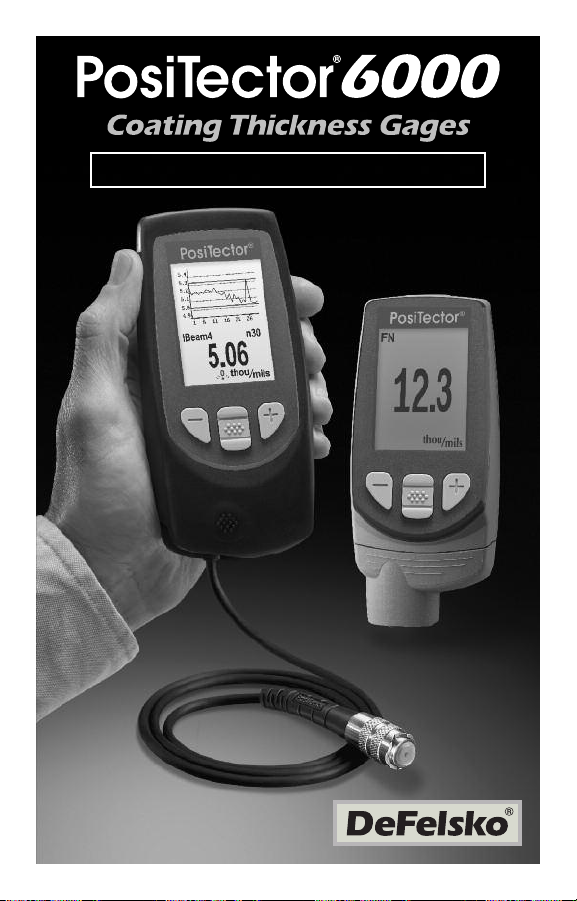

Page 1

Quick Guide v. 7.3

Page 2

Introduction

Introduction

Th

e

Pos

i

Te

c

tor

6

0

0

0

h

a

n

d

-h

e

ld

,

e

le

ct

ro

n

ic Ga

g

e

n

d

e

s

tru

c

ti

v

el

y

m

ea

s

ures

the

thi

c

k

nes

s

of

c

o

ati

n

gs

quick

ly

and

accur

at

ely.

I

t

consis

t

s

of

A

dv

anc

ed) an

d p

robe (B

u

i

l

t-In

or S

Thi

s

Qui

c

k

Gu

i

d

e

s

u

m

m

a

ri

z

e

s

th

m

e

n

t. Do

wnl

oa

d the

ful

l

i

www

.d

efel

s

k

o

.c

o

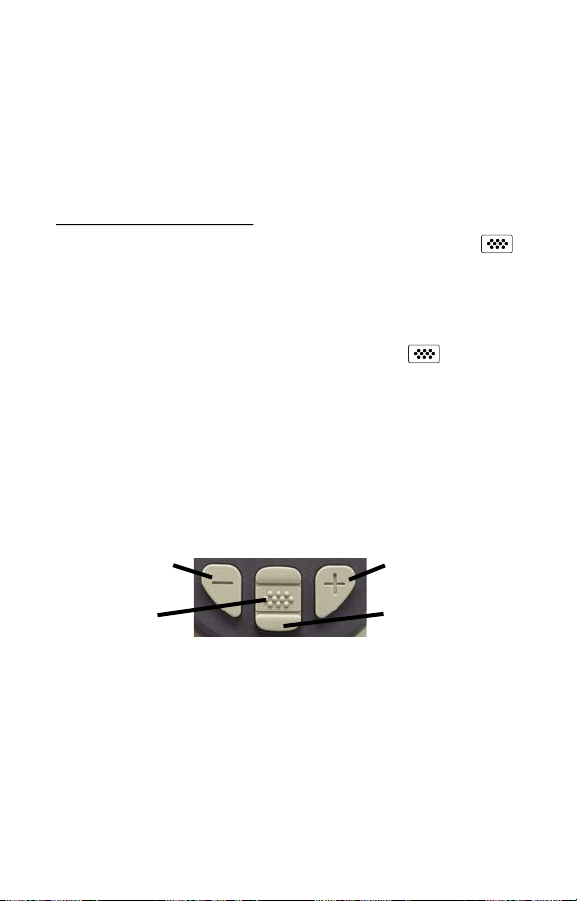

The PosiTector 6000 powers-up when the center navigation

button is pressed. To preserve battery life, the instrument

powers down after approximately 5 minutes of no activity. All

settings are retained.

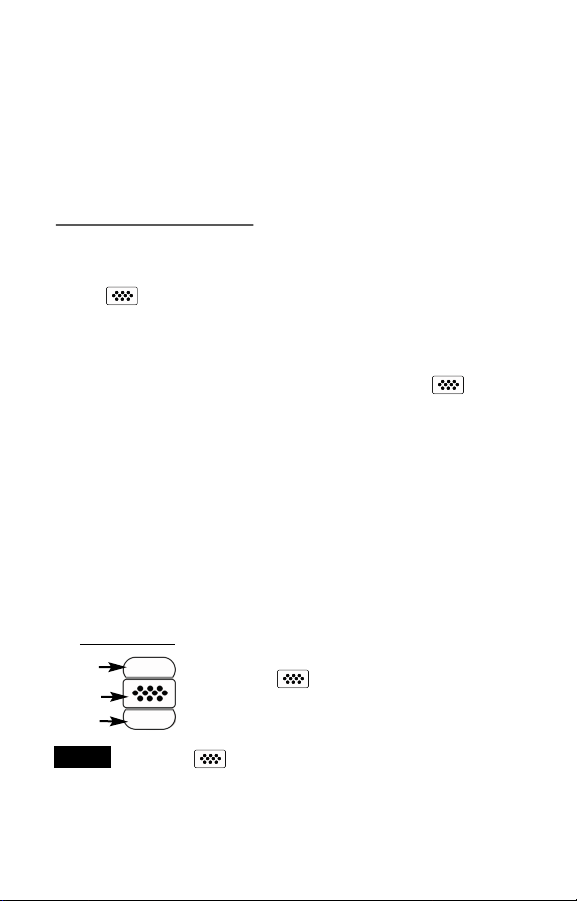

1. Remove the protective rubber cap (if supplied) from probe.

2. Power-up Gage by pressing the center navigation button.

3. Place the probe FLAT on the surface to be measured. HOLD

STEADY. When a valid measurement is calculated, the Gage

BEEPS twice and the measurement is displayed.

4. Lift probe AT LEAST 2 INCHES (5cm) from the surface between

measurements - OR - leave probe on the surface in the same

location for continuous measurements.

Gage functions are menu controlled. To access the Menu, powerup the gage, then press the center navigation button.

Navigation Button

Up

Center

Down

n

m

/m

anua

Quick Start

Quick Start

Menu Operation

Menu Operation

To navigate, use the Up and Down buttons to

scroll and to SELECT.

Select Exit to exit from any menu.

e

s

tru

c

ti

on

l

s

ep

m

bas

arate).

i

c

a

nua

a

fu

l

at:

nc

body

ti

ons

(

Standar

of

on

o

m

etal

d

th

e

i

ns

tru

n

-

s

,

or

-

NOTE:

The center button is purposely recessed to help

eliminate unintentional powering-up of the gage.

1

Page 3

Button Functions- Normal Operation

Adjust Down

Access the Menu

Probes

Probes

T

o

d

i

s

c

o

n

n

e

c

t

a

p

r

o

b

e

f

r

o

m

a

b

o

d

y

,

i

n

s

t

r

u

m

e

n

t

a

n

d

s

l

i

d

e

t

h

e

h

o

r

i

z

o

n

t

a

l

l

y

(

i

n

t

h

e

d

i

b

o

d

y

.

R

e

v

e

r

s

W

h

e

n

p

o

d

e

s

e

l

Additionally, the PosiTector accepts a number of probe types

including magnetic and eddy current coating thickness, surface

profile, environmental and ultrasonic wall thickness probes.

For the latest information on probe interchangeability,

see www.defelsko.com/probes

Calibration, Verification, and Adjustment

Calibration, Verification, and Adjustment

The PosiTector 6000 non-destructively measures the thickness of

coatings on metals.Three steps ensure best accuracy…

1. Calibration: typically done by the manufacturer or qualified lab.

All probes include a Certificate of Calibration.

2. Verification of Accuracy: as done by the user on known

reference standards such as the included plastic shims or

optional coated thickness standards.

3. Adjustment: Adjustment, or Cal Adjustment is the act of

aligning the Gage’s thickness readings to match that of a known

sample in order to improve the effectiveness of the Gage on a

specific surface or in a specific portion of its measurement

range. 1-point or 2-point Cal adjustments are possible.

w

t

e

r

m

i

n

e

s

f

-

w

c

h

e

c

k

.

r

e

t

h

e

s

e

s

e

r

e

d

-

u

p

h

a

t

t

y

p

e

p

e

c

t

i

o

n

o

f

t

t

e

p

s

t

o

a

t

h

e

P

o

o

f

p

r

o

b

e

p

l

a

s

t

i

c

p

r

h

e

a

r

r

o

w

t

t

a

c

h

a

n

s

i

T

e

c

t

o

r

i

s

a

t

t

a

c

h

o

w

e

r

-

o

b

e

c

)

a

w

a

y

e

w

p

r

o

a

u

t

o

e

d

a

n

Adjust Up

Restore brightness

after dimming

(Advanced only)

d

o

w

n

t

h

e

o

n

n

e

c

t

o

r

f

r

o

m

t

h

e

b

e

.

m

a

t

i

c

a

l

l

y

d

d

o

e

s

a

2

Page 4

Probes are factory calibrated and perform an automatic self-check

each time a measurement is taken. For many applications no

further adjustment is necessary after a Reset (pg. 4). Just check

ZERO on the uncoated substrate, then measure. However,

sometimes Gage readings can be influenced by changes in

substrate shape, composition, surface roughness or by measuring

in a different location on the part. That is why Cal adjustments are

made possible. The XX symbol disappears whenever a Cal

adjustment is made to the Gage.

Where a Cal adjustment method has not been specified, use a

1-point method first. If measuring the included shims on your

surface reveals inaccuracies, use the 2-point method. Factory Cal

settings can be restored at any time by performing a Reset (pg. 4),

creating a NEW Cal setting (See Cal Memory pg. 4), or by

DELETING the adjustments made to the Cal 1 calibration setting

(pg. 4). The XX symbol appears on the display whenever factory

Cal settings are in use.

With “FN” Gages, calibration adjustments are made only to the “F”

or “N” mode (stored independently under a particular Cal),

whichever was measured last.

Cal Settings Menu

Cal Settings Menu

1 Pt Adjust

or correction value, there are 4 ways to perform this:

(i) Simple Zero Adjustment- Measure your uncoated part. Lift

the probe and adjust to "0" using the (+) and (-) buttons.

(ii) Average Zero Adjustment A preferred method

to (i) is to average 3 to 10 measurements on the uncoated part.

(iii) Simple Adjustment to a Known Thickness- Measure a

shim of known thickness placed on the uncoated part. Lift the

probe and adjust to the shim thickness using the (+) and (-)

buttons.

(iv) Average Adjustment to a Known Thickness

A preferred method to (iii) is to average 3 to 10 measurements

of a shim of known thickness placed on the uncoated part using

the (+) and (-) buttons.

1-Pt Cal Adjustment- Also known as an offset

Zero

1 Pt Adjust

3

Page 5

2 Pt Adjust

Provides greater accuracy within a limited, defined range. Measure

a thin value (often zero) and a thicker value. These values should

bracket your expected thickness range.

Cal Lock

When checked, the icon appears and the current Cal settings

are “locked” to prevent further user adjustments.

N Lock

Use when operating regularly on non-ferrous substrates. The

icon appears and the probe will only use the eddy current principle

to shorten measurement time and extend battery life. Useful when

measuring coatings over plated steel.

Cal Memory

The current cal setting (ex. Cal 3) displays in the upper right corner

of the LCD. A stored cal setting can be restored when you return

to a particular part. Cal 1 can be adjusted but never deleted, and

is always made active with factory settings after a Reset (pg. 4). A

new cal setting cannot be created if a batch is open with readings.

Reset

Reset (soft reset) restores factory settings and returns the

instrument to a known condition. The following occurs:

- All batches, stored measurements, images, and batch names

are erased.

- All calibration adjustments and Cal Memory are cleared and

returned to the Gage’s factory calibration settings.

- Menu settings are returned to the following:

Memory = OFF

High Res = OFF

Statistics Mode = OFF

Hi Lo Alarm = OFF

Scan Mode = OFF

(FN ferrous/ non-ferrous cobmination probes only)

(Advanced models only)

Setup Menu

Setup Menu

Cal Lock = OFF

Bluetooth = OFF

Display = None

N Lock = OFF

4

Page 6

Perform a more thorough Hard Reset by powering down the

instrument, waiting several seconds, then simultaneously holding

both the center and (+) buttons until the Reset symbol

appears. This returns the instrument to a known, “out-of-the-box”

condition. It performs the same function as a menu Reset with the

addition of:

- Bluetooth Pairing info is cleared.

- Menu settings are returned to the following:

Units = microns

Flip Display = Normal

Auto Sync = OFF

White on Black = OFF

Fast Mode = OFF

NOTES:

Increases the displayed resolution. Accuracy is not affected.

Increases measurement speed for most probes. Useful for quick

inspection or when measuring large areas with thick coatings

where proper probe positioning is not critical. Swift up/down probe

movement is required. Reduced accuracy may be noted.

In ordinary operation, the PosiTector 6000 takes thickness

measurements every 2 seconds when placed onto a surface.

Normally, the user raises the probe after it has taken a single

measurement and relocates it to a second location. Scan mode

modifies this behavior in two ways. First, measurements are taken

much faster. Second, all measurements are recorded when

memory is on. As the probe slides along the surface in scan mode,

the PosiTector 6000 takes single measurements in quick

succession. This may reduce the life of the probe. Recommended

for smooth surfaces only.

- Keep the gage away from metal during a Reset.

- Date, Time and WiFi are not affected by either Reset.

Hi Res

Fast

Scan

Language = English

Battery Type = Alkaline

Backlight = Normal

Bluetooth Streaming = OFF

USB Drive= ON

(Advanced models only)

5

Page 7

Battery Type

Selects the type of batteries used in the Gage from a choice of

“Alkaline”, “Lithium” or “NiMH” (Nickel-metal hydride

rechargeable). If NiMH is selected, the Gage will trickle charge the

batteries while connected via USB to a PC or optional AC charger.

The battery state indicator icon is calibrated for the selected

battery type. No damage will occur if the wrong battery type is

selected.

NOTE:

DeFelsko recommends the use of eneloop (NiMH)

rechargeable batteries.

S

tatistics

S

tatistics

S

t

at

i

st

i

cs

A

st

at

i

st

i

cal

i

st

i

x -

↑

sum

em

ent

cs.

Ave

- Maximu

by

ra

g

m

easur

st

at

HiLo Alarm

Allows the Gage to visibly and audibly alert the user when

measurements exceed user-specified limits.

The PosiTector 6000 has internal memory storage for recording

measurement data. Stored measurements can be reviewed

on-screen or accessed via computers, tablets and smart phones.

Measurements are date and time-stamped.

x

m

ar

y w

i

l

l

appear

pr

essi

ng

e

m V

a

lu

e

Memory Management

Memory Management

t

he

M

M

on t

(

-

)

but

σ - Sta

- Minimu

↓

ode

ode

he di

t

spl

on.

n

dard De

m V

ay

.

R

em

ove t

he l

P

r

ess

(

viatio

a

lue

+) t

n

ast

o

cl

ear

Standard models store up to 250 readings in one batch.

Advanced models store 100,000 readings in up to 1,000

batches. “New Batch” closes any currently opened batch and

creates a new batch name using the lowest available number. The

icon appears. New batch names are date stamped when they

are created.

6

Page 8

Scroll through display

modes (Advanced only)

Delete last reading

Access the Menu

Create a new batch

(Advanced only)

Restore brightness

after dimming

(Advanced only)

Screen Capture

Press both (-)(+) buttons at any time to capture and save an image

copy of the current display. The last 10 screen captures are stored

in memory and can be accessed when connected to a computer

(see PosiSoft USB Drive pg. 7).

NOTE:

This Quick Guide summarizes the basic functions

of the Gage. Download the full instruction manual at:

www.defelsko.com/manuals

New PA2

Helps determine if film thickness over a large area conforms to

user specified min/max levels. See www.defelsko.com/pa2

New 90/10

Determines if a coating system complies with the IMO

performance standard for protective coatings.

See www.defelsko.com/9010

Accessing Stored Measurements Data

Accessing Stored Measurements Data

PosiSoft solutions for viewing, analyzing and reporting data:

PosiSoft USB Drive - connect the PosiTector to a PC/Mac using

the supplied USB cable to access and print stored readings, graphs,

photos, notes and screen captures. No software or internet

connection required. USB Drive must be selected. (see pg.8)

PosiSoft.net - a free web-based application offering secure

centralized storage of PosiTector readings. Access your data from

any web connected device. Go to: www.PosiSoft.net

PosiSoft Software - Desktop Software for downloading, viewing

and printing your measurement data.

PosiSoft Mobile (Advanced models only) - access readings, graphs,

capture photos and update annotations through WiFi enabled

devices, such as tablets, smart phones and computers.

7

Page 9

Connect Menu

Connect Menu

Sync Now

When selected, Gage immediately synchronizes stored

measurement data via USB, Bluetooth or WiFi to PosiSoft.net.

(PosiSoft Desktop Manager and an internet connection are

required when using USB or Bluetooth.)

Auto SYNC

Allows the Gage to automatically synchronize with PosiSoft.net

when initially connected to the internet via a PC running PosiSoft

Desktop Manager or a local WiFi network.

Additional measurements added to memory while connected are

synchronized only when the USB cable is disconnected, then

reconnected or when the Sync Now option is selected.

USB Drive

The Gage uses a USB mass storage device class which provides

a simple interface to retrieve data in a manner similar to USB flash

drives, cameras or digital audio players.

NOTE:

When connected, power is supplied through the USB

cable. The batteries are not used and the body will not

automatically power down. If rechargeable (NiMH) batteries are

installed, the Gage will trickle charge the batteries.

Bluetooth

Allows individual readings to be sent to a computer, printer or

compatible device as they are taken using Bluetooth wireless

technology. See www.defelsko.com/bluetooth

WiFi

Allows wireless communication with devices such as tablets,

smart phones and computers connected to your local wireless

network or portable mobile hot spot. See www.defelsko.com/WiFi

(Advanced models only)

(Advanced models only)

Updates

Determines if a software update is available for your Gage.

See www.defelsko.com/update

WARNING:

update (see pg. 5)

The Gage may perform a Hard Reset after an

8

Page 10

Returning for Service

Returning for Service

Before returning the instrument for service…

1.Install new or newly recharged batteries in the proper alignment

as shown within battery compartment.

2.Examine the probe tip for dirt or damage. The probe should

move up and down freely.

3.Perform a Hard Reset (pg. 5).

4.Place a plastic shim onto bare metal (steel or non-ferrous metal,

depending upon whether you have an “F” or “N ” probe) and

attempt a measurement.

If you must return the Gage for service, describe the problem fully

and include measurement results, if any. Be sure to also include

the probe, your company name, company contact, telephone

number and fax number or email address.

Website: www.defelsko.com/support

Limited Warranty, Sole Remedy

Limited Warranty, Sole Remedy

and Limited Liability

and Limited Liability

DeFelsko's sole warranty, remedy, and liability are the express

limited warranty, remedy, and limited liability that are set forth on

its website: www.defelsko.com/terms

www.defelsko.com

© DeFelsko Corporation USA 2012

This manual is copyrighted with all rights reserved and may not be reproduced or transmitted, in whole

or part, by any means, without written permission from DeFelsko Corporation.

DeFelsko and PosiTector are trademarks of DeFelsko Corporation registered in the U.S. and in other

countries. Other brand or product names are trademarks or registered trademarks of their respective

holders.

Every effort has been made to ensure that the information in this manual is accurate. DeFelsko is not

responsible for printing or clerical errors.

All Rights Reserved

9

Page 11

Guia rápida v. 7.1

Page 12

Introducción

Introducción

E

l

m

e

di

d

o

r

el

e

c

tró

n

i

c

o

portá

i

l

P

osiTec

tor

600

0

m

i

de

de

m

an

rápi

da,

p

rec

i

s

a

y

no

des

tru

c

ti

v

a

el

e

s

pe

s

or

de

re

c

u

b

cu

a

lq

u

ie

r

me

t

a

l.

Est

á

f

o

rma

d

o

p

o

r

u

n

es

es

ep

en

ara

bás

:

cu

d

i

A

dv

a

nc

e

d) y

un

a

s

on

d

a

(i

n

te

grad

a o s

E

s

ta gu

ía ráp

i

da

res

um

e

l

as

fun

c

i

De

s

c

argu

e

el

m

an

ua

l

d

e

i

www

.d

e

fe

l

s

k

o

.c

o

m

El PosiTector 6000 se enciende al pulsar el botón central .

Para conservar las pilas, el Medidor se apaga después de aproximadamente 5 minutos de inactividad. Se conservarán todas las

configuraciones.

1.Retire la goma de la tapa protectora roja de la sonda si la lleva.

2.Encienda el Medidor pulsando el botón central .

3.Ponga la sonda perpendicular sobre la superficie a medir.

MANTÉNGALA FIRME. Cuando se tome una medida válida, el

Medidor emitirá dos pitidos, y la medida aparecerá en el display.

4.Levante la sonda POR LO MENOS 5 cm (2 pulg.) por encima

de la superficie entre mediciones - O - deje la sonda sobre la

superficie en el mismo sitio para tomar medidas continuas.

/m

anua

ns

l

on

tru

c

c

i

on

s

ri

e

rp

o

(St

a).

c

as

d

el

i

era

m

i

en

tos

e

a

n

d

a

rd

n

s

tru

m

e

nto.

Funciones de los botones - Operaciones normales

Ajuste hacia arriba

Ajuste hacia abajo

n

o

Acceso al menú

Restauración del

brillo si se ha bajado (sólo Advanced)

2

Page 13

P

a

r

a

d

e

s

c

o

n

e

c

t

a

r

u

n

a

s

o

n

d

a

d

e

l

c

u

e

r

p

o

,

a

p

a

g

u

e

e

i

n

s

t

r

u

m

e

n

t

o

y

t

i

r

e

d

e

l

c

o

n

e

c

t

o

r

d

e

p

l

á

s

t

i

c

e

n

s

e

n

t

i

d

o

h

o

r

i

z

o

n

t

a

l

(

e

n

d

i

r

e

c

c

a

f

u

e

r

a

.

I

n

v

i

e

r

t

a

l

o

s

p

a

s

o

n

d

a

.

C

u

a

n

d

o

s

e

a

u

t

o

m

á

t

a

u

t

o

c

o

m

Calibración, verificación y ajuste

e

i

c

a

m

e

n

t

e

p

r

o

b

a

c

Calibración, verificación y ajuste

s

n

c

i

e

n

d

a

,

e

l

t

i

p

o

d

e

i

ó

n

.

i

o

s

p

a

r

a

e

l

P

o

s

o

n

d

a

c

o

o

ó

n

a

l

a

f

c

o

n

e

c

t

a

r

s

i

T

e

c

t

o

r

n

e

c

t

a

d

a

y

d

e

l

e

c

h

u

n

d

e

r

e

a

l

l

a

s

o

n

d

a

a

)

h

a

c

i

a

a

n

u

e

v

a

t

e

r

m

i

n

a

r

á

l

i

z

a

r

á

u

n

a

El PosiTector 6000 mide de manera no destructiva los espesores

de revestimientos de metales. Los pasos que garantizan la mayor

precisión son tres:

1. Calibración: realizada normalmente por el fabricante o un laboratorio cualificado. Todas las sondas incluyen Certificado de

Calibración.

2. Comprobación de precisión: que realiza el usuario con referencias como las galgas de plástico o los soportes estándar de

espesores opcionales.

3. Adjuste: Ajuste o ajuste de calibración es el acto de alinear las

mediciones del medidor para hacerlas coincidir con una muestra

conocida mejorando su efectividad en una superficie específica o

una porción específica de su rango de medición. Se pueden

realizar ajustes de calibración de 1 ó 2 puntos

Las sondas vienen calibradas de fábrica y realizan una autocomprobación

cada vez que se toma una muestra. Para muchas aplicaciones, no es

necesario realizar un posterior ajuste tras un Reset (Pág. 4). Basta realizar

una puesta a CERO sobre el substrato no recubierto y tomar la medida. Sin

embargo, a veces las lecturas del Medidor pueden verse afectadas por

cambios en la forma, la composición o la rugosidad del substrato, o al tomar

medidas en un lugar diferente de la pieza. Por ello pueden realizarse los

ajustes de calibración. El símbolo desaparecerá cuando se realice un

ajuste de calibración en el medidor.

Cuando no se haya especificado un método, utilice en primer lugar un

método de 1 punto. Si al medir las galgas facilitadas en su superficie se

detectan imprecisiones, utilice el método de 2 puntos. Las configuraciones

de calibración de fábrica se pueden restaurar en cualquier momento

reiniciando (Pág. 4), creando una NUEVA configuración de calibración (pg.

3), o BORRANDO los ajustes realizados en la configuración de calibración

Cal 1 (Pág. 3).

3

Page 14

El símbolo aparecerá en la pantalla siempre que se estén utilizando las

configuraciones de fábrica.

Con los Medidores "FN", los ajustes de calibración se realizan sólo

en modo "F" o "N" y se almacenan por separado bajo un Cal

específico dependiendo de la última medida.

Menú de configuración Cal

Menú de configuración Cal

Ajuste Cal 1 punto

- También conocido como un valor de cor-

rección o un offset. Puede llevarse a cabo de 4 maneras diferentes:

(i) Adjuste Simple zero - Mida su pieza sin revestimiento. Levante la

sonda y ajuste a "0" con los botones (+) y (-).

Zero

(ii) Adjuste promediado a z

es obtener la media de entre 3 y 10 mediciones de la pieza sin revestimiento.

(iii) Ajuste simple a un espesor conocido - Mida una galga de espesor

conocido colocada en una pieza sin revestimiento. Levante la sonda y

ajuste al espesor de la galga utilizando los botones (+) y (-).

(iv) Ajuste promediado a un espesor conocido

El método preferido para (iii) es obtener la media de entre 3 y 10

mediciones de una galga de espesor conocido colocado en la pieza sin

revestimiento.

ero El método preferido para (i)

Adjuste en 1 punto

Adjuste en 2 punto

Proporciona mayor exactitud dentro de un margen limitado y definido. Mida

un valor de poco espesor (frecuentemente cero) y uno de mayor espesor.

Estos valores soportarán el rango esperado de espesor.

Cal Lock

Una vez comprobado, el icono aparecerá y la actual configuración de calibración se bloqueará para evitar otros ajustes del

usuario. Desactive para realizar otros ajustes.

N Lock

(Solo combinación de sondas FN férricas/no férricas)

Utilícelas cuando opere regularmente con sustratos no férricos. El

icono aparecerá y la sonda solo utilizará el principio de las

corrientes de Foucault para acortar los tiempos de medición y

alargar la vida de la batería. Es útil en la medición de

revestimientos sobre acero galvanizado.

4

Page 15

Sólo para modelos Advanced)

Cal Memoria

La actual configuración de calibración (p. ej. Cal 3) se muestra en la parte

superior derecha de la pantalla. Una configuración de calibración almacenada puede restaurarse cuando vuelva a una pieza en particular. Cal 1

podrá ajustarse pero nunca borrarse y siempre se activará con la configuración de fábrica tras un Reset (Pág. 5). No podrá crearse una nueva configuración de calibración si está abierta una serie con lecturas.

(

Menú Configuración

Menú Configuración

Reset

Reset restaura las configuraciones de fábrica y devuelve al

instrumento a su condición inicial. Ocurre lo siguiente:

- Todas las series y las mediciones almacenadas, imágenes y

series se borrarán.

- Todos los ajustes de calibraciones y la memoria de calibración

se eliminarán y devolverán al medidor la configuración de

fábrica.

- Las configuraciones del menú serán de nuevo las siguientes:

Memoria = OFF

Resolucion = OFF

Modo estadísticas = OFF

Limites de Alarma = OFF

Cal Lock = OFF

Bluetooth = OFF

Display = None

N Lock = OFF

Modo Scan = OFF

Realice un Reinicio completo apagando el instrumento. Espere

varios segundos y de manera simultánea pulse los dos botones

central y (+) hasta que el símbolo Reset aparezca. Es una

función práctica si el equipo tiene problemas para encenderse u

operar. Realiza la misma función que el Reinicio y además:

- Borra la información de la conexión Bluetooth

- Las configuraciones del menú serán de nuevo las siguientes:

Units = microns

Voltear LCD = Normal

Auto Sync = OFF

Invertir LCD = OFF

Mode Fast = OFF

Idioma = English

Tipo de bateria = Alkaline

Backlight = Normal

Bluetooth Streaming = OFF

USB Drive= ON

5

Page 16

NOTAS:

- Mantenga el Medidor alejado de piezas metálicas durante el

- La fecha y hora no cambiarán al realizar un Reinicio.

Reinicio

.

Resolucion

Incrementa la resolución de pantalla. No afecta a la precisión.

Fast

Incrementa la rapidez de medición para la mayoría de las sondas.

Útil para inspecciones rápidas o cuando se realizan medidas de

áreas amplias con recubrimientos delgados cuando la posición de

la sonda no es crítica. Será necesario un movimiento de arriba a

abajo de la sonda. Puede apreciarse una reducción de precisión.

Scan

Es útil al tomar varias mediciones en un área pequeña y

almacenarlas en la memoria cuando la sonda está en contacto

con la superficie. Puede reducir la vida de la sonda.

Recomendado sólo para superficies suaves.

Tipo de batería

Selecciona el tipo de baterías utilizadas en el instrumento entre

"Alcalina", "Litio" o "NiMH" (Níquel - metal híbrido recargable). Si

se ha seleccionado NiMH el equipo cargará las baterías poco a

poco si está conectado por USB a un PC o a un cargador opcional

CA. El indicador del estado de las pilas se calibra para el tipo de

pila seleccionado. No habrá daños si el tipo de batería

seleccionado es erróneo.

NOTA:

DeFelsko recomienda el uso de baterías recargables

eneloop (NiMH).

Estadísticas

Un resumen de las estadísticas aparecerá en la pantalla. Pulse el

botón (-) para borrar la última medida. Pulse (+) para borrar las

estadísticas.

(Sólo para modelos avanzados)

Modo Estadísticas

Modo Estadísticas

x

6

Page 17

x - Promedio

- Valor máximo

↑

σ - Desviación Estándar

- Valor mínimo

↓

Alarma HiLo

(Alarma de límites) El medidor muestra y emite un sonido de alerta cuando

las mediciones exceden los límites especificados por el usuario.

El PosiTector 6000 puede registrar lecturas en la memoria para la impresión a la impresora inalámbrica Bluetooth opcional, la descarga (pág. 7) o

la sincronización con PosiTector.net. Las lecturas son con fecha y hora en

que se toman.

Desplazamiento por

los modos de visualización (sólo

Advanced)

Eliminar última lectura

Acceso al menú

Modo Memoria

Modo Memoria

Crear una nueva

serie

(sólo Advanced)

Restauración del

brillo si se ha bajado (sólo Advanced)

Los modelos Standard almacenan hasta 250 lecturas en una serie.

Los modelos Advanced almacenan 100,000 lecturas en hasta

1,000 series. "New batch" (Nueva serie) cierra cualquier serie

abierta y crea un nuevo nombre de serie con el número siguiente

más bajo. Aparecerá el icono . Los nombres de series nuevas

quedarán registrados con la fecha en que se crearon.

Nueva PA2

Ayuda a determinar si el espesor de una película en un área

grande se ajusta a los niveles mín y máx especificados. Consulte

www.defelsko.com/pa2

Nuevo 90/10

Determina si un sistema de revestimiento cumple con la

norma IMO para revestimientos protectores. Consulte

www.defelsko.com/pspc

7

Page 18

Descargar lecturas a un ordenador

Descargar lecturas a un ordenador

Almacenamiento masivo USB - conecta su PosiTector a un

PC/Mac con el cable USB incluido para acceder e imprimir lecturas

y gráficos almacenados. No se requiere conexión a internet ni

software especializado.

PosiTector.net - aplicación web gratuita que ofrece un

almacenamiento seguro y centralizado de las lecturas de espesor.

Acceda a sus lecturas desde cualquier dispositivo internet.

www.PosiTector.net

Menú Conectar

Sync Now

Inicia de manera inmediata la sincronización con PosiTector.net al

conectar (Bluetooth o USB) a un PC con acceso a Internet con

PosiTector Desktop Manager.

Auto SYNC

Sincroniza de manera automática con PosiTector.net si está

conectado inicialmente a un PC con acceso a Internet con

PosiTector Desktop Manager.

Sólo se sincronizarán las mediciones adicionales añadidas a la

memoria durante la conexión cuando el cable USB esté desconectado y se reconecte o cuando Conectar > Sync Now esté seleccionado.

Menú Conectar

USB Drive

El instrumento utiliza un dispositivo de almacenamiento masivo

USB que proporciona una interfaz sencilla para recuperar los

datos de manera semejante a un USB Flash, una cámara o un

reproductor digital de audio.

NOTA:

través del cable USB. Las baterías no estarán en uso y la base

no se apagará automáticamente. Si dispone de baterías

recargables (NiMH), el equipo las cargará poco a poco.

Cuando está conectado, la alimentación se obtiene a

8

Page 19

Bluetooth

Permite enviar lecturas individuales a un ordenador o dispositivo portátil

compatible con tecnología Bluetooth. Consulte

www.defelsko.com/bluetooth

(Sólo para modelos avanzados)

Updates

Determina si hay actualizaciones disponibles de software para su

instrumento.

Deberá estar conectado a un ordenador con conexión a Internet.

NOTA:

Gestor del escritorio de PosiTector.

Consulte: www.defelsko.com/update

Devolución para reparaciones

Devolución para reparaciones

Antes de devolver el instrumento para reparaciones...

1.Utilice pilas alcalinas nuevas verificando que estén debida

mente colocadas en el compartimiento de las pilas.

2.Examine la punta de la sonda por si está sucia o dañada. Las

sondas deberán poder moverse hacia arriba y hacia abajo sin

problemas.

3.Realice un Reinicio del Medidor (Pág. 5).

4.Coloque una galga de plástico sobre metal no recubierto (de

acero o no de acero, dependiendo de is tiene una sonda “F ” o

“N ”) y realice una medición.

Si debe devolver el instrumento para reparaciones, rellene el formulario

e incluya el formulario de servicio de www.defelsko.com/support

instrumento.

Garantía limitada, solución única y

Garantía limitada, solución única y

obligación limitada

obligación limitada

con el

La garantía única de DeFelsko, la solución, y la obligación son

la garantía limitada expresa, la solución y la obligación limitada

expuestas en su sitio web: www.defelsko.com/terms

© DeFelsko Corporation USA 2011

Este manual está protegido por copyright. Todos los derechos de este manual están reservados y no

podrá ser parcial o totalmente reproducido o transmitido por ningún medio sin el consentimiento previo

por escrito de DeFelsko Corporation.

DeFelsko y PosiTector son marcas comerciales de DeFelsko Corporation registradas en los EE.UU. y

en otros países. Otras marcas o nombres de productos son marcas comerciales o registradas de sus

propietarios respectivos.

Se han tomado todas las precauciones posibles para asegurar la precisión de toda la información contenida en este manual. DeFelsko no aceptará responsabilidad por errores tipográficos o de impresión.

Reservados todos los derechos.

9

Page 20

Kurzanleitung v. 7.1

Page 21

Einleitung

Einleitung

Da

s

P

osiTe

c

tor

60

00

i

s

t ei

n

e

l

ek

tron

i

s

c

he

s

Ha

nd

m

e

s

s

g

z

ers

sch

(S

s

e

D

i

fi

n

w

w

tan

p

e

d

s

w.d

tö

n

e

d

arat).

e

Ku

e

n

d

rung

ll

u

n

ard od

rz

a

i

e

v

e

fe

l

s

k

s

fre

i

d

i

e

Di

c

k

e

v

on

B

es

c

h

i

c

h

tu

ng

en

d

g

e

n

a

u

m

isst

.

Es

b

e

st

er

A

d

v

an

c

ed

) u

n

l

e

i

tu

n

g

fa

s

s

t

d

i

e

G

ru

o

l

l

s

tä

n

d

i

g

e

o

Be

.c

o

m

/m

a

n

u

n

d

i

e

n

u

n

g

s

a

l

s

nd

e

ei

n

em

d

fu

n

k

ti

o

n

e

a

n

w

e

i

s

u

n

a

h

t

a

u

s

S

e

ns

or (i

n

d

e

s

G

e

g

rä

u

n

te

r:

uf

e

in

ts

al

l

e

e

m

ntegri

z

u

s

erät, da

n

M

Ge

e

rt oder

a

m

m

eta

h

e

l

l

ä

u

n

.

Si

Das PosiTector 6000 schaltet sich ein, wenn die mittlere

Navigationstaste gedrückt wird. Um Batterien zu sparen,

schaltet sich das Gerät bei Nichtbenutzung nach etwa 5 Minuten

automatisch ab. Alle Einstellungen bleiben erhalten.

1.Entfernen Sie die Schutzkappe aus Gummi (falls vorhanden) von der

Sonde.

2.Schalten Sie das Messgerät ein, indem Sie die mittlere Navigationstaste

drücken .

3.Setzen Sie die Sonde FLACH auf die zu messende Oberfläche. RUHIG

HALTEN. Sobald eine gültige Messung erzielt wurde, PIEPT das Gerät

zweimal und das Messergebnis wird angezeigt.

4. Heben Sie die Sonde zwischen den einzelnen Messungen um

MINDESTENS 5 cm an, ODER belassen Sie sie an derselben Stelle, um

kontinuierliche Messungen durchzuführen.

Tastenfunktionen - Normalbetrieb

Nach unten

justieren

Gehen Sie in das

Menü

Nach oben

justieren

Wiederherstellen

der Helligkeit nach

dem Abdunkeln

(Nur Advanced

Ausführung)

s

en

se

e

3

Page 22

U

m

d

e

n

S

e

n

s

o

r

v

o

m

G

e

h

ä

u

s

e

z

u

t

r

e

n

n

e

n

,

s

c

h

a

l

t

e

n

S

i

d

a

s

G

e

r

ä

t

a

b

u

n

d

z

i

e

h

e

n

d

e

n

P

l

a

s

t

i

k

s

t

e

c

k

e

r

d

e

w

a

a

g

e

r

e

c

h

t

(

i

n

P

f

e

i

l

r

i

c

h

t

u

n

g

)

v

o

m

G

e

E

i

n

s

e

t

z

e

n

e

i

n

e

s

n

e

u

e

n

S

e

n

s

u

m

g

e

k

e

h

r

t

e

r

R

e

i

h

e

n

N

a

c

h

d

e

m

E

i

n

s

c

a

u

t

o

m

a

t

i

s

c

Kalibrierung, Überprüfung & Einstellung

Kalibrierung, Überprüfung & Einstellung

h

h

,

d

e

n

S

e

o

f

o

l

g

e

w

i

e

a

l

t

e

n

b

e

n

s

o

r

t

y

p

u

h

r

s

w

e

r

d

e

d

e

r

h

o

l

t

.

s

t

i

m

m

t

n

d

f

ü

h

r

t

s

ä

u

s

e

a

b

n

d

i

e

s

e

S

d

a

s

P

o

e

i

n

e

n

S

e

e

S

e

n

s

o

r

s

.

F

ü

r

d

a

s

c

h

r

i

t

t

e

i

n

s

i

T

e

c

t

o

r

l

b

s

t

t

e

s

t

d

u

r

c

h

.

Das PosiTector 6000 misst zerstörungsfrei die Dicke der

Beschichtungen auf Metall. Drei Schritte garantieren beste

Genauigkeit...

1. Kalibrierung: Wird typischerweise vom Hersteller oder einem

qualifizierten Labor durchgeführt. Alle Sensoren besitzen ein

Kalibrierzeugnis.

2. Überprüfung der Genauigkeit: Wird seitens des Nutzers auf

bekannte Referenz-Standards wie die mitgelieferten KunststoffFolien oder optionale Schichtdicken-Standards durchgeführt.

3. Einstellung: Als Einstellung, oder Kalibriereinstellung, wird der

Vorgang bezeichnet, bei dem die Dickenmesswerte der

Messeinrichtung an ein bekanntes Muster angepasst werden, um

die Effektivität der Messeinrichtung an eine spezifische Oberfläche

oder einen spezifischen Teil des Messbereichs anzupassen.Es

sind 1-Punkt- oder 2-Punkt-Kalibriereinstellungen möglich

Die Sensoren werden im Werk kalibriert und führen bei jeder Messung einen

Selbsttest durch. Bei vielen Anwendungen sind keine weiteren

Einstellungen nach einem Reset notwendig. (S. 5). Nur NULL sollte auf

einer unbeschichteten Oberfläche geprüft werden, dann messen. Aber

manchmal können die Messwerte durch die Änderung der Form des

Trägermaterials, durch die Zusammensetzung, die Oberflächenrauheit oder

durch die Messung an verschiedene Stellen eines Werkstücks beeinflusst

werden. Deshalb wird eine Kalibriereinstellung ermöglich. Das Symbol

verschwindet immer dann, wenn an dem Messgerät eine

Kalibriereinstellung durchgeführt wurde.

Falls keine Methode für die Kalibriereinstellung festgelegt wurde, benutzen

Sie die 1-Punkt-Methode. Wenn Sie bei der Messung mit den beigefügten

Kunststoff-Folien auf Ihrem Trägermaterial Ungenauigkeiten feststellen,

gehen Sie nach der 2-Punkt-Methode vor. Die Werkseinstellungen

4

Page 23

der Kalibriereinstellung können mittels Reset jederzeit wieder hergestellt

werden (S. 5), wenn eine neue Kalibriereinstellung mit NEU erstellt wird

(S. 4), oder auch mit LÖSCHEN der Kalibriereinstellung Kal 1 (S. 4),

Dies erscheint auf dem Display immer dann, wenn die Werkseinstellungen

der Kalibrierung benutzt werden.

Bei den "FN"-Messgeräten wird die Kalibriereinstellung nur im "F"-oder

"N"-Modus durchgeführt und unabhängig in einer eigenen Kalibrierung

gespeichert, je nach dem was zuletzt gemessen wurde.

Kal-Einstellung Menü

Kal-Einstellung Menü

1-Pkt-Kal Einstellung

gibt es 4 verschiedene Möglichkeiten:

(i) Einfache Null-Einstellung - Messen Sie das nicht beschichtete

Werkstück. Heben Sie den Sensor an und stellen Sie mit den Tasten (+)

und (-) Null "0" ein.

(ii) Einstellung auf Null-Mittelwert - Eine bevorzugte Methode

zu (i) ist es, 3 bis 10 Messungen an dem unbeschichteten Werkstück

durchzuführen.

(iii) Einfache Einstellung auf eine bekannte Dicke - Messen Sie z.B.

eine Folie mit bekannter Dicke auf dem unbeschichteten Werkstück.

Heben Sie den Sensor an und stellen Sie mit den Tasten (+) und (-) die

Dicke ein.

(iv) Mittelwerteinstellung auf eine bekannte Dicke - Eine

bevorzugte Methode zu (iii) ist es, 3 bis 10 Messungen mit einer Folie

bekannter Dicke auf dem unbeschichteten Werkzeug durchzuführen.

- Auch als Offset oder Korrekturwert bekannt, dafür

Null

1 Punkt

2 Punkt

Diese Einstellung bietet eine größere Genauigkeit innerhalb eines begrenzten,

definierten Bereiches. Messen Sie eine dünnere Dicke (oft Null) und einen dickeren

Wert. Diese Werte sollten im Bereich der erwarteten Dicke liegen.

Kal Sperre

Wird diese Funktion gewählt, erscheint das Symbol und die aktuellen

Kalibriereinstellungen werden "festgestellt", um weitere Einstellungen

durch den Benutzer zu vermeiden. Diese Funktion wird mit abgewählen,

um weitere Einstellungen vorzunehmen.

N Sperre

Verwenden Sie diese Einstellung bei FN-Sonden, wenn Sie regelmäßig an

nichteisenhaltigem Trägermaterial arbeiten. Das Symbol erscheint und

der Sensor arbeitet nur im Wirbelstromverfahren, um die Messung zu

verkürzen und um die Batterie zu schonen. Dies ist nützlich, wenn

Beschichtungsmessungen z.B. auf verzinktem Stahl durchgeführt werden.

(Nur für FN - Kombination von Sensoren für eisen-

haltige und nichteisenhaltige Werkstücke)

5

Page 24

Nur Advanced Modelle)

Kal Speicher

Die aktuelle Kalibriereinstellung (z.B. Kal 3) erscheint in der oberen rechte

Ecke der LCD-Anzeige. Eine gespeicherte Kalibriereinstellung kann wieder

hergestellt werden, wenn Sie erneut ein spezielles Werkstück messen

wollen. Kal 1 kann eingestellt, aber nicht gelöscht werden und ist immer

nach Reset mit den Werkseinstellungen aktiv (S. 5). Eine neue

Kaleinstellung kann nicht erzeugt werden, wenn ein Block mit Messwerten

geöffnet ist.

(

Setup-Menü

Setup-Menü

Reset

Reset stellt die Werkseinstellungen wieder her und führt das Gerät zu einer

bekannten Serieneinstellung zurück.

Folgendes geschieht:

- Alle Blöcke und gespeicherten Messungen, Abbildungen und

Blocknamen werden gelöscht.

- Alle Kalibrierungseinstellungen und der Kal-Speicher werden gelöscht

und die Werkseinstellungen werden wieder hergestellt.

- Die folgenden Menüeinstellungen werden wieder eingestellt:

Speicher = AUS

High Res = AUS

Statistik Modus = AUS

Hi Lo Alarm = AUS

Kal Sperre = AUS

Bluetooth = AUS

Anzeige = Keine

N Sperre = AUS

Scan-Modus = AUS

Sie können einen noch gründlicheren Hard Reset durchführen

indem Sie das Gerät ausschalten, einige Sekunden warten, und

dann gleichzeitig beide, die mittlere Taste und die (+) Taste

ücken, bis das Reset Symbol erscheint. Dies ist praktisch,

dr

wenn sich das Gerät nicht einschalten lässt oder nicht korrekt

arbeitet. Dabei geschieht das Gleiche wie bei einem Menü-Reset

und zusätzlich wird die:

- Bluetooth-Paarung gelöscht

- Die Menüs werden wie folgt eingestellt:

Einheiten = micron

LCD drehen = Normal

Auto Sync = AUS

Umkehren LCD = AUS

Schnell Modus = AUS

Sprache = Englisch

Batterietyp = Alkaline

Backlight = Normal

Bluetooth Streaming = AUS

USB Drive= EIN

6

Page 25

HINWEISE:

Die dargestellte Auflösung wird erhöht. Die Genauigkeit wird nicht

beeinflusst.

Die Geschwindigkeit wird für die meisten Sensoren erhöht. Dies ist nützlich

für eine schnelle Prüfung oder wenn große Bereiche mit dicken

Beschichtungen gemessen werden, bei denen die korrekte Positionierung

des Sensors nicht kritisch ist. Schnelles Auf- und Ab-Bewegen des Sensors

ist erforderlich. Es kann eine geringere Genauigkeit auftreten.

Dies ist nützlich, wenn verschiedene Messungen in einem kleinen Bereich

gemacht werden sollen und diese im Speicher gespeichert werden während

der Sensor die Oberfläche berührt. Dies kann die Lebensdauer des Sensors

beeinträchtigen. Nur empfohlen für glatte Oberflächen.

- Halten Sie das Gerät während eines Reset von Metall

fern.

- Datum und Zeit werden von keiner der beiden Reset-

Arten beeinflusst.

Hi Res

Schnell

Scan

(Nur bei Advanced-Modellen)

Battery Type

Hier wird der im Gerät verwendete Batterietyp zwischen "Alkali",

"Lithium" oder "NiMH" (wiederaufladbare Nickel-Metall-HybridBatterie) ausgewählt. Wenn NiMH ausgewählt wurde, werden die

Batterien ständig nachgeladen, während sie über einen USBAnschluss an einen PC oder ein optionales Ladegerät

angeschlossen sind. Das Symbol für die Anzeige des

Batteriestatus wird für den ausgewählten Batterietyp dargestellt.

Es entsteht kein Schaden, wenn der falsche Batterietyp

ausgewählt wird.

HINWEISE:

DeFelsko empfiehlt den wiederaufladbaren Akkutyp

eneloop (NiMH).

Statistik-Modus

Statistik-Modus

Statistik

x

Es erscheint eine statistische Zusammenfassung auf der Anzeige.

Sie entfernen die letzte Messung durch Drücken der Taste (-).

Durch Drücken der Taste (+) wird die Statistik gelöscht.

7

Page 26

x - Mittelwert

σ - Standardabweichung

- Maximalwert

↑

- Minimalwert

↓

Hi Lo Alarm

Mit dieser Funktion löst das Messgerät einen optischen und akustischen

Alarm aus, wenn die Messungen die vom Benutzer festgelegten Grenzwerte

überschreiten.

Die PosiTector 6000 kann Messungen im Speicher aufzeichnen, um sie zu

drucken und herunterzuladen (S. 7) oder um sie mit dem PosiTector.net zu

synchronisieren. Die Messwerte bekommen bei der Messung einen

Zeitstempel.

Ansehen der

Anzeigearten (Nur

AdvancedAusführung)

Löschen der letzten

Messwerte

Zum Menü

Speichermodus

Speichermodus

Neuen Block anlegen

(Nur Advanced

Ausführung)

Wiederherstellen

der Helligkeit nach

dem Abdunkeln

(Nur AdvancedAusführung)

Standardmodelle speichern bis zu 250 Messwerte in einem

Block.

Advanced Modelle speichern 100.000 Messwerte in bis zu

1.000 Blöcken. “Neuer Block” schließt einen offenen Block und

erzeugt einen neuen Blocknamen mit der niedrigsten verfügbaren

Nummer. Das Symbol erscheint. Neue Blocknamen bekommen

einen Zeitstempel wenn sie erstellt werden.

Neu PA2

Damit kann festgestellt werden, ob die Schichtdicke über einen

großen Bereich hinweg den Spezifikationen des Benutzers

min/max genügt. Siehe www.defelsko.com/pa2

Neu 90/10

Es wird bestimmt, ob ein Beschichtungssystem dem IMO-Standard für

Schutzschichten entspricht. Siehe www.defelsko.com/pspc

8

Page 27

Herunterladen von Messwerten in einen Compute

Herunterladen von Messwerten in einen Compute

USB-Massenspeicher - Verbinden Sie Ihr PosiTector mit einem

PC/Mac über ein USB-Kabel, um auf die gespeicherten Messwerte

und Grafiken zuzugreifen und sie zu drucken. Es ist keine Software

oder Internetverbindung erforderlich.

PosiTector.net - Eine freie web-basierte Anwendung, die die

sichere zentralisierte Speicherung von Messwerten bietet. Sie

haben Zugriff auf Ihre Messwerte von jedem Gerät aus, das sich im

Netz befindet. www.PosiTector.net

Verbinden Menü

Verbinden Menü

Sync Now

Die Synchronisation mit dem PosiTector.net wird sofort eingeleitet,

wenn es über einen PC, auf dem der PosiTector Desktop Manager

läuft, mit dem Internet verbunden wird (USB oder Bluetooth).

Auto SYNC

Die Synchronisation mit dem PosiTector.net wird automatisch

eingeleitet, wenn es über einen PC, auf dem der PosiTector

Desktop Manager läuft, mit dem Internet verbunden wird.

Zusätzliche Messungen, die in dem Speicher gespeichert werden

während die Verbindung besteht, werden nur synchronisiert, wenn

das USB-Kabel getrennt und wieder angeschlossen wird, oder

wenn Verbinden > Sync Now ausgewählt wurde.

USB Drive

Das Gerät benutzt ein Klasse von USB-Massenspeichergerät

Format, das eine einfache Schnittstelle bietet, um Daten in einer

Weise abzurufen, die ähnlich wie bei den USB-Flash-Laufwerken,Kameras oder digitalen Audioplayern ist.

HINWEISE:

Kabel versorgt. Die Batterien werden nicht benötigt und das Gerät

wird nicht automatisch abgeschaltet. Wenn wiederaufladbare

Akkus (NiMH) eingebaut sind, werden diese im Gerät

nachgeladen.

Wenn es angeschlossen ist, wird es über das USB-

r

r

9

Page 28

Bluetooth

(Nur erweiterte Modelle)

Damit können einzelne Messwerte an einen Computer oder ein

kompatibles Gerät geschickt werden, sobald sie gemessen werden, wobei

die drahtlose Bluetooth-Technologie angewandt wird. Siehe

www.defelsko.com/bluetooth

Updates

Hier wird ermittelt, ob ein Software-Update für Ihr Gerät zur Verfügung steht.

HINWEISE:

Muss an einen mit dem Internet verbundenen PC

angeschlossen sein, auf dem der PosiTector Desktop Manager läuft. Siehe

www.defelsko.com/update

Rücksendung zur Wartung

Rücksendung zur Wartung

Bevor Sie das Gerät zur Wartung zurücksenden…

1. Setzen Sie neue Batterien mit der richtigen Polung in das Batteriefach ,

wie gezeigt, ein.

2. Untersuchen Sie die Spitze des Sensors nach Schmutz oder

Beschädigung. Der Sensor sollte sich frei nach oben und unten bewegen.

3. Führen Sie ein Reset am Messgerät durch (S. 5).

4. Legen Sie eine Kuststoff-Folie auf das unbeschichtete Metall (Stahl oder

Nichteisenmetall, je nach dem ob Sie einen “F ” oder “N ”-Sensor haben)

und versuchen Sie eine Messung.

Wenn Sie das Gerät zur Wartung zurücksenden müssen, füllen Sie bitte

das Service-Formular aus, das Sie unter www.defelsko.com/support herunterladen können und legen Sie es dem Gerät bei.

Begrenzte Garantie, alleinige Abhilfe und beschränkte

Begrenzte Garantie, alleinige Abhilfe und beschränkte

Haftung

Haftung

DeFelsko alleinige Garantie, Abhilfe und Haftung sind ausdrücklich auf die

Garantieleistung, Abhilfe und beschränkte Haftung begrenzt, so wie es in

ihrer Website dargelegt ist.

www.defelsko.com/support

© DeFelsko Corporation USA 2011

Dieses Handbuch ist urheberrechtlich geschützt. Es darf ohne schriftliche Genehmigung der DeFelsko

Corporation weder insgesamt noch in Teilen in irgendeiner Weise vervielfältigt oder weitergegeben werden.

DeFelsko und PosiTector sind in den USA und anderen Ländern eingetragene Warenzeichen der

DeFelsko Corporation. Alle anderen Marken- und Produktnamen sind Marken oder eingetragene

Marken der jeweiligen Besitzer.

Die in dieser Betriebsanleitung enthaltenen Informationen wurden nach bestem Wissen und Gewissen

zusammengestellt. Für Druck- oder Bearbeitungsfehler übernimmt DeFelsko keine Verantwortung.

Alle Rechte vorbehalten

10

Page 29

Guide d’utilisation v. 7.1

Page 30

Introduction

Introduction

L

e

P

osiTe

c

tor

600

0

es

t un

a

pp

are

i

l

é

l

ec

tron

i

qu

m

es

u

re

de

m

a

ni

è

re n

on

-d

e

s

truc

ti

v

e

et d

l

’

é

p

a

i

s

s

eu

r

de

s

re

v

ê

te

m

e

nts

s

u

d’

un

c

orp

s

(S

tan

da

rd

s

ép

arée).

Ce

gui

de

d’

l

.

Té

.defel

u

l

é

c

harg

s

k

o

pa

rei

www

Il est possible de mettre le PosiTector 6000 sous-tension en

appuyant sur le bouton de navigation du milieu. Pour

économiser la batterie, l’instrument est mis hors tension après

environ 5 minutes d’inactivité. Tous les paramètres sont

conservés.

1.Retirer le capuchon protecteur rouge de la sonde (le cas

échéant).

2.Activer l'appareil en appuyant sur la touche de navigation

centrale

3.Appliquer la sonde bien à PLAT sur la surface à mesurer.

MAINTENIR SANS BOUGER. Lorsqu'une mesure valide est

relevée, l'appareil émet un double bip et la mesure s'affiche.

4.Éloigner la sonde d'AU MOINS 5 cm (2 pouces) de la surface

entre les différentes mesures - OU - laisser la sonde sur la

surface au même endroit pour les mesures continues.

o

ti

l

i

s

ati

o

n

ré

ez

l

e m

.c

o

m

/m

anual

u

Av

c

ap

ode d

s

r

a

nc

i

tul

e

’

em

to

u

é

) et d

l

es

pl

oi

s

c

l

es

fonc

o

e fa

’

u

m

m

ne

ti

pl

ç

on

éta

s

o

n

et à l

ux

o

s

e portab

rapi

.

Il

nde

de

’

a

d

de et p

s

e

c

om

(Intégrée

ba

s

e

de

res

s

e :

l

e qu

réc

po

l

o

’

i

a

Fonction des boutons – Fonctionnement normal

Réglage bas

Accès au menu

Réglage haut

Restauration de la

luminosité après

atténuation (Avancé

uniquement)

i

s

e

s

e

u

p

-

3

Page 31

P

o

u

r

d

é

c

o

n

n

e

c

t

e

r

l

a

s

o

n

d

e

d

u

b

o

î

t

i

e

r

,

m

e

t

t

r

e

l

’

i

n

s

t

r

u

m

e

n

t

h

o

r

t

e

n

s

i

o

n

e

t

r

e

t

i

r

e

r

h

o

r

i

z

o

n

t

a

l

e

m

e

n

t

l

e

c

o

n

n

e

c

t

e

u

r

d

e

m

a

t

i

è

r

e

p

l

a

s

t

i

q

u

e

(

d

a

n

s

l

e

s

e

n

s

d

e

l

a

f

l

è

S

u

i

v

r

e

c

e

s

i

n

s

t

r

u

c

t

i

o

n

s

d

a

n

s

l

’

o

r

n

o

u

v

e

l

l

e

s

o

n

d

e

A

u

m

o

m

e

n

t

d

e

l

a

m

i

s

a

u

t

o

m

a

t

i

q

u

e

a

u

t

m

o

c

o

n

t

r

ô

l

e

.

Étalonnage, vérification & ajustement

Étalonnage, vérification & ajustement

e

e

n

t

l

e

t

y

d

s

o

u

s

t

e

n

p

e

d

e

s

o

n

c

r

e

i

n

v

e

r

s

e

s

i

o

n

,

l

e

P

o

d

e

c

o

n

n

e

h

e

)

h

o

r

s

p

o

u

r

c

o

n

s

i

T

e

c

t

o

r

c

t

é

e

t

p

r

o

s

s

o

n

d

e

e

n

d

u

b

o

î

t

i

e

r

n

c

.

e

c

t

e

r

u

n

e

d

é

t

e

r

m

i

n

e

è

d

e

à

u

n

Le PosiTector 6000 mesure de façon non-destructive l’épaisseur

de revêtement sur des métaux. Trois étapes assurent une

meilleure précision…

1. Étalonnage: habituellement effectué par le fabricant ou un

laboratoire qualifié. Toutes les sondes bénéficient d’un Certificat

d’étalonnage.

2. Vérification de la précision: mise en œuvre par l’utilisateur

sur des étalons de référence connus comme des cales en

plastique ou des étalons d’épaisseur de revêtement facultatifs.

3. Ajustement: un ajustement, ou ajustement d’étalonnage,

consiste à aligner les mesures d’épaisseur de l’appareil avec un

échantillon connu de manière à améliorer l’efficacité de

l’instrument sur une surface spécifique ou dans une partie

spécifique de sa plage de mesure. Des ajustements d’étalonnage

de 1 point ou 2 points sont possibles.

Les sondes sont étalonnées en usine et subissent un contrôle automatique

après chaque mesure. Pour la plupart des applications, aucun ajustement

supplémentaire n’est requis après une Réinitialisation (Page 4). Il suffit de

contrôler le ZÉRO sur le substrat non-revêtu, puis de mesurer. Cependant,

les lectures de l’appareil peuvent être influencées par des variations de

forme, la composition, l’état de surface du substrat ou par une mesure sur

différents points sur la pièce. C’est pourquoi les ajustements d’étalonnage

sont rendus possibles. Le symbole disparait à chaque fois qu’un

ajustement d’étalonnage est réalisé sur l’appareil.

Lorsqu’aucune méthode d’ajustement d’étalonnage n’a été spécifiée, utiliser

d’abord la méthode à 1 point. Lorsque la mesure les cales fournies révèlent

des imprécisions de surface, utiliser la méthode à 2 points. Les paramètres

d’étalonnage d’usine peuvent être restaurés à tout moment en procédant

(Page 4) ou en créant un NOUVEAU paramètres d’étalonnage (Page 3), ou

en SUPPRIMANT les ajustements réalisés pour le paramètre d’étalonnage

CAL 1 (Page 3).

4

Page 32

Le symbole apparaît à l’écran à chaque fois que les

paramètres d’étalonnage d’usine sont utilisés.

Avec les sondes “FN”, les ajustements d’étalonnage sont réalisés unique-

ment en mode “F” ou “N” puis enregistrés indépendamment dans un étalonnage donné, soit le dernier utilisé pour la mesure.

Menu des paramètres d’étalonnage

Menu des paramètres d’étalonnage

Réglage de calibrage à 1 point - Aussi connu comme valeur de

compensation ou de correction, il est possible de mettre cet

ajustement en œuvre de 4 façons :

(i) Ajustement simple du zéro - Mesurez votre pièce non-revêtue.

Soulevez la sonde et ajustez le “0” en utilisant les boutons (+) et (-).

(ii) Adjustement moyen du zéro La méthode préférée à

(i) consiste à pondérer 3 à 10 mesures sur la pièce non-revêtue.

(iii) Simple ajustement à une épaisseur connue - Mesurez une cale

d’épaisseur connue placée sur la pièce non-revêtue. Levez la sonde et

l’ajustez à l’épaisseur de la cale via les boutons (+) et (-).

(iv) Ajustement moyen sur une épaisseur connue

La méthode préférée à (iii) consiste à pondérer 3 à 10 mesures d’une

cale d’épaisseur connue placée sur une pièce non-revêtue.

Zéro

Régl. 1 Pt.

Régl. 2 Pt.

Offre une précision supérieure dans une place limitée et définie. Mesurer

une valeur faible (souvent zéro) et une valeur plus importante. Ces valeurs

correspondent aux limites de votre plage d’épaisseurs escomptée.

Verrou Cal

Lorsque coché, l’icône apparaît et les paramètres d’étalonnage actuels

sont “verrouillé” pour empêcher tout autre ajustement. Décochez pour

procéder à d’autres ajustements.

Verrou N

Utilisé en cas d’utilisation régulière de substrats non-ferreux. L’icône

apparaît et la sonde utilise uniquement le principe des courants de Foucault

pour raccourcir la durée de a mesure et prolonger l’autonomie de la batterie.

Utile lors de la mesure de revêtements sur de l’acier plaqué.

(Combinaison de sondes ferreuses / non-ferreuses

FN uniquement)

5

Page 33

Modèles avancés uniquement)

Mémorie Cal

(

Le paramètre d’étalonnage actuel (ex. Cal 3) est affiché dans le

coin supérieur droit de l’écran LCD. Un paramètre d’étalonnage

enregistré peut être restauré lorsque vous revenez sur une pièce

donnée. Cal 1 peut être ajusté mais jamais supprimé, et il est

toujours actif avec les paramètres d’usine après une réinitialisation (Page 5). Un nouveau paramètre Cal ne peut pas être créé

si un lot de valeurs de mesure est ouvert.

Menu de configuration

Menu de configuration

Reset

Le bouton Reset restaure les réglages d'usine et de retourner

l'appareil à une condition connue. Les événements suivants se

produisent :

- Tous les lots et toutes les valeurs enregistrées, les images et les noms

de lot sont supprimés.

- Tous les ajustements d’étalonnage et la mémoire d’étalonnage sont

effacés et réinitialisés avec les paramètres d’étalonnage usine de

l’appareil.

- Les paramètres du menu sont réinitialisés comme suit :

Mémoire = OFF

Haute Rés = OFF

Mode statistique = OFF

Limites HiLo = OFF

Verrou Cal = OFF

Bluetooth = OFF

Affichage = None

Verrou N = OFF

Mode Scan = OFF

Effectuez une Réinitialisation (Reset) plus complète en mettre l’instrument

hors tension. Attendez quelques secondes, puis appuyer simultanément sur

les boutons et (+) jusqu’à ce que le symbole Reset apparaisse.

C’est pratique lorsque l’instrument ne peut pas être mis sous tension ou qu’il

ne fonctionne pas correctement. Il s’agit de la même fonction que la

réinitialisation Reset du menu avec en plus:

- L’information de désactivation de l'appairage Bluetooth.

- Les paramètres du menu sont réinitialisés comme suit :

Unités = microns

Affichage Inversé = Normal

Auto Sync = OFF

Inverse LCD = OFF

Mode rapide = OFF

Langue = English

Type de piles = Alcalines

Rétro-éclairage = Normal

Bluetooth Streaming = OFF

USB Drive= ON

6

Page 34

REMARQUES:

Haute Res.

Augmente la résolution d’affichage. La précision n’est pas affectée.

- Maintenir la sonde à distance de toute pièce

métallique lors d’une Réinitialisation.

- La date et l’heure ne sont pas affectées par une

Réinitialisation.

Rapide

Augmente la vitesse de mesure pour la plupart des sondes. Utile pour une

inspection rapide ou lors de la mesure de surfaces importantes revêtues

d’un revêtement épais où le positionnement correct de la sonde n’est pas

critique. Un mouvement de décalage vers le haut/le bas de la sonde est requis. Une précision réduite peut être relevée.

Scan

Utile lors de la prise de plusieurs mesures sur une faible surface

et l’enregistrement de celles-ci dans la mémoire alors que la sonde

est en contact avec la surface. Peut réduire la durée de vie de la

sonde. Recommandé pour les surfaces lisses uniquement.

Type de piles

Sélectionne le type de piles utilisées dans l’appareil entre

“Alcaline”, “Lithium” ou “NiMH” (Nickel-métal hydride

rechargeable). Si NiMH est sélectionné, l’instrument commence

à charger les piles après sa connexion via USB avec un PC ou un

chargeur CA facultatif. L’icône de l’indicateur d’état de la batterie

est calibré pour le type de batterie. Aucun dommage ne survient si

un type de pile erroné est sélectionné.

REMARQUE:

rechargeables eneloop (NiMH).

Statistiques

Un résumé statistique apparaît à l’écran. Supprimer la dernière

mesure en appuyant sur le bouton (-). Presser (+) pour supprimer

les statistiques.

(Modèles Avancés uniquement)

DeFelsko recommande l’utilisation de piles

Mode Statistiques

Mode Statistiques

x

7

Page 35

x - Moyenne

σ - Déviation standard

- Valeur maxi

↑

- Valeur mini

↓

Limites HiLo

Permet à l’appareil d’alerter l’utilisateur de façon visuelle et audible lorsque

les mesures dépassent les limites préalablement spécifiées.

Le PosiTector 6000 peut enregistrer des lectures en mémoire pour une

impression à l'imprimante sans fil Bluetooth en option, le téléchargement (p.

7) ou la synchronisation avec PosiTector.net. Les lectures sont horodatés

comme ils sont pris.

Défilement à travers les modes

d’affichage (Avancé

uniquement)

Suppression de la

dernière valeur

mesurée

Accès au menu

Mode mémoire

Mode mémoire

Création d’un nouveau lot

(Avancé uniquement)

Restauration de la

luminosité après

atténuation (Avancé

uniquement)

Les Modèles standard stockent jusqu’à 250 mesures dans un

seul lot.

Les Modèles avancés stockent 100,000 mesures dans un

maximum de 1,000 lots. Un “nouveau lot” clôt chaque lot ouvert et

crée un nouveau lot avec le dernier numéro disponible.L’icône

apparaît. Les nouveaux noms de lots sont horodatés au fur et à

mesure de leur création.

Nouveau PA2

Aide à déterminer si l’épaisseur de film d’une surface importante

est conforme aux niveaux min/max spécifiés par l’utilisateur. Voir

www.defelsko.com/pa2. Voir www.defelsko.com/pa2

Nouveau 90/10

Détermine si un système de revêtement est conforme avec la

norme de performance IMO relative aux revêtements de

protection. Voir www.defelsko.com/pspc

8

Page 36

Téléchargement des valeurs de mesure dans un PC

Téléchargement des valeurs de mesure dans un PC

Stockage de masse USB - Connectez votre PosiTector à un

PC/Mac en utilisant le câble USB fourni pour accéder et imprimer

les valeurs de mesure et les graphiques enregistrés. Aucun logiciel

ni aucune connexion Internet n’est requise.

PosiTector.net - Application Web offrant un stockage centralisé

sécurisé des valeurs de mesure d’épaisseur. Vous pouvez accéder

à vos valeurs de mesure à partir d’un PC connecté au Web.

www.PosiTector.net

Menu Connexion

Menu Connexion

Sync Now

Cette fonction démarre immédiatement la synchronisation avec

PosiTector.net une fois connecté (via USB ou Bluetooth) à un PC

connecté à Internet supportant l’application PosiTector Desktop

Manager.

Auto SYNC

Cette fonction synchronise automatiquement l’appareil avec

PosiTector.net après s’être connecté à un PC lui-même connecté

à Internet supportant l’application PosiTector Desktop Manager.

Les mesures supplémentaires ajoutées à la mémoire au moment

de la connexion sont synchronisées uniquement si le câble USB

est débranché, puis rebranché ou lorsque la fonction Connexion

> Sync Now est utilisée.

USB Drive

L’instrument utilise une unité de stockage de masse USB qui

fournit une interface simple pour récupérer les données de la

même manière que les lecteurs flash USB, les appareils

photographiques ou les lecteurs audio numériques.

REMARQUE:

électrique est assurée par le câble USB. Les piles ne sont pas

utilisées et le boîtier n’est pas automatiquement mis hors tension.

Si des piles rechargeables (NiMH) sont installées, l’instrument

procède à la charge des piles.

Lorsque l’instrument est connecté, l’alimentation

9

Page 37

Bluetooth

Cette fonction permet de transmettre des valeurs de mesure individuelles

vers un PC ou un dispositif compatible via la technologie sans fil Bluetooth.

Voir www.defelsko.com/bluetooth

(Modèles avancés uniquement)

Updates

Cette fonction détermine si une mise à jour du logiciel est disponible pour

votre appareil.

REMARQUE:

l’application PosiTector Desktop Manager. Voir www.defelsko.com/update

L’appareil doit être branché à un PC connectéàInternet via

Retour pour maintenance

Retour pour maintenance

Avant de retourner l’instrument pour maintenance…

1.Installez des piles neuves en respectant l’orientation précisée

dans le compartiment des piles.

2.Examinez la tête de la sonde de température de surface en

cas d’encrassement ou de dommage.

3.Procédez à une Réinitialisation de la sonde (Page 5).

4.Placez une cale en plastique sur du métal nu (acier ou métal

non-ferreux, selon que vous utilisiez une sonde de type “F ” ou

“N”) et procédez à une mesure.

Si vous devez retourner l’instrument pour maintenance (ou

entretien), veuillez remplir et joindre avec l’instrument le formulaire de maintenance disponible à l’adresse

www.defelsko.com/support

Garantie limitée, recours unique et

Garantie limitée, recours unique et

responsabilité limitée

responsabilité limitée

La garantie, les recours et la responsabilité de DeFelsko se limitent aux

dispositions du site Internet de l’entreprise: www.defelsko.com/terms