Page 1

Model 100

Installation Guide

© 2000 Directed Electronics, Inc. Vista, CA N411R 3-00

Downloaded from: http://www.guardianalarms.net

Page 2

2 © 2000 Directed Electronics, Inc. Vista, CA

table of contents

Bitwriter™, Code Hopping™, DEI®, Doubleguard®, ESP™, FailSafe®, Ghost Switch™, Learn Routine™, NiteLite®, Nuisance Prevention Circuitry®, NPC®, Revenger®, Silent Mode™, Soft Chirp®, Stinger®, Valet®,

Vehicle Recovery System®, VRS®, and Warn Away®are all Trademarks or Registered Trademarks of

Directed Electronics, Inc.

What Is Included . . . . . . . . . . . . . . . . . . . . . 3

Primary Harness (H1), 12-Pin Connector . . . . . 4

Relay Harness (H2), 6-Pin Connector . . . . . . . 4

Primary Harness (H1) Wire Connection Guide. . 5

Plug-In LED and Valet/Program Switch. . . . . . 10

Relay Harness (H2) Wire Connection Guide . . 11

Identifying the Door Lock System. . . . . . . . 11

At the Switch. . . . . . . . . . . . . . . . . . . . . 12

Type A Door Locks. . . . . . . . . . . . . . . . . . 12

Type B Door Locks. . . . . . . . . . . . . . . . . . 13

Testing Reversing Polarity Systems . . . . . . . 14

Type C Door Locks. . . . . . . . . . . . . . . . . . 15

Type D Door Locks. . . . . . . . . . . . . . . . . . 16

Type E Door Locks. . . . . . . . . . . . . . . . . . 17

Type F Door Locks . . . . . . . . . . . . . . . . . . 18

Type G Door Locks. . . . . . . . . . . . . . . . . . 19

Type H Door Locks . . . . . . . . . . . . . . . . . 20

Transmitter/Receiver Learn Routine. . . . . . . . 21

To advance from one channel to another . . . 22

To exit learn routine . . . . . . . . . . . . . . . . 22

Transmitter Configuration . . . . . . . . . . . . . . 22

Standard Configuration. . . . . . . . . . . . . . . 22

Operating Settings Learn Routine . . . . . . . . . 23

To access another feature . . . . . . . . . . . . . 24

To exit the learn routine. . . . . . . . . . . . . . 24

Features Menu . . . . . . . . . . . . . . . . . . . . . . 24

Feature Descriptions . . . . . . . . . . . . . . . . . . 25

Troubleshooting . . . . . . . . . . . . . . . . . . . . . 26

Page 3

© 2000 Directed Electronics, Inc. Vista, CA 3

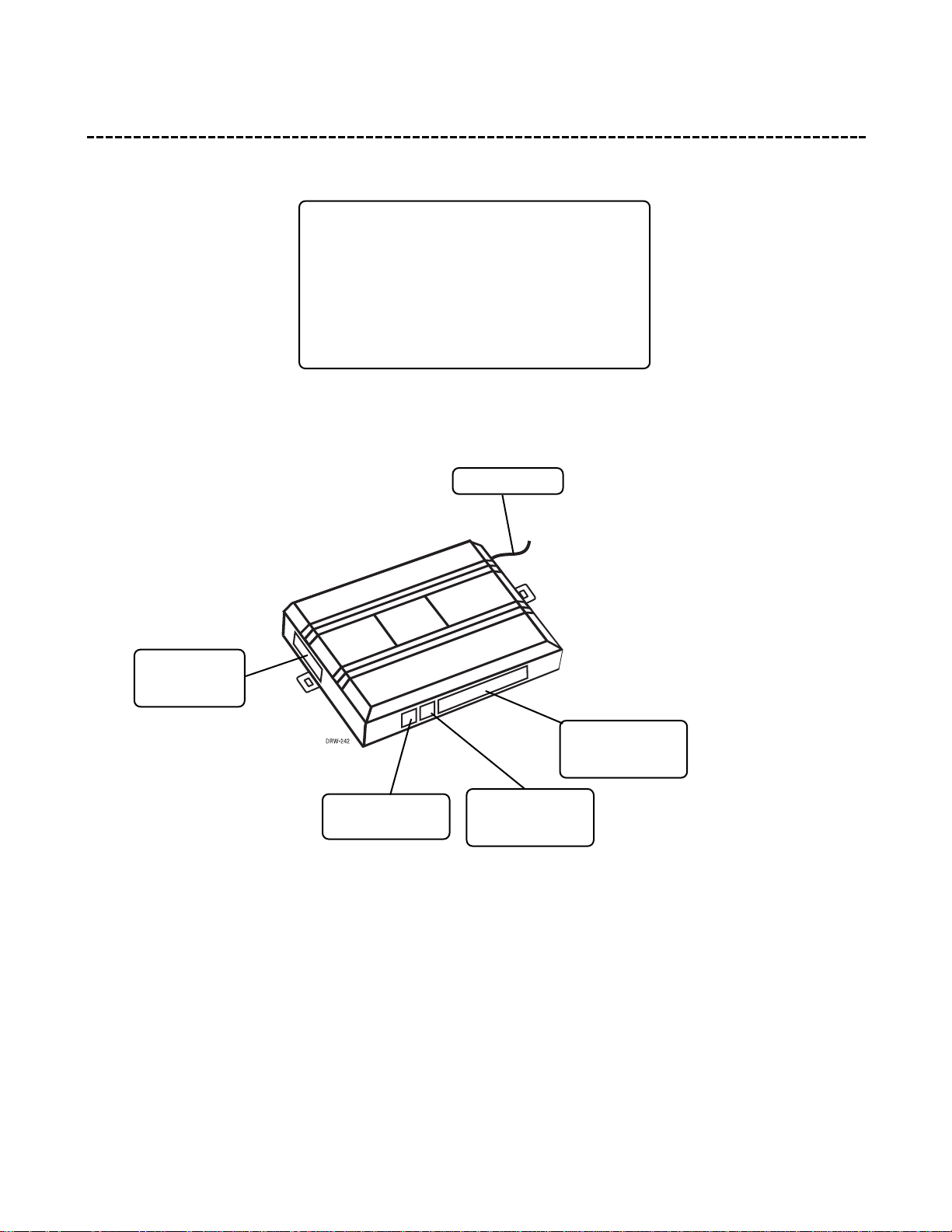

what is included

■ The control module (see diagram)

■ Two two-button remote transmitters

■ The plug-in status LED

■ The plug-in Valet

®

/Program switch

■ The 12-pin primary harness

■ The 6-pin door lock harness

12-Pin Primary

Harness (H1)

Port

2-pin White

LED Port

6-pin Door

Lock Harness

Port

2-Pin Blue

Valet/Program

Port

Antenna

Page 4

4 © 2000 Directed Electronics, Inc. Vista, CA

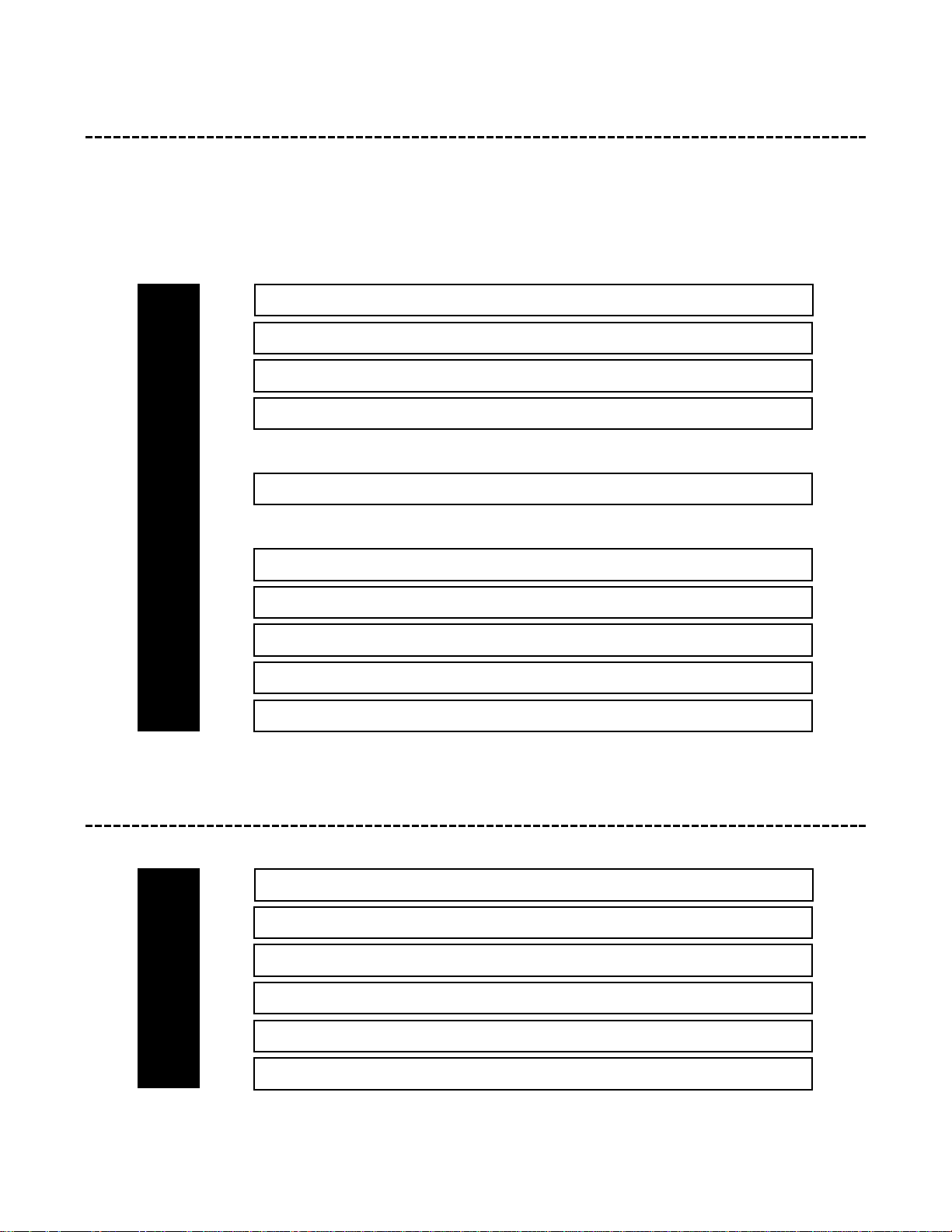

primary harness (H1), 12-pin connector

The primary harness is the standard 12-pin harness used by DEI security systems. Two pins in the harness do not

have wires (H1/5 and H1/7). The functions of all the wires that are used in the primary harness are outlined in

this section. The wire connections are described in the Primary Harness (H1) Wire Connection Guide section.

______

______

______

______

______

______

______

______

______

______

relay harness (H2), 6-pin connector

______

______

______

______

______

______

*NOTE: VIOLET and VIOLET/BLACK are common at the fuse holder.

VIOLET* UNLOCK #87 NORMALLY OPEN (INPUT)

BLUE/BLACK UNLOCK #30 COMMON (OUTPUT)

BROWN/BLACK UNLOCK #87A NORMALLY CLOSED

VIOLET/BLACK* LOCK #87 NORMALLY OPEN (INPUT)

GREEN/BLACK LOCK #30 COMMON (OUTPUT)

WHITE/BLACK LOCK #87A NORMALLY CLOSED

H2/A

H2/B

H2/C

H2/D

H2/E

H2/F

RED/WHITE (-) 200 mA CHANNEL 2 VALIDITY OUTPUT

RED (+) CONSTANT POWER INPUT

BROWN (-) HORN HONK OUTPUT

YELLOW (+) SWITCHED IGNITION INPUT

BLACK (-) CHASSIS GROUND INPUT

BLUE (-) 200 mA SECOND UNLOCK OUTPUT

BLACK/WHITE (-) 200 mA DOMELIGHT SUPERVISION OUTPUT

WHITE/BLUE (-) 200 mA CHANNEL 3 VALIDITY OUTPUT

WHITE (+) LIGHT FLASH OUTPUT

ORANGE (-) 500 mA GROUND-WHEN-ARMED OUTPUT

H1/1

H1/2

H1/3

H1/4

H1/5

H1/6

H1/7

H1/8

H1/9

H1/10

H1/11

H1/12

Page 5

© 2000 Directed Electronics, Inc. Vista, CA 5

primary harness (H1) wire connection guide

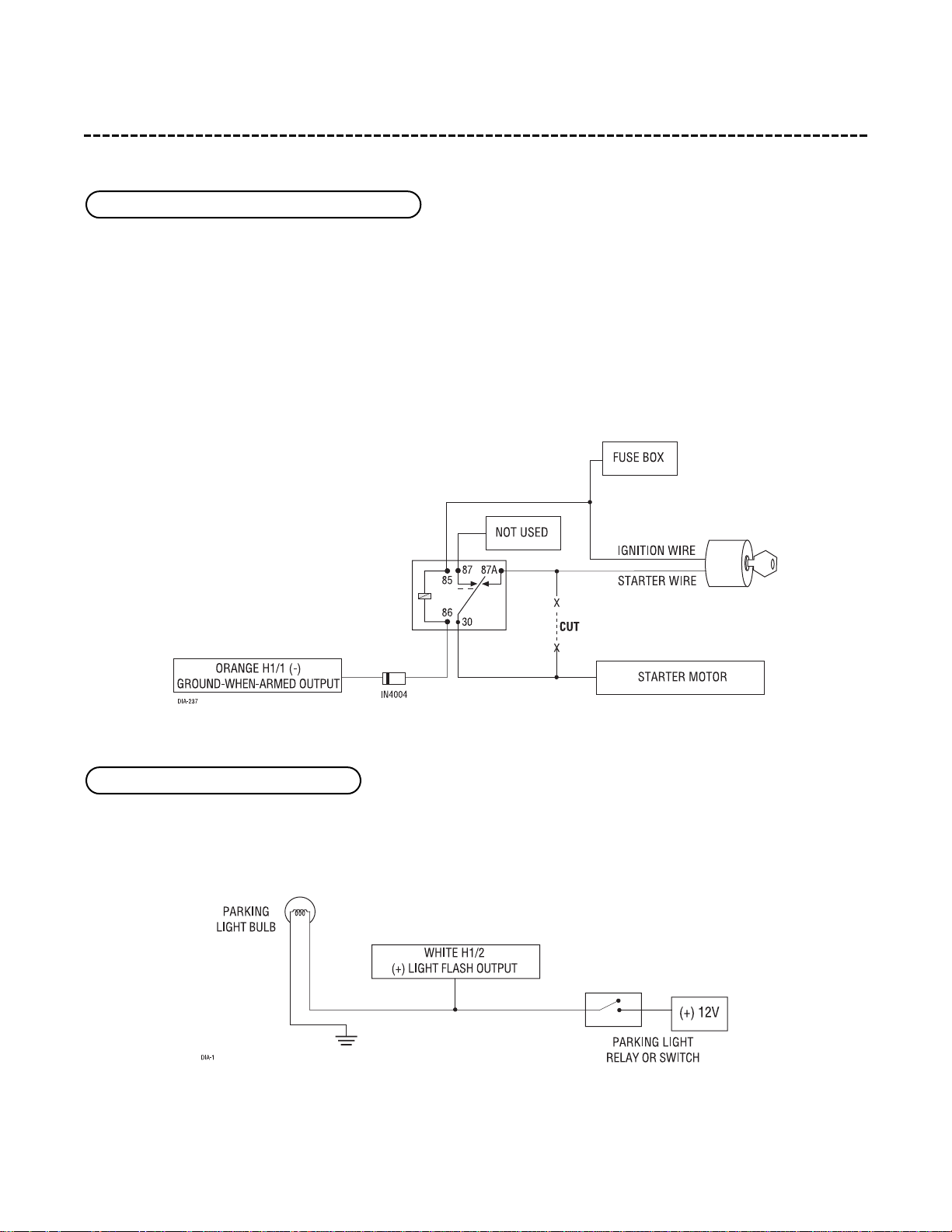

This wire supplies a (-) 500 mA ground as long as the system is armed. This output ceases as soon as the system

is disarmed. The orange wire can be used to control an optional starter kill relay or a DEI 8617.

NOTE: If connecting the orange wire to control another module, such as a 529T or 530T window

controller, a 1 amp diode (type 1N4004) will be required. Insert the diode as shown below.

IMPORTANT! Never interrupt any wire other than the starter wire.

This wire should be connected to the (+) parking light wire. This output is protected with a 10 amp fuse. Never

increase the value of the light flash fuse. If more current is required, use an external relay.

H1/2 WHITE (+) light flash output

H1/1 ORANGE (-) ground-when-armed output

Page 6

6 © 2000 Directed Electronics, Inc. Vista, CA

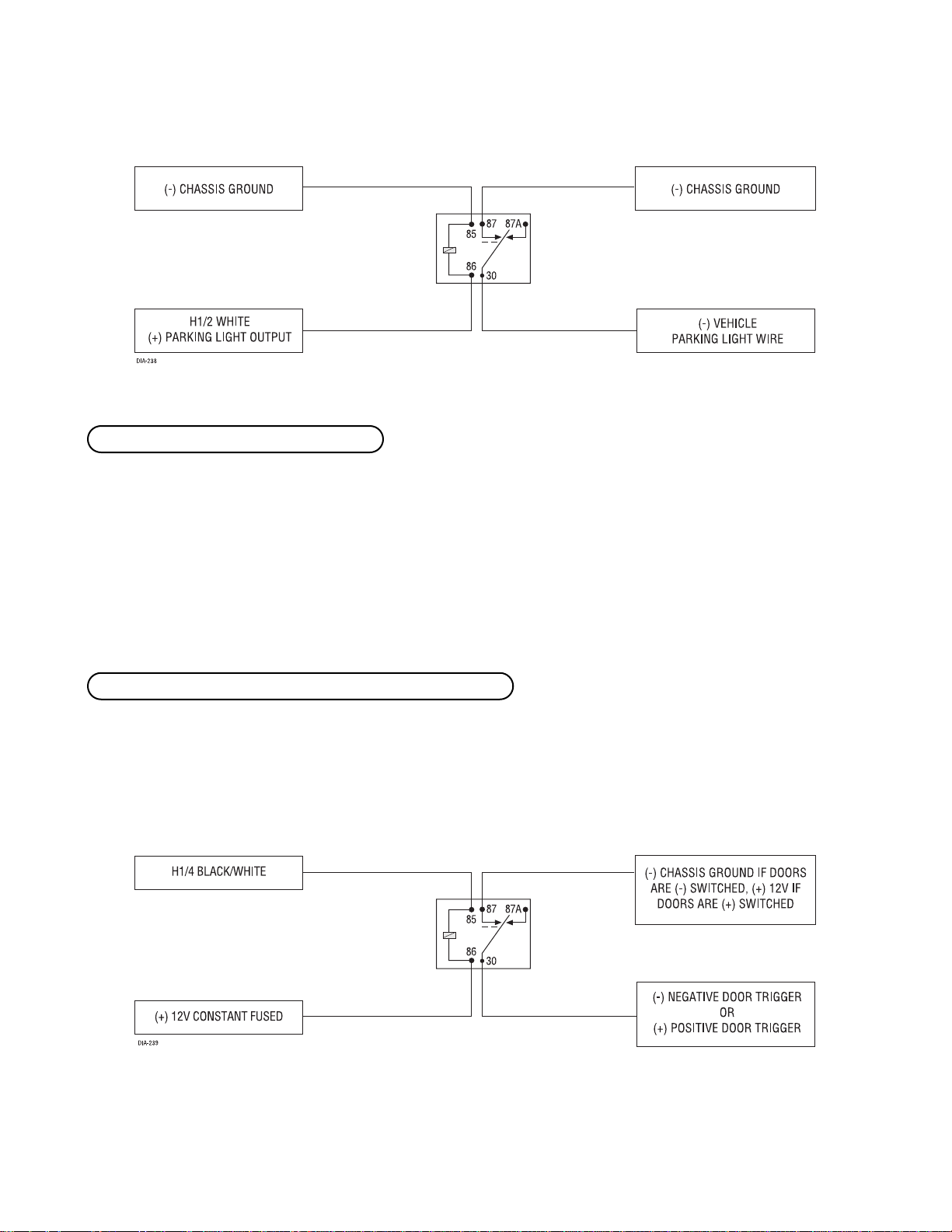

NOTE: When connecting this wire to a (-) parking light wire, a relay is required. See the following

diagram for the relay application.

This wire provides a (-) 200 mA output whenever the transmitter code controlling Channel 3 is received. This

output will continue as long as that transmission is received. Use for options such as 551T Valet® Start system,

529T or 530T power window controllers, etc.

IMPORTANT! Never use this wire to drive anything except a relay or a low-current input! The transistorized output can only provide 200 mA of current, and connecting directly to a solenoid, motor,

or other high-current device will cause it to fail.

Connect this wire to the optional domelight supervision relay as shown below:

IMPORTANT! This output is only intended to drive a relay. It cannot be connected directly to the

domelight circuit, as the output cannot support the current draw of one or more light bulbs.

H1/4 BLACK/WHITE (-) domelight supervision relay output

H1/3 WHITE/BLUE (-) channel 3 output

Page 7

© 2000 Directed Electronics, Inc. Vista, CA 7

This output is used for progressive door unlock. A progressive unlock system unlocks the driver's door when the

unlock (disarm) button is pressed and unlocks the passenger doors if the unlock (disarm) button is pressed again

within 15 seconds after unlocking the driver's door. The BLUE wire outputs a low current (-) pulse on the second

press of the unlock button of the transmitter. This negative unlock output is used to unlock the passenger doors.

Driv

er’s Door Unlock Only (Type A)

H1/6 BLUE (-) 200mA second unlock output

Page 8

8 © 2000 Directed Electronics, Inc. Vista, CA

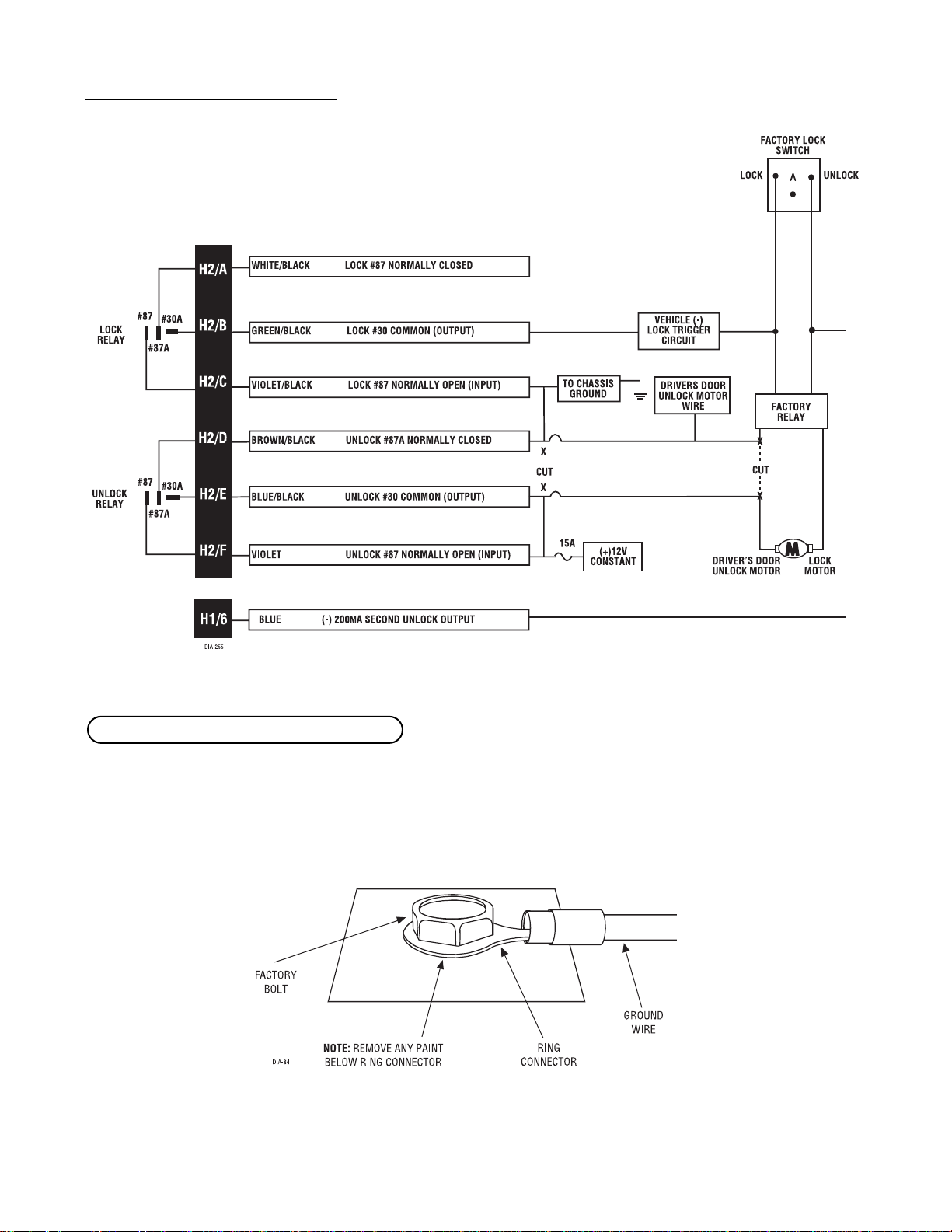

Driver’s Door Unlock Only (Type B)

Connect the H1/8 BLACK wire to bare metal, preferably with a factory bolt rather than your own screw (screws

tend to either strip or loosen with time). We recommend grounding all your components to the same point in

the vehicle.

H1/8 BLACK (-) chassis ground connection

Page 9

© 2000 Directed Electronics, Inc. Vista, CA 9

Connect this wire to an ignition source. This input must show (+)12V with the key in run position and during

cranking. Make sure that this wire cannot be shorted to the chassis at any point. This wire will trigger the system

if the ignition is turned on before the unit is disarmed (doors unlocked with the remote). It will also honk the

vehicle’s horn and flash the parking lights (if connected).

NOTE: Feature 4 (Security Features) must be turned on in order for this wire to trigger the system.

See Features Menu section of this guide.

This wire supplies a (-) 200 mA output that can be used to honk the vehicle horn. It outputs a single pulse to

confirm that the doors are locked if the lock button on the remote is pressed more than once. It also outputs

two pulses to confirm that the doors are unlocked if the unlock button on the remote is pressed more than two

times. This wire also outputs pulses for 30 seconds whenever the Panic Mode is activated. If the vehicle has a

(+) horn circuit, an outboard relay can be used to interface with the system, as shown in the following diagram.

Before connecting this wire, remove the supplied fuse. Connect to the positive battery terminal or the constant

12V supply to the ignition switch.

NOTE: Always use a fuse within 12 inches of the point you obtain (+)12V power. Do not use the

15A fuse in the harness for this purpose. This fuse protects the module itself.

H1/11 RED (+)12V constant power input

H1/10 BROWN (-) horn honk output

H1/9 YELLOW (+) ignition input

Page 10

10 © 2000 Directed Electronics, Inc. Vista, CA

When the system receives the transmitter code controlling Channel 2 for longer than 1.5 seconds, the red/white

wire will supply an output as long as the transmission continues. This is often used to operate a trunk/hatch

release or other relay-driven functions.

IMPORTANT! Never use this wire to drive anything but a relay or a low-current input! The transistorized output can only supply 200 mA of current. Connecting directly to a solenoid, motor, or other

high-current device will cause it to fail.

plug-in LED and valet/program switch

The LED and the Valet/Program switch both plug into the control module. The status LED plugs into the white

two-pin port, while the Valet

®

/Program switch should be plugged into the blue two-pin port. The status LED and

Valet

®

/Program switch each fit into 9/32-inch holes.

Status LED Valet

®

/Program Switch

H1/12 RED/WHITE channel 2, (-) 200mA output

Page 11

© 2000 Directed Electronics, Inc. Vista, CA 11

relay harness (H2) wire connection guide

The system has door lock relays on-board, and can directly interface with most electric power door lock systems

drawing 30 amps or less. It can also drive aftermarket actuators directly. (Some vehicles require that an after-

market actuator be added to the driver’s door to allow system control, see Type D wiring section).

The easiest way to determine which type of door lock system you are working with is to remove the master locking

switch itself, which is usually on the driver’s door or on the center console. Once you have determined which type

of factory door lock circuit you are working with, and the color codes of the switch wires to be used, you can

usually simplify the installation by locating the same wires in the vehicle’s kick panel. If no central locking switch

is found, the installation may require a door lock actuator.

NOTE: Always retest the wires in the kick panel to be sure they function in the same way as the

wires on the switch.

There are eight common types of door lock circuits (some vehicles use more unusual systems):

■ Type A: Three-wire (+) pulse controlling factory lock relays. Most GM, some Ford and Chrysler, 1995 Saturn,

some new VW, newer BMW.

■ Type B: Three-wire (-) pulse controlling factory lock relays. Most Asian vehicles, early Saturn, some BMW and

Porsche.

■ Type C: Direct-wired reversing-polarity switches. The switches are wired directly to the motors. This type of

system has no factory relays. Most Fords, many GM two-doors cars and trucks, many Chryslers.

■ Type D: Adding one or more aftermarket actuators. These include slave systems without an actuator in the

driver’s door, but with factory actuators in all the other doors. Type D also includes cars without power locks,

which will have actuators added. All Saabs before 1994, all Volvo except 850i, all Subaru, most Isuzu, and

many Mazdas. Some mid-eighties Nissans, pre-1985 Mercedes-Benz and Audi.

■ Type E: Electrically-activated vacuum systems. The vehicle must have a vacuum actuator in each door. Make

sure that locking the doors from the driver's or passenger side using the key activates all the actuators in the

vehicle. This requires a slight modification to the door lock harness. Mercedes-Benz and Audi 1985 and newer.

■ Type F: One-wire system - cut to lock, ground to unlock. This system is found in late-model Nissan Sentras,

some Nissan 240SX, and Nissan 300ZX 1992 and later. It is also found in older Mitsubishis, and some early

Mazda MPV’s.

■ Type G: Positive (+) multiplex. This system is most commonly found in Ford, Mazda, Chrysler and GM vehi-

cles. The door lock switch or door key cylinder may contain either one or two resistors.

■ Type H: Negative (-) multiplex. The system is most commonly found in Ford, Mazda, Chrysler and GM vehi-

cles. The door lock switch or door key cylinder may contain either one or two resistors.

identifying the door lock system

Page 12

12 © 2000 Directed Electronics, Inc. Vista, CA

■ Three-wire switches will have either a constant ground input or a constant (+)12V input, along with the

pulsed lock and unlock outputs to the factory relays.

■ Many BMW’s and VW’s have no external switch. The switches are inside the actuator, and instead of pulsing,

the proper wires will flip-flop from (+)12V to (-) ground as the door locks are operated.

■ Direct-wired switches will have a (+)12V constant input and one or two (-) ground inputs, along with two

output leads going directly to the lock motors.

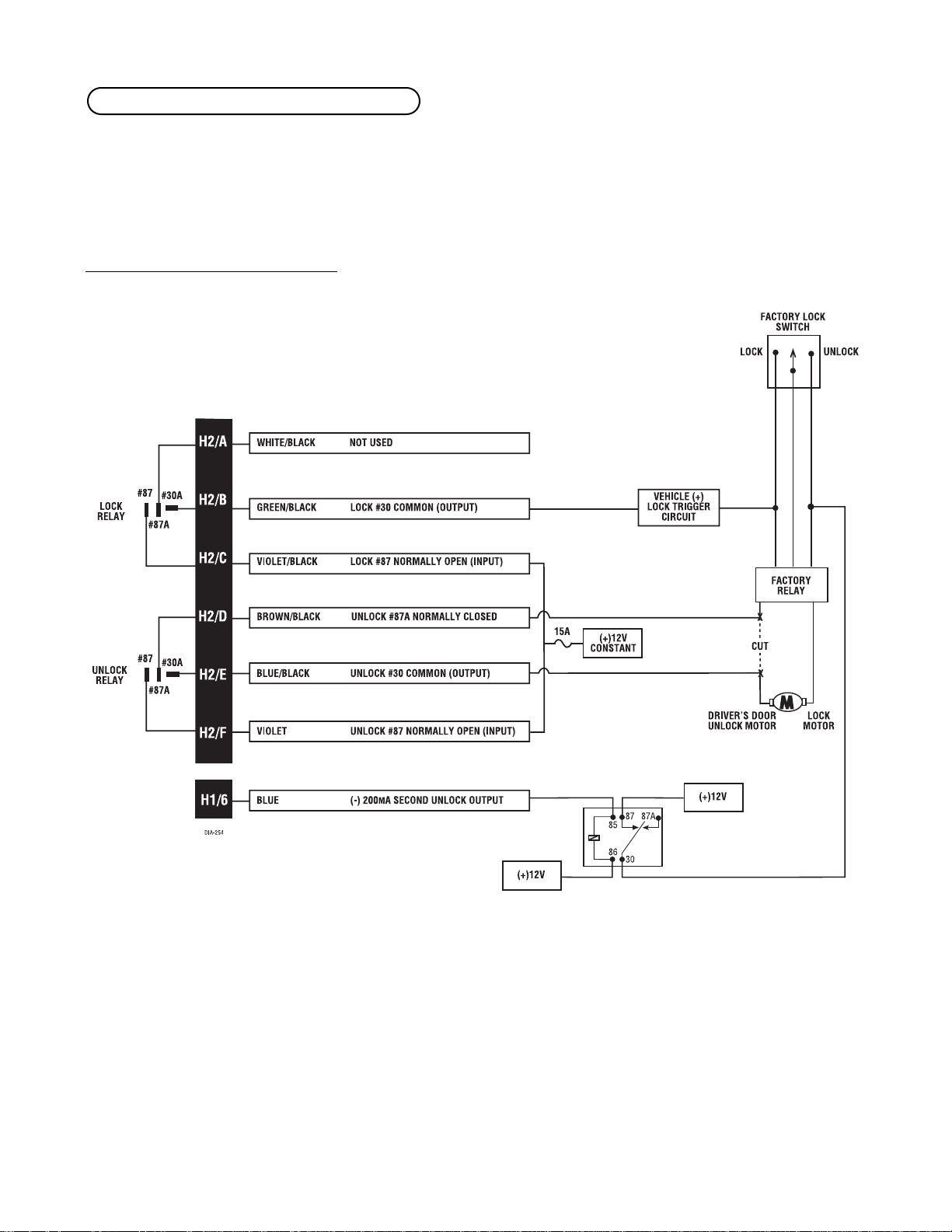

type A: positive-triggered, relay-driven system

at the switch

Page 13

© 2000 Directed Electronics, Inc. Vista, CA 13

This system is common in many Toyota, Nissan, Honda, and Saturn models, as well as Fords with the keyless-entry

system (some other Fords also use Type B).

The switch will have three wires on it, and one wire will test ground all the time. One wire will pulse (-) when

the switch locks the doors, and the other wire will pulse (-) when the switch unlocks the doors. This type of

system is difficult to mistake for any other type.

type B: negative-triggered, relay-driven system

Page 14

14 © 2000 Directed Electronics, Inc. Vista, CA

Use these instructions if the power door lock switch has four or five heavy-gauge wires. This type of switch has

two outputs that rest at (-) ground.

IMPORTANT! To interface with these systems, you must cut two switch leads. The relays must duplicate the factory door lock switches’ operation. The master switch will have one or two ground

inputs, one (+)12V input, and two switch outputs going directly to the slave switch and through

to the motors. These outputs rest at (-) ground. The lock or unlock wire is switched to (+)12V, while

the other wire is still grounded, thus completing the circuit and powering the motor. This will disconnect the switch from the motor before supplying the motor with (+)12V, avoiding sending

(+)12V directly to (-) ground.

It is critical to identify the proper wires and locate the master switch to interface properly. Locate wires that

show voltage when the switch is moved to the lock or unlock position. Cut one of the suspect wires and check

operation of the locks from both switches. If one switch loses all operation in both directions then you have cut

one of the correct wires and the switch that is entirely dead is the master switch. If both switches still operate

in any way and one or more door motors have stopped responding entirely, you have cut a motor lead. Reconnect

it and continue to test for another wire. Once both wires have been located and the master switch identified,

cut both wires and interface as described in the following paragraphs.

WARNING! If these wires are not connected properly, you will send (+)12V directly to (-) ground,

possibly damaging the system or the factory switch.

■ H2/A WHITE/BLACK: Once both door lock wires are located and cut, connect the white/black wire to the

master switch side of the lock wire. The master switch side will show (+)12V when the master switch is oper-

ated to the lock position and (-) ground when the master switch is in the middle position.

■ H2/B GREEN/BLACK: Connect the green/black wire to the other side of the lock wire. This is the motor side

of the lock wire and it goes to the lock motor through the slave switch.

■ H2/C VIOLET/BLACK: This wire must be connected to a constant (+)12 volts. The best connection point for

this wire is the constant (+)12V supply for the door lock switch*, or directly to the positive (+) battery post

with a fuse at the battery post.

*NOTE: Except in GM cars with retained accessory power (RAP). In these vehicles, the (+)12V feed

to the door lock switches is turned off if the doors are closed for any length of time.

NOTE: Most direct-wired power lock systems require 15 amps of current to operate. Connecting the

violet/black wire to a poor source of voltage will keep the door locks from operating properly.

■ H2/D BROWN/BLACK: Connect the brown/black wire to the master switch side of the unlock wire. The master

switch side will show (+)12V when the master switch is in the unlock position and (-) ground when the

master switch is in the middle position.

■ H2/E BLUE/BLACK: Connect the blue/black wire to the other side of the unlock wire.

testing reversing polarity systems

Page 15

© 2000 Directed Electronics, Inc. Vista, CA 15

type C: reversing polarity system

Page 16

16 © 2000 Directed Electronics, Inc. Vista, CA

Vehicles without factory power door locks require the installation of one actuator per door. This requires mount-

ing the door lock actuator inside the door. Other vehicles may only require one actuator installed in the driver's

door if all door locks are operated when the driver's lock is used.

type D: adding one or more after-market actuators

Page 17

© 2000 Directed Electronics, Inc. Vista, CA 17

This system is found in Mercedes-Benz and Audi 1985 and newer. The door locks are controlled by an electrically

activated vacuum pump. The control wire will show (+)12V when doors are unlocked and (-) ground when locked.

NOTE: The system must be programmed for 3.5-second door lock pulses, and the violet jumper

between the #87 lock terminal and the #87 unlock terminal must be cut.

type E: electrically-activated vacuum

Page 18

18 © 2000 Directed Electronics, Inc. Vista, CA

This type of door lock system usually requires a negative pulse to unlock, and cutting the wire to lock the door.

(With some vehicles, these are reversed.) It is found in the late-model Nissan Sentras, some Nissan 240SX, Nissan

300ZX 1992 and later. It is also found in some Mazda MPV's.

NOTE: The violet jumper between the #87 lock terminal and the #87 unlock terminal must be cut.

type F: one-wire system (cut to lock, ground to unlock)

Page 19

© 2000 Directed Electronics, Inc. Vista, CA 19

This system is most commonly found in Ford, Mazda, Chrysler and GM vehicles. The door lock switch or door key

cylinder may contain either one or two resistors.

SINGLE-RESISTOR TYPE: If one resistor is used in the door lock switch/key cylinder, the wire will pulse (+)12V

in one direction and less than (+)12V when operated in the opposite direction.

TWO-RESISTOR TYPE: If two resistors are used in the factory door lock switch/key cylinder, the switch/key cylin-

der will read less than (+)12V in both directions.

DETERMINING THE PROPER RESISTOR VALUES: To determine the resistor values, the door lock switch/key cylinder

must be isolated from the factory door lock system. For testing, use a calibrated digital multimeter that is set to ohms.

IMPORTANT: To ensure an accurate resistance reading, do not touch the resistor or leads during testing.

1. Cut the output wire from the door lock switch/key cylinder in half.

2. Test with the meter from the switch side of the cut door lock switch/key cylinder wire to a reliable constant

(+)12V source. Some good constant (+)12V references are the power input source to the door lock switch/key

cylinder, the ignition switch power wire, or the (+) terminal of the battery.

3. Operate the door lock switch/key cylinder in both directions to determine the resistor values. If the multi-

meter displays zero resistance in one direction, no resistor is needed for that direction.

4. Once the resistor value(s) is determined, refer to the wiring diagram for proper wiring.

type G: positive (+) multiplex

Page 20

20 © 2000 Directed Electronics, Inc. Vista, CA

The system is most commonly found in Ford, Mazda, Chrysler and GM vehicles. The door lock switch or door key

cylinder may contain either one or two resistors.

SINGLE-RESISTOR TYPE: If one resistor is used in the door lock switch/key cylinder, the wire will pulse ground

in one direction and resistance to ground when operated in the opposite direction.

TWO-RESISTOR TYPE: If two resistors are used in the factory door lock switch/key cylinder, the door lock

switch/key cylinder will read resistance to ground in both directions.

DETERMINING THE PROPER RESISTOR VALUES: To determine the resistor values, the door lock switch/key cylinder

must be isolated from the factory door lock system. For testing, use a calibrated digital multimeter that is set to ohms.

IMPORTANT: To ensure an accurate resistance reading, do not touch the resistor or leads during testing.

1. Cut the output wire from the door lock switch/key cylinder in half.

2. Test with the meter from the switch side of the cut door lock switch/key cylinder wire to a reliable ground

source. Some good ground references are the ground input source to the door lock switch/key cylinder or the

battery ground.

3. Operate the door lock switch/key cylinder in both directions to determine the resistor values. If the multi-

meter displays zero resistance in one direction, no resistor is needed for that direction.

4. Once the resistor value(s) is determined, refer to the wiring diagram for proper wiring.

type H: (-) negative multiplex

Page 21

© 2000 Directed Electronics, Inc. Vista, CA 21

transmitter/receiver learn routine

™

Transmitters are taught to the system using the Learn Routine. This system will learn up to four transmitters.

Both transmitters are factory programmed using Button I for Arm/Panic On; Button II for Disarm/Panic

Off/Channel Two; and Buttons I and II together operate Channel Three. This configuration can be changed or new

remotes can be added to the system using the Learn Routine.

1. Key. Turn the ignition to the run position. (The YELLOW H1/9 wire must be already be con-

nected.)

2. Valet

®

/Program switch. Press and release the Valet®/Program switch the correct number of

times corresponding to the desired channel number (see chart below). Then press the

Valet/Program switch once more and HOLD it. The LED will blink to indicate the selected

channel and the horn will honk (if connected). Do not release the Valet/Program switch.

Pressing the Valet/Program Switch five times will delete all transmitters that are pro-

grammed into the system, as well as change the operating settings back to the default

settings (see Operating Settings Learn Routine section of this guide). To use this option,

select Channel 5 (LED will blink five times) then transmit from any button of a known trans-

mitter.

3. Transmit. While holding the Valet®/Program switch, press the button on the transmitter

that you would like to control the selected receiver channel. One honk will confirm that

the code has been learned.

NOTE: For Channel 4, press Button I to program the Auto Learn Standard Configuration on a twobutton transmitter. If programming an optional four-button transmitter, then press Button I to

assign the standard configuration to Buttons I and II; or press Button III to assign the standard

configuration to Buttons III and IV, instead.

CHANNEL PRESS AND RELEASE

NUMBER THE VALET/PROGRAM SWITCH TO PROGRAM FUNCTION

1 One time Arm/Panic

2 Two times Disarm/Channel 2

3 Three times Channel 3

4 Four times Auto Learn Standard Configuration*

5 Five times Delete all transmitters

*NOTE: For the Auto Learn Standard Configuration, see the Transmitter Configuration

section of this guide.

Page 22

22 © 2000 Directed Electronics, Inc. Vista, CA

4. Release. Once the code is learned, the Valet/Program switch can be released.

You can advance from one channel to another by releasing the Valet

®

/Program switch and tapping it to advance

channels and then holding it. For instance: You have programmed Channel 1 and you want to program Channel

2. Release the Valet

®

/Program switch. Press it one time and release it to advance from Channel 1 to Channel 2.

Now, press and HOLD the Valet/Program switch down and the unit will chirp twice. As before, do not release it.

If you want to program Channel 3 after programming Channel 1, release the Valet/Program switch, press it twice

and then release it to advance to Channel 3. Then press the Valet/Program switch once more and HOLD it. The

horn will honk three times to confirm it is ready to receive the code from the transmitter to program Channel 3.

The learn routine will be exited if:

■ The ignition is turned off.

■ The Valet/Program switch is pressed too many times.

■ More than 15 seconds elapses between steps.

One long horn honk (if connected) indicates that the Learn Routine has been exited.

transmitter configuration

The transmitters can be programmed with the Standard Configuration by using the Channel 4 Auto Learn Standard

Configuration function in the Transmitter/Receiver Learn Routine. When programmed for Standard Configuration,

the transmitter buttons are assigned to the following functions:

Button I................................................operates ........................................Arm/Panic

Button II ..............................................operates ........................................Disarm/Channel Two

Buttons I and II.....................................operate..........................................Channel Three

NOTE: If using an optional four-button remote, the Standard Configuration may alternately

be taught to Buttons III and IV by pressing Button III in Step 3 of the Transmitter/Receiver

Learn Routine.

to exit learn routine

to advance from one channel to another

Page 23

© 2000 Directed Electronics, Inc. Vista, CA 23

operating settings learn routine

™

Many of the operating settings of this unit are programmable. They can be changed whenever necessary through

the operating settings learn routine.

1. Key. Turn the ignition on and then back off. (The H1/9 YELLOW switched ignition input

must be connected.)

2. Choose. Within 10 seconds, press and release the Valet

®

/Program switch the number of

times corresponding to the feature number you want to program (see the Features Menu

section of this guide). The LED ON settings listed in the Features Menu table are the factory

default settings.

Once the Valet/Program switch has been pressed and released the number of times corre-

sponding to the feature you wish to program, press it once more and HOLD it. After a second,

the LED will flash to indicate which feature you have accessed. For example, groups of five

flashes would indicate access to Feature 5. The horn will also honk five times (if connected).

3. Transmit. While holding the Valet®/Program switch, you can select the desired feature set-

tings using the remote transmitter. As shipped, the unit is configured to the default LED

ON settings. Pressing the Channel 1 transmitter button (usually Button I) while holding

down the Valet/Program switch will program the feature to the LED ON setting. The LED will

light solid (stop flashing) to indicate the setting. The horn will honk once (if connected).

Pressing the Channel 2 transmitter button (usually Button II) while holding down the

Valet/Program switch will change the setting to the LED OFF setting. The LED will turn off

indicating the change and the horn will honk twice (if connected).

4. Release. The Valet

®

/Program switch can now be released.

For example, to program Feature 1 from ON to OFF, within 10 seconds of turning the ignition off, press and release

the Valet

®

/Program switch once. Then press it again and HOLD it. The LED will flash in groups of one and the

horn will honk once (if connected). While holding the Valet

®

/Program switch, press the Channel 2 transmitter

button. The LED will stop flashing and go out. The horn will honk twice if connected. The ignition-controlled door

locks feature has now been programmed off. If this is not the desired setting, without releasing the

Valet

®

/Program switch, press the Channel 1 button on the transmitter. The LED will light solid and the horn will

honk once if connected. The ignition-controlled door locks feature has now programmed on. Release the

Valet

®

/Program switch after the desired selection has been made.

Page 24

24 © 2000 Directed Electronics, Inc. Vista, CA

You can advance from feature to feature by pressing and releasing the Valet®/Program switch the number of times

necessary to get from the feature you just programmed to the feature you wish to access. For example, if you just

programmed Feature 1 and you want to program Feature 2:

1. Release the Valet

®

/Program switch.

2. Press and release the Valet/Program switch once to advance from Feature 1 to Feature 2.

3. Press the Valet

®

/Program switch once more and HOLD it.

4. The LED will flash in groups of two and the horn will honk twice (if connected) to confirm that you have

accessed Feature 2.

The learn routine will be exited if:

■ The ignition is turned on.

■ The Valet

®

/Program switch is pressed too many times.

■ More than 15 seconds elapses between steps.

One long horn honk (if connected) indicates that the Learn Routine has been exited.

features menu

FEATURE DEFAULT LED ON SETTINGS LED OFF SETTINGS

NUMBER (PRESS CHANNEL 1 TRANSMITTER BUTTON) (PRESS CHANNEL 2 TRANSMITTER BUTTON)

1 Ignition-controlled door locks ON Ignition-controlled door locks OFF

2 0.8 second door lock pulse duration 3.5 second door lock pulse duration

3 Double pulse unlock OFF Double pulse unlock ON

4 Security features ON Security features OFF

5 Code Hopping ON Code Hopping OFF

NOTE: The LED ON settings are the default settings, except where indicated in bold type.

to exit the learn routine

to access another feature

Page 25

© 2000 Directed Electronics, Inc. Vista, CA 25

feature descriptions

1 IGNITION CONTROLLED DOOR LOCKS ON/OFF: When turned on, the doors will lock three seconds after the

ignition is turned on and unlock when the ignition is turned off.

2 DOOR LOCK PULSE DURATION: Some European vehicles, such as Mercedes-Benz and Audi, require longer lock

and unlock pulses to operate the vacuum pump. Programming the system to provide 3.5 second pulses will

accommodate door lock interface in these vehicles. The default setting is 0.8 second door lock pulses. See

Mercedes-Benz and Audi - 1985 and Newer (Type E Door Locks section) diagram.

3 DOUBLE PULSE UNLOCK OFF/ON: Some vehicles require two pulses on a single wire to unlock the doors. When

the double pulse unlock feature is turned on, the H2/E BLUE/BLACK wire will supply two negative pulses instead

of a single pulse. This makes it possible to directly interface with double pulse vehicles without any extra parts.

4 SECURITY FEATURES ON/OFF: In the ON setting, the unit will trigger an ignition panic sequence, and the

H1/1 ORANGE ground-when-armed output will remain active when the ignition key is turned on. In the OFF

setting, the ground-when-armed output and the ignition panic sequence will be inactive.

5 CODE HOPPING

™

ON/OFF: This system features Code Hopping™as an option. Code Hopping™is a feature that

uses a mathematical formula to change the system’s code each time the transmitter and receiver communicate.

This makes the group of bits or "word" from the transmitter very long. The longer the word is, the easier it is to

block its transmission to the unit. Disabling the Code Hopping

™

feature lets the receiver ignore the Code Hopping

™

part of the transmitted word. As a result, the unit may have better range with Code Hopping™off.

Page 26

26 © 2000 Directed Electronics, Inc. Vista, CA

troubleshooting

The Valet®switch does not work.

■ Is it plugged into the correct socket? See Plug-In LED and Valet

®

/Program Switch section. Is the H1/9 YELLOW

wire properly connected? See Primary Harness (H1) Wire Connection Guide section of this guide.

Status LED does not work.

■ Is the LED plugged into the small white port on the side of the control unit? See Plug-In LED and

Valet

®

/Program Switch section.

Door locks operate backwards.

■ This unit has easily-reversed lock/unlock outputs. Recheck Relay Harness (H2), Wire Connection Guide section

to see if you have reversed these.

Loading...

Loading...