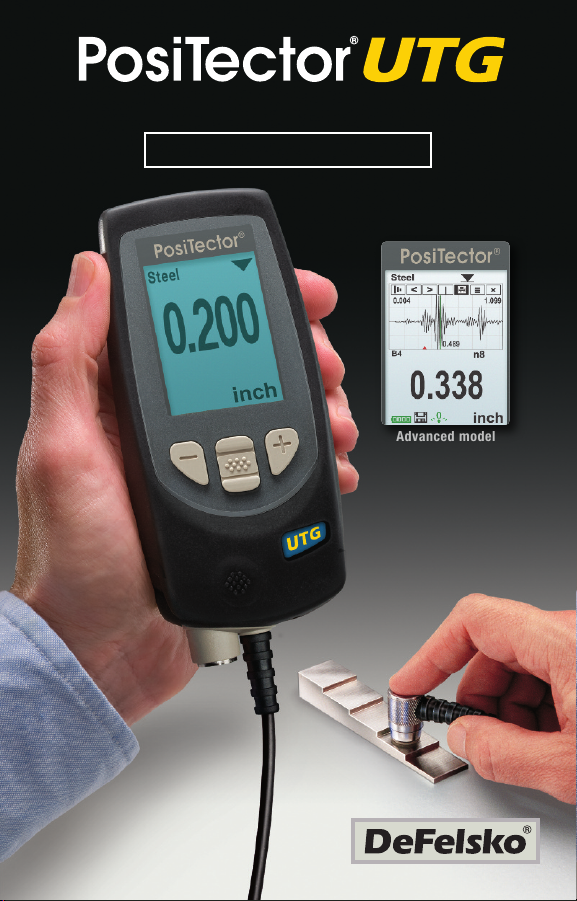

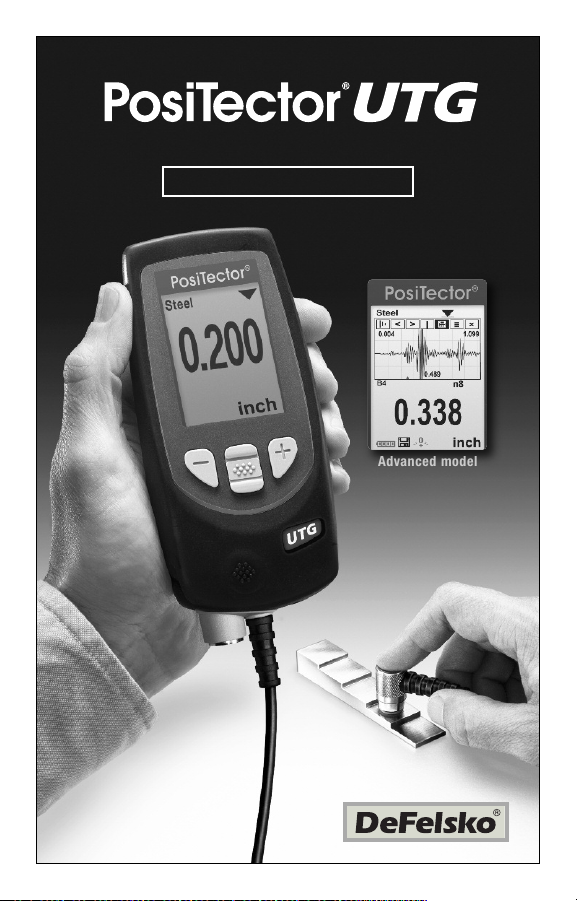

Page 1

Ultrasonic Thickness Gage

Quick Guide v. 3.0

Adv ance d m odel

Page 2

Introduction

Introduction

Th

e P

os

iTector

UTG i

s

a

h

a

nd-he

l

d Ul

tras

oni

c

Thi

c

k

ne

s

s

Ga

tha

t

u

s

es

th

e

n

o

n-d

es

tru

c

ti

v

e

ul

tras

o

ni

c

p

ul

s

e-e

c

ho

m

eas

ure

th

e wal

l

th

i

c

k

n

e

s

s

of a

wi

d

e v

c

ons

i

s

ts

of a b

od

y

(S

ta

n

dard

o

r

A

s

z

truc

s

d

e

s

th

e

ti

o

n m

UTGM

, s

e

e pg

. 2).

Thi

s

Qu

i

c

k

Gui

d

e

s

u

m

m

m

e

nt. Down

www

The PosiTector UTG powers-up when the center navigation

button is pressed. To preserve battery life, the instrument

powers down after approximately 5 minutes of no activity. All

settings are retained.

1. Remove the protective rubber cap from the probe.

2. Power-up Gage by pressing the center navigation button.

3. Zero the probe (see pg. 6)

4. Select the correct velocity of sound (see pg. 7)

5. Measure the part (see pg. 3)

l

oa

fel

s

k

d the ful

o

.c

om

.d

e

ari

l

i

n

/m

anual

Quick Start

Quick Start

v

bas

an

an

ari

c

ed

) a

i

c

func

u

al

a

t:

e

n

ti

ty

of m

d

p

o

ns

pri

ro

be (

o

f

n

a

teri

UTGC

th

e

g

c

i

p

l

e

al

s

.

i

ns

tru

e

to

It

o

r

-

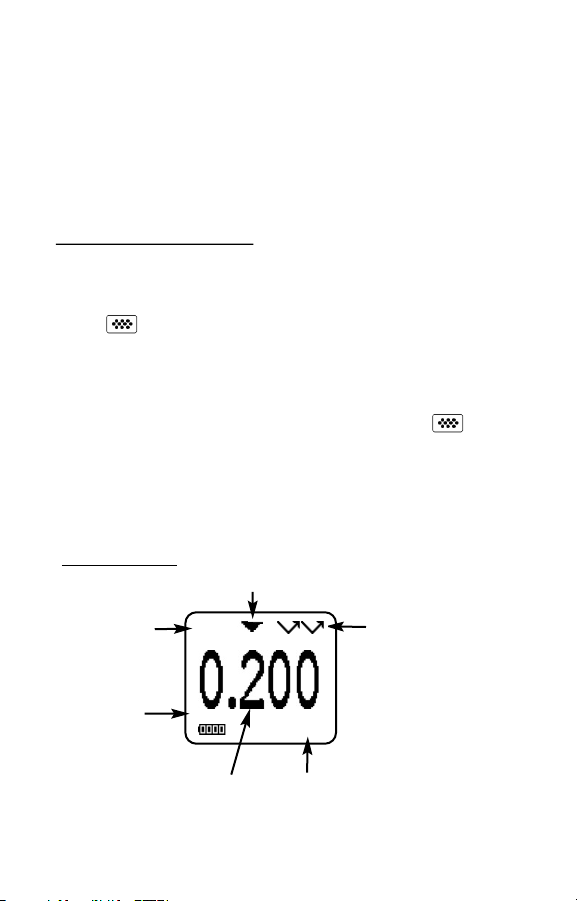

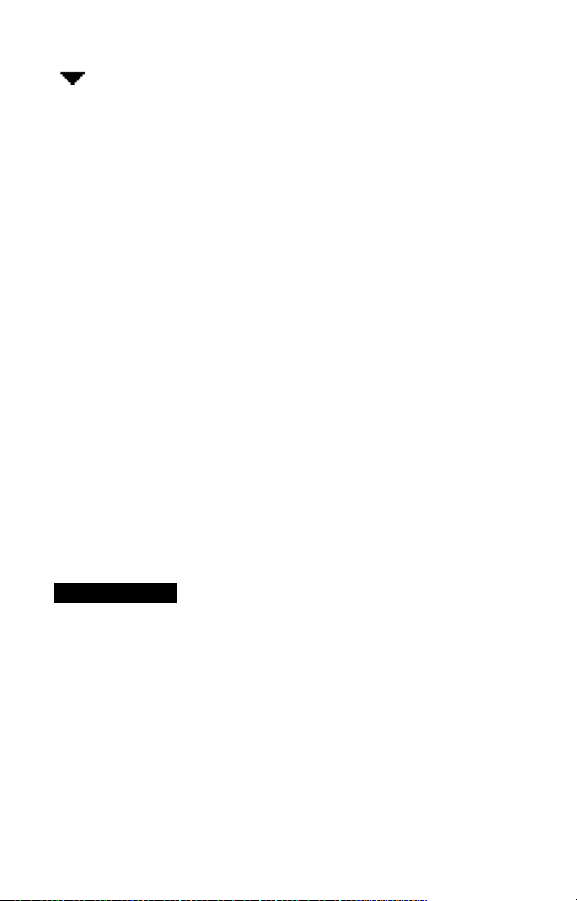

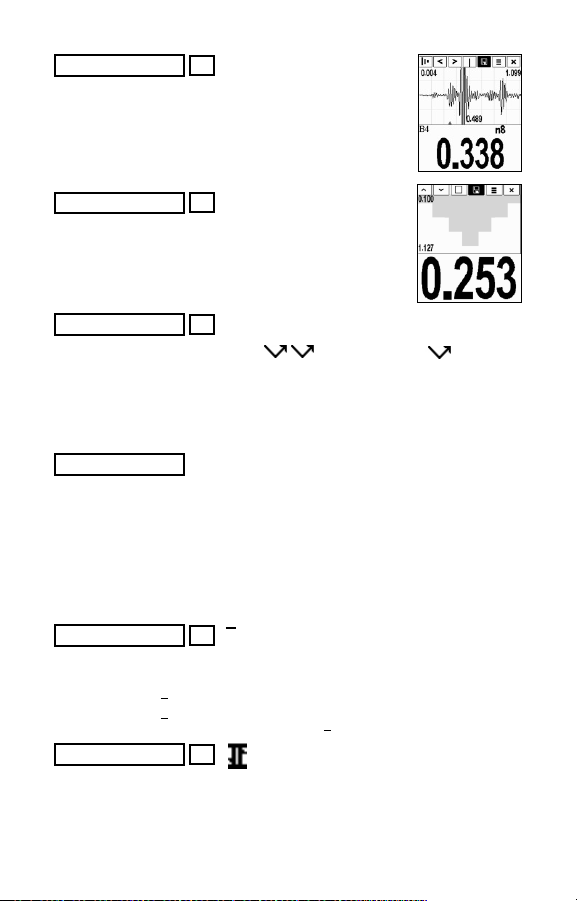

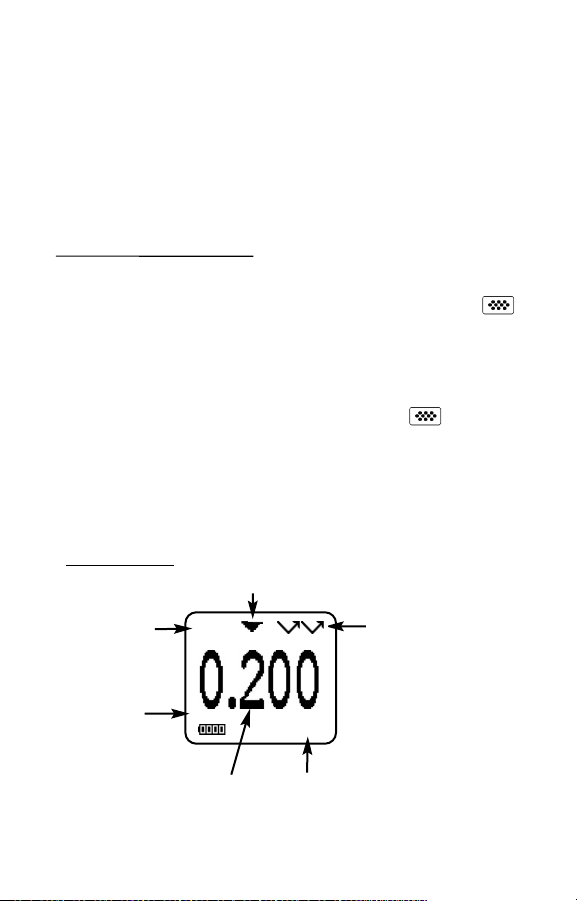

Typical Display

Currently

selected

material

Battery

Icon

The Coupled Symbol appears when the

probe is ultrasonically connected with a

surface.

Steel

Current

Measurement

inch

Unit of

Measurement

Measurement

Mode currently set

to multiple-echo

(UTGM probe only)

1

Page 3

Probes

Probes

T

o

d

i

s

c

o

n

n

e

c

t

a

p

r

o

b

e

f

r

o

m

a

b

o

d

y

,

p

o

w

e

r

-

d

o

w

n

t

h

i

n

s

t

r

u

m

e

n

t

a

n

d

s

l

i

d

e

t

h

e

p

l

a

s

t

i

c

p

r

o

b

e

h

o

r

i

z

o

n

t

a

l

l

y

(

i

n

t

h

e

d

i

r

e

c

t

i

o

n

o

f

t

h

e

a

r

b

o

d

y

.

R

e

v

e

r

s

e

t

h

e

s

e

s

t

e

p

s

t

o

W

h

e

n

p

o

w

e

r

e

d

-

u

p

t

h

e

d

e

t

e

r

m

i

n

e

s

w

h

a

t

t

y

s

e

l

f

-

c

h

e

c

k

.

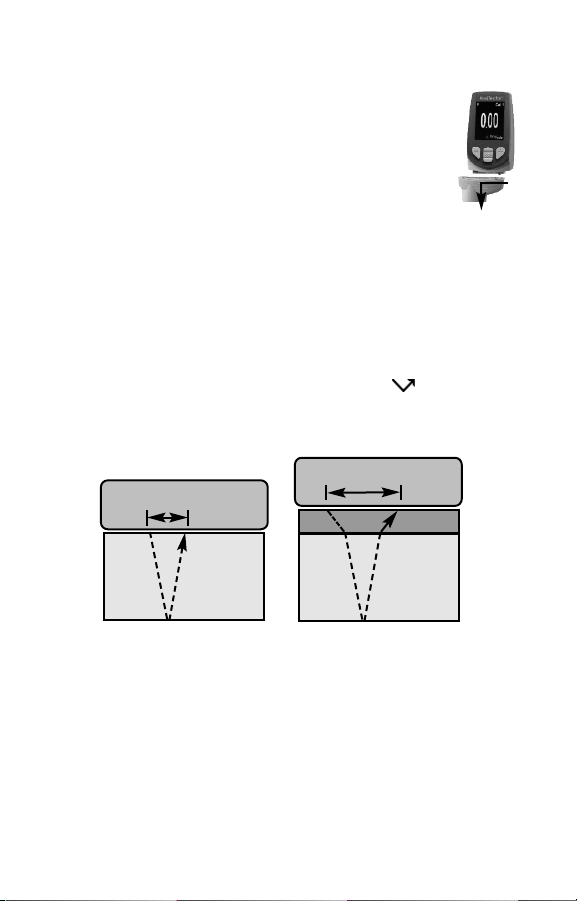

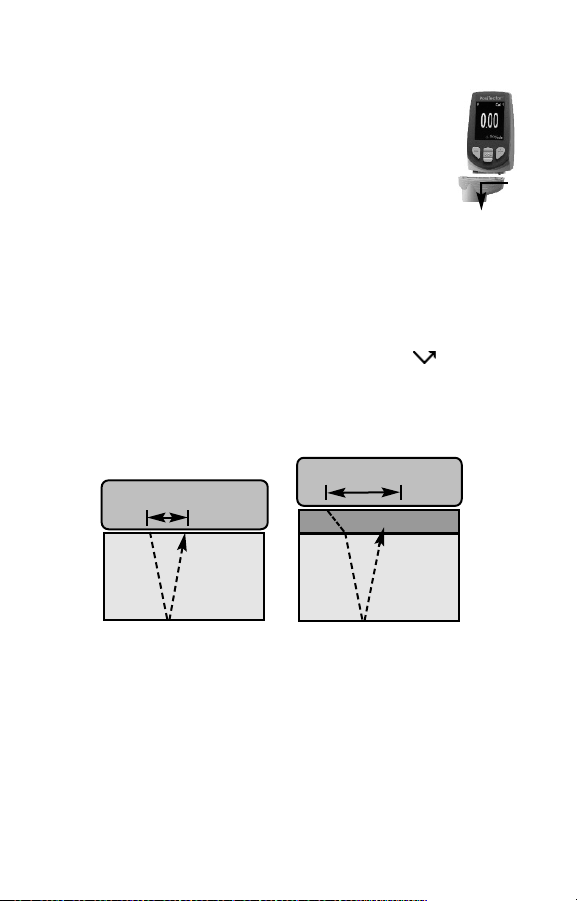

PosiTector UTG probes transmit an ultrasonic pulse into the

material to be measured. This pulse travels through the material

towards the other side. When it encounters an interface such as air

(back wall) or another material, the pulse is reflected back to the

probe. The time required for the pulse to propogate through the

material is measured by the Gage, represented as t1and t2 below.

PosiTector UTGC and UTGM (in single-echo mode) probes

determine thickness by measuring t1(uncoated) or t2 (coated),

dividing it by two and then multiplying by the velocity of sound for

that material (steel). See Figure 1.

Probe

p

t

1

P

e

o

f

p

r

o

r

a

t

t

a

c

h

a

o

s

i

T

e

c

t

b

e

i

s

a

t

t

Probe

c

o

w

)

a

w

a

y

n

e

w

p

r

o

o

r

a

u

t

o

a

c

h

e

d

a

n

t

2

o

n

f

r

b

e

m

d

n

e

c

o

m

.

a

t

i

c

d

o

e

coating

e

t

o

r

t

h

e

a

l

l

y

s

a

steel

Figure 1

For uncoated materials t1relates directly to material thickness.

When a material is coated the propagation time is increased and

is shown above as t

Coatings such as paint have a slower velocity of sound than that

of metal. Thus the single-echo technique will produce a thickness

result greater than the actual combined coating+metal thickness.

.

2

t

steel

t

>

1

2

2

Page 4

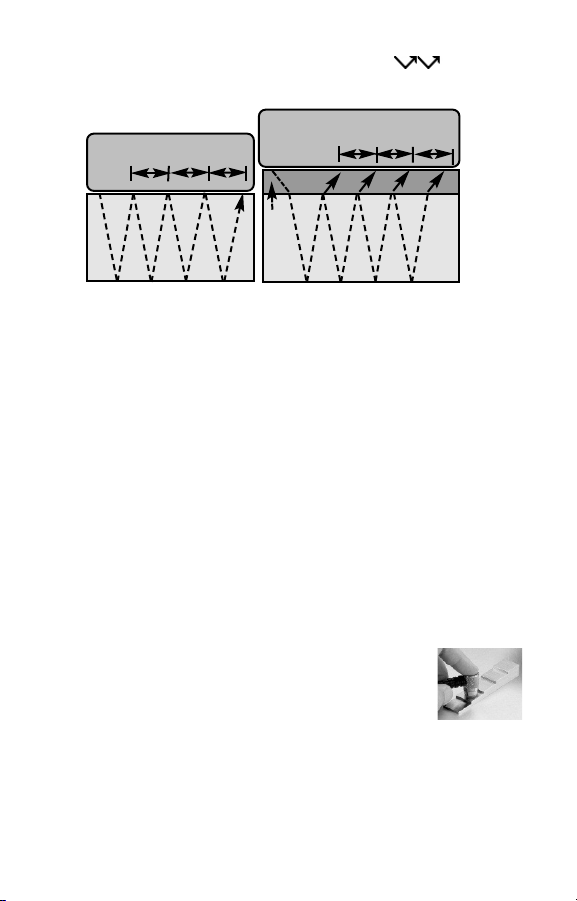

The PosiTector UTGM in multiple-echo mode determines

thickness by measuring the time between at least three consecutive back wall echoes.

t

t

t

1

Probe

2t3

t

Figure 2

Probe

g

tin

a

Co

1

t

2

3

steel

In the figure above, multiple-echo mode measures only the time

between echoes. Regardless of whether the steel is coated or not,

all times between echoes are the same. In multiple-echo mode

the Gage determines thickness by measuring t1+t2+t3, dividing it

by six and then multiplying by the velocity of sound for that material. The resultant thickness calculation made by the instrument is

therefore an accurate measurement of the steel thickness only,

disregarding the coating thickness.

The velocity of sound is expressed in inches per microsecond or

meters per second. It is different for all materials. For example,

sound travels through steel faster (~0.233 in/µs) than it travels

through plastic (~0.086 in/µs).

How to Measure

How to Measure

1. Remove rubber cap from probe. Couplant (glycol

gel - included) must be applied to the surface to be

tested to eliminate air gaps between the wear face

and the surface. A single drop of couplant is sufficient

when taking a spot measurement.

2. Place the probe flat on the surface. Use moderate pressure to

press against the top of the probe with the thumb or index finger.

3

Page 5

When the probe senses echoed ultrasound, a coupled symbol

will appear on the display and thickness values will be displayed. While the probe is coupled, the PosiTector UTG continually updates the display.

3. When the probe is removed from the surface, the last measurement will remain on the display.

Occasionally, excess couplant will remain on the probe when the

probe is lifted from the surface. This may cause the PosiTector

UTG to display a final measurement value different from those

observed when the probe was on the surface. Discard this value

and repeat the measurement.

Surface Conditions

Surface Conditions

Ultrasonic measurements are affected by the condition,

roughness and contour of the surface to be tested.

Measurement results may vary on coarse surfaces. Where

possible, it is recommended to seat the transducer on a smooth

flat surface that is parallel to the opposite side of the material.

On rough surfaces, the use of a generous amount of couplant

minimizes the surface effects and serves to protect the transducer

from wear, particularly when dragging the probe across a surface.

UTGM Probes:

(in multiple-echo mode) may occasionally be unable to give a

measurement result even when the "coupled" symbol appears.

Use additional couplant and lighter pressure on the probe when

measuring. Alternatively, laying a plastic shim on the surface with

couplant applied to both sides to simulate a painted surface will

help produce a steel-only thickness measurement (multiple-echo

mode). Switching the Gage to single-echo SE mode (see pg. 9)

will also help produce a steel-only thickness measurement.

On smooth, uncoated metal surfaces the Gage

4

Page 6

Calibration, Verification and Adjustment

Calibration, Verification and Adjustment

Three steps ensure best accuracy…

1.Calibration - typically done by the manufacturer or a qualified

lab. All probes include a Certificate of Calibration

2.Verification of Accuracy - as done by the user on known

reference standards such as calibration step blocks.

3.Adjustment - to a known thickness or sound velocity for the

material to be measured

Calibration

Calibration is the controlled and documented process of

measuring traceable calibration standards and verifying that the

results are within the stated accuracy of the Gage. Calibrations

are typically performed by the Gage manufacturer or by a certified

calibration laboratory in a controlled environment using a

documented process.

Verification

Gage accuracy can and should be verified using known reference

standards of the material to be tested.

Verification is an accuracy check performed by the user using

known reference standards. A successful verification requires the

Gage to read within the combined accuracy of the Gage and the

reference standards.

Adjustment

Adjustment, or Calibration Adjustment is the act of aligning the

Gage's thickness readings to match that of a known reference

sample. See Calibration Adjustment pg. 6.

5

Page 7

Cal Settings Menu

Cal Settings Menu

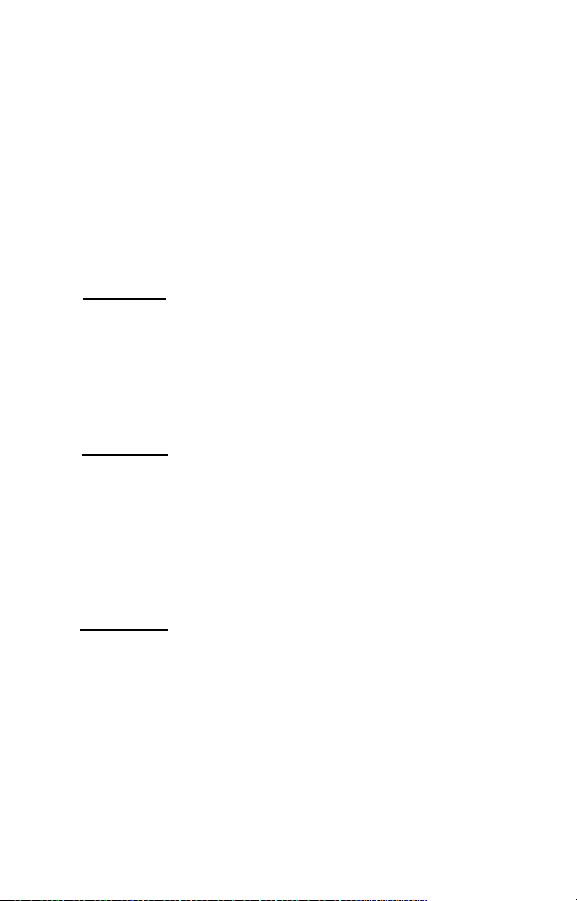

Zero

PosiTector UTG probes can be "zeroed" to compensate for tem-

perature and wear. This action is not required when operating in

multiple-echo mode (UTG M probes only) except when the instrument is new and after a Reset (pg. 8). However it ensures best

accuracy when operating in SE (single-echo) mode. Therefore it is

a good idea to "zero" the probe before each work shift and when

the temperature of the part changes. During zeroing, it does not

matter what the current velocity setting is.

1. Make sure the instrument is on and the probe is wiped clean.

2. Apply a single drop of couplant onto the zero plate located on

the underside of the probe connector. DO NOT apply couplant

directly onto the probe face.

3. Select the Zero menu option and follow the on-screen prompts.

Calibration Adjustment

The PosiTector UTG is factory calibrated. But in order for it to take

accurate thickness measurements of a particular material it must

be set to the correct sound velocity for that material. Be aware that

material composition (and thus its sound velocity) can vary from

stated tables and even between lots from a manufacturer.

Adjustment to a sample of known thickness of the material to be

measured ensures that the Gage is adjusted as close as possible

to the sound velocity of that specific material. Samples should be

flat, smooth and as thick as the maximum expected thickness of

the piece to be tested.

The PosiTector UTG allows four simple adjustment choices. All

four methods are based on the simple premise of adjusting the

sound velocity. The first three adjustment methods make 1-point

calibration adjustments to optimize the linearity of the PosiTector

UTG over small ranges. The fourth method makes a 2-point

calibration adjustment to allow for greater accuracy over a large

range.

6

Page 8

Thickness

The most common method of adjustment is to measure a sample

of known thickness. Select a reference standard of material as

close as possible in composition to the intended application. For

best results, the thickness of the reference standard should be

equal to or slightly greater than the thickness of the part to be

measured.

Material

If a known thickness of the material is not available, but the material is known, this quick adjustment allows the user to load one of

several preprogrammed material velocities.

Velocity

If the sound velocity for the test material is known, the Gage can

be adjusted to that specific sound velocity.

2 Pt Adjust

A 2-Point adjustment allows for greater accuracy while

simultaneously adjusting probe zero. Select two reference

standards as close as possible in composition to the intended

application. For best results, the thickness of the thicker reference

standard should be equal to, or slightly greater than the thickest

part to be measured. The thickness of the thinner reference

standard should be as close as possible to the lower end of the

expected measurement range.

Cal Lock

When checked, the icon appears and the current Cal settings

are “locked” to prevent further user adjustments. Uncheck to make

further adjustments.

7

Page 9

Setup Menu

Setup Menu

Reset

Reset (soft reset) restores factory settings and returns the

instrument to a known condition. The following occurs:

- All batches, stored measurements, images, and batch names

are erased.

- All calibration adjustments are cleared and returned to the

Gage’s factory calibration settings.

- Menu settings are returned to the following:

Memory = OFF

Statistics Mode = OFF

Hi Lo Alarm = OFF

Scan Mode = OFF

A Scan = OFF

B Scan = OFF

Cal Lock = OFF

Bluetooth = OFF

Display = None

SE Mode = OFF

Perform a more thorough Hard Reset by powering down the

instrument, waiting several seconds, then simultaneously holding

both the center and (+) buttons until the Reset symbol

appears. This returns the instrument to a known, “out-of-the-box”

condition. It performs the same function as a menu Reset with the

addition of:

- Bluetooth Pairing info is cleared.

- Menu settings are returned to the following:

Units = millimeter

Flip Display = Normal

Auto Sync = OFF

White on Black = OFF

Language = English

- Date and Time are not affected by either Reset.

NOTE:

Battery Type = Alkaline

Backlight = Normal

Bluetooth Streaming = OFF

USB Drive= ON

Scan

Normally, the PosiTector UTG takes a single spot measurement

at a rate of 6 readings per second while in contact with a surface.

When the probe is lifted, the last reading will remain on the display.

It is sometimes necessary to examine a larger region to locate the

thinnest point. When Scan is selected, the PosiTector UTG will

measure at a rate of 20 readings per second and display min/max

values.

8

Page 10

A Scan

A display in which the received pulse amplitude is

represented along y axis and the travel distance

of the ultrasonic pulse is represented along the x

axis.

(Advanced models only)

B Scan

A display in which a cross sectional profile of the

test material is represented.

SE Mode

Switches from multiple-echo to single-echo mode:

- To detect pits and flaws

- To increase the measurement range

- To obtain thickness measurements in circumstances where

multiple-echo can not

Battery Type

from a choice of “Alkaline”, “Lithium” or “NiMH” (Nickel-metal hydride

rechargeable). If NiMH is selected, the instrument will trickle charge the

batteries while connected via USB to a PC or optional AC charger (gage

must be powered ON). The battery state indicator icon is calibrated for the

selected battery type. No damage will occur if the wrong battery type is

selected. DeFelsko recommends eneloop (NiMH) rechargeable batteries.

Statistics

A statistical summary will appear on the display. Remove the last

measurement by pressing the (-) button. Press (+) to clear

statistics.

HiLo Alarm

Allows the Gage to visibly and audibly alert the user when

measurements exceed user-specified limits.

x - Average

↑

(Advanced models only)

(UTGM multiple-echo probes only)

Selects the type of batteries used in the instrument

Statistics Mode

Statistics Mode

x

- Maximum Value

σ - Standard Deviation

↓ - Minimum Value

9

Page 11

Memory Management

Memory Management

The PosiTector UTG can record readings in memory for printing

to the optional Bluetooth wireless printer, downloading or

synchronizing with PosiTector.net. Readings are time-stamped as

they are taken.

Scroll through display modes

(Advanced only)

Delete last reading

Access the Menu

Create a new batch

(Advanced only)

Restore brightness

after dimming

(Advanced only)

Standard models store up to 250 readings in one batch.

Advanced models store 100,000 readings in up to 1,000

batches. “New Batch” closes any currently opened batch and

creates a new batch name using the lowest available number. The

icon appears. New batch names are date stamped when they

are created.

NOTE:

This Quick Guide summarizes the basic functions of the

instrument. Download the full instruction manual at:

www.defelsko.com/manuals

Screen Capture

Press both (-)(+) buttons at any time to capture and save an image

copy of the current display. The last 10 screen captures are stored

in memory and can be accessed when connected to a computer

(see USB mass storage pg. 11).

Outputting Stored Readings

Outputting Stored Readings

USB mass storage - connect your PosiTector to a PC/Mac using

the supplied USB cable to access and print stored readings and

graphs. No software or internet connection required.

PosiTector.net - a free web-based application offering secure

centralized storage of thickness readings. Access your readings

from any web connected device. www.PosiTector.net

10

Page 12

Connect Menu

Sync Now

Immediately initiates synchronization with PosiTector.net when

connected (USB or Bluetooth) to an internet connected PC

running PosiTector Desktop Manager.

Auto SYNC

Allows the instrument to automatically synchronize with

PosiTector.net when initially connected to an internet connected

PC running PosiTector Desktop Manager.

Additional measurements added to memory while connected are

synchronized only when the USB cable is disconnected, then

reconnected or when Connect>Sync Now is selected.

USB Drive

The instrument uses a USB mass storage device class which

provides a simple interface to retrieve data in a manner similar to

USB flash drives, cameras or digital audio players.

NOTE:

cable. The batteries are not used and the body will not

automatically power down. If rechargeable (NiMH) batteries are

installed, the instrument will trickle charge the batteries.

Allows individual readings to be sent to a computer or compatible

device as they are taken using Bluetooth wireless technology.

See www.defelsko.com/bluetooth

Determines if a software update is available for your instrument.

Must be connected to an internet connected PC running

PosiTector Desktop Manager. See www.defelsko.com/update

NOTE:

When connected, power is supplied through the USB

Bluetooth

Updates

The instrument may perform a Hard Reset (pg. 8)

Connect Menu

(Advanced models only)

11

Page 13

Returning for Service

Returning for Service

Before returning the instrument for service…

1.Install new or newly recharged batteries in the proper alignment

as shown within battery compartment.

2.Examine the probe tip for dirt or damage.

3.Perform a Hard Reset (pg. 8) and a Zero (pg. 6)

If you must return the instrument for service, describe the problem

fully and include measurement results, if any. Be sure to also

include the probe, your company name, company contact,

telephone number and fax number or email address.

Website: www.defelsko.com/support

Limited Warranty, Sole Remedy and Limited

Limited Warranty, Sole Remedy and Limited

Liability

Liability

DeFelsko's sole warranty, remedy, and liability are the express

limited warranty, remedy, and limited liability that are set forth on

its website: www.defelsko.com/terms

www.defelsko.com

© DeFelsko Corporation USA 2012

This manual is copyrighted with all rights reserved and may not be reproduced or transmitted, in whole

or part, by any means, without written permission from DeFelsko Corporation.

DeFelsko and PosiTector are trademarks of DeFelsko Corporation registered in the U.S. and in other

countries. Other brand or product names are trademarks or registered trademarks of their respective

holders.

Every effort has been made to ensure that the information in this manual is accurate. DeFelsko is not

responsible for printing or clerical errors.

All Rights Reserved

12

Page 14

Ultrasonic Thickness Gage

Guia rápida v. 3.0

Adv ance d m odel

Page 15

Introducción

Introducción

El

Posi

Tect

or

UTG

es

un

m

edi

dor

de

espesor

es

ul

t

r

asóni

por

t

át

i

l

que ut

i

l

i

m

edir

el

m

at

er

i

al

una sonda (

Est

a guí

Descar

gue el

www.

def

El PosiTector UTG se enciende al pulsar el botón central .

Para ahorrar energía, el equipo se apagará tras unos 5 minutos

de inactividad. Se conservarán todas las configuraciones.

1. Retire el tapón protector de goma de la sonda.

2. Encienda el Medidor pulsando el botón central .

3. Ajuste a cero la sonda (consulte pág. 6)

4. Seleccione la velocidad correcta de sonido (consulte pág. 7)

5. Mida la pieza (consulte pág. 3)

Pantalla típica

Selección

de material

actual

Icono

batería

za un pr

espesor

es.

Est

á f

UTGC o UTGM

a r

ápi

da r

m

anual

el

sko.

com

i

nci

pi

de

or

m

esum

de i

/

m

anual

El símbolo de acoplamiento aparecerá

cuando la sonda esté correctamente colocada y sea posible la medición por ultrasonido.

Acero

o no dest

paredes

ado por

un cuer

,

consul

e l

as f

unci

nst

r

ucci

s

Inicio rápido

Inicio rápido

pulgadas

r

uct

de

una

po (

t

e pág.

ones bási

ones en:

i

vo i

m

pul

am

St

andar

2)

cas del

Modo de medición

actualmente configurado como multieco

(sólo sonda UTGM)

so/

plia

vari

d o Advanced)

.

equi

eco par

edad

po.

co

de

a

y

Medida

actual

Unidad de

medida

1

Page 16

Sondes

Sondes

P

a

r

a

s

e

p

a

r

a

r

l

a

s

o

n

d

a

d

e

l

c

u

e

r

p

o

,

a

p

a

g

u

e

e

l

e

q

u

i

p

o

y

t

i

r

e

d

e

c

o

n

e

c

t

o

r

d

e

p

l

á

s

t

i

c

o

d

e

l

a

s

o

n

d

a

e

n

e

l

p

l

a

n

o

h

o

r

i

z

o

d

i

r

e

c

c

i

ó

n

i

n

d

i

c

a

d

a

p

o

r

l

a

f

l

e

c

h

a

)

,

s

e

p

a

r

I

n

v

i

e

r

t

a

l

o

s

p

a

s

o

s

p

a

r

a

c

o

n

e

c

t

a

r

u

C

u

a

n

d

o

s

e

e

n

c

i

e

n

d

e

,

e

l

P

o

s

i

T

e

c

t

e

l

t

i

p

o

d

e

s

o

n

d

a

c

o

n

e

c

t

a

o

d

a

y

r

e

a

l

i

á

n

a

n

u

e

v

a

r

d

e

t

e

r

m

i

z

n

a

u

n

a

v

e

r

n

n

d

o

l

a

d

e

s

o

n

d

a

.

a

a

u

t

o

m

á

i

f

i

c

a

c

i

ó

n

.

l

t

a

l

(

e

n

l

a

l

c

u

e

r

p

o

.

t

i

c

a

m

e

n

t

e

Las sondas PosiTector UTG transmiten un impulso ultrasónico al

material que va a medirse. Este impulso viaja a través del material hacia su otra cara. Cuando encuentra una superficie como el

aire (cara posterior) u otro material, el impulso se refleja hacia la

sonda. La sonda mide el tiempo que requiere la propagación en el

material, representado por t1y t2más abajo.

Las sondas PosiTector UTGC y UTGM (en modo eco simple)

determinan el espesor midiendo t1(sin revestimiento) o t2(con

revestimiento), dividiéndolo por dos y multiplicándolo por la propagación del sonido en ese material (acero). Consulte la figura 1.

t

t

1

Sonda

2

Sonda

Revestimiento

acero

Figura 1

t

acero

t

>

1

2

Para materiales no revestidos, t1está relacionado directamente

con el espesor del material. Si un material está revestido, el

tiempo de propagación se incrementa como se muestra en t

.

2

Los revestimientos como la pintura tienen una menor propagación del sonido que el metal. Sin embargo la técnica del eco

simple produce un resultado de espesor mayor que el espesor

real del combinado revestimiento+metal.

2

Page 17

El PosiTector UTGME en modo eco múltiple determina el

espesor midiendo el tiempo entre al menos tres caras posteriores

consecutivas.

t

t

t

1

Sonda

2t3

t

Figura 2

Sonda

to

timen

eves

R

1

t

2

3

acero

En la figura anterior, el modo eco múltiple solo mide el tiempo

entre ecos. En función de que el acero esté revestido o no, el

tiempo entre ecos es siempre el mismo. En modo eco múltiple, el

medidor determina el espesor midiendo t1+t2+t3, dividiéndolo por

seis y multiplicándolo por la propagación del sonido de este material. El cálculo del espesor resultante que realiza el equipo es por

lo tanto una medición precisa del espesor del acero solo, sin tener

en cuenta el espesor del revestimiento.

La propagación del sonido aparece expresada en pulgadas por

microsegundo o metros por segundo. Es diferente para cada

material. Por ejemplo, el sonido viaja a través del acero más rápido (~0.233 in/µs) que a través del plástico (~0.086 in/µs).

Cómo medir

Cómo medir

1. Retire el tapón de goma de la sonda. El acoplante (gel glicol incluido) deberá aplicarse a la superficie que se desea

medir para eliminar capas de aire entre la cara sufridera y la

superficie. Una sola gota de acoplante es suficiente cuando

se realiza una medición in situ.

2. Ponga la sonda perpendicular sobre la superficie que se

va a medir. Presione ligeramente sobre la parte superior de

la sonda con el dedo pulgar o el índice.

3

Page 18

Cuando la sonda detecta los ultrasonidos del eco, un símbolo de

acoplado aparecerá en la pantalla y los valores del espesor

se mostrarán. Mientras la sonda esté acoplada, el PosiTector

UTG actualizará de manera constante la pantalla.

3. Cuando se retire la sonda de la superficie, la última medición se

conservará en la pantalla.

De manera ocasional, el exceso de acoplante permanecerá en la

sonda cuando ésta se retire de la superficie. Esto podría ocasionar

que el PosiTector UTG mostrara una medición final diferente de

la observada cuando la sonda estaba sobre la superficie. Descarte

este valor y repita la medición.

Condiciones de la superficie

Condiciones de la superficie

Las mediciones ultrasónicas están sujetas a la aspereza y

contorno de la superficie que va a medirse.

Los resultados podrían variar en superficies gruesas. Cuando

sea posible, se recomienda asentar el transductor sobre una

superficie lisa y plana paralela a la cara opuesta del material.

En superficies ásperas, el empleo de una cantidad generosa de

acoplante minimizará sus efectos y permitirá evitar el desgaste

del transductor, de manera especial cuando se arrastre la sonda

sobre la superficie.

Sondas UTGM:

revestimiento, el medidor (en modo eco múltiple) podría no ser

capaz de dar un resultado de medición incluso mostrando el

símbolo "acoplado". Utilice acoplante adicional y presione menos

en la sonda cuando realice una medición. De manera alternativa,

si coloca un laminilla de plástico con gel acoplante sobre ambas

caras de la superficie a medir puede simular una superficie

pintada para obtener una medición en un espesor de sólo acero

(sin salir del modo eco múltiple). También puede el cambiar el

medidor a modo de eco simple modo SE (consulte pág. 9) para

facilitar una medición de espesor de acero sin recubrimiento.

En superficies metálicas lisas y sin

4

Page 19

Calibración, verificación y ajuste

Calibración, verificación y ajuste

Para garantizar la mayor exactitud, siga estos tres pasos...

1.Calibración - generalmente realizada por el fabricante o por un

laboratorio acreditado. Todas las sondas incluyen un Certificado

de Calibración.

2.Verificación de la precisión - se realiza por el usuario solo que

usa bloques de calibración tipo escalera (step block) en vez de

patrones de referencia.

3.Adjuste - puede ajustar el factor de velocidad propagación del

sonido conocido de acuerdo al espesor o al material que va a

medirse.

Calibración

La calibración es el proceso controlado y documentado de

medición sobre patrones de calibración trazables y la verificación

de los resultados para confirmar que estos se encuentran dentro

del nivel de precisión establecido del Medidor. El proceso de

calibración generalmente lo realiza el fabricante del Medidor o un

laboratorio de calibración certificado en un entorno controlado y

siguiendo un proceso documentado.

Verificación

Es conveniente y necesario verificar la precisión del Medidor

empleando patrones de referencia del material que se va a

comprobar.

El proceso de verificación es una comprobación de la exactitud

realizada por el usuario. Utiliza galgas patrón con espesores

conocidos. Una verificación exitosa implica que el resultado de la

medición se encuentre dentro del rango de precisión combinado

del medidor y del bloque patrón.

Adjuste

El Ajuste, o Ajuste de Calibración, consiste en alinear las lecturas

del Medidor para emparejarlas con una muestra de referencia

conocida. Consulte Ajuste de Calibración, pág. 6.

5

Page 20

Menú de configuración Cal

Menú de configuración Cal

Zero

Las sondas PosiTector UTG pueden reiniciarse para compensar

la temperatura y el desgaste. Esta acción no es necesaria cuando

se opera en modo eco múltiple (sólo sondas UTG M) excepto

cuando el equipo es nuevo y tras un Reset (pág. 8). Sin embargo

facilita una mayor precisión cuando opera en modo SE (eco simple). Por lo tanto, es una buena idea reincializar la sonda antes de

cambiar de trabajo y cuando la temperatura de la pieza cambia.

Durante el reinicio no es importante qué velocidad está configurada.

1. Asegúrese de que el equipo está encendido y la sonda está limpia.

2. Aplique una sola gota de acoplante sobre la placa cero situada en el

envés del conector de la sonda. NO aplique acoplante directamente en la

cara de la sonda.

3. Seleccione la opción de menú Zero y siga las instrucciones en la pantalla.

Ajuste de la calibración

El PosiTector UTG está calibrado de fábrica. Pero para conseguir

mediciones precisas de un material particular deberá estar

configurado con la velocidad la propagación del sonido adecuada

para el material a medir. Ha de saber que la composición física del

material (y de esta manera su capacidad para propagar el sonido)

pueden variar con respecto a tablas definidas e incluso entre lotes

del mismo fabricante. El ajuste a una muestra de espesor

conocido del material que se va a medir garantiza que el Medidor

se ajusta lo más posible a la propagación del sonido de este

material específico. Las muestras han de ser planas, lisas y tan

gruesas como el máximo esperado para la pieza que va a

medirse.

El PosiTector UTG permite cuatro selecciones de ajuste

sencillas. Los cuatro métodos están basados en la simple premisa

del ajuste de la propagación del sonido. Los tres primeros

métodos de ajuste hacen un ajuste de calibración de 1 punto para

optimizar la linealidad del PosiTector UTG en rangos pequeños.

El cuarto método realiza un ajuste de calibración de 2 puntos para

facilitar una mayor precisión en un amplio rango.

6

Page 21

Espesor

El método más común de ajuste es medir una muestra de espesor conocido. Seleccione una referencia patrón de material tan

cercana como sea posible a la composición de la aplicación destinada. Para un mejor resultado, el espesor de la referencia patrón

deberá ser igual o ligeramente mayor que el espesor de la pieza

que se va a medir.

Material

Si no está disponible un espesor conocido del material pero éste

se conoce, este ajuste rápido permite al usuario cargar una o

varias propagaciones de material predefinidas.

Velocidad

Si la propagación del sonido para la prueba de material es conocida, el Medidor podrá ajustarse a esta propagación específica.

2 puntos de Ajuste

Un ajuste de 2 puntos permite una mayor precisión cuando se

reinicia de manera simultánea la sonda. Seleccione dos

referencias patrón tan cercanas como sea posible a la

composición de la aplicación destinada. Para un mejor resultado,

el espesor de la referencia más gruesa deberá ser igual o

ligeramente mayor que el espesor de la pieza que se va a medir.

El espesor de la referencia patrón más fina deberá estar lo más

cerca posible del valor inferior del rango de medición esperado

Cal Lock

Cuando está activado, aparecerá el icono y las configuraciones

de calibración actuales se "bloquearán" para evitar su

modificación. Desactive para realizar otros ajustes.

7

Page 22

Menú deconfiguración

Menú deconfiguración

Reset

Reset (reinicio parcial) restaura la configuración de fábrica y restablece en

el equipo una condición conocida. Ocurre lo siguiente:

- Todas las series y las mediciones almacenadas, imágenes y nombres

de series se borrarán.

- Todos los ajustes de calibración se borrarán y devolverán el

Medidor a su configuración de calibración original

- Las configuraciones del menú serán de nuevo las siguientes:

Memoria = OFF

Modo Estadísticas = OFF

Alarma HiLo = OFF

Modo Scan = OFF

Scan A = OFF

Scan B = OFF

Cal Lock = OFF

Bluetooth = OFF

Display = None

Modo SE = OFF

Puede reiniciar el equipo de manera más completa (Hard Reset)

apagando el equipo, esperando varios segundos y pulsando

simultáneamente los botones central y (+) hasta que aparezca

el símbolo Reset . Esto restablecerá el equipo a su condición

conocida de fábrica. Realiza la misma función que el Reinicio y

además:

- Borra la información de la conexión Bluetooth

- Las configuraciones del menú serán de nuevo las siguientes:

Units = milímetro

Voltear LCD = Normal

Auto Sync = OFF

Invertir LCD = OFF

Idioma = Inglés

- La fecha y hora no cambiarán al realizar un Reinicio.

NOTA:

Scan

Tipo de bateria = Alkaline

Backlight = Normal

Bluetooth Streaming = OFF

USB Drive= ON

Normalmente, el PosiTector UTG realiza una medición en un solo

punto con 6 lecturas por segundo durante el contacto con una

superficie. Cuando se retira la sonda de la superficie, la última

medición se conservará en la pantalla.

En ocasiones es necesario examinar una zona más amplia para

localizar el punto más espeso. Cuando está seleccionado Scan, el

PosiTector UTG realizará una medición de 20 lecturas por

segundo y mostrará los valores mín/máx.

8

Page 23

A Scan

Una pantalla que muestra la amplitud de impulso

recibido en el eje Y y la distancia recorrida del

impulso ultrasónico en el eje X.

(Sólo para modelos Advanced)

B Scan

Una pantalla que muestra el corte transversal del

material medido.

Modo SE

Cambia de modo eco múltiple a eco simple :

- Para detectar poros y fallas

- Para incrementar el rango de medición

- Para obtener mediciones de espesor en circunstancias en las

que el eco múltiple no puede

Tipo de batería

del tipo “Alcalina”, “Litio” o “NiMH” (híbrido níquel-metal recargable). Si se

ha seleccionado NiMH el equipo cargará las baterías poco a poco si está

conectado por USB a un PC o a un cargador opcional CA (el medidor puede

estar encendido). El indicador del estado de las pilas se calibra para el tipo

de pila seleccionado. No habrá daños si el tipo de batería seleccionado es

erróneo. DeFelsko recomienda baterías recargables eneloop (NiMH).

Estadísticas

Un resumen de las estadísticas aparecerá en la pantalla. Pulse el

botón (-) para borrar la última medida. Oprima (+) para borrar las

estadísticas

Alarma HiLo

Permite al Medidor avisar al usuario con una señal visual y sonoara cuando

las medidas no se adecúen a los límites determinados por el usuario.

x - Promedio

↑

(Sólo para modelos Advanced)

(sólo sondas UTGM eco múltiple)

Selecciona el tipo de baterías empleadas en el equipo

Modo Estadísticas

Modo Estadísticas

x

- Valor máximo

σ - Desviación típica

↓ - Valor mínimo

9

Page 24

Gestión de memoria

Gestión de memoria

El PosiTector UTG puede registrar lecturas en la memoria para

su impresión con la impresora Bluetooth opcional, su descarga o

su sincronización con PosiTector.net. Al tomar cada lectura, queda

registrada la hora en que se realizó.

Desplazamiento por

los modos de visualización (sólo

Advanced)

Eliminar última lectura

Acceso al menú

Los modelos Standard almacenan hasta 250 lecturas en una serie.

Los modelos Advanced almacenan 100,000 lecturas en hasta 1.000

Crear una nueva

serie(sólo Advanced)

Restauración del brillo si se ha oscurecido (sólo Advanced)

series. La instrucción "New Batch" cierra cualquier serie abierta y

crea un nuevo nombre de serie con el número consecutivo más

cercano. Aparecerá el icono . Los nombres de series nuevas

quedarán registrados con la fecha en que se crearon.

Esta guía rápida describe las funciones básicas del

NOTA:

equipo. Descargue el manual de instrucciones en:

www.defelsko.com/manuals

Captura de pantalla

Presione los botones (-)(+) al tiempo para copiar y guardar la imagen de la pantalla actual. Las últimas 10 capturas de pantalla

serán almacenadas en la memoria y podrá acceder a ellas cuando esté conectado a un ordenador (consultar almacenamiento

masivo en USB pág. 11).

Extraer lecturas almacenadas

Extraer lecturas almacenadas

Almacenamiento masivo USB - conecte su PosiTector a un PC/Mac con

el cable USB suministrado para acceder e imprimir lecturas y gráficos

almacenados. No se requiere conexión a internet ni software especializado.

PosiTector.net - aplicación web gratuita que ofrece un almacenamiento

seguro y centralizado de las lecturas de espesor. Acceda a sus lecturas

desde cualquier dispositivo internet. www.PosiTector.net

10

Page 25

Menú Conectar

Menú Conectar

Sync Now

Inicia de manera inmediata la sincronización con PosiTector.net al

conectar (Bluetooth o USB) a un PC con PosiTector Desktop

Manager.

Auto SYNC

Permite que el instrumento sincronice de manera automática con

PosiTector.net, requiere estar conectado inicialmente a un PC con

PosiTector Desktop Manager.

Sólo se sincronizarán las mediciones adicionales añadidas a la

memoria durante la conexión hasta que el cable USB esté

desconectado y se reconecte o cuando Connect > Sync. Now

esté seleccionado.

USB Drive

El equipo utiliza un dispositivo de almacenamiento masivo USB

que proporciona una interfaz sencilla para recuperar los datos de

manera semejante a un USB Flash, una cámara o un reproductor

digital de audio.

NOTA:

través del cable USB. Las baterías no estarán en uso y la base no

se apagará automáticamente. Si dispone de baterías recargables

(NiMH), el equipo las cargará poco a poco.

Permite enviar lecturas individuales a un ordenador o dispositivo

compatible con tecnología Bluetooth.

Consulte www.defelsko.com/bluetooth

Determina si hay actualizaciones disponibles de software para su

instrumento. Deberá estar conectado a un PC conectado a

internet con PosiTector Desktop Manager.

Consulte www.defelsko.com/update

NOTA:

Cuando está conectado, la alimentación se obtiene a

Bluetooth

Updates

El instrumento deberá reiniciarse (pág. 8)

(sólo modelos Advanced)

11

Page 26

Devolución para reparaciones

Devolución para reparaciones

Antes de devolver el Medidor para reparaciones...

1.Coloque las pilas nuevas en la disposición indicada en la tapa.

2.Examine la punta de la sonda por si está sucia o dañada. Las

sondas deben poder moverse hacia arriba y hacia abajo sin

problemas.

3.Reinicie el Medidor (Pág. 8).

Si debe devolver el Medidor para reparaciones, describa el problema con detalle e incluya los resultados de medición, si los tiene.

Asegúrese también de incluir el Medidor, la sonda, el nombre de

su empresa, el nombre de la persona de contacto, sus números

de teléfono y de fax o su dirección de correo electrónico.

Sitio Web: www.defelsko.com/support

Garantía limitada, solución única y

Garantía limitada, solución única y

obligación limitada

obligación limitada

La garantía única de DeFelsko, la solución, y la obligación son

la garantía limitada expresa, la solución y la obligación limitada

expuestas en su sitio web: www.defelsko.com/terms

www.defelsko.com

© DeFelsko Corporation USA 2012

Este manual está protegido por copyright. Todos los derechos de este manual están reservados y no

podrá ser parcial o totalmente reproducido o transmitido por ningún medio sin el consentimiento previo

por escrito de DeFelsko Corporation.

DeFelsko y PosiTector son marcas comerciales de DeFelsko Corporation registradas en los EE.UU. y

en otros países. Otras marcas o nombres de productos son marcas comerciales o registradas de sus

propietarios respectivos.

Se han tomado todas las precauciones posibles para asegurar la precisión de toda la información contenida en este manual. DeFelsko no aceptará responsabilidad por errores tipográficos o de impresión.

Reservados todos los derechos.

12

Page 27

Ultrasonic Thickness Gage

Kurzanleitung v. 3.0

Adv ance d m odel

Page 28

Einführung

Einführung

Da

s

P

o

s

i

Te

c

t

o

r UT

G

i

st

e

i

n

h

a

n

d

l

i

ch

e

s Ul

t

r

a

sch

a

l

l

d

i

cke

n

m

e

ssg

e

w

d

e

o

Di

z

un

e

i

i

d

us

e

n

l

W

e

e

es

ter

c

h

e

s

d

a

s

n

i

c

h

tz

e

rs

tö

re

n

d

e

U

l

tra

s

c

h

a

l

l

-Im

p

u

l

s

-Ec

h

o

-Pri

n

a

n

d

d

i

c

k

e

u

n

te

rs

c

h

i

e

d

l

i

c

h

s

te

r M

a

te

ri

a

l

i

e

n

z

u

r

G

ru

n

d

e

i

n

h

e

i

t

(Sta

n

d

a

rd

o

d

e

r

r

U

TG

M

, s

i

e

h

e

S. 2

).

e

K

ur

z

anl

ei

tung

a

m

www

m

e

n. Di

.d

e

fe

fas

e

v

ol

l

s

tän

l

s

k

o

.c

o

m

Ad

s

t

di

e

G

di

ge

B

ed

/m

anual

s e

Schnellstart

Schnellstart

v

a

n

c

r

undfunk

i

e

nu

i

n

s

e

m

e

d

)

u

n

ti

ng

s

anl

h

e

n

u

e

s

s

d

e

onen

ei

n

d

e

n

. Es

i

n

e

r

des

tung k

he

ru

z

So

n

r

i

p

n

u

tz

t,

u

b

e

s

te

h

t a

n

d

e

(

U

TG

G

er

ätes

ö

nn

en

S

te

r l

a

d

e

n

Das PosiTector UTG schaltet sich durch Drücken der mittleren

Navigationstaste ein. Um die Lebensdauer der Batterien zu

verlängern, schaltet sich das Gerät nach etwa 5 Minuten

automatisch aus. Alle Einstellungen bleiben erhalten.

1. Entfernen Sie die Gummischutzkappe von der Sonde.

2.Schalten Sie das Messgerät ein, indem Sie die mittlere

Navigationstaste drücken.

3. Setzen Sie die Sonde auf Null (siehe S. 6)

4. Wählen Sie die richtige Schallgeschwindigkeit (siehe S. 7)

5. Messen Sie das Werkstück (siehe S. 3)

Das Kopplungssymbol erscheint, wenn die

Typische Anzeige

Sonde mit ultraschalltechnisch mit einer

Oberfläche verbunden wird.

Aktuell

gewähltes

Material

Batterie

anzeige

Stahl

inch

Messmodus:

Aktuell auf

Mehrfachecho

eingestellt

(nur bei UTGMSonde)

ä

t

,

m

u

s

C

i

e

.

Aktueller

Messwert

Messeinheit

1

Page 29

Sonden

Sonden

U

m

e

i

n

e

S

o

n

d

e

v

o

m

G

r

u

n

d

g

e

r

ä

t

z

u

e

n

t

f

e

r

n

e

n

,

s

c

h

a

l

t

e

n

S

i

e

d

a

I

n

s

t

r

u

m

e

n

t

v

o

r

h

e

r

a

u

s

u

n

d

s

c

h

i

e

b

e

n

d

a

n

n

d

e

n

S

o

n

d

e

n

a

n

s

c

h

l

u

s

s

h

o

r

i

z

o

n

t

a

l

(

i

n

P

f

e

i

l

r

i

c

w

e

g

.

S

c

h

r

i

t

t

e

i

n

u

m

g

e

k

e

h

r

t

e

r

n

e

u

e

S

o

n

d

e

a

m

G

r

u

N

a

c

h

d

e

m

E

i

n

s

c

h

a

l

d

e

n

a

n

g

e

d

s

u

r

c

h

.

t

c

h

l

o

s

s

e

n

e

R

n

d

g

e

r

ä

t

a

n

z

e

n

i

d

e

n

t

i

f

i

z

i

n

S

o

n

d

e

n

h

e

i

h

e

n

f

o

l

g

e

u

b

r

i

n

g

e

n

.

e

r

t

d

a

s

P

o

t

y

p

u

n

d

f

t

u

n

g

)

v

o

m

w

i

e

d

e

r

h

o

l

e

s

i

T

e

c

t

o

r

ü

a

h

r

t

e

i

n

e

n

s

K

u

n

s

t

s

t

o

f

f

u

-

G

e

h

ä

u

s

e

n

u

m

e

i

n

e

t

o

m

a

t

i

s

c

h

S

e

l

b

s

t

t

e

s

t

PosiTector-UTG-Sonden übertragen einen Ultraschallimpuls in

das zu messende Material. Dieser Impuls durchläuft das Material

bis zur anderen Seite. Wenn er auf eine Kontaktfläche wie Luft

(Rückwand) oder ein anderes Material trifft, wird dieser Impuls

zurück zur Sonde reflektiert. Die Zeit, die ein Impuls benötigt um

sich im Material auszubreiten, wird vom Messgerät gemessen,

nachstehend dargestellt als t1und t2.

PosiTector-UTGC- und UTGM-Sonden (im Einzelecho-Modus ) bes-

timmen die Dicke, indem sie t1(unbeschichtet) oder t2(beschichtet)

messen, durch 2 teilen und dann mit der Schallgeschwindigkeit des

Materials (hier Stahl) multiplizieren. Siehe Abbildung 1.

t

t

1

Sonde

2

Sonde

Beschichtung

Stahl

Abbildung 1

Für unbeschichtete Materialien bezieht sich t1direkt auf die Materialdicke.

Wenn ein Material beschichtet ist, erhöht sich die Ausbreitungszeit und

wird wie oben als t2angezeigt.

Beschichtungen wie z.B. Lacke haben eine langsamere

Schallgeschwindigkeit als Metall. Daher erzeugt die Einzelechotechnik ein

Dickenergebnis, das größer ist als die tatsächliche, kombinierte Dicke von

Beschichtung + Metall.

Stahl

t

t

>

1

2

2

Page 30

Der PosiTector UTGM im Mehrfachecho-Modus bestimmt die

Dicke, indem es die Zeit zwischen mindestens drei aufeinanderfolgenden

Rückwandechos misst.

t

t

t

1

Sonde

2t3

t

Sonde

1

t

2

3

Beschichtung

Abbildung 2

Stahl

In der obigen Abbildung 2 misst der Mehrfachecho-Modus nur die

Zeit zwischen den Echos. Unabhängig davon ob das Material

(hier Stahl) beschichtet ist oder nicht, sind alle Zeiten zwischen

den Echos gleich. Im Mehrfachecho-Modus bestimmt das

Messgerät die Dicke, indem es

t

misst, durch 6 teilt und

1+t2+t3

dann durch die Schallgeschwindigkeit des Materials teilt. Die sich

ergebende Dickenberechnung, die das Instrument durchführt, ist

daher nur eine genaue Messung der Materialdicke ohne

Berücksichtigung der Beschichtungsdicke.

Die Schallgeschwindigkeit wird in Zoll pro Mikrosekunde oder

Metern pro Sekunde angegeben. Sie ist für alle Stoffe unterschiedlich. Zum Beispiel läuft der Schall durch Stahl schneller

(~0,233 in/µs), als durch Kunststoff (~0,086 in/µs).

Wie wird gemessen

Wie wird gemessen

Entfernen Sie die Gummischutzkappe von der Sonde.

1.

Das Kopplungsmittel (Glykolgel – im Lieferumfang ) muss auf

die zu testende Oberfläche aufgetragen werden, um den

Luftspalt zwischen der der Sonde und der Oberfläche zu

beseitigen. Ein einziger Tropfen Kopplungsmittel genügt,

wenn eine Punktmessung durchgeführt werden soll.

2. Setzen Sie die Sonde flach auf die Oberfläche. Verwenden Sie einen

sanften Druck, indem Sie mit dem Zeigefinger leicht auf die Oberseite der

Sonde drücken.

3

Page 31

Wenn die Sonde ein Ultraschallecho erkennt, erscheint ein

Kopplungssymbol in der Anzeige und die Dickenmesswerte werden angezeigt. Während die Sonde mit der Oberfläche gekoppelt

ist, aktualisiert der PosiTector UTG fortlaufend die Anzeige.

3. Wenn die Sonde von der Oberfläche entfernt wird, bleibt die letzte Messung in der Anzeige erhalten.

Gelegentlich kann Kopplungsmittel auf der Sonde zurückbleiben,

wenn die Sonde von der Oberfläche abgehoben wird. Dies kann

dazu führen, dass das PosiTector UTG einen eventuell verfälschten Messwert anzeigt, der sich von den zuvor gemessenen Werten

unterscheidet als die Sonde noch mit der Oberfläche gekoppelt

war. Löschen Sie diesen Wert und wiederholen Sie die Messung

bei Bedarf.

Oberflächenbeschaffenheit

Oberflächenbeschaffenheit

Ultraschallmessungen werden durch den Zustand, die Rauheit und die

Kontur der Oberfläche beeinflusst.

Die Messergebnisse können auf rauen oder strukturierten Oberflächen

unterschiedlich sein. Soweit realisierbar wird empfohlen die Sonde auf eine

möglichst glatte, flache und saubere Oberfläche zu setzen, die parallel zur

gegenüberliegenden Seite des Materials liegt.

Auf rauen Oberflächen minimiert die Verwendung einer großzügigen

Menge Kopplungsmittel die Oberflächenauswirkungen und dient auch

dazu, die Sonde vor Verschleiß zu schützen, insbesondere wenn die Sonde

über eine Oberfläche gezogen wird.

UTGM-Sonden:

das Messgerät (im Mehrfachecho-Modus) gelegentlich nicht in der Lage

sein ein Messergebnis zu erzielen, auch wenn das “Kopplungssymbol”

erscheint. Verwenden Sie zusätzliches Kopplungsmittel und einen

leichteren Druck auf die Sonde während des Messens. Alternativ hilft es,

wenn man eine Kunststofffolie auf die Oberfläche legt, bei der

Kopplungsmittel auf beide Seiten aufgetragen wird, zur Simulation einer

lackierte Oberfläche, um dabei eine Dickenmessung nur für Stahl (im

Mehrfachecho-Modus) durchzuführen. Wenn man das Messgerät auf

Einzelecho-Modus SE umstellt (siehe S. 9), hilft dies auch eine

Dickenmessung nur für Stahl durchzuführen.

Auf glatten, unbeschichteten Metalloberflächen kann

4

Page 32

Kalibrierung, Überprüfung und Einstellung

Kalibrierung, Überprüfung und Einstellung

Drei Schritte sichern die größte Genauigkeit...

1.Kalibrierung - erfolgt typischerweise durch den Hersteller oder

ein qualifiziertes Labor. Alle Sonden werden mit einer

Kalibrierungsbescheinigung geliefert.

2.Überprüfung der Genauigkeit - wird vom Benutzer anhand

bekannter Referenznormale wie z.B. Kalibrierungsstufenblöcke

durchgeführt.

3.Einstellung - auf einebekannte Dicke oder

Schallgeschwindigkeit für das zu messende Material

Kalibrierung

Kalibrierung ist das kontrollierte und dokumentierte Verfahren

einer Messung mittels rückführbarer Kalibrierungsstandards und

dem Vergleich, dass die Messresultate innerhalb der

angegebenen Genauigkeit und Toleranz des Messgeräts liegen.

Kalibrierungen werden typischerweise vom Hersteller des

Messgeräts oder von einem zugelassenen Kalibrierungslabor in

einer kontrollierten Umgebung unter Verwendung eines

dokumentierten Verfahrens durchgeführt.

Überprüfung

Die Genauigkeit des Messgeräts kann und sollte unter

Verwendung bekannter Referenznormale des zu testenden

Materials durchgeführt werden.

Die Überprüfung ist eine Kontrolle der Genauigkeit, die vom

Benutzer unter Verwendung bekannter Referenzstandards

durchgeführt wird. Eine erfolgreiche Überprüfung erfordert, dass

das Messgerät innerhalb der kombinierten Toleranz des

Messgeräts und der Referenznormals liegt.

Einstellung

Einstellung oder Kalibrierungseinstellung ist das Anpassen der

abgelesenen Dickenmessung des Messgeräts, so dass diese

denjenigen einer bekannten Referenzprobe entsprechen. Siehe

Kalibrierungseinstellung S. 6.

5

Page 33

Menü Kalibrierung

Menü Kalibrierung

Null

PosiTector-UTG-Sonden können “auf Null” gesetzt werden, um Temperatur

und Verschleiß auszugleichen. Diese Maßnahme ist im Betrieb

“Mehrfachecho-Modus” (nur UTGM-Sonden) nicht erforderlich, außer das

Instrument ist neu oder es wurde ein Reset durchgeführt (S. 8). Jedoch stellt

dies die größtmögliche Genauigkeit im “SE - Einzelecho-Modus” sicher.

Deshalb ist es ratsam, die Sonde vor jeder Arbeitsschicht und bei

Temperaturänderung des Werkstücks “auf Null” zu stellen. Während der

Nullstellung spiel es keine Rolle welche Schallgeschwindigkeit eingestellt

ist.

1. Stellen Sie sicher, dass das Instrument eingeschaltet und die Sonde

sauber und frei von Kopplungsmittel ist.

2. Tragen Sie einen einzelnen Tropfen Kopplungsmittel auf die Nullplatte

auf, die sich an der Unterseite des Sondenanschlusses befindet. Tragen

Sie KEIN Kopplungsmittel direkt auf die Sondenfläche auf.

3.Wählen Sie die Menüoption Null aus und befolgen Sie die

Eingabeaufforderungen am Bildschirm.

Kalibrierungseinstellung

Der PosiTector UTG ist ab Werk kalibriert. Damit genaue

Dickenmessungen eines bestimmten Materials durchgeführt werden

können, muss das Gerät auf die korrekte Schallgeschwindigkeit des

Materials eingestellt werden. Beachten Sie, dass die Materialeigenschaften

(und somit auch die Schallgeschwindigkeit) von der im Gerät hinterlegten

Tabelle abweichen können. Die Einstellung auf ein Muster mit bekannter

Dicke des zu messenden Materials stellt sicher, dass das Messgerät so

genau wie möglich auf die Schallgeschwindigkeit des bestimmten Materials

eingestellt wird. Die Proben sollten flach, glatt und so dick wie die größte zu

erwartete Dicke des zu testenden Werkstücks sein.

Der PosiTector UTG lässt vier einfache Einstellungen zu. Alle vier

Methoden basieren auf der einfachen Voraussetzung der

Einstellung der Schallgeschwindigkeit. Die ersten drei

Einstellmethoden nehmen 1-Punkt-Kalibrierungseinstellungen vor,

um die Linearität des PosiTector UTG innerhalb eines kleinen

Messbereichs zu optimieren. Die vierte Methode nimmt eine 2Punkt-Kalibrierungseinstellung vor, um eine größere Genauigkeit

über einen großen Messbereich zu ermöglichen.

6

Page 34

Dicke

Die gebräuchlichste Einstellmethode ist die Messung eines

Musters mit bekannter Dicke. Wählen Sie ein Referenznormal,

das in der Materialzusammensetzung der beabsichtigten

Anwendung relativ ähnlich ist. Um optimale Ergebnisse zu erzielen, sollte die Dicke der Referenznormale gleich oder etwas

größer als die des zu messenden Werkstücks sein.

Material

Wenn kein Normal mit bekannter Dicke zur Verfügung steht, aber das

Material bekannt ist, kann der Anwender aus einer Liste vorgegebener

Materialien mit hinterlegten Schallgeschwindigkeiten auswählen.

Geschwindigkeit

Wenn die Schallgeschwindigkeit des Werkstücks bekannt ist, kann

das Messgerät auf diese spezifische Schallgeschwindigkeit

eingestellt werden.

2 Punkt

Eine 2-Punkt-Einstellung ermöglicht eine größere Genauigkeit bei

gleichzeitiger Nullsetzung der Sonde. Wählen Sie zwei

Referenznormale, die in der Zusammensetzung der

beabsichtigten Anwendung so ähnlich wie möglich sind. Um die

besten Ergebnisse zu erzielen, sollte die Dicke des dickeren

Referenznormals gleich oder etwas größer als das dickste zu

messende Werkstück sein. Die Dicke des dünneren

Referenznormals sollte so nahe wie möglich am unteren Ende des

zu erwarteten Messbereichs liegen.

Kal Sperre

Bei dieser Funktion erscheint das Symbol , und die aktuellen

Kalibrierungseinstellungen werden “gesperrt”, um weitere

Einstellungen durch den Benutzer zu verhindern. Entfernen Sie die

Markierung, um weitere Einstellungen vorzunehmen.

7

Page 35

Menü Setup

Menü Setup

Reset

Reset (Soft Reset) Funktion stellt die Werkseinstellungen wieder her und

setzt das Gerät auf eine bekannte, werksseitige Originaleinstellung zurück.

Folgendes passiert:

- Alle Blöcke, gespeicherten Messungen, Abbildungen und Blocknamen

werden gelöscht.

- Alle individuellen Kalibrierungseinstellungen werden entfernt und auf die

Werkseinstellungen der Kalibrierung zurückgesetzt.

- Die Menüeinstellungen werden wie folgt zurückgesetzt:

Speicher = AUS

Statistik Modus = AUS

Hi Lo Alarm = AUS

Scan Modus = AUS

Führen Sie ein noch gründlicheres Reset (Hard-Reset) durch, indem Sie

das Gerät ausschalten, einige Sekunden warten, dann gleichzeitig die

beiden Tasten und (+) solange drücken bis das Symbol Zurücksetzen

erscheint . Dies setzt das Gerät auf den originalen Werkszustand zurück.

Diese Art des Hard-Reset führt dieselben Funktionen durch, wie bereits im

Menü Reset (Soft-Reset) beschrieben, mit folgenden Zusätzen:

A Scan = AUS

B Scan = AUS

Kal Speere = AUS

Bluetooth = AUS

Anzeige = Keine

SE Mode = AUS

- Die Bluetooth-Koppplungsinformationen/Paarungen werden gelöscht.

- Die Menüeinstellungen werden wie folgt zurückgesetzt:

Einheiten = Millimeter

LCD drehen = Normal

Auto Sync = AUS

Umkehren LCD = AUS

Sprache = Englisch

HINWEI

Normalerweise führt das PosiTector UTG eine Ein-Punkt-Messung mit

einer Rate von 6 Messungen pro Sekunde durch, während die Sonde auf

einer Oberfläche befindet. Wenn die Sonde angehoben wird, verbleibt die

letzte Ablesung in der Anzeige.

Manchmal ist es notwendig einen größeren Bereich zu untersuchen oder

abzutasten, um z.B. die dünnste Materialstelle zu finden. Wenn Scan

gewählt wird, misst das PosiTector UTG mit einer Rate von 20 Messungen

pro Sekunde und zeigt die höchsten und niedrigsten Messwerte an.

- Datum und Uhrzeit werden von beiden Reset Funktionen

S:

nicht beeinflusst.

Scan

Batterietyp = Alkaline

Backlight = Normal

Bluetooth Streaming = AUS

USB Drive= AN

8

Page 36

A Scan

(nur Advanced Modelle)

Eine Anzeige, bei der die erhaltene

Impulsamplitude entlang der y-Achse und der

Strecke des Ultraschallimpulses entlang der xAchse dargestellt wird.

B Scan

(nur Advanced Modelle)

Eine Anzeige, bei der ein Querschnittprofil des

Materials dargestellt wird.

SE Modus

Schaltet vom Mehrfachecho-Modus in den Einzelecho-Modus

um:

- Poren, Brüche und andere Fehler aufzuspüren

- den Messbereich zu erweitern

- unter Umständen Dickenmessungen zu erhalten, bei denen der

Mehrfachecho-Modus nicht funktioniert

Batterie Typ

verwendeten Batterietyp aus: “Alkaline”, “Lithium” oder “NiMH” (NickelMetallhydrid wieder aufladbar). Wenn NiMH gewählt wird, lädt das Gerät die

Batterien während es über USB an einen PC oder ein optionales

Wechselstrom-Ladegerät angeschlossen ist (Messgerät muss EIN

geschaltet sein) auf. Das Batteriezustandsanzeigesymbol wird für den

gewählten Batterietyp individuell kalibriert. Es entsteht kein Schaden wenn

der falsche Batterietyp ausgewählt wird. DeFelsko empfiehlt wieder

aufladbare Batterien des Typs eneloop (NiMH).

Statistik

Eine statistische Zusammenfassung erscheint in der Anzeige. Sie entfernen

die letzte Messung, indem Sie die Taste (-) drücken. Drücken Sie (+), um

die Statistik zu löschen.

HiLo Alarm

Ermöglicht dem Messgerät mittels Alarm den Benutzer visuell und akustisch

zu warnen, wenn Messwerte die vom Benutzer vorgegebenen Grenzwerte

über- oder unterschreiten.

(nur UTGM-Mehrfachecho-Sonden)

Mit dieser Funktion wählen Sie den im Instrument

Menü Statistik

Menü Statistik

x

x - Mittelwert

- Maximalwert

↑

σ - Standardabweichung

↓ - Minimalwert

9

Page 37

Menü Speicher

Menü Speicher

Das PosiTector UTG kann Messungen zum Ausdruck auf einen optionalen

Bluetooth-Drahtlosdrucker, zum Herunterladen oder zur Synchronisation mit

PosiTector.net im Speicher aufzeichnen. Die Messwerte erhalten während

sie aufgenommen werden einen “Zeitstempel”.

Durch Anzeigemodi

scrollen

(nur Advanced)

Letzte Messung

löschen

Auf das Menü

zugreifen

Standardmodelle

Advanced Modelle speichern bis zu 100.000 Messungen in bis zu 1.000

Blöcken. “Neuer Block” schließt einen aktuell geöffneten Block und erzeugt

einen neuen Blocknamen unter Verwendung der niedrigsten zur Verfügung

stehenden Nummer. Das Symbol erscheint. Neue Blocknamen erhalten

einen Zeitstempel wenn sie erstellt werden.

HINWEIS:

zusammen. Die vollständige Bedienungsanleitung können Sie unter

www.defelsko.com/manuals

speichern bis zu 250 Messungen in einem Block.

Diese Kurzanleitung fasst die Grundfunktionen des Gerätes

herunter laden.

Einen neuen Block

erstellen

(nur Advanced)

Helligkeit wiederherstellen nach

dem Abdunkeln

(nur Advanced)

Bildschirmkopie

Sie können jederzeit durch gleichzeitiges Drücken der beide Tasten (-) (+)

eine Bildschirmkopie der aktuellen Anzeige erstellen und speichern. Die

letzten 10 Bildschirmkopien werden im Speicher gesichert und es kann über

einen bestehenden Computeranschluss darauf zugegriffen werden (siehe

USB-Massenspeicherung S. 11).

Herunterladen von Messwerten in einen Computer

Herunterladen von Messwerten in einen Computer

USB Massenspeicher – schließen Sie das PosiTector mit dem mitgelieferten

USB-Kabel an einen PC/Mac an, um auf gespeicherte Messwerte und

Schaubilder zuzugreifen und diese auszudrucken. Es ist keine gesonderte

Software und kein Internet-Anschluss dazu erforderlich.

PosiTector.net – eine kostenlose, webbasierende Anwendung, die eine

sichere, zentrale Speicherung von erfassten Messwerten bietet. Greifen Sie

von jedem mit dem Web verbundenen Gerät auf Ihre Messergebnisse zu.

www.PosiTector.net

10

Page 38

Menü Verbinden

Menü Verbinden

Sync Now

Die Synchronisation mit dem PosiTector.net wird sofort eingeleitet,

wenn es über einen PC, auf dem der PosiTector Desktop Manager

läuft, mit dem Internet verbunden wird (USB oder Bluetooth).

Auto SYNC

Ermöglicht die automatische Synchronisierung des Messgerätes

mit PosiTector.net, wenn ein Anschluss an einen mit dem Internet

verbundenen PC besteht, auf dem der PosiTector Desktop

Manager läuft.

Zusätzliche Messwerte, die dem Speicher hinzugefügt werden

während der Anschluss besteht, werden erst synchronisiert, wenn

das USB-Kabel abgetrennt und dann erneut angeschlossen wird

oder wenn Verbindung>Synchro gewählt wird.

USB Drive

Das Messgerät verwendet einen USB-Massenspeicher, der eine

einfache Schnittstelle bietet, um Daten in ähnlicher Weise wie sie

bei USB-Flashlaufwerken, Kameras oder digitalen Audioplayern

verwendet wird, abzurufen.

HINWEISE:

zugeführt. Die Batterien werden nicht verwendet, und das Gerät

schaltet sich nicht automatisch aus. Wenn wieder aufladbare

(NiMH) Batterien verwendet werden, lädt das Gerät die Batterien

auf.

Bluetooth

ermöglicht an den Computer oder ein kompatibles Gerät mit der

Bluetooth-Drahtlostechnik Einzelablesungen zu senden, während

sie erfasst werden. Siehe: www.defelsko.com/bluetooth

Updates

Bestimmt, ob eine Softwareaktualisierung für das Gerät vorhanden

ist. Muss an einen mit dem Internet verbundenen PC

angeschlossen sein, auf dem der PosiTector Desktop Manager

läuft. Siehe: www.defelsko.com/update

HINWEISE:

Bei Anschließen wird Strom über das USB-Kabel

(nur Advanced Modelle)

Das Instrument kann einen Hard Reset (hartes

Zurücksetzen) durchführen (S. 8)

11

Page 39

Rücksendung zur Reparatur

Rücksendung zur Reparatur

Bevor Sie das Gerät zur Reparatur einsenden...

1. Setzen Sie neue Batterien in der richtigen Richtung wie an der

Klappe vorgeschrieben ein.

2. Prüfen Sie die Sondenspitze auf Verschmutzung oder

Beschädigung. Die Sonde sollte sich problemlos auf- und ab

bewegen lassen.

3.Führen Sie ein Geräte-Reset (Seite 8) durch.

Falls das Gerät zur Reparatur eingeschickt werden muss,

beschreiben Sie das Problem möglichst vollständig und fügen Sie

Messergebnisse bei, falls vorhanden. Achten Sie darauf, dass das

Messgerät zusammen mit dem Namen Ihrer Firma, Namen der

Kontaktperson, Telefon-, Faxnummer und E-Mail-Adresse einge-

sandt wird.

Website: www.defelsko.com/support

Begrenzte Garantie, alleinige Abhilfe und

Begrenzte Garantie, alleinige Abhilfe und

beschränkte Haftung

beschränkte Haftung

DeFelsko alleinige Garantie, Abhilfe und Haftung sind ausdrück-

lich auf die Garantieleistung, Abhilfe und beschränkte Haftung

begrenzt, so wie es in ihrer Website dargelegt ist.

www.defelsko.com/support

www.defelsko.com

© DeFelsko Corporation USA 2012

Dieses Handbuch ist urheberrechtlich geschützt. Es darf ohne schriftliche Genehmigung der DeFelsko

Corporation weder insgesamt noch in Teilen in irgendeiner Weise vervielfältigt oder weitergegeben wer-

den.

DeFelsko und PosiTector sind in den USA und anderen Ländern eingetragene Warenzeichen der

DeFelsko Corporation. Alle anderen Marken- und Produktnamen sind Marken oder eingetragene

Marken der jeweiligen Besitzer.

Die in dieser Betriebsanleitung enthaltenen Informationen wurden nach bestem Wissen und Gewissen

zusammengestellt. Für Druck- oder Bearbeitungsfehler übernimmt DeFelsko keine Verantwortung.

Alle Rechte vorbehalten.

12

Page 40

Ultrasonic Thickness Gage

Guide d’utilisation v. 3.0

Adv ance d m odel

Page 41

Introduction

Introduction

L

e

P

os

i

T

e

c

t

or

UTG

e

st

u

n

in

st

r

u

me

n

t

d

e

me

su

r

e

d

'

é

p

a

isse

u

r

u

lt

r

a

so

n

.

e

Té

iq

o

n

-

d

e

st

r

u

ct

t

é

r

ia

u

x.

I

l se

UTG

(

C

lé

ch

a

r

g

m/

ma

n

u

a

ls

p

o

p

o

co

UTG

Ce

la

n

r

u

mp

g

t

a

r

o

b

me

o

M,

u

t

ice

le

q

u

i u

t

ilise

le

p

r

in

cip

e

d

'

é

ch

o

p

u

lsa

t

io

n

u

lt

r

a

so

n

iq

u

e

su

r

e

r

l'

é

p

a

isse

u

r

d

e

p

a

r

o

i su

r

u

n

la

r

g

e

é

se

d

'

u

n

co

r

p

s

(

st

a

n

d

a

r

d

o

u

a

vo

ir

p

a

g

e

2

)

.

id

e

r

a

p

id

e

r

é

su

me

le

s

f

d

'

in

st

r

u

ct

io

o

n

s co

mp

lè

Démarrage rapide

Démarrage rapide

va

n

ct

io

n

s d

e

t

e

à

l'

a

d

r

e

n

b

sse

ve

cé

)

e

t

d

a

se

d

e

l'

:

www