DeFelsko PosiTector UTG, PosiTector UTGC, PosiTector UTG-STD, PosiTector UTG-ME, PosiTector UTG-CA Calibration Procedure

...Page 1

Management Procedure 2585

Revision: F

Date Issued: Feb 21, 2003

Date Revised: June 10, 2019

Calibration Procedure

DeFelsko Corporation

PosiTector UTG, UTG-STD, UTG-ME, UTG-

C, UTG-CA, UTG-CLF, UTG-CX, UTG-M &

UTG-P

Ultrasonic Thickness Gage

Table of Contents

1 Introduction and UUC Performance Requirements ............................................................................................ 2

Table 1-1 Measurement Ranges ......................................................................................................................... 2

2 Measurement Standards and Support Equipment Performance Requirements .................................................. 2

Table 2-1 UUC Accuracy Requirements and Description ................................................................................. 2

Table 2-2 Minimum Use Specification .............................................................................................................. 3

Table 2-3 Actual Equipment Specification ........................................................................................................ 3

Table 2-4 Calibration Environmental and Warm Up Requirements .................................................................. 3

3 Preliminary Operations ....................................................................................................................................... 3

4 Calibration Process ............................................................................................................................................. 4

5 Performance Requirements ................................................................................................................................ 5

Table 5-1 Performance Requirements and Calibration Data for PosiTector UTG ............................................. 5

Management Procedure Change Notice ........................................................................................................................ 6

Management Procedure 2585 Rev. F

1

Page 2

1 Introduction and UUC Performance Requirements

1.1 This procedure describes the calibration of the PosiTector UTG Ultrasonic Thickness

Gage and probe.

Table 1-1 Measurement Ranges

Models Measurement Range * Velocity Range

UTG, UTG-STD, UTG-C

UTG-CA, UTG-CLF, UTG-CX

UTG-M & UTG-ME

UTG-P

* The actual measurement range of the system depends on the material being measured.

Ranges shown are based on carbon steel.

The unit being calibrated will be referred to as the UUC (unit-under-calibration).

2 Measurement Standards and Support Equipment Performance Requirements

2.1 The UUC accuracy requirements are based upon the published UUC performance

specifications.

2.2 Minimum-Use-Specifications are the minimum test equipment specifications required to

meet all the UUC accuracy requirements and the test uncertainty ratio applied.

2.3 The uncertainty ratio applied in this Calibration Procedure is 4:1 unless otherwise stated.

The UTG-P has an uncertainty ratio of 2:1.

Table 2-1 UUC Accuracy Requirements and Description

Model Range

UTG, UTG-STD, UTG-C

UTG-CA, UTG-CLF, UTG-CX

(0.040 - 5.000”)

1.0 - 125 mm

(0.040 - 5.000”)

2.5 - 125 mm

(0.100 - 5.000”)

0.200 – 12.000 mm

(0.008 – 0.472”)

1.0 - 125 mm

1,250 to 10,000 m/s

(0.0492 to 0.3930 in/µs)

Performance

Specifications Test Method

± 0.03 mm

(± 0.001”)

Compare to

Step Blocks

UTG-M & UTG-ME

UTG-P

Management Procedure 2585 Rev. F

2.5 - 125 mm

(0.100 - 5.000”)

0.200 – 12.000 mm

(0.008 – 0.472”)

± 0.03 mm

(± 0.001”)

± 0.010 mm

(± 0.0004”)

Compare to

Step Blocks

Compare to

Step Blocks

2

Page 3

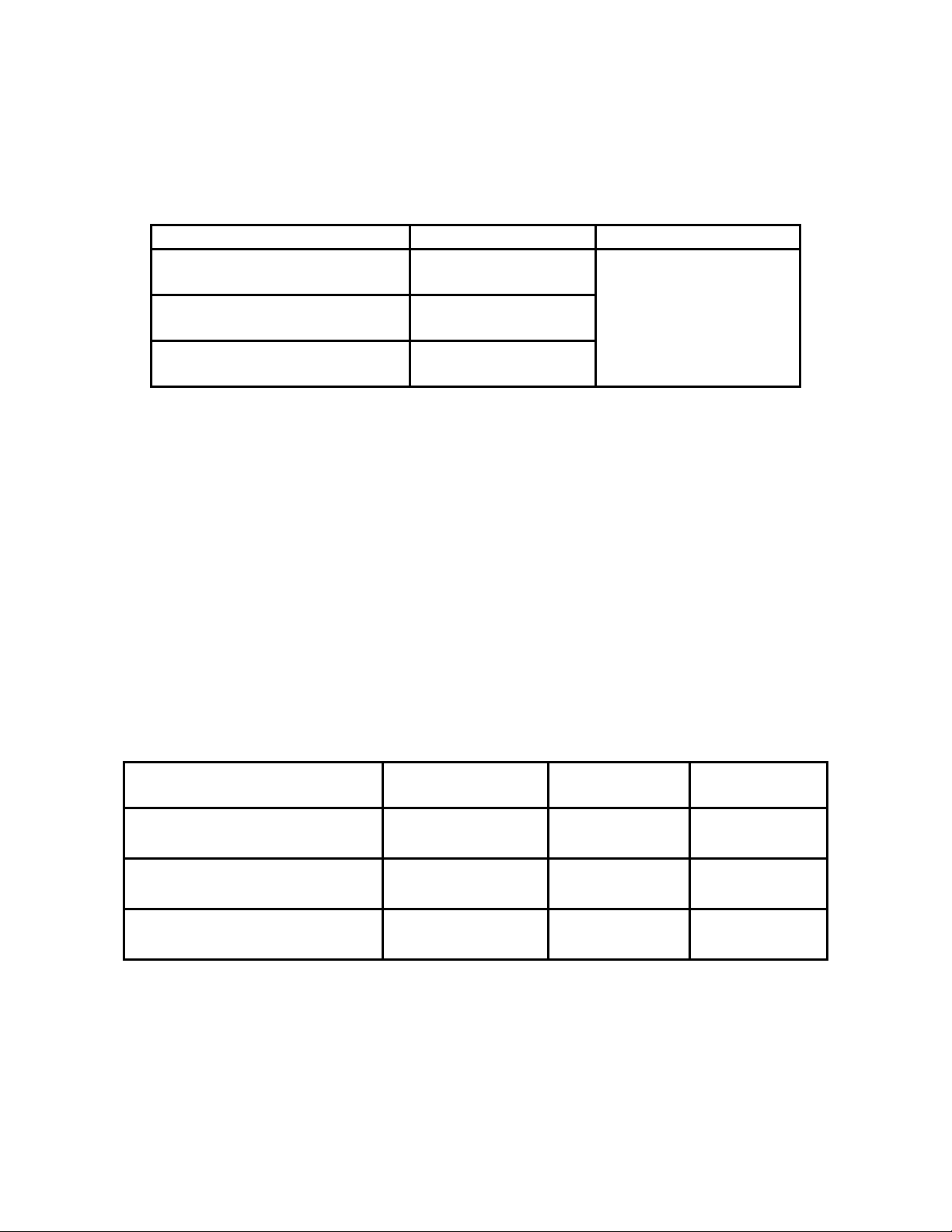

Table 2-2 Minimum Use Specification

Model Range Accuracy

UTG, UTG-STD, UTG-C

UTG-CA, UTG-CLF, UTG-CX

UTG-M & UTG-ME

UTG-P

Table 2-3 Actual Equipment Specification

UUC Model Equipment

Generic Name

UTG, UTG-STD, UTG-C

UTG-CA, UTG-CLF,

UTG-CX, UTG-M &

UTG-ME

UTG-P Step Blocks

Caution: The instructions in this Calibration Procedure relate specifically to the equipment and

conditions listed in this section. If other equipment is substituted, the information and

instructions must be interpreted accordingly.

Table 2-4 Calibration Environmental and Warm Up Requirements

Measurement Standards & Support Equipment

Environmental Requirements:

Measurement Standards & Support Equipment

Warm-up and Stabilization Requirements:

Step Blocks

Actual Equipment Specifications Manufacturer &

2.50 - 12.50 mm

(0.100 - 0.500”)

(0.020 – 0.098”)

1.0 - 125 mm

(0.040 - 5.000”)

2.5 - 125 mm

(0.100 - 5.000”)

0.200 – 12.000 mm

(0.008 – 0.472”)

Range Accuracy

± 0.005 mm

(± 0.00020”)

0.50 - 2.50 mm

Temperature: 23 ± 5° C.

Relative Humidity: Less than 95%

None

± 0.005 mm

(± 0.00020”)

± 0.008 mm

(± 0.00025”)

± 0.008 mm

(± 0.00025”)

± 0.003 mm

(± 0.0001”)

Model Applicable

PH Tool Custom

5 Step Block

PH Tool Custom

5 Step Block

3 Preliminary Operations

Note: Review the entire document before starting the calibration process.

3.1 Visual Inspection

3.1.1 Visually inspect the UUC for:

• Probe tip wear or damage

• Other damage or wear

• Proper identification

3.1.2 Damage or excess wear shall be repaired prior to beginning the calibration process.

3.2 Gage Reset

Management Procedure 2585 Rev. F

3

Page 4

Note: Please refer to UUC instruction manual for menu navigation instructions, details

on features and operating instructions (i.e. required amount of couplant and pressure).

3.2.1 For bodies with serial number after 700,000; when the unit is powered down,

simultaneously hold the “+” and middle buttons until the rest symbol appears. All other

bodies press and hold the “+”.

3.2.2 All probes except UTG-P: After reset, select the Main Menu “Cal Settings” function and

then “Zero”. Follow the on screen prompt to measure the zero plate provided with the

probe. After zeroing, verify the probe on the thinnest and thickest steps of the 5-step

block. Allowable tolerances following zeroing are ± 0.05 mm (0.002”).

3.2.3 UTG-P probes: Verify the probe face is clean. After reset, select the Main Menu “Cal

Settings” function and then “Zero”. Hold the probe in air and follow the on screen

prompt. After zeroing, verify the probe on the thinnest and thickest steps of the

appropriate 5-step block. Allowable tolerances following zeroing are ± 0.05 mm

(0.002”).

4 Calibration Process

Note: Whenever the test requirement is not met, verify the results of each test and take

corrective action before proceeding.

4.1 Review the Performance Requirements Table 5-1.

4.2 Select the 2-Pt Adjust feature from the Cal Settings section of the menu. Perform a two-

point calibration using the thinnest and thickest of the steps on the appropriate 5-step

block. This will adjust the sound velocity of the gage and the zero reference to the

material of the step block.

4.3 Using the appropriate Certificate of Calibration template for the UUC, record the

thickness from the Reference Standard label.

4.4 Determine the allowed range of readings using the calculation methods shown in column

A of table 5-1.

4.5 Use the UUC to take measurements on each step of the 5-step block. Verify that the

readings are within the allowable limits and record the readings on the Certificate of

Calibration.

Management Procedure 2585 Rev. F

4

Page 5

5 Performance Requirements

Note: The technician will collect the data needed to complete column B of Table 5-1. Do

not write in this procedure.

Table 5-1 Performance Requirements and Calibration Data for PosiTector UTG

Reference

Thickness

(mm)

A B

For imperial/metric readings convert using 1” = 25.4 mm

n For UTG-P: Calculation: A - 0.010 mm

For all other probes: Calculation: A - 0.03 mm

Y For UTG-P: Calculation: A + 0.010 mm

For all other probes: Calculation: A + 0.03 mm

Min. Reading

Allowedn

(mm)

Max. Reading

AllowedY

(mm)

Actual Gage

Measurement

(mm)

Management Procedure 2585 Rev. F

5

Page 6

Management Procedure Change Notice

Procedure Number: MP 2585

Revision Level: F

Date of Change: June 10 , 2019

Title: Calibration Procedure for PosiTector UTG, UTG STD,

UTG-C, UTG-CA, UTG-CLF, UTG-CX, UTG-M, UTGME & UTG-P

Reason for Change:

• New products

Description of Change:

• Updated Table 1-1

• Retitled and updated tables 2-1, 2-2 & 2-3

• Re-wrote section 2

• Re-wrote Sections 1.1 and 3.2.2.

• Added section 3.2.3

• Updated calculations in table 5

I confirm I have read and understand the procedure and the change described above.

Printed Name Signature Date

Management Procedure 2585 Rev. F

Management Form 0010.02-05/1998

6

Loading...

Loading...