or rotation of the product

may be necessary to maintain overall temperature. Warming

of food product can occur very quickly outside of the unit.

When loading or rotating the product, avoid leaving food items

in a non-refrigerated location for any length of time to prevent

warming or spoilage.

The cold pan is not intended to be used with

ice.

®

Eutetic

The unit must be turned off when not in use or overnight for

defrosting and cleaning.

Temperature Control Settings:

17°F (8ºC) differential

25°F (-4ºC) cut-in

8°F (-13ºC)cut-out

Operation N8200

N8200 Series frost tops are designed to maintain an even layer

of frost to pleasantly display product. Once turned on, the

compressor will run continuously. The unit should be turned off

overnight or when not in use. There is no temperature control

on the N8200 series. The ON/OFF switch is the only means

available to cycle the unit.

Operation N8200G

N8200G Series granite cold slabs are designed to maintain a

low temperature surface for quick turn products such as ice

cream. Frost patterns will vary depending on room conditions

such as temperature, humidity and airow. The “work zone”

of the granite surface is considered to be inside a 2” (5.1cm)

perimeter. Temperatures in the perimeter zone may be higher

and again the frost patterns in this area will vary based on room

conditions.

Since it takes time for the frost to accumulate initially, the unit

should be turned on approximately one hour before it is actually

required. Product should not be placed on the frost top prior to

turning the unit on, because it may freeze to the surface of the

unit.

The unit must be turned off when not in use or overnight for

defrosting and cleaning.

Unit is controlled by an on/off switch. Once turned on, the unit

will run continuously. There is no temperature control in this

unit. Turn the unit on approximately two hours prior to use to

allow for ample cool down time. The unit must be turned off

when not in use or overnight for defrosting and cleaning.

12

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

™

®

Page 13

Delfield

DARNGE

STPE S

Operation N8600 Hot/Cold Series

Hot Operation

N8600 Series hot and cold combination pans must be operated

with water in the well for proper hot operation. Fill well with a

minimum of 4” (10.2cm) of water. Place function switch in HOT

position to begin heating. Turn thermostat dial to the desired

temperature.

Never use anything other than plain water

in the wells or tank. Failure to observe this

warning may result in personal injury or

damage to the unit.

When operated at the highest temperature

setting, the top of the unit will become very

hot. Staff and customers using the equipment

should be informed about this.

To turn unit off, simply move the function switch to OFF position.

Drain water and allow unit to cool before cleaning or switching

to cold operation.

Cold Operation

Simply place the function switch to the COLD position. The

compressor controller has been factory set and no temperature

adjustment should be necessary. If the cold pan is to be used

with ice, it is recommended that the optional perforated bottoms

be used. These will allow ice to melt properly.

N8000 Series Drop-In Installation and Operation Manual

Switching from hot to cold operation

Follow this procedure:

1. Place the function switch in the OFF position

and drain out hot water.

2. Allow the unit to cool until it can be safely

cleaned.

3. When clean up procedures are complete, unit

will be ready for cold operation. This takes

about one hour.

To assure maximum compressor life, do not

switch from “hot” to “cold” operation without

allowing a cool down period. Never switch from

hot to cold operation while hot water remains in

the pans. Failure to observe this warning will

greatly reduce compressor life and eventually

cause premature compressor failure.

Switching from cold to hot operation

No special procedure is required to switch from the cold to hot

operation. Be certain to ll will with a minimum of 4” of water.

The unit is designed so that the compressor

and the heating elements cannot operate at

the same time. Continued operation of the

compressor in the “hot position” should not

be considered normal. Call for service if this

happens.

N8600 Immersion Heater Reset Switch

As a safety feature the N8600 food well immersion heater has a

reset switch. If the heater gets too hot, it will turn off. Low or no

water can be the cause.

The unit must be turned off when you push

the manual reset switch.

Access Hole for N8600 Immersion

Heater Reset Switch

The unit must be turned off when not in use or overnight for

defrosting and cleaning.

™

®

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

13

Page 14

N8000 Series Drop-In Installation and Operation Manual

Delfield

DARNGE

DARNGE

DARNGE

Operation N8700-D, N8700N, N8700-R & N8800 Series

These units are designed to hold warm food product between

140ºF to 160ºF (60ºC to 71ºC).

N8700-D, N8700N and N8700-R series individually heated

hot food units may be operated “wet” (with water in the wells)

or “dry”. However, “wet” operation is recommended for better

performance.

N8800 Series single tank hot food units are designed to be

operated “wet” (with water in the tank) only.

Proper water level (approximately 2” [5.1cm])

must be maintained to prevent damage to the

tank on the N8800 Series units.

After the unit is hard wired to the electrical system, select

desired temperature by rotating temperature control. A knob

and indicator light are provided for each individual heated food

well.

First Time Use

Before the unit is used the rst time for serving, turn the

temperature knob to “HI” and heat the well for 20 to 30 minutes.

Any residue or dust that adhered to the heater element(s) will

be burned off during this initial preheat period.

When serving thick sauces always use the hot food well in

“wet” operation. This provides more uniform temperature for

the sauce.

Never place food directly in well. Always use

pans.

For most efficient operation, keep covered inserts in each well

during preheating or when empty.

Always place covers on pans when not serving to prevent food

from drying out.

Wet Operation

Fill the food well with a minimum of 2” (5.1cm) of water and

cover with lid or empty pan. To preheat water, set temperature

control at “HI”. With pans in place, wells will boil water. Food

temperature will vary depending on type and amount of product.

To minimize steam and water usage, set control at lowest

setting that will maintain proper food temperature. To reduce

preheating time, use hot water to ll the well.

When operating these units “wet,” never use

anything other than plain water in the wells or

tank. Failure to observe this warning may result

in personal injury or damage to the unit.

When operated at the highest temperature

setting, the top of the unit will become very

hot. Staff and customers using the equipment

should be informed about this.

Steam can cause serious burns. Always use

some type of protective covering on your hands

and arms when removing lids from the unit. Lift

the lid in a way that will direct escaping steam

away from your face and body.

Dry Operation N8700 Series only

Wet operation is usually much more efficient and is preferred.

However, these units may be operated without water with no

damage to the unit.

When operated dry, the bottom of the well will discolor. To clean,

use a stainless steel cleaner or mild abrasive.

The dry well should never be preheated longer

than 15 minutes.

When operated dry, the well bottoms become

very hot. Do not allow unprotected skin to

contact any well surface.

14

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

™

®

Page 15

Delfield

Maintenance

N8000 Series Drop-In Installation and Operation Manual

Drain Maintenance - N8100-FA Series

Each unit has a drain located inside the unit that removes

the condensation from the evaporator coil and routes it to an

external condensate evaporator pan. Each drain can become

loose or disconnected during normal use. If you notice water

accumulation on the inside of the unit be sure the drain tube

is connected to the evaporator drain pan. If water is collecting

underneath the unit make sure the end of the drain tube is in

the condensate evaporator in the machine compartment. The

leveling of the unit is important as the units are designed to

drain properly when level. Be sure all drain lines are free of

obstructions.

The power switch must be turned to OFF and

the unit disconnected from the power source

whenever performing service, maintenance

functions or cleaning the refrigerated area.

Stainless Steel Care and Cleaning

To prevent discoloration or rust on stainless steel several

important steps need to be taken. First, we need to understand

the properties of stainless steel. Stainless steel contains 70- 80%

iron, which will rust. It also contains 12-30% chromium, which

forms an invisible passive lm over the steel’s surface, which

acts as a shield against corrosion. As long as the protective

layer is intact, the metal is still stainless. If the lm is broken or

contaminated, outside elements can begin to breakdown the

steel and begin to form discoloration or rust. Proper cleaning

of stainless steel requires soft cloths or plastic scouring pads.

Cleaning the Condenser Coil

In order to maintain proper refrigeration performance, the

condenser ns must be cleaned of dust, dirt and grease

regularly. It is recommended that this be done at least every

three months. If conditions are such that the condenser is totally

blocked in three months, the frequency of cleaning should be

increased. Clean the condenser with a vacuum cleaner or stiff

brush. If extremely dirty, a commercially available condenser

cleaner may be required.

Failure to maintain a clean condenser coil can initially cause high

temperatures and excessive run times. Continuous operation

with a dirty or clogged condenser coil can result in compressor

failure. Neglecting the condenser coil cleaning procedures will

void any warranties associated with the compressor and cost to

replace the compressor.

Never use a high-pressure water wash for this

cleaning procedure as water can damage the

electrical components located near or at the

CAUTION

condenser coil.

NEVER USE STEEL PADS, WIRE BRUSHES OR SCRAPERS!

Cleaning solutions need to be alkaline based or non-chloride

cleaners. Any cleaner containing chlorides will damage

the protective lm of the stainless steel. Chlorides are also

commonly found in hard water, salts, and household and

industrial cleaners. If cleaners containing chlorides are used be

sure to rinse repeatedly and dry thoroughly. Routine cleaning

of stainless steel can be done with soap and water. Extreme

stains or grease should be cleaned with a non-abrasive cleaner

and plastic scrub pad. Always rub with the grain of the steel.

There are stainless steel cleaners available which can restore

and preserve the nish of the steels protective layer. Early signs

of stainless steel breakdown are small pits and cracks. If this

has begun, clean thoroughly and start to apply stainless steel

cleaners in attempt to restore the passivity of the steel.

Never use an acid based cleaning solution!

Many food products have an acidic content,

which can deteriorate the nish. Be sure to clean

CAUTION

the stainless steel surfaces of ALL food

products. Common items include, tomatoes,

peppers and other vegetables.

™

®

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

15

Page 16

N8000 Series Drop-In Installation and Operation Manual

Delfield

MODELS - NORDIC BREEZE

Unit Assembly N8100-FA

UPRIGHT AIR DIFFUSER

WITH AIR DEFLECTOR

BLACK AIRFLOW EXTRUSIONS

PERFORATED PAN CLIP

ADAPTER BARS

COIL ASSY COVER

PLEXIGLAS END CAPS

Wiring Diagram N8100-FA

L1

1

2

35

DEFROST TIMER

PRESSURE

CONTROL

CONDENSING UNIT

N

G

16

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

COOLING FANS

™

®

Page 17

Delfield

Wiring Diagram N8100B, N8100NB & N8100-BR

L1

COOLING T'STAT

N

G

Wiring Diagram 8100-EF, 8100-EFN

N8000 Series Drop-In Installation and Operation Manual

CONDENSER FAN

S

C

R

COMPRESSOR

115V

ON/OFF SWITCH

L1

COOLING T'STAT

N

G

Wiring Diagram N8200 & N8200G

ON/OFF SWITCH

L1

N

G

CONDENSER FAN

C

COMPRESSOR

120V

CONDENSER FAN

S

C

R

COMPRESSOR

115V

S

R

™

®

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

17

Page 18

N8000 Series Drop-In Installation and Operation Manual

Delfield

Wiring Diagram N8630

CONDENSING UNIT

COOLING

THERMOSTAT

M

HEATER #1

HEATER #1

CONTACTOR

HEATER #1

LIMIT SWITCH

THERMOSTAT

120V-1PH-3KW HEATER

3-WAY

SWITCH

L1

N

Wiring Diagram N8643 & N8656

CONDENSING UNIT

M

HEATER #1

COOLING

THERMOSTAT

HEATER #1

CONTACTOR

HEATER #1

LIMIT SWITCH

THERMOSTAT

3-WAY

SWITCH

L1

L2

18

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

N

240V-1PH-5KW HEATER

™

®

Page 19

Delfield

Wiring Diagram N8669 & N8681

LI G

N8000 Series Drop-In Installation and Operation Manual

CONDENSING UNIT

HEATER #1

M

COOLING

THERMOSTAT

HEATER #1

CONTACTOR

3-WAY

SWITCH

L1

L2

THERMOSTAT

HEATER #1

LIMIT SWITCH

HEATER #2

LIMIT SWITCH

N

(2) 240V-1PH-5KW HEATERS

HEATER #2

CONTACTOR

HEATER #2

Wiring Diagram N8800 208/230V

™

THERMOSTAT

®

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

L2

DOUBLE POLE

THERMOSTAT ON

MODELS N8873 &

N8887 ONLY

19

Page 20

N8000 Series Drop-In Installation and Operation Manual

Delfield

Wiring Diagram N8700-D, N8700N & N8700-R

PILOT LIGHT

(FURNISHED)

LINE

WIRES

#

OF

WARMERS

1

2

3

4

5

6

L1 G L2

H1

P

L1

L2

H2

INFINITE CONTROL

TO ADDITIONAL

FOOD WARMERS

AMPERES

120V,

PHASE

1

1 PHASE

208V,

WITH “OFF”

IN LINE

230V,

PHASE

1

POSITION

WIRES

8.3 4.8 5.3

16.7 9.6 10.6

25 14.4 15.9 14.4/15.9

33.3 19.2 21.3

24 26.6

28.8 31.3

19.2/21.3

24/26.1

28.8/31.3

1000 W - 120V

OR 1000/1222 W -

208-230 V

HEATING ELEMENT

208-230V, 3 PHASE

L1 L2 L3

14.4/15.9

19.2/21.3

19.2/21.3

28.8/31.3

14.4/15.9

14.4/15.9

19.2/21.3

28.8/31.3

L1 L2 G L3

20

30A SWITCH

(OPTIONAL)

HA–1

HA–2

HA–3

HA–4

HA–5

HA–6

HA = HEATER ASSEMBLY

20A, 3–POLE SWITCH

(OPTIONAL)

HA–1

HA–2

HA–4

HA–5

HA = HEATER ASSEMBLY

Standard Single Phase Optional Three Phase

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

ALL WIRING

MINIMUM 14 AWG

250C

HA–3

HA–6

™

®

Page 21

Delfield

Drop In Louver Panel

N8000 Series Drop-In Installation and Operation Manual

25”

Louver part #359-411-0003

Cutout dimension is 11” x 22” (27.9 cm x 55.9 cm).

Miscellaneous Parts 8000 SERIES

Deleld Part # Description

265-AXE-0000 Divider bar, 2.00” x 20.93”

243-ALS-0032 Divider bar, 13.00” x .90”

243-AB0-0001 Divider bar, 21.00” x .90”

3234242 Plastic drain

1701273 Trim gasket (sold by foot)

13”

Cap Tube Chart - R134A Refrigerant

Model Number Cap Tube Size/Length

N8118B .036ID x 72”

N8130B .036ID x 72”

N8143B .036ID x 72”

N8144-BR .036ID x 72”

N8146NB .042ID x 120”

N8156B .042ID x 120”

N8159-BR .036ID x 72”

N8168NB .042ID x 120”

N8169B .042ID x 120”

N8176-BR .042ID x 120”

N8181B .054ID x 110”

N8194-BR .042ID x 120”

™

®

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

21

Page 22

N8000 Series Drop-In Installation and Operation Manual

Delfield

Replacement Parts N8100-FA

8

7

6

9

1

2

5

4

3

10

11

12

13

14

15

16

17

N8131-FA N8144-FA N8157-FA N8169-FA N8182-FA

Key Description 2-PAN 3-PAN 4-PAN 5-PAN 6-PAN

1 Upright diffuser 226-0V3-0030 226-0V3-0031 226-0V3-0032 226-0V3-0033 226-0V3-0034

2 Air deector 226-A9L-0030 226-A9L-0031 226-A9L-0032 226-A9L-0033 226-A9L-0034

3 Coil 3510086 3510086 3510086 3510086 3510086

4 Expansion valve 3516273 3516273 3516273 3516273 3516273

5 Coil assembly cover 019-0V0-0030 019-0V0-0038 019-0V0-0032 019-0V0-0033 019-0V0-0034

6 Fan assembly cover 226-0V1-0030 226-0V1-0031 226-0V1-0032 226-0V1-0033 226-0V1-0034

7 Adapter bar 243-AB0-0001 243-AB0-0001 243-AB0-0001 243-AB0-0001 243-AB0-0001

8 Perforated pan clip 270-0V5-0030 270-0V5-0031 270-0V5-0032 270-0V5-0033 270-0V5-0034

9 Black airow extrusion 316-991-0030 316-991-0031 316-991-0032 316-991-0033 316-991-0034

10 Cover support bracket 226-0V2-0030 226-0V2-0030 226-0V2-0030 226-0V2-0030 226-0V2-0030

11 Fan guard 3516173 3516173 3516173 3516173 3516173

12 Fan blade 3516172 3516172 3516172 3516172 3516172

13 Fan motor 2162691 2162691 2162691 2162691 2162691

14 Fan bracket 031-264-0000 031-264-0000 031-264-0000 031-264-0000 031-264-0000

15 Plexiglas end cap 091-0XL-0030 091-0XL-0030 091-0XL-0030 091-0XL-0030 091-0XL-0030

16 S/S thumb screw 9321541 9321541 9321541 9321541 9321541

17 Cond. Unit 000-BN5-0030 000-BN5-0035 000-BN5-0035 000-BN5-0036 000-BN5-0036

— Timer 2194345 2194345 2194345 2194345 2194345

— Pressure Control 2193927 2193927 2193927 2193927 2193927

— Rocker switch 2190154 2190154 2190154 2190154 2190154

™

22

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

®

Page 23

N8000 Series Drop-In Installation and Operation Manual

Delfield

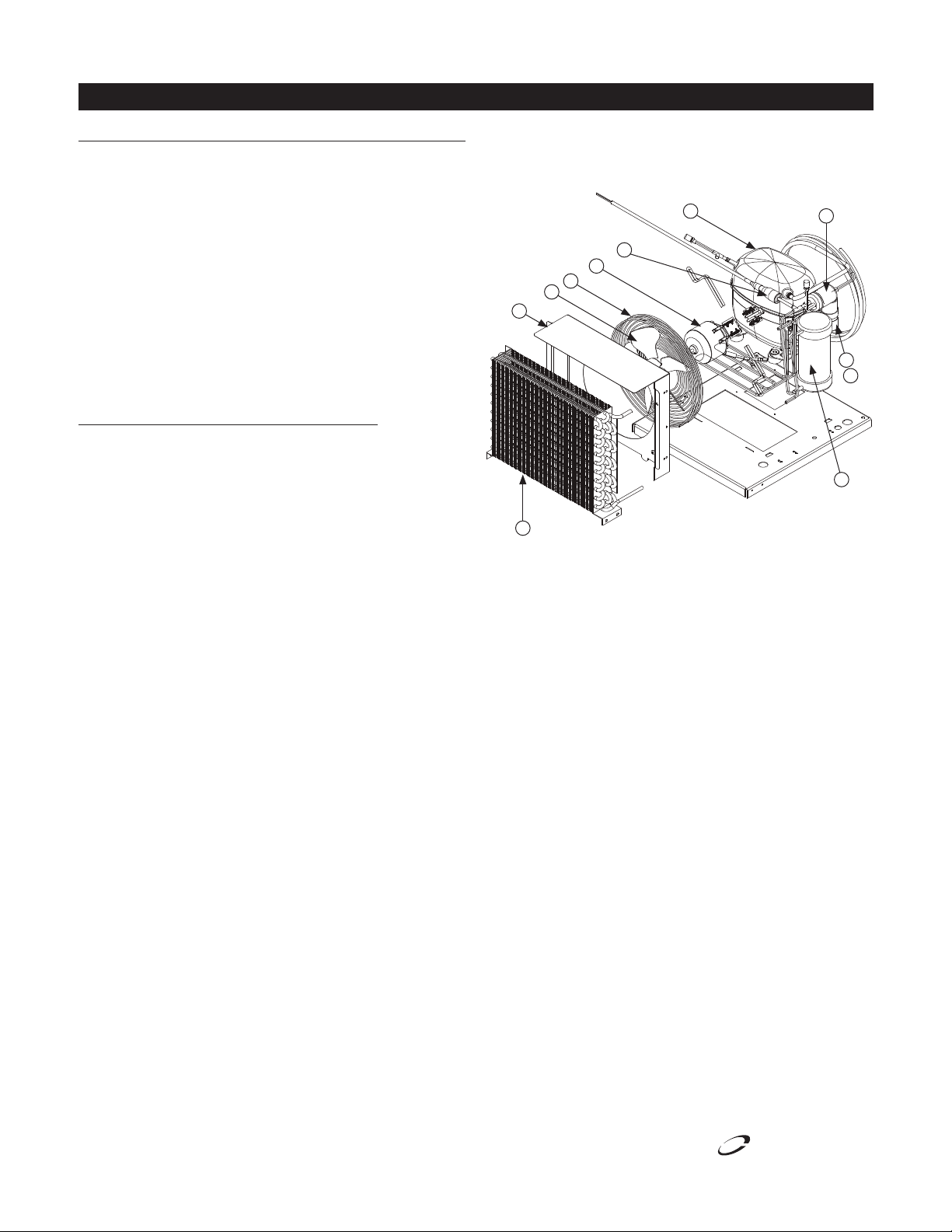

Condensing Unit 1/4 H.P. R404a Low

8100-EF Series, 8100-EFN Series, N8131-FA, N8231, N8231G, N8245, N8245G, N8259, N8273, N8630, N8643, N8656, N8669

Key Deleld Part # Description

- 000-BN5-0030 Condensing Unit Assembly, 115V

- 000-BN5-003J Condensing Unit Assembly, 220V/50Hz

1 026-C58-0030 Shroud, Condenser Coil

2 3516457 Blade, Fan, 7.25”

3 2162717 Motor, fan, 9W, 115V

3 2162720 Motor, fan, 9W, 230V

4 2160020 Guard, Fan, 7.25”

5 3526999 Compressor, NF5.5CLX, 115V/60Hz, Danfoss

5 3527013 Compressor 220/50Hz, Danfoss

6 2194787 Capacitor, Start 280MFD

7 3516444 Compressor relay and overload, NF5.5CLX

8 3516322 Filter-dryer, (2) inlet .25”

9 075-231-0030 Pan, condensate

10 3516454 Condenser Coil

1

4

2

3

Miscellaneous Parts Not Included in Condensing Unit

- 2194099 15 Amp switch, 120V

- 2194400 15 Amp switch, 220V

- 2183348 Cord/plug assembly

- 3516225 Expansion valve

5

6

7

10

Condensing Unit Assembly 1/3 H.P. R404a, Low, N8259G, N8287, N8681

Key Deleld Part # Description

- 000-BN5-003G Condensing Unit Assembly, 115V

- 000-BN5-003M Condensing Unit Assembly, 220V/50Hz

1 026-C58-0030 Shroud, Condenser Coil

2 3516457 Blade, Fan, 7.25”

3 2162717 Motor, fan, 9W, 115V

3 2162720 Motor, fan, 9W, 230V

4 2160020 Guard, Fan, 7.25”

5 3527000 Compressor, NF7.0. 115V/60Hz, Danfoss

5 3527012 Compressor, 220V/50Hz Danfoss

6 3516324 High pressure switch

7 2194788 Capacitor, Start 320MFD

8 3516438 Compressor relay and overload, NF7CLX

9 3516322 Filter-dryer, (2) inlet .25”

10 3516458 Receiver tank

1

11 075-231-0030 Pan, condensate

12 3516454 Condenser Coil

4

3

2

5

8

9

6

7

8

Miscellaneous Parts Not Included in Condensing Unit

- 3516225 Expansion valve

- 2194099 15 Amp switch, 120V

- 2194400 15 Amp switch, 220V

- 2183348 Cord/plug assembly

™

®

11

12

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

9

10

23

Page 24

N8000 Series Drop-In Installation and Operation Manual

Delfield

Condensing Unit Assembly 1/2 H.P. R404a, Low, N8273G

Key Deleld Part # Description

- 000-BN5-0033 Condensing Unit Assembly, 115V

- 000-BN5-003N Condensing Unit Assembly, 220V/50Hz

1 026-C58-0031 Shroud, 1/2 HP Condenser Coil

2 3516554 Blade, Fan, 9.00”, 5-pedal

3 2160019 Guard, Fan, Condenser, Upright

4 2162716 Motor, Fan, 16W, 115V

4 2162721 Motor, Fan 16W, 230V

5 3516324 High Pressure Switch

6 3527001 Compressor, SC12CLX.2,115V/60Hz, Danfoss

6 3527011 Compressor, 220V/50Hz, Danfoss

7 3516322 Filter-dryer, (2) inlet .25”

8 2194789 Capacitor, Start 240MFD

9 3516441 Compressor relay, SC12CLX.2

10 3516459 Receiver

11 3516455 Condenser Coil

Miscellaneous Parts Not Included in Condensing Unit

- 3516225 Expansion valve

- 2194099 15 Amp switch, 120V

- 2194400 15 Amp switch, 220V

- 2183348 Cord/plug assembly

2

1

6

5

4

3

7

8

9

10

11

24

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

™

®

Page 25

N8000 Series Drop-In Installation and Operation Manual

Delfield

9

7 6

5

8

2

3

4

1

Narrow Base Condensing Unit Assembly 1/5 H.P. R134A, Low

N8118B, N8130B, N8143B, N8144-BR, N8146NB, N8159-BR, N8168NB

Key Deleld Part # Description

1 2183300 Harness, wire, power cord, 8100

2 3526694 Compressor, 1/5 h.p.,115v/60hz

2 3526718 Compressor, 1/5 h.p., 220v/50hz

3 3516047 Cold Control

4 024-ADB-0040 Compressor stand

5 031-264-0000 Bracket, fan motor, blower coil

6 3516172 Blade, fan, 5.56, CCW, Lexan, clear

7 2162691 Motor, fan, 115v, 50/60, UPPCO/bay

7 2162692 Motor, fan, 230V, 50/60, UPPCO/bay

8 026-ANM-0030 Fan baffle

9 3516067 Coil, condenser, 9 x 10, R-134a, 8100

- 3516191 Filter dryer

- 2194400 15 Amp switch, 220V

Narrow Base Condensing Unit Assembly N8156B, N8169B, N8176-BR, N8181B, N8194-BR

Key Deleld Part # Description

1 2183300 Harness, wire, power cord

2 3526703 Compressor, 1/3HP, 115/60, R134A, N8181B

2 3526695 Compressor, 1/4 h.p.,115v/60hz, N8156B,

N8169B, N8176-BR, N8194-BR

2 3526719 Compressor, 1/4 h.p., 220v/50hz

3 3516047 Cold control

4 024-ADB-0041 Stand, compressor

5 2194013 Fan assembly, condenser, 8” blade, 115V

5 2162689 Fan assembly, condenser, 8” blade, 220V

6 026-ANM-0033 Baffle, fan

7 3516067 Coil, condenser, 9x10, R134A

- 3516191 Filter dryer

- 2194400 15 Amp switch, 220V

1

4

5

6

2

3

™

7

®

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

25

Page 26

N8000 Series Drop-In Installation and Operation Manual

Delfield

Condensing Unit Assembly 1/2 H.P. N8144-FA, N8157-FA

Key Deleld Part # Description

- 000-BN5-0035 Condensing Unit Assembly

1 026-C58-0031 Shroud, 1/2 HP condenser coil

2 3516554 Blade, fan 9.00”, 5 pedal

3 2160019 Guard, fan, condenser, upright

4 2162716 Motor, fan, 16W, 115V

5 3516462 Capacitor, start, assembly

6 3527026 Compressor, SC12MLX, 115V/60Hz, Danfoss

7 3516331 High pressure switch

8 3516322 Filter dryer, (2) inlet, .25”

9 3516459 Receiver

10 075-231-0031 Pan, condensate

11 3516455 Coil, 1/2 HP condensing

2

1

4

3

6

5

7

8

8

11

Condensing Unit Assembly 3/4 H.P. N8169-FA, N8182-FA

Key Deleld Part # Description

- 000-BN5-0036 Condensing Unit Assembly

1 026-C58-0032 Shroud, 3/4 HP condenser coil

2 2160019 Guard, fan, condenser, upright

3 3516442 Capacitor, start, run, assembly

4 3527021 Compressor, SC18MLX, 115V/60Hz, Danfoss

5 3516322 Filter dryer, (2) inlet, .25”

6 3516360 Tank, receiver

7 3516456 Coil, condenser, 3/4 HP

- 075-231-0031 Pan, condensate

- 3516433 Blade, fan 25º, 10”, CW, upright

- 2162716 Motor, fan, 16W, 115V

3

2

1

10

4

5

6

26

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

7

™

®

Page 27

N8000 Series Drop-In Installation and Operation Manual

Delfield

Food Well Assembly With Thermostat control N8600

10

For models N8600

1

2

9

8

7

6

5

4

3

Key Deleld Part # Description

1 2194940 Immersion heater 120V, 1Ph 3KW

1 2194942 Immersion heater 240V 1Ph 5KW

2 026-AO6-0041 Box, control, galv, 8600 series

3 372-ANQ-003D Front, collar, mounting, 8600

4 2193979 Switch, 3 position, 30Amp

5 372-ANS-0001 Cover, control box, 8700 series

6 2194190 Light, pilot, 125V, red

7 2194202 Thermostat, electric (heated)

8 3234556 Knob, thermostat control (heated)

9 2194185 Contactor, relay 30 Amp 120V

10 3516047 Temperature control (cold)

™

®

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

27

Page 28

N8000 Series Drop-In Installation and Operation Manual

Delfield

Food Well Assembly With Innite Control N8700

For models N8700D, N8700N, N8700ND, N8700R

Key Deleld Part # Description

1 3434703 Insulation, berglass, 9” x 48”

2 2194335 Thermostat, non-adjustable, 480˚F

3 026-103-0002 Bottom cover

4 3434663 Insulation, blanket, 24” wide

5 026-061-0001 Plate, deector, DFW, with or without drain

6 2194007 Element, heating, 208/230v, 1000/1222w

6 2194006 Element, heating, 120v

7 000-BQ9-Z0000 Well, hot food, with drain

7 000-BQ9-Z0001 Well, hot food, without drain

- 3234557 Knob, innite control

- 2194110 Control, innite, 240v, 14a

- 2194107 Control, innite, 120v

1

2

4

3

5

1

Food Well Assembly With Thermostat Control N8800

For models N8831, N8859, N8873, N8887

Key Deleld Part # Description

1 3234556 Knob, thermostat control

2 2193984 Thermostat 30A, N8873. N8887

2 2194012 Thermostat, 25A, N8831, N8845, N8859

3 2194007 Element, heating, 208/230v, 1000/1222w

3 2194006 Element, heating, 120v, 1000w

4 026-061-0001 Plate, deector, DFW, with drain

- 3434704 Insulation, berglass, 1” thick

- 3434664 Insulation, berfrax, 1” thick

6

7

4

28

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

1

2

3

™

®

Page 29

N8000 Series Drop-In Installation and Operation Manual

Delfield

Standard Labor Guidelines To Repair Or Replace Parts On Deleld Equipment

Advice and recommendations given by Deleld Service Technicians do not constitute or guarantee any special

coverage.

•Amaximumof1-hourisallowedtodiagnose a defective component.

•Amaximumof1-hourisallowedforretrieval of parts not in stock.

•Amaximumtravel distance of 100 miles round trip and 2-hours will be reimbursed.

•Overtime,installation/start-up,normalcontroladjustments,generalmaintenance,glassbreakage,freight

damage, and/or correcting and end-user installation error will not be reimbursed under warranty unless preapproved with a Service Work Authorization from Deleld. You must submit the number with the service claim.

Labor Of 1-Hour Is Allowed To Replace:

•CompressorStartComponentsandOverloadProtector • CondensateElement

•CondenserFanMotorandBlade • Contactor/Relay

•Hi-limit/ThermalProtectorSwitch • InniteSwitch

•SolenoidCoil • Thermostat

Labor Of 2 Hours To Replace:

•HeatingElement • Locate/RepairLeak

•SolenoidValve

Labor Of 3 Hours To Replace:

•CapillaryTubing • Condenser

•ExpansionValve

Labor Of 4 Hours To Replace:

•Compressor

This includes recovery of refrigerant and leak check.

$55.00 maximum reimbursement for refrigerant recovery (includes recovery machine, pump, torch, oil, ux, minor

ttings, solder, brazing rod, nitrogen, or similar fees.)

Refrigerants:

•R134AAmaximumof$5.00/lb.or31/oz.willbereimbursed.

•R404AAmaximumof$15.00/lb.or$1.00/oz.willbereimbursed.

™

®

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

29

Page 30

N8000 Series Drop-In Installation and Operation Manual

Delfield

Standard One Year Limited Warranty (One year parts, 90 days labor)

The Deleld Company (“Deleld”) warrants to the Original

Purchaser of the Deleld product (herein called the “Unit”) that

such Unit, and all parts thereof, will be free from defects in

material and workmanship under normal use and service for a

period of one (1) year from the date of shipment of the Unit to

the Original Purchaser or, if the Original Purchaser returns

the warranty card completely lled out including the date of

installation within thirty (30) days of receipt of the Unit, one

(1) year from the date of installation. During this one year

warranty period, Deleld will repair or replace any defective part

or portion there of returned to Deleld by the Original Purchaser

which Deleld determines was defective due to faulty material

or workmanship. The Original purchaser will pay all labor,

crating, freight and related costs incurred in the removal of the

Unit of defective component and shipment to Deleld, except

that during a period of either ninety (90) days from the date of

shipment of the Unit to the Original Purchaser or, if the Original

Purchaser returns the warranty card completely lled out

including the date of installation within thirty (30) days of receipt

of the Unit, ninety (90) days from the date of installation Deleld

will pay all related labor costs. Deleld will pay the return costs

if the Unit or part thereof was defective.

The term “Original Purchaser” as used herein means that

person, rm, association, or corporation for whom the Unit was

originally installed.

This warranty does not apply to any Unit or part thereof that has

been subjected to misuse, neglect, alteration, or accident, such

as accidental damage to the exterior nish, operated contrary

to the recommendations specied by Deleld; or repaired or

altered by anyone other than Deleld in any way so as to, in

Deleld’s sole judgement, affect its quality or efficiency. This

warranty does not apply to any Unit that has been moved from

the location where it was originally installed. This warranty

also does not cover the refrigerator drier or the light bulbs

used in the Unit. The warranty is subject to the user’s

normal maintenance and care responsibility as set forth

in the Service and Installation Manual, such as cleaning

the condenser coil, and is in lieu of all other obligations

of Deleld. Deleld neither assumes, nor authorizes any

other person to assume for Deleld, any other liability in

connection with Deleld’s products.

Removal or defacement of the original Serial Number or Model

Number from any Unit shall be deemed to release Deleld from

all obligations hereunder or any other obligations, express or

implied.

Parts furnished by suppliers to Deleld are guaranteed by