DEK Remote Barcode Reader 1D, Remote Barcode Reader 2D, Handheld Barcode Reader 1D, Handheld Barcode Reader 2D Technical Reference Manual

Page 1

BARCODE READER

OVERVIEW

Chapter Issue 3 Jan 08 Technical Reference Manual 26.1

CHAPTER 26 BARCODE READER

OVERVIEW

WARNING

RADIATION. RISK OF INJURY TO THE EYES DUE TO LASER LIGHT BEING

PRESENT IN THE VICINITY OF THE LABEL. DO NOT LOOK AT THE LIGHT

SOURCE OR REFLECTIONS FROM A SURFACE.

There are four types of barcode readers that may be fitted to the machine:

• Remote Barcode Reader 1D

• Remote Barcode Reader 2D

• Handheld Barcode Reader 1D

• Handheld Barcode Reader 2D

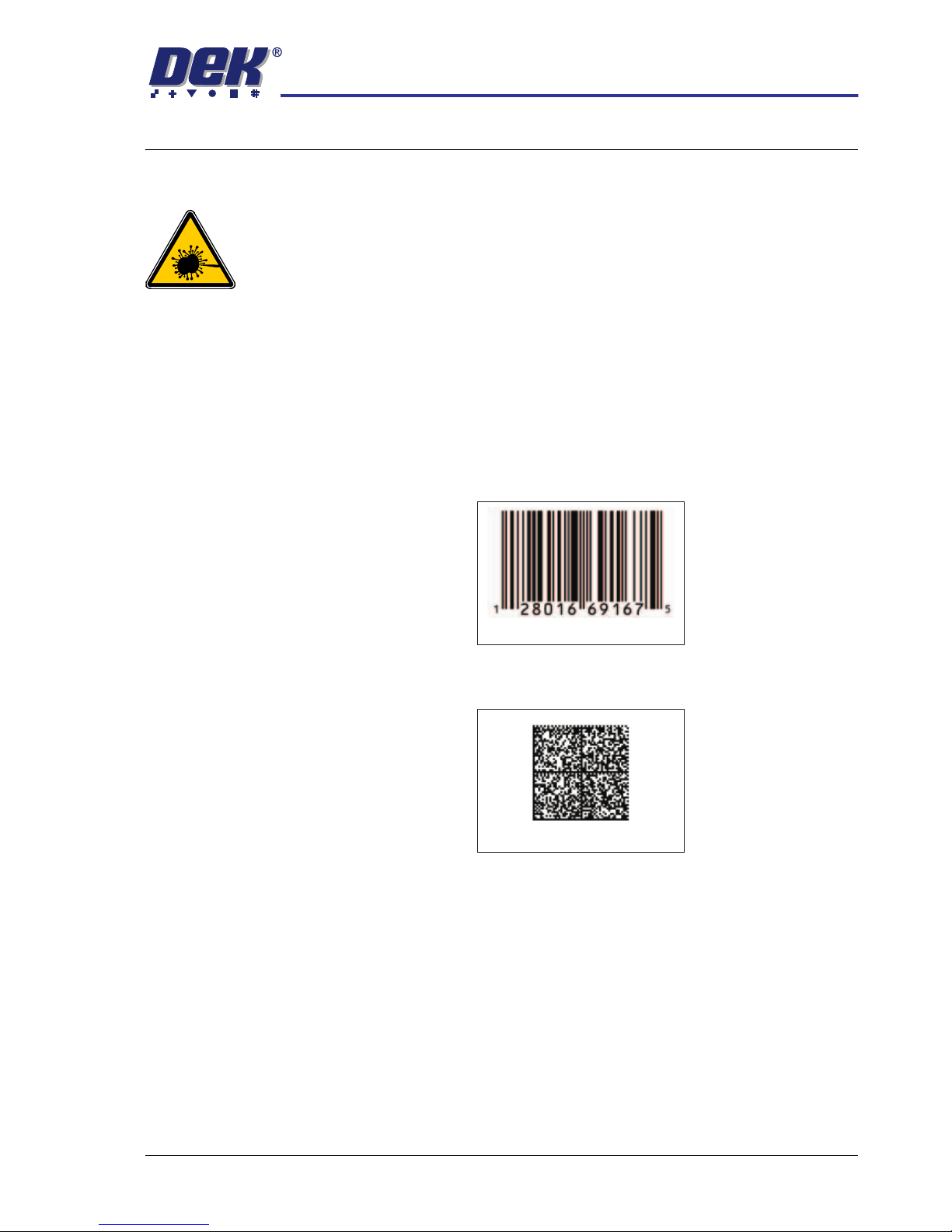

1D or one dimensional barcodes are the most common barcodes consisting of

a single row of different width bars.

2D or two dimensional barcodes consist of square modules constructed in a

matrix that may be square or rectangular.

NOTE

There are many different formats of barcodes and the above are single exam-

ples to demonstrate the difference between 1D and 2D barcodes.

Example of a 1D Barcode

Example of a 2D Barcode

Page 2

BARCODE READER

OVERVIEW

26.2 Technical Reference Manual Chapter Issue 3 Jan 08

Remote Barcode

Reader

The remote barcode reader is normally located on the input conveyor to the

machine and reads the barcode of the incoming product board.

The remote barcode reader provides GEM and SPC of the product barcode

before the product is passed to the printer. Use of the reader enables the host

program to decide on the action to be taken for this product and provides a

method for SPC to log product details for tracking.

The remote barcode reader also provides information to the Verification and

Traceability software option.

Different types of remote barcode readers may be used, a typical example is

shown below:

During the board/product transfer cycle, with the remote barcode option enabled, the trigger barcode scan sensor detects the board on the conveyor and

triggers the remote barcode reader to read the barcode, before the board is

passed to the printer.

Handheld Barcode

Reader

The primary function of the handheld barcode reader is to scan consumables

and user information for the Verification and Traceability software. The consumables scanned include:

•Screen

• Print Material

• Solvent

• Cleaner Paper

• Vortex Cassette

The handheld barcode reader may also be used to scan the first board of a

batch that is to be checked by the remote barcode reader during a print run.

1D Remote Barcode Reader

2D Remote Barcode Reader

Page 3

BARCODE READER

OVERVIEW

Chapter Issue 3 Jan 08 Technical Reference Manual 26.3

Different types of handheld barcode readers may be used, a typical example is

shown below:

NOTE

The 2D handheld barcode reader supplied by DEK requires an additional 12V

supply to power the reader. The 1D handheld barcode reader supplied by DEK

is powered from the USB port.

1D Handheld Barcode Reader

2D Barcode ReaderHandheld

Page 4

BARCODE READER

ELECTRICAL SCHEMATIC

26.4 Technical Reference Manual Chapter Issue 3 Jan 08

ELECTRICAL SCHEMATIC

01

03

M37 Power Supply

+12V

+12V

0V

0V

8PL104

M37PL13

01

03

02

03

01

01

04

03

03

02

01

04

03

02

01

04

03

02

01

04

03

02

01

04

Machine PC

Handheld

Barcode

Reader

6PL23

6PL22

01

03

02

07

04

05

13

25

NC

NC

10

18

09

19

01

02

03

01

02

03

04

Chassis

RTS232

TX232

RX232

CTS232

Signal GND

VS

GND

PS+

VS

PS-

Trigger

Barcode

Scan

6SE07

+12V

0V

Signal

Alarm

Remote Barcode Reader

3PL34

4PL01

4PL37

4PL05

8SK145

03

03

02

02

01

01

04

04

06

09

07

08

05

6PL17

01

03

02

07

04

05

13

25

3PL20

USB to

RS232

Converter

3PL57

USB8

USB1

NOTE

The USB to RS232 Converter

is moulded into the 9 Pin D type

connector hood.

4 Port

USB Hub

Connector

Moulding

M37PL14

(2D handheld barcode reader only)

Page 5

BARCODE READER

REPLACEMENT PROCEDURES

Chapter Issue 3 Jan 08 Technical Reference Manual 26.5

REPLACEMENT PROCEDURES

Fitting the Remote

Barcode Reader

1. Select Shut Down and switch the mains isolator to OFF.

2. Fit the remote barcode reader to the upline conveyor ensuring that the

reader is in a position to read the barcode on the product board during

transit.

3. If required, fit the trigger sensor just forward (upline) of the reader.

NOTE

The leading edge of the incoming board triggers the remote barcode reader

to activate enabling it to read the barcode on the board.

4. Remove the rear panel to gain access to the PC.

5. Route the cable from the conveyor, under the Dek machine exiting at the

rear of the machine.

6. Connect the USB plug to USB8 on the PC.

7. Connect the power lead M37PL13 to M37SK13 on the rear of the M37

Power Supply Enclosure.

8. Refit the rear panel ensuring that the cable is not trapped.

9. Power up the machine.

10. Select Maintenance.

11. Select Machine Setup.

12. Select Barcodes.

Shut Down

PC Enclosure Rear Panel

I

O

USB8

Maintenance

Machine

Setup

Barcodes

Page 6

BARCODE READER

REPLACEMENT PROCEDURES

26.6 Technical Reference Manual Chapter Issue 3 Jan 08

13. Select Remote Barcode HW.

14. Select Fitted.

15. Select Accept.

16. Select Start Character.

17. Set the start character for the barcode.

18. Select Accept.

19. Select Name Length.

20. Set the name length for the barcode.

21. Select Accept.

NOTE

The barcode setup is shown in code format. The code format for a barcode

of length 14 starting at character 4 would be:

###PPPPPPPPPPPPPP###

22. Select Back.

23. Select Back.

24. Select Back.

25. Use the documentation supplied with the reader to setup the Remote

Barcode Reader for the product to be used.

Remote Barcode HW

Not Fitted

Fitted

Accept

Start Character

1

Accept

Name Length

32

Accept

Back

Back

Back

Page 7

BARCODE READER

REPLACEMENT PROCEDURES

Chapter Issue 3 Jan 08 Technical Reference Manual 26.7

Fitting the

Handheld Barcode

Reader

1. Select Shut Down and switch the mains isolator to OFF.

2. Gain access to the 4 port USB hub behind the front panel.

3. Connect the handheld barcode reader to the spare USB port on the hub.

4. If a 2D handheld barcode reader is being used, connect the dc power

connector (located near the 4 port USB hub) to the moulded connector on

the cable of the handheld barcode reader.

5. Refit the front cover ensuring that the cable is routed between the MMI

monitor bracket and the front cover.

6. Power up the machine.

7. Select Maintenance.

8. Select Machine Setup.

9. Select Barcodes.

10. Select Handheld Barcode HW.

Shut Down

USB Connector dc Connector

Maintenance

Machine

Setup

Barcodes

Handheld Barcode HW

Not Fitted

Page 8

BARCODE READER

REPLACEMENT PROCEDURES

26.8 Technical Reference Manual Chapter Issue 3 Jan 08

11. Select Fitted.

12. Select Accept.

13. Select Start Character.

14. Set the start character for the barcode.

15. Select Accept.

16. Select Name Length.

17. Set the name length for the barcode.

18. Select Accept.

NOTE

The barcode setup is shown in code format. The code format for a barcode

of length 14 starting at character 4 would be:

###PPPPPPPPPPPPPP###

19. Select Back.

20. Select Back.

21. Select Back.

22. Use the documentation supplied with the reader to setup the language,

keyboard format and barcode symbology.

Fitted

Accept

Start Character

1

Accept

Name Length

32

Accept

Back

Back

Back

Loading...

Loading...