Page 1

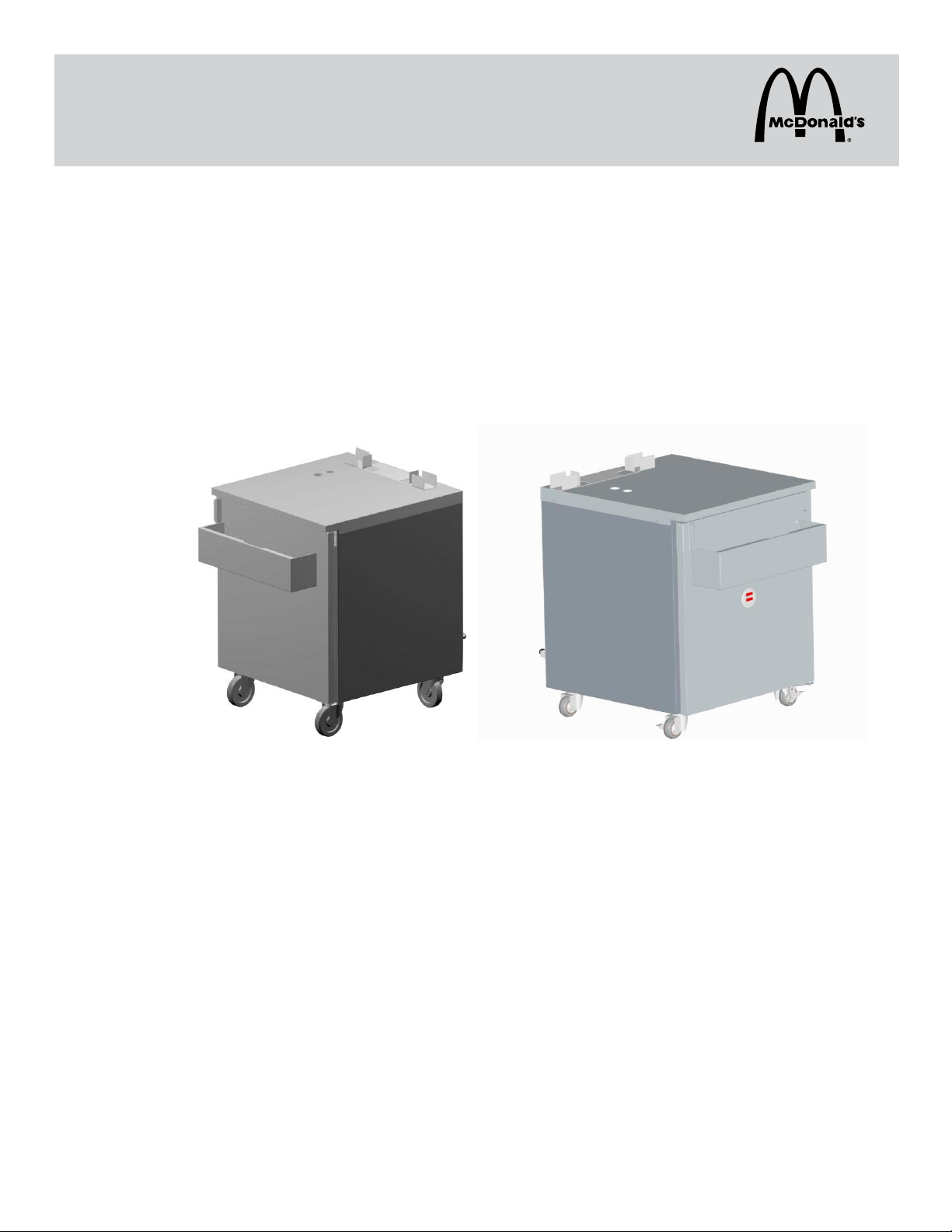

Undercounter Refrigerator

The Delfield Company, Model: 406-MD2-CP2, 406-MD2-CP3

Operation Manual

Manufactured exclusively for

McDonald’s® By:

Delfield

980 S. Isabella Rd.

Mt. Pleasant, MI 48858

Tel. (989) 773-7981 Fax (989) 773-2060

406-MD2-CP2

115V/60Hz

406-MD2-CP3

220V/50Hz

Undercounter Refrigerator

Note: Do not install these unit(s) in any area with an ambient temperature in excess

of 95˚F/35˚C. Doing so will cause damage to the unit(s).

©2009•McDonald’s Corporation

All Rights Reserved

Printed in January 2009

The United States of America

Printed in

Page 2

Delfield

™

®

TABLE OF CONTENTS

Important Warning And Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Serial Tag Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Leveling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Stabilizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Defrosting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Undercounter Refrigerator Daily PM Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Undercounter Refrigerator Quarterly Clean Condenser Coil PM Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Undercounter Refrigerator Quarterly Inspect Door Gasket PM Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Replacement Parts Listing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Standard Labor Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Manufacturers Limited Lifetime Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Two Year Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Service Labor Contract . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-15

Page 2

For factory assistance, call

888-436-5442

or 989-773-7981

Fax 888-779-2040

www.delfield.com

Page 3

Delfield

™

®

IMPORTANT WARNING AND SAFETY INFORMATION

WARNING READ THIS MANUAL THOROUGHLY BEFORE OPERATING,

INSTALLING, OR PERFORMING MAINTENANCE ON THE EQUIPMENT.

WARNING FAILURE TO FOLLOW INSTRUCTIONS IN THIS MANUAL CAN CAUSE

PROPERTY DAMAGE, INJURY OR DEATH.

WARNING DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS

OR LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

WARNING UNLESS ALL COVER AND ACCESS PANELS ARE IN PLACE AND

PROPERLY SECURED, DO NOT OPERATE THIS EQUIPMENT.

CAUTION

Observe the following:

• Minimum clearances must be maintained from all walls and combustible materials.

• Keep the equipment area free and clear of combustible material.

• Adequate clearance for air openings.

• Operate equipment only on the type of electricity indicated on the specification plate.

• Retain this manual for future reference.

For factory assistance, call

888-436-5442

or 989-773-7981

Fax 888-779-2040

www.delfield.com

Page 3

Page 4

Delfield

™

®

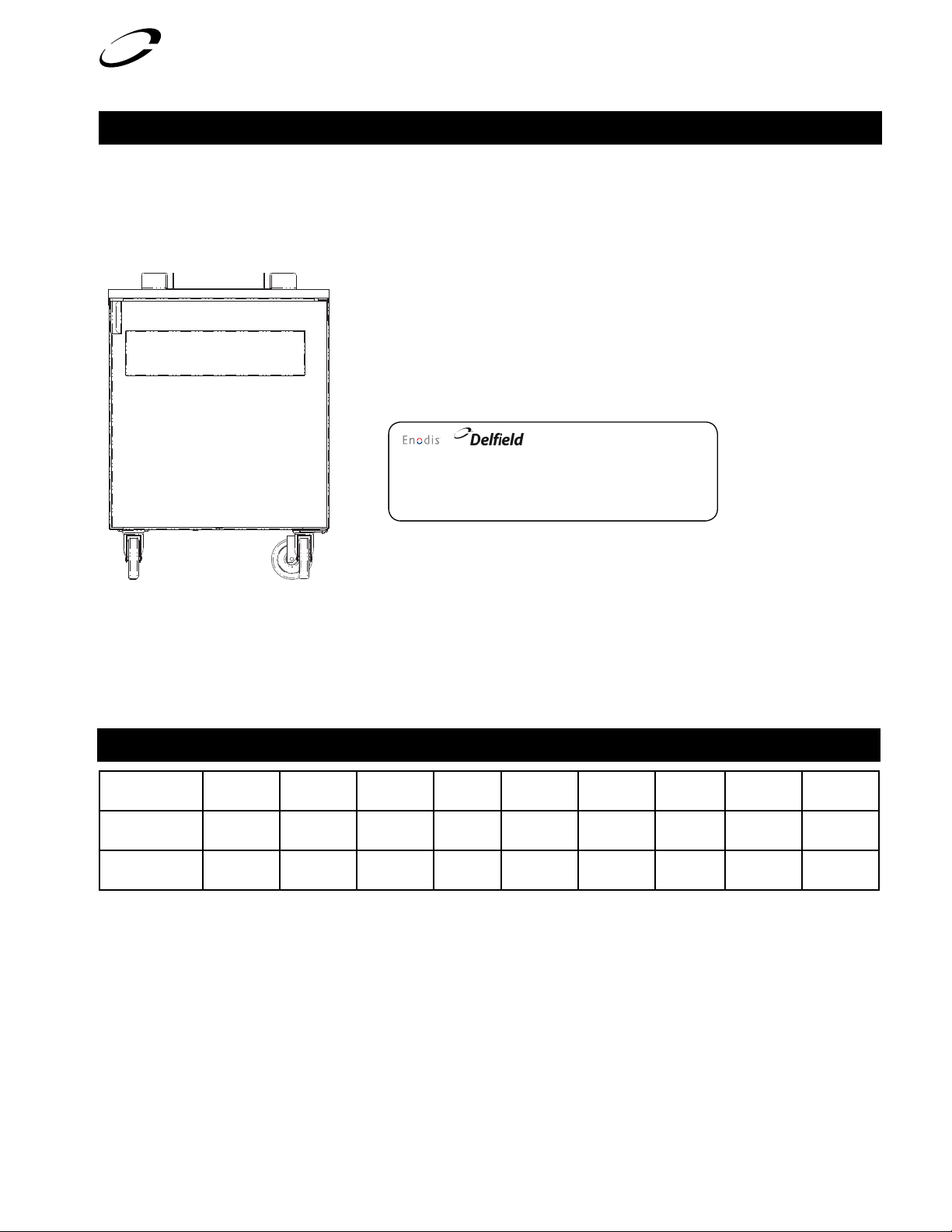

Serial Number

Always have the serial number of your unit available when calling for parts or service.

Serial Tag Location

The Undercounter Refrigerator Serial Tag is located on the right side of the interior back wall.

Figure 1.

Undercounter Refrigerator

Specifications

Model

406-MD2-CP2

406-MD2-CP3 1

Number of

Shelves

1

Shelf Area

2

7.2ft

(.67m2)

7.2ft2

(.67m2)

M O DE L 40 6

R E FR IG . R- 40 4A 7 O Z

E L EC . RE Q( 1) 1 15 V- 60 HZ -7 A

M A X. O VE RC UR RE NT P RO T. DE VI CE 15 A

D E SI GN P RE SS UR ES :

H I GH S ID E 45 0 PS IG L O W SI DE 2 50 P SI G

FO R PA RT S OR S E RVI C E PL EA SE C AL L FO R PA RT S/ SE RV IC E 80 0 7 33 88 29

CO VING TON, TE NNES SEE

S E RI AL N O. 0 80 61 52 00 08 24

M I N. C IR CU IT A MP AC IT Y 15 A

Sample Serial Tag

Storage

Capacity

5.7ft3

(.16m3)

5.7ft3

(.16m3)

H.P

1/5 7oz 115/60/1 7.0

1/5 198g 220/50/1 3.5

R404

Charge

V/Hz/Ph AMPS

Ship

Weight

176lbs

(79.83kg)

176lbs

(79.83kg)

Plug Type

NEMA

5-15P

I

Page 4

For factory assistance, call

888-436-5442

or 989-773-7981

Fax 888-779-2040

www.delfield.com

Page 5

Delfield

™

®

CAUTION

Installation

Location

Undercounter refrigerators are intended for indoor use only.

Be sure the location chosen has a floor strong enough to support

the total weight of the cabinet and contents. Reinforce the floor

as necessary to provide for maximum loading. Take care when

moving the equipment that nothing gets pinched between

the unit and stationary objects. Sheet metal edges, although

deburred, could cause cuts in certain situations.

For the most efficient refrigeration, be sure to provide good air

circulation inside and out.

Inside cabinet: Do not pack refrigerator so full that air cannot

circulate.

Outside cabinet: Be sure that the unit has access to ample

air. A minimum space of 3” (7.6cm) at the back of the unit

and 1” (2.5cm) at the top and sides is required to conform to

Underwriters Laboratories’ standards. On undercounter units

it is imperative that the proper air flow be maintained. The

refrigeration system is designed so air will flow under the unit,

over the compressor/condenser area, and out at the top rear of

the unit. Avoid hot corners and locations near stoves and ovens.

Any restriction of the proper air flow outlined

above, total or partial, will void the warranty on

the unit.

Leveling

A level cabinet will perform better because the drain pan will drain

properly, the doors will line up with the frames and the cabinet

will not be subject to undue strain.

Never stand on the unit! Doing so may result in bodily

injury. They are not designed to hold the weight of an

adult and will collapse if misused in this manner.

Stabilizing

These models are supplied on casters for your convenience, for

ease of cleaning underneath and mobility.

The unit must be installed in a stable condition with

the front wheels locked. Locking the front casters

after installation is the owner’s and operator’s

responsibility. This will keep the unit from rolling

or tipping.

Electrical connection

Refer to the amperage data, the serial tag, your local code or the

National Electrical Code to be sure the unit is connected to the

proper power source. A protected circuit of the correct voltage

and amperage must be run for connection of the line cord, or

permanent connection to the unit.

A 7’ (2.1 m) long grounded supply cord and plug are provided

with standard units. Simply plug the unit in to begin operation.

The thermostat must be turned to OFF and the unit

disconnected from the power source whenever

performing service, maintenance functions or

cleaning the refrigerated area.

If the supply cord is damaged it must be replaced

before operating this equipment. Do not connect

a damaged supply cord to a power source. The

cord must be replaced by a qualified service

personnel.

Operation

Be sure that fan guards are in place before operating. After

the unit is connected to power it will automatically begin

operating. With the door closed, the temperature of the

cabinet should reach 36°F to 40°F (2°C to 4°C) in about one

hour. The temperature control, located on the back panel

inside the refrigerator, can be adjusted to meet the current

conditions.

Temperature control instruction

A thermostat located in the evaporator housing on interior

rear of the unit, controls the temperature in the box. The

factory setting for the control is “4” and maintains about 38°F

(3°C) in the box. Set toward “1” for higher temperatures and

toward “7” for lower temperatures.

Continuous opening and closing of the door will hamper the

unit’s ability to maintain optimum refrigeration temperature.

Plumbing

Self-contained models are standard with a condensate evaporator.

If, for some reason, a unit does not have a condensate evaporator,

or the evaporator fails, the unit’s drain must have an outlet to an

appropriate drainage area or container.

Moisture collecting from improper drainage can

create a slippery surface on the floor and a hazard to

employees. It is the owner’s responsibility to provide

a container or outlet for drainage.

Defrosting

Refrigerators defrost automatically with every cycle of the

compressor. The water generated is routed to a pan on the

rear of the unit and is evaporated by the heat given off by

the compressor.

For factory assistance, call

888-436-5442

or 989-773-7981

Fax 888-779-2040

www.delfield.com

Page 5

Page 6

Delfield

™

®

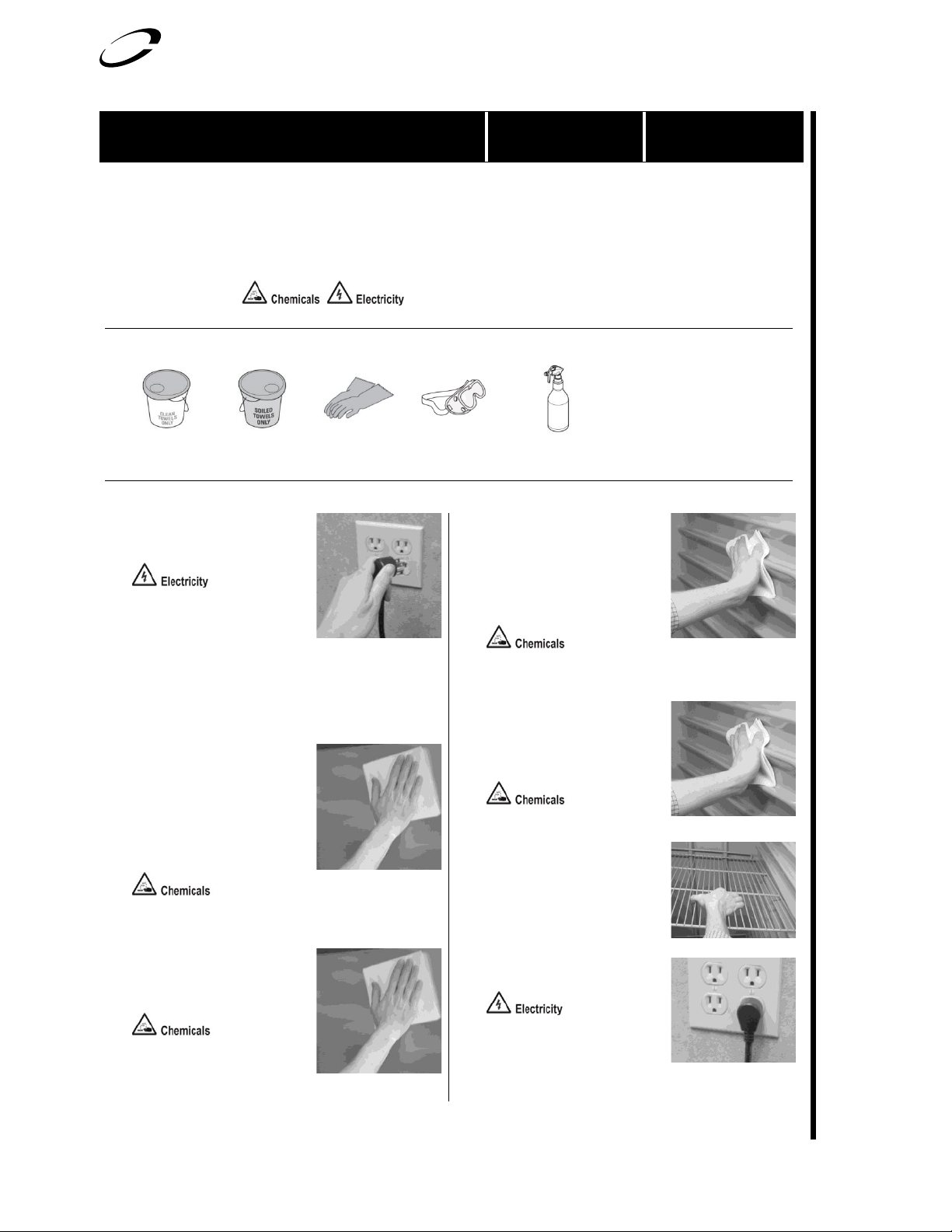

Inspect And Clean

Daily

RF 2 D1

©McDonald’s Corporation · Planned Maintenance Manual · Revised January 2009 Page 1 of 1

Delfield Under Counter And Work Top Refrigerator/Freezer 402, 403, 406, 407

Daily

RF2 D1

Why

Clean the exterior to prevent discoloration or rust. Clean the interior to keep it food safe.

Time required

5 minutes to prepare

15 minutes to complete

Time of day

At close

For 24-hour restaurants: during low-volume periods

Hazard icons

Tools and supplies

Bucket, clean and

sanitized towels

Bucket, soiled towels

Gloves, rubber

Goggles

EXCEED Glass and

Multi Surface Cleaner

Procedure

1

Unplug power cord. Move

products from inside unit to

walk-in.

2

Wear hand and eye protection.

Wear rubber gloves and

safety goggles when handling

cleaner and sanitizer.

3

Clean exterior with EXCEED.

Spray exterior surfaces with

EXCEED Glass and Multi

Surface Cleaner. Using a

clean towel, wipe unit with

the “grain” of the stainless

steel to avoid marring the

finish.

EXCEED Glass and Multi

Surface Cleaner

4

Sanitize exterior.

Wipe exterior with a clean,

sanitized towel dampened

with McD Sanitizer solution.

McD Sanitizer Solution

5

Clean interior with EXCEED.

Remove shelves from interior.

Spray interior, shelves and

gaskets with EXCEED Glass

and Multi Surface Cleaner.

Using a clean towel, wipe

interior, shelves and gaskets.

EXCEED Glass and Multi

Surface Cleaner

6

Sanitize interior.

Wipe interior, shelves and

gasket with a clean, sanitized

towel dampened with McD

Sanitizer solution.

McD Sanitizer Solution

7

Put shelves back into the

cabinet.

8

Plug power cord in. Put

product back into unit.

Page 6

For factory assistance, call

888-436-5442

or 989-773-7981

Fax 888-779-2040

www.delfield.com

#929 428 5

Page 7

Delfield

™

®

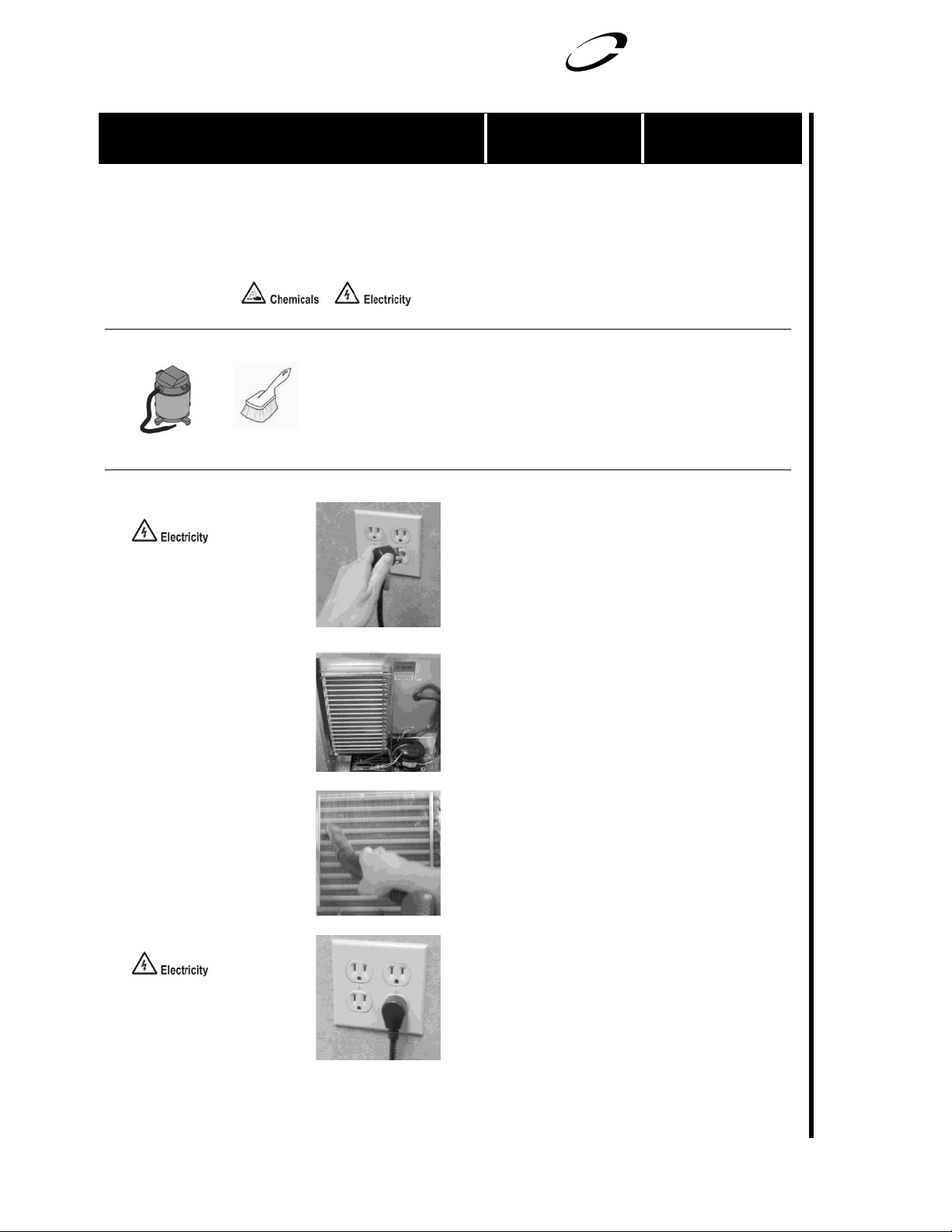

Clean Condenser Coil

Quarterly

RF 2 Q1

©McDonald’s Corporation · Planned Maintenance Manual · Revised January 2009 Page 1 of 1

Delfield Under Counter And Work Top Refrigerator/Freezer 402, 403, 406, 407

Quarterly

RF 2 Q1

Why

In order to maintain proper refrigeration performance, the condenser must be clean.

Time required

5 minutes to prepare

15 minutes to complete

Time of day

At close

For 24-hour restaurants: during low-volume periods

Hazard icons

Tools and supplies

Vacuum, wet/dry

Brush, wire

Procedure

1

Unplug unit power cord.

2

Locate condenser on back of

unit.

3

Clean condenser.

Vacuum or wire brush dust

and particles from condenser.

Remove particles from

cabinet.

4

Plug the unit power cord in.

For factory assistance, call

888-436-5442

or 989-773-7981

Fax 888-779-2040

www.delfield.com

#929 428 5

Page 7

Page 8

Delfield

™

®

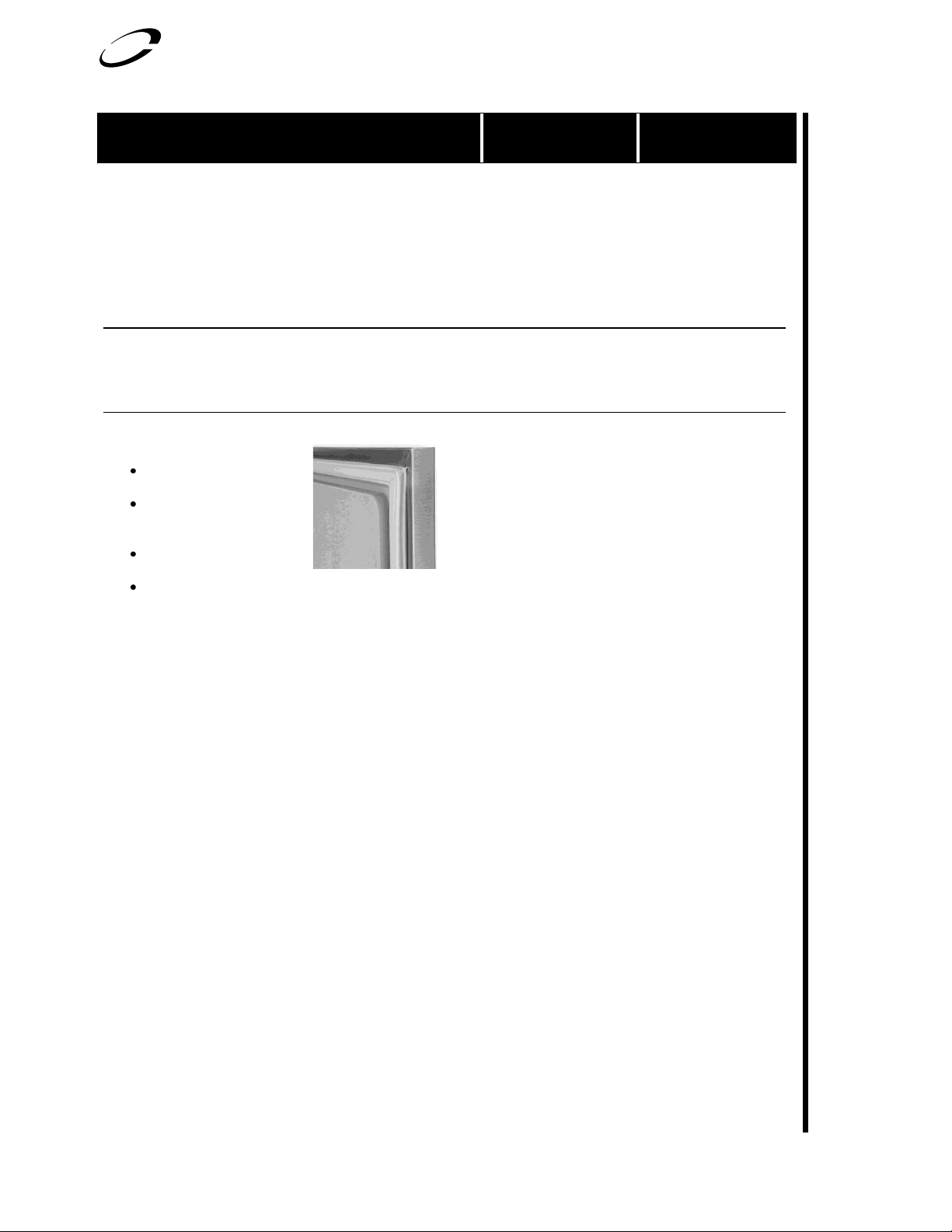

Inspect Door Gaskets

Quarterly

RF 2 Q2

©McDonald’s Corporation · Planned Maintenance Manual · Revised January 2009 Page 1 of 1

Delfield Under Counter And Work Top Refrigerator/Freezer 402, 403, 406, 407

Quarterly

RF 2 Q2

Why

In order to maintain proper refrigeration performance, the gasket must seal the door to the unit.

Time required

0 minutes to prepare

10 minutes to complete

Time of day

At close

For 24-hour restaurants: during low-volume periods

Hazard icons

None

Tools and supplies

None

Procedure

1

Inspect door gaskets.

Check that the door gaskets

are present.

Check that there is no

space between the unit

frame and the gasket.

Check that the gasket is

tight against the door itself.

Check that there are no

rips, tears, or cracks on any

part of the gasket.

2

If necessary, order a new

gasket.

Call 1-800-733-8829 to find a

local parts distributor. Have

the model and serial number

available when calling the

distributor.

Page 8

For factory assistance, call

888-436-5442

or 989-773-7981

Fax 888-779-2040

www.delfield.com

#929 428 5

Page 9

Delfield

™

®

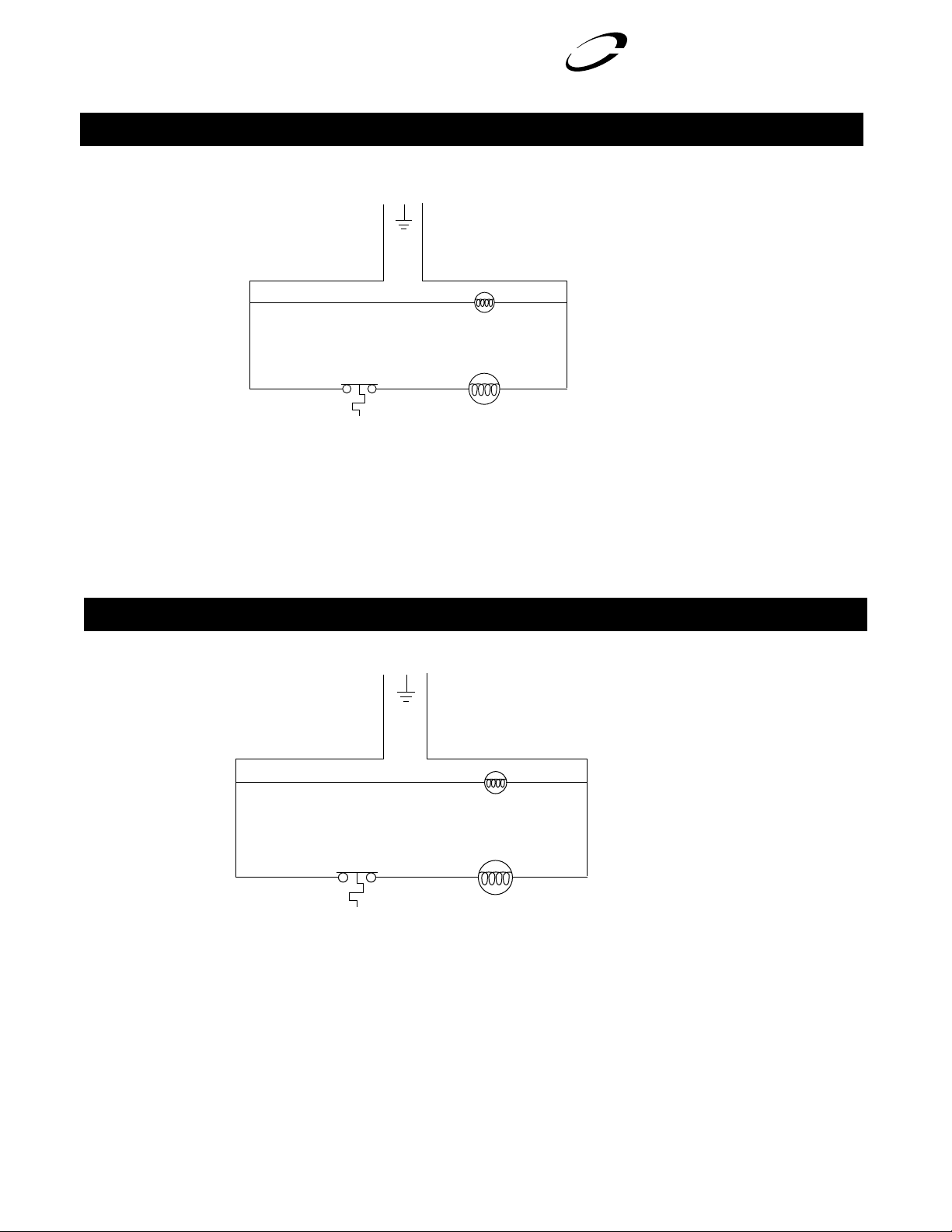

406-MD2-CP2 Wiring Diagram

L1 G N

Condensing

Unit

Evaporator Fan

NEMA 5-15P

Supply Cord &

Plug Furnished

115V/60Hz/1Ø

Temperature

Control

WhiteBlack

L1 G N

Condensing

Unit

Evaporator Fan

230V/50Hz/1Ø

Temperature

Control

BlueBrown

Supply Cord &

Plug Furnished

406-MD2-CP3 Wiring Diagram

For factory assistance, call

888-436-5442

or 989-773-7981

Fax 888-779-2040

www.delfield.com

Page 9

Page 10

Delfield

™

®

Replacement Parts

see memo below

HINGE MEMO: If the model has MD that stands for McDonalds and they “tried” the spring loaded hinges on a few units for them

Must verify hinge type: RF000066 = spring-loaded cartridge kit 0420067 = pivot style hinge kit

406-MD2-CP2

Part # Description

0074057 Capillary tube, .042” id x 144”

3234160 Caster, 5”

3234161 Caster, 5” with brake

3526997 Compressor

3516446 Compressor relay

2194787 Compressor start capacitor

0053452 Condensate heater only

0330154 Condensate pan assembly

(includes condensate heater)

3516275 Condenser coil

3516172 Condenser fan blade

3516173 Condenser fan guard

2162691 Condenser fan motor

000-B3I-003E Door assembly, hinged right

1702623 Door gasket

3516116 Evaporator coil

3516172 Evaporator fan blade

3516173 Evaporator fan guard

2162691 Evaporator motor

3516321 Filter drier

3237569 Hinge bracket, bottom left

3237563 Hinge bracket, bottom right

3237568 Hinge bracket, top left

3237562 Hinge bracket, top right

3237516 Hinge cartridge (spring loaded)

3234225A Pivot cap, nylon, 1” square

117-CB5-0030 Pump bracket

3978030 Shelf

5189779 shelf clip

MCP00207 Shoulder screw

000-CB1-0030 Speed rail assembly

2194759KT Temperature control

(includes control, knob and dial plate)

2194761 Temperature control knob only

3516135 Thermometer, hanging

120-C85-0030 Whipped cream box

406-MD2-CP3

Part # Description

120-CB6-0030 Bracket, coffee machine

9321079 Bumper

129-C15-0103 Bumper bracket

0074057 Capillary tube, .042” id x 144”

3235515 Caster 4”

3235516 Caster 4”, with brake

3526940 Compressor (220V)

0053452 Condensate heater only

0330154 Condensate pan assy

(includes condensate heater)

3516275 Condenser coil

3516172 Condenser fan blade

3516173 Condenser fan guard

2162692 Condenser motor (220V)

000-B3I-003H Door assembly, right hinged

1702623 Door gasket

3516172 Evaporator fan blade

3516173 Evaporator fan guard

2162692 Evaporator motor (220V)

3516116 Evaporator coil

3516321 Filter drier

3237569 Hinge bracket, bottom left

3237563 Hinge bracket, bottom right

3237568 Hinge bracket, top left

3237562 Hinge bracket, top right

3237516 Hinge cartridge (spring loaded)

3234225A Pivot cap, nylon, 1” square

3978030 Shelf

5189779 shelf clip

MCP00207 Shoulder screw

2194759KT Temperature control

(includes control, knob and dial plate)

2194761 Temperature control knob only

3516135 Thermometer, hanging

3516059 Thermometer, solar digital

000-CB1-0030 Speed rail assembly

Page 10

For factory assistance, call

888-436-5442

or 989-773-7981

Fax 888-779-2040

www.delfield.com

Page 11

Delfield

™

®

Standard Labor Guidelines To Repair or Replace Parts on Delfield Equipment

Improper servicing or service not performed by an authorized service agent could result in an explosion or damage.

Advice and recommendations given by Delfield Service Technicians do not constitute or guarantee any special coverage.

• A maximum of 1-hour is allowed to

• A maximum of 1-hour is allowed for

• A maximum

• Overtime, installation/start-up, normal control adjustments, general maintenance, glass breakage, freight damage, and/or

correcting and end-user installation error will not be reimbursed under warranty unless pre-approved with a Service Work

Authorization from Delfield. You must submit the number with the service claim.

LABOR OF 1-HOUR IS ALLOWED TO REPLACE:

Compressor Start Components and Overload Protector

•

Door Hinges, Locks, and Gaskets

•

Evaporator/Condenser Fan Motor and Blade

•

Thermostat

•

LABOR OF 2 HOURS TO REPLACE:

Defrost Element

•

Locate/Repair Leak

•

LABOR OF 3 HOURS TO REPLACE:

Capillary Tube

•

Condenser or Evaporator Coil

•

LABOR OF 4 HOURS TO REPLACE

• Compressor, this includes recovery of refrigerant and leak check.

$55.00U.S. maximum reimbursement for refrigerant recovery (includes recovery machine, pump, torch, oil, flux, minor

fittings, solder, brazing rod, nitrogen, or similar fees.)

travel distance of 100 miles round trip and 2-hours will be reimbursed.

diagnose a defective component.

retrieval of parts not in stock.

REFRIGERANTS

• R404A A maximum of $15.00U.S./lb. or $1.00U.S./oz. will be reimbursed.

For factory assistance, call

888-436-5442

or 989-773-7981

Fax 888-779-2040

www.delfield.com

Page 11

Page 12

Delfield

™

®

Manufacturers Limited Lifetime Warranty

Delfield warrants to the original purchaser-user, subject to the

limitations and exclusions set forth below, that the ABS interior of the

Delfield models identified above will be free of manufactured defects

for as long as the equipment is owned by the original purchaser-user

and is in operation.

What is covered.

The interior liner of the Vantage 6000 Series™ Reach In or

400/4000/4400/4500 Series prep tables, is covered against

manufactured defects under normal use. For purposes of this

Warranty, interior liner is defined as the portion of the interior liner

which is made of ABS material. This warranty applies only to products

sold and installed after March 1, 2000 in the United States, Canada,

Puerto Rico, and Mexico. For purposes of this warranty, lifetime is

defined as the expected usable life for the equipment of 12 years.

Delfield’s Obligation

Limited strictly to shipping OEM replacement parts or repair kits for

any covered ABS interior. A Delfield authorized service dealer and

Delfield’s Service Department must confirm the liner defect has

occurred under normal conditions and is not due to misuse as defined

below. All decisions regarding the ABS interior shall be made by

Delfield’s Service Department and shall be binding upon the parties.

No labor or service charges or allowances are covered by this warranty.

Warranty service must be performed by a Delfield approved authorized

service agent.

User Responsibility

The product must be installed, cleaned and maintained as described in

the Service and Installation manual which is furnished with the product.

Only approved replacement parts may be used. Failure to adhere to

the requirements of this paragraph may void warranty coverage.

Exclusions

This warranty does not cover labor, service, charges for travel time,

mileage, or premium charges. This warranty also does not include

defects resulting from:

Operation of the product beyond the specification set forth in the

•

Service and Installation Manual.

Failure to clean and maintain the product as described in the Service

•

and Installation Manual.

Installation of the product in a manner other than as set forth in the

•

Service and Installation.

Use of installation of replacement parts not approved by Delfield;

•

or

The introduction hot items directly onto the ABS liner.

•

This warranty is in lieu of all other warranties or guarantees of

any kind, express or implied, except Delfield’s One Year Parts

and 90-Day Labor Warranty 400/4000/4400/4500 Series. ANY

IMPLIED WARRANTIES OR MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE ARE HEREBY DISCLAIMED AND EXCLUDED.

IN NO EVENT SHALL DELFIELD BE LIABLE FOR INCIDENTAL OR

CONSEQUENTIAL DAMAGES OF ANY KIND OR NATURE, OR FOR

ANY DEFECT RESULTING IN WHOLE OR IN PART FROM MISUSE,

ALTERATION, IMPROPER INSTALLATION OR INADEQUATE

MAINTENANCE OF THE PRODUCT OR ANY PART THEREOF.

No part or assembly which has been subject to accident, alteration or

misuse, or which has not been installed or serviced in accordance with

the Operation Manual furnished with the product, or which is from

equipment on which the serial number has been altered or removed,

shall be covered by this warranty.

Procedures

All claims for replacement parts or repair kits must be made through

a Delfield Parts Depot or an authorized Delfield dealer. The defective

part invoice must be returned to Delfield within 15 days after the date

of service to be eligible for warranty coverage. All claims must include

the model number, serial number, an original date of installation and

customer identification. Use of parts other than original Delfield

replacement parts will not be covered.

Page 12

For factory assistance, call

888-436-5442

or 989-773-7981

Fax 888-779-2040

www.delfield.com

Page 13

Delfield

™

®

Two Year Warranty

The Delfield Company (“Delfield”) warrants to the Original Purchaser of

the Delfield product (herein called the “Unit”) that such Unit, and all

parts thereof, will be free from defects in material and workmanship

under normal use and service for a period of two (2) years from the

date of shipment of the Unit to the Original Purchaser or, if the Original

Purchaser returns the warranty card completely filled out including the

date of installation within thirty (30) days of receipt of the Unit, one (1)

year from the date of installation. During this two year warranty period,

Delfield will repair or replace any defective part or portion there of returned

to Delfield by the Original Purchaser which Delfield determines was

defective due to faulty material or workmanship. The Original purchaser

will pay all labor, crating, freight and related costs incurred in the removal

of the Unit of defective component and shipment to Delfield, except that

during a period of either ninety (90) days from the date of shipment of

the Unit to the Original Purchaser or, if the Original Purchaser returns

the warranty card completely filled out including the date of installation

within thirty (30) days of receipt of the Unit, ninety (90) days from the

date of installation Delfield will pay all related labor costs. Delfield will

pay the return costs if the Unit or part thereof was defective.

The term “Original Purchaser” as used herein means that person, firm,

association, or corporation for whom the Unit was originally installed.

This warranty does not apply to any Unit or part thereof that has been

subjected to misuse, neglect, alteration, or accident, such as accidental

damage to the exterior finish, operated contrary to the recommendations

specified by Delfield; or repaired or altered by anyone other than Delfield

in any way so as to, in Delfield’s sole judgement, affect its quality or

efficiency. This warranty does not apply to any Unit that has been moved

from the location where it was originally installed. This warranty also

does not cover the refrigerator drier or the light bulbs used in the Unit.

The warranty is subject to the user’s normal maintenance and care

responsibility as set forth in the Service and Installation Manual, such

as cleaning the condenser coil, and is in lieu of all other obligations

of Delfield. Delfield neither assumes, nor authorizes any other person

to assume for Delfield, any other liability in connection with Delfield’s

products.

Removal or defacement of the original Serial Number or Model Number

from any Unit shall be deemed to release Delfield from all obligations

hereunder or any other obligations, express or implied.

Parts furnished by suppliers to Delfield are guaranteed by Delfield only

to the extent of the original manufacturer’s express warranty to Delfield.

Failure of the Original Purchaser to receive such manufacturer’s express

warranty to Delfield. Failure of the Original Purchaser to receive such

manufacturers warranty shall in no way create any warranty, expressed

or implied, or any other obligation or liability on Delfield’s part in respect

thereof.

IF THE CUSTOMER IS USING A PART THAT RESULTS IN A VOIDED

WARRANTY AND A DELFIELD AUTHORIZED REPRESENTATIVE

TRAVELS TO THE INSTALLATION ADDRESS TO PERFORM WARRANTY

SERVICE, THE SERVICE REPRESENTATIVE WILL ADVISE CUSTOMER

THE WARRANTY IS VOID. SUCH SERVICE CALLS WILL BE BILLED

TO CUSTOMER AT THE AUTHORIZED SERVICE CENTER’S THEN

APPLICABLE TIME AND MATERIALS RATES. CONSIDER: CUSTOMER

MAY INITIATE A SERVICE AGREEMENT WITHOUT PARTS COVERAGE.

If shipment of a replacement part is requested prior to the arrival in the

Delfield factory of the part claimed to be defective, the Original Purchaser

must accept delivery of the replacement part of a C.O.D. basis, with credit

being issued after the part has been received and inspected at Delfield’s

plant and determined by Delfield to be within this warranty.

Under no condition does this warranty give the Original Purchaser the

right to replace the defective Unit with a complete Unit of the same

manufacturer or of another make. Unless authorized by Delfield in

writing, this warranty does not permit the replacement of any part,

including the motor-compressor, to be made with the part of another

make or manufacturer.

No claims can be made under this warranty for spoilage of any products

for any reason, including system failure.

The installation contractor shall be responsible for building access,

entrance and field conditions to insure sufficient clearance to allow any

hood(s), vent(s), or Unit(s) if necessary, to be brought into the building.

Delfield will not be responsible for structural changes or damages

incurred during installation of the Unit or any exhaust system.

Delfield shall not be liable in any manner for any default or delay in

performance hereunder caused by or resulting from any contingency

beyond Delfield’s control, including, but not limited to, war, governmental

restrictions or restraints, strike, lockouts, injunctions, fire, flood, acts of

nature, short or reduced supply of raw materials, or discontinuance of

the parts by the original part manufacturer.

Except as provided in any Additional Four Year Protection Plan, if

applicable, and the Service Labor Contract, if applicable, the foregoing

is exclusive and in lieu of all other warranties, whether written or

oral, express or implied. This warranty supersedes and excludes any

prior oral or written representations or warranties. Delfield expressly

disclaims any implied warranties of merchantability, fitness for a

particular purpose of compliance with any law, treaty, rule or regulation

relating to the discharge of substances into the environment. The sole

and exclusive remedies of any person relating to the Unit, and the full

liability of Delfield for any breach of this warranty, will be as provided

in this warranty.

Other than this Delfield Two Year Limited Warranty, any applicable Delfield

Additional Four Year Protection Plan or applicable Delfield Service Labor

Contract, the Original Purchaser agrees and acknowledges that no other

warranties are offered or provided in connection with or for the unit or

any other part thereof.

In no event will Delfield be liable for special, incidental or consequential

damages, or for damages in the nature of penalties.

IF DURING THE WARRANTY PERIOD, CUSTOMER USES A PART FOR

THIS DELFIELD EQUIPMENT OTHER THAN AN UNMODIFIED NEW OR

RECYCLED PART PURCHASED DIRECTLY FROM DELFIELD OR ANY OF

ITS AUTHORIZED SERVICE CENTERS AND/OR THE PART BEING USED

IS MODIFIED FROM ITS ORIGINAL CONFIGURATION, THIS WARRANTY

WILL BE VOID. FURTHER, DELFIELD AND ITS AFFILIATES WILL NOT

BE LIABLE FOR ANY CLAIMS DAMAGES OR EXPENSES INCURRED BY

THE CUSTOMER WHICH ARISE DIRECTLY OR INDIRECTLY, IN WHOLE

OR IN PART, DUE TO THE INSTALLATION OF ANY MODIFIED PART AND/

OR PART RECEIVED FROM AN UNAUTHORIZED SERVICE CENTER. If

the warranty becomes void, Customer may purchase from Delfield, if

available, a Service Agreement or service at the then current time and

materials rate.

For more information on Delfield warranty’s log on and check out the

service section of our web site at www.delfield.com.

For factory assistance, call

888-436-5442

or 989-773-7981

Fax 888-779-2040

www.delfield.com

Page 13

Page 14

Delfield

™

®

The Delfield Company

SERVICE LABOR CONTRACT

ONE (1) YEAR TWO (2) YEAR

Shipment

Model # Serial # Date

The Delfield Company (“Delfield”) offers this service labor contract (the “Service Labor

Contract”), available at a nominal fee at the time of submission and acceptance of the

order for the above listed Delfield unit (the “Unit”), in accordance with the following terms

and conditions:

The Service Labor Contract is in addition to Delfield’s Standard One Year Limited

Warranty (the “One Year Warranty”) and Delfield Additional Four Year Protection Plan (the

“Four Year Warranty”). The terms and conditions of the One Year Warranty and the Four

Year Warranty are set forth in their entirety in those warranties.

The Service Labor Contract covers the cost of labor where, in Delfield’s sole judgment,

the Unit has proven to be defective in use and where recommended factory maintenance

has been performed. The Service Labor Contract does not cover costs of initial installation or start-up, normal control adjustments or maintenance, food or business loss.

The one year Service Labor Contract shall cover those costs incurred by the Original

Purchaser for a period of one (1) year from the date of shipment of the Unit to the Original

Purchaser and the two year Service Labor Contract shall cover those costs incurred by

the Original Purchaser for a period of two (2) years from date of shipment of the Unit to

the Original Purchaser.

The term “Original Purchaser” as used herein means that person, firm, association, or

corporation for whom the Unit was originally installed.

Any claims under this Service Labor Contract must be made in advance of the needed

repairs. Delfield will not pay for repairs not authorized in advance. Upon completion of

the repairs, an itemized statement must be submitted to Delfield’s Customer Service

Department at the address below and must contain the following information:

1) Dealer name, invoice number, model number and serial number of the Unit.

2) Date the Unit was shipped.

3) Date the Unit failed, together with the name and address of the service agency called

in to repair the Unit.

4) Full description of and circumstances surrounding the failure of the Unit.

5) Itemized bill of the repairs made to the Unit.

(continued)

Page 14

For factory assistance, call

888-436-5442

or 989-773-7981

Fax 888-779-2040

www.delfield.com

Page 15

Delfield

™

®

The Delfield Company

(continued from previous page)

Upon review and approval of the claim by Delfield’s Customer Service Department, payment

will be made promptly only for the following costs:

Cost of service labor necessary to repair the Unit, provided that it is based on

1)

straight time only and the duration is, in the sole judgment of Delfield, within reason

for the repair made.

2)

Travel mileage of the service agency called upon to make the repair, provided

the distance is, in the sole judgment of Delfield, with a reasonable radius of the

installation site.

3) Cost of replacement parts, provided that permission to purchase locally was autho

rized by Delfield’s Customer Service Department in advance of the purchase.

Delfield shall not be liable in any manner for any default or delay in performance hereunder

caused by or resulting from any contingency beyond Delfield’s control, including, but not limited to, war, governmental restrictions or restraints, strikes, lockouts, injunctions, fire, floods,

acts of nature, short or reduced supply of raw materials, or discontinuance of the parts by the

original part manufacturer.

This Service Labor Contract is offered on all Delfield units, except remote refrigerators,

freezers and ventilation systems, installed in the United States and certain other preapproved locations in Canada and Mexico (the “Approved Locations”). It is not available on

cabinets supplied for remote installations nor on any units installed outside the Approved

Locations. This Service Labor Contract does not cover repairs to any Unit that has been

moved from the location where it was originally installed.

-

EXCEPT AS PROVIDED IN ANY APPLICABLE TWO YEAR LIMITED WARRANTY OR

APPLICABLE ADDITIONAL FOR YEAR PROTECTION PLAN, THE FOREGOING IS

EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, WHETHER WRITTEN OR

ORAL, EXPRESS OR IMPLIED. THIS SERVICE LABOR CONTRACT SUPERSEDES AND

EXCLUDES ANY PRIOR ORAL OR WRITTEN REPRESENTATIONS OR WARRANTIES.

DELFIELD EXPRESSLY DISCLAIMS ANY IMPLIED WARRANTIES OF MERCHANTABILITY,

FITNESS FOR A PARTICULAR PURPOSE OR COMPLIANCE WITH ANY LAW, TREATY,

RULE OR REGULATION RELATING TO DISCHARGE OF SUBSTANCES INTO THE

ENVIRONMENT. THE SOLE AND EXCLUSIVE REMEDIES OF ANY PERSON RELATING TO

THE UNIT, AND THE FULL LIABILITY OF DELFIELD FOR ANY BREACH OF THE SERVICE

LABOR CONTRACT, SHALL BE AS PROVIDED IN THIS SERVICE LABOR CONTRACT.

IN NO EVENT WILL DELFIELD BE LIABLE FOR SPECIAL, INCIDENTAL OR CONSEQUENTIAL

DAMAGES, OR FOR DAMAGES IN THE NATURE OF PENALTIES.

For factory assistance, call

888-436-5442

or 989-773-7981

Fax 888-779-2040

www.delfield.com

Page 15

Page 16

Delfield

™

®

Mt. Pleasant, MI

Delfield

™

®

Covington, TN

Thank you for choosing Delfield!

Help is a phone call away. Help our team of professional, courteous

customer service reps by having your model number and serial number

available at the time of your call (800) 733-8829.

Model: ____________________ S/N: ___________________

Installation Date: ____________

For a list of Delfield’s authorized parts depots,

visit our website at www.delfield.com.

980 S. Isabella Rd., Mt. Pleasant, MI 48858, U.S.A. • (989) 773-7981 or (800) 733-8829 • Fax (989) 773-3210 • www.delfield.com

Delfield reserves the right to make changes in design or specifications without prior notice. ©2009 The Delfield Company. All rights reserved. Printed in the U.S.A.

DM406-MD2-CP 01/09

9294260

Page 17

Réfrigérateur de comptoir

The Delfield Company, modèle : 406-MD2-CP2, 406-MD2-CP3

Manuel d’utilisation

Fabriqué en exclusivité pour McDonald’s® par :

Delfield

980 S. Isabella Rd.

Mt. Pleasant, MI 48858 U.S.A.

Tél. (989) 773-7981 Fax (989) 773-2060

406-MD2-CP2

115 V/60 Hz

406-MD2-CP3

220 V/50 Hz

Réfrigérateur de comptoir

Remarque : Ne pas installer cet ou ces appareils à un endroit où la température

ambiante dépasse 35 °C/95 °F pour ne pas risquer de les endommager.

©2009•McDonald’s Corporation

Tous droits réservés

Imprimé en janvier 2009

États-Unis d’Amérique

Imprimé aux

Page 18

TABLE DES MATIÈRES

Importants avertissement et informations sur la sécurité................................................................ 3

Numéro de série ............................................................................................................................. 4

Emplacement de la plaque signalétique .................................................................................... 4

Caractéristiques...............................................................................................................................4

Installation ...................................................................................................................................... 5

Implantation .................................................................................................................................5

Mise à niveau .............................................................................................................................. 5

Stabilisation .................................................................................................................................5

Plomberie .................................................................................................................................... 5

Branchement électrique ..............................................................................................................5

Fonctionnement ............................................................................................................................... 5

Dégivrage ........................................................................................................................................5

Réfrigérateur sous comptoir et plan de travail Quotidien ................................................................6

Réfrigérateur xous comptoir et plan de travail Trimestriel ...........................................................7-8

Schémas de câblage .......................................................................................................................9

Liste de pièces de rechange ......................................................................................................... 10

Normes relatives à la main d’œuvre ............................................................................................. 11

Garantie limitée à vie du fabricant ................................................................................................12

Garantie de deux ans ....................................................................................................................13

Contrat d’entretien ....................................................................................................................14-15

Page 2

Pour demander l’assistance de

l’usine, appeler le

888-436-5442 ou 989-773-7981

Fax 888-779-2040

www.delfield.com

Page 19

MISE EN GARDE ET INFORMATIONS DE SÉCURITÉ IMPORTANTES

AVERTISSEMENT

LIRE CE MANUEL ATTENTIVEMENT AVANT D’UTILISER, INSTALLER

OU ENTRETENIR LE MATÉRIEL.

AVERTISSEMENT

L’INOBSERVATION DES INSTRUCTIONS DONNÉES DANS CE

MANUEL PEUT ENTRAÎNER DES DÉGÂTS MATÉRIELS ET DES

BLESSURES GRAVES VOIRE MORTELLES.

AVERTISSEMENT

NE PAS ENTREPOSER NI UTILISER DE L’ESSENCE OU D’AUTRES

VAPEURS OU LIQUIDES INFLAMMABLES AU VOISINAGE DE CET

APPAREIL OU DE TOUT AUTRE.

AVERTISSEMENT

NE PAS UTILISER CET APPAREIL SI TOUS LES PANNEAUX DE

COUVERTURE ET D’ACCÈS NE SONT PAS EN PLACE ET BIEN

FIXÉS.

ATTENTION

Observer les recommandations suivantes :

• Des dégagements minima doivent être maintenus par rapport à tous

• Maintenir la zone dans laquelle se trouve l’appareil libre de matières c

• Maintenir un dégagement suffisant pour les bouches d’air.

• Ne faire fonctionner l’appareil que sur le type de courant indiqué

• Conserver ce manuel pour pouvoir s’y reporter à l’avenir.

les murs et matériaux combustibles.

ombustibles.

sur la plaque signalétique.

Pour demander l’assistance de

l’usine, appeler le

888-436-5442 ou 989-773-7981

Fax 888-779-2040

www.delfield.com

Page 3

Page 20

Numéro de série

Toujours avoir le numéro de série de l’appareil à portée de la main quand on commande des pièces ou fait

une demande d’assistance.

Emplacement de la plaque signalétique

La plaque signalétique du réfrigérateur comptoir se trouve sur le côté droit de la paroi intérieure arrière.

Example de plaque signalétique

Figure 1.

Réfrigérateur de comptoir

Caractéristiques

Modèle

406-MD2-CP2

406-MD2-CP3 1

Nombre de

clayettes

1

Surface des

clayettes

2

0,67 m

(7,2 pi2)

2

0,67 m

(7,2 pi2)

Capacité Puissance

0,16 m3

(5,7 pi3)

0,16 m3

(5,7 pi3)

1/5 7oz 115/60/1 7,0

1/5 198g 220/50/1 3,5

Charge

R404

V/Hz/Ph A

Poids à

l’exp.

79,83 kg

(176 lbs)

79,83 kg

(176 lbs)

Type de

prise

NEMA

5-15P

I

Page 4

Pour demander l’assistance de

l’usine, appeler le

888-436-5442 ou 989-773-7981

Fax 888-779-2040

www.delfield.com

Page 21

Installation

CAUTION

Implantation

Les réfrigérateurs de comptoir sont conçus pour être utilisés à

l’intérieur uniquement. Veiller à ce que l’emplacement choisi ait

un plancher suffisamment solide pour supporter le poids total

de l’appareil et de son contenu. Renforcer le sol le cas échéant

pour qu’il puisse supporter une charge maximum. Lorsqu’on

déplace l’appareil, veiller à ce que rien ne soit écrasé entre

lui et des objets fixes. Les bords de tôles, bien qu’ébarbés,

pourraient causer des coupures dans certaines situations.

Pour maximiser l’efficacité de la réfrigération, veiller à prévoir

une bonne circulation d’air à l’intérieur comme à l’extérieur.

Intérieur de l’appareil : Ne pas trop remplir le réfrigérateur, ce qui empêcherait l’air de circuler.

Extérieur de l’appareil : Veiller à ce que l’appareil soit bien

aéré. Un espace d’au moins 7,6 cm (3 po) derrière l’appareil

et de 2,5 cm (1 po) sur le dessus et les côtés est exigé pour

respecter les normes applicables. Il est impératif de maintenir la

circulation d’air correcte autour des réfrigérateurs de comptoir.

Le système de réfrigération est conçu pour que l’air circule sous

l’appareil et sur la zone du compresseur/condenseur, et qu’il

sorte à la partie supérieure arrière de l’appareil. Éviter les coins

et emplacements chauds proches de cuisinières et de fours.

Toute limitation totale ou partielle de la circulation d’air correcte telle que décrite plus

REMARQUE

haut annulera la garantie de l’appareil.

Mise à niveau

Un appareil à niveau aura un meilleur rendement parce

que le bac d’évacuation se videra correctement, la

porte et l’encadrement seront alignés, et la carrosserie ne sera pas soumise à des contraintes excessives.

Ne jamais monter sur l’appareil! Sinon, on risque de

se blesser. L’appareil n’est pas conçu pour supporter

le poids d’un adulte et s’affaissera si on monte dessus.

Branchement électrique

Se reporter aux données d’intensité, à la plaque signalétique, au code local ou au code national de l’électricité pour

s’assurer que l’appareil est raccordé à la source d’alimentation

correcte. Un circuit protégé de la tension et de l’intensité

correctes doit être installé pour raccordement du cordon

d’alimentation ou raccordement permanent à l’appareil.

Un cordon d’alimentation de 2,1 m (7 pi) de long à mise à la

terre et une prise tripolaire est fourni avec les appareils standard. Il suffit de brancher l’appareil pour le mettre en service.

Le thermostat doit être placé sur OFF (arrêt) et

l’appareil débranché de la source d’alimentation

pour effectuer des opérations de réparation,

d’entretien ou de nettoyage de la zone réfrigérée.

Si le cordon d’alimentation est endommagé, le

remplacer avant de faire fonctionner l’appareil.

Ne pas raccorder un cordon d’alimentation

endommagé à une source de courant. Le cordon

doit être remplacé par un réparateur qualifié.

Fonctionnement

S’assurer que les protèges-ventilateur sont en place avant de

faire fonctionner l’appareil. L’appareil se met automatiquement

en marche dès qu’il est branché. Si la porte est maintenue fermée, la température dans l‘appareil devrait atteindre 2 à 4 °C

(36 à 40 °F) en une heure environ. La commande de température, qui se trouve sur le panneau arrière intérieur du réfrigérateur, peut être réglée en fonction des conditions ambiantes.

Stabilisation

Ces modèles sont livrés sur roulettes pour offrir une commodité

et une mobilité plus grandes et faciliter le nettoyage du dessous.

L’appareil doit être stable et ses roulettes avant bloquées. Il incombe au propriétaire et à l’utilisateur

REMARQUE

de bloquer les roulettes avant après l’installation.

Cela empêchera l’appareil de rouler ou de basculer.

Plomberie

Les modèles autonomes sont équipés en standard d’un

évaporateur de condensats. Si, pour une raison quelconque,

un appareil n’est pas doté d’un évaporateur de condensats

ou que celui-ci tombe en panne, l’évacuation de l’appareil

doit se faire dans une zone ou un récipient approprié.

L’humidité s’accumulant par suite d’une évacuation

incorrecte peut créer un plancher glissant dangereux

ATTENTION

pour les employés. Il incombe au propriétaire de

prévoir un récipient ou une sortie d’évacuation.

Pour demander l’assistance de

l’usine, appeler le

888-436-5442 ou 989-773-7981

Fax 888-779-2040

www.delfield.com

Réglage de la température

Un thermostat, qui se trouve dans le carter d’évaporateur

sur la partie intérieure arrière de l’appareil, commande la

température dans le compartiment. Il est réglé à l’usine à

la position « 4 » et maintient une température d’environ

3 °C (38 °F) dans le compartiment. Le tourner vers « 1 »

pour augmenter la température et vers « 7 » pour l’abaisser.

Une ouverture et une fermeture constantes de la porte empêcheront l’appareil de maintenir une température de réfrigération optimum.

Dégivrage

Les réfrigérateurs se dégivrent automatiquement lors de

chaque cycle du compresseur. L’eau produite est acheminée jusqu’à un bac sur l’arrière de l’appareil et s’évapore

sous l’effet de la chaleur dégagée par le compresseur.

Page 5

Page 22

Contrôle et nettoyage Quotidien RF 2 D1

©McDonaldʼs Corporation · Manuel dʼentretien programmé · Révision de janvier 2009 Page 1 / 1

Réfrigérateur/congélateur sous comptoir et plan de travail Delfield 402, 403, 406, 407

Quotidien RF2 D1

Objet

Nettoyage de l’extérieur pour empêcher la décoloration ou la rouille. Nettoyage de l’intérieur pour

protéger les aliments de la contamination.

Temps nécessaire

5 minutes de préparation 15 minutes d’exécution

Période

À la fermeture Restaurants ouverts 24 h sur 24 : pendant les périodes

creuses

Icônes de danger

Outillage et fournitures

Seau, chiffons

propres et

désinfectés

Seau, chiffons sales Gants, caoutchouc Lunettes Nettoyant

verre/multisurface

EXCEEDr

Marche à suivre

1

Débrancher le cordon d’alimentation.

Enlever les aliments de l’intérieur pour

y accéder.

2

Porter des gants et des lunettes.

Porter des gants en caoutchouc et des

lunettes de protection pour manipuler

le nettoyant et le désinfectant.

3

Nettoyer l’extérieur avec du EXCEED.

Pulvériser du nettoyant

verre/multisurface EXCEED sur les

surfaces extérieures. Les essuyer avec

un chiffon propre dans le sens du fil

de l’acier inoxydable pour éviter

d’abîmer le fini.

Nettoyant verre/multisurface

EXCEED

4

Désinfecter l’extérieur.

Frotter l'extérieur avec un chiffon

propre désinfecté imbibé de solution

désinfectante McD.

Solution désinfectante McD

5

Nettoyer l’intérieur avec du EXCEED.

Enlever les clayettes de l’intérieur.

Les pulvériser, ainsi que l’intérieur et

les joints, avec du nettoyant

verre/multisurface EXCEED. Frotter

l’intérieur, les clayettes et les joints

avec un chiffon propre.

Nettoyant verre/multisurface

EXCEED

6

Désinfecter l’intérieur.

Frotter l'intérieur, les clayettes et les

joints avec un chiffon propre

désinfecté imbibé de solution

désinfectante McD.

Solution désinfectante McD

7

Remettre les clayettes dans l’appareil.

8

Brancher le cordon d’alimentation.

Remettre les aliments dans l’appareil.

Page 6

Pour demander l’assistance de

l’usine, appeler le

888-436-5442 ou 989-773-7981

Fax 888-779-2040

www.delfield.com

#929 4285

Page 23

Nettoyage du serpentin réfrigérant Trimestriel RF 2 Q1

©McDonaldʼs Corporation · Manuel dʼentretien programmé · Révision de janvier 2009 Page 1 / 1

Réfrigérateur/congélateur sous comptoir et plan de travail Delfield 402, 403, 406, 407

Trimestriel RF 2 Q1

Objet

Pour maintenir une bonne réfrigération, le condenseur doit être propre.

Temps nécessaire

5 minutes de préparation 15 minutes d’exécution

Période

À la fermeture Restaurants ouverts 24 h sur 24 : pendant les périodes

creuses

Icônes de danger

Outillage et fournitures

Aspirateur pour eau

et poussières

Brosse métallique

Marche à suivre

1

Débrancher le cordon

d’alimentation.

2

Repérer le condenseur au dos

de l’appareil.

3

Nettoyer le condenseur.

Enlever la poussière et les

particules du condenseur avec

un aspirateur ou une brosse

métallique. Enlever les

particules de la caisse.

4

Rebrancher le cordon

d’alimentation de l’appareil.

Pour demander l’assistance de

l’usine, appeler le

888-436-5442 ou 989-773-7981

Fax 888-779-2040

www.delfield.com

#929 4285

Page 7

Page 24

Contrôle des joints de porte Trimestriel RF 2 Q2

©McDonaldʼs Corporation · Manuel dʼentretien programmé · Révision de janvier 2009 Page 1 / 1

Réfrigérateur/congélateur sous comptoir et plan de travail Delfield 402, 403, 406, 407

Trimestriel RF 2 Q2

Objet

Pour maintenir une bonne réfrigération, le joint doit sceller la porte de l’appareil.

Temps nécessaire

0 minute de préparation 10 minutes d’exécution

Période

À la fermeture Restaurants ouverts 24 h sur 24 : pendant les périodes

creuses

Icônes de danger

Néant

Outillage et fournitures

Néant

Marche à suivre

1

Examiner les joints de porte.

x

Vérifier que les joints de

porte sont en place.

x

Vérifier que le joint n’est

pas écarté de l'encadrement

de l’appareil.

x

Vérifier que le joint est

bien ajusté contre la porte

elle-même.

x

Vérifier que le joint n’est

pas déchiré ni fendillé en

un point quelconque.

2

Si nécessaire, commander un

joint neuf.

Appeler le 1-800-733-8829

pour trouver un distributeur

de pièces local. Disposer des

numéros de modèle et de série

lorsqu’on appelle le

distributeur.

Page 8

Pour demander l’assistance de

l’usine, appeler le

888-436-5442 ou 989-773-7981

Fax 888-779-2040

www.delfield.com

#929 4285

Page 25

Schéma de câblage 406-MD2-CP2

L1 G N

Condensing

Unit

Evaporator Fan

NEMA 5-15P

Supply Cord &

Plug Furnished

115V/60Hz/1Ø

Temperature

Control

WhiteBlack

L1 G N

Condensing

Unit

Evaporator Fan

230V/50Hz/1Ø

Temperature

Control

BlueBrown

Supply Cord &

Plug Furnished

115 V/60 Hz/1Ø Cordon d’alimentation

Noir

Ventilateur d’évaporateur

Commande de

température

T

Blanc

Condenseur

et prise

NEMA 5-15P fournis

Schéma de câblage 406-MD2-CP3

Ventilateur d’évaporateur

Commande de

température

T230 V/50 Hz/1Ø

BleuMarron

Condenseur

Cordon

d’alimentation

et prise fournis

Pour demander l’assistance de

l’usine, appeler le

888-436-5442 ou 989-773-7981

Fax 888-779-2040

www.delfield.com

Page 9

Page 26

Pièces de rechange

406-MD2-CP2

406-MD2-CP3

N° réf. Description

0074057 Tube capillaire, 042 po diam. int. x 144 po

3234160 Roulette, 5 po

3234161 Roulette, 5 po avec frein

3526997 Compresseur

3516446 Relais de compresseur

2194787

0053452 Réchauffeur de condensats seul

0330154 Bac à condensats

(réchauffeur de condensats inclus)

3516275 Serpentin réfrigérant

3516172 Pale de ventilateur de condenseur

3516173 Protège-ventilateur de condenseur

2162691 Moteur de ventilateur de condenseur

000-B3I-003E Porte, charnières à droite

1702623 Joint de porte

3516116 Serpentin évaporateur

3516172 Pale de ventilateur d’évaporateur

351 6173 Protège-ventilateur d’évaporateur

2162691 Moteur d’évaporateur

3516321 Déshydrateur-filtre

3237563 Support de charnière, inférieur droit

3237562 Support de charnière, supérieur droit

3237569 Support de charnière, inférieur gauche

3237568 Support de charnière, supérieur gauche

3237516 Cartouche de charnière (à ressort)

3234225A Chapeau de pivot, Nylon, 1 po carré

117-CB5-0030 Support de pompe

3978030 Clayette

5189779 Attache de clayette

MCP00207 Vis à épaulement

000-CB1-0030 Barre d’accès rapide

2194759KT Commande de température

(inclut la commande, le bouton et le cadran)

2194761 Bouton de commande de température seul

3516135 Thermomètre, suspendu

120-C85-0030 Boîte à crême fouettée

Condensateur de mise en marche du compresseur

N° réf. Description

120-CB6-0030 Support, cafetière

9321079 Tampon amortisseur

129-C15-0103 Support de tampon-amortisseur

0074057 Tube capillaire, 042 po diam. int. x 144 po

3235515 Roulette, 4 po

3235516 Roulette, 4 po avec frein

3526940 Compresseur (220 V)

0053452 Réchauffeur de condensats seul

0330154 Bac à condensats

(réchauffeur de condensats inclus)

3516275 Serpentin réfrigérant

3516172 Pale de ventilateur de condenseur

3516173 Protège-ventilateur de condenseur

2162692 Moteur de condenseur (220 V)

000-B3I-003H Porte, charnières à droite

1702623 Joint de porte

3516172 Pale de ventilateur d’évaporateur

3516173 Protège-ventilateur d’évaporateur

2162692 Moteur d’évaporateur (220 V)

3516116 Serpentin évaporateur

3516321 Déshydrateur-filtre

3237563 Support de charnière, inférieur droit

3237562 Support de charnière, supérieur droit

3237569 Support de charnière, inférieur gauche

3237568 Support de charnière, supérieur gauche

3237516 Cartouche de charnière (à ressort)

3234225A Chapeau de pivot, Nylon, 1 po carré

3978030 Clayette

5189779 Attache de clayette

MCP00207 Vis à épaulement

2194759KT Commande de température

(inclut la commande, le bouton et le cadran)

2194761 Bouton de commande de température seul

3516135 Thermomètre, suspendu

3516059 Thermomètre, solaire numérique

000-CB1-0030 Barre d’accès rapide

Page 10

Pour demander l’assistance de

l’usine, appeler le

888-436-5442 ou 989-773-7981

Fax 888-779-2040

www.delfield.com

Page 27

Normes relatives à la main d’œuvre pour la réparation ou

le remplacement de pièces sur les appareils Delfield

Une réparation incorrecte ou effectuée par un réparateur non agréé pourrait occasionner une explosion ou des dégâts.

Les conseils et recommandations prodigués par les techniciens d’entretien de Delfield ne constituent ni ne garantissent

aucune couverture spéciale.

• Un maximum de 1 heure est alloué au

• Un maximum de 1 heure est alloué pour

Les frais de déplacement seront remboursés pour un trajet maximum de 160 km (100 miles) ou de 2 heures aller-

•

retour.

• Les heures supplémentaires, l’installation/mise en service, les réglages normaux des commandes, l’entretien général,

la rupture d’éléments en verre, les avaries en cours de transport et/ou la correction d’une erreur d’installation commise par l’utilisateur final ne seront pas remboursés au titre de la garantie, sauf s’ils ont été autorisés à l’avance par

un ordre de travail de réparation émis par Delfield. Le numéro de cet ordre doit être fourni en même temps que la

demande d’indemnité au titre de la réparation.

1 HEURE DE TRAVAIL EST AUTORISÉE POUR REMPLACER LES PIÈCES SUIVANTES :

• Composants de mise en marche de compresseur et protecteur contre les surcharges

• Charnières, verrous et joints de portes

• Moteur et pales de ventilateur d'évaporateur/condenseur

• Thermostat

2 HEURES DE TRAVAILPOUR EFFECTUER CE QUI SUIT :

• Dégivrage d’élément

• Repérage/réparation d’une fuite

3 HEURES DE TRAVAILPOUR REMPLACER CE QUI SUIT :

• Tube capillaire

• Serpentin réfrigérant ou évaporateur

4 HEURES DE TRAVAILPOUR REMPLACER CE QUI SUIT :

• Compresseur ; cela inclut la récupération du fluide frigorigène et le contrôle d’étanchéité.

diagnostic d’un composant défectueux.

se procurer des pièces qui ne sont pas en stock.

Remboursement de 55 dollars US au maximum pour la récupération du fluide frigorigène (y compris les frais de récupérateur, pompe, chalumeau, huile, flux, accessoires mineurs, brasure, baguette de brasage, azote et autres frais similaires.)

FLUIDE FRIGORIGÈNES

• 404A Un maximum de 15 dollars U.S./lb. or 1 dollar U.S./oz. sera remboursé.

Pour demander l’assistance de

l’usine, appeler le

888-436-5442 ou 989-773-7981

Fax 888-779-2040

www.delfield.com

Page 11

Page 28

Garantie limitée à vie du fabricant

Delfield garantit à l’acheteur-utilisateur initial, sous réserves des

limites et exclusions indiquées plus loin, que l’intérieur en ABS des

modèles Delfield identifiés plus haut sera exempt de défauts de fabrication tant que l’appareil appartient à l’acheteur-utilisateur initial et

est en service.

Couverture

La cuve interne des armoires réfrigérées Vantage 6000 Series™ ou

des tables de préparation série 400/4000/4400/4500 est couverte

contre les défauts de fabrication dans les conditions normales

d’utilisation. Pour ce qui concerne cette garantie, la cuve interne

est définie comme la partie de l’intérieur qui est fabriquée en ABS.

Cette garantie ne s’applique qu’aux produits commercialisés et

installés après le 1er mars 2000 aux Etats-Unis, au Canada, à

Puerto Rico et au Mexique. Pour ce qui concerne cette garantie, la

vie est définie comme la durée de service prévue de l’appareil, c’est

à-dire 12 ans.

Obligations de Delfield

Elles se limitent strictement à l’expédition de pièces de rechange ou

kits de réparation d’origine pour tout intérieur en ABS couvert. Un

concessionnaire-réparateur agréé Delfield et le service d’entretien

de Delfield doivent confirmer que le défaut de la cuve s’est manifesté dans des conditions normales d’utilisation et n’est pas dû à

un usage incorrect tel qu’il est défini plus loin. Toutes les décisions

concernant l’intérieur en ABS doivent être prises par le service

d’entretien de Delfield et s’imposent à toutes les parties. Aucun frais

ni allocation au titre de la main d’œuvre ou de la réparation n’est

couvert par cette garantie. La réparation au titre de la garantie doit

être effectuée par un réparateur agréé par Delfield.

Responsabilité de l’utilisateur

Le produit doit être installé, nettoyé et entretenu comme indiqué dans le manuel d’entretien et d’installation qui accompagne

le produit. Seules des pièces de rechange agréées peuvent être

utilisées. L’inobservation des prescriptions de ce paragraphe peut

annuler la garantie.

Exclusions

La présente garantie ne couvre pas les frais de main d’œuvre, de

réparation ou de déplacement ni les suppléments. Elle exclut également les défauts résultant des actions suivantes :

• Utilisation du produit au-delà des spécifications indiquées dans

le manuel d'entretien et d’installation.

• Non respect des instructions de nettoyage et d’entretien don

nées dans le manuel d'entretien et d'installation.

• Installation du produit d’une manière autre que celle qui est

décrite dans le manuel d’entretien et d’installation.

• Utilisation ou montage de pièces de rechange non agréées par

Delfield ;

ou

• Placement d’aliments chauds directement sur l’ABS.

La présente garantie se substitue à toute autre garantie quelle

qu’en soit la nature, formelle ou tacite, à l’exception de la

garantie de 1 an pour les pièces et 90 jours pour la main d’œuvre

offerte par Delfield pour la série 400/4000/4400/4500. TOUTE

GARANTIE TACITE DE QUALITÉ MARCHANDE OU D’ADAPTATION

À UN USAGE PARTICULIER EST REJETÉE ET EXCLUE PAR LE

PRÉSENT DOCUMENT. DELFIELD NE SERA EN AUCUN CAS

RESPONSABLE DE DOMMAGES ACCESSOIRES OU INDIRECTS

DE TOUT TYPE OU NATURE QUE CE SOIT NI DE TOUT DÉFAUT

RÉSULTANT EN TOUT OU PARTIE D’UN USAGE INCORRECT,

D’UNE MODIFICATION, D’UNE INSTALLATION INCORRECTE

OU D’UN ENTRETIEN INSUFFISANT DU PRODUIT OU DE L’UNE

QUELCONQUE DE SES PIÈCES.

Aucun ensemble ou pièce qui a été exposé à un accident, modification ou usage incorrect, qui n’a pas été installé ou entretenu

conformément au manuel d’utilisation accompagnant le produit ou

qui provient d’un appareil dont le numéro de série a été modifié ou

effacé ne sera couvert par la présente garantie.

-

Procédures

Toutes les demandes de pièces de rechange ou kits de réparation

doivent être présentées par l’intermédiaire d’un dépôt de pièces

Delfield ou d’un concessionnaire agréé Delfield. La facture correspondant à la pièce défectueuse doit être retournée à Delfield dans

les 15 jours qui suivent la date de la réparation pour bénéficier de

la couverture de la garantie. Toutes les demandes doivent inclure le

numéro de modèle, le numéro de série, la date d’installation initiale

et l’identification du client. L’utilisation de pièces autres que des

pièces de rechange d’origine Delfield ne sera pas couverte.

Page 12

Pour demander l’assistance de

l’usine, appeler le

888-436-5442 ou 989-773-7981

Fax 888-779-2040

www.delfield.com

Page 29

Garantie de deux ans

Delfield Company (« Delfield ») garantit à l’acheteur initial du produit Delfield

(appelé ici l’’« appareil ») que cet appareil et toutes ses pièces sont exempts

de défauts de matières et de fabrication dans des conditions d’utilisation et

d’entretien normales pendant une période de deux (2) ans à compter de la date

d’expédition de l’appareil à l’acheteur initial ou, si ce dernier retourne la carte de

garantie dûment remplie et indiquant la date d’installation dans les trente (30)

jours qui suivent la réception de l’appareil, d’un (1) an à compter de la date

d’installation. Pendant cette période de garantie de deux ans, Delfield réparera ou

remplacera en tout ou en partie toute pièce défectueuse qui lui est retournée par

l’acheteur initial et dont Delfield déterminera qu’elle est défectueuse en termes de

matière ou de fabrication. L’acheteur initial règlera tous les frais de main d’œuvre,

d’emballage, de transport et connexes encourus lors de la dépose de l’appareil

ou de la pièce défectueuse et du transport chez Delfield, si ce n’est que, pendant

une période de quatre-vingt dix (90) jours à compter de la date d’expédition de

l’appareil à l’acheteur initial ou, si ce dernier retourne la carte de garantie dûment

remplie et indiquant la date d’installation dans les trente (30) jours qui suivent

la réception de l’appareil, de quatre-vingt dix (90) jours à compter de la date

d’installation, Delfield règlera tous les frais de main d’œuvre encourus. Delfield

règlera les frais de retour si l’appareil ou la pièce s’est révélé défectueux.

Le terme « acheteur initial » tel qu’il est employé ici signifie la personne,

l’entreprise ou l’association pour laquelle l’appareil a été installé à l’origine.

La présente garantie ne s’applique à aucun appareil ni aucune de ses pièces

qui a souffert d’abus, de négligence, de modifications ou d’un accident

tels que des dégâts accidentels subis par le fini extérieur, a été utilisé sans

respecter les recommandations de Delfield, ou a été réparé ou modifié

par quiconque autre que Delfield d’une façon qui, selon la seule opinion

de Delfield, affecte sa qualité ou son rendement. La présente garantie ne

s’applique pas à un appareil qui a été déplacé hors de l’endroit où il avait

été installé à l’origine. Elle ne couvre pas non plus le déshydrateur de réfrigération ni les ampoules utilisés dans l’appareil. La garantie s’applique

dans la mesure où l’utilisateur s’acquitte de sa responsabilité en

termes d’entretien normal tel que le définit le manuel d’entretien et

d’installation, comme par exemple le nettoyage du serpentin de réfrigération , et se substitue à toutes les autres obligations de Delfield.

Delfield n’assume ni n’autorise quiconque à assumer en son nom

aucune autre responsabilité liée à des produits Delfield.

L’effacement du numéro de série ou de modèle d’origine de tout appareil

sera considéré comme libérant Delfield de toute obligation ci-dessous ou

de toute autre obligation explicite ou tacite.

Les pièces acquises auprès de fournisseurs de Delfield sont garanties par

Delfield dans les mêmes termes que la garantie explicite dont Delfield bénéficie de la part du fabricant de ces pièces. Absence au bénéfice de l’acheteur

initial d’une garantie formelle du fabricant analogue à celle que reçoit Delfield.

L’absence d’une telle garantie du fabricant au bénéfice de l’acheteur initial ne

créera en aucun cas une quelconque garantie explicite ou tacite ni une autre

obligation ou responsabilité quelconque de la part de Delfield en la matière.

SI LE CLIENT UTILISE UNE PIÈCE QUI ENTRAÎNE L’ANNULATION DE LA

GARANTIE ET QU’UN REPRÉSENTANT AGRÉÉ DE DELFIELD SE REND

À L’ADRESSE D’INSTALLATION POUR EFFECTUER UN ENTRETIEN AU

TITRE DE LA GARANTIE, LE REPRÉSENTANT AVISERA LE CLIENT DE

L’ANNULATION DE LA GARANTIE. DE TELLES INTERVENTIONS SERONT

FACTURÉES AU CLIENT AUX TARIFS DE MAIN D’ŒUVRE ET DE PIÈCES

APPLIQUÉS ALORS PAR LE CENTRE DE RÉPARATION AGRÉÉ.. À

ENVISAGER : LE CLIENT PEUT PRENDRE L’INITIATIVE DE LA SIGNATURE

D’UN CONTRAT D’ENTRETIEN EXCLUANT LES PIÈCES.

Si l’expédition d’une pièce de rechange est demandée avant l’arrivée à l’usine

Delfield de la pièce prétendûment défectueuse, l’acheteur initlal doit affecter

la livraison de la pièce de rechange contre remboursement. Son compte sera

crédité une fois que la pièce a été reçue et examinée à l’usine Delfield et que

Delfield a déterminé qu’elle est couverte par la présente garantie.

La garantie ne donne en aucun cas à l’acheteur initial le droit de remplacer

l’appareil défectueux par un appareil complet du même fabricant ou d’une

autre marque. Sauf autorisation écrite de Delfield, la présente garantie ne

permet pas le remplacement d’une pièce quelconque, y compris le motocompresseur, par une pièce d’un autre fabricant ou marque.

Aucune demande d’indemnité ne peut être présentée au titre de la garantie

pour détérioration d’aliments quelle qu’en soit la raison, y compris le panne

d’un système.

L’entreprise d’installation devra s’assurer que l’accès aux locaux, l’entrée

et l’état des lieux permettront un dégagement suffisant pour qu’elle

puisse faire rentrer tout évent, hotte ou appareil si nécessaire dans le

bâtiment. Delfeld ne sera pas responsable des changements ou dégâts

subis par le bâtiment lors de l’installation de l’appareil ou de tout système

d’évacuation.

Delfield ne sera en rien responsable de tout défaut ou retard de fonctionnement causé par ou résultant d’évènements imprévus échappant au

contrôle de Delfield, y compris, entre autres, une guerre, des restrictions

ou contraintes administratives, une grève, des lock-outs, un incendie, des

inondations, la force majeure, un manque de matières premières ou la cessation de la fabrication des pièces par le fabricant des pièces d’origine.

Sauf dispositions contraires de tout plan de protection supplémentaire

de quatre ans et du contrat d’entretien applicables, ce qui précède constitue la garantie exclusive qui se substitue à toute autre, qu’elle soit

écrite ou verbale, explicite ou tacite. Cette garantie remplace et exclut

toute déclaration ou garantie verbale ou écrite antérieure. Delfield nie

expressément toute garantie tacite de qualité marchande, d’adaptation à

un usage particulier ou de respect de tout traité, loi, règle ou réglementation concernant l’évacuation de substances dans l’environnement. Les

seuls et uniques dédommagements liés à l’appareil pour toute personne

et la pleine responsabilité de Delfield en cas de violation de la présente

garantie sont ceux qui sont prévus dans cette dernière.

En dehors de cette garantie limitée de deux ans de Delfield, tout plan de

protection supplémentaire de quatre ans ou contrat d’entretien offerts par

Delfield, l’acheteur initial convient et reconnaît qu’aucune autre garantie

relative à cet appareil ni à l’une quelconque de ses pièces n’est offerte ni

prévue.

Delfield ne sera en aucun cas responsable de dommages particuliers,

accessoires ou indirects, ni de pénalités.

SI, PENDANT LA PÉRIODE DE GARANTIE, LE CLIENT UTILISE POUR CET

APPAREIL DELFIELD UNE PIÈCE AUTRE QUE NEUVE NON MODIFIÉE

OU RECYCLÉE ACHETÉE DIRECTEMENT AUPRÈS DE DELFIELD OU

DE L’UN DE SES CENTRES DE RÉPARATION AGRÉÉS ET/OU SI LA

CONFIGURATION D’ORIGINE DE LA PIÈCE UTILISÉE A ÉTÉ MODIFIÉE,

LA PRÉSENTE GARANTIE SERA NULLE ET NON AVENUE. EN OUTRE,

DELFIELD ET SES FILIALES NE SERONT RESPONSABLES D’AUCUN

DOMMAGE, DEMANDE D’INDEMNITÉ OU DÉPENSE ENCOURUS PAR

LE CLIENT ET QUI RÉSULTENT DIRECTEMENT OU INDIRECTEMENT, EN

TOUT OU PARTIE, DU MONTAGE DE TOUTE PIÈCE MODIFIÉE OU REÇUE

D’UN CENTRE DE RÉPARATION NON AGRÉÉ. Si la garantie devient nulle

et non avenue, le client peut acheter auprès de Delfield, le cas échéant,

un contrat d’entretien ou faire effectuer la réparation au tarif des pièces

et de la main d’œuvre alors en vigueur.

Pour plus de détails sur la garantie de Delfield, ouvrir une session et consulter la section de service après-vente de notre site Web à www.delfield.

com.

Pour demander l’assistance de

l’usine, appeler le

888-436-5442 ou 989-773-7981

Fax 888-779-2040

www.delfield.com

Page 13

Page 30

The Delfield Company

CONTRAT D’ENTRETIEN

UN (1) AN DEUX (2) ANS

N° de modèle______________ N° de série ___________ Date d’expédition ___________

Delfield Company (« Delfield ») offre ce contrat d’entretien (le « contrat d’entretien »)

pour une somme minime au moment de la présentation et de l’acceptation de l’ordre pour

l’appareil Delfield mentionné plus haut (l’« appareil ») conformément aux modalités suivantes :

Le contrat d’entretien s’ajoute à la garantie limitée d’un an (la « garantie d’un an ») et

au plan de protection supplémentaire de quatre ans (la « garantie de quatre ans ») de

Delfield. Les modalités de la garantie d’un an et de celle de quatre ans sont exposées

dans leur intégralité dans ces garanties.