DEK 180W EL, 180W Owner's Manual Supplement

Heavy Duty Power Equipment

Owner's Manual Supplement

Gasoline Engine Powered Welder Generators

180W, 180W EL

Welding is potentially a very hazardous activity. It should only be attempted

by a trained welder with a thorough knowledge of proper welding tech-

niques and safety procedures. Be sure to read and follow the safety in-

structions and precautions described below.

Failure to use the proper gage of cable may lead to painful burns.

Precautions:

1. When using the welder, do not connect the generator

to a household circuit. This could cause damage to

the generator or to elecb'ical wiring or appliances in

the house.

2. For continuous operations, DO NOT exceed the rated

load capacity (6.0 kW). Substantial overloading will

cause the circuit beaker to switch off. Marginal over-

loading may not cause the circuit breaker to switch

off but it will shorten the service life of your welder/

generator.

3. Notice: Voltage is present at the welding cables

whenever the engine is running.

Welder Operation:

Welding Cable Selection:

An undersized cable will resultin unacceptably high resistanceto

currentflow. This resistancewill shortenthe life ofthe generator

and can potentiallymake the welding cables hot enough to

cause painful burns. Whenever possible, refer to the cable

manufacturer's recommendations.

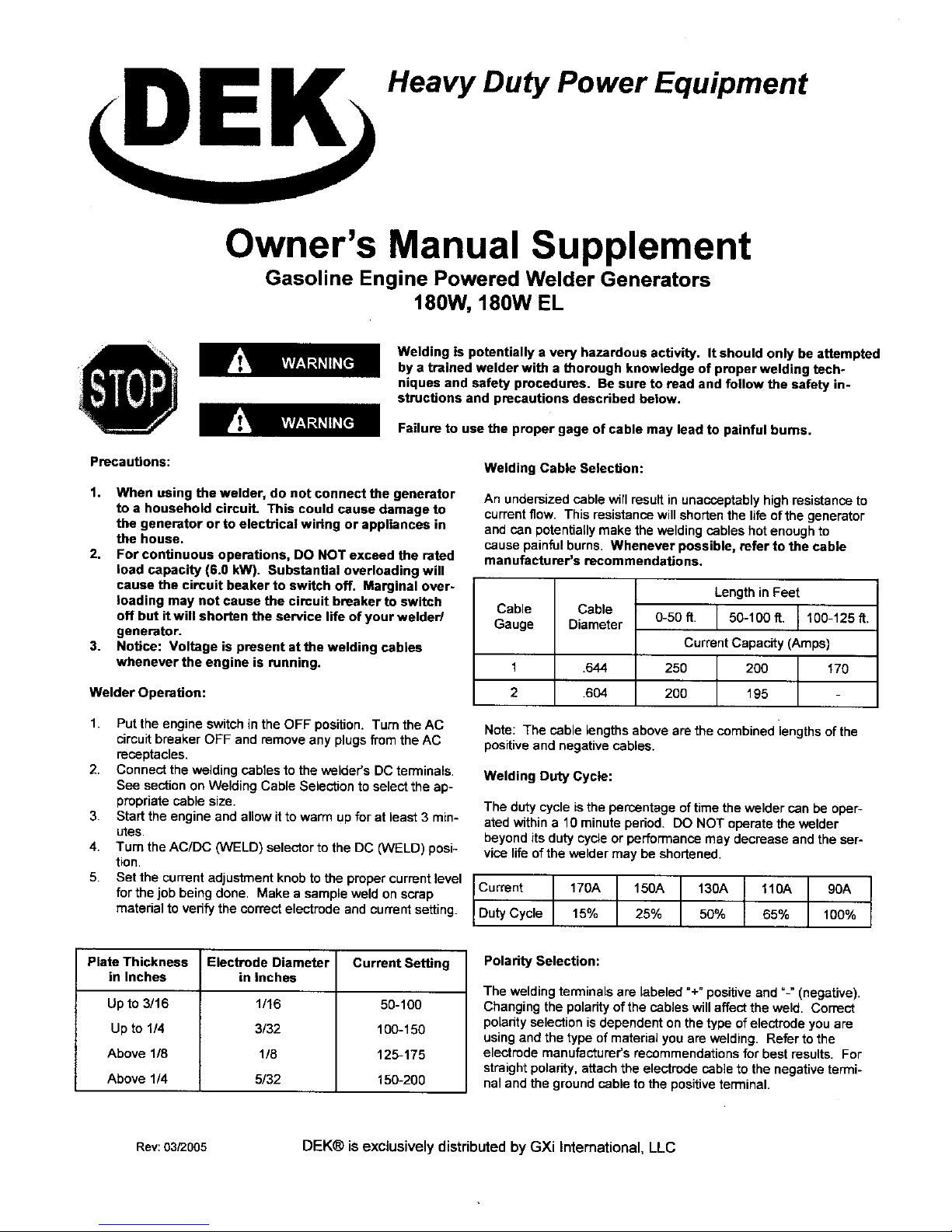

Cable

Gauge

1

2

Cable

Diameter

.644

.604

Lengthin Feet

0-50 ft. I 50-100 ft. 100-125 ft.

w

CurrentCapacity (Amps)

250 200 170

200 195

1. Put the engine switch in the OFF position. Turn the AC

circuitbreaker OFF and remove any plugs fi'om the AC

receptacles.

2. Connect the welding cables to the welder's DC terminals.

See section on Welding Cable Selection to selectthe ap-

propriatecable size.

3. Start the engine and allow itto warm UPfor at least 3 min-

utes.

4. Turn the AC/DC (WELD) selector tothe DC (WELD) posi-

tion.

5. Set the current adjustment knob to the proper currentlevel

for the job being done. Make a sample weld on scrap

material to verify the correct electrode and currentsetting.

Note: The cable lengths above are the combined lengths of the

positive and negative cables,

Welding Duty Cycle:

The duty cycle is the percentage of time the welder can be oper-

ated within a 10 minute period. DO NOT operate the welder

beyondits duty cycle or performance may decrease and the ser-

vice life ofthe welder may be shortened.

Current 17OA 150A 13OA 110A 9OA

Duty Cycle 15% 25% 50% 65% 100%

Plate Thickness Electrode Diameter Current Setting

in inches in inches

Up to 3/16 1/16 50-100

Up to 1/4 3/32 100-150

Above 1/8 1/8 125-175

Above 1/4 5/32 150-200

Polarity Selection:

The welding terminals are labeled "+" positiveand =-" (negative).

Changing the paladty of the cables will affect the weld. Correct

polarity selection is dependent on the type of electrode you are

using and the type of material you are welding. Refer to the

electrode manufacturer's recommendations for best results. For

straightpolarity, attachthe electrode cable to the negative termi-

nal and the ground cable to the positive terminal.

Rev:03/2005 DEK® is exclusivelydistributed by GXi International,LLC

Loading...

Loading...