DeFelsko PosiTector RTR Full Manual

Introduction ......................................................... 1

Kit Contents ........................................................ 1

Quick Start .......................................................... 1

Certification ......................................................... 2

Probes ................................................................. 4

How to Measure .................................................. 5

Calibration & Verification of Accuracy ................. 8

Menu Operation .................................................. 9

Statistics .............................................................. 9

Cal Settings Menu ............................................... 10

Zero ................................................................ 10

Tape Grade .................................................... 10

Linearize ........................................................ 11

Setup Menu ......................................................... 12

Reset .............................................................. 12

Gage Info ....................................................... 12

Memory Management ......................................... 14

Standard Models ........................................... 14

Advanced Models .......................................... 15

Annotate ......................................................... 16

Display ........................................................... 17

Summaries ..................................................... 18

Screen Capture .............................................. 18

Accessing Stored Measurement Data ................ 19

PosiSoft Desktop Manager (PDM) ................. 19

PosiSoft.net .................................................... 20

PosiSoft Software .......................................... 20

PosiSoft Mobile .............................................. 21

Table of Contents

Table of Contents

Connect Menu ..................................................... 22

Sync Now ....................................................... 22

Auto Sync ....................................................... 22

USB Drive ...................................................... 22

Bluetooth ........................................................ 24

Bluetooth Wireless Printer ............................. 25

WiFi ................................................................ 25

Updates .......................................................... 26

Power Supply / Battery Indicator ........................ 27

Rechargeable Batteries ...................................... 27

Additional Accessories ........................................ 27

Technical Data .................................................... 30

Returning For Service ......................................... 31

Warranty .............................................................. 31

1

Introduction

Introduction

The PosiTector Replica Tape Reader (RTR) is a hand-held

electronic instrument that measures burnished

TestexTMPress-O-FilmTMreplica tape to produce peak-to-valley

surface profile height measurements. It consists of a body

(Standard or Advanced) and probe.

Quick Start

Quick Start

The PosiTector RTR powers-up when the center navigation

button is pressed. To preserve battery life, the Gage powers

down after approximately 5 minutes of no activity. All settings are

retained.

To ensure best accuracy, the user will be required to zero

the probe every time the Gage is powered-up. It is therefore a

good idea to clean the probe regularly with the included cleaning

card. Cleaning is best performed when the Gage is powered down.

NOTE:

With the Gage powered down...

1. Clean the probe with the included cleaning card. (pg. 7)

2. Power-up Gage by pressing the center navigation button.

3. Zero the probe. (pg. 10)

4. Measure the included check shim to verify accuracy. (pg. 8)

5. Measure the burnished replica tape. (pg. 7)

PosiTector RTR Kit Contents

- PosiTector body (Standard or Advanced)

- PosiTector probe (RTR-H)

- Stainless steel burnishing tool

- Cleaning cards (5)

- Surface cleaning putty

- Check shim

- Protective lens shield

- Wrist strap

- 3 AAA alkaline batteries

- Quick Guide instruction booklet

- Protective rubber holster with belt clip

- Nylon carrying case with shoulder strap

- USB Cable

- Certificate of Calibration traceable to NIST

- PosiSoft.net account

- Two (2) year warranty on Body and Probe

2

Up

Down

Center

To navigate, use the Up and Down buttons to

scroll and to SELECT.

Select Exit to exit from any menu.

Navigation Button

The center button is purposely recessed to help

eliminate unintentional powering-up of the Gage.

Menu Operation

Menu Operation

Gage functions are menu controlled. To access the Menu,

power-up the Gage, then press the center navigation button.

NOTE:

Certification

PosiTector RTR probes include a Certificate of Calibration.

For organizations with re-certification requirements, instruments

may be returned at regular intervals for calibration.

DeFelsko recommends that customers establish calibration

intervals based upon their own experience and work environment.

Based on our product knowledge, data and customer feedback, a

one year calibration interval from either the date of calibration, date

of purchase, or date of receipt is a typical starting point.

Wrist Strap

We recommend attaching and wearing the

supplied wrist strap.

1

2

Protective Lens Shield

The LCD is covered with a thin plastic film for protection against

fingerprints and other marks during shipment. This film, while

usually removed before using the Gage, can be left in place to

protect against paint overspray or debris. Replacements can be

purchased.

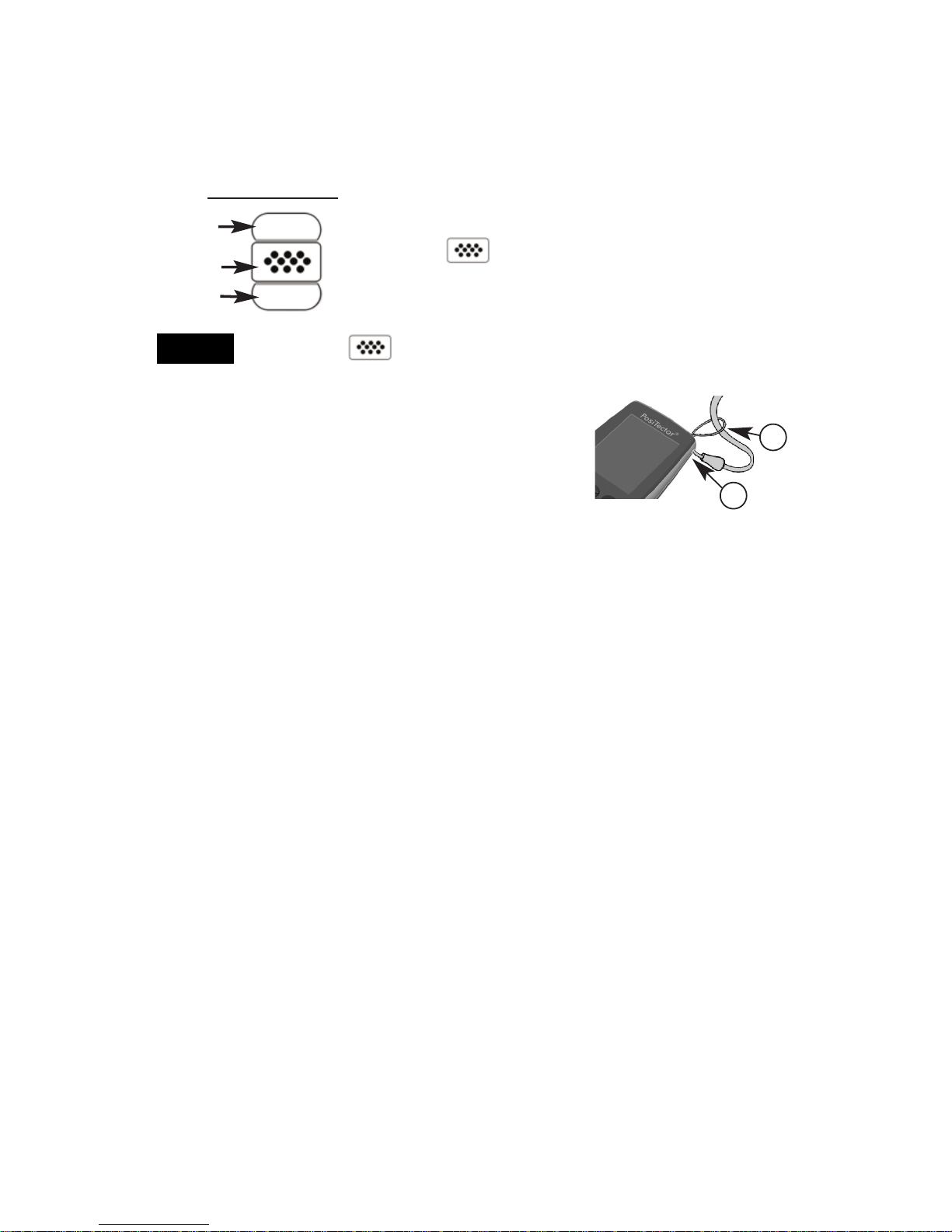

3

USB Port

LCD Display

Probe Connector

PosiTector Body

Typical Display

Current

Measurement

Unit of Measurement

thou/mils

Battery Icon

2.1

Measurement

Opening (Anvils)

Button Operated

Spring Micrometer

applies constant

anvil pressure

XC

H

L

Tape Grade

Linearize

Mode (pg. 11)

4

Probes

Probes

To disconnect a probe from a body, power-down the

Gage and slide the plastic probe connector horizontally

(in the direction of the arrow) away from the body.

Reverse these steps to attach a new probe.

When powered-up, the PosiTector automatically

determines which probe is attached and does a

self-check.

Additionally, the PosiTector accepts a number of probe types

including magnetic and eddy current coating thickness, surface

profile, environmental and ultrasonic wall thickness probes.

Perform the latest software Updates (pg. 26) to ensure probe

compatibility with your Gage. For the latest information on probe

interchangeability see www.defelsko.com/probes

5

How to Measure

How to Measure

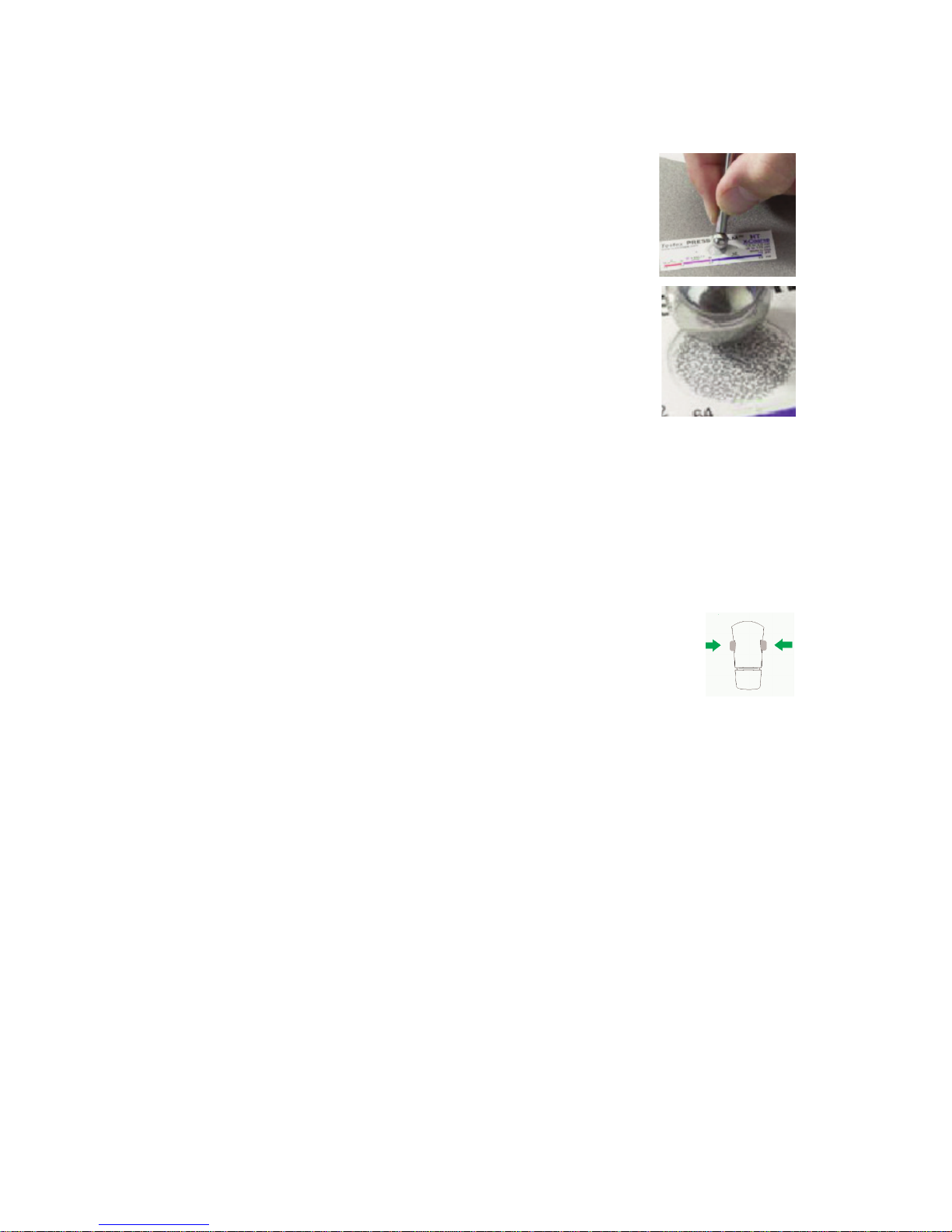

Prepare the test surface

Burnish the replica tape (create a replica)

1. Prepare the test surface

2. Burnish the replica tape

3. Prepare the Gage

4. Measure

Locate a representative site for measurement.

Clean the surface to be tested. DeFelsko

recommends the use of the included putty to

remove dust, debris, or residual blast media from

the surface. Firmly press the putty onto the surface

using your fingers, and remove.

Press-O-Film Replica Tape

Press-O-Film Replica Tape

Press-O-Film provides a simple way to obtain an impression of a

surface for analysis. It consists of a layer of crushable plastic micro

foam affixed to a 50.8 µm (2 mil)

incompressible polyester film. When

compressed against a roughened surface, the

foam collapses and acquires an accurate

impression, or reverse replica, of the surface. It is available in a

number of grades to accommodate measurements in different

profile ranges.

Placing the compressed tape (replica) into the PosiTector RTR

gives a measure of the average maximum peak-to-valley height of

the surface roughness profile. The Gage automatically subtracts

the thickness of the polyester substrate from all measurements.

Select the appropriate grade of replica tape based on the target

profile. See tape instructions for assistance.

Pull a single adhesive-backed replica tape free of its release paper.

A “bull’s eye” circle of paper should remain on the release paper

(it is not used for measurement).

6

Apply replica tape to blasted surface. Press the adhesive-backed

ends of the paper to hold it firmly in place during the burnishing

process.

Firmly compress replica film using the rounded end

of the included stainless steel burnishing tool.

Apply sufficient pressure in a circular and x-y

rubbing motion to produce a replica with a uniform

pebble grain appearance. It normally takes 30 to 60

seconds to fully compress all parts of the film on

most surfaces. In general, too much compression is

safer than too little. After burnishing is complete,

remove the replica tape from the surface.

Prepare the Gage

With the Gage powered-down, clean the measurement surfaces

using the included cleaning card. Swipe the card through the

opening a few times while firmly pressing both probe buttons to

remove dust particles and residual tape adhesive.

Power-up the Gage by pressing the center navigation

button. An image appears indicating that the probe

requires zeroing.

Simultaneously press and hold both probe buttons firmly until the

Gage beeps and the arrows point outward. Do not place anything

in the measurement opening during this procedure.

Measure the included check shim to verify accuracy (pg. 8).

Ensure the correct grade of replica tape, C or XC, is displayed in

the upper left corner of the LCD (pg. 10).

7

The probe contains two measuring surfaces that can become

contaminated with dust particles and residual tape adhesive. It is

therefore a good idea to clean the probe regularly with the included

cleaning card. Cleaning is essential prior to performing a probe

zero (pg. 10) or a verification of accuracy (pg. 8). It is best

performed when the Gage is powered down.

With the Gage powered-down, swipe the card through the opening

a few times while firmly pressing both probe buttons.

The card can also be used to clean the surfaces of analog spring

micrometers. Replacement cards are available from your dealer.

Cleaning Card

Measure

Insert the burnished replica tape into the

measurement opening. Ensure the tape is

properly positioned so that the burnished region

is centered within the opening in the probe with

the adhesive (sticky) side down.

To position the tape, move the tape to the back of the probe and

align the two dots (printed on replica tape) with arrows on both

sides of the measurement opening.

If you are using older tape that does not have the printed dots,

simply align by centering the tape within the measurement

opening.

Once positioned, firmly press both probe buttons simultaneously

and hold until the Gage beeps and the measurement is displayed.

During measurement, a constant anvil pressure is applied to the

replica tape regardless of how hard the two buttons are pressed.

The Gage automatically subtracts the 50.8 μm (2 mil) of

incompressible polyester film. No further adjustments are required.

Align dots with arrows on probe

8

Verification of Accuracy

Gage accuracy is verified using the included check shim.

Ensure that the probe has been cleaned with the included

cleaning card and that the probe has been zeroed (pg. 10).

Place the check shim into the measurement opening.

The average of several measurements should be within the

combined tolerance of both the Gage and the shim. If not, the

Gage may need to be returned to your dealer for service.

The check shim is specifically intended for the PosiTector RTR.

The Gage is designed to measure burnished replica tape within a

limited measuring range and automatically subtracts 50.8 μm

(2 mil) from height measurements to account for the

incompressible polyester film. Therefore plastic shims intended for

other instruments such as coating thickness gages will not be

measured properly.

Calibration

Gage calibration is typically performed by the manufacturer or

accredited lab. All probes include a Certificate of Calibration.

Calibration & Verification of Accuracy

Calibration & Verification of Accuracy

Loading...

Loading...