Page 1

Coating Thickness Gage

QUICK GUIDE

v. 2 . 0

Page 2

Introduction

Introduction

T

h

e

P

o

s

i

T

e

c

t

o

r

P

C

P

o

w

d

e

r

C

h

e

c

k

e

r

i

s

a

h

a

n

d

-

h

e

l

d

,

C

o

a

t

i

n

g

T

h

i

c

k

n

e

s

s

G

a

g

e

t

h

a

t

u

s

e

s

a

n

a

i

r

b

u

l

t

r

a

s

o

u

n

d

t

o

a

n

a

l

y

z

e

c

o

a

t

i

n

g

p

o

w

d

c

a

l

c

u

l

a

t

e

a

n

d

d

i

s

p

l

a

y

a

p

r

e

T

h

e

G

a

g

e

c

o

n

s

i

s

t

s

o

f

a

n

(

P

C

)

p

r

o

b

e

t

h

a

t

e

c

h

n

o

l

o

o

t

h

e

r

w

h

P

o

s

i

T

e

c

t

T

h

i

s

Q

u

D

o

w

n

l

o

a

1. POWER-UP both units (probe first).

a) Power-up probe by pressing the button.

b) Power-up PosiTector body by pressing the center

navigation button.

A beep and the letters “PC” will display on the upper left

corner of the PosiTector LCD. This indicates both units are

ready to measure.

2. ZERO the probe (pg 6)

3. ADJUST to the specific powder if necessary (pg 8)

4. MEASURE the applied powder (pg 2)

t

g

y

.

T

h

e

y

i

l

e

m

e

a

s

o

r

b

o

d

y

t

i

c

k

G

u

i

d

e

d

t

h

e

f

u

l

l

c

o

m

m

m

u

s

t

s

u

r

i

n

g

.

A

o

s

t

a

y

w

s

u

m

m

i

n

s

t

r

u

c

t

i

Quick Star t

Quick Star t

A

u

n

t

a

r

i

t

a

r

o

n

e

d

i

c

t

e

d

c

u

d

v

a

n

c

e

d

i

c

a

t

e

w

i

y

w

i

t

h

i

n

u

h

b

b

e

r

h

o

t

h

e

o

p

e

i

z

e

s

t

h

e

m

a

n

u

a

l

a

o

r

a

p

p

l

i

e

d

r

b

l

b

e

d

t

h

i

c

k

n

o

d

y

a

n

d

t

h

e

a

c

h

1

0

m

e

t

e

r

s

t

e

r

w

i

t

h

r

a

t

o

r

w

h

i

l

a

s

i

c

f

u

n

t

:

w

w

w

.

d

e

n

r

n

e

h

i

g

h

t

o

s

b

e

c

o

r

i

g

i

d

s

u

e

s

s

.

a

P

o

w

d

e

t

h

e

r

v

i

a

(

3

0

f

e

e

e

l

t

l

o

o

p

m

e

a

s

u

r

t

i

o

n

s

o

f

f

e

l

s

k

o

.

c

o

m

o

n

-

c

o

n

t

a

c

f

r

b

s

r

t

)

a

i

n

t

h

t

e

q

u

e

n

c

y

t

r

a

t

e

s

t

o

C

h

e

c

k

e

r

w

i

r

e

l

e

s

s

o

f

e

a

c

h

l

l

o

w

s

t

h

e

g

.

e

G

a

g

e

.

/

m

a

n

u

a

l

s

NOTE:

To preserve batter y life, the PosiTector body and

PC probe power down after approximately 5 minutes of no activity.

All settings are retained.

1

Page 3

Menu Operation

Menu Operation

Gage functions are menu controlled. To access the Menu,

power-up the PC Probe and PosiTector body, then press the

center navigation button.

Navigation Button

Up

Center

Down

NOTES:

The center button is purposely recessed to help eliminate

unintentional power-up.

When no probe is attached, a limited menu will be displayed.

Connect probe for full menu.

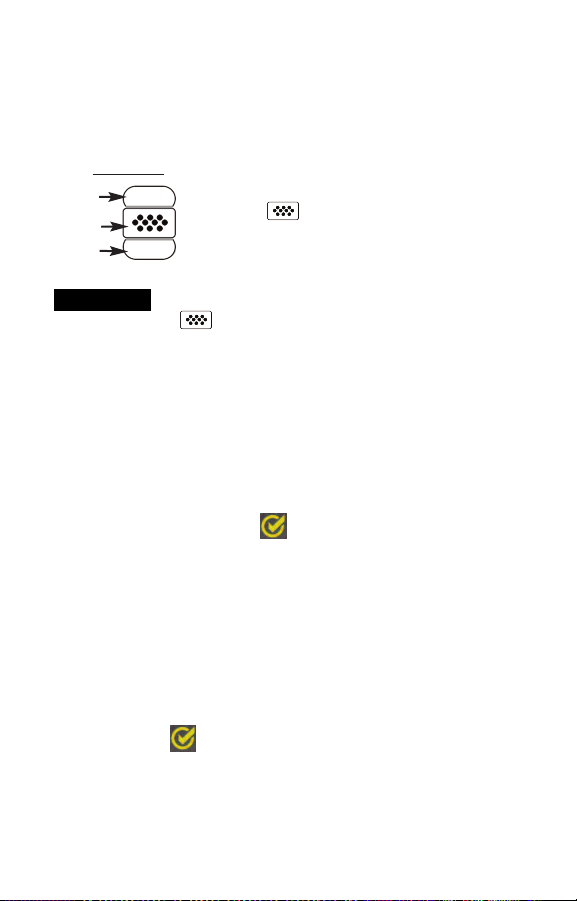

Power-up both units. Bring the probe to within 5 cm (2 inches) of

the coating powder.

Press and hold the button. Bring the probe closer to the powder.

While watching the probe display, align the Distance Paddle with

the Distance Target Bar. (pg 3)

While the probe button is depressed, probe distance and angle

should be varied slightly keeping:

(a) the Distance Paddle close to the Distance Target Bar

(b) the Amplitude Indicator at maximum height (pg 3).

To navigate, use the Up and Down buttons to

scroll and to SELECT.

Select Exit to exit from any menu.

How to Measure

How to Measure

Release the button when you hear a double BEEP or see a

thickness measurement on either display.

2

Page 4

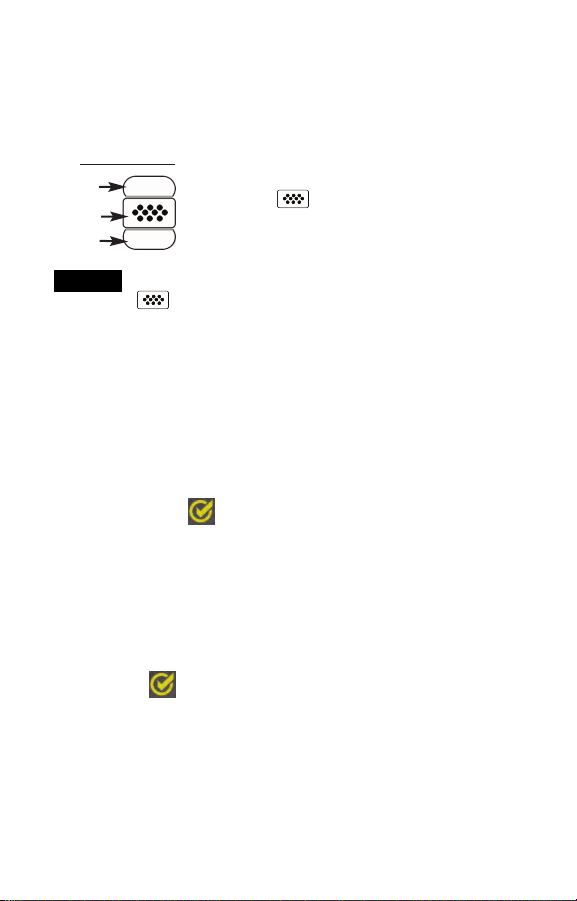

Probe Display: ( button not pressed)

Probe Batteries Status (pg 10)

Probe Connected Indicator

Predicted Cured Thickness Result

Probe Display: ( button pressed)

Results Indicator

Maximum

Amplitude Dot

Amplitude Indicator

Wireless Indicator: The symbol indicates the PosiTector body

and wireless probe are communicating properly.

Results Indicator: When the probe is in the proper position and

good samples are being taken, a solid blue dot blinks on the probe

display, the PosiTector body displays a flashing green dot and

emits a high beep. When samples are inconclusive, an “X” blinks

on the probe display, the PosiTector body displays a flashing red

dot and emits a low beep.

Distance Paddle: Graphically represents the distance to the

target. It rises and falls to indicate distance from the probe tip to

the surface of the powder.

Distance Target Bar: The optimum distance for measurement is

18 mm (3/4 inch) between the tip of the probe and the surface of

the applied powder. During measurement, keep the Distance

Paddle close to the Distance Target Bar.

Distance Target Bar

Distance Paddle

Predicted Cured

Thickness Result

3

Page 5

Amplitude Indicator : Strength of the ultrasonic echo.

A high position indicates good probe orientation relative to

perpendicular. The bar will generally reach higher positions when

measuring thin powder and when the probe is at a 90-degree

angle to the powder surface.

Maximum Amplitude Dot: Marks the highest position the

Amplitude Indicator reached during the current measurement

attempt.

Predicted Cured Thickness Result: When a valid measurement

is calculated, the PosiTector body BEEPS twice and the predicted

cured measurement result is displayed on both the PC probe and

PosiTector body. Continuing to hold the probe button will result in

additional samples being collected.

There are 4 types of displayed measurement results:

43 Predicted thickness result.

0 The collected samples have resulted in a good reading,

but the resultant predicted cured thickness is less than the

minimum range.

++ The collected samples have resulted in a good reading,

but the resultant predicted cured thickness is greater than

the maximum range.

-- An indeterminate or invalid reading.

Measurement Notes

Measurement Notes

If a thickness result does not appear after 5 seconds, release the

measurement button and try again. Wait 1 to 2 seconds between

readings.

Small, erratically swinging parts may present measurement

challenges. Steady the part whenever possible. If erroneous

readings continually result, change the measurement strategy

by rotating the probe, altering its alignment to the part, or by

measuring a different location on the part.

For best results use Statistics mode (pg 10) to generate averages.

The average of a series of measurements is often a more

meaningful prediction of cured thickness than a single reading.

4

Page 6

Probes

Probes

The PosiTector body accepts a number of probe types including

magnetic, eddy current and ultrasonic coating thickness, surface

profile, environmental and ultrasonic wall thickness probes.

For the latest information on probe interchangeability,

see www.defelsko.com/probes

Wireless Powder Checker probes:

The PosiTector PC wireless probe connects to all Advanced

PosiTector bodies. See Powder Probes (pg 13) for connection

details.

Physically connected PosiTector probes:

To disconnect a probe from a PosiTector body, slide the

plastic probe connector horizontally (in the direction of

the ar row) away from the PosiTector body.

Reverse these steps to attach a new probe.

The PosiTector automatically determines what type of

probe is attached and does a self-check.

NOTE:

During power-up a physically connected probe is

recognized when a PC probe is not available (powered-off).

To reconnect to a PC wireless probe (after power-up), select

Connect, within the Connect > Powder Probes menu. (pg 13)

The PosiTector body will automatically connect to an active

wireless PC probe during power-up. PC probe must be turned on.

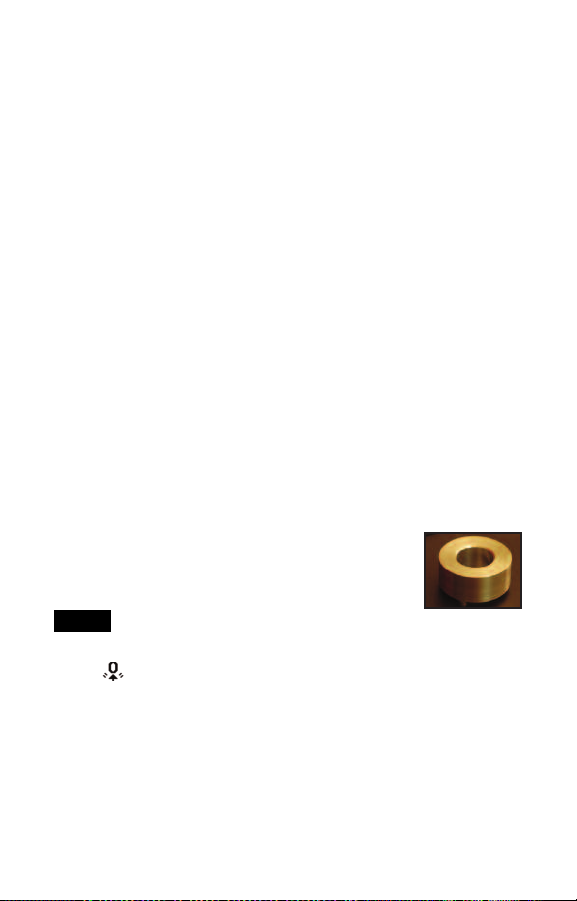

Maintenance

The screen at the measuring end of the PC probe can be

unscrewed for cleaning. Accumulated powder should be carefully

removed from the screen by no more than 0.2 MPa (20 - 30 psi)

of compressed air. Do not blow air directly into the probe.

Replacement screens are available.

5

Page 7

Verification of Accuracy

Verification of Accuracy

Before first use on a new powder and periodically thereafter, the

user should perform an accuracy check. This ensures the gage

measures properly by comparing predicted thickness values with

actual cured thickness values.

Zero the probe (pg 6).1.

Spray powder onto a flat, smooth metal sample.2.

Measure the uncured powder with the PosiTector PC.3.

Cure the powder.4.

Measure cured thickness with a magnetic or eddy current5.

coating thickness gage such as the PosiTector 6000.

Compare results.6.

A successful verification requires that the average of a series

of measurements by both instruments be within their combined

tolerances. If not, adjust the PosiTector PC using one of the

methods described on page 7.

For best accuracy, perform a Zero at the beginning of every shift

to compensate for temperature and humidity changes. It is also

required after a Reset (pg 9).

Zero

Zero

Place the measuring end of the PC probe into the

Powder Probe Fixture.

Select Zero from the Gage menu.

NOTE:

The Zero process can take up to 30 seconds.

Factory Calibration Symbol

Factory Calibration Symbol

This symbol indicates the instrument is measuring with factory

calibration settings. It appears whenever a Reset (pg 9) is

performed or whenever a new calibration setting (pg 9) is created.

It disappears whenever a calibration adjustment is made (pg 8)

or when a user calibration is loaded from cal memory (pg 9).

A probe Zero (pg 6) does not change the status of the symbol.

6

Page 8

Calibration and Adjustment

Calibration and Adjustment

The PosiTector PC probe is factory calibrated and performs an

automatic self-check each time it calculates a measurement. For many

powder measurement applications no further adjustment is necessary.

Simply Zero at the beginning of each shift, then measure.

Sometimes gage measurement calculations can be influenced by the

composition of the coating powder. A calibration adjustment improves

accuracy in these circumstances.

Adjustment, or Calibration Adjustment, is the act of aligning the

gage's predictions to match those of a known cured sample.

Begin by performing a Verification of Accuracy (pg 6) to determine

if there is a need for an adjustment. If the average of several

thickness results is outside the combined tolerances of the two

measuring instruments (PosiTector PC and dry film thickness

instrument) then two adjustment techniques are available to correct

the variance (see Adjustment Techniques, pg 7).

User adjustments are stored in the current Cal setting. It may be

desirable to open a new Cal setting first (see Cal Memory, pg 9).

Adjustment Techniques

Adjustment Techniques

To ensure the gage is working properly, the user should periodically

perform an accuracy check by comparing predicted thickness

values with actual cured thickness values (pg 6).

If the average of a series of measurements by both instruments

(PosiTector PC and dry film thickness instrument) is not within

combined tolerances, the PosiTector PC can be adjusted using

one of two methods...

1 Pt Adjust - The first and most common choice.1.

2 Pt Adjust - If a 1 Pt Adjust does not improve accuracy.2.

See Cal Settings menu, pg 8 for more details.

7

Page 9

Cal Settings Menu

Cal Settings Menu

1 Pt Adjust

Spray approximately 75 microns (3 mils) of powder onto a1.

flat, smooth metal sample.

Select 1 Pt Adjust then select Measure. 2.

Take at least 3 uncured powder measurements with the3.

PosiTector PC. Results will be stored in the gage.

Select OK.4.

Cure the powder.5.

Measure cured thickness with a magnetic or eddy current6.

coating thickness gage. Record the results.

Select 1 Pt Adjust then select Adjust.7.

Adjust the displayed reading average lower (-) or higher (+) 8.

to match the cured thickness value. Select OK.

2 Pt Adjust

Spray powder onto 2 flat, smooth metal samples. Place1.

approximately 40 microns (1.5 mils) on one and 75 microns

(3 mils) on the other.

Select 2 Pt Adjust then select Measure. 2.

Take at least 3 uncured powder measurements on the thin3.

powder panel with the PosiTector PC. Results will be stored

in the gage. Select OK.

Take at least 3 uncured powder measurements on the thick4.

powder panel with the PosiTector PC. Results will be stored

in the gage. Select OK.

Cure the powder on both panels.5.

Measure cured thickness on both panels with a magnetic or6.

eddy current coating thickness gage. Record the results.

Select 2 Pt Adjust then select Adjust.7.

Adjust the displayed 1st point reading average lower (-) or8.

higher (+) to match the cured thickness values. Select OK.

Adjust the displayed 2nd point reading average lower (-) or9.

higher (+) to match the cured thickness values. Select OK.

Gage may be powered off. It will retain the cal

NOTE:

measurements during a power cycle.

Gage may be powered off. It will retain the cal

NOTE:

measurements during a power cycle.

8

Page 10

Cal Memory

When measuring a specific part with a specific powder, it is often

convenient to be able to store any unique calibration adjustments

made for that application. Then, if you return to that part, the

corresponding Cal setting can be conveniently and quickly

restored.

Cal Lock

✔

When selected, the icon will appear and all calibration settings

are “locked” to prevent further user adjustments. Uncheck to make

further adjustments.

Setup Menu

Setup Menu

Reset

Reset (soft reset) restores factory settings and returns the Gage

to a known condition. The following occurs:

- All batches, stored measurements, images, and batch names

are erased.

- Menu settings are returned to the following:

Memory = OFF

Statistics = OFF

Bluetooth = OFF

Display = None

Cal Lock = OFF

Perform a more thorough Hard Reset by powering down the Gage,

waiting several seconds, then simultaneously holding both the

center and (+) buttons until the Reset symbol appears.

This returns the Gage to a known, “out-of-the-box” condition.

It performs the same function as a menu Reset with the addition of:

- All calibration adjustments and Cal Memory are cleared and

returned to the Gage’s factory calibration settings.

- Bluetooth Pairing info is cleared.

- Menu settings are returned to the following:

Units = microns

Flip Display = Normal

Auto Sync = OFF

NOTES:

- A probe Zero (pg 6) must be performed after a Reset.

White on Black = OFF

Language = English

Battery Type = Alkaline

Backlight = Normal

USB Drive= ON

- Date, Time and WiFi are not affected by either Reset.

9

Page 11

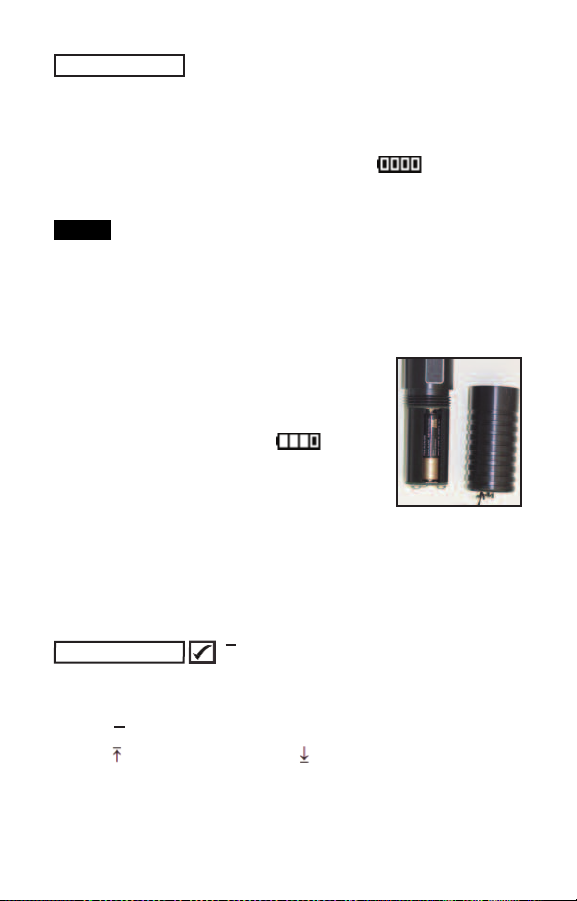

Battery Type

Selects the type of batteries used in the PosiTector body from a

choice of “Alkaline”, “Lithium” or “NiMH” (Nickel-metal hydride

rechargeable). If NiMH is selected, the PosiTector will trickle

charge the batteries while connected via USB to a PC or optional

AC charger. The battery state indicator icon is calibrated

for the selected battery type. No damage will occur if the wrong

battery type is selected.

NOTE:

rechargeable batteries.

Use only “AA alkaline batteries” (3) in the

probe. Nickel-cadmium and nickel-metal

hydride rechargeable batteries will work but

the probe battery state indicator icon may

appear to have weak batteries . The

gage will turn off automatically when batteries

are very low, preceded by a low battery warning

on the display. If batteries are very low the

gage may startup but then turn off quickly.

A statistical summary will appear on the display. Remove the last

measurement by pressing the

statistics.

DeFelsko recommends the use of eneloop (NiMH)

Statistics

x

(PosiTector body only)

Changing Probe Ba tteries

Changing Probe Ba tteries

Stati

stic

s

stic

Mode

s

Mode

Stati

x

(-) button. Press

Average

Maximum Value

σ Standard Deviation

Minimum Value

(+)

to clear

10

Page 12

Memory Management

Memory Management

The PosiTector PC has internal memory storage for recording

measurement data. Stored measurements can be reviewed

on-screen or accessed via computers, tablets and smart phones.

Measurements are date and time-stamped.

Memor y stores 100,000 readings in up to 1,000 batches.

“New Batch” closes any currently opened batch and creates a new

batch name using the lowest available number. The icon

appears. New batch names are date stamped when created.

Scroll through

display modes

Delete last reading

Access the Menu

NOTE:

This Quick Guide summarizes the basic functions

of the Gage. Download the full instruction manual at:

www.defelsko.com/manuals

Accessing Stored Measurements Data

Accessing Stored Measurements Data

PosiSoft solutions for viewing, analyzing and reporting data:

PosiSoft USB Drive - connect the PosiTector to a PC/Mac using

the supplied USB cable to access and print stored readings,

graphs, photos, notes and screen captures. No software or

internet connection required. USB Drive (pg 12) must be selected.

PosiSoft.net - a free web-based application offering secure

centralized storage of PosiTector readings. Access your data

from any web connected device. Go to: www.PosiSoft.net

PosiSoft 3.0 - Desktop Software for downloading, viewing and

printing your measurement data.

PosiSoft Mobile (Advanced models only) - access readings, graphs,

capture photos and update annotations through WiFi enabled

devices, such as tablets, smart phones and computers.

Create a new batch

Restore brightness

after dimming

11

Page 13

Connect Menu

Connect Menu

Sync Now

When selected, Gage immediately synchronizes stored

measurement data via USB, Bluetooth or WiFi to PosiSoft.net.

(PosiSoft Desktop Manager and an internet connection are

required when using USB or Bluetooth.)

Auto SYNC

Allows the Gage to automatically synchronize with PosiSoft.net

when initially connected to the internet via a PC running PosiSoft

Desktop Manager or a local WiFi network.

Additional measurements added to memory while connected are

synchronized only when the USB cable is disconnected, then

reconnected or when the Sync Now option is selected.

USB Drive

The Gage uses a USB mass storage device class which provides

a simple interface to retrieve data in a manner similar to USB

flash drives, cameras or digital audio players.

NOTE:

When connected, power is supplied through the USB

cable. The batteries are not used and the PosiTector body will not

automatically power down. If rechargeable (NiMH) batteries are

installed, the Gage will trickle charge the batteries.

Bluetooth

Allows individual readings to be sent to a computer, printer or

compatible device as they are taken using Bluetooth wireless

technology. See www.defelsko.com/bluetooth

WiFi

Allows wireless communication with devices such as tablets,

smart phones and computers connected to your local wireless

network or portable mobile hot spot. See www.defelsko.com/WiFi

12

Page 14

Powder Probes

Displays menu options that enable the PosiTector body to

communicate with wireless PosiTector PC probes.

List

Displays all previously connected PC probes.

Change Order

Select which PC probe the PosiTector body will connect to first

during power-up.

Add New

Allows PosiTector body to pair with a wireless PC probe for

the first time.

When selected, the PosiTector body will display, “Ensure1.

probe is turned on and in reset state before continuing!”

Refer to Full Guide for Probe RESET instructions at

www.defelsko.com/manuals

Select Next. The PosiTector body will search for available2.

PC probes.

Select the PC Probe to connect. PC Probes are displayed3.

by their serial numbers.

Probe Off

Disconnects PC probe from PosiTector body and causes the PC

probe to power off. If a physically connected probe is attached,

the PosiTector will automatically recognize it.

Connect

Allows PosiTector body to connect to or switch between

wireless PC probes and physically connected probes. PC

probe must be turned on.

Updates

Determines if a software update is available for your Gage.

See www.defelsko.com/update

WARNING:

(see pg 9).

The Gage may perform a Hard Reset after an update

13

Page 15

Returning for Ser vice

Returning for Ser vice

Before returning the Gage for service…

1.Install new or newly recharged batteries in the proper alignment

as shown within battery compartment (pg 10).

2.Examine the probe screen for dir t or damage (pg 5).

3.Perform a Hard Reset (pg 9) and a Zero (pg 6).

If you must return the Gage for service, describe the problem fully

and include measurement results, if any. Be sure to also include

the probe, your company name, company contact, telephone

number and fax number or email address.

Website: www.defelsko.com/support

Limited Warranty, Sole Remedy

Limited Warranty, Sole Remedy

and Limited Liability

and Limited Liability

DeFelsko's sole warranty, remedy, and liability are the express

limited warranty, remedy, and limited liability that are set forth on

its website: www.defelsko.com/terms

www.defelsko.com

© DeFelsko Corporation USA 2014

This manual is copyrighted with all rights reserved and may not be reproduced or transmitted, in whole

or part, by any means, without written permission from DeFelsko Corporation.

DeFelsko, PosiTector and PosiSoft are trademarks of DeFelsko Corporation registered in the U.S. and in

other countries. Other brand or product names are trademarks or registered trademarks of their respective holders.

Every effort has been made to ensure that the information in this manual is accurate. DeFelsko is not

responsible for printing or clerical errors.

All Rights Reserved

14

Page 16

—NOTES—

Page 17

—NOTES—

Page 18

Coating Thickness Gage

Guia rápida

v. 2 . 0

Page 19

Introducción

Introducción

E

l

P

o

s

i

T

e

c

t

o

r

P

C

P

o

w

d

e

r

C

h

e

c

k

e

r

e

s

u

n

m

e

d

i

d

o

r

d

e

e

s

p

e

s

o

r

r

e

c

u

b

r

i

m

i

e

n

t

o

m

a

n

u

a

l

,

s

i

n

c

o

n

t

a

c

t

o

q

u

e

u

t

i

l

i

z

a

u

n

u

l

t

r

a

s

o

n

i

d

o

d

e

a

l

t

a

f

r

e

c

u

e

n

c

i

a

a

e

r

o

t

r

a

n

s

p

o

r

t

r

e

c

u

b

r

i

m

i

e

n

t

o

d

e

p

o

l

v

o

a

p

l

i

c

a

d

o

a

s

y

m

o

s

t

r

a

r

l

a

p

r

e

d

i

c

c

i

ó

n

d

e

u

E

l

d

i

s

p

o

s

i

t

i

v

o

c

o

n

s

t

a

d

e

u

n

C

h

e

c

k

e

r

(

P

C

)

q

u

i

n

a

l

á

m

b

r

i

r

a

u

d

E

D

w

1. ENCIENDA ambas unidades (primero la sonda).

2. AJUSTE A CERO la sonda (pág 6)

3. AJUSTE al polvo específico si fuera necesario (pág 8)

4. MIDA el polvo aplicado (pág 2)

Para proteger la duración de las baterías, la base del PosiTector y

la sonda PC se apagarán tras unos 5 minutos de inactividad.

Se conservarán todas las configuraciones.

c

d

i

o

d

e

1

n

a

c

o

r

r

e

a

u

r

a

n

t

e

l

a

s

t

a

g

u

í

a

e

s

c

a

r

g

u

w

w

.

d

e

f

e

l

a) Encienda la sonda pulsando el botón .

b) Encienda la base del PosiTector pulsando el botón de

central.

Una señal sonora y las letras "PC" se mostrarán en la esquina

superior izquierda de la pantalla LCD del PosiTector.

Esto indicará que ambas unidades están listas para medir.

NOTA:

e

a

.

D

u

r

a

n

0

m

e

t

r

o

s

p

e

r

m

i

t

e

m

e

d

i

c

i

ó

r

á

p

i

d

a

e

e

l

s

k

o

.

c

o

m

a

s

e

c

o

m

t

e

l

a

m

e

(

3

0

p

i

e

s

)

a

b

a

s

e

d

n

.

r

e

s

u

m

e

m

a

n

u

a

l

/

m

a

n

u

a

l

s

Inicio rápido

Inicio rápido

u

n

e

s

p

e

s

o

b

a

s

e

A

d

u

n

i

c

a

n

e

d

i

c

i

ó

n

d

d

e

d

i

s

t

a

e

l

P

o

s

i

T

e

l

a

s

f

u

n

c

d

e

i

n

s

a

s

t

r

a

t

o

s

r

r

c

u

r

a

d

o

v

a

n

c

e

d

y

n

t

r

e

s

í

m

e

b

e

n

p

e

r

n

c

i

a

.

U

n

a

c

t

o

r

a

c

o

m

i

o

n

e

s

b

á

t

r

u

c

c

i

o

n

e

a

d

o

p

a

r

a

í

g

i

d

o

s

p

a

.

u

n

a

s

o

n

d

e

d

i

a

n

t

e

m

a

n

e

c

e

r

f

u

n

d

a

d

e

p

a

ñ

a

r

a

s

i

c

a

s

d

e

s

c

o

m

p

d

s

e

ñ

a

l

d

a

n

a

l

i

z

a

r

r

t

l

l

e

a

c

a

l

c

u

l

a

a

P

o

w

d

e

e

c

n

o

l

o

g

í

d

e

n

t

r

o

u

g

o

m

a

c

o

o

p

e

r

a

d

o

m

e

d

i

d

o

l

e

t

o

e

n

e

e

l

r

r

a

n

n

r

r

.

:

1

Page 20

Menú de operación

Menú de operación

Las funciones del medidor se controlan por medio de menús.

Para acceder al menú, encienda la sonda PC y la base del

PosiTector, luego pulse el botón central.

Botón central

Arriba

Centro

Abajo

NOTAS:

El botón central está rebajado a propósito para evitar que

se encienda de manera no intencionada.

Cuando no haya sonda conectada se mostrará un menú limitado.

Conecte una sonda para ver el menú completo.

Encienda ambas unidades. Acerque la sonda a menos de 5 cm

(2 pulgadas) del polvo de recubrimiento.

Mantenga apretado el botón . Acerque más la sonda al polvo.

Observe la pantalla de la sonda procurando alinear el marcador

del límite de distancia con la barra de distancia al objetivo. (pág 3)

Mientras mantiene apretado el botón de la sonda, puede variar

ligeramente la distancia y el ángulo de la sonda. Procure

mantener:

(a) el marcador de distancia cercano a la barra de distancia

al objetivo

(b) el indicador de amplitud en su altura máxima (pág. 3).

Para desplazarse utilice los botones Arriba y

Abajo y para SELECCIONAR.

Seleccione Salir para salir de cualquier

menú.

Cómo medir

Cómo medir

Libere el botón al oír un doble pitido o vea una medida del

espesor en pantalla.

2

Page 21

Pantalla de la sonda: (botón sin pulsar)

Estado de las baterías de la sonda (pág 10)

Indicador de sonda conectada

Resultado de predicción de espesor

curado

Pantalla de la sonda: (botón pulsado)

Indicador de

resultados

Punto luminoso de

amplitud máxima

Indicador de amplitud

Indicador inalámbrico: El símbolo indica que la base del

PosiTector y la sonda inalámbrica disponen de conexión correcta.

Indicador de resultados: Cuando la sonda esté en la posición

adecuada y se tomen muestras correctas parpadeará un punto

azul en la pantalla de la sonda y un punto verde en la base y se

emitirá un fuer te pitido. Cuando las muestras no sean

concluyentes, una "X" parpadeará en la pantalla de la sonda y la

base del PosiTector mostrará un punto rojo parpadeante y emitirá

un leve pitido.

Límite de distancia: Representa gráficamente la distancia al

objetivo. Sube y baja para indicar la distancia desde la sonda a la

superficie del polvo.

Línea de distancia al objetivo: La distancia óptima para la

medición es 18 mm (3/4 pulgadas) entre la punta de la sonda y la

superficie del polvo aplicado. Durante la medición, mantenga el

límite de distancia cercano a la barra de distancia al objetivo.

Línea de distancia

al objetivo

Barra de distancia

Predicción de curado

Resultado de espesor

3

Page 22

Indicador de amplitud: La fuerza del eco ultrasónico. Una

posición superior indicará una correcta orientación de la sonda en

relación con la perpendicular. De manera general, la barra

alcanzará posiciones superiores cuando mida polvo fino y cuando

la sonda se encuentre en un ángulo de 90° con respecto a la

superficie.

Punto de máxima amplitud: Marca la posición superior que

alcanza el indicador de amplitud durante la medición en curso.

Resultado de predicción de espesor curado: Cuando se calcule

una medición válida, la base del PosiTector sonará dos veces y el

resultado predicho de la medición del curado se mostrará tanto en

la sonda PC como en la base PosiTector. Si continúa pulsando el

botón se tomarán muestras adicionales.

Hay 4 tipos de visualización de resultados de medición:

43 Resultado de espesor predicho.

0 Las muestras recogidas han producido una buena lectura,

pero el espesor curado predicho resultante es menor que

el rango mínimo.

++ Las muestras recogidas ofrecen una lectura correcta pero

el espesor curado predicho resultante es mayor que el

rango máximo.

-- Una lectura indeterminada o inválida.

Notas de medición

Notas de medición

Si no aparece resultado de espesor tras 5 segundos, libere el

botón de medición y vuelva a intentarlo. Espere 1 o 2 segundos

entre lecturas.

Las piezas pequeñas o móviles pueden presentar un reto durante

la medición. Estabilice la pieza siempre que sea posible. Si

obtiene lecturas erróneas continuamente, cambie la estrategia de

medición girando la sonda, modificando su alineación con la pieza

o midiendo en una ubicación diferente de la pieza.

Para obtener mejores resultados emplee el modo Estadísticas

(pág 10) para generar promedios. El promedio de una serie de

mediciones es a menudo una predicción más significativa del

espesor curado que una simple lectura.

4

Page 23

Sondas

Sondas

La base PosiTector acepta una variedad de tipos de sonda

incluyendo para espesor de recubrimientos magnéticas, de

corrientes de Foucault y de ultrasonidos, perfil de superficie,

ambientales y sondas ultrasónicas para espesor de pared.

Para obtener la información más reciente sobre la compatibilidad

de la sonda consulte www.defelsko.com/probes

Sondas Wireless Powder Checker:

La sonda inalámbrica PosiTector PC se conecta a todas las bases

PosiTector Advanced. Consulte Sondas Polvo (pág 13) para

detalles de conexión.

Sondas PosiTector conectadas por cable:

Para desconectar una sonda de una base PosiTector,

deslice el conector de plástico de la sonda

horizontalmente (en la dirección de la flecha) retirandola

de la base PosiTector. Invierta los pasos para conectar

una nueva sonda.

El PosiTector determinará automáticamente el tipo de

sonda conectada y realizará una verificación.

NOTA:

sonda PC disponible (sonda apagada), entonces la base reconocerá la

sonda que este físicamente conectada a ella.

Para volver a conectar a una sonda inalámbrica PC (sonda activada),

seleccione Conectar, desde el menú Conectar>Sondas Polvo.

(pág 13)

La base PosiTector se conectará automáticamente a una sonda PC

inalámbrica activa durante el encendido. La sonda PC deberá estar

encendida antes de encender la base.

Durante el encendido, cuando no se pueda detectar una

Mantenimiento

La pantalla en la parte sensible de la sonda PC puede

desenroscarse para su limpieza. El polvo acumulado deberá

eliminarse de la pantalla con aire comprimido a no más de 0.2

MPa (20 – 30 psi). No dirija aire directamente a la sonda. Hay

pantallas de repuesto disponibles opcionalmente.

5

Page 24

Comprobación de la precisión

Comprobación de la precisión

Antes del primer uso con un polvo nuevo y también

periódicamente, el usuario deberá realizar una comprobación de

la precisión. Esto garantiza que el medidor realiza las mediciones

correctamente comparando los valores de predicción de espesor

con los valores obtenidos en la medición de espesor curado

actual.

Ajuste a cero la sonda (pág 6).1.

Rocíe con polvo una muestra metálica plana y suave.2.

Mida el polvo sin curar con el

Cure el polvo.4.

Mida el espesor curado con un medidor de recubrimiento5.

magnético o de corrientes de Foucault como el PosiTector

6000.

Compare los resultados.6.

Una comprobación correcta implica que el promedio de una serie

de mediciones por ambos instrumentos se encuentre dentro de

sus tolerancias combinadas. Si no es así, ajuste el PosiTector PC

utilizando uno de los métodos descritos en la página 7.

Para mayor precisión lleve a cabo un Ajuste a cero al inicio de

cada turno para compensar las variaciones de temperatura y

humedad. También se requiere después de un Reinicio (pág.9).

Coloque la punta de medición de la sonda PC

en el elemento fijo de sonda para polvo.

Seleccione Cero en el menú Medidor.

Cero

Cero

PosiTector PC.3.

NOTA:

Este símbolo indica que el instrumento utiliza la calibración de

fábrica. Aparece siempre que se Reinicia (pág. 9) o se configura

una nueva calibración (pág. 9). Desaparece siempre que se

realiza un ajuste de calibración (pág. 8) o cuando se carga una

calibración de usuario de la memoria de calibración (pág. 9).

El ajuste a cero de la sonda (pág. 6) no cambiará el estado del

símbolo.

El proceso de ajuste a cero puede llevar unos 30

segundos.

Símbolo de calibración de fábrica

Símbolo de calibración de fábrica

6

Page 25

Calibración y ajustes

Calibración y ajustes

El PosiTector PC viene calibrado de fábrica y se verifica a si

mismo automáticamente cada vez que calcula una medición. Para

varias aplicaciones de medición de polvo no necesitará ajustes

adicionales. Simplemente ajuste a cero en cada cambio de turno

y realice la medición.

En ocasiones los cálculos del medidor pueden verse influidos por

la composición del polvo de recubrimiento. Un ajuste de la

calibración mejorará la precisión en estas circunstancias.

El Ajuste, o Ajuste de Calibración, consiste en hacer coincidir las

predicciones de espesor en el medidor con el valor de una

muestra curada de espesor conocido.

Empiece realizando una comprobación de precisión (pág. 6) para

determinar si es necesario algún ajuste. Si el promedio de varios

resultados de espesor está fuera de las tolerancias combinadas

de los dos instrumentos de medición (PosiTector PC y medidor de

espesor de película seca) usted dispone de dos técnicas de ajuste

para corregir la varianza (véase Técnicas de ajuste, Pág. 7).

Los ajustes introducidos por el usuario se quedarán como de

Ajustes Cal. Puede ser oportuno crear un ajuste de Cal nuevo

antes de iniciar (véase Cal Memoria, Pág. 9)

Técnicas de ajuste

Técnicas de ajuste

Para asegurarse de que el medidor funciona correctamente el

usuario deberá comprobar periódicamente su precisión

comparando los valores de predicción de espesor con los valores

actuales de espesores curados (pág. 6).

Si el promedio de una serie de mediciones por ambos

instrumentos (PosiTector PC y medidor de espesor de película

seca) no está dentro de las tolerancias combinadas, puede ajustar

el PosiTector PC usando uno de ambos métodos...

1. 1 Punto - La opción primera y más común.

2. 2 Puntos - Si un ajuste de 1 Punto no mejora la precisión.

Consulte menú Ajustes Cal, pág. 8 para más detalles.

7

Page 26

Menú de Ajustes Cal

Menú de Ajustes Cal

1 Punto

Rocíe unas 75 micras (3 mils) de polvo en una muestra1.

metálica plana y suave.

Seleccione 1 Punto y a continuación, Medir. 2.

Tome al menos 3 mediciones en polvo sin curar con el 3.

PosiTector PC. Los resultados se almacenarán en el

medidor.

Seleccione OK.4.

Cure el polvo.5.

NOTA:

Mida el espesor curado con un medidor de espesores de6.

recubrimiento magnético o de corrientes de Foucault. Anote

los resultados.

Seleccione 1 Punto y a continuación, Ajustar.7.

Ajuste la lectura promedio indicada en pantalla hacia abajo 8.

(-) o hacia arriba (+) para que coincida con el valor del

espesor curado. Seleccione OK.

Rocíe con polvo en 2 muestras metálicas lisas. Distribuya1.

aproximadamente 40 micras (1,5 milésimas de pulgada) en

una y 75 micras (3 milésimas) en la otra.

Seleccione 2 Puntos y a continuación, Medir. 2.

Tome al menos 3 mediciones de polvo sin curar del panel con3.

polvo fino con el PosiTector PC. Los resultados se

almacenarán en el medidor. Seleccione OK.

Tome al menos 3 mediciones de polvo sin curar del panel con4.

polvo grueso con el PosiTector PC. Los resultados se

almacenarán en el medidor. Seleccione OK.

Cure el polvo en ambos paneles.5.

NOTA:

Mida el espesor curado en ambos paneles con un medidor de6.

espesor de recubrimientos magnético o de corrientes de

Foucault. Escriba los resultados.

Seleccione 2 Puntos y a continuación, Ajustar.7.

El medidor puede estar apagado. Conservará las

mediciones de Cal durante un ciclo de encendido.

2 Puntos

El medidor puede apagarse. Conservará las

mediciones de Cal durante un ciclo de encendido.

8

Page 27

8. Ajuste el primer punto promedio de lectura en pantalla hacia

abajo (-) o hacia arriba (+) para que coincida con los valores

de espesor curados. Seleccione OK.

9. Ajuste el segundo punto medio de lectura en pantalla hacia

abajo (-) o hacia arriba (+) para que coincida con los valores

de espesor curados. Seleccione OK.

ia

mor

e

l M

Ca

al

Luego

ent

án"

ust

gunos

,

ón

.

e

para

es

v

de

as

e poder

esa

aurar

ápi

ecer

es se "

zar

i

eal

t

acenar

m

al

caci

i

pl

a

conf

a

l

da y conv

cono y l

i

á el

oquear

bl

nuev

Fijar Cal = OFF

ón.

guraci

i

eni

os aj

Al

i

f

especí

es

ust

aj

e

v

vuel

braci

i

cal

Fija

Cuando sel

guraci

i

conf

su m

ar

t

evi

Reinicio

Reset (reinicio parcial) devolverá la configuración de fábrica y

restablecerá en el equipo una condición conocida. Ocurrirá lo

siguiente:

- Todas las series, mediciones almacenadas, imágenes y

nombres de series se borrarán.

- Las configuraciones del menú serán de nuevo las siguientes:

Memoria = OFF

Estadísticas = OFF

Puede reiniciar el equipo de manera más completa (Hard Reset)

apagando el equipo, esperando varios segundos y pulsando

simultáneamente los botones central y (+) hasta que

aparezca el símbolo Reset . Esto restablecerá el medidor a su

condición conocida de fábrica.

Realiza la misma función que el Reinicio y además:

- Todos los ajustes de calibraciones y la Cal Memoria se

eliminarán y se restablecerá la configuración de fábrica del

medidor.

- Borrará la información de la conexión Bluetooth.

a m

,

co

i

cal

de

edi

m

a

ón corr

l

Ca

r

ecci

ones de cal

f

odi

enudo es conv

eal

r

ón

braci

eza,

pi

esa

r

ent

espondi

✔

a opci

one est

caci

i

braci

i

Desact

ón.

Menú de Establecer

Menú de Establecer

ón de una pi

ci

edi

a m

l

zar

i

eal

r

eza en par

ent

eni

para

zados

i

e de m

Bluetooth = OFF

Pantalla = NINGUNO

podr

ón,

ón act

e para r

iv

est

r

á

anera r

par

a

ual

con un pol

ar

cul

i

9

o

si

Page 28

- Las configuraciones del menú serán de nuevo las siguientes:

Unidades = micras

Rotar LCD = Normal

Auto SINCR = OFF

Fondo Negro = OFF

NOTAS:

- Tras Reiniciar deberá ajustar a cero la sonda (pág 6).

- La fecha, hora y WiFi no se modificarán al Reiniciar.

Batería

Selecciona el tipo de baterías utilizado en la base PosiTector entre

"alcalinas" "litio" o "NiMH" (níquel- hidruro metálico recargables).

Si se ha seleccionado NiMH el PosiTector cargará las baterías

poco a poco si está conectado por USB a un PC o a un cargador

opcional de red. El indicador de estado de batería se

calibrará según el tipo de pila seleccionado. No habrá daños si el

tipo de batería seleccionado es erróneo.

NOTA:

pilas recargables.

Cambio de las baterías de la sonda

Cambio de las baterías de la sonda

Para la sonda utilice sólo pilas alcalinas AA (3).

Las baterías recargables de níquel-cadmio y

de níquel- hidruro metálico funcionarán pero el

icono indicador de estado de la batería puede

mostrar el nivel de las baterías bajo .

El medidor se apagará automáticamente

cuando las pilas estén muy bajas, pero antes

mostrará una advertencia de batería baja en la

pantalla. Si las baterías están muy bajas puede

que el medidor arranque pero se apagará

rápidamente.

Estadísticas

Un resumen estadístico aparecerá en la pantalla. Pulse el botón

(-)

para borrar la última medida. Pulse (+) para borrar las

estadísticas.

x

(sólo base PosiTector)

DeFelsko recomienda el empleo de eneloop (NiMH)

Modo Estadísticas

Modo Estadísticas

Promedio

Valor máximo

Idioma = Inglés

Batería = Alcalina

Luz de Pantalla = Nor mal

USB Drive = ON

x

σ Desviación Estándar

Valor mínimo

10

Page 29

Gestión de memoria

Gestión de memoria

El PosiTector PC dispone de memoria de almacenamiento interna

para registro de datos de mediciones. Podrá revisar las

mediciones almacenadas en pantalla o acceder a ellas mediante

ordenadores, tablets y smar tphones. Las mediciones incluyen

fecha y hora.

La memoria puede almacenar 100.000 lecturas en hasta 1.000

series. "Lote Nuevo" cierra cualquier serie abierta y crea un nuevo

nombre de serie con el número más bajo disponible. Aparecerá el

icono . Los nombres de lote incorporan la fecha de creación.

Desplazarse por

modos de visualización

Eliminar última lectura

Acceso al menú

NOTA:

medidor. Descargue el manual de instrucciones en:

www.defelsko.com/manuals

Acceso a lo s dat os almacenados de mediciones

Acceso a lo s dat os almacenados de mediciones

Soluciones PosiSoft para visualización, análisis y reporteo de datos:

Esta Guía rápida resume las funciones básicas del

Crear una nueva

lote

Restaurar el brillo

tras oscurecimiento

PosiSoft USB Drive - Conecte el PosiTector a un PC o Mac con

el cable USB suministrado para acceder e imprimir las lecturas

almacenadas, gráficos, fotos, notas e impresiones de pantalla. No

requiere software ni conexión a Inter net. Deberá haberse

seleccionado menú para USB Drive (pág 12).

PosiSoft.net - aplicación web gratuita que ofrece un

almacenamiento seguro y centralizado de las lecturas del

PosiTector. Acceda a sus lecturas desde cualquier dispositivo con

conexión a internet. Visite: www.PosiSoft.net

PosiSoft 3.0 - Software de gestión para descargar, ver e imprimir

sus datos de medición.

PosiSoft Mobile (sólo modelos Advanced) - acceda a lecturas,

gráficos, capture fotos y actualice anotaciones a través de

dispositivos habilitados para WiFi, tales como tablets,

smartphones y ordenadores.

11

Page 30

Menú Conectar

Menú Conectar

Sincroniza ya

Cuando se selecciona, el medidor sincroniza inmediatamente los

datos de medición almacenados a través de USB, Bluetooth o

WiFi con PosiSoft.net. (se requiere PosiSoft Desktop Manager y

una conexión a Internet cuando utilice USB o Bluetooth).

Auto SINCR

Permite al medidor sincronizar automáticamente con PosiSoft.net

cuando esté conectado a Internet a través de un PC con PosiSoft

Desktop Manager o una red WiFi local.

Las mediciones adicionales que se sumen a la memoria mientras

esta conectado se añadirán a la sincronización hasta que el cable

USB sea desconectado y conectado de nuevo o cuando

Sincroniza ya. Now esté seleccionado.

USB Drive

El medidor utiliza un dispositivo de almacenamiento masivo USB

que proporciona una interfaz sencilla para recuperar los datos de

manera semejante a un USB Flash, una cámara o un reproductor

digital de audio.

NOTA:

a través del USB. Las baterías no estarán en uso y la base

PosiTector no se apagará automáticamente. Si dispone de

baterías recargables (NiMH), el medidor las cargará poco a poco.

Bluetooth

Facilita el envío de las lecturas individuales a un ordenador,

impresora o dispositivo compatible puesto que utilizan tecnología

Bluetooth. Consulte www.defelsko.com/bluetooth

Cuando está conectado, la alimentación se obtiene

WiFi

Permite la conexión inalámbrica con dispositivos como tablets,

smartphones y ordenadores conectados a su red inalámbrica o

sistemas móviles. Consulte www.defelsko.com/WiFi

12

Page 31

Sondas Polvo

Muestra las opciones de menú que permiten la comunicación de

la base PosiTector con las sondas inalámbricas PosiTector PC.

Listar

Muestra todas las sondas PC conectadas anteriormente.

Orden

Selecciona a qué sonda PC se conectará la base PosiTector

en primer lugar durante el encendido.

Nuevo

Permite que la base del PosiTector se conecte a una sonda

inalámbrica PC por primera vez.

Una vez seleccionada, la base PosiTector mostrará,1.

"Asegúrese de que la sonda está encendida y se ha

reiniciado antes de continuar. "Consulte la Guía completa

para el reinicio de la sonda en

www.defelsko.com/manuals

Seleccione Siguiente. La base PosiTector buscará las2.

sondas PC presentes.

Seleccione la sonda PC que desea conectar. Las sondas3.

PC se muestran por número de serie.

Apaga Sonda

Desconecta la sonda PC de la base PosiTector hace que la

sonda PC se apague. Si otra sonda está conectada

físicamente, el PosiTector la reconocerá automáticamente.

Conectar

Facilita que la base PosiTector conecte o cambie entre sondas

inalámbricas PC y sondas conectadas físicamente. La sonda

PC deberá estar encendida.

Actualizar

Determina si hay actualizaciones disponibles de software para su

medidor. Consulte www.defelsko.com/update

ADVERTENCIA:

completo (Hard Reset) tras una actualización (consulte pág. 9).

El medidor puede realizar un Reinicio

13

Page 32

Devolución para reparaciones

Devolución para reparaciones

Antes de devolver el medidor para reparaciones:

Ponga baterías nuevas o recién recargadas en el1.

compartimento de las baterías según instrucciones

(pág 10).

Examine la pantalla de la sonda por si está sucia o dañada2.

(pág 5).

Lleve a cabo un Reinicio completo (Hard Reset) (pág 9) y3.

ajuste a cero (pág 6).

Si debe devolver el medidor para reparaciones, describa el

problema con detalle e incluya los resultados de medición, si los

tiene. Asegúrese también de incluir la sonda, el nombre de su

empresa, el nombre de la persona de contacto, sus números de

teléfono y de fax o su dirección de correo electrónico.

Página Web: www.defelsko.com/support

Garantía limitada, solución única

Garantía limitada, solución única

y obligación limitada

y obligación limitada

La garantía única de DeFelsko, la solución, y la obligación son la

garantía limitada expresa, la solución y la obligación limitada

expuestas en su sitio web: www.defelsko.com/terms

www.defelsko.com

© DeFelsko Corporation USA 2014

Este manual está protegido por copyright. Todos los derechos de este manual están reservados y no

podrá ser parcial o totalmente reproducido o transmitido por ningún medio sin el consentimiento previo

por escrito de DeFelsko Corporation.

DeFelsko, PosiTector y PosiSoft son marcas comerciales de DeFelsko Corporation registradas en los

EE.UU. y en otros países. Otras marcas o nombres de productos son marcas comerciales o registradas

de sus propietarios respectivos.

Se han tomado todas las precauciones posibles para asegurar la precisión de toda la infor mación

contenida en este manual. DeFelsko no aceptará responsabilidad por errores tipográficos o de impresión.

Reservados todos los derechos.

14

Page 33

—NOTAS—

Page 34

Coating Thickness Gage

Kurzanleitung

v. 2 . 0

Page 35

Einführung

Einführung

D

e

r

P

o

s

i

T

e

c

t

o

r

®

P

C

P

o

w

d

e

r

C

h

e

c

k

e

r

®

i

s

t

e

i

n

b

e

r

ü

h

r

u

n

g

s

l

o

s

S

c

h

i

c

h

t

d

i

c

k

e

n

m

e

s

s

g

e

r

ä

t

,

d

a

s

m

i

t

H

i

l

f

e

e

i

n

e

r

d

u

r

c

ü

b

e

r

t

r

a

g

e

n

e

n

H

o

c

h

f

r

e

q

u

e

n

z

-

S

c

h

a

l

l

w

e

l

l

e

B

w

e

l

c

h

e

s

a

u

f

e

i

n

e

m

f

e

s

t

e

n

U

n

t

e

r

g

r

u

n

D

a

s

H

a

n

d

g

e

r

ä

t

b

e

r

e

c

h

n

e

t

d

e

m

E

i

n

b

r

e

n

n

e

n

.

D

a

s

I

n

s

t

r

u

m

e

n

t

b

e

i

n

e

r

S

k

G

G

B

D

z

w

1. Beide Geräte EINSCHALTEN (Sonde zuerst).

2. Stellen Sie die PC-Sonde auf Null-Punkt (S. 6)

3. Führen Sie, falls nötig, eine ANPASSUNG an das spezifische

4. MESSEN Sie das aufgetragene Pulver (S. 2)

Um die Lebensdauer der Batterie zu verlängern, schalten sich das

PosiTector-Grundgerät und die PC sonde nach etwa 5 Minuten

Nichtbenutzung automatisch ab. Alle Einstellungen bleiben

erhalten.

o

o

m

m

u

n

i

z

e

r

ä

t

e

n

i

u

m

m

i

h

o

a

s

i

s

e

i

n

h

i

e

s

e

K

u

u

s

a

m

m

e

w

w

.

d

e

f

e

Schritt1) PC-Sonde einschalten durch Drücken der Taste .

Schritt 2) PosiTector-Grundgerät einschalten durch

Ein Signalton ertönt, und die Buchstaben „PC“ werden in der oberen

linken Ecke der PosiTector-LCD Anzeige angezeigt. Dadurch wird

angegeben, dass beide Einheiten messbereit sind.

Pulver durch (S. 8)

HINWEIS:

e

n

d

e

,

d

i

e

i

e

r

e

n

.

W

c

l

e

r

z

n

l

s

ä

h

t

m

e

h

r

s

t

e

r

m

i

t

i

t

w

ä

h

r

e

a

n

l

e

i

t

u

n

.

L

a

d

e

n

k

o

.

c

o

m

/

Drücken der mittleren Navigationstaste .

d

s

t

e

h

t

a

u

s

G

n

g

m

m

i

t

e

i

n

a

h

r

e

n

d

e

i

n

a

l

s

1

0

M

ü

r

t

e

l

s

c

h

d

d

e

s

M

f

a

s

s

t

d

S

i

e

d

i

e

a

n

u

a

l

s

h

Schnellstart

Schnellstart

d

i

e

z

u

e

r

w

e

i

n

e

r

B

a

n

d

e

r

ü

b

e

s

M

e

s

s

e

t

e

r

v

o

n

l

a

u

f

e

e

r

m

e

s

s

v

o

r

g

a

i

e

G

r

u

n

d

v

o

l

l

s

t

ä

n

d

e

r

u

n

t

e

r

.

e

a

u

f

g

e

t

r

a

r

t

e

n

d

e

s

i

s

e

i

n

h

e

e

r

B

l

u

e

v

o

r

g

a

n

g

e

i

n

a

n

d

e

ö

g

l

i

c

h

t

n

g

s

b

e

i

s

f

u

n

k

t

i

o

n

i

g

e

B

e

t

r

h

s

c

h

i

c

h

t

u

a

g

e

n

i

s

t

,

S

c

h

i

c

h

t

d

i

t

(

G

r

u

n

d

t

o

o

t

h

-

F

u

s

s

o

l

l

t

e

n

r

e

n

t

f

e

r

n

d

e

m

A

n

w

i

c

h

z

u

t

r

e

n

d

e

s

M

i

e

b

s

a

n

l

e

i

e

d

i

e

L

u

n

g

s

p

u

l

v

e

a

n

a

l

y

s

i

e

i

c

k

e

n

a

c

g

e

r

ä

t

)

u

n

n

k

t

e

c

h

n

d

i

e

b

e

i

d

e

t

s

e

i

n

.

E

e

n

d

e

r

d

a

g

e

n

.

e

s

s

g

e

r

ä

t

u

n

g

u

n

t

1

s

f

t

r

,

r

t

.

h

d

i

k

n

i

n

i

e

t

s

e

r

Page 36

Menübetrieb

Menübetrieb

Die Funktionen des Messgeräts sind menügesteuert. Um auf das

Menü zuzugreifen, schalten Sie die PC-Sonde und das

PosiTector-Grundgerät ein und drücken Sie anschließend die

mittlere Navigationstaste.

Navigationstaste

Oben

Mitte

Unten

HINWEISE:

Die mittlere Taste ist absichtlich vertieft, um ein

unabsichtliches Einschalten zu verhindern.

Wenn keine Sonde angebracht ist, wird ein eingeschränktes Menü

angezeigt. Schließen Sie eine Sonde an, um das vollständige

Menü zu sehen.

Schalten Sie beide Einheiten ein. Halten Sie die Sonde im Abstand

von bis zu 5 cm zum Beschichtungspulver.

Die Taste drücken und festhalten. Führen Sie die Sonde näher

an das Pulver heran. Richten Sie während Sie auf die

Sondenanzeige achten den Distanzbalken auf der

Distanzzielleiste aus (S. 3).

Während die Sondentaste heruntergedrückt wird, sollten der

Abstand und Winkel der Sonde leicht verändert werden, indem:

(a) der Distanzbalken in der Nähe der Distanzzielleiste und

(b) die Amplitudenanzeige in maximaler Höhe gehalten werden

(S. 3).

Navigieren Sie mit den Tasten Oben oder

Unten zum gewünschten Menüpunkt und

bestätigen diesen zur Auswahl mit der

mittleren Taste.

Wählen Sie Zurueck innerhalb eines

beliebigen Menüs, um dieses zu verlassen.

Wie misst man

Wie misst man

Lassen Sie die Taste los, wenn Sie einen doppelten

SIGNALTON hören oder auf einer der Anzeigen einen Messwert

sehen.

2

Page 37

Sondenanzeige: (Taste nicht gedrückt)

Sondenbatteriestatus (S. 11)

Sonden-Verbindung aktiv

Voraussichtliche Sichtdicke nach dem

Einbrennen

Sondenanzeige: (Taste gedrückt)

Ergebnisanzeige

Höchstpunkt

der Amplitude

Amplitudenanzeige

Bluetooth-Funkanzeige: Das Symbol zeigt an, dass das

PosiTector-Grundgerät und die Funksonde richtig miteinander

kommunizieren.

Ergebnisanzeige: Wenn die Sonde sich in der richtigen Position

befindet und verwertbare Messungen genommen wurden, blinkt

ein blauer Punkt auf der Sondenanzeige, das PosiTector-

Grundgerät zeigt einen blinkenden grünen Punkt und sendet einen

hohen Signalton aus. Wenn die Messungen nicht verwertbar sind,

blinkt ein „X“ auf der Sondenanzeige, das PosiTector-Grundgerät

zeigt einen blinkenden roten Punkt und sendet einen tiefen

Signalton aus.

Distanzbalken: Stellt die Entfernung bis zum Ziel grafisch dar. Es

steigt und fällt und zeigt so die Entfernung von der Sondenspitze

bis zur Pulveroberfläche an.

Distanzzielleiste: Die optimale Entfernung für die Messung

beträgt 18 mm zwischen der Sondenspitze und der Oberfläche des

aufgetragenen Pulvers. Halten Sie während des Messvorgangs

den Distanzbalken in der Nähe der Distanzzielleiste.

Distanzzielleiste

Distanzbalken

Voraussichtliche

Schichtdicke nach

dem Einbrennen

3

Page 38

Amplitudenanzeige: Stärke des Ultraschallechos. Ein hoher

Ausschlag stellt eine gute, lotrechte Ausrichtung der Sonde zur

Oberfläche dar. Die Amplitude erreicht im Allgemeinen einen

höheren Ausschlag, wenn dünne Pulverdicken gemessen werden

und wenn die Sonde sich in einem optimalen 90-Grad-Winkel zur

Pulveroberfläche befindet.

Höchstpunkt der Amplitude: Markiert die höchste Position, die

die Amplitudenanzeige während der laufenden Messung erreichte.

Voraussichtliche Schichtdicke nach dem Einbrennen: Wenn

ein gültiger Messwert berechnet wird, PIEPT das PosiTector-

Grundgerät zweimal und die voraussichtliche Sichtdicke nach den

Einbrennen wird auf der PC-Sonde und auf dem PosiTector-

Grundgerät angezeigt. Wird die Sondentaste weiterhin gedrückt

gehalten, werden weitere Messungen vorgenommen.

Es gibt vier Ar ten angezeigter Messergebnisse:

43 Voraussichtliche Schichtdicke.

0 Die Messung hat einen Wert ergeben, aber die

voraussichtliche Schichtdicke ist kleiner als der MinimalMessbereich.

++ Die Messung hat einen Wert ergeben, aber die

voraussichtliche Schichtdicke ist größer als der MaximalMessbereich.

-- Eine unbestimmte oder ungültige Messung.

Messhinweise

Messhinweise

Wenn nach 5 Sekunden kein Messergebnis erscheint, lassen Sie

die Messtaste los und versuchen Sie es noch einmal. Warten Sie

1 bis 2 Sekunden zwischen der erneuten Messung.

Kleine, unregelmäßig schwingende Objekte können

Schwierigkeiten bei der Messung hervorrufen. Stabilisieren Sie

das Objekt, soweit möglich. Wenn sich ständig fehlerhafte

Messungen ergeben, ändern Sie die Messstrategie, indem Sie die

Sonde drehen, ihre Ausrichtung auf das Objekt ändern oder eine

andere Stelle am Objekt messen.

Verwenden Sie den Statistik-Modus (S. 11), um die besten

Ergebnisse zu erzielen, und um Durchschnittswerte zu erzeugen.

Der Durchschnitt einer Reihe von Messungen bietet oft eine

sinnvollere Voraussage der Schichtdicke als eine einzelne

Messung.

4

Page 39

Sonden

Sonden

Am PosiTector-Grundgerät können zahlreiche Sondentypen

angeschlossen werden, einschließlich Magnet-, Wirbelstrom- und

Ultraschall-Schichtdicken-, Oberflächenprofil-, Klima- und

Ultraschall-Wanddickensonden.

Die neuesten Informationen über die Austauschbarkeit von

Sonden erhalten Sie unter www.defelsko.com/probes

Kabellose PC Funksonden:

Die PosiTector PC Funksonde verbindet sich mit allen Advanced

PosiTector Grundgeräten. Verbindungsdetails siehe Powder

Probes (S. 14).

PosiTector Sonden:

Um eine Sonde vom Grundgerät zu entfernen, schalten

Sie das Instrument aus und ziehen den KunststoffSondenanschluss horizontal (in Pfeilrichtung) vom

Grundgerät ab. Schritte in umgekehrter Reihenfolge

wiederholen, um eine neue Sonde anzubringen.

Nach dem Einschalten identifiziert das PosiTector

automatisch den angeschlossenen Sondentyp und führt

einen Selbsttest durch.

HINWEIS:

Während des Einschaltens werden angeschlossene Sonde

automatisch erkannt, wenn die PC sonde nicht verfügbar

(ausgeschaltet) ist.

Um wieder eine Verbindung mit einer PC Funksonde herzustellen

(nach dem Einschalten), wählen Sie Connect innerhalb des Menüs

Verbindung > Powder Probes (S. 14).

Das PosiTector-Grundgerät verbindet sich während des Einschaltens

automatisch mit einer aktiven PC Funksonde. Die PC sonde muss

eingeschaltet sein.

Wartung

Der Schutzschirm (gelb) am Sondenkopf der PC sonde kann zur

Reinigung abgeschraubt werden. Angesammeltes Pulver sollte mit

nicht mehr als 0,2 bar (20-30 psi) Druckluft sorgfältig vom Schirm

entfernt werden. Richten Sie keine Luft direkt auf die Sonde.

Ersatzschirme sind als Ersatzteil erhältlich.

5

Page 40

Überprüfung der Genauigkeit

Überprüfung der Genauigkeit

BVon Zeit zu Zeit und vor der ersten Verwendung bei einem neuen

Pulver sollte der Benutzer eine Genauigkeitskontrolle durchführen.

Dies stellt sicher, dass das Messgerät richtig funktioniert, indem

gemessene Schichtdicke mit dem tatsächlichen Werten verglichen

wird.

Stellen Sie die Sonde auf Null-Punkt (S. 6).1.

Beschichten Sie eine flache, glatte Metallprobe mit Pulver.2.

Messen Sie das unbehandelte Pulver mit dem

Brennen Sie das anschließend Pulver.4.

Messen Sie die Schichtdicke des eingebrannten Pulvers mit5.

einem Schichtdickenmesser wie z.B. dem PosiTector 6000.

Vergleichen Sie die Ergebnisse.6.

Eine erfolgreiche Überprüfung erfordert, dass der Durchschnitt

einer Reihe von Messwerten mit beiden Instrumente innerhalb

ihrer kombinierten Toleranzen liegt. Wenn nicht, passen Sie den

PosiTector PC an, indem Sie eine der auf Seite 7 beschriebenen

Methoden verwenden.

Um die bestmögliche Genauigkeit zu erreichen, führen Sie zu

Beginn jeder Schicht eine Null-Punkt durch, um Temperatur und

Feuchtigkeitsänderungen auszugleichen. Dies ist auch nach einer

Reset (Rücksetzung) erforderlich (S. 10).

Null-Punkt

Null-Punkt

Stellen Sie den Sondenkopf der PC sonde in die

im Lieferumfang enthaltene Sondenfixierung.

Wählen Sie die Menüoption Null-Punkt aus.

HINWEIS:

Dieses Symbol zeigt an, dass das Instrument mit den

Werkskalibrierungseinstellungen misst. Es erscheint immer dann,

wenn eine Reset (Rücksetzung) (S. 10) durchgeführt wird oder

wenn eine neue Kalibrierungseinstellung (S. 9) erstellt wird.

Es verschwindet immer dann, wenn eine Kalibrierungsanpassung

(S. 8) durchgeführt oder wenn eine Benutzerkalibrierung aus dem

Kal-Speicher geladen wird (S. 10). Eine Null-Punkt (S. 6)

Einstellung ändert den Status des Symbols nicht.

Der Nullstellungsprozess kann bis zu

30 Sekunden dauern.

Werkskalibrierungssymbol

Werkskalibrierungssymbol

PosiTector PC.3.

6

Page 41

Kalibrierung und Anpassung

Kalibrierung und Anpassung

Die PosiTector PC sonde ist werkseitig kalibriert und führt jedes

Mal wenn einen Messwert berechnet wird, einen automatischen

Selbsttest durch. Für viele Pulveranwendungen ist keine weitere

Anpassung notwendig. Stellen Sie das Gerät zu Arbeitsbeginn

einfach auf Null-Punkt und messen Sie anschließend.

Manchmal können Messwertberechnungen des Messgeräts durch

die Zusammensetzung des Beschichtungspulvers beeinflusst

werden. Unter diesen Umständen verbessert eine

Kalibrierungsanpassung die Genauigkeit.

Anpassung oder Kalibrierungsanpassung ist das Anpassen der

voraussichtlichen Schichtdickenbestimmung des Messgeräts, so

dass diese denjenigen einer bekannten Referenzprobe

entsprechen.

Beginnen Sie, indem Sie eine Überprüfung der Genauigkeit (S. 6)

durchführen, um zu bestimmen, ob eine Anpassung erforderlich

ist. Wenn der Durchschnitt mehrerer Messungen außerhalb der

kombinierten Toleranzen der beiden Messinstrumente (PosiTector

PC und Trockenfilm-Schichtdickenmessinstrument) liegt, stehen

drei Anpassungstechniken zur Verfügung, um die Abweichung zu

korrigieren (siehe Anpassungstechniken, S. 7).

Benutzeranpassungen werden in der aktuellen Kalibrierung

gespeichert. Es kann wünschenswert sein, zuerst eine neue

Kalibrierung zu öffnen (siehe KAL-Speicher, S. 9).

Anpassungstechniken

Anpassungstechniken

Um sicherzustellen, dass das Messgerät richtig funktioniert, sollte

der Benutzer von Zeit zu Zeit eine Genauigkeitskontrolle durchführen, indem vorausgesagte Dickenwerte mit tatsächlichen

Werten der behandelten Dicke verglichen werden (S. 6). Wenn der

Durchschnitt einer Reihe von Messungen mit beiden Instrumenten

(PosiTector PC und Trockenfilm Schichtdickenmessgerät) nicht

innerhalb der kombinierten Toleranzen liegt, kann der PosiTector

PC mit einer von drei Methoden angepasst werden.

1-Punkt - Die erste und häufigste Wahl.1.

2-Punkt - Wenn eine 1-Punkt die Genauigkeit nicht2.

verbessert.

Weitere Details siehe Kalibrierung menü, S. 8.

7

Page 42

Kalibrierung menü

Kalibrierung menü

1-Punkt

Sprühen Sie auf elektrostatischem Weg etwa 75 µm Pulver1.

auf eine flache, glatte Metallplatte.

Wählen Sie 1-Punkt, anschließend Measure. 2.

Führen Sie mindestens 3 Messungen des nicht3.

eingebrannten Pulvers mit dem PosiTector PC durch. Die

Ergebnisse werden im Messgerät gespeichert.

Wählen Sie OK.4.

Brennen Sie das Pulver ein.5.

HINWEIS:

Das Messgerät kann ausgeschaltet sein. Es speichert die

Kalibrierungsmessungen während eines Einschaltzyklus.

Messen Sie die Dicke des eingebrannten Pulvers mit einem6.

geeigneten Schichtdickenmessgerät. Notieren Sie das

Ergebnis.

Wählen Sie 1-Punkt, anschließend Adjust.7.

Stellen Sie den angezeigten Messwertdurchschnitt mit (-)8.

niedriger oder mit (+) höher ein, um dem Wert an die

eingebrannten Schichtdicke anzupassen. Wählen Sie

anschließend OK.

2-Punkt

Sprühen Sie auf elektrostatischem Weg Pulver auf zwei1.