Page 1

Page 2

Introduction

The PosiTector®PC Powder Checker®is a hand-held, non-contact

Coating Thickness Gage that uses an airborne high frequency

ultrasound to analyze coating powder applied to rigid substrates to

calculate and display a predicted cured thickness.

The instrument consists of a base unit and a probe that communicate

with each other via Bluetooth wireless technology. They must stay

within 10 meters (30 feet) of each other while measuring. A rubber

holster with belt loop allows the base unit to stay with the operator while

measuring.

Note: Do not use compressed air on the probe. Tips for cleaning the

screen guard can be found on pg 15.

Note: Throughout this manual, the symbol indicates more

information about the particular topic or feature is available on our

website. Go to: www.defelsko.com/manuals

Power-up / Power-down

Step 1: Power-up the probe by pressing the button.

Step 2: Power-up the base unit by pressing any one of the 3 buttons. A

beep and a solid probe icon on the base unit indicates both units are

ready to measure.

To preserve battery life, both units power-down after approximately 5

minutes of inactivity. All settings are retained.

When a USB cable is connected to the base unit, power is supplied

through the USB cable. The batteries are not used and the base unit

will not automatically power down. The probe will still automatically

power down.

The base unit can be powered down at any time by holding down both

(-) and (+) buttons simultaneously for 5 seconds. The probe will also

power down.

1

Page 3

Operation Overview

1. POWER UP both units.

2. ZERO the probe (see pg. 6)

3. ADJUST to the specific powder if necessary (see pg. 8)

4. MEASURE the applied powder (see below)

How to Measure

1. Power-up both units. Bring the probe to within 5 cm (2 inches) of the

coating powder.

2. Press and hold the button. Bring the probe closer to the powder.

While watching the probe display, align the Distance Paddle with the

Distance Target Bar. (see pg. 3)

3. While the probe button is depressed, probe distance and angle

should be varied slightly keeping:

(a) the Distance Paddle close to the Distance Target Bar, and

(b) the Amplitude Indicator at maximum height.

4. Release the button when you hear a double BEEP or see a

thickness measurement on either display.

Both units will power-down automatically after approximately 5 minutes

of inactivity.

Measurement Notes:

If a thickness result does not appear after 5 seconds, release the

measurement button and try again. Wait 1 to 2 seconds between

readings.

Small, erratically swinging parts may present measurement challenges.

Steady the part whenever possible.

If erroneous readings continually result, change the measurement

strategy by rotating the probe, altering its alignment to the part, or by

measuring a different location on the part.

For best results use Statistics mode (pg. 12) to generate averages.

The average of a series of measurements is often a more meaningful

prediction of cured thickness than a single reading.

2

Page 4

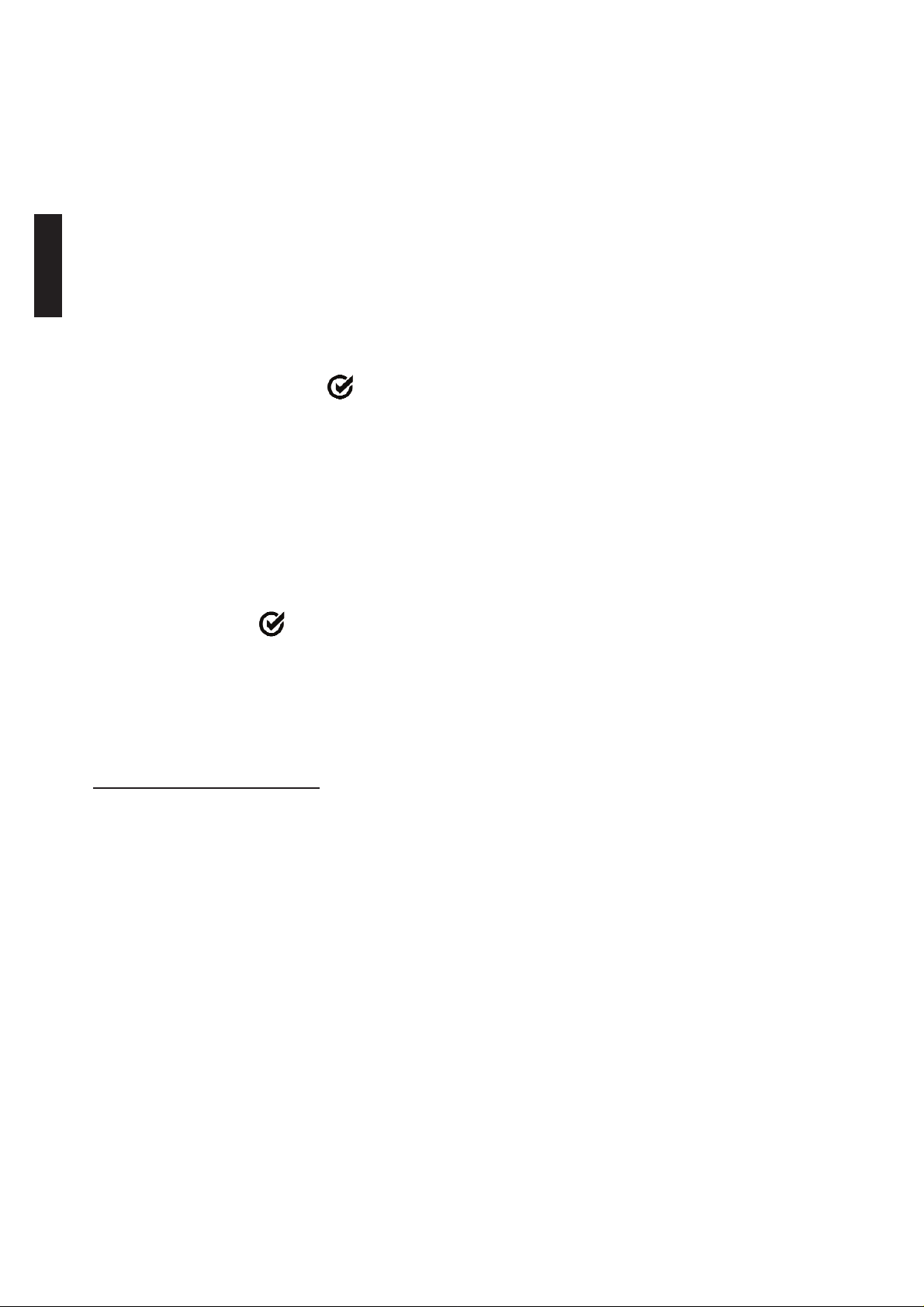

Displays

3

Solid indicates good

wireless connection to

probe. Flashing

indicates no probe

connection.

Base Unit Display:

Last

Measurement

Current Calibration

Setting

Unit of

Measurement

Maximum Amplitude Dot

Probe Display (button not pressed):

Amplitude Indicator

Results Indicator

Distance Target Bar

Probe Batteries Status (pg. 15)

Bluetooth Function Indicator

Predicted Cured Thickness Result

Distance Paddle

Predicted Cured

Thickness Result

Probe Display (button pressed):

Factory Calibration

Symbol (pg. 8)

Page 5

Bluetooth Function Indicator: The symbol indicates the base unit

and wireless probe are communicating properly.

Results Indicator: When the probe is in the proper position and good

samples are being taken, a solid DOT blinks on the probe display, the

base unit LED blinks green and emits a high beep. When samples are

inconclusive, an "X" blinks on the probe display, the base unit LED

blinks red and emits a low beep.

Distance Paddle: Graphically represents the distance to the target. It

rises and falls to indicate distance from the probe tip to the surface of

the powder.

Distance Target Bar: The optimum distance for measurement is 18

mm (3/4 inch) between the tip of the probe and the surface of the

applied powder. During measurement, keep the Distance Paddle close

to the Distance Target Bar.

Amplitude Indicator: Strength of the ultrasonic echo. A high position

indicates good probe orientation relative to perpendicular. The bar will

generally reach higher positions when measuring thin powder and when

the probe is at a 90-degree angle to the powder surface.

Maximum Amplitude Dot: Marks the highest position the Amplitude

Indicator reached during the current measurement attempt.

Predicted Cured Thickness Result: When a valid measurement is

calculated, the base unit BEEPS twice, the LED blinks green, and the

predicted cured measurement result is displayed on both the probe and

base unit. Continuing to hold the probe button will result in additional

samples being taken.

There are 4 types of displayed measurement results:

43 — Predicted thickness result.

0 — The collected samples have resulted in a good reading, but the

resultant predicted cured thickness is less than the minimum range.

++ — The collected samples have resulted in a good reading, but the

resultant predicted cured thickness is greater than the maximum range.

- - — An indeterminate or invalid reading.

4

Page 6

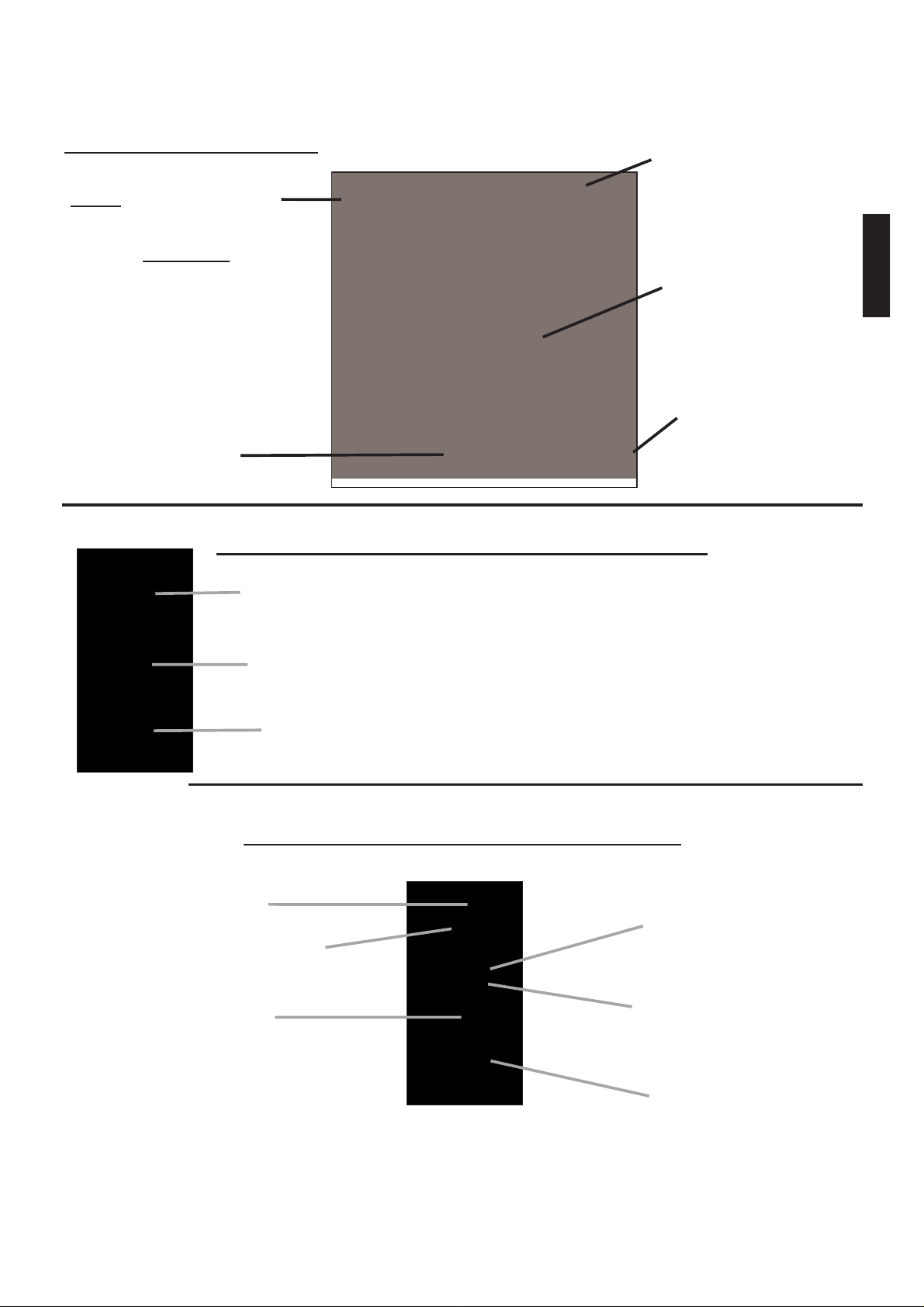

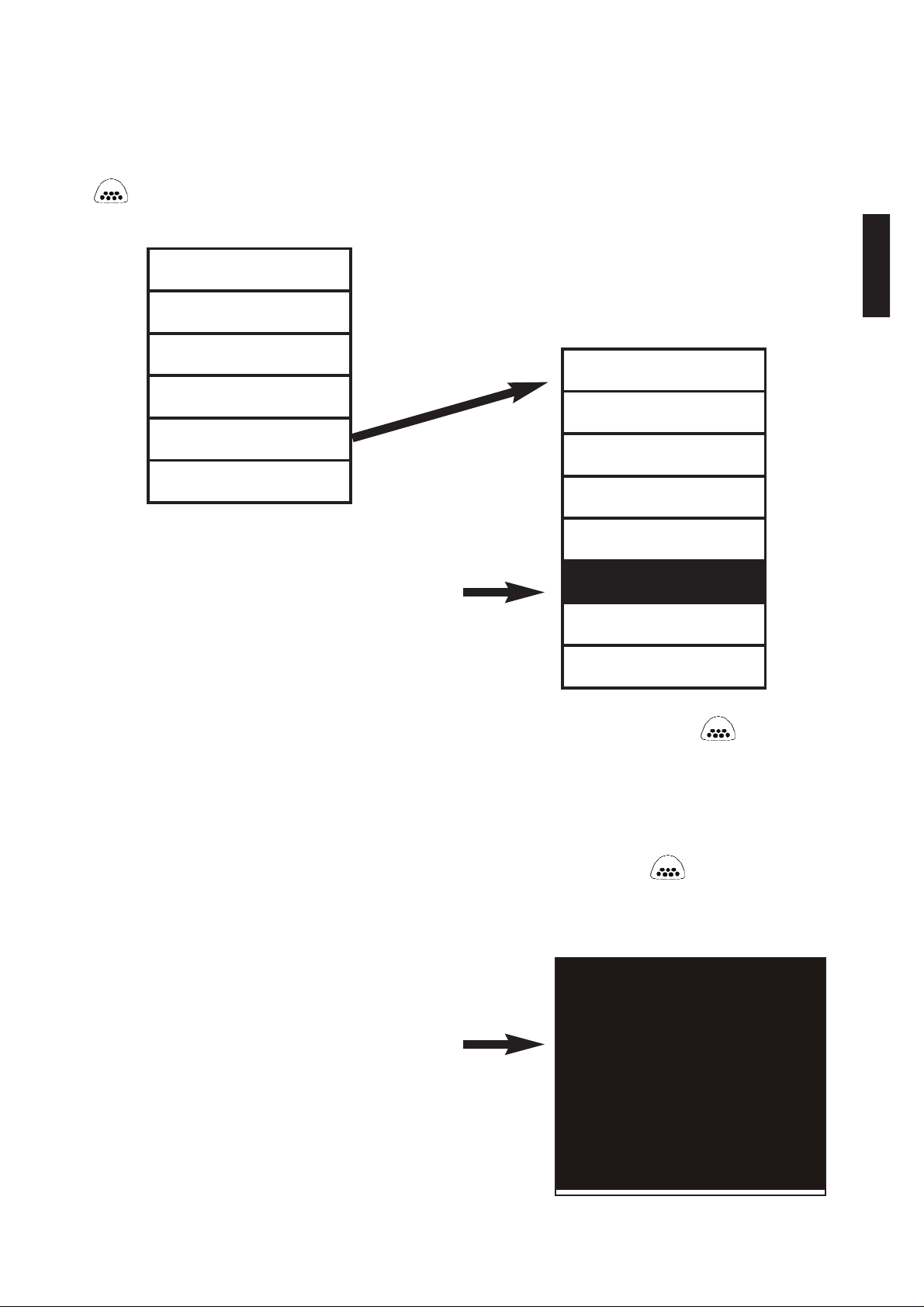

Menu Operation

Instrument functions on the base unit are menu controlled. To access

the full Menu, power-up both the probe and base unit. Then press the

(.:::.button. If the probe is not powered-up a condensed menu is

displayed.

5

Reset

Flip Display

Gage Info

Units

Set Clock

Language

USB Drive

Exit

Memory

Statistics*

Zero*

Cal Settings

Setup

Exit

* Appears when probe is ON

Current selection is displayed

with darkened background

To navigate, press (-) to scroll DOWN, (+) to scroll UP and (.:::.) to

SELECT. To exit any menu, press both (-) and (+) buttons

simultaneously or select Exit from the Menu.

List boxes have a down arrow on the right-hand side. Use the (-) or (+)

buttons until your desired choice appears, then press (.:::.) to select this

choice and move focus onto the next item.

A "tick" indicates this square

box has been selected

“List” box

Page 7

6

Verification of Accuracy

Before first use on a new powder and periodically thereafter, the user

should perform an accuracy check. This ensures the gage is working

properly by comparing predicted thickness values with actual cured

thickness values.

1. Zero the probe (pg. 6).

2. Electrostatically spray powder onto a flat, smooth metal sample.

3. Measure the uncured powder with the PosiTector PC.

4. Cure the powder.

5. Measure cured thickness with a magnetic or eddy current coating

thickness gage such as the PosiTector 6000. Compare results.

A successful verification requires that the average of a series of

measurements by both instruments be within their combined tolerances.

If not, adjust the PosiTector PC using one of the methods described on

page 8.

For best accuracy, perform a Zero at the beginning of every shift to

compensate for temperature and humidity changes. It is also required

after a Reset (pg. 13).

Zero Menu Option

1. Place the included Powder Probe Fixture onto a hard, flat,

smooth surface (i.e. glass or metal).

2. Place the measuring end of the probe into the Fixture.

3. Power-up both units.

4. On the base unit select the Zero

menu option. The zero process

can take up to 30 seconds.

Zero

Page 8

7

Calibration and Adjustment

The PosiTector PC is factory calibrated and performs an automatic

self-check each time it calculates a measurement. For many powder

measurement applications no further adjustment is necessary. Simply

Zero at the beginning of each shift, then measure.

Sometimes gage measurement calculations can be influenced by the

composition of the coating powder. A calibration adjustment improves

accuracy in these circumstances.

Adjustment, or Calibration Adjustment, is the act of aligning the gage's

predictions to match those of a known cured sample.

Begin by performing a Verification of Accuracy (pg. 6) to determine if

there is a need for an adjustment. If the average of several thickness

results is outside the combined tolerances of the two measuring

instruments (PosiTector PC and dry film thickness instrument) then 3

adjustment techniques are available to correct the variance.

User adjustments are stored in the current Cal setting. It may be

desirable to open a new Cal setting first (pg. 10).

Cal Settings

CAL

Cal Memory

1 Pt Adjust*

2 Pt Adjust*

Powder Comp*

Exit

* These menu options

appear only when the

probe is powered-up.

Page 9

8

Factory Calibration Symbol

This symbol indicates the instrument is measuring with factory

calibration settings. It appears whenever a Reset (pg. 13) is

performed or whenever a new calibration setting (pg. 10) is

created. It disappears whenever a calibration adjustment is made (pg.

8) or when a user calibration is loaded from cal memory (pg. 10). A

probe Zero (pg. 6) does not change the status of the symbol.

Adjustment Techniques

To ensure the gage is working properly, the user should periodically

perform an accuracy check by comparing predicted thickness values

with actual cured thickness values (pg. 6).

If the average of a series of measurements by both instruments is not

within combined tolerances, the PosiTector PC can be adjusted using

one of three methods.

1) 1-point Adjustment - The first and most common choice.

2) 2-point Adjustment - If a 1 Pt Adjust does not improve accuracy.

3) Powder Compensation - If adjustments fail to improve accuracy.

1. Zero the probe (pg. 6).

2. Electrostatically spray approximately 75 microns (3 mils) of powder

onto a flat, smooth metal sample.

3. Open a New CAL setting (optional - pg. 10).

4. Select New Batch (pg. 11).

5. Take at least 3 uncured powder measurements with the PosiTector

PC. Results will be stored in the Batch.

6. Cure the powder.

7. Measure cured thickness with a magnetic or eddy current coating

thickness gage. Record the results.

8. Select "1 Pt Adjust" then select the batch name from Step 4 into

which the previous measurements had been placed.

9. Adjust the displayed batch average lower (-) or higher (+) to match

the cured thickness value.

1 Pt Adjust

Page 10

9

1. Zero the probe (pg. 6).

2. Electrostatically spray powder onto 2 flat, smooth metal samples.

Place approximately 40 microns (1.5 mils) on one and 75 microns

(3 mils) on the other.

3. Open a New CAL setting (optional - pg. 10).

4. Select New Batch (pg. 11)

5. Take at least 3 uncured powder measurements on the thin powder

panel with the PosiTector PC. Results will be stored in the Batch.

6. Open a second new Batch.

7. Take at least 3 uncured powder measurements on the thick powder

panel with the PosiTector PC. Results will be stored in the

second Batch.

8. Cure the powder on both panels.

9. Measure cured thickness with a magnetic or eddy current coating

thickness gage. Record the results.

10. Select "2 Pt Adjust" then select the appropriate batch names

when asked.

11. Adjust the displayed batch averages lower (-) or higher (+) to match

the cured thickness values.

1. Zero the probe (pg. 6).

2. Electrostatically spray a thick layer of powder (135 microns / 5 mils)

onto a flat, smooth metal sample. Lay the panel on a table surface.

3. Place the included Powder Probe Fixture onto the coated panel.

4. Place the measuring end of the probe into the Fixture.

5. On the base unit select the "Powder Comp" menu option. This can

take up to 30 seconds.

6. A 1- or 2-point adjustment may be required after this operation.

2 Pt Adjust

Powder Comp

Note: The symbol on the display will turn off after

the successful completion of an adjustment.

Page 11

10

Calibration Memory

When measuring a particular part with a specific powder, it is often

convenient to be able to store any unique calibration adjustments made

for that application. Then, if you return to that part, the corresponding

Cal setting can be conveniently and quickly restored.

A Cal setting is any of the three calibration adjustments (pg. 8). The

PosiTector PC always displays the current calibration setting (ex. Cal

3) in the upper right corner of the display.

The gage reverts back to its factory default Cal 1 setting after a Reset

(pg. 13) or if the user deletes all calibration settings (below).

-Creates a new calibration setting using the next available number

(Maximum of 9). By default, these new Cal settings are initially created

with the gage's factory settings as indicated with the symbol that

appears at the bottom of the display.

-Loads an existing calibration setting. Use the (-) or (+) buttons to scroll

the List box until the desired setting appears, then press

(.:::..

-Removes a calibration setting completely from the list. That Cal

number can be reused later with the "New" command.

-Sends a list of all Calibration Settings to the IR printer using the gage's

built-in IR port.

Cal Memory

New

Open

Delete

Print

Page 12

11

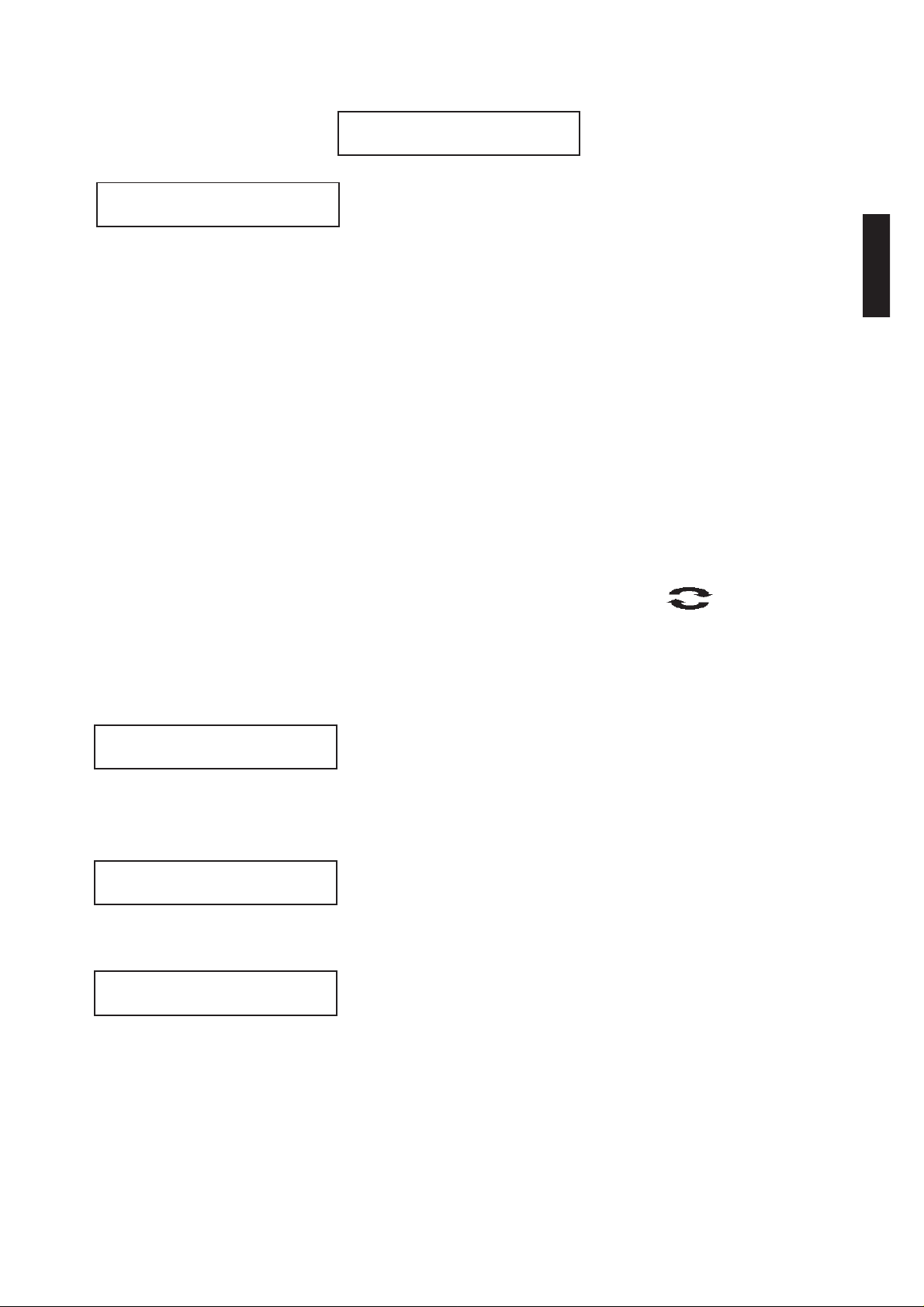

Memory Mode

The PosiTector PC can record 1,000 measurements in up to 100

groups (batches) for on-screen statistical purposes, for printing to an

optional IR printer, or for downloading to a computer using the included

USB cable. Readings are time-stamped as they are taken.

(This menu option appears only when the probe is powered-up)

-Closes any currently opened batch and creates a new batch name

using the next higher number. For example, if only Batch 1 and Batch

3 exist, then Batch 4 would be created and made the current batch.

S

tatistics are displayed and each measurement will now be

simultaneously shown on the display and stored into this new batch.

On-screen statistics are immediately updated with each measurement.

New batch names are date stamped at the time they are created.

Opening a New Batch will turn Statistics mode OFF.

Shortcuts: When a batch is open, create a new batch by pressing (+).

Remove the last reading from the current open batch by pressing (-).

Memory

New Batch

Mean (average)

Max and Min

measurement

Current Batch

No. of

measurements

Last reading

Standard Deviation

Open

-Selects a previously created batch to open and makes current. If it

contains measurements, on-screen statistics will immediately reflect

values calculated from this batch. Opening an existing Batch will turn

Statistics mode OFF.

Page 13

12

-Stops the recording process, closes the current batch, and removes

the statistics from the display.

-Removes the selected batch completely from memory. The name is

deleted and all measurements are erased.

-Lists all readings on the display from the currently selected batch. The

last batch is viewed if no batch is currently open. Upon selection, the

last 10 measurement values are initially shown. Scroll using the (-) or

(+) buttons. Hold for 1 second to scroll a page at a time.

-Prints all stored measurements from the selected batch, or all batches,

to the optional IR printer. Press both (-) and (+) buttons simultaneously

to cancel printing.

Downloading Measurement

s

A computer can view and download measurements stored in memory

using the included USB cable. Measurements are not erased from

memory after downloading. See "USB Drive" on pg. 14.

Statistics Mode

The PosiTector PC can display basic statistical

information as measurements are taken. Individual

measurement results are not stored into memory.

When Statistics is selected, a symbol and a

statistical summary appear on the display.

Notes:

Remove the last measurement by pressing the (-) button.

Clear statistics by pressing the (+) button.

Turning Statistics mode ON will close a currently open batch.

Turning Statistics mode OFF will clear all current statistical information.

Close

Delete

View

Print

Statistics

Page 14

13

Setup Menu

Reset restores factory settings and returns the gage to a known, out-of-

the-box condition. It is handy when you want to "start all over".

The following occurs:

- All batches are closed and stored measurements are erased.

- Calibration adjustments are cleared and the instrument is returned to

the gage's factory calibration settings as CAL 1.

- Menu settings are returned to the following:

Memory = OFF

Statistics = OFF

USB Drive = ON

A more thorough Reset can be performed by holding the (+) button

when the gage is powered down until the Reset symbol appears. It

performs the same function as a menu Reset with the addition of Units

= microns, Language = English, and Flip Display = Normal.

A probe Zero (pg. 6) must be performed after any Reset.

This option causes the base unit display to read upside down. Ideal for

viewing while the base unit is attached to a waist belt so that the display

is conveniently pointed toward the operator.

This menu button converts the display and all stored readings from

microns to mils or vice versa.

All batches are date-stamped when created and all measurements are

time-stamped (24 hour format) when stored into these batches. It is

therefore important to keep both the date and time current using this

menu option.

Setup

Reset

Set Clock

Units

Flip Display

Page 15

14

USB Drive - Selected

The PosiTector PC uses a USB mass storage device class which

provides a simple interface to retrieve data in a manner similar to USB

flash drives, cameras, or digital audio players.

When the "USB Drive" option is selected with a tick mark , any

computer can view and download measurements stored in memory (in

batches) by navigating a virtual drive labeled POWDER using the

included USB cable.

USB Drive

A formatted HTML report is viewed by selecting the "index.html" file

found in the root directory. Optionally, "readings0.txt" files located in

each batch folder (i.e. B1) provide access to measurement values.

New drive

Measurement values,

reports, graphs, or the

entire POWDER virtual

drive can be copied onto

your computer or imported

into a document or

spreadsheet for permanent

storage. The "logo.jpg" file

can be replaced with a

corporate logo.

While the USB cable is connected to a computer, new measurements

will not be included in reports and text files until the USB cable is

unplugged and re-connected.

ü

Page 16

15

USB Drive - Un-Selected

When this option is not selected with a tick mark , measurement

values can be downloaded, as they are taken, to a computer, data

collector, or powder controller using a serial gadget driver.

Note: When the USB Drive option is changed (selected or de-selected),

the instrument must be powered-down, then powered-up to undertake

the change.

Note: When a USB cable is connected to the base unit, power is

supplied through the USB cable. The batteries are not used and the

base unit will not automatically power down.

Maintenance

The base unit requires no maintenance except battery replacement.

Clean with a soft brush or cloth.

The screen at the measuring end of the probe can be unscrewed for

cleaning. Accumulated powder should be carefully removed from the

screen by no more than 0.2 MPa (20 - 30 psi) of compressed air. Do

not direct air directly into the probe. Replacement screens are available.

Changing the Batteries

The battery symbol displays a full bar with

fresh alkaline batteries installed. As the batteries

weaken, the bar will be reduced. When the

battery symbol is low the gage can still be

used, but the batteries should be changed at the

earliest opportunity. Use only "AAA" alkaline

batteries (3) in the base unit and "AA" alkaline

batteries (3) in the probe. Nickel-cadmium and

nickel-metal hydride rechargeable batteries will

work but the gage may appear to have weak batteries. The gage will

turn off automatically when batteries are very low, preceded by a low

battery warning on the display. If batteries are very low the gage may

startup but then turn off quickly.

Note: To retain all user settings and stored memory readings, only

replace the batteries after the gage has automatically powered-down.

Page 17

16

Returning for Service

Before returning the instrument for service…

1. Install new alkaline batteries in the proper alignment shown within

battery compartments.

2. Examine the probe screen for dirt or damage.

3. Perform a Reset (pg. 13) and a Zero (pg. 6)

If you must return the instrument for service, describe the problem fully

and include measurement results, if any. Be sure to also include the

base unit, probe, your company name, company contact, telephone

number and fax number or email address. Return to your point of

purchase.

Website: www.defelsko.com/support

Technical Data

Conforms to ASTM D7378

Base unit dimensions: 146 x 64 x 31 mm (5.75" x 2.5" x 1.2")

Probe dimensions: 222 x 50mm diameter (8.75" x 2" diameter)

Alkaline Batteries: Base unit 3 "AAA" batteries. Probe 3 "AA" batteries

Temperature Range: 0 to 40°C (+32° to +104°F)

Measuring Range: 20 - 110 microns (0.8 - 4.3 mils)

Measuring Resolution: 1 micron (0.05 mil)

Measuring Distance: approximately 18 mm (3/4 inch)

Measurement Area: 2 mm (0.08 inch)

Measuring Time: approximately 2 to 5 seconds

Accuracy: ±5 microns (± 0.2 mils)

The probe uses ultrasound frequencies above 100KHz with sound

pressure levels well below 110 dB (relative to 20uPa).

Available Options

A variety of accessories are available to help you get the most from

your PosiTector PC Powder Checker.

Page 18

17

Limited Warranty, Sole Remedy and Limited Liability

DeFelsko's sole warranty, remedy, and liability are the express limited

warranty, remedy, and limited liability that are set forth on its website:

www.defelsko.com/terms

Warning: The PosiTector PC Powder Checker contains a

very powerful magnetic mount for attaching the protective

rubber holster to nearby steel structures. As with all magnets,

avoid contact with electronic instruments or devices sensitive to

magnetic fields such as pace makers and coating thickness

gages. Care should also be given to the storing and shipping of

any strong magnet to prevent contact with sensitive devices.

Page 19

Page 20

Loading...

Loading...