Page 1

®

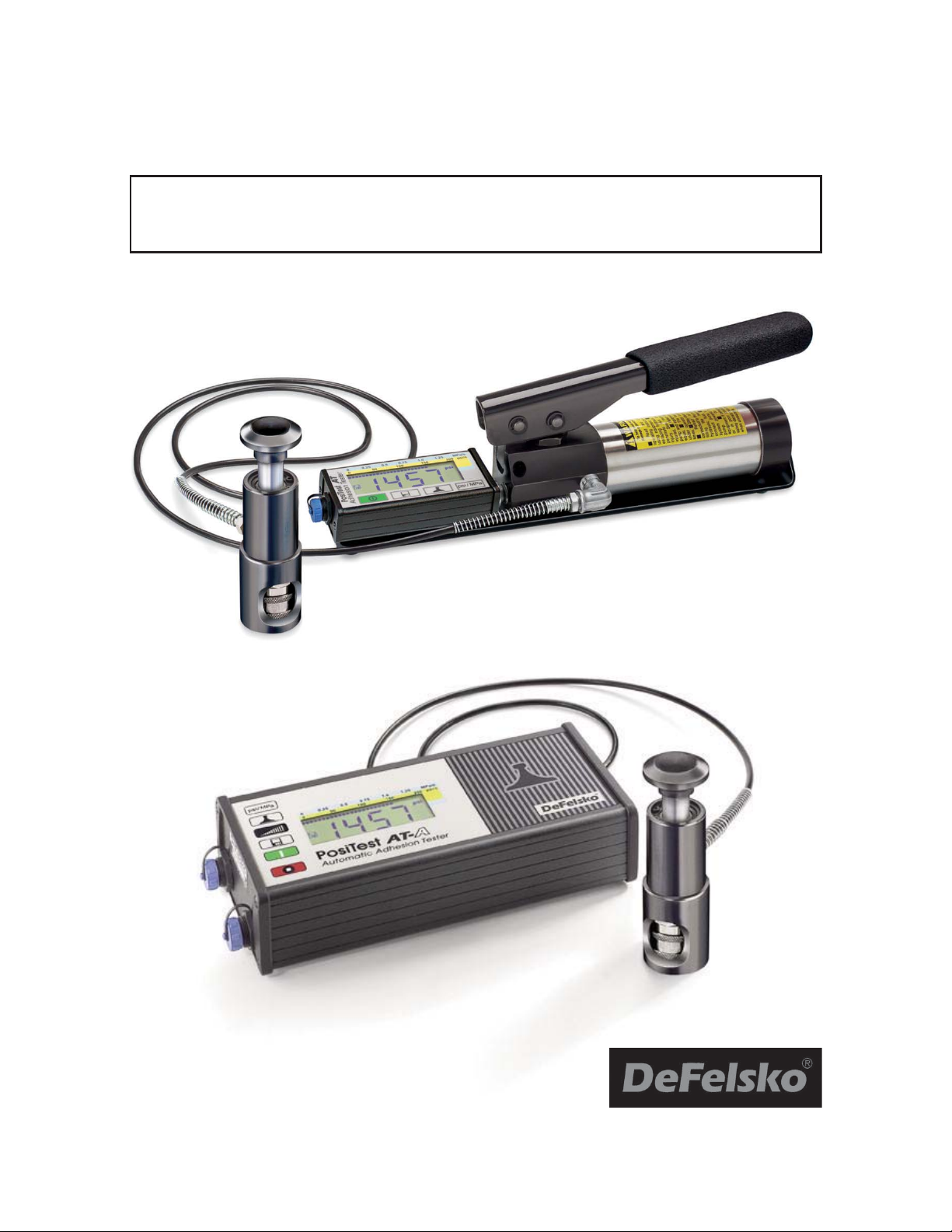

PosiTest

Pull-Off Adhesion Tester

INSTRUCTION MANUAL v. 4.0

PosiTest AT-M

(manual)

PosiTest AT-A

(automatic)

Page 2

Introduction

Introduction

The portable, hand-operated PosiTest Pull-Off Adhesion Tester measures the

force required to pull a specified test diameter of coating away from its substrate

using hydraulic pressure. The pressure is displayed on a digital LCD and represents the coating's strength of adhesion to the substrate.

In accordance with ASTM D4541, D7234, ISO 4624 and others, the PosiTest

evaluates the adhesion (pull-off strength) of a coating by determining the greatest

tensile pull-off force that it can bear before detaching. Breaking points,

demonstrated by fractured surfaces, occur along the weakest plane within the

system consisting of the dolly, adhesive, coating layers and substrate.

NOTE:

about the particular topic or feature is available on our website.

Throughout this manual, the symbol indicates more information

Go to: www.defelsko.com/manuals

Basic steps for testing coating adhesion with a PosiTest Adhesion Tester:

1. Dolly & Coating Preparation

The dolly and the coating are cleaned and abraded. (see pg. 4)

2. Adhesive & Dolly Application

The adhesive is prepared and applied to the dolly . The dolly is then adhered

to the coated surface and the adhesive is allowed to cure. (see pg.4)

3. Test Area Separation - Optional step

The test area of the coating is separated from the area surrounding the

dolly by cutting or drilling. (see pg. 5)

4. Pull-off Test

a) PosiTest AT-M (manual) (see pg. 6)

b) PosiTest AT-A (automatic) (see pg. 8)

5. Analysis of Test Results

The dolly and the coating are examined and evaluated to determine the

nature of the coating failure. (see pg. 10)

6. Store Pull-Off Test Results - Optional step

The PosiTest’s internal memory stores maximum pull pressure, pull rate,

test duration and dolly size for up to 200 pulls. (see pg. 10)

Page 3

Page 3

Step 1: Dolly & Coating Preparation

Step 1: Dolly & Coating Preparation

Dolly Preparation

1. To remove oxidation and contaminants, place the included abrasive pad on a

flat surface and rub the base of the dolly across the pad 4-5 times.

2. As required, remove residue left from the abrading process using a dry cloth

or paper towel.

Coating Preparation

1. Lightly roughen the coating using the included abrasive pad.

NOTE:

necessary to remove surface contaminants, or when the bond strength between

the adhesive and the coating is insufficient for pull testing.

2. To promote the bond between the dolly and the coating, degrease the area of

the coating to be tested using alcohol or acetone to remove any oil, moisture

or dust.

NOTE:

sives do not alter the properties of the coating. Test by applying a small amount

of degreaser or adhesive to a sample area and observing effects.

Step 2: Adhesive & Dolly Application

Step 2: Adhesive & Dolly Application

As coating abrasion may introduce flaws, it should only be used when

Ensure that any alternative abrasion techniques, degreasers or adhe-

Adhesive Selection

The adhesive included in the PosiTest Adhesion Tester kit has been selected due

to its versatility. This adhesive has minimal impact on a variety of coatings and

has a tensile strength exceeding the maximum performance capabilities of the

pressure system under ideal conditions. Other adhesives may be preferred based

on requirements such as cure time, coating type, working temperature and pulloff strength. Quick curing one-part cyanoacrylates (super glues) may be sufficient

for painted surfaces, but two-part epoxies are preferred for porous or rough coat-

ings

Dolly Application

1. Mix the adhesive per manufacturer’s instructions and apply a uniform film of

adhesive on the base of the dolly (approximately 2-4 mils or 50-100 microns

for best results)

2. Attach the dolly to the prepared coating test area.

NOTE:

hold the dolly in place during the cure time may be required, i.e. removable tape.

If the coated surface to be tested is overhead or vertical, a means to

Page 4

Page 4

3. Gently push down on the dolly to squeeze out excess adhesive. Do not twist

or slide the dolly back and forth on the coating as air bubbles may be generated.

4. Carefully remove excess adhesive from around the edges of the dolly with

included cotton swabs.

5. Allow to cure per the adhesive manufacturer's instructions

NOTE:

with heat. Similarly, cold environments may cause a longer cure time and weaker bond strength.

Step 3: Test Area Separation

Step 3: Test Area Separation

The decision of when to cut around a dolly is dependent on the standard,

specification or contractual agreement to which the test is to comply. The primary

purpose for cutting through the coating is to isolate a specific diameter test area.

When the decision to cut into the coating has been made, it is recommended to

cut all the way through to the substrate. As a minimum, it is suggested to carefully

cut away excess adhesive from the dolly application process. This typically

prevents a larger area of coating from being pulled away from the substrate,

resulting in a higher pull-off pressure.

Many adhesives cure faster and provide a stronger bond when cured

Cutting Instructions

1. Cut through the coating around the edges of the dolly with the included cut-

ting tool, removing any excess adhesive.

2. Clear away any debris from the cutting process.

NOTE:

- Cutting may induce coating surface flaws such as microcracking that

may alter test results.

- For coatings with strong lateral bonding it is recommended to cut

completely through the coating down to the substrate.

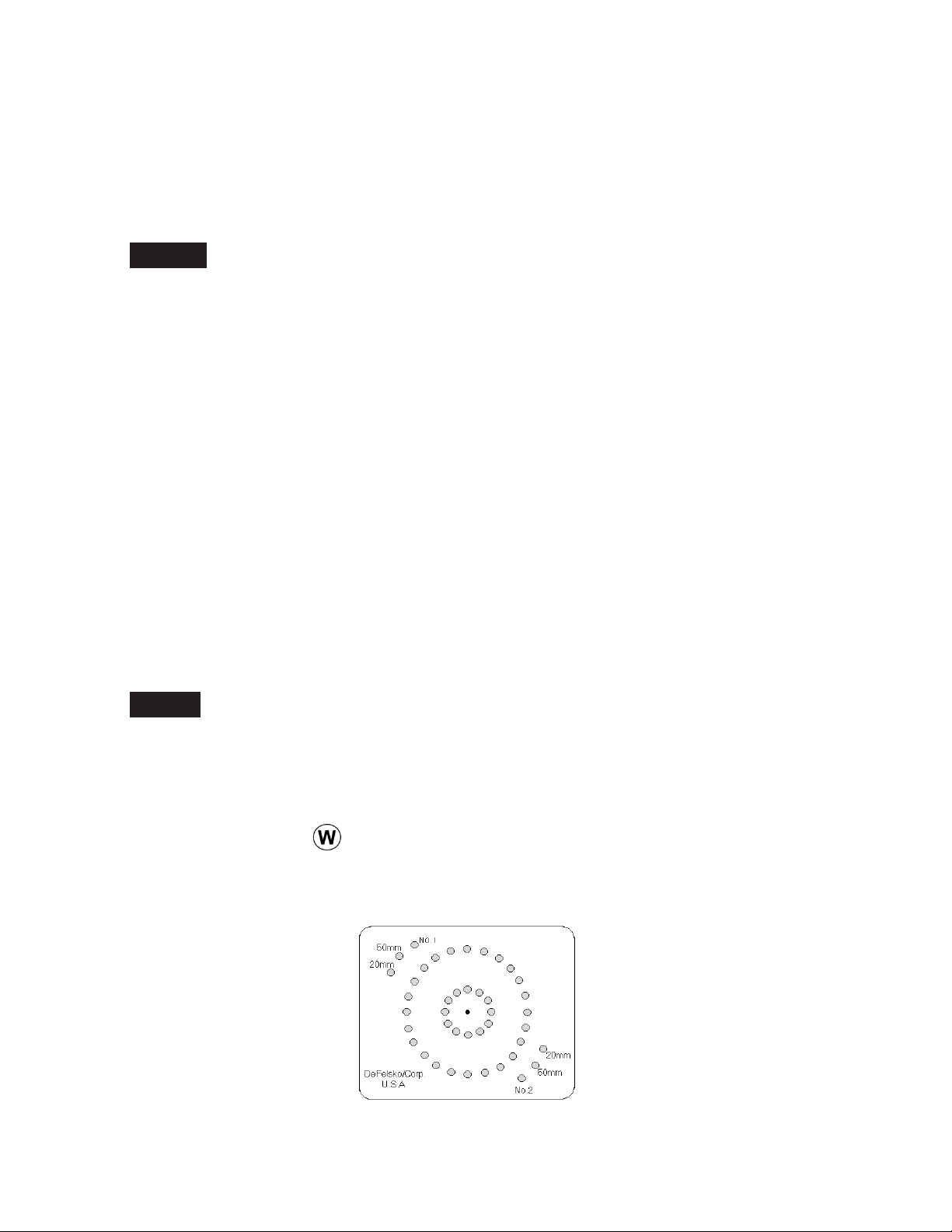

Drilling Template

When testing very thick coatings, an optional drilling template may be preferred.

Page 5

Page 5

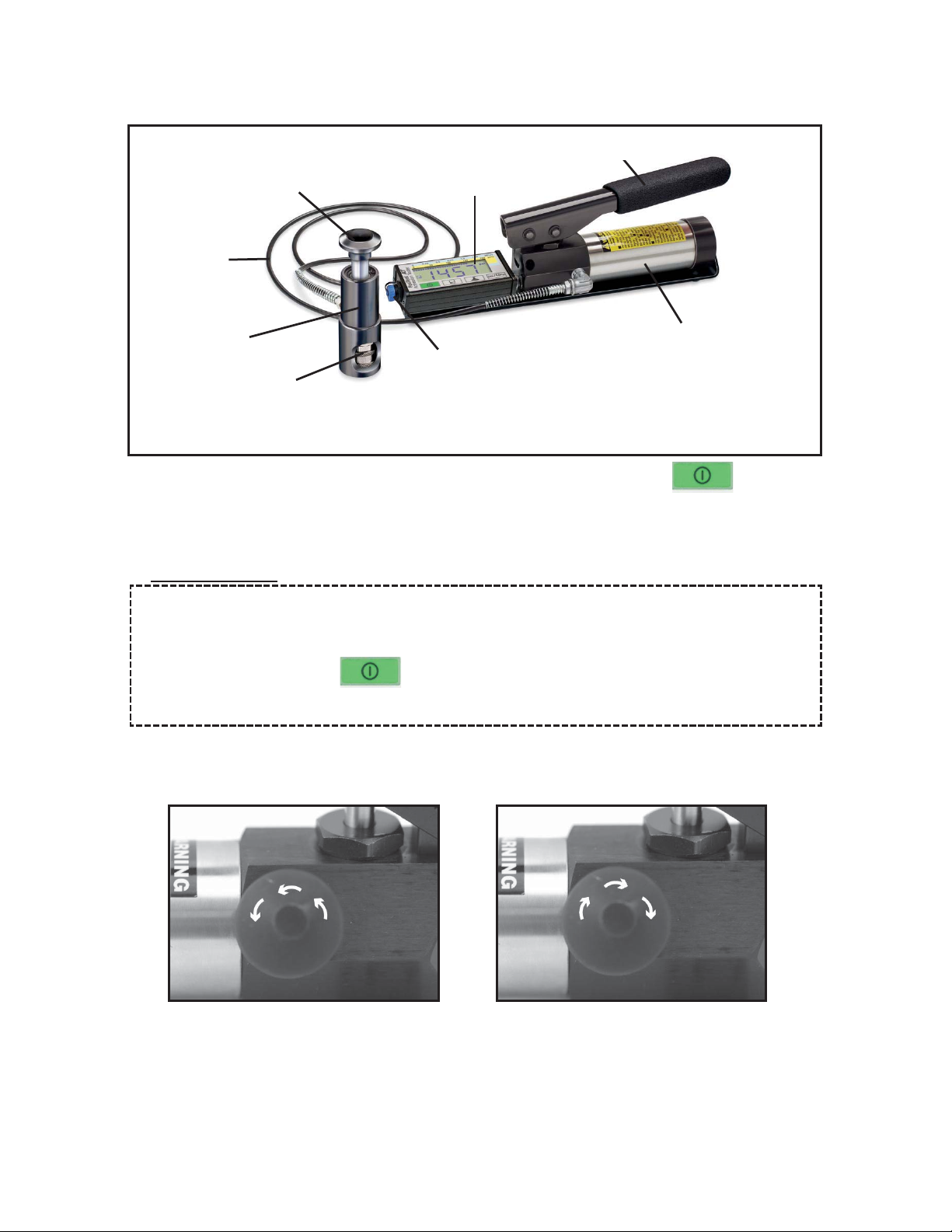

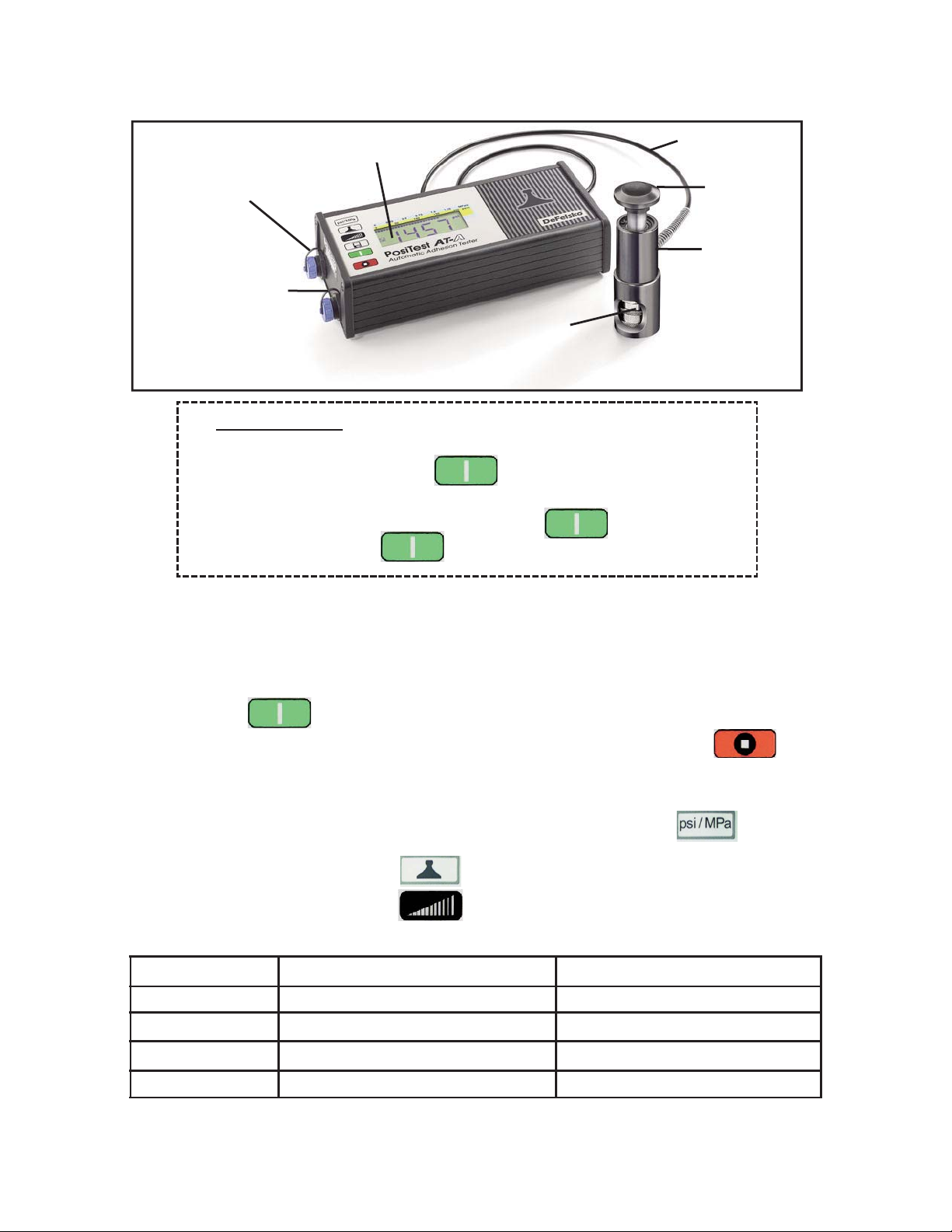

Step 4a: Pull-Off Test

Step 4a: Pull-Off Test

(PosiTest AT-M Manual)

Pump Handle

Actuator Handle

Hose

Actuator

Assembly

Quick Coupling

The PosiTest AT-M powers-up and displays dashes when the button is

pressed. To preserve battery life, the instrument powers down after 5 minutes of

no activity.

LCD

Pump

USB Data Transfer /

Power Port

Quick Guide

(1) Open the pressure relief valve completely (turn counter clockwise)

(2) Connect the actuator to the dolly

(3) Close the pressure relief valve completely (turn clockwise)

(4) Zero - Press the Zero button.

(5) Pump pressure into the system until the dolly pulls the coating away

1. Ensure the pressure relief valve on the pump is completely open. (turn

counter clockwise)

OPEN

CLOSE

2. Push the actuator handle completely down into the actuator assembly. Place

the actuator assembly over the dolly head and attach the quick coupling to the

dolly by reaching through the holes in the actuator assembly and lifting the quick

coupling. Release the quick coupling when the dolly head is completely engaged.

Page 6

Page 6

3. Close the pressure relief valve on the pump completely. (turn clockwise)

NOTE:

button. Select the pressure units by pressing the button. The

instrument will maintain these adjustments even after the button is

pressed.

As required, verify and adjust the dolly size by pressing the

4. Zero the instrument BEFORE pumping by pressing the button. This

prepares the instrument for the test by clearing the display, and zeroing the

instrument.

5. Prime the pump slowly until the displayed reading approaches the priming

pressure. The priming pressure is the point that the instrument begins calculating

and displaying the pull rate. It is also the pressure at which the ability to store

readings is enabled. Priming pressures for the various dolly diameters are:

10 mm 400 psi 2.8 MPa

14 mm 200 psi 1.4 MPa

20 mm 100 psi 0.7 MPa

50 mm 50 psi 0.4 MPa

NOTE:

pump handle to its full upright position and then complete a single stroke at the

desired pull rate until the actuator separates the dolly from the coating.

For optimum results, prior to exceeding the priming pressure, return the

6. Open the pressure relief valve and remove the dolly from the actuator

assembly.

7. Readings may be stored into memory by pressing the button (pg. 10).

Troubleshooting (PosiTest AT-M)

Digital display “freezes” at a low value

The Tester uses a sudden drop in actuator pressure as an indication that the dolly

has been pulled from the surface. The test stops and the highest pressure

remains on the display for easy viewing and recording. Pumping up pressure too

quickly at the beginning of a test can cause a sudden pressure pulse, fooling the

Tester into thinking the test is complete. If this happens, restart the test by

opening the pressure relief valve, closing it, then pressing the button. For

more information, see Step 5 above.

Page 7

Page 7

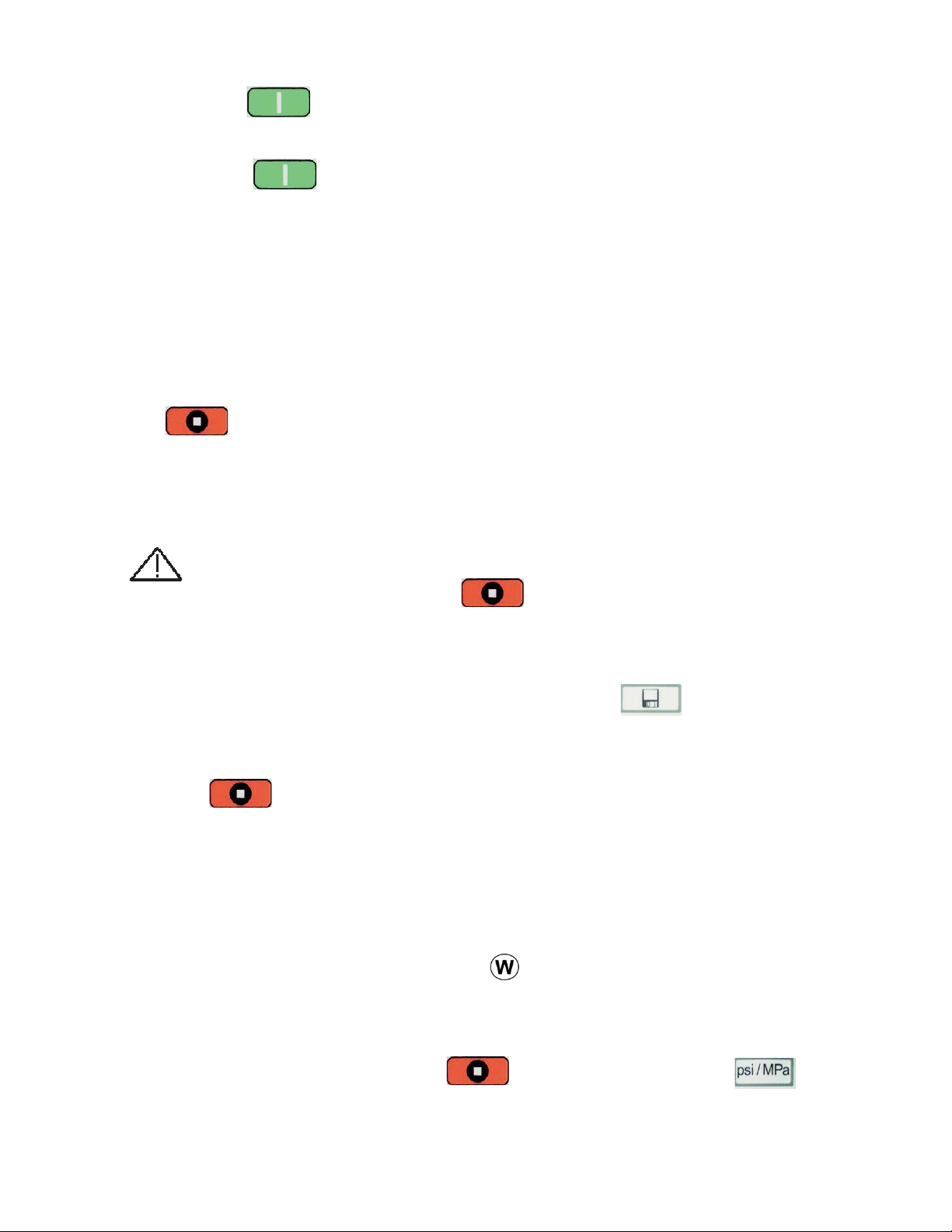

Step 4b: Pull-Off Test

Step 4b: Pull-Off Test

(PosiTest AT-A Automatic)

Hose

Actuator

Handle

Actuator

Assembly

USB port

AC Adapter Port

(Charges batteries

and powers instrument)

LCD

Quick

Coupling

Quick Guide

(1) Connect the actuator to the dolly

(2) Power-up with the button

(3) Verify measurement units, dolly size and pull rate

(4) Ready the instrument with the button

(5) Test with the button

1. Place the actuator assembly over the dolly head and attach the quick coupling

to the dolly by reaching through the holes in the actuator assembly and lifting the

quick coupling. Release the quick coupling when the dolly head is completely

engaged.

2. Press the button to power-up the instrument if necessary. The instru-

ment will power-down after 5 minutes of no activity or by holding the button for 2 seconds.

3. Check settings:

(a) Verify displayed measurement units. Change with the button if

necessary.

(b) Verify dolly size with the button and change if necessary.

(c) Verify pull rate with the button and change if necessary. The

following user selectable rates are available:

Dolly Size PSI Rates MPa Rates

10 mm 125, 200, 400, 600, 725 1.00, 2.00, 3.00, 4.00, 5.00

14 mm 60, 100, 200, 300, 360 0.40, 0.70, 1.40, 2.00, 2.50

20 mm 30, 50, 100, 150, 180 0.20, 0.30, 0.70, 1.00, 1.20

50 mm 5, 8, 16, 24, 30 0.04, 0.08, 0.12, 0.16, 0.20

Page 8

Page 8

4. Press the button to ready the instrument. This prepares the PosiTest

for the test by clearing the display and zeroing the instrument.

5. Press the button again to start the test that consists of 4 stages

that occur automatically:

Stage 1. Initiation - the display shows a blinking "0".

Stage 2. Priming - the pump applies initial pressure to the dolly.

Stage 3. Test - when the priming pressure has been achieved (see step 5 on pg.

7) the instrument begins calculating and displaying the pull rate established by the

user. Pressure build-up stops when the dolly is pulled from the surface or when

the button is pressed.

Stage 4. Retraction - the maximum pull-off pressure value blinks on the display

while the pump retracts the actuator. The buttons are locked during this stage.

CAUTION: To avoid injury, keep fingers away from the quick coupling

and actuator assembly until the pull test has completed and the actuator

has been fully retracted. Press to stop the pull test at any time.

6. Remove the dolly from the actuator assembly.

7. Readings may be stored into memory by pressing the button (pg. 10).

All settings and test results in memory are retained during power-down.

The red button may be pressed to stop the pull test at any time. The

maximum pressure value will remain on the display while the pump retracts the

actuator. This value can be stored into memory and will be uniquely identified by

the optional PosiSoft software. Stopping the pull test before destruction is handy

when specifications allow the test to be stopped when required adhesion

strengths have been exceeded. Uncouple the actuator from the dolly and then

remove the dolly from the surface with a sharp, sideways hammer tap.

Troubleshooting (PosiTest AT-A)

Instrument is unresponsive or will not power down

In the unlikely event that the PosiTest becomes unresponsive or will not

power down, press and hold the button, then press the

button. The instrument will power down.

Page 9

Page 9

Step 5: Analysis of Test Results

Step 5: Analysis of Test Results

Test results can be considered 100% valid when the coating is completely

removed from the substrate. When only a portion of the coating is removed, specific results should be noted including the fracture pattern to determine the cohesive properties of the coating and adhesion properties between the dolly and

adhesive, adhesive and coating, distinct coating layers, and coating and substrate.

Step 6: Storing Pull-Off values into Memory

Step 6: Storing Pull-Off values into Memory

The PosiTest’s internal memory stores maximum pull pressure, pull rate,

test duration and dolly size for up to 200 pulls.

Press the button upon completion of a test to store pull-off test

results. The display will show the pull rate and alternate between the test

number and the maximum pull pressure for that test. The con will

appear to indicate that there are test results in memory.

Press the button repeatedly to view previously stored test results.

The PosiTest AT-A also displays dolly size and pull rate by

pressing their respective buttons.

Complete information on all test results can be downloaded to a PC and

viewed using the optional PosiSoft software. Test results are not erased

from memory after downloading. Press (AT-M manual) or

(AT-A automatic) to exit viewing mode.

To remove all stored test results from memory, press and hold the

or button, then press the button. The icon will

disappear from the display.

All settings and test results in memory are retained during power-down.

Available Options

Available Options

A variety of accessories are available to help you get the most out of your

PosiTest Pull-Off Adhesion Tester.

Page 10

Page 10

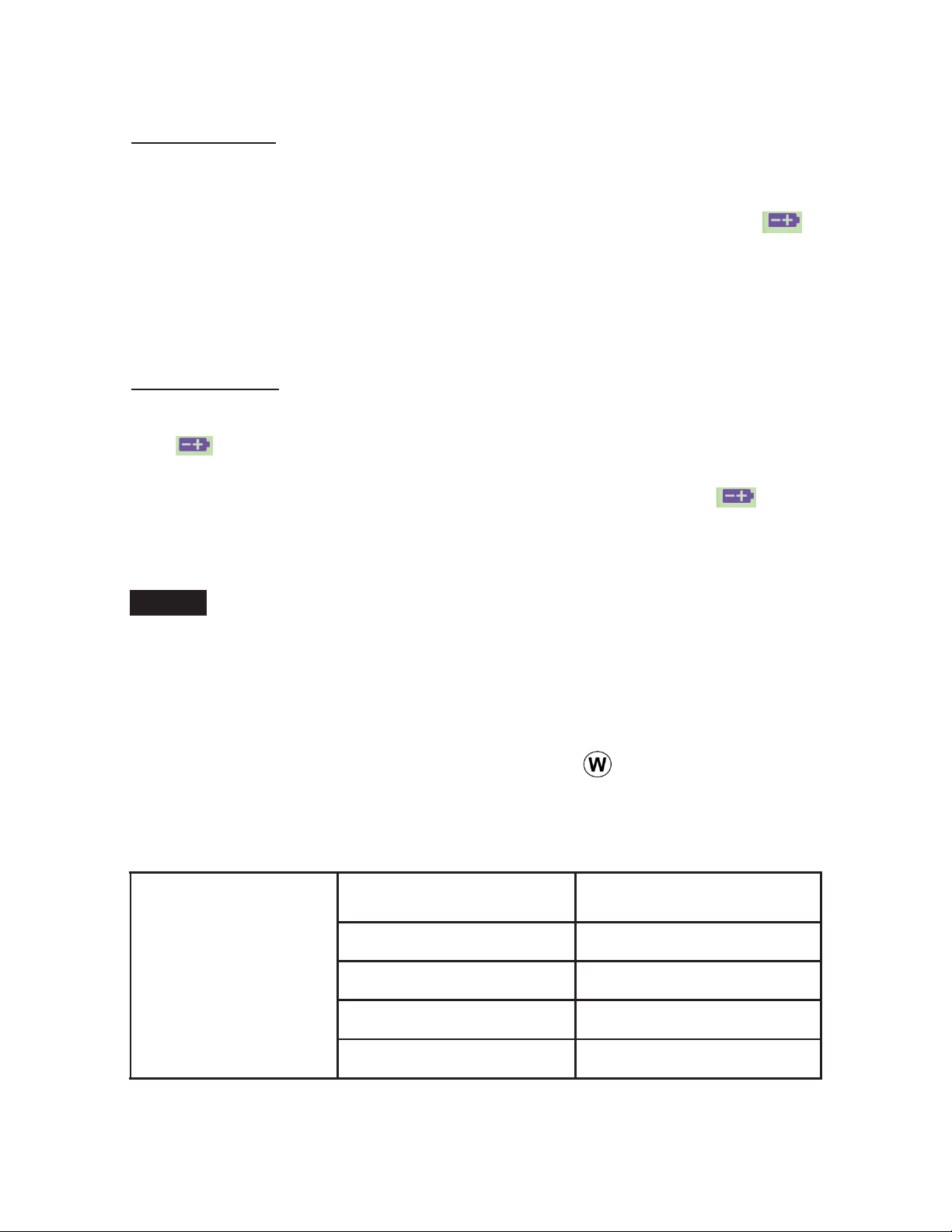

Power Supply / Low Battery Indicator

Power Supply / Low Battery Indicator

PosiTest AT-M (manual)

Power Source: Built-in rechargeable NiMH battery (~60 hours continuous)

The built-in rechargeable NiMH batteries** are charged using the included USB

AC power supply/charger. Ensure batteries are charged prior to use. The

symbol will blink while the instrument is recharging and disappear when fully

charged. The charging process will take up to 14 hours depending on remaining

battery power.

Alternatively, the AC power supply or any computer USB port can be used to

power and charge the instrument.

PosiTest AT-A (automatic)

Power Source: Built-in rechargeable NiMH battery (>200 pulls with full charge)

The symbol will appear when remaining battery power is below 35%.

The built-in rechargeable NiMH batteries** are charged using the included AC

power supply/charger . Ensure batteries are charged prior to use. The symbol

will blink while the instrument is recharging and disappear when fully charged.

The charging process will take 2-3 hours depending on remaining battery power .

Alternatively, the AC power supply can be used to power the instrument.

NOTE:

connection will drain battery power when connected for an extended period of

time.

**Do not attempt to remove or replace the internal NiMH battery pack. In the

unlikely event power issues are experienced, please contact our technical

support for assistance.

The USB port will not charge or power the PosiTest AT-A. The USB

Technical Data

Technical Data

Conforms to: ASTM D 4541, ASTM D 7234, ISO 4624 and others.

Specifications:

Resolution: 1 psi (0.01 MPa) Accuracy: ±1% Full Scale

Dolly Size (mm) Max Pull-Off Pressure

10 mm

10,000 psi (70 MPa)

Adhesion

Strength

14 mm

20 mm

6,000 psi (40 MPa)

3,000 psi (20 MPa)

50 mm*

*requires optional 50 mm accessory kit

Page 11

500 psi (3.5 MPa)

Page 11

Calibration

Calibration

The PosiTest is shipped with a Certificate of Calibration showing traceability to a

national standard. For organizations with re-certification requirements, the

PosiTest may be returned at regular intervals for calibration. DeFelsko

recommends that our customers establish the instrument calibration intervals

based upon their own experience and work environment. Based on our product

knowledge, data and customer feedback, a one year calibration interval from

either the date of calibration, date of purchase, or date of receipt is a typical

starting point.

Returning for Service

Returning for Service

There are no user serviceable components. Any service must be performed by

DeFelsko Corporation.

If you need to return the Instrument for service, describe the problem fully and

include reading results, if any. Be sure to include contact information including

your company name, company contact, telephone number and fax number or

email address.

www.defelsko.com/support

Limited Warranty, Sole Remedy and Limited Liability

Limited Warranty, Sole Remedy and Limited Liability

DeFelsko’s sole warranty, remedy, and liability are the express limited warranty,

remedy, and limited liability that are set forth on its website:

www.defelsko.com/terms

www.defelsko.com

© DeFelsko Corporation USA 2011. All Rights Reserved

This manual is copyrighted with all rights reserved and may not be reproduced or transmitted, in whole or part, by any means, without written permission from DeFelsko Corporation.

DeFelsko, PosiTector, PosiTest and PosiSoft are trademarks of DeFelsko Corporation registered in the U.S. and in other countries. Other brand or product names are trademarks or

registered trademarks of their respective holders.

Protection provided by the equipment may be impaired if the equipment is used in a manner

not specified by the manufacturer.

Every effort has been made to ensure that the information in this manual is accurate.

DeFelsko is not responsible for printing or clerical errors.

Page 12

Medidor de adherencia

por tracción de PosiTest

MANUAL DE INSTRUCCIONES v. 4.0

PosiTest AT-M

(manual)

PosiTest AT-A

(Automático)

Simple. Duradero. Preciso.

Page 13

Introducción

Introducción

El medidor de adherencia manual portátil por tracción Positest mide la fuerza

necesaria para realizar una tracción de prueba sobre un diámetro específico para

separar un revestimiento de su sustrato con presión hidráulica. La presión se

muestra en una pantalla LCD digital y representa la fuerza de adhesión del revestimiento a su sustrato.

De acuerdo con las normas ASTM D4541, D7234, ISO 4624 y otras, el PosiTest

evalúa la adhesión (fuerza de tracción) de un revestimiento determinando la

mayor fuerza de tensión por tracción que puede soportar antes de separarse.

Los puntos de fractura que se muestran en las superficies se suceden a lo

largo del plano más débil del sistema formado por la dolly, las capas de revestimiento y el sustrato.

NOTA:

El símbolo que encontrará en diferentes secciones de este

manual indica que puede encontrar mayor información sobre ese tema o

esa característica en nuestra página web.

Visite: www.defelsko.com/manuals

Pasos básicos para probar la adherencia del revestimiento con un medidor de

adherencia de PosiTest:

1. Preparación del dolly y del recubrimiento

La dolly y el revestimiento estarán limpios y lijados. (consulte la pág. 4)

2. Aplicación del adhesivo y del dolly

Prepare el adhesivo y aplíquelo al dolly. Pegue el dolly a superficie preprada y

deje que el pegamento fragüe. (consulte la pág. 4)

3. Prueba de desprendimiento de la zona - paso opcional

Separe el revestimiento del área de prueba del resto del recubrimiento cortando alrededor del dolly. (consulte la pág. 5)

4. Prueba de tración

a) PosiTest AT-M (manual) (consulte la pág. 6)

b) PosiTest AT-A (automático) (consulte la pág. 8)

5. Análisis de los resultados

Examine el dolly , el revestimiento y evalúelos para determinar el fallo. (consulte

la pág. 10)

6. Almacenamiento de los datos de la prueba de tración - paso opcional

La memoria interna de PosiTest almacena la presión máxima de la prueba de

tración, la duración de la prueba y el calibre del dolly hasta 200 traciónes. (consulte la pág. 10)

Página 3

Page 14

Paso 1: Preparación del dolly y el revestimiento

Paso 1: Preparación del dolly y el revestimiento

Preparación del dolly

1. Para eliminar óxido y contaminantes coloque la lija provista sobre una

superficie plana y frote con ella la base de la dolly unas 4 o 5 veces.

2. Si fuera necesario, elimine los residuos resultantes del proceso de lijado con

una bayeta o papel secos.

Preparación del revestimiento

1. Cree una ligera rugosidad en el revestimiento con la lija facilitada.

NOTA:

cuando sea necesario para eliminar residuos de la superficie o cuando la fuerza

de adhesión entre el adhesivo y el revestimiento sea insuficiente para la prueba

de tracción.

2. Para facilitar la adhesión entre el dolly y el revestimiento, desengrase la zona

del revestimiento que se va a probar con alcohol o acetona y retirar así

cualquier grasa, humedad o polvo.

NOTA:

pegado no alteran las propiedades del revestimiento. Haga una prueba aplicando una pequeña cantidad de desengrasante o adhesivo sobre una zona

de muestra y observe los efectos.

Paso 2: Aplicación del adhesivo y el dolly

Paso 2: Aplicación del adhesivo y el dolly

Selección del adhesivo

El adhesivo facilitado con el medidor de adhesión PosiTest se ha seleccionado

por su flexibilidad. Este adhesivo tiene un impacto mínimo en numerosos revestimientos y tiene una fuerza de tensión que supera las capacidades máximas

de rendimiento del sistema de presión en condiciones ideales. Otros adhesivos

pueden ser mejores según las necesidades como el tiempo de fragua, tipo de

revestimiento, temperatura de trabajo y fuerza de tensión. Los cianoacrilatos de

fragua rápida de un componente pueden ser apropiados para superficies pintadas mientras que las resinas de dos componentes son más adecuadas para

revestimientos porosos o ásperos.

Como el lijado del revestimiento puede crear defectos, utilícelo solo

Asegúrese de que las técnicas alternativas de lijado, desengrasado o

Aplicación del dolly

1. Mezcle el adhesivo según las instrucciones del fabricante y aplique una

película uniforme de adhesivo en la base del dolly (aproximadamente 50100 micras para obtener mejores resultados)

2. Pegue el dolly al área preparada para la prueba del revestimiento.

NOTA:

vertical o está bajo el techo, puede ser necesario algún sistema de fijación para

el dolly durante el tiempo de fragua, por ejemplo, una cinta adhesiva.

Si la superficie de contacto del revestimiento que se va a probar es

Página 4

Page 15

3. Presione suavemente el dolly para que aflore cualquier exceso de adhesivo.

No tuerza ni mueva la dolly sobre el revestimiento ya que podrían generarse

burbujas de aire.

4. Retire con cuidado el exceso de adhesivo de las orillas del dolly con los apli-

cadores de algodón facilitados con el paquete de adhesivo.

5. Permita que el adhesivo fragüe según las instrucciones del fabricante

NOTA:

al aplicar calor. Asimismo, los ambientes fríos pueden causar que la fragua se

retarde más y que la fuerza de adhesión sea menor.

Paso 3: Separación de la zona de prueba

Paso 3: Separación de la zona de prueba

La decisión de cuándo se ha de cortar alrededor de una dolly depende de la

norma, especificación o acuerdo contractual para la prueba ha de cumplir. El

propósito fundamental de cortar el revestimiento es aislar una zona de diámetro

específico de prueba. Cuando se haya decidido en qué momento cortar el

revestimiento, se recomienda cortar también el sustrato. Como mínimo, se

sugiere cortar con cuidado el exceso de adhesivo empleado en el proceso de

aplicación de la dolly. Esto evita que se arranque una zona de sustrato mayor,

que demandará a una mayor presión de tracción.

Muchos adhesivos fraguan más rápido y proporcionan mayor adhesión

Instrucciones de corte

1. Corte laserando el revestimiento alrededor de los bordes de la dolly con la

herramienta de corte facilitada eliminando los excedentes de adhesivo.

2. Elimine cualquier residuo resultante del proceso de corte.

NOTA:

-El corte puede crear defectos de superficie en el revestimiento, como

microfracturas, que podrían alterar los resultados de la prueba.

-Para revestimientos con adhesión lateral fuerte se recomienda

cortarlos completamente hasta llegar el sustrato.

Plantilla de corte

Si se prueban revestimientos muy finos puede ser necesaria una plantilla de corte.

Página 5

Page 16

Step 4a: Prueba de tracción

Step 4a: Prueba de tracción

(PosiTest AT-M Manual)

Manija de la bomba

La palanca

del actuador

Manguera

El conjunto

del actuador

USB porta

Acoplamiento

rápido

LCD

La bomba

El PosiTest AT-M arranca y enciende su pantalla cuando se pulsa el

botón . Para proteger la duración de las baterías el medidor se apagará

tras unos 5 minutos de inactividad.

Guía rápida

(1) Abra completamente la válvula de purga (en dirección contraria a las agujas del reloj)

(2) Conecte el actuador a la dolly

(3) Cierre completamente la válvula de purga (en dirección de las agujas del reloj)

(4) Puesta a cero - Apriete el botón Cero

(5) Bombee presión en el sistema hasta que la dolly arranque el revestimiento

1. Asegúrese de que la válvula de purga de la bomba esté completamente

abierta. (En dirección contraria a las agujas del reloj)

abierta

2. Empuje la palanca del actuador completamente hacia abajo en el conjunto del

actuador. Coloque el conjunto del actuador sobre la cabeza del dolly y únale el

acoplamiento rápido atravesando los agujeros del conjunto del actuador y

levantándolo. Suelte el acoplamiento rápido cuando la cabeza de la dolly quede

totalmente enganchada.

cerrar

Página 6

Page 17

3. Cierre la válvula de purga en la bomba totalmente. (en dirección de las agujas del reloj)

NOTA:

Si fuera necesario compruebe y ajuste el tamaño del dolly

apretando el botón . Seleccione la unidad de presión pulsado el

botón . El equipo mantendrá estos ajustes incluso después de

apretar el botón .

4. Ponga a cero el equipo ANTES de pulsar el botón . El equipo se

preparará para la prueba borrando la pantalla y reiniciándose.

5. Cebe la bomba lentamente hasta que la lectura demostrada se acerque a la

presión de cebado. La presión de cebado es el punto en el que el equipo

empieza a calcular y mostrar la tasa de tracción. También es la presión a la

que existe posibilidad de almacenar lecturas. Las presiones de cebado para

los diferentes diámetros de dolly son:

10 mm 400 psi 2.8 MPa

14 mm 200 psi 1.4 MPa

20 mm 100 psi 0.7 MPa

50 mm 50 psi 0.4 MPa

NOTA:

coloque de nuevo la palanca de la bomba en su posición más elevada y

complete el recorrido a la tasa de tracción deseada hasta que el actuador

separe la dolly del revestimiento.

6. Abra la válvula de purga y retire el dolly del conjunto del actuador.

7. Las lecturas pueden almacenarse en la memoria pulsando el botón (la pág.

10).

Para unos resultados óptimos, antes de superar la presión de cebado,

Solución de Errores (PosiTest AT-M)

La pantalla se congela en un valor bajo

El medidor interpreta una caída de presión en el actuador como la señal de que

la dolly ya se ha desprendido de la superficie de manera repentina. La prueba se

detiene y la última presión más elevada se mantiene en la pantalla para facilitar

su vista y almacenamiento. Operar el actuador de presión de manera demasiado

brusca al iniciar una prueba puede causar un incremento repentino de la presión

engañando al medidor , que considerará que la prueba se ha completado. Si esto

ocurre, reinicie la prueba abriendo la válvula de purga, cerrándola y pulsando el

botón . Para mayor información consulte el paso 5 anterior.

Página 7

Page 18

Paso 4b: Prueba de tracción

Paso 4b: Prueba de tracción

(PosiTest AT-A automático)

USB porta

El Puerto del Adaptador de CA

provee de carga a las baterías

y enciende el instrumento

Guía rápida

(1) Conecte el actuador a la dolly

(2) Arranque con el botón

(3) Compruebe las unidades de medida, el tamaño

del dolly y la tasa de tracción

(4) Prepare el equipo con el botón

(5) Haga la prueba con el botón

LCD

Manguera

La palanca

del actuador

El conjunto

del actuador

Acoplamiento

rápido

1. Coloque el conjunto del actuador sobre la cabeza del dolly y únale el acoplamiento rápido atravesando los agujeros del conjunto del actuador y levantándolo. Suelte

el acoplamiento rápido cuando la cabeza del dolly quede totalmente enganchada.

2. Apriete el botón para arrancar el equipo si fuera necesario. El equipo

se apagará tras 5 minutos sin actividad o pulsando el botón durante 2

segundos.

3. Compruebe la configuración:

(a) Compruebe las unidades de medida mostradas. Cambie con el botón

si fuera necesario.

(b) Compruebe el tamaño del dolly con el botón y cámbielo si fuera

necesario.

(c) Compruebe la tasa de tracción con el botón y cámbielo si fuera

necesario. Están disponible los siguientes valores de usuario:

Tamaño de dolly Valores PSI Valores MPa

10 mm 125, 200, 400, 600, 725 1.00, 2.00, 3.00, 4.00, 5.00

14 mm 60, 100, 200, 300, 360 0.40, 0.70, 1.40, 2.00, 2.50

20 mm 30, 50, 100, 150, 180 0.20, 0.30, 0.70, 1.00, 1.20

50 mm 5, 8, 16, 24, 30 0.04, 0.08, 0.12, 0.16, 0.20

Página 8

Page 19

4. Pulse el botón para preparar el equipo si fuera necesario. El PosiTest estará

preparado para la prueba borrando la pantalla y reiniciando el equipo.

5. Pulse el botón y arranque de nuevo la prueba que consiste en 4 fases que

se suceden de manera automática:

Fase 1. Inicio- la pantalla muestra un "0" intermitente.

Fase 2. Cebado - la bomba aplica la presión inicial al dolly.

Fase 3. Prueba - cuando se alcanza la presión de cebado (consulte paso

5 en la pág. 7) el instrumento empezará a calcular y mostrará la tasa de

tracción establecida por el usuario. El aumento de presión parará cuando

el dolly se separe de la superficie o cuando se pulse el botón

Fase 4. Retracción - el valor máximo de presión de tracción parpadeará

en la pantalla cuando la bomba retraiga el actuador. Los botones se

bloquean durante esta fase.

ATENCIÓN: Para evitar daños mantenga los dedos lejos del

acoplamiento rápido y el conjunto del actuador hasta que la

prueba de tracción se haya completado y el actuador se haya

retraído completamente. Pulse para parar la prueba de

tracción en cualquier momento.

6. Retire el dolly del conjunto del actuador.

7. Las lecturas pueden almacenarse en la memoria pulsando el botón (la

pág. 10).

Toda la configuración y los resultados de las pruebas se conservan cuando el

equipo está apagado.

Puede pulsar el botón rojo para parar la prueba de tracción en cualquier momento.

El valor máximo de presión se conservará en la pantalla cuando la bomba retraiga el

actuador. Este valor puede almacenarse en memoria y solo podrá identificarse con las

aplicaciones PosiSoft. Parar la prueba de tracción antes de la destrucción puede ser útil

cuando las especificaciones permitan parar la prueba al superarse las fuerzas necesarias

de adhesión. Desconecte el actuador de la dolly y retírela de la superficie con un golpe

lateral incisivo de martillo.

Fallos (PosiTest AT-A)

El equipo no responde o no se apaga

En el caso improbable de que el PosiTest no responda o no se apague, mantenga

pulsado el botón y luego pulse el botón . El equipo se apagará.

Página 9

Page 20

Paso 5: Análisis de los resultados

Paso 5: Análisis de los resultados

Los resultados de la prueba podrán considerarse 100% válidos cuando se retire

completamente el revestimiento del sustrato. Cuando solo se retire una porción

del revestimiento, los resultados específicos deberán anotarse, incluso la pauta

de fractura, para determinar las propiedades de cohesión del revestimiento y de

adhesión entre el dolly y el adhesivo, el adhesivo y el revestimiento, las diferentes

capas del revestimiento y el revestimiento y el sustrato.

Paso 6: Almacenamiento de valores de tracción en la memoria

Paso 6: Almacenamiento de valores de tracción en la memoria

La memoria interna de PosiTest almacena la presión máxima de tracción, la tasa de tracción, la duración de la prueba y el calibre de la dolly

hasta 200 tracciones.

Pulse el botón a la finalización de una prueba para almacenar

resultados de prueba de tracción. La pantalla mostrará la tasa de tracción

y alternará entre el número de prueba y la presión de tracción máxima

para esa prueba. El icono recerá e indicará que hay resultados de

pruebas en memoria.

Pulse el botón para ver los resultados almacenados de pruebas

anteriores. El PosiTest AT-A también mostrará el tamaño de la dolly

y la tasa de tracción pulsando sus respectivos botones.

La información completa de todos los resultados de pruebas puede

descargarse a un ordenador y verse utilizando las aplicaciones

informáticas opcionales de PosiSoft. Los resultados de las pruebas no se

eliminarán de la memoria tras la descarga. Pulse (AT- M manual)

o (AT-A automático) para salir del modo vista.

Para eliminar de la memoria todos los resultados de pruebas

almacenados mantenga pulsado el botón o y pulse

entonces el botón . El icono desaparecerá de la pantalla.

Toda la configuración y los resultados de las pruebas se conservan

cuando el equipo está apagado.

Opciones disponibles

Opciones disponibles

Existe una amplia variedad de accesorios que le permitirán optimizar su

medidor de adhesión por tracción PosiTest.

Página 10

Page 21

Alimentación eléctrica / Indicador de batería baja

Alimentación eléctrica / Indicador de batería baja

PosiTest AT-M (manual)

Alimentación eléctrica: Batería recargable incluida NiMH (~ 60 horas en

continuo)

Las baterías recargables de NiMH** se cargan utilizando el cable USB

CA facilitado. Asegúrese de que las baterías estén cargadas antes de su

empleo. El símbolo parpadeará cuando el equipo esté en carga y

desaparecerá cuando esté cargado totalmente. El proceso de carga

llevará hasta 14 horas según la carga que quede en las baterías.

De manera alternativa puede utilizarse corriente alterna o cualquier

puerto USB de ordenador para enchufar y cargar el equipo.

PosiTest

AT-A (automático)

Alimentación eléctrica: Batería recargable incluida NiMH (> 200 horas en

continuo)

El símbolo aparecerá cuando la carga de la batería esté por debajo

del 35%.

Las baterías recargables de NiMH** se cargan utilizando el cable USB CA facilitado.

Asegúrese de que las baterías estén cargadas antes de su empleo. El símbolo

parpadeará cuando el equipo esté en carga y desaparecerá cuando esté cargado

totalmente. El proceso de carga llevará entre 2 y 3 horas según la carga que quede en las

baterías. De manera alternativa puede utilizarse corriente alterna para enchufar el equipo.

NOTA:

descargará la batería si está conectado por un espacio de tiempo prolongado.

**No quite ni reemplace la batería interna de NiMH. En el caso improbable de que existan

incidencias con la alimentación póngase en contacto con nuestro servicio técnico.

Cumple con: ASTM D 4541, ASTM D 7234, ISO 4624 y otras.

Especificaciones:

El puerto USB no cargará ni alimentará el PosiTest AT-A. La conexión USB

Datos técnicos

Datos técnicos

Resolución: 1 psi (0.01 MPa) Exactitud: ±1% a escala completa

Tamaño de dolly (mm) Presión máx. de tracción

10,000 psi (70 MPa)

6,000 psi (40 MPa)

3,000 psi (20 MPa)

Fuerza de adhesión

10 mm

14 mm

20 mm

50 mm*

*requiere de un juego de accesorios opcional para 50 mm

Página 11

500 psi (3.5 MPa)

Page 22

Calibración

Calibración

El PosiTest se suministra con un certificado de calibración que muestra la trazabilidad para

una norma nacional (USA). Aquellas organizaciones que requieran que el equipo tenga

segunda certificación pueden devolver los medidores con regularidad para que sean

recalibrados. DeFelsko recomienda que sean los usuarios quienes, según su experiencia

y condiciones de trabajo, determinen la periodicidad con que necesitarán recalibrar sus

medidores. Basados en nuestro conocimiento del producto, los datos y la información

procedente de los clientes, recomendamos empezar con un intervalo de calibración de un

año a contar desde la fecha de la última calibración, desde la fecha de compra del medidor,

o desde la fecha de entrega del mismo.

Devolución para reparaciones

Devolución para reparaciones

No hay componentes que el usuario pueda reparar. Será DeFelsko Corporation

quien realizará cualquier servicio.

Si debe devolver el equipo para su reparación describa el problema con detalle

e incluya los resultados de medición si los tiene. Asegúrese de incluir información de contacto incluyendo el nombre de su empresa, el nombre de la persona

de contacto, sus números de teléfono y de fax o su dirección de correo electrónico.

www.defelsko.com/support

Garantía limitada, solución única y obligación limitada

Garantía limitada, solución única y obligación limitada

La garantía única de DeFelsko, su solución, y su obligación son la garantía y

solución limitadas y expresas y la obligación limitada expuestas en su sitio web:

www.defelsko.com/terms

www.defelsko.com

© DeFelsko Corporation USA 2011. Reservados todos los derechos.

Este manual está protegido por copyright. Todos los derechos de este manual están reservados y no podrá ser parcial o totalmente reproducido o transmitido por ningún medio sin

el consentimiento previo por escrito de DeFelsko Corporation.

DeFelsko, PosiTector PosiTest y PosiSoft son marcas comerciales de DeFelsko

Corporation registradas en los EE.UU. y en otros países. Otras marcas o nombres de productos son marcas comerciales o registradas de sus propietarios respectivos.

La protección que el equipo proporciona puede verse afectada si el equipo se emplea de

una manera no especificada por el fabricante.

Se han tomado todas las precauciones posibles para asegurar la precisión de toda la información contenida en este manual. DeFelsko no aceptará responsabilidad por errores

tipográficos o de impresión.

Page 23

PosiTest-Haftfestigkeitstester

4 . 0

GEBRAUCHSANWEISUNG v.

PosiTest AT-M

(manuell)

PosiTest AT-A

(automatisch)

Einfach. Robust. Genau.

Page 24

Einführung

Einführung

Der tragbare PosiTest-Abzugs-Haftfestigkeitstester misst die Kraft, die erforder-

lich ist, um einen spezifizierten Testbereich einer Beschichtung mittels hydraulischen Drucks vom Substrat abzulösen. Der Druck wird auf einem digitalen LCD

angezeigt und stellt die Haftfestigkeit der Beschichtung auf dem Substrat dar.

In Übereinstimmung mit ASTM D4541, D7234, ISO 4624 u. a. bewertet der

PosiTest die Haftung (Abzugsstärke) einer Beschichtung, indem er die größte

Bruchabzugskraft bestimmt, die sie aushalten kann, bevor sie sich löst.

Bruchstellen, die sich durch gebrochene Oberflächen zeigen, treten entlang der

schwächsten Ebene im System auf, die aus dem Prüfkörper (Dolly), Klebstoff,

Beschichtungen und Substrat besteht.

HINWEIS:

In dieser gesamten Anleitung weist das Symbol darauf hin,

dass weitere Informationen über das jeweilige Thema oder die Eigenschaft auf

unserer Website erhältlich sind.

Gehen Sie auf: www.defelsko.com/manuals

Grundschritte zum Testen der Beschichtungshaftung mit einem PosiTestHaftfestigkeitstester:

1. Vorbereitung des Prüfkörpers (Dolly) und der Beschichtung

Der Dolly und die Beschichtung werden gereinigt und angeschliffen (siehe S. 4).

2. Auftragen des Klebstoffs und Anbringen des Dollys

Der Klebstoff wird angemischt und auf den Dolly aufgetragen. Der Dolly wird dann

auf die beschichtete Oberfläche geklebt. Den Klebstoff immer aushärten lassen

(siehe S. 4).

3. Testfläche freilegen - Optionaler Schritt

Der Testbereich der Beschichtung wird durch Schneiden oder Bohren vom Bereich

um den Dolly freigelegt. (siehe S. 5).

4. Abzugstest

a) PosiTest AT-M (manuell) (siehe S. 6)

b) PosiTest AT-A (automatisch) (siehe S. 8)

5. Analyse der Testergebnisse

Der Dolly und die Beschichtung werden untersucht und bewertet, um die Art des

Beschichtungsfehlers zu bestimmen (siehe S. 10).

6. Abzugstestergebnisse speichern - Optionaler Schritt

Der interne Speicher des PosiTest speichert die Maximalwerte für Zugkraft,

Ziehgeschwindigkeit, Testdauer und Größe des Dollys für bis zu 200 Abzüge (siehe

S. 10).

Seite 3

Page 25

Schritt 1: Vorbereitung des Prüfkörpers (Dolly) und der Beschichtung

Schritt 1: Vorbereitung des Prüfkörpers (Dolly) und der Beschichtung

Vorbereitung des Dolly

1. Zur Entfernung von Rost und Verschmutzungen das mitgelieferte

Schleifvlies auf eine flache Oberfläche legen und den Fuß des Dollys 45mal über das Vlies reiben.

2. Falls erforderlich, Rückstände aus dem Schleifprozess mit einem trockenen

Tuch oder Papiertuch entfernen.

Vorbereitung der Beschichtung

1. Die Beschichtung mit dem mitgelieferten Schleifvlies leicht anrauen.

HINWEIS:

Da das Abschleifen von Beschichtungen Fehler hervorrufen kann,

sollte es nur wenn unbedingt nötig angewandt werden, z.B. um

Oberflächenverschmutzungen zu entfernen oder wenn die Verbindung zwischen

dem Klebstoff und der Beschichtung für einen Abzugstest unzureichend ist.

2. Um die Verbindung zwischen dem Dolly und der Beschichtung zu erhöhen,

ist der zu testende Bereich der Beschichtung mit Alkohol oder Aceton zu entfetten, um Öl, Feuchtigkeit oder Staub zu entfernen.

HINWEIS:

Stellen Sie sicher, dass alternative Schleiftechniken,

Entfettungsmittel oder Klebstoffe die Eigenschaften der Beschichtung nicht

verändern. Testen Sie, indem Sie eine kleine Menge Entfettungsmittel oder

Klebstoff auf einen Musterbereich auftragen und die Wirkungen beobachten.

Schritt 2: Auftragen des Klebstoffs und Anbringen des Prüfkörpers (Dolly)

Schritt 2: Auftragen des Klebstoffs und Anbringen des Prüfkörpers (Dolly)

Auswahl des Klebstoffs

Der im Set des PosiTest-Haftfestigkeitstesters enthaltene Klebstoff wurde aufgrund seiner

Vielseitigkeit gewählt. Dieser Klebstoff hat einen minimalen Einfluss auf die meisten

Beschichtungen und hat eine Bruchfestigkeit, die die maximale Leistungsfähigkeit des

Drucksystems unter idealen Bedingungen übersteigt. Andere Klebstoffe sind möglicherweise aufgrund von Anforderungen wie Härtungszeit, Beschichtungstyp, Arbeitstemperatur

und Abzugsstärke zu bevorzugen. Schnell härtende Ein-KomponentenCyanoacrylatklebstoffe (Sekundenkleber) können für lackierte Oberflächen ausreichend

sein, aber Zwei-Komponenten-Epoxidklebstoffe sind für poröse oder raue Beschichtungen

zu bevorzugen.

Anbringen des Dollys

1. Den Klebstoff nach den Anweisungen des Herstellers mischen und einen gle-

ichmäßigen Klebstofffilm auf den Fuß des Dollys auftragen (um die besten

Ergebnisse zu erzielen etwa 50-100 Mikrometer (µm)

2. Den Dolly auf die vorbereitete Beschichtungstestfläche aufkleben.

HINWEIS:

ist es eventuell erforderlich den Dolly während der Härtungszeit zu fixieren, z.B. durch ein

entfernbares Klebeband.

Wenn die zu testende, beschichtete Oberfläche über Kopf oder vertikal liegt,

Seite 4

Page 26

3. Den Dolly leicht andrücken, um überschüssigen Klebstoff herauszuquetschen.

Den Dolly nicht auf der Beschichtung hin und her drehen oder schieben, da

so Luftblasen entstehen können.

4. Überschüssigen Klebstoff rund um den Dolly sorgfältig mit den mitgelieferten

Reinigungsstäbchen entfernen.

5. Nach den Anweisungen des Klebstoffherstellers aushärten lassen.

HINWEIS:

Viele Klebstoffe härten schneller aus und sorgen für eine stärkere

Verbindung, wenn sie mit zusätzlicher Wärme gehärtet werden. In ähnlicher

Weise können kalte Umgebungen eine längere Härtungszeit und eine

schwächere Verbindungsstärke verursachen.

Schritt 3: Testfläche freilegen

Schritt 3: Testfläche freilegen

Die Entscheidung, wann man um einen Dolly herum schneiden sollte, hängt von der Norm,

von der Spezifikation oder von der vertraglichen Vereinbarung ab, der der Test unterliegen

soll. Der Hauptzweck des Schneidens durch die Beschichtung ist die Isolierung einer

Testfläche mit einem bestimmten Durchmesser. Wenn die Entscheidung getroffen wurde,

in die Beschichtung zu schneiden, ist es empfehlenswert, ganz bis zum Substrat zu

schneiden. Es ist mindestens erforderlich überschüssigen Klebstoff beim Anbringen des

Dollys sorgfältig wegzuschneiden. Dadurch wird verhindert, dass eine größere Fläche der

Beschichtung vom Substrat weggezogen wird, was zu einem höheren Abzugsdruck führt.

Anleitung zum Schneidvorgang

1. Durch die Beschichtung um den Dolly herum mit der mitgelieferten

Lochkreissäge schneiden und überschüssigen Klebstoff entfernen.

2. Ablagerungen vom Schneidevorgang entfernen.

HINWEIS:

- Das Schneiden kann zu Fehlern der Beschichtungsoberfläche

wie Mikrorissen führen, die die Testergebnisse beeinflussen können.

- Für Beschichtungen mit starken seitlichen Haftkräften wird empfohlen,

vollständig durch die Beschichtung bis zum Substrat zu schneiden.

Bohrschablone

Beim Testen sehr dicker Beschichtungen ist eine optionale Bohrschablone

eventuell sinnvoll.

Seite 5

Page 27

Schritt 4a: Abzugstest

Schritt 4a: Abzugstest

Auslösergriff

vollständig

Schlauch

Auslöseranlage

herunterdrücken

(PosiTest AT-M manuell)

Pumpe Griff

LCD

Pumpe

Schnellkupplung

loslassen

USB Anschluss

Der PosiTest A T-M schaltet sich ein und zeigt Striche an, wenn die Taste

gedrückt wird. Um die Lebensdauer der Batterie zu schonen,

schaltet sich das Instrument nach etwa 5 Minuten Nichtgebrauchs aus.

Schnellanleitung

(1) Das Druckablassventil vollständig öffnen (gegen den Uhrzeigersinn drehen)

(2) Die Zugvorrichtung mit dem Dolly verbinden

(3) Das Druckablassventil vollständig schließen (im Uhrzeigersinn drehen)

(4) Nullstellung - Die Taste drücken

(5) Druck in das System pumpen, bis der Dolly die Beschichtung abzieht.

1. Sicherstellen, dass das Druckablassventil an der Pumpe vollständig

geöffnet ist (gegen den Uhrzeigersinn drehen).

Öffnen

Schließen

2. Den Griff der Zugvorrichtung ganz herunterdrücken. Die Zugvorrichtung über den Kopf

des Dollys setzen und die Schnellkupplung am Dolly befestigen, indem Sie durch die

Löcher in der Zugvorrichtung greifen und die Schnellkupplung anheben. Die

Schnellkupplung loslassen, wenn der Kopf des Dollys vollständig eingerastet ist.

Seite 6

Page 28

3. Das Druckablassventil an der Pumpe vollständig schließen (im Uhrzeigersinn

drehen).

HINWEIS:

überprüfen und einstellen. Die Druckeinheiten durch Drücken der Taste

wählen. Das Instrument behält diese Einstellungen auch, nachdem die Taste

gedrückt wurde.

Soweit erforderlich, die Größe des Dollys durch Drücken der Taste

4. Eine Nullstellung des Instruments VOR dem Pumpen durch Drücken der Taste

durchführen. Dadurch wird das Instrument auf den Test vorbereitet, indem die

Anzeige gelöscht und das Instrument auf Null gestellt wird.

5. Mit dem Pumpenhandgriff etwas Druck in das System pumpen bis das Gerät mit der

Berechnung und der Anzeige des Vordrucks beginnt (vgl. Tabelle unten). Ab diesem Punkt

beginnt auch die Berechnung und Anzeige der Ziehgeschwindigkeit, ebenso ist ab diesem

auch die Speicherung der Messwerte aktiviert. Die Vordruckwerte für die verschiedenen

Durchmesser der Dollys sind:

10 mm 400 psi 2.8 MPa

14 mm 200 psi 1.4 MPa

20 mm 100 psi 0.7 MPa

50 mm 50 psi 0.4 MPa

HINWEIS:

Erreichen des Vordruckpunktes in die senkrechte Ausgangsposition. Erhöhen Sie den

Druck kontinuierlich und gleichmäßig mit nur einem Hub - nicht ruckartig - bis die

Zugvorrichtung den Dolly von der Beschichtung abzieht.

Um ein optimales Resultat zu erzielen, ist der Pumpenhandgriff nach

6. Das Druckablassventil öffnen und den Dolly aus der Zugvorrichtung entfernen.

7. Messwerte können durch Drücken der Taste im Speicher abgelegt werden (S.

10).

Fehlerbehebung (PosiTest AT-M)

Digitale Anzeige "friert" bei einem niedrigen Wert ein

Das Gerät nimmt einen plötzlichen Druckabfall als Hinweis, dass der Dolly von

der Oberfläche abgezogen wurde. Der Test wird beendet, und der höchste Druck

bleibt zur Ansicht und Aufzeichnung in der Anzeige. Ein zu schnelles Pumpen am

Anfang eines Tests kann einen plötzlichen Druckanstieg verursachen, der dem

Gerät vortäuscht, dass der Test abgeschlossen sei. Wenn dies geschieht, ist der

Test neu zu starten, indem man das Druckablassventil öffnet und wieder schließt

und dann die Taste drückt. Weitere Informationen siehe oben unter

Schritt5.

Seite 7

Page 29

Schritt 4b: Abzugstest

Schritt 4b: Abzugstest

(PosiTest AT-A automatisch)

Schlauch

Auslösergriff

vollständig

Auslöseranlage

herunterdrücken

USB Anschluss

Wechselstrom-AdapterHafen

(Gebührenbatterie-und-

energieninstrument)

LCD

Schnellkupplung

loslassen

Schnellanleitung

(1) Die Zugvorrichtung mit dem Prüfkörper (Dolly) verbinden

(2) Mit der Taste einschalten

(3)

Maßeinheiten, Größe des Dollys und die Ziehgeschwindigkeit überprüfen

(4) Das Instrument mit der Taste in Bereitschaft versetzen

(5) Mit der Taste den Test starten

1. Die Zugvorrichtung über den Kopf des Dollys setzen und die Schnellkupplung am Dolly

befestigen, indem Sie durch die Löcher in der Zugvorrichtung greifen und die

Schnellkupplung anheben. Die Schnellkupplung loslassen, wenn der Kopf des Dollys voll-

ständig eingerastet ist.

2. Falls nötig, die T aste drücken, um das Instrument einzuschalten. Das Instrument

schaltet sich nach 5 Minuten Nichtgebrauchs ab - oder, indem man die Taste zwei

Sekunden lang gedrückt hält.

3. Einstellungen kontrollieren:

(a) Eingestellte Maßeinheiten überprüfen. Falls nötig, mit der Taste ändern

(b) Die Größe des Dollys mit der Taste überprüfen und gegebenenfalls

ändern.

(c) Die Ziehgeschwindigkeit mit der Taste überprüfen und eventuell

ändern. Folgende vom Benutzer wählbare Werte stehen zur Verfügung:

Größe des Gegenhalters

PSI-Werte MPa-Werte

10 mm 125, 200, 400, 600, 725 1.00, 2.00, 3.00, 4.00, 5.00

14 mm 60, 100, 200, 300, 360 0.40, 0.70, 1.40, 2.00, 2.50

20 mm 30, 50, 100, 150, 180 0.20, 0.30, 0.70, 1.00, 1.20

50 mm 5, 8, 16, 24, 30 0.04, 0.08, 0.12, 0.16, 0.20

Seite 8

Page 30

4. Die Taste drücken, um das Instrument in Bereitschaft zu setzen.

Dadurch wird der PosiTest auf den Test vorbereitet, indem die Anzeige gelöscht

und das Instrument auf Null gesetzt wird.

5. Die Taste erneut drücken, um den Test zu beginnen, der aus vier

automatischen Schritten besteht:

Schritt 1. Einleitung - im Display blinkt eine "0".

Schritt 2. Vorbereitung - das Gerät pumpt den Vordruck auf den Dolly.

Schritt 3. Test - wenn der Vordruck erreicht wurde (siehe Schritt 5 auf S. 7),

beginnt das Instrument, mit der Berechnung und zeigt die vom Benutzer

eingestellte Ziehgeschwindigkeit an. Der Druckaufbau hört auf, wenn der Dolly

von der Oberfläche abgezogen wird oder wenn die Taste gedrückt wird.

Schritt 4. Rückstellung - der maximale Zugkraftwert blinkt in der Anzeige,

während die Pumpe die Zugvorrichtung zurückzieht. Die Tasten sind während

dieses Schrittes gesperrt.

ACHTUNG: Um Verletzungen zu vermeiden, die Finger von der

Schnellkupplung und Zugvorrichtung fernhalten, bis der Abzugstest abgeschlossen

ist und die Zugvorrichtung sich vollständig in der Ausgangsposition befindet. Die

Taste drücken, um den Abzugstest jederzeit anzuhalten.

6. Den Dolly aus der Zugvorrichtung entfernen.

7. Messwerte können durch Drücken der Taste im Speicher abgelegt werden (S.

10).

Alle Einstellungen und Testergebnisse im Speicher bleiben erhalten, während das Gerät

abgeschaltet ist.

Die rote Taste kann gedrückt werden, um den Abzugstest jederzeit anzuhalten.

Der maximale Zugkraftwert verbleibt in der Anzeige, während die Pumpe die Zugvorrichtung

zurückzieht. Dieser Wert kann im Speicher abgelegt werden und kann in die optionale

Software PosiSoft übertragen werden. Das Anhalten des Abzugstests vor der Zerstörung

der Oberfläche ist sinnvoll, wenn die Spezifikationen es zulassen, dass der Test angehalten

wird, wenn die geforderten Haftzugkräfte überschritten wurden. Die Zugvorrichtung vom

Dolly abkuppeln und dann den Dolly mit einem kurzen, seitlichen Hammerschlag von der

Oberfläche entfernen.

Fehlerbehebung (PosiTest AT-A)

Das Instrument reagiert nicht oder schaltet sich nicht ab

Im unwahrscheinlichen Fall, dass der PosiTest nicht reagiert oder sich nicht

abschaltet, die Taste gedrückt halten und dann die Taste drücken.

Das Instrument schaltet sich ab.

Seite 9

Page 31

Schritt 5: Analyse der Testergebnisse

Schritt 5: Analyse der Testergebnisse

Testergebnisse können zu 100% gültig angesehen werden, wenn die

Beschichtung vollständig vom Substrat entfernt wurde. Wenn nur ein Teil der

Beschichtung entfernt wurde, sollten die spezifizierten Ergebnisse notiert werden,

einschließlich des Bruchmusters, um die Bindeeigenschaften der Beschichtung

und die Haftungseigenschaften zwischen Dolly und Klebstoff, Klebstoff und

Beschichtung, verschiedenen Beschichtungslagen sowie Beschichtung und

Substrat zu bestimmen.

Schritt 6: Abzugswerte im Speicher ablegen

Schritt 6: Abzugswerte im Speicher ablegen

Der interne Speicher des PosiTest speichert die Maximalwerte für Zugkraft,

Ziehgeschwindigkeit, Testdauer und Größe des Dollys für bis zu 200 Abzüge.

Nach Beendigung eines Tests die Taste drücken, um die Ergebnisse des

Abzugstests zu speichern. Die Anzeige stellt die Ziehgeschwindigkeit dar und

wechselt zwischen der Testnummer und der maximalen Ziehkraft bei diesem

Test. Das Symbol erscheint, um anzuzeigen, dass sich Testergebnisse

im Speicher befinden.

Die Taste wiederholt drücken, um zuvor gespeicherte Testergebnisse

anzuzeigen. Der PosiTest AT-A zeigt auch die Größe des Dollys und die

Ziehgeschwindigkeit an, indem man die jeweilige Taste drückt.

Die vollständigen Informationen über alle Testergebnisse können auf einen PC

heruntergeladen und mit der optionalen Software PosiSoft angesehen werden.

Die Testergebnisse werden nach dem Herunterladen nicht aus dem Speicher

gelöscht. Die Taste (AT-M manuell) oder (AT-A automatisch)

drücken, um den Ansichtsmodus zu verlassen.

Um alle gespeicherten Testergebnisse aus dem Speicher zu entfernen,

die Taste oder gedrückt halten und dann die Taste

drücken. Das Symbol verschwindet aus dem Display.

Alle Einstellungen und Testergebnisse im Speicher bleiben erhalten,

während das Gerät abgeschaltet ist.

Verfügbare Optionen

Verfügbare Optionen

Eine Vielfalt an Zubehör ist verfügbar, um Ihnen zu helfen, den größtmöglichen

Nutzen aus Ihrem PosiTest-Haftfähigkeitstester zu ziehen.

Seite 10

Page 32

Stromanschlussanzeige/Anzeige eines leeren Akkumulators

Stromanschlussanzeige/Anzeige eines leeren Akkumulators

PosiTest AT-M (manuell)

Stromquelle: Eingebauter wiederaufladbarer NiMH-Akku (~60 Stunden

fortlaufender Betrieb)

Der eingebaute, wiederaufladbare NiMH-Akku** wird mit dem mitgelieferten USBWechselstromanschluss/Ladegerät aufgeladen. Vor Testbeginn sicherstellen,

dass der Akku aufgeladen ist. Das Symbol blinkt, während das Instrument

sich neu auflädt, und verschwindet, wenn es vollständig aufgeladen ist. Der

Ladevorgang dauert bis zu 14 Stunden, je nach Restladung.

Alternativ kann der Wechselstromanschluss oder jeder Computer-USBAnschluss verwendet werden, um das Instrument mit Strom zu versorgen und

aufzuladen.

PosiTest

Stromquelle: Eingebauter wiederaufladbarer NiMH-Akku (>200 Züge bei voller Ladung)

Das Symbol erscheint, wenn die verbleibende Batterieladung unter 35% liegt.

Der eingebaute, wiederaufladbare NiMH-Akku** wird mit dem mitgelieferten

Wechselstromanschluss/Ladegerät aufgeladen. Vor Testbeginn sicherstellen, dass der

Akku aufgeladen ist. Das Symbol blinkt, während das Instrument sich neu auflädt, und

verschwindet, wenn es vollständig aufgeladen ist. Der Ladevorgang dauert 2-3 Stunden, je

nach Restladung. Alternativ kann der Wechselstromanschluss verwendet werden, um das

Instrument mit Strom zu versorgen.

HINWEIS:

Strom. Der USB-Anschluss verringert Akkuladung, wenn er für einen längeren Zeitraum

angeschlossen ist.

**Versuchen Sie nicht, den eingebauten NiMH-Akkumulator zu entfernen oder zu ersetzen. Im unwahrscheinlichen

Fall, dass Stromprobleme auftreten, wenden Sie sich bitte an unsere technische Unterstützung, um Hilfe zu

erhalten.

Entsprechend: ASTM D 4541, ASTM D 7234, ISO 4624 u. a.

Spezifikationen:

AT-A (automatisch)

Der USB-Anschluss lädt den PosiT est A T-A nicht auf oder versorgt diesen mit

Technische Daten

Technische Daten

Auflösung: 1 psi (0.01 MPa) Genauigkeit: ±1% über den gesamten Messbereich

Größe des Prüfkörpers (mm) Max. Zugkraft

10 mm

Haftkraft

14 mm

20 mm

50 mm*

*erfordert optionales 50-mm-Zubehörset

Seite 11

10,000 psi (70 MPa)

6,000 psi (40 MPa)

3,000 psi (20 MPa)

500 psi (3.5 MPa)

Page 33

Kalibrierung

Kalibrierung

Der PosiTest wird mit einem Kalibrierungszertifikat versendet, das eine

Rückverfolgbarkeit zu einer nationalen Norm nachweist. Bei Unternehmen mit

Neubescheinigungsanforderungen kann der PosiTest in regelmäßigen Abständen

zur Kalibrierung zurückgesendet werden. DeFelsko empfiehlt, dass unsere

Kunden nach ihrer eigenen Erfahrung und Arbeitsumgebung

Kalibrierungsabstände für die Instrumente erstellen. Nach unserer

Produktkenntnis, Daten- und Kundenrückläufen ist ein Kalibrierungsabstand von

einem Jahr ab dem Datum der Kalibrierung, dem Kaufdatum oder dem

Empfangsdatum ein üblicher Anfangspunkt.

Einsenden zur Reparatur

Einsenden zur Reparatur

Es sind keine vom Benutzer reparierbaren Teile vorhanden. Alle Reparaturen

müssen von der DeFelsko Corporation durchgeführt werden.

Wenn Sie das Instrument zur Reparatur einsenden müssen, beschreiben Sie das

Problem vollständig und fügen Sie gegebenenfalls Ableseergebnisse bei. Achten

Sie darauf, auch Kontaktinformationen beizufügen, darunter Ihren Firmennamen,

Firmenansprechpartner, die Telefonnummer und Faxnummer oder E-Mail-

Adresse.

www.defelsko.com/support

Begrenzte Garantie, einziges Rechtsmittel und beschränkte Haftung

Begrenzte Garantie, einziges Rechtsmittel und beschränkte Haftung

Die einzige Garantie, das einzige Rechtsmittel und die einzige Haftung von

DeFelsko sind die ausdrücklich begrenzte Garantie, Rechtsmittel und Haftung,

die auf seiner Website dargelegt sind:

www.defelsko.com/terms

www.defelsko.com

© DeFelsko Corporation USA 2011. Alle Rechte vorbehalten

Diese Anleitung unterliegt dem Urheberrecht, wobei alle Rechte vorbehalten sind, und darf

in keiner Weise ganz oder teilweise ohne schriftliche Genehmigung der DeFelsko

Corporation vervielfältigt oder übermittelt werden.

DeFelsko, PosiTector, PosiTest und PosiSoft sind in den USA und in anderen Ländern

eingetragene Warenzeichen der DeFelsko Corporation. Andere Marken- oder

Produktnamen sind Warenzeichen oder eingetragene W arenzeichen der jeweiligen Inhaber .

Der im Gerät enthaltene Schutz kann beeinträchtigt werden, wenn das Gerät auf eine Weise

verwendet wird, die vom Hersteller nicht angegeben ist.

Es wurde jede Anstrengung unternommen, um sicherzustellen, dass die Informationen in

dieser Anleitung zutreffend sind. DeFelsko trägt keine Verantwortung für Druck- oder

Schreibfehler.

Page 34

Testeur d'adhérence par arrachement PosiTest

4 . 0

NOTICE D'INSTRUCTIONS version

PosiTest AT-M

(manuel)

PosiTest AT-A

(automatique)

Simple. Robuste. Précis.

Page 35

Introduction

Introduction

Le testeur d'adhérence par arrachement portable et à main PosiTest mesure la

force nécessaire pour l'arrachement d'une pastille de revêtement de diamètre

connu collée sur un support au moyen d'une pompe hydraulique. La pression est

indiquée sur l'écran LCD et représente la force d'adhérence du revêtement sur

son support.

En accord avec les normes ASTM D4541, D7234, ISO 4624 et autres, le testeur

d'adhérence par arrachement PosiTest évalue l'adhérence (force d'arrachement)

d'un revêtement en déterminant la force d'arrachement à la traction la plus élevée

avant détachement. Les points de rupture, démontrés par les surfaces fracturées,

surviennent sur le plan le plus fin du système constitué d'un plot, de l'adhésif, des

couches de revêtement et du support.

REMARQUE:

d'informations à propos d'un thème ou une fonction particulière sont disponibles

sur notre site Internet.

Étapes de base pour tester l'adhérence d'un revêtement à l'aide du testeur

d'adhérence PosiTest:

Dans tout ce manuel, le symbole indique que davantage

Allez à l'adresse : www.defelsko.com/manuals

1. Préparation du plot et du revêtement

Le plot et le revêtement sont nettoyés et abrasés (voir la page 4)

2. Application de la colle et du plot

La colle est préparée et appliquée sur le plot. Le plot est ensuite collé sur

la surface revêtue. Laisser sécher la colle (voir la page 4)

3. Séparation de la zone testée - Étape optionnelle

La zone du revêtement à tester est séparée sur le pourtour du plot par

découpe ou perçage. (voir la page 5)

4. Test d'arrachement

a) PosiTest AT-M (manuel) (voir la page 6)

b) PosiTest AT-A (automatique) (voir la page 8)

5. Analyse des résultats d'essai

Le plot et le revêtement sont examinés et évalués pour déterminer la nature

du défaut de revêtement. (voir la page 10)

6. Enregistrement des valeurs d'arrachement - Étape optionnelle

La mémoire interne du PosiTest AT est en mesure de stocker la pression

d'arrachement maximum, la vitesse d'arrachement, la durée de l'essai et la

taille du pot pour un maximum de 200 essais d'arrachement. (voir la

page10)

Page 3

Page 36

Étape 1: préparation du plot et du revêtement

Étape 1: préparation du plot et du revêtement

Préparation du plot

1. Pour éliminer l'oxydation et les contaminants, placer la pastille abrasive

fournie sur une surface plane et frotter la base du plot 4 à 5 fois avec la

pastille.

2. Au besoin, éliminer les résidus du procédé d'abrasion à l'aide d'un morceau

de tissu sec ou d'une serviette en papier.

Préparation du revêtement

1. Frotter légèrement le revêtement à l'aide de la pastille abrasive fournie.

REMARQUE:

cette méthode ne doit être utilisée que lorsque nécessaire pour éliminer les

contaminants de la surface, ou lorsque la force de liaison entre la colle et le

revêtement est insuffisante pour le test d'arrachement.

2. Afin de faciliter la liaison entre le plot et le revêtement, dégraisser la surface

du revêtement à tester avec de l'alcool ou de l'acétone de manière à éliminer

toute huile, humidité ou poussière.

REMARQUE:

seurs ou les adhésifs n'altèrent pas les propriétés du revêtement. Tester en appliquant une petite quantité de dégraisseur ou de colle sur un échantillon et observer les effets.

Étape 2: application de la colle et du plot

Étape 2: application de la colle et du plot

comme l'abrasion du revêtement peut présenter des défauts,

veiller à ce que les autres techniques d'abrasion, les dégrais-

Choix de la colle

La colle fournie dans le kit de test d'adhérence par arrachement PosiTest a été

sélectionnée en raison de sa polyvalence. Cette colle a un impact minime sur une

grande variété de revêtements et présente une résistance à la traction qui

dépasse les performances maximales du système de pression en conditions

idéales. D'autres colles peuvent être préférées sur la base du temps de prise, du

type de revêtement, de la température de service et de la résistance à l'arrachement. Les cyanoacrylates (super glues) à pris rapide peuvent s'avérer suffisantes

pour les surfaces peintes, mais les colles époxy bi-composant sont préférées

pour les revêtements poreux ou irréguliers.

Application du plot

1.

Mélanger la colle conformément aux instructions du fabricant et en appliquer

une couche uniforme sur la base du plot (environ 2 à 4 mils ou 50 à 100 pour

de meilleurs résultats)

2. Fixer le plot sur la zone de test préparée du revêtement.

REMARQUE:

un moyen permettant de maintenir le plot en place durant la prise peut s'avérer

nécessaire, comme du ruban adhésif.

Si la surface du revêtement à tester est en surplomb ou verticale,

Page 4

Page 37

3. Appuyer doucement sur le plot pour évacuer l'excès de colle. Ne pas vriller ou

glisser le plot d'avant en arrière sur le revêtement car cela risque de générer

des bulles d'air.

4. Éliminer précautionneusement l'excès de colle du bord du plot à l'aide des

écouvillons en coton fournis.

5. Laisser prendre la colle conformément aux instructions du fabricant.

REMARQUE:

son plus forte en séchant avec de la chaleur. De la même manière, les environnements froids peuvent entraîner des temps de prise plus longs et une force de

liaison plus faible.

Étape 3: séparation de la zone testée

Étape 3: séparation de la zone testée

La décision de découper un plot dépend de la norme, des spécifications ou de

l'accord contractuel avec lequel le test doit se conformer. L'objectif principal de

la découpe du revêtement est d'isoler une zone de test d'un diamètre donné.

Lorsque la décision de découpe dans le revêtement a été prise, il est

recommandé de couper complètement à travers le support. Il est au minimum

conseillé de couper précautionneusement l'excès de colle au moment du

processus d'application du plot. Habituellement, cela permet d'empêcher qu'une

grande surface de revêtement se soit arrachée du support, ce qui nécessiterait

une pression d'arrachement plus élevée.

La plupart des colles sèche plus rapidement et fournit une liai-

Instructions de découpe

1.

Découper le revêtement autour du plot à l'aide de l'outil de coupe fourni,

tout en éliminant l'excès de colle.

2. Éliminer les débris produits par le processus de découpe.

REMARQUE:

- La découpe peut induire des défauts à la surface du revête

ment comme des microfissures qui risquent d'altérer les résul

tats du test.

-Pour les revêtements présentant une forte liaison latérale, il

est recommandé de découper complètement le revêtement jusqu'au

support.

Gabarit de perçage

Un gabarit de perçage optionnel peut s'avérer très utile lorsque les revêtements à tester

sont très épais.

Page 5

Page 38

Étape 4a: test d'arrachement

Étape 4a: test d'arrachement

(PosiTest AT-M manuel)

LCD

Levier de

l'actionneur

Bas

L'ensemble

actionneur

Le couplage rapide

Le PosiTest A T-M est mis sous tension et affiche des traits interrompus lorsque le

bouton est pressé. Pour économiser la batterie, l'instrument est mis hors

tension après 5 minutes d'inactivité.

USB port

Le levier de la pompe

Pompe

Guide rapide

(1) Ouvrir complètement la soupape de décharge (rotation dans le sens

inverse des aiguilles d'une montre)

(2) Raccorder l'actionneur au plot

(3) Fermer complètement la soupape de décharge de pression (rotation

dans le sens des aiguilles d'une montre)

(4) Zéro - Presser le bouton zéro

(5) Pomper la pression dans le système jusqu'à ce que le plot arrache le

revêtement.

1. Vérifier que la soupape de décharge de pression de la pompe est

complètement ouverte. (Rotation dans le sens des aiguilles d'une montre)

OUVRIR

FERMER

2. Pousser le levier de l'actionneur complètement dans l'ensemble actionneur. Placer

l'ensemble actionneur sur la tête du plot et fixer le couplage rapide sur le dit plot via les

perçages de l'ensemble actionneur. Lever ensuite le couplage rapide. Libérer le couplage

rapide lorsque la tête du plot est complètement engagée.

Page 6

Page 39

3. Fermer complètement la soupape de décharge de pression de la pompe.

(Rotation dans le sens des aiguilles d'une montre)

REMARQUE:

Comme requis, vérifier et ajuster la taille du plot en

pressant le bouton . Sélectionner l'unité de pression en pressant

le bouton L'instrument conservera ces ajustements même

après avoir pressé le bouton

4.

Mettre l'instrument à zéro AVANT tout pompage en pressant le bouton

Ceci prépare l'instrument pour la prochaine lecture en effaçant l'afficheur

et en remettant l'instrument à zéro (réinitialisation).

5. Amorcer la pompe jusqu'à ce que la lecture affichée approche la pression

d'amorçage. La pression d'amorçage correspond au point de départ du calcul et

de l'affichage de l'intensité nominale d'arrachement par l'instrument. Il s'agit

également de la pression à laquelle la fonction de mémorisation des mesures est

activée. Les pressions d'amorçage pour chaque diamètre de plot différent sont:

10 mm 400 psi 2.8 MPa

14 mm 200 psi 1.4 MPa

20 mm 100 psi 0.7 MPa

50 mm 50 psi 0.4 MPa

REMARQUE:

d'amorçage, retourner le levier de la pompe en position haute puis exécuter une

course simple à l'intensité nominale d'arrachement souhaitée jusqu'à ce que

l'actionneur sépare le plot du revêtement.

Pour des résultats optimums, et avant de dépasser la pression

6. Ouvrir la soupape de décharge et retirer le plot de l'ensemble actionneur.

7. Les mesures peuvent être mises en mémoire en pressant le bouton

(page 10).

Dépannage (PosiTest AT-M)

Affichage numérique figé sur une valeur basse

Le testeur utilise une chute soudaine de pression de l'actionneur comme

indication de l'arrachement du plot de la surface. Le test s'arrête et la pression la

plus élevée reste affichée à l'écran pour une visualisation et un enregistrement

aisés. Le fait de pomper la pression trop rapidement au début du test peut

entraîner une brusque impulsion de pression, trompant le testeur en lui faisant

croire que le test est terminé. Si cela se produit, redémarrer le test en ouvrant la

soupape de décharge de pression, en la refermant puis en pressant le bouton

. Voir l'Étape 5 ci-dessus pour de plus amples informations.

Page 7

Page 40

Étape 4b: test d'arrachement

Étape 4b: test d'arrachement

(PosiTest AT-A Automatique)

LCD

USB port

AC Adapteur Port

(Intégrées charges

et instrument des pouvoirs)

Guide rapide

(1).Raccorder l'actionneur au plot

(2) Mettre l'appareil sous tension en pressant le

bouton

(3) Vérifier les unités de mesure, le diamètre du plot

et l'intensité nominale d'arrachement

(4) Lire l'instrument avec le bouton

(5) Tester avec le bouton

Flexible

Levier de

l'actionneur

L'ensemble

actionneur

Le couplage

rapide

1. Placer l'ensemble actionneur sur la tête du plot et fixer le couplage rapide au

plot via les perçages de l'ensemble actionneur. Lever ensuite le couplage rapide.

Libérer le couplage rapide lorsque la tête du plot est complètement engagée.

2. Presser le bouton pour mettre l'instrument sous tension. L'instrument

est mis hors tension après 5 minutes d'inactivité ou en pressant le bouton

pendant 2 secondes.

3. Vérifier les réglages:

(a) Vérifier les unités de mesure affichées. Changer d'unité avec le bouton

si nécessaire.

(b) Vérifier la taille du plot avec le bouton et la changer si nécessaire.

(c) Vérifier l'intensité d'arrachement avec le bouton et la changer si

nécessaire. Les pressions nominales sélectionnables par l'utilisateur suivantes

sont disponibles:

Taille de plot Pressions en PSI Pression en MPa

10 mm 125, 200, 400, 600, 725 1.00, 2.00, 3.00, 4.00, 5.00

14 mm 60, 100, 200, 300, 360 0.40, 0.70, 1.40, 2.00, 2.50

20 mm 30, 50, 100, 150, 180 0.20, 0.30, 0.70, 1.00, 1.20

50 mm 5, 8, 16, 24, 30 0.04, 0.08, 0.12, 0.16, 0.20

Page 8

Page 41

4. Presser sur le bouton pour préparer l'instrument. Cette opération

prépare le PosiTest en vue du test en effaçant le contenu de l'affichage et en

remettant à zéro l'instrument.

5. Presser de nouveau sur le bouton pour démarrer le test. Ce dernier

se déroule en 4 étapes qui surviennent automatiquement:

Étape 1. Initiation - l'affichage affiche un "0" clignotant.

Étape 2. Amorçage - la pompe applique une pression initiale sur le plot.

Étape 3. Test - lorsque la pression d'amorçage a été atteinte (voir l'étape 5 en

page 7), l'instrument commence à calculer et à afficher la force d'arrachement

spécifiée par l'utilisateur. L'accumulation de pression s'interrompt lorsque le plot

est arraché de la surface ou lorsque le bouton est pressé.

Étape 4. Retrait - la valeur de pression d'arrachement maximum clignote sur

l'affichage alors que la pompe rétracte l'actionneur. Les boutons sont verrouillés

durant toute cette étape.

ATTENTION: afin d'éviter toute blessure, garder les doigts à distance du

couplage rapide et de l'actionneur jusqu'à ce que le test d'arrachement soit

terminé et que l'actionneur soit complètement rétracté. Presser sur le

bouton pour arrêter le test d'arrachement à tout moment.

6. Retirer le plot de l'ensemble actionneur.

7. Les mesures peuvent être enregistrées dans la mémoire en pressant le

bouton (page 10).

Tous les réglages et résultats de test en mémoire sont conservés après la mise

hors tension.