Page 1

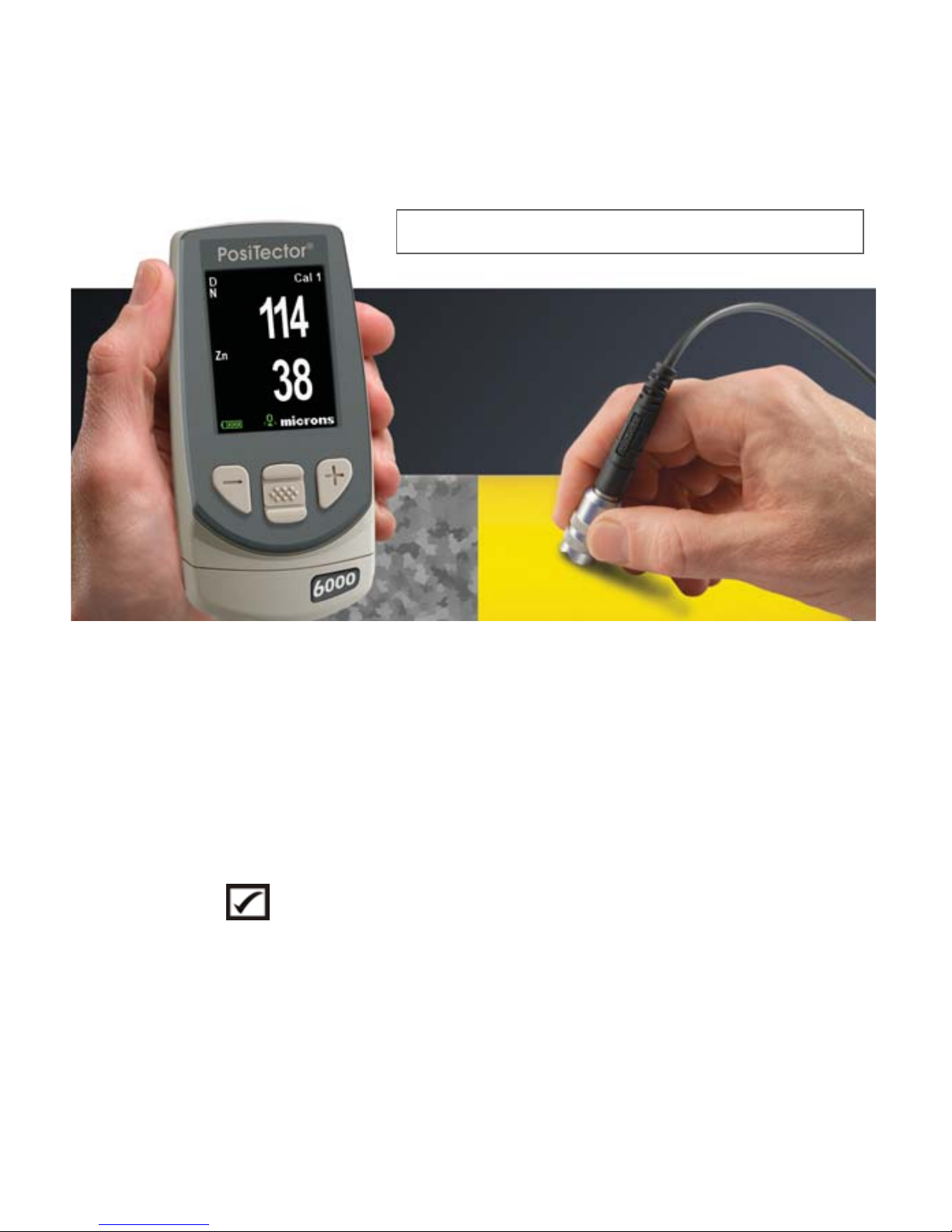

When attached to either a PosiTector Standard or Advanced body, the PosiTector

6000

FNDS

probe measures the individual thicknesses of both the paint and the zinc layers

in a duplex coating system with a single reading.

Duplex coating systems use a combination of two corrosion protection systems –

typically paint or powder coating over galvanized steel (hot-dip, electro or zinc spray

metallizing). The resultant corrosion protection is superior to either protection system

used independently.

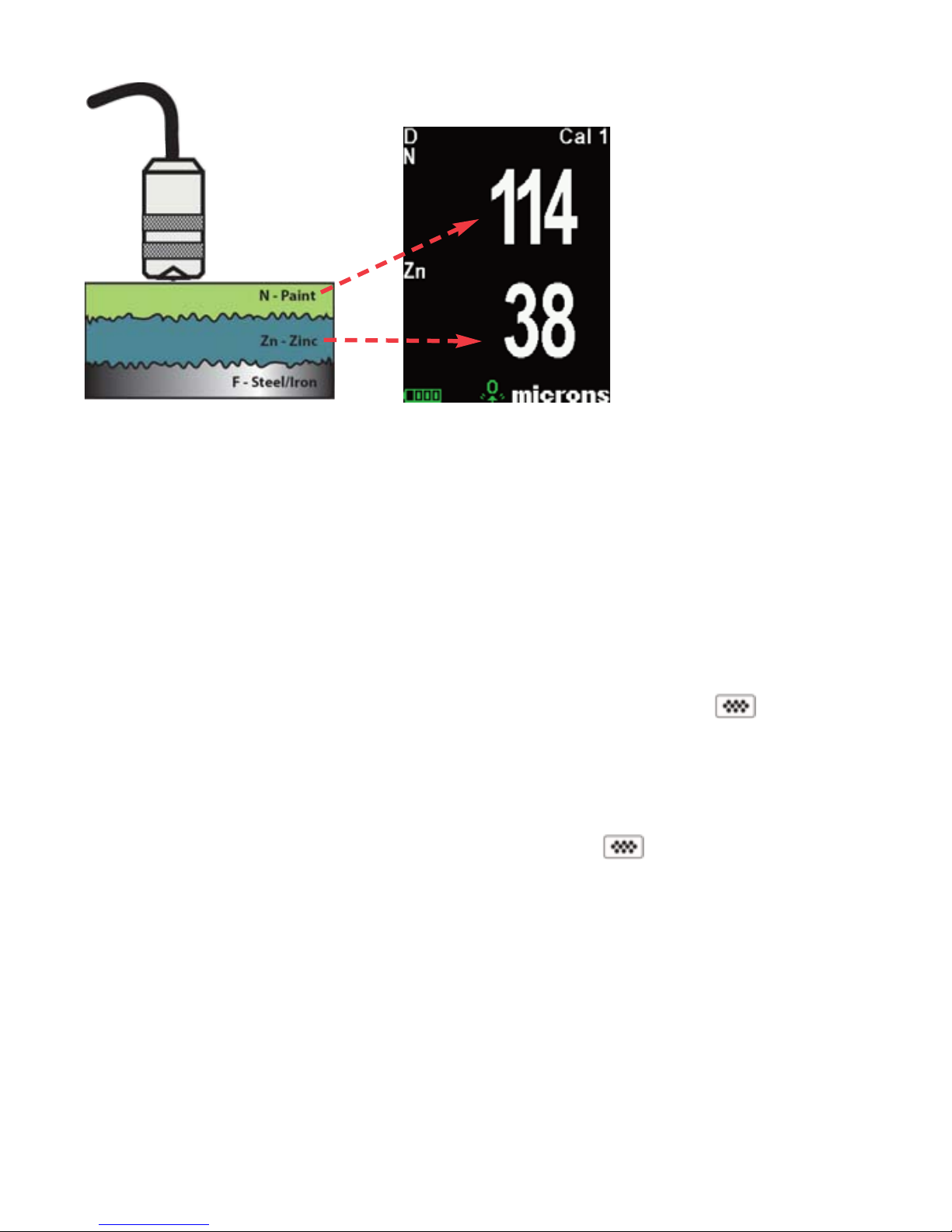

Duplex Mode

In Duplex mode, the Gage utilizes both magnetic (ferrous) and eddy current (nonferrous) principles simultaneously to calculate and display the individual paint and zinc

layer thicknesses. The magnetic principle is used to measure the combined paint/zinc

thickness over the ferrous substrate and the eddy current principle is used to measure

the paint thickness over the non-ferrous zinc coating. The zinc thickness is calculated

by subtracting the paint thickness from the combined paint/zinc thickness

measurement.

PosiTector

®

6000 FNDS probe

for Duplex Coatings

Addendum to Instruction Manual v. 7

Page 2

How to Measure

The PosiTector

6000

powers up when the center navigation button is pressed.

To preserve battery life, the instrument powers down after approximately 5 minutes

of no activity. All settings are retained.

1. Remove the protective rubber cap from the probe.

2. Power-up the Gage by pressing the center navigation button.

3. Place the probe on the surface to be measured. When a measurement is calculated,

the Gage BEEPS and the measurement is displayed.

NOTE: A “---” dashed line value and a low tone indicates the Gage was unable to

calculate the zinc layer thickness

4. Lift the probe AT LEAST 2 inches (5 cm) between readings or leave the probe on the

surface in the same location for continuous measurements.

Verify accuracy on reference standards at the beginning and the end of each shift, or

if the gage is dropped or suspected of giving erroneous readings.

When enabled (default), the Gage will display two measurement values (as shown

above). To disable, uncheck

Duplex

within the

Setup

Menu. Alternatively, press the

Up navigation button to toggle Duplex On/Off (when Memory is OFF).

When disabled, the Gage will operate like a conventional combination ferrous/nonferrous instrument (similar to the PosiTector

6000 FNS

probe). Ideal for measuring

non-magnetic coatings over steel and non-conductive coatings over non-ferrous metal

substrates.

N = Paint Thickness

Zn = Zinc Thickness

Page 3

The first time a part is measured, and any time the process changes, check zero on

both the bare steel substrate and on the uncoated zinc surface. Adjust if necessary

(see Calibration Adjustment).

Calibration Adjustment

Adjustment, or calibration adjustment is the act of aligning the Gage’s thickness

readings to match that of a known sample in order to improve the effectiveness of the

Gage on a specific surface or in a specific portion of its measurement range.

PosiTector

6000 FNDS

probes are factory calibrated and perform an automatic selfcheck each time a measurement is taken. For many hot-dip galvanized applications,

no further adjustment is necessary from the factory calibration. The symbol

disappears whenever a calibration adjustment is made.

F Zero Adjustment

Measure the uncoated steel substrate (if available). If the average of several “N”

readings is not within tolerance of “0”, perform an F Zero adjustment.

1) Select F Zero from the Cal Settings menu.

2) Press (+) to select the number of readings to be used to obtain an average, typically

3 to 10 readings. The greater the variation between readings, the more zero readings

should be taken to obtain an average.

3) Repeatedly measure the uncoated steel part. The Gage will wait two seconds after

placing the probe on the surface to allow the user to correctly position the probe. After

the last measurement, the Gage will calculate a Zero which represents the average of

all the F Zero readings taken.

Zn Zero Adjustment

Measure the unpainted zinc surface (if available). If the average of several “N” readings

is not within tolerance of “0”, perform an Zn Zero adjustment.

1) Select Zn Zero from the Cal Settings menu.

2) Press (+) to select the number of readings to be used to obtain an average, typically

3 to 10 readings. The greater the variation between readings, the more readings should

be taken to obtain an average.

3) Repeatedly measure the unpainted galvanized part. The Gage will wait two seconds

after placing the probe on the surface to allow the user to correctly position the probe.

Page 4

After the last measurement, the Gage will calculate a Zero which represents the

average of all the Zn Zero readings taken.

N 1 Pt Adjustment

For rough zinc surfaces (i.e. zinc spray metallizing), it may be desirable to adjust the

Gage to a known thickness, such as a shim placed over the zinc, rather than adjusting

it to zero. This ensures the Gage measures the thickness of paint over the metallizing

“peaks”.

1) Select N 1 Pt Adjust from the Cal Settings menu.

2) Press (+) to select the number of readings to be used to obtain an average, typically

3 to 10 readings. The greater the variation between readings, the more readings should

be taken to obtain an average.

3) Repeatedly measure the known thickness reference on the unpainted galvanized

part. The Gage will wait two seconds between readings to allow the user to correctly

position the probe on the surface. After the last measurement, the Gage will calculate

and display the reading which represents the average of all the measurements taken.

If the expected reading is not obtained (within tolerance), lift the probe from the surface

and adjust the reading down (-) or up (+) to the expected thickness and press .

NOTE: The reference thickness should be similar to the expected paint thickness.

© DeFelsko Corporation USA 2016 All Rights Reserved

For more detailed instructions, see the included PosiTector

6000 Quick Guide.

PosiTector

6000 FNDS

probes are compatible with all PosiTector Advanced

models (serial numbers 730,000+) and Standard models with color display.

Probe Specifications

Mils Microns

Minimum Zinc Thickness 0.5 mil 13 µm

Paint Layer Accuracy

+/- (0.05 mil + 1%) 0-2 mils

+/- (0.1 mil + 1%) > 2 mils

+/- (1 µm + 1%) 0-50 µm

+/- (2 µm + 1%) > 50 µm

Zinc Layer Accuracy

+/- (0.1 mil + 1%) 0-2 mils

+/- (0.2 mil + 1%) > 2 mils

+/- (2 µm + 1%) 0-50 µm

+/- (4 µm + 1%) > 50 µm

For full specifications refer to defelsko.com/p6000/p6000_probe_details.htm

Loading...

Loading...