Delfield N8118B, N8130B, N8156B, N8169B, N8181B Service Manual

...

™

Delfield

N8000, N8000-R, N8100B, N8100-BR,

N8100-FA, 8100-EF, N8200, N8200G, N8600,

N8700-D, N8700-R, N8800 Drop Ins

Service, Installation and Care Manual

Please read this manual completely before attempting to install or operate this equipment! Notify

carrier of damage! Inspect all components immediately.

®

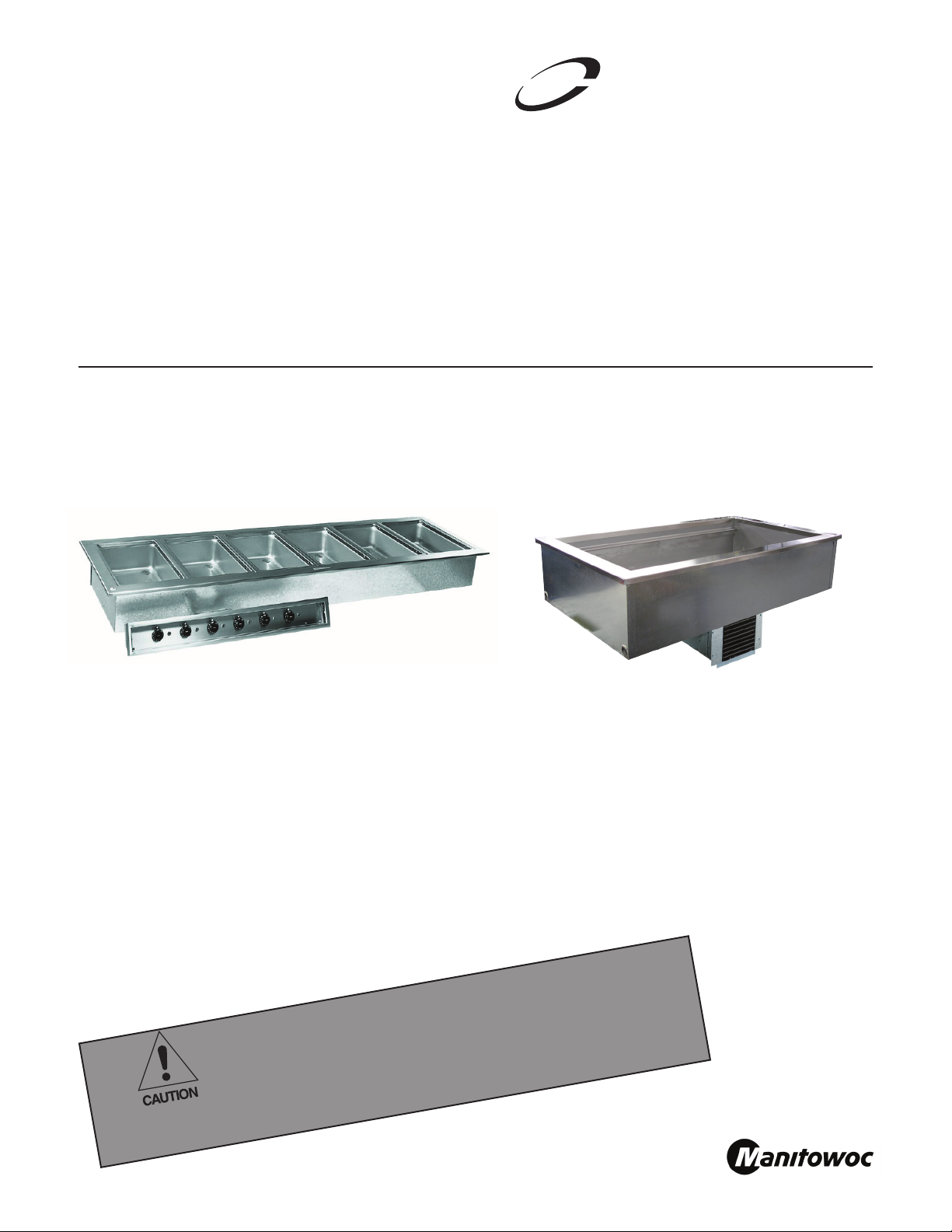

Hot Food Wells, Cold Pans, Granite Cold Slabs,

Frost Tops and Hot/Cold Food Wells

IMPORTANT INFORMATION

READ BEFORE USE

PLEASE SAVE THESE INSTRUCTIONS!

January 2012

N8000 Series Drop-In Installation and Operation Manual

Delfield

Important Warning And Safety Information

WARNING Read This Manual Thoroughly Before Operating, Installing, Or Performing

Maintenance On The Equipment.

WARNING Failure To Follow Instructions In This Manual Can Cause Property Damage,

Injury Or Death.

WARNING Do Not Store Or Use Gasoline Or Other Flammable Vapors Or Liquids In The

Vicinity Of This Or Any Other Appliance.

WARNING Unless All Cover And Access Panels Are In Place And Properly Secured, Do

Not Operate This Equipment.

WARNING Do Not Clean With Water Jet.

CAUTION Observe the following:

• Minimum clearances must be maintained from all walls and combustible

materials.

• Keep the equipment area free and clear of combustible material.

• Adequate clearance for air openings.

• Operate equipment only on the type of electricity indicated on the

specification plate.

• Retain this manual for future reference.

2

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

™

®

N8000 Series Drop-In Installation and Operation Manual

Delfield

Contents Serial Number Location

Receiving And Inspecting Unit .................................................... 3

Specifications ......................................................................... 4-7

Installation

Curved Drop-In Cutout Details .................................................. 8

N8000, N8000N, N8000-R, N8100B, N8100NB, N8100-BR, N8200,

N8200G, 8100-FA, 8100-EF Series ............................................ 9

N8600 Series ........................................................................... 9

N8700-D, N8700N, N8700-R & N8800 Series ........................... 10

Operation

N8100B, N8100NB, N8100-BR ................................................ 11

N8100-FA .............................................................................. 11

8100-EF ................................................................................ 12

N8200 & N8200G ................................................................... 12

N8600 ................................................................................... 13

N8700-D, N8700N, N8700-R & N8800 Series ........................... 14

Maintenance ............................................................................ 15

Unit Assembly N8100-FA .......................................................... 16

Wiring Diagram

N8100-FA .............................................................................. 16

N8100B, N8100NB & N8100-BR .............................................. 17

8100-EF & 8100-EFN .............................................................. 17

N8200 & N8200G ................................................................... 17

N8600 .............................................................................. 18-19

N8800 ................................................................................... 19

N8700-D, N8700N & N8700-R ................................................ 20

Louver Diagram ....................................................................... 21

Miscellaneous Replacement Parts ............................................. 21

N8100-FA Replacement Parts List ............................................. 22

Condensing Unit Assembly Parts List ................................... 23-26

Food Well Assembly Parts List ............................................. 27-28

Standard Labor Guidelines ........................................................ 29

Standard Warranties ........................................................... 30-31

The serial number on self-contained refrigerated units is on the electrical

specications tag located near the condensing unit.

The serial number on remote refrigerated units is on the outside bottom

of the food well.

On hot food pans and hot/cold combination pans, the serial number tag

is located on the back of the control raceway or remote panel.

The serial number tag also lists the refrigerant used and the amount

of charge.

Always have the serial number of your unit available when calling for

parts or service.

This manual covers only standard 8000 series units. If you have a

custom designed unit, you should contact our parts/service department

at (800) 733-8829 for questions.

©2012 The Deleld Company. All rights reserved. Reproduction without written

permission is prohibited. “Deleld” is a registered trademark of The Deleld

Company.

Receiving And Inspecting The Equipment

Even though most equipment is shipped crated, care should

be taken during unloading so the equipment is not damaged

while being moved into the building.

1. Visually inspect the exterior of the package and skid or

container. Any damage should be noted and reported to

the delivering carrier immediately.

2. If damaged, open and inspect the contents with the carrier.

3. In the event that the exterior is not damaged, yet upon

opening, there is concealed damage to the equipment

notify the carrier. Notication should be made verbally as

well as in written form.

4. Request an inspection by the shipping company of the

damaged equipment. This should be done within 10 days

from receipt of the equipment.

™

®

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

5. Also open the compressor compartment housing and

visually inspect the refrigeration package. Be sure lines

are secure and base is still intact.

6. Freight carriers can supply the necessary damage forms

upon request.

7. Retain all crating material until an inspection has been

made or waived.

Uncrating The Equipment

First cut and remove the banding from around the crate.

Remove the front of the crate material, use of some tools will

be required.

3

N8000 Series Drop-In Installation and Operation Manual

Delfield

Specifications

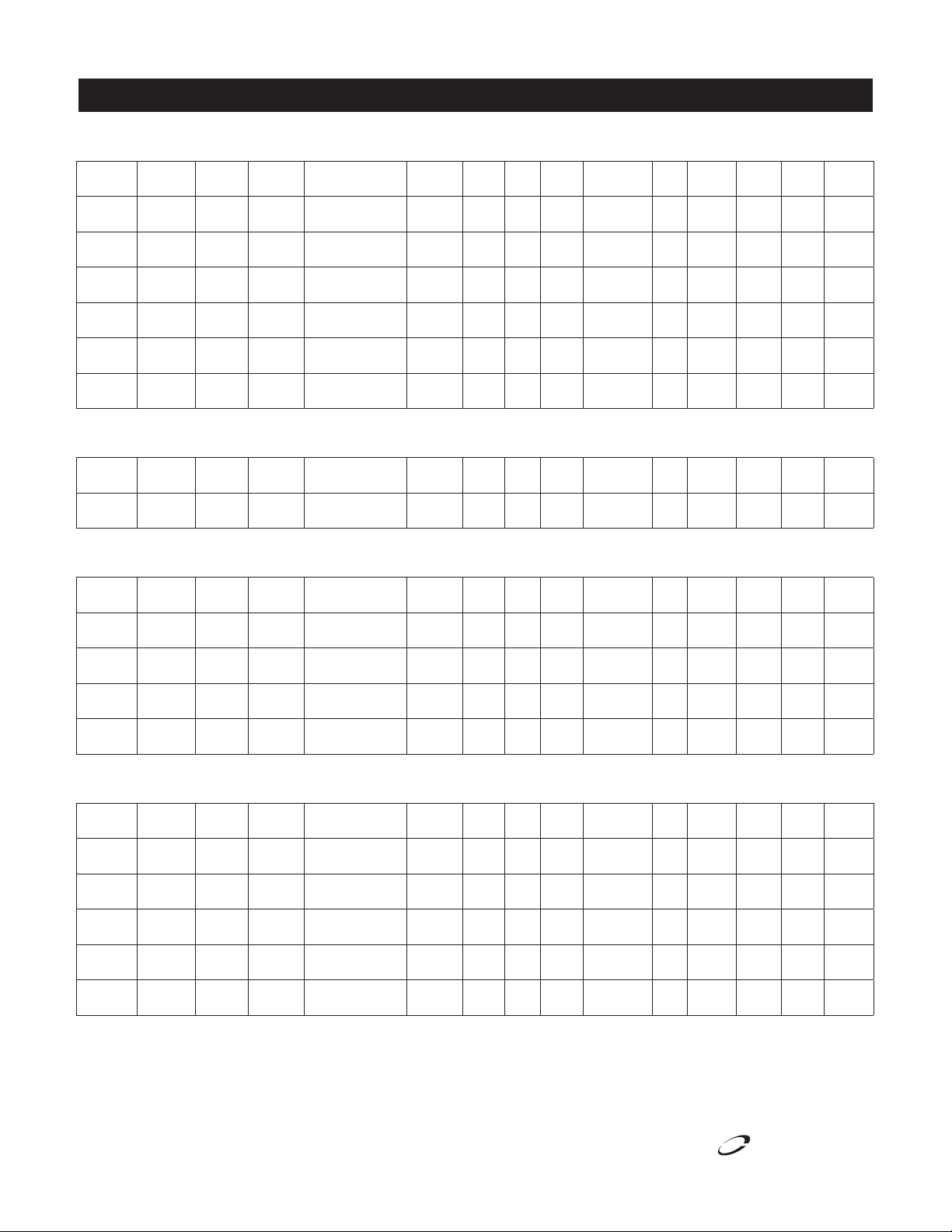

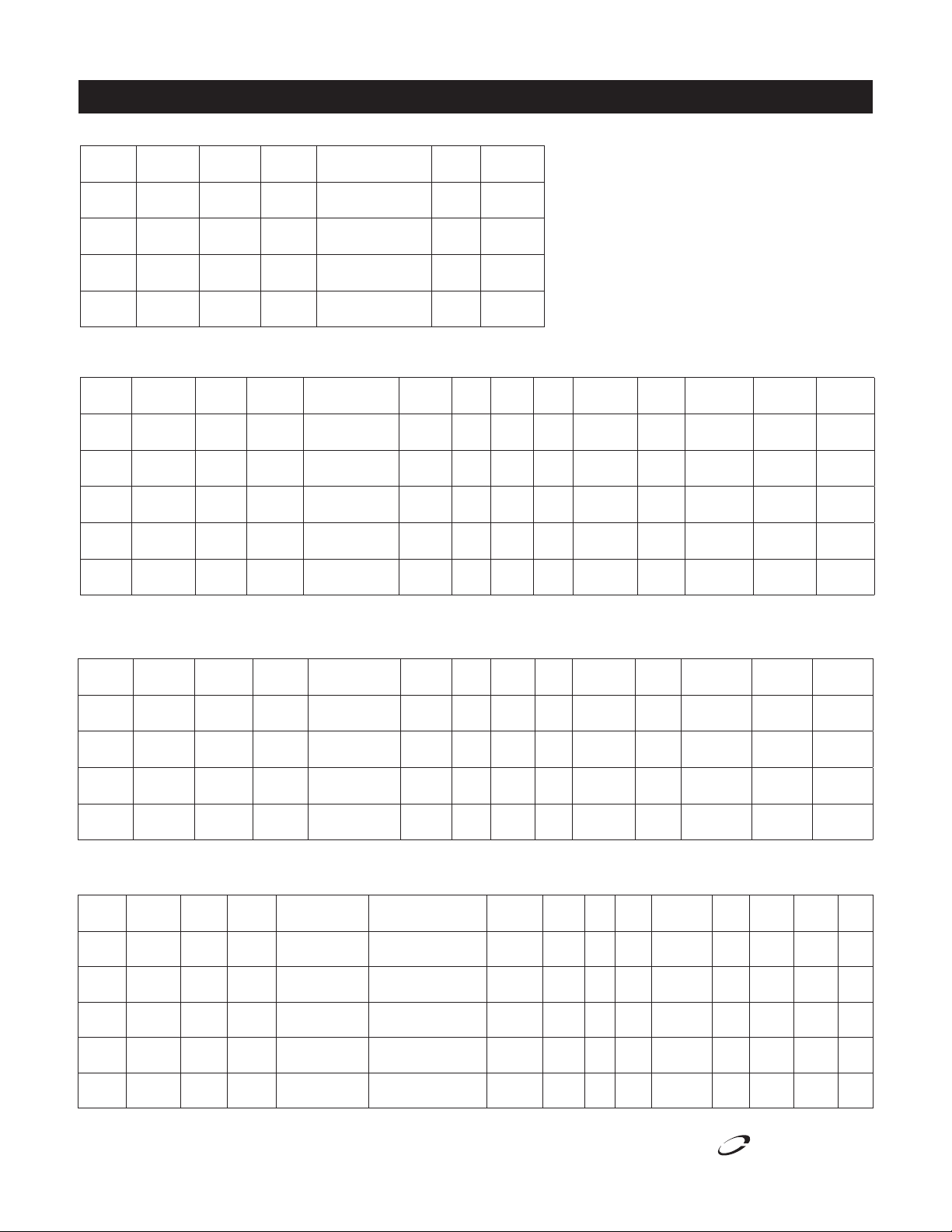

N8100B Series Self-Contained Mechanically Cooled Pans - R134A

Model

N8118B

N8130B

N8143B

N8156B

N8169B

N8181B

L D H

18”

(45.7cm)

30.75”

(78.1cm)

43.5”

(110.5cm)

56.25”

(142.9cm)

69”

(175.3cm)

81.75”

(208cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

21.87”

(55.5cm)

21.87”

(55.5cm)

21.87”

(55.5cm)

21.87”

(55.5cm)

21.87”

(55.5cm)

21.87”

(55.5cm)

Counter Cutout

Dimensions V/Hz/Ph Amps H.P. BTU

17” X 25”

(43.2cm x 63.5cm)

29.75” x 25”

(75.6cm x 63.5cm)

42.50” X 25”

(108.6cm x 63.5cm)

55.25” x 25”

(140.3cm x 63.5cm)

68” X 25”

(172.7cm x 63.5cm)

80.75” x 25”

(205.1cm x 63.5cm)

115/60/1

115/60/1 4.0 1/5 379

115/60/1

115/60/1 7.0 1/4 758

115/60/1 7.0 1/4 948

115/60/1 8.0 1/3 1138

4.0 1/5 204

4.0 1/5 569

N8100NB Series Self-Contained Mechanically Cooled Pans Narrow Style - R134A

N8146NB

N8168NB

46.75”

(118.7cm)

67.5”

(171.5cm)

18”

(45.7cm)

18”

(45.7cm)

21.81”

(55.4cm)

21.81”

(55.4cm)

45.75” x 17”

(113.7cm x 43.2cm)

66.5” x 17”

(168.9cm x 43.2cm)

115/60/1 4.0 1/5 454 17/40º/-5º 680 175lbs

115/60/1 4.0 1/5 676 26/31º/4º 804 240lbs

Evap BTU/

TD/TEMP

19/38º/-3º

26/31º/4°

35/26º/9º

43/32º/3º

51/29º/6º

59/32º/3º

Sys

Cap

708 100lbs

812 140lbs

889 173lbs

1373 205lbs

1469 225lbs

1921 258lbs

Ship

Weight

(45kg)

(64kg)

(78kg)

(93kg)

(102kg)

(117kg)

(80kg)

(109kg)

Refrig.

NEMA

Charge

Plug

5-15P

8.0oz

8.0oz 5-15P 2

5-15P

8.0oz

16.0oz 5-15P 4

16.0oz 5-15P 5

11.5oz 5-15P 6

5-15P

8.0oz

8.0oz 5-15P 3

12”x20”

Pans

1

3

2

N8100BR Series Curved Self-Contained Mechanically Cooled Pans - R134A

Model

N8144-BR

N8159-BR

N8176-BR

N8194-BR

L D H

40.43”

(103cm)

57.22”

(145cm)

73.68”

(187cm)

89.86”

(228cm)

26.05”

(66cm)

26.05”

(66cm)

26.05”

(66cm)

26.05”

(66cm)

21.81”

(55cm)

21.81”

(55cm)

21.81”

(55cm)

21.81”

(55cm)

Counter Cutout

Dimensions V/Hz/Ph Amps H.P. BTU

see drawing on

page 8

see drawing on

page 8

see drawing on

page 8

see drawing on

page 8

115/60/1 4.0 1/5 379

115/60/1

115/60/1 7.0 1/4 758

115/60/1 7.0 1/4 948

4.0 1/5 569

Evap BTU/

TD/TEMP

26/31º/4°

35/26º/9º

43/32º/3º

51/29º/6º

N8100-FA Series Forced Air Drop-In Mechanically Cooled Cold Pans - R404A

Model L D H

N8131-FA

N8144-FA

N8157-FA

N8169-FA

N8182-FA

31.25”

(79.4cm)

44”

(111.8cm)

56.75”

(144.1cm)

69.5”

(176.5cm)

82.25”

(208.9cm)

26.67”

(67.7cm)

26.67”

(67.7cm)

26.67”

(67.7cm)

26.67”

(67.7cm)

26.67”

(67.7cm)

26.62”

(68cm)

26.62”

(68cm)

26.62”

(68cm)

28.62”

(72.7cm)

28.62”

(72.7cm)

Counter Cutout

Dimensions V/Hz/Ph Amps H.P. BTU

30.25” x 25.5”

(76.8cm x 64.8cm)

43” x 25.5”

109.2cm x 64.8cm)

55.75” x 25.5”

(141.6cm x 64.8cm)

68.5” x 25.5”

174.0cm x 64.8cm)

81.25” x 25.5”

206.4cm x 64.8cm)

115/60/1 7.8 1/4 1339 140/15º/20

115/60/1 9.2 1/2 2035 140/22º/13

115/60/1 9.2 1/2 2731 280/14º/21° 3806

115/60/1 14.8 3/4

115/60/1 14.8 3/4 4070 280/20º/15° 5545

Evap BTU/

TD/TEMP

º

º

3374 280/20º/15° 5545

Sys

Ship

Cap

Weight

812 161lbs

(72kg)

889 184lbs

(83kg)

1373 233lbs

(105kg)

1469 243lbs

(109kg)

Sys

Ship

Cap

Weight

168lbs

2154

(76kg)

175lbs

3142

(79kg)

225lbs

(102kg)

235lbs

(107kg)

406lbs

(184kg)

Refrig.

NEMA

Charge

Plug

8.0oz 5-15P 2

5-15P

8.0oz

16.0oz 5-15P 4

16.0oz 5-15P 5

Refrig.

NEMA

Charge

Plug

16.0oz 5-15P 2

32.0oz 5-15P 3

32.0oz 5-15P 4

48.0oz 5-20P 5

48.0oz 5-20P 6

12”x20”

Pans

3

12”x20”

Pans

4

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

™

®

N8000 Series Drop-In Installation and Operation Manual

Delfield

Specifications

8100-EF Series LiquiTec® Eutetic Fluid Refrigerated Cold Pans - R404A

Model L D H

8118-EF

8132-EF

8145-EF

8159-EF

8172-EF

8186-EF

18.20”

(46.2cm)

31.76”

(80.7cm)

45.32”

(115.1cm)

58.88”

(149.6cm)

72.44”

(184cm)

86”

(218.4cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

23.25”

(59.1cm)

23.25”

(59.1cm)

23.25”

(59.1cm)

23.25”

(59.1cm)

23.25”

(59.1cm)

23.25”

(59.1cm)

Counter Cutout

Dimensions V/Hz/Ph Amps H.P.

17” x 25”

(43.2cm x 63.5cm)

30.75” x 25”

(78.1cm x 63.5cm)

44.25” x 25”

(112.4cm x 63.5cm)

57.87” x 25”

(147cm x 63.5cm)

71.5” x 25”

(181.6cm x 63.5cm)

85” x 25”

(215.9cm x 63.5cm)

115/60/1 7.5 1/4 204 19/50º/-15° 928 169lbs

115/60/1 7.5 1/4 379 26/42º/-7° 1112 215lbs

115/60/1 7.5 1/4 569 35/36º/-1° 1259 265lbs

115/60/1 7.5 1/4 758 43/32º/3° 1373 285lbs

115/60/1 7.5 1/4 948 51/29º/6° 1469 295lbs

115/60/1 7.5 1/4 1138 59/26º/9° 1529 394lbs

8100-EFN Series LiquiTec® Slim Line Eutetic Fluid Refrigerated Cold Pans - R404A

Model L D H

8148-EFN

8169-EFN

8191-EFN

47.66”

(121.1cm)

69.22”

(175.8cm)

90.78”

(230.6cm)

18”

(45.7cm)

18”

(45.7cm)

18”

(45.7cm)

23.25”

(59.1cm)

23.25”

(59.1cm)

23.25”

(59.1cm)

Counter Cutout

Dimensions V/Hz/Ph Amps H.P.

46.88” x 17.25”

(119.1cm x 43.8cm)

68.5” x 17.25”

(174cm x 43.8cm)

90” x 17.25”

(228.6cm x 43.8cm)

115/60/1 7.5 1/4 379 26/42º/-7° 1112 235lbs

115/60/1 7.5 1/4 569 35/36º/-1° 1259 285lbs

115/60/1 7.5 1/4 758 43/32º/13° 1373 295lbs

BTU

Load

BTU

Load

Evap BTU/

TD/TEMP

Evap BTU/

TD/TEMP

Sys

Cap

Sys

Cap

Ship

Weight

(77kg)

(98kg)

(120kg)

(130kg)

(134kg)

(179kg)

Ship

Weight

(107kg)

(130kg)

(134kg)

Refrig.

NEMA

Charge

Plug

24.0oz 5-15P 1

24.0oz 5-15P 2

24.0oz 5-15P 3

24.0oz 5-15P 4

24.0oz 5-15P 5

24.0oz 5-15P 6

Refrig.

NEMA

Charge

Plug

24.0oz 5-15P 2

24.0oz 5-15P 3

24.0oz 5-15P 4

12x20

Pans

12x20

Pans

N8000 Series Ice Cooled Cold Pans

Model

N8018

N8030

N8043

N8056

N8069

N8081

L D H

18”

(45.7cm)

30.75”

(78.1cm)

43.5”

(110.5cm)

56.25”

(142.9cm)

69”

(175.3cm)

81.75”

(208cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

10.75”

(27.3cm)

10.75”

(27.3cm)

10.75”

(27.3cm)

10.75”

(27.3cm)

10.75”

(27.3cm)

10.75”

(27.3cm)

Counter Cutout

Dimensions

17” x 25”

(43.2cm x 63.5cm)

29.75” x 25”

(75.6cm x 63.5cm)

42.5” x 25”

(107.9cm x 63.5cm)

55.25” x 25”

(140.3cm x 63.5cm)

68” x 25”

(172.7cm x 63.5cm)

80.75” x 25”

(205.1cm x 63.5cm)

N8000N Series Narrow Ice Cooled Cold Pans

N8046N

N8068N

46.75”

(118.8cm)

67.5”

(171.5cm)

18”

(45.7cm)

18”

(45.7cm)

10.75”

(27.3cm)

10.75”

(27.3cm)

45.75” x 17”

(116.2cm x 43.2cm)

66.50” x 17”

(168.9cm x 43.2cm)

Ship

Weight

38lbs

(17kg)

84lbs

(38kg)

110lbs

(50kg)

139lbs

(63kg)

160lbs

(73kg)

197lbs

(89kg)

100lbs

(45kg)

120lbs

(55kg)

12”x20”

Pans Held

1

2

3

4

5

6

2

3

™

®

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

5

N8000 Series Drop-In Installation and Operation Manual

Delfield

Specifications

N8000-R Series Curved Ice Cooled Cold Pans

Model

N8044-R

N8059-R

N8076-R

N8094-R

L D H

40.48”

(103cm)

57.22”

(145cm)

73.68”

(187cm)

89.89”

(228cm)

26.05”

(66cm)

26.05”

(66cm)

26.05”

(66cm)

26.05”

(66cm)

10.77”

(27cm)

10.77”

(27cm)

10.77”

(27cm)

10.77”

(27cm)

Counter Cutout

Dimensions

see drawing on page 8 100lbs

see drawing on page 8 118lbs

see drawing on page 8 145lbs

see drawing on page 8 164lbs

N8200 Series Self-Contained Frost Tops - R404A

Model

N8231

N8245

N8259

N8273

N8287

L D H

31.75"

(80.6cm)

45.63”

(115.9cm)

59.5”

(151.1cm)

73.38"

(186.4cm)

87.25"

(221.6cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

15.75”

(40cm)

15.75”

(40cm)

15.75”

(40cm)

15.75”

(40cm)

15.75”

(40cm)

Counter Cutout

Dimensions V/Hz/Ph Amps H.P. BTU

30.75” x 25"

(78.1cm x 63.5cm)

44.63” x 25”

(113.3cm x 63.5cm)

58.50” x 25”

(148.6cm x 63.5cm)

72.38” x 25”

(183.8cm x 63.5cm)

86.25" x 25"

(219.1cm x 63.5cm)

Ship

Weight

(45kg)

(53kg)

(65kg)

(74kg)

115/60/1 7.5 1/4

115/60/1 7.5 1/4

115/60/1 7.5 1/4

115/60/1 8.0 1/4

115/60/1 8.0 1/3

12”x20”

Pans Held

2

3

4

5

Evap BTU/

TD/TEMP

379 26/42º/-7° 1112

569 35/36º/-1° 1259

758 43/32º/3° 1373

948 51/29º/6° 1469

1138 59/30º/5° 1787

Sys

Cap Ship Weight

142lbs

(64kg)

168lbs

(76kg)

193lbs

(88kg)

209lbs

(95kg)

239lbs

(108kg)

Refrig.

Charge

24.0oz

24.0oz

24.0oz

24.0oz

24.0oz

NEMA

Plug

5-15P

5-15P

5-15P

5-15P

5-15P

N8200G Series Self-Contained Granite Cold Slabs

Model

N8231G

N8245G

N8259G

N8273G

L D H

31.75”

(80.6cm)

45.63”

(115.9cm)

59.5”

(151.1cm)

73.38”

(186.4cm)

25.87”

(65.7cm)

25.87”

(65.7cm)

25.87”

(65.7cm)

25.87”

(65.7cm)

19”

(48.3cm)

19”

(48.3cm)

19”

(48.3cm)

19”

(48.3cm)

Counter Cutout

Dimensions V/Hz/Ph Amps H.P. BTU

30.75” X 25”

(78.1cm x 63.5cm)

44.63” x 25”

(113.4cm x 63.5cm)

58.5” x 25”

(148.6cm x 63.5cm)

72.38” x 25”

(183.8cm x 63.5cm)

115/60/1 7.5 1/4

115/60/1 7.5 1/4

115/60/1 8.0 1/3

115/60/1 9.0 1/2

Evap BTU/

TD/TEMP

379 26/42º/-7° 1112

569 35/36º/-1° 1259

758 43/37º/-2° 1572

948 51/43º/-8° 2183

N8600 Series Self Contained Combination Hot/Cold Food Wells - R404A

Model

N8630

N8643

N8656

N8669

N8681

L D H

30.75”

(78.1cm)

43.5”

(110.5cm)

56.25”

(142.9cm)

69”

(175.3cm)

81.75”

(207.6cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

23.75”

(60.3cm)

23.75”

(60.3cm)

23.75”

(60.3cm)

23.75”

(60.3cm)

23.75”

(60.3cm)

Counter Cutout

Dimensions

29.75” X 25”

(75.5cm x 63.5cm)

42.50” x 25”

(107.9cm x 63.5cm)

55.25” x 25”

(140.3cm x 63.5cm)

68” x 25”

(172.7cm x 63.5cm)

80.75” x 25”

(205.1cm x 63.5cm)

Control Panel Cutout

Dimensions

12.25” x 4.25” x 7.00”

(31.1cm x 10.8cm x 17.8cm)

12.25” x 4.25” x 7.00”

(31.1cm x 10.8cm x 17.8cm)

12.25” x 4.25” x 7.00”

(31.1cm x 10.8cm x 17.8cm)

12.25” x 4.25” x 7.00”

(31.1cm x 10.8cm x 17.8cm)

12.25” x 4.25” x 7.00”

(31.1cm x 10.8cm x 17.8cm)

V/Hz/Ph Amps H.P. BTU

120/60/1 24.0 1/4

120/240

/60/1

120/240

/60/1

120/240

/60/1

120/240

/60/1

21.0 1/4

21.0 1/4

42.0 1/4

42.0 1/3

Sys

Cap Ship Weight

219lbs

(99kg)

284lbs

(129kg)

338lbs

(153kg)

425lbs

(193kg)

Evap BTU/TDSys

Cap

379 26/42º/-7° 1112

569 35/36º/-1° 1259

758 43/32º/3° 1373

948 51/29º/6° 1469

1138 59/30º/5° 1787

Refrig.

Charge

24.0oz

24.0oz

24.0oz

32.0oz

Ship

Weight

164lbs

(74kg)

198lbs

(90kg)

233lbs

(106kg)

266lbs

(121kg)

301lbs

(137kg)

NEMA

Plug

5-15P

5-15P

5-15P

5-15P

Refrig.

Charge

16.0oz 2

16.0oz 3

16.0oz 4

16.0oz 5

24.0oz 6

12”x20”

Pans

6

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

™

®

N8000 Series Drop-In Installation and Operation Manual

Delfield

Specifications

N8700D Series Individually Controlled Heated Food Wells

Model

N8717-D

N8731-D

N8745-D

N8759-D

N8773-D

N8787-D

L D H

17.88”

(45.4cm)

31.75”

(80.6cm)

45.63”

(115.9cm)

59.5”

(151.1cm)

73.38”

(186.4cm)

87.25”

(221.4cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

9.5”

(24cm)*

9.5”

(24cm)*

9.5”

(24cm)*

9.5”

(24cm)*

9.5”

(24cm)*

9.5”

(24cm)*

Counter Cutout

Dimensions

16.88” X 25”

(42.8cm x 63.5cm)

30.75” x 25”

(78.1cm x 63.5cm)

44.62” x 25”

(113.3cm x 63.5cm)

58.5” x 25”

(148.6cm x 63.5cm)

72.37” x 25”

(183.8cm x 63.5cm)

86.25” x 25”

(219.1cm x 63.5cm)

*14” Overall height including drain connection

N8700-R Series Curved Individually Controlled Heated Food Wells

Model

N8744-R

N8759-R

N8776-R

N8794-R

L D H

40.48”

(103cm)

57.22”

(145cm)

73.68”

(187cm)

89.80”

(228cm)

26.05”

(66cm)

26.05”

(66cm)

26.00”

(66cm)

25.91”

(66cm)

9.5”

(24cm)*

9.5”

(24cm)*

9.5”

(24cm)*

9.5”

(24cm)*

*14” Overall height including drain connection

Counter Cutout

Dimensions

see drawing on page 8 10.31” x 4.62” x 7.00”

see drawing on page 8 14.5” x 4.62” x 7.00”

see drawing on page 8 18.69” x 4.62” x 7.00”

see drawing on page 8 22.88” x 4.62” x 7.00”

Control Panel Cutout

Dimensions

7.00” x 4.62” x 7.00”

(17.8cm x 11.7cm x 17.8cm)

10.31” x 4.62” x 7.00”

(26.2cm x 11.7cm x 17.8cm)

14.5” x 4.62” x 7.00”

(36.8cm x 11.7cm x 17.8cm)

18.69” x 4.62” x 7.00”

(47.5cm x 11.7cm x 17.8cm)

22.88” x 4.62” x 7.00”

(58.1cm x 11.7cm x 17.8cm)

27” x 4.62” x 7.00”

(68.6cm x 11.7cm x 17.8cm)

Control Panel Cutout

Dimensions

(26cm x 12cm x 18cm)

(37cm x 12cm x 18cm)

(47cm x 12cm x 18cm)

(58cm x 12cm x 18cm)

V/Hz/Ph Amps

120/60/1 8.3 41lbs

120/60/1 16.6 99lbs

208-230

/60/1

208-230

/60/1

208-230

/60/1

208-230

/60/1

V/Hz/Ph Amps

120/60/1 16.6 99lbs

208-230

/60/1

208-230

/60/1

208-230

/60/1

Ship

Weight

(19kg)

(45kg)

15.0/16.0 134lbs

(61kg)

20.0/22.0 166lbs

(75kg)

24.0/27.0 186lbs

(84kg)

29.0/32.0 236lbs

(107kg)

Ship

Weight

(45kg)

15.0/16.0 134lbs

(61kg)

20.0/22.0 166lbs

(75kg)

24.0/27.0 186lbs

(84kg)

12”x20”

Pans

1

2

3

4

5

6

12”x20”

Pans

2

3

4

5

N8700N Series Individually Controlled Heated Narrow Food Wells

Model

N8746N

N8746ND

N8768N

N8768ND

L D H

45.61”

(116cm)

67.48”

(172cm)

15.87”

(40cm)

15.87”

(40cm)

9.5”

(24cm)

9.5”

(24cm)

*ND Models are standard with drains

Counter Cutout

Dimensions

44.62” x 15.0”

(113.3cm x 38.1cm)

66.50” x 15.0”

(168.9cm x 38.1cm)

Control Panel Cutout Dimensions

10.31” x 4.62” x 7.00”

(26.2cm x 11.7cm x 17.8cm)

14.50” x 4.62” x 7.00”

(36.8cm x 11.7cm x 17.8cm)

V/Hz/Ph Amps

120/60/1 17.0 100lbs

208-230

/60/1

N8800 Series Single Tank Electric Hot Food Wells

Model

N8831

N8845

N8859

N8873

N8887

L D H

31.75”

(80.6cm)

45.63”

(115.9cm)

59.5”

(151.1cm)

73.38”

(186.4cm)

87.25”

(221.6cm)

™

26”

(66cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

26”

(66cm)

®

11”

(27.9cm)

11”

(27.9cm)

11”

(27.9cm)

11”

(27.9cm)

11”

(27.9cm)

Counter Cutout

Dimensions

30.75” X 25”

(78.1cm x

63.5

44.63” x 25”

(113.4cm x

63.5

58.5” x 25”

(148.6cm x

63.5

72.38” x 25”

(183.8cm x

63.5

86.25” x 25”

(219.1cm x

63.5

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

Control Panel Cutout Dimensions

12.25” x 4.25” x 7.00”

cm)

(31.1cm x 10.8cm x 17.8cm)

12.25” x 4.25” x 7.00”

cm)

(31.1cm x 10.8cm x 17.8cm)

12.25” x 4.25” x 7.00”

cm)

(31.1cm x 10.8cm x 17.8cm)

12.25” x 4.25” x 7.00”

cm)

(31.1cm x 10.8cm x 17.8cm)

12.25” x 4.25” x 7.00”

cm)

(31.1cm x 10.8cm x 17.8cm)

V/Hz/Ph Amps

120/60/1 17.0 100lbs

208-230

/60/1

208-230

/60/1

208-230

/60/1

208-230

/60/1

Ship

Weight

(45kg)

15.0/16.0 130lbs

(59kg)

Ship

Weight

(45kg)

15.0/16.0 136lbs

(62kg)

20.0/22.0 158lbs

(72kg)

24.0/27.0 195lbs

(88kg)

29.0/32.0 224lbs

(102kg)

12”x20”

Pans

2

3

12”x20”

Pans

2

3

4

5

6

7

N8000 Series Drop-In Installation and Operation Manual

Delfield

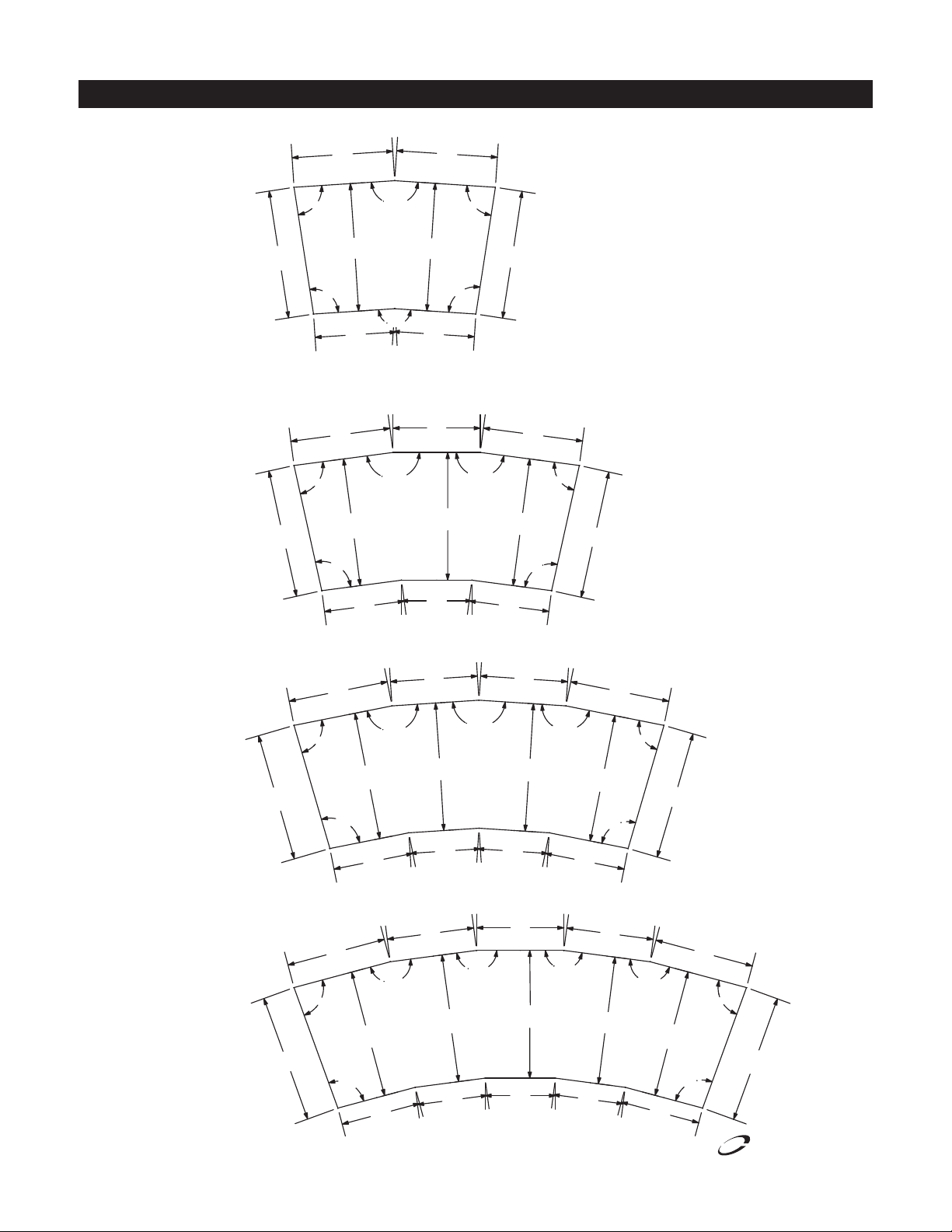

Curved Drop-In Cutout Details

2 pan standard curved drop-in cutout detail

Models:

• N8044-R

• N8144-BR

• N8744-R

85˚

19.75”

50cm

172.50˚

19.75”

50cm

85˚

25.10”

64cm

95˚

3 pan standard curved drop-in cutout detail

Models:

• N8059-R

• N8159-BR

• N8759-R

25.10”

64cm

85˚

4 pan standard curved drop-in cutout detail

Models:

• N8076-R

• N8176-BR

• N8776-R

25.10”

64cm

85˚

19.56”

50cm

19.56”

50cm

95˚

95˚

25.00”

64cm

15.92”

40cm

25.00”

64cm

15.73”

40cm

25.00”

64cm

15.73”

40cm

172.50˚

172.50˚

172.50˚

25.00”

64cm

15.92”

40cm

17.06”

43cm

13.78”

35cm

17.06”

43cm

25.00”

64cm

25.00”

64cm

13.78”

35cm

95˚

172.50˚

172.50˚

25.10”

64cm

15.73”

40cm

13.78”

35cm

25.00”

64cm

17.06”

43cm

25.00”

64cm

19.56”

50cm

95˚

85˚

172.50˚

25.10”

64cm

15.73”

40cm

25.00”

64cm

19.56”

50cm

95˚

85˚

25.10”

64cm

5 pan standard curved drop-in cutout detail

Models:

• N8094-R

• N8194-BR

• N8794-R

8

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

25.10”

64cm

172.50˚

17.06”

43cm

25.00”

64cm

13.78”

35cm

172.50˚

13.78”

35cm

17.06”

43cm

25.00”

64cm

172.50˚

15.67”

40cm

25.00”

64cm

95˚

19.50”

50cm

85˚

25.10”

64cm

™

®

17.06”

172.50˚

43cm

25.00”

64cm

13.78”

35cm

19.50”

50cm

85˚

25.00”

64cm

95˚

15.67”

40cm

N8000 Series Drop-In Installation and Operation Manual

Delfield

CAUTION

DANGER

DANGER

Installation N8000, N8000N, N8000-R, N8100B, N8100NB, N8100-BR, N8200, N8200G, N8100-FA & 8100-EF

These units are intended for indoor use only. A room

temperature of no more than 86°F (30°C) is recommended.

Be sure the location chosen has a counter strong enough to

support the total weight of the unit and contents. A fully loaded

model may weigh as much as 600 pounds! Reinforce the

counter as necessary to provide maximum loading.

Unit requires that the sides and bottom are not

any closer than 3” (7.6cm) to any combustible

material.

The counter cut-out sizes and power requirements are shown

on the specication pages. A gasket is installed in the ange

of each unit. The weight of the unit on the gasket forms a seal

preventing liquids from seeping into the cut-out opening.

Louvers

Self-contained refrigerated units (N8100, N8100NB, N8100-BR,

N8200 and N8200G Series) require airow to the compressor.

A 13” x 25” (33 cm x 63.5 cm) louver is provided by Deleld and

must be installed in the counter in front of the condenser. The

louver cutout dimension is 11” x 22” (27.9 cm x 55.9 cm). The

rear must have an opening to permit removal of heated air. The

opening must be at least 8” x 11”, a total of 88 square inches

(20.3 cm x 27.9 cm, a total of 566 square centimeters).

Plumbing

The units drain must have an outlet to an appropriate drainage

area or container. A drain trap must be installed. N8200 series

have 1/2” drain and N8200G series have 3/4” drain located on

end/center. The 1” diameter drain on N8000, N8000-R, N8100,

N8100NB, N8100-BR, N8100-FA and 8100-EF Series units

is shipped loose and must be connected during installation.

N8157-FA, N8169-FA, and N8182-FA have two drains.

Electrical connection

Refer to the amperage data on the specication pages, the

serial tag or your local code to be sure the unit is connected

to the proper power source. A protected circuit of the correct

voltage and amperage must be run for con nec tion of the line

cord.

Some units have an ON/OFF switch located behind the

louvered panel in the machine compartment. Simply turn the

switch to ON to begin operation.

Some units have an OFF position on the thermostat dial which is

located behind the louvered panel in the machine compartment.

Simply turn the dial to begin operation.

Moisture collecting from improper drainage

can create a slippery surface on the oor

and a hazard to employees. It is the owner’s

responsibility to provide a container or outlet

for drainage.

Some N8000, N8000N, N8000-R, N8100B,

N8100NB and N8100-BR may have

polyethylene insulation in the drain hole.

This can easily be cut out without any contact

or damage to the units interior insulation or

refrigeration lines.

The unit must be disconnected from the

power source whenever performing service

or maintenance functions.

Never operate the unit without the louvered

panel in place!

Installation N8600

These units are intended for indoor use only. A room temperature

of no more than 86°F (30°C) is recommended. Be sure the

location chosen has a counter strong enough to support the

total weight of the unit and contents. A fully loaded model

may weigh as much as 600 pounds! Reinforce the counter as

necessary to provide for maximum loading.

Unit requires that the sides and bottom are not

any closer than 3” (7.6cm) to any combustible

material.

The counter cut-out sizes and power requirements are shown

on the specication pages. A gasket is installed in the ange

of each unit. The weight of the unit on the gasket forms a seal

preventing liquids from seeping into the cut-out opening.

The cut-out dimensions for the control box on N8600 Series

units is 4.25” x 12.25” (10.8 cm x 31.1 cm).

Louvers

For proper refrigerated operation, N8600 Series units require

airow to the compressor. A 13” x 25” louver is (33.0 cm x 63.5

cm) is provided by Deleld and must be installed in the counter

in front of the condenser. The louver cutout dimension is 11”

™

®

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

x 22” (27.9 cm x 55.9 cm). The rear must have an opening to

permit removal of heated air. The opening must be at least 8” x

11”, a total of 88 square inches (20.3 cm x 27.9 cm, a total of 566

square centimeters).

Plumbing

The units 1” (2.54cm) drain must have an outlet to an appropriate

drainage area or container.

Moisture collecting from improper drainage

can create a slippery surface on the oor

and a hazard to employees. It is the owner’s

CAUTION

responsibility to provide a container or outlet

for drainage.

Electrical connection

Refer to the amperage data on the specication pages, the

serial tag or your local code to be sure the unit is connected to

the proper power source.

The unit must be disconnected from the

power source whenever performing service

or maintenance functions.

Never operate the unit without the louvered

panel in place!

9

N8000 Series Drop-In Installation and Operation Manual

Delfield

CAUTION

DANGER

Installation N8700-D, N8700N, N8700-R & N8800 Series

These units are intended for indoor use only. Be sure the

location chosen has a counter strong enough to support the

total weight of the unit and contents. A fully loaded model

may weigh as much as 600 pounds! Reinforce the counter as

necessary to provide maximum loading.

Plumbing

N8700-D, N8700N-D and N8700-R Plumbing: Unit is equipped

with 1/2” (1.3cm) drains, (one per well located in right rear corner

1/2” (1.3cm) female N.P.T.) manifold and 1/2” (1.3cm) gate valve.

Unit requires that the sides and bottom are not

any closer than 3” (7.6cm) to any combustible

material.

The counter cut-out sizes and power requirements are shown

on the specication pages. A gasket is installed in the ange

of each unit. The weight of the unit on the gasket forms a seal

preventing liquids from seeping into the cut-out opening.

N8700 Series pans should be installed with the

drains at the back, away from the operator’s

sides.

The controls on N8700-D, N8700-R and N8800 series units

are mounted in a control panel, designed to be installed at a

“remote” location. The control panel should be installed so that

the indicator light for each control is to the right of the control.

N8700, N8700N and N8700-R series units have 48” (121.9cm)

of conduit and N8800 Series units have 24” (61.0cm) of conduit

between the pans and the remote control panel to facilitate this

installation.

N8800 Plumbing: Well is sloped to a 1.00” (2.5cm) male N.P.T.

stainless steel drain.

Moisture collecting from improper drainage

can create a slippery surface on the oor

and a hazard to employees. It is the owner’s

responsibility to provide a container or outlet

for drainage.

Electrical connection

Refer to the amperage data on the specication pages, the

serial tag or your local code to be sure the unit is connected to

the proper power source.

The unit must be disconnected from the

power source whenever performing service

or maintenance functions.

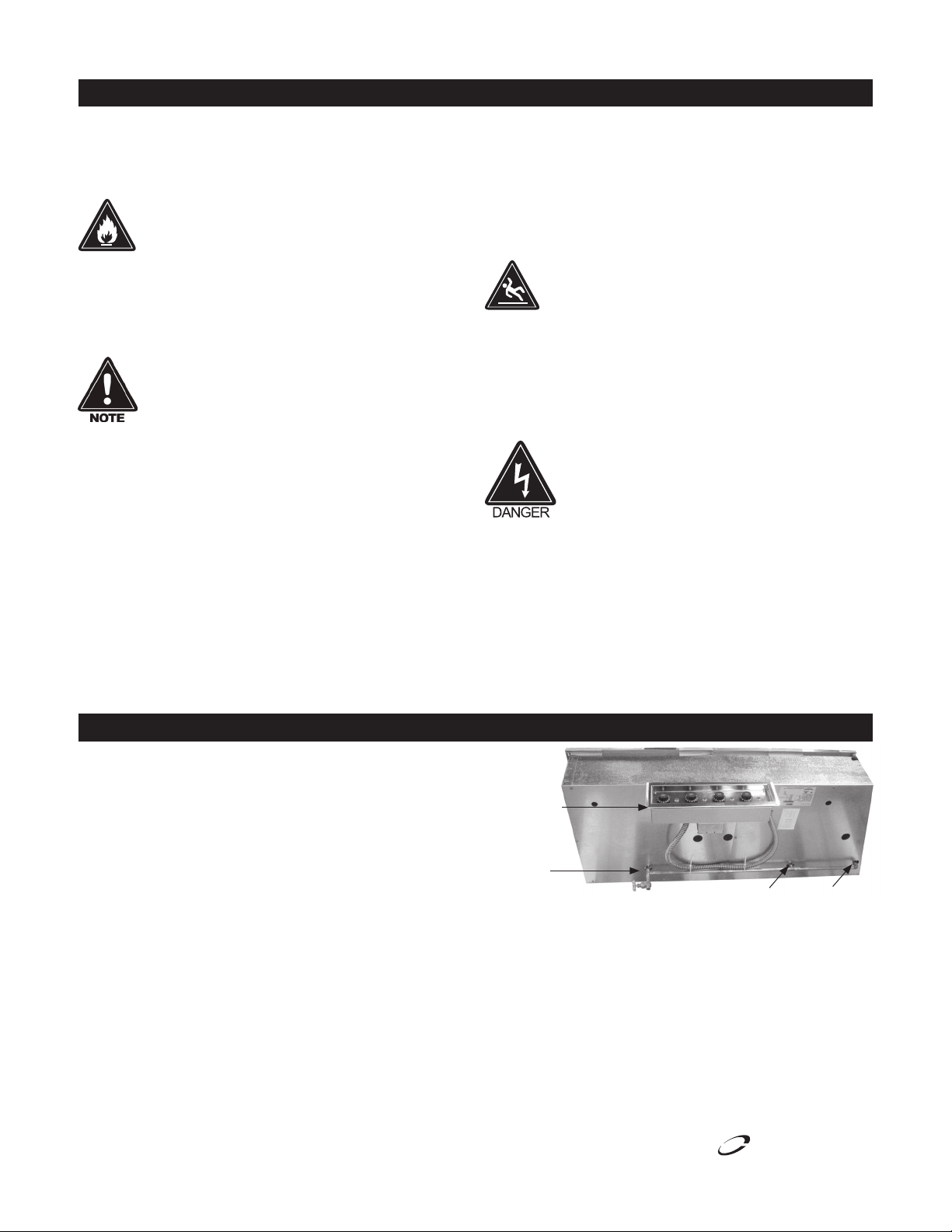

Control Panel Installation, N8700-D, N8700N & N8700-R Series

The control panel is designed to be installed on the side

opposite the drains.

If you choose to install the control panel on the same side as the

drains the control panel will either be upside down or the knobs

will control the opposite wells.

10

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

Control panel

installed

opposite drains

Drains

™

®

Loading...

Loading...