Page 1

Quick Guide v. 3.0

Ultrasonic Coating Thickness Gage

Standard

and

Advanced

Page 2

Introduction

Introduction

The PosiTector 200 is a hand-held Coating Thickness Gage that

uses a non-destructive ultrasonic principle to measure coating

thickness on a wide variety of substrates. It consists of a body

(Standard or Advanced) and a probe (see Probes pg. 2).

This Quick Guide summarizes the basic functions of the Gage.

Download the full instruction manual at:

www.defelsko.com/manuals

Quick Start

Quick Start

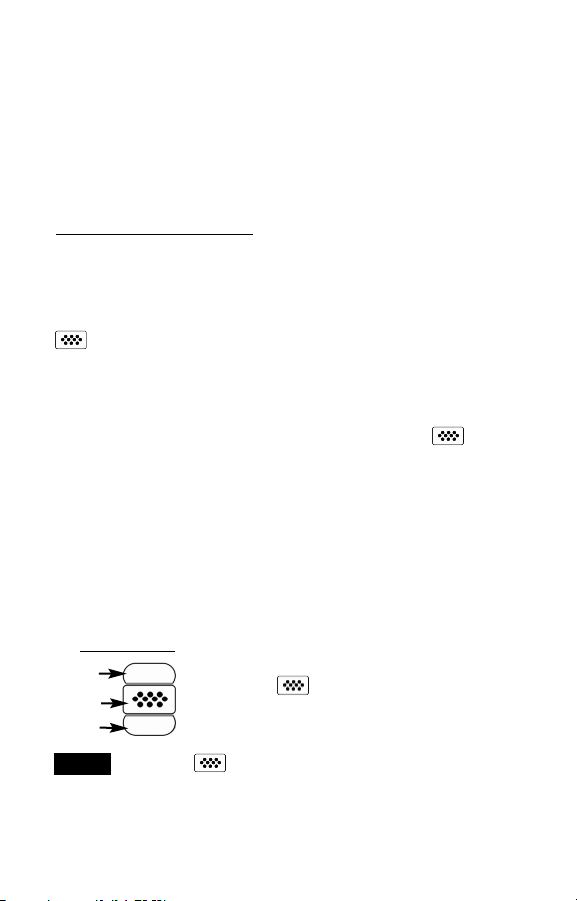

The PosiTector 200 powers-up when the center navigation button

is pressed. To preserve battery life, the instrument powers

down after approximately 5 minutes of no activity. All settings are

retained.

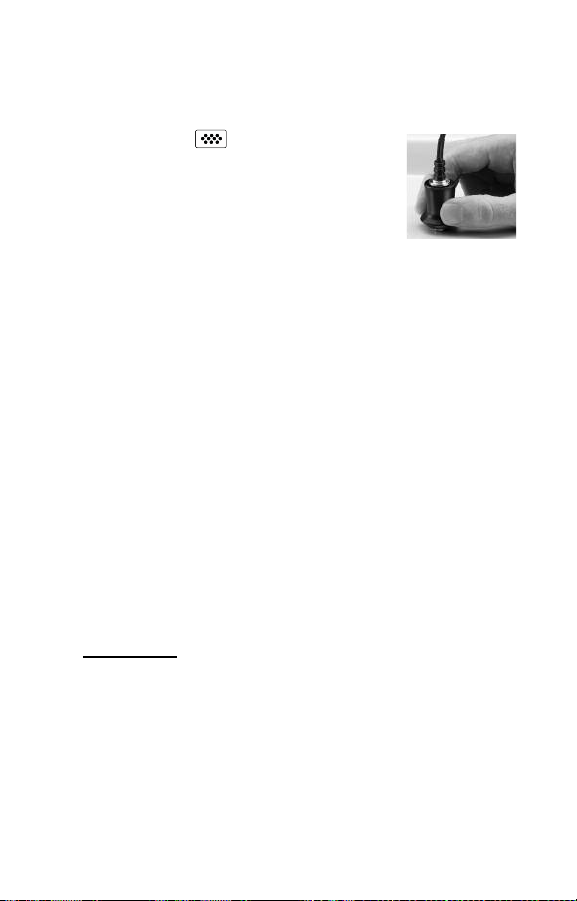

1. Remove the protective rubber cap from the probe.

2. Power-up Gage by pressing the center navigation button.

3. Zero the probe. (see pg. 5)

4. Adjust to a known thickness, if necessary. (see pg. 6)

5. Measure the part. (see pg. 3)

Menu Operation

Menu Operation

Gage functions are menu controlled. To access the Menu, powerup the gage, then press the center navigation button.

Navigation Button

Up

Center

Down

To navigate, use the Up and Down buttons to

scroll and to SELECT.

Select Exit to exit from any menu.

The center button is purposely recessed to help

NOTE:

eliminate unintentional powering-up of the gage.

1

Page 3

Probes

Probes

T

o

d

i

s

c

o

n

n

e

c

t

a

p

r

o

b

e

f

r

o

m

a

b

o

d

y

,

p

o

w

e

r

-

d

o

w

n

t

h

i

n

s

t

r

u

m

e

n

t

a

n

d

s

l

i

d

e

t

h

e

p

l

a

s

t

i

c

p

r

o

b

e

h

o

r

i

z

o

n

t

a

l

l

y

(

i

n

t

h

e

d

i

r

e

c

t

i

o

n

o

f

t

h

e

a

r

b

o

d

y

.

R

e

v

e

r

s

e

t

h

e

s

e

s

t

e

p

s

t

W

h

e

n

p

o

w

e

r

e

d

-

u

p

,

t

h

e

d

e

t

e

r

m

i

n

e

s

w

h

i

c

h

s

e

l

f

-

c

h

e

c

k

.

PosiTector 200 probes are available for measuring a wide variety

of coating thickness applications.

B probe - 13 to 1000 microns (0.5 to 40 mils)

Ideal for polymer coatings on wood, plastic, composites, etc.

C probe - 50 to 3800 microns (2 to 150 mils)

Ideal for thicker coatings on concrete, fiberglass, etc.

D probe - 50 to 7600 microns (2 to 300 mils)

Ideal for thick, soft (attenuative) coatings such as polyurea

NOTE:

Range limits apply to polymer coatings only.

Additionally, the PosiTector accepts a number of probe types

including magnetic and eddy current coating thickness, surface

profile, environmental and ultrasonic wall thickness probes.

For the latest information on probe interchangeability, see

www.defelsko.com/probes

Couplant is required to propagate ultrasound into the coating.

Water is a good couplant for smooth coatings. Use the supplied

glycol gel for rougher coatings. While it is unlikely that the

couplant will damage the finish or leave a stain on the surface, we

suggest testing the surface by using the couplant on a sample. If

testing indicates that staining has occurred, a small amount of

water can be used instead of couplant. Consult the Material Safety

Data Sheet available on our website and your coating supplier if

you suspect the couplant may damage the coating. Other liquids

such as liquid soap may also be used.

p

r

o

b

e

Couplant

Couplant

P

r

o

a

t

t

a

c

h

o

s

i

T

e

c

i

s

a

t

t

a

c

c

o

w

)

a

w

a

a

t

h

y

n

e

w

p

r

o

r

a

u

t

o

e

d

a

n

d

e

o

n

n

e

c

t

o

r

f

r

o

m

t

h

e

o

b

e

.

m

a

t

i

c

a

l

l

y

d

o

e

s

a

2

Page 4

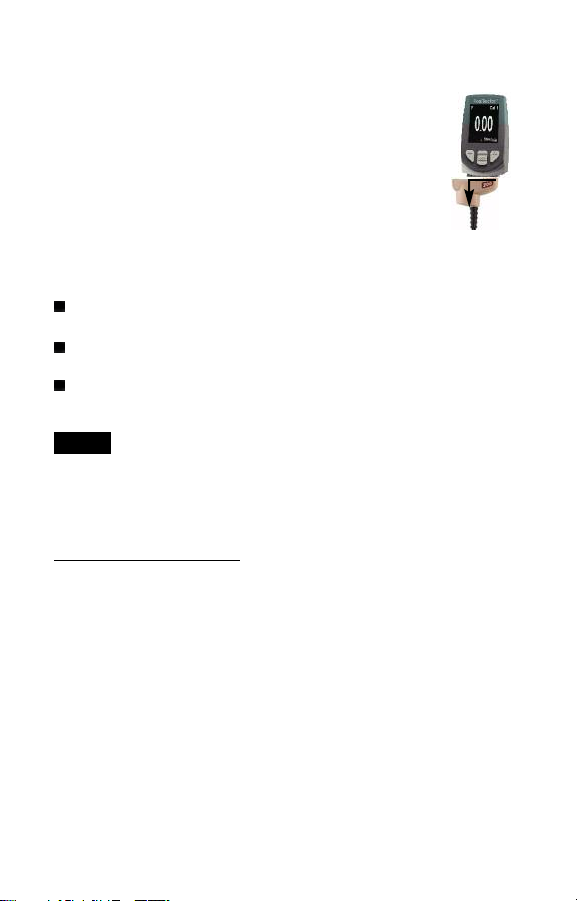

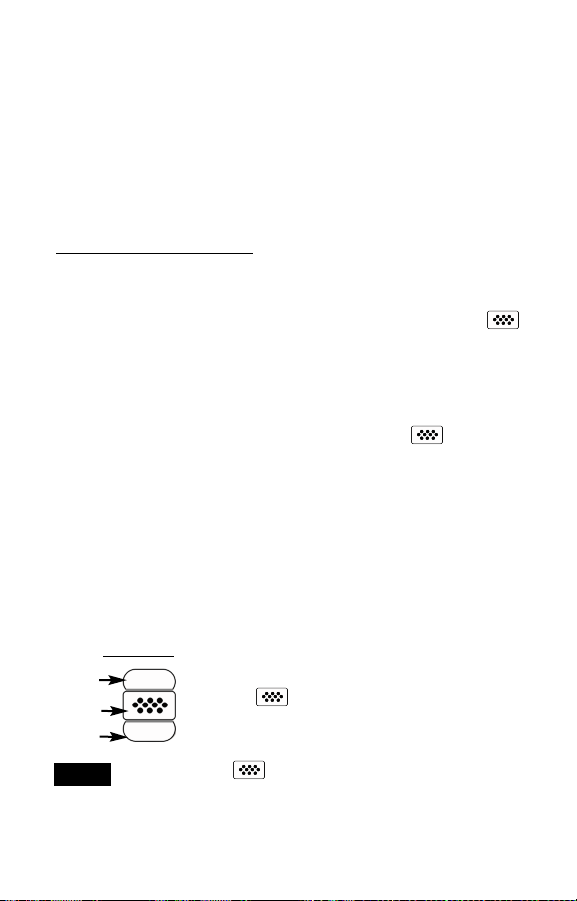

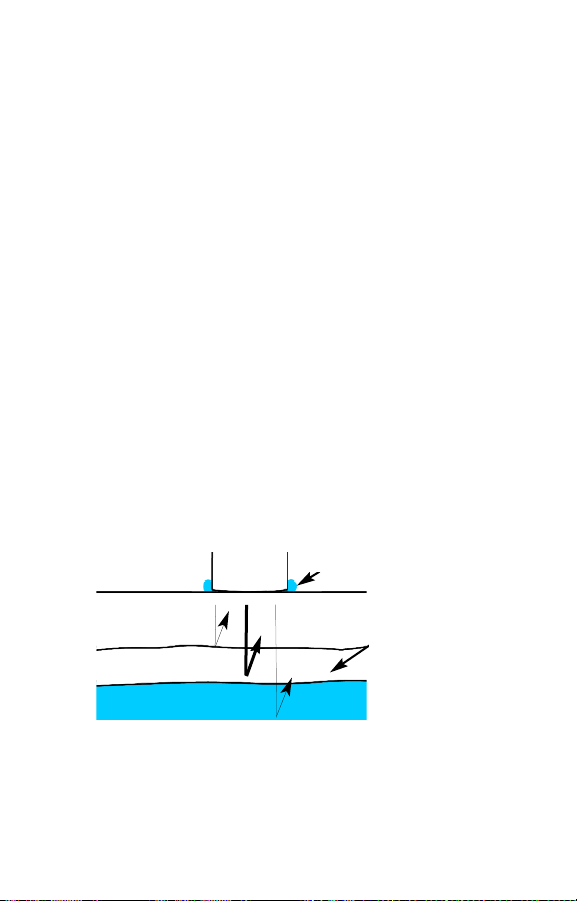

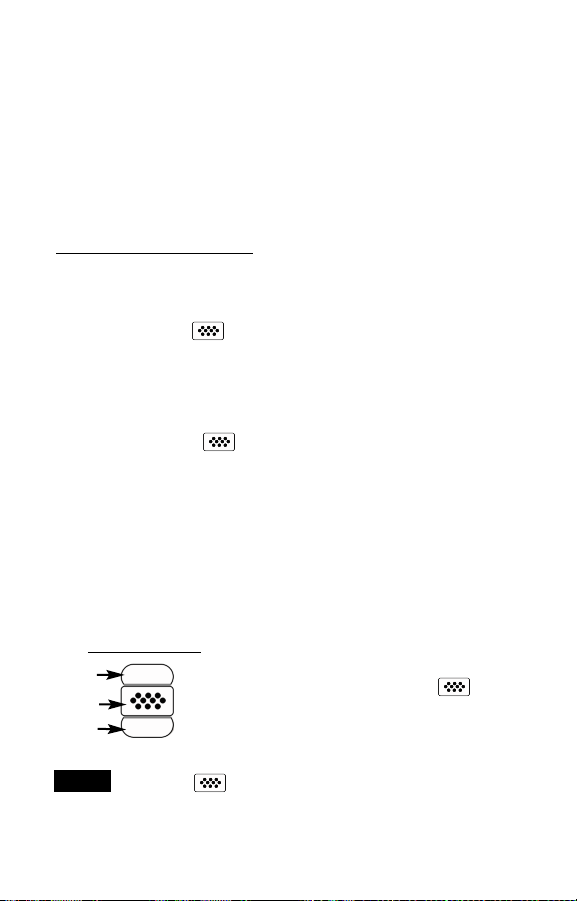

PosiTector 200 - Theory of Operation

PosiTector 200 probes emit a high frequency sound pulse that

travels into the coating via a coupling gel and reflects from ANY

surface that is different in density. Coating thickness readings are

obtained by measuring the time taken for the ultrasonic signal to

propagate from the probe to the coating/substrate interface and

back. The travel time is divided by two and multiplied by the

velocity of sound for the coating to obtain the thickness of the

coating.

Probe

Coating 1

Coating 2

Substrate

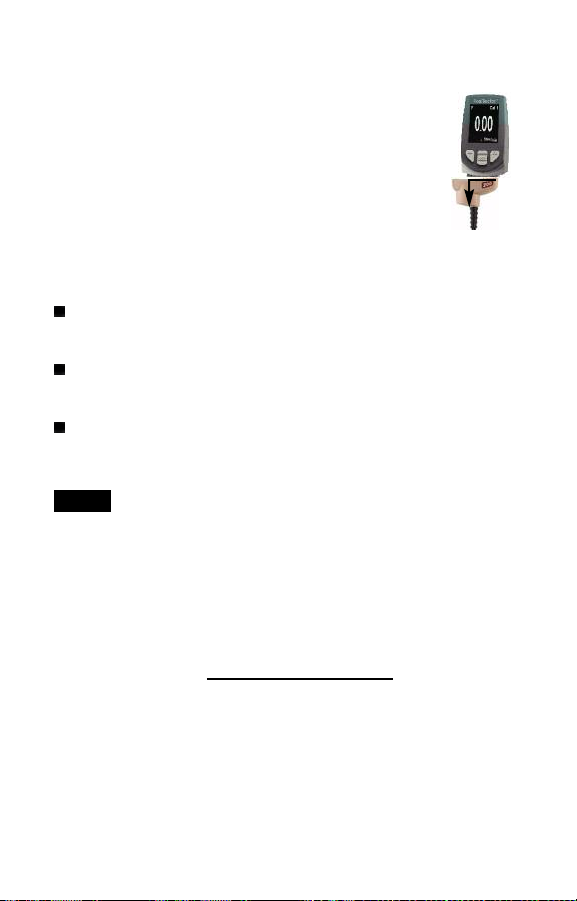

How to Measure

How to Measure

1. Remove the protective rubber cap from probe.

2. Power-up Gage by pressing the center navigation button.

3. Apply couplant (see pg. 2) to the surface of

the part.

4. Place the probe FLAT on the surface and

press down.

5. Lift the probe when you hear a double BEEP,

- OR - leave probe on the surface in the same location for

continuous measurements.

6. When completely finished, wipe the probe clean of couplant

then return the Gage to the protective pouch. There is no need

to disconnect the probe from the PosiTector during storage.

Couplant

The PosiTector 200

interprets the largest

“echo” within the

selected range as

the coating/coating

or coating/substrate

echo.

3

Page 5

Calibration, Verification and Adjustment

Calibration, Verification and Adjustment

Three steps ensure best accuracy…

1.Calibration - typically done by the manufacturer or a qualified

lab. All probes include a Certificate of Calibration.

2.Verification of Accuracy - as done by the user on known

reference standards such as the included plastic shims or

optional coating thickness standards.

3.Adjustment - to a known thickness.

Calibration

Calibration is the controlled and documented process of

measuring traceable calibration standards and verifying that the

results are within the stated accuracy of the Gage. Calibrations

are typically performed by the Gage manufacturer or by a certified

calibration laboratory in a controlled environment using a

documented process.

Verification

Verification is an accuracy check performed by the user using

known reference standards. A successful verification requires the

Gage to read within the combined accuracy of the Gage and the

reference standards.

Adjustment

Adjustment, or Calibration Adjustment is the act of aligning the

Gage's thickness readings to match that of a known reference

sample in order to improve accuracy of a gage on a specific

coating. See Thickness pg. 6

4

Page 6

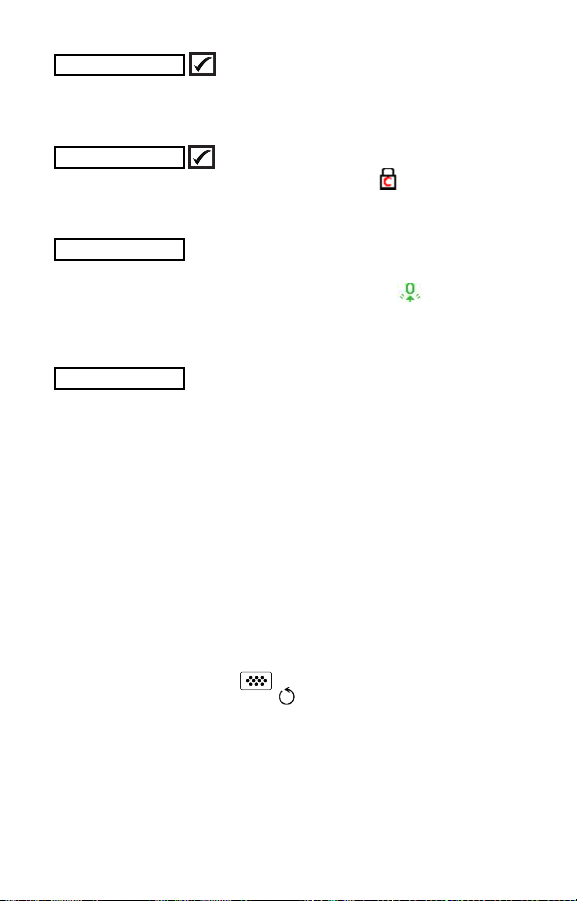

Cal Settings Menu

Cal Settings Menu

Zero

The probe must be periodically zeroed using the Zero menu option

to compensate for both extreme temperature and probe wear

effects. Before using, allow the probe to reach ambient

temperature. Wipe the probe clean of couplant. The icon

appears after probe is zeroed.

If measurements will be made in extreme hot or cold temperatures,

it is recommended to Zero the probe in the working environment.

If measurements will be made on rough substrates, it is

recommended to periodically Zero the probe to compensate for

wear.

Set Range

The measuring range of each probe can be changed depending on

the specific application or the expected thickness range of the

coating system.

For most applications, the default range values do not have to be

adjusted. But some conditions, like surface roughness, may cause

the Gage to display very low or non-repeatable readings. In this

case, the low range may be increased to cause the Gage to only

display readings above the Lo value set by the user.

To adjust Set Range values...

1. Select or .

2. Use the (-)(+) buttons to decrease/increase the displayed value.

IMPORTANT:

The PosiTector 200 interprets the largest “echo” or “echoes”

within the selected range as the coating/coating or

coating/substrate echo. If the coating thickness is outside this

range, incorrect or dashed readings may occur.

5

Page 7

Here are some typical Range settings...

Expected paint thickness Lo Hi

500µm (20 mils) on concrete 130µm (5 mils) 1000µm (40 mils)

50µm (2 mils) on wood 25µm (1 mil) 250µm (10 mils)

Thickness

The PosiTector 200 measures most polymer coatings accurately

out-of-box with no adjustment required.

To determine if an adjustment is necessary, select a coating

sample of known thickness as close as possible in composition to

the intended application. For best results, the thickness of the

sample should be equal to or slightly greater than the maximum

expected thickness of the coating to be measured.

Measure the coated sample. If the average of a series of

measurements on the sample is not close to the known

thickness...

1. Select the Thickness menu option.

2. Use (-) or (+) to decrease/increase the displayed measurement

thickness value to match the known thickness of the sample.

3. For Advanced models with multiple layers selected, use the

Down navigation button to select the next layer and adjust as

necessary.

4. To save adjustments, use Down navigation button to highlight

OK and press the center navigation button.

Polyurea

(PosiTector 200 D probes only)

When checked, the Gage loads a pre-programmed calibration

adjustment optimized for measurement of polyurea coatings.

Cal Lock

When checked, the icon appears and the current calibration

adjustment is “locked” to prevent further user adjustments.

Cal Reset

Restores the gage back to factory calibration and range settings.

The icon will appear on the display.

6

Page 8

Setup Menu

Setup Menu

Reset

Reset (soft reset) restores factory settings and returns the Gage to

a known condition. The following occurs:

- All batches, stored measurements, images, batch names and

screen captures are erased.

- All calibration and range adjustments are cleared and returned

to the Gage’s factory settings.

- Menu settings are returned to the following:

Memory = OFF

Graphics = ON

Cal Lock = OFF

Bluetooth = OFF

Display = None

Layers = 1

Layer Name = Layer 1

Layer Color = blue

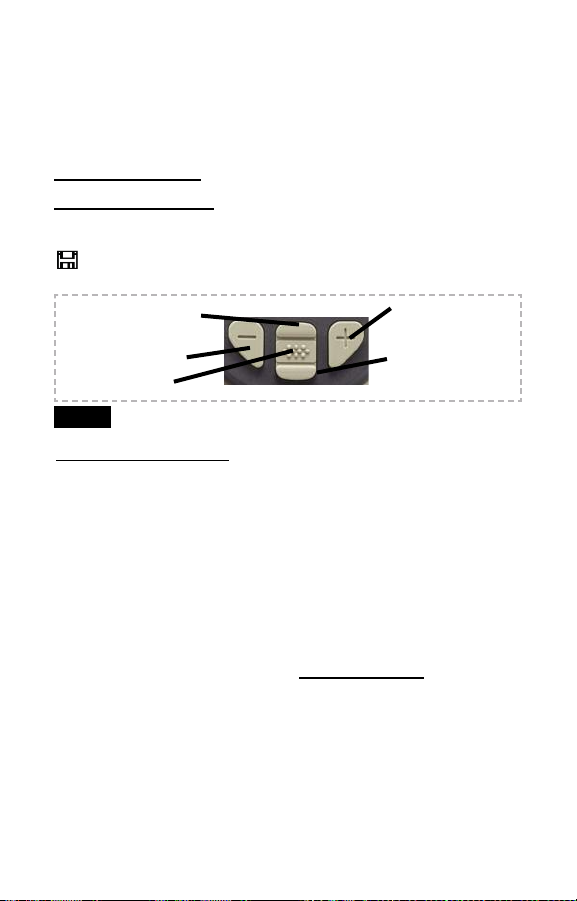

Perform a more thorough Hard Reset by powering down the

Gage, waiting several seconds, then simultaneously holding both

the center and (+) buttons until the Reset symbol

appears. This returns the instrument to a known, “out-of-the-box”

condition. It performs the same function as a menu Reset with the

addition of:

- Bluetooth Pairing info is cleared.

- Menu settings are returned to the following:

Units = microns

Flip Display = Normal

White on Black = OFF

Language = English

NOTE:

Date, Time and WiFi are not affected by either Reset.

Battery Type = Alkaline

Backlight = Normal

USB Drive= ON

Auto Sync = OFF

Battery Type

Selects the type of batteries used in the Gage from a choice of

“Alkaline”, “Lithium” or “NiMH” (Nickel-metal hydride

rechargeable). If NiMH is selected, the Gage will trickle charge the

batteries while connected via USB to a PC or optional AC charger.

The battery state indicator icon is calibrated for the selected

battery type. No damage will occur if the wrong battery type is

selected.

NOTE:

DeFelsko recommends the use of eneloop (NiMH)

rechargeable batteries.

7

Page 9

Advanced models only)

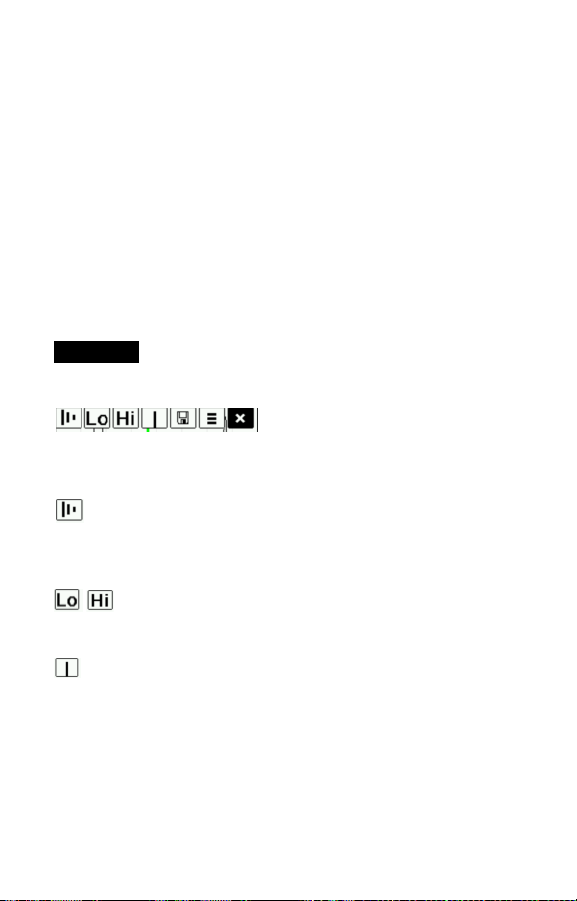

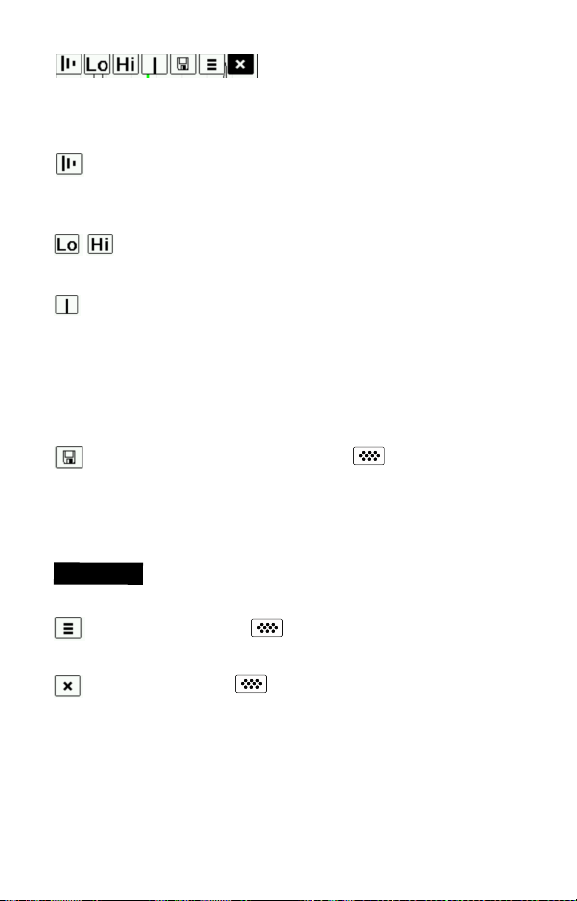

Graphics

(

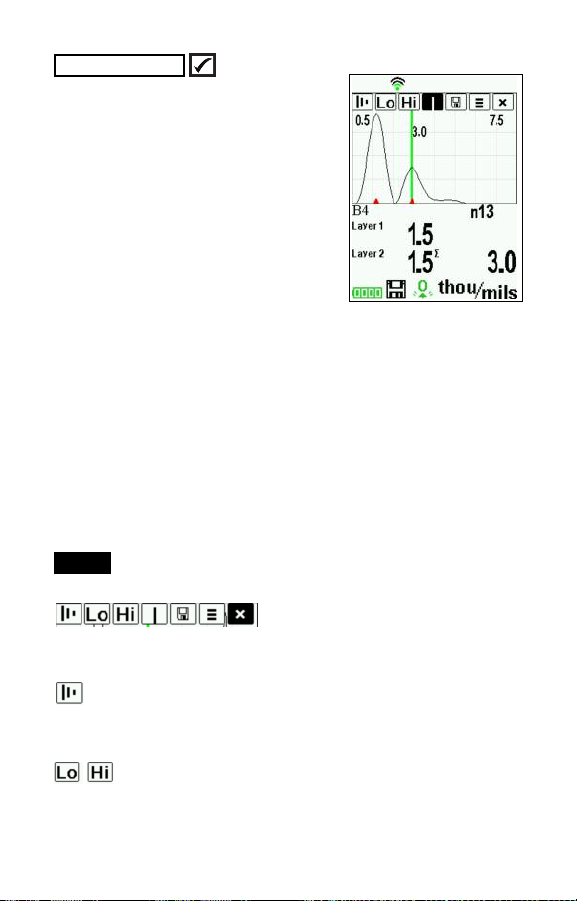

When selected, the Gage displays a

graphical representation of the ultrasonic pulse as it travels through the coating

system.

As the probe is depressed and the

ultrasonic pulse travels through the

coating system, the pulse encounters

changes in density at the interfaces

between coating layers and between the

coating and the substrate.

These interfaces are depicted by a "peak". The greater the change

in density, the higher the peak. The more gradual the change in

density, the greater the width of the peak. For example, two coating

layers made of essentially the same material and "blended" would

result in a low, wide peak. Two materials of very different density

and a well-defined interface would result in a high, narrow peak.

The PosiTector 200 chooses the highest peak (single layer) or

peaks (multi-layer) within the Set Range. For example, if the

number of layers is set to 3, the three highest peaks would be

identified with small red triangles. The peak values are also

displayed numerically as thickness measurements.

NOTE:

The Graphics display can also be accessed using the

Set Range menu option.

Use the navigation Up (move left) and Down (move right) buttons

to highlight icons on the graphic display.

Zoom - Visually magnifies the waveform of the displayed

peaks for more visibility. Pressing the (+) or (-) button repeatedly

will increase/decrease the zoom.

Set Range - Press the (-) or (+) buttons to adjust the

Gage’s Lo or Hi measuring range. (see pg. 5

)

8

Page 10

Cursor - The Cursor allows for further analysis of displayed

waveform. Use the (-)(+) buttons to move the green cursor line left

or right over the waveform. The thickness value is displayed at the

top right of the cursor line. This feature is particularly

useful in multi-layer applications where there are more than

3 distinct layers.

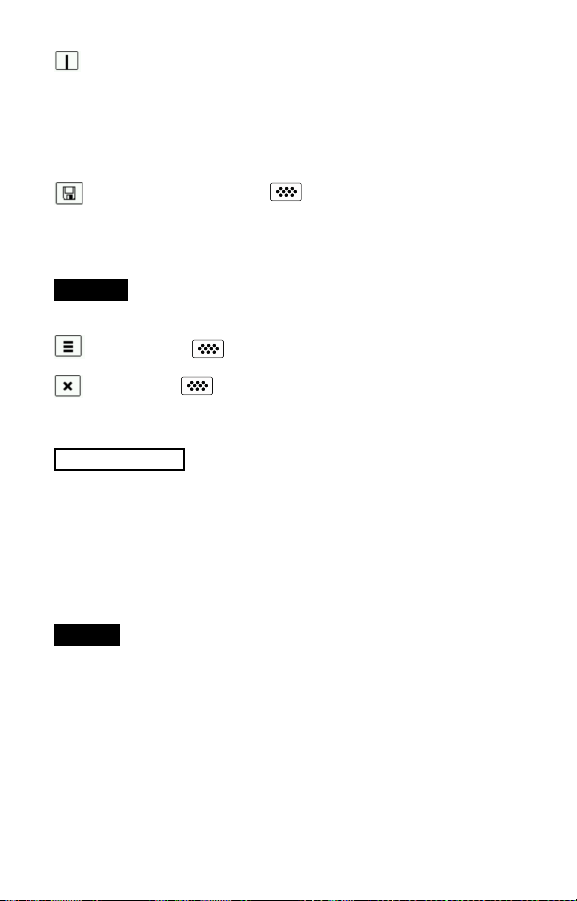

Screen Capture - Press to capture and save an image

copy of the current display. The last 10 screen captures are stored

in memory and can be accessed when connected to a computer.

(see PosiSoft USB Drive pg. 10)

Shortcut:

capture any screen.

button to return to the Graphics display.

Advanced models of the PosiTector 200 are capable of

numerically displaying up to 3 individual layer thicknesses in a

multi-layer system.

Select the Layers menu option to:

NOTES:

Press and hold the (-)(+) buttons simultaneously to

Menu - Press to access the Gage’s main menu.

Exit - Press to close the Graphics display. Press the Up

Layers

- Choose up to 3 individual layer thickness values.

- Edit layer names and Batch Chart colors.

• Before setting up the Gage for multi-layer measurement, it

is recommended that you first take measurements in single

layer mode and interpret the results using the Graphics

option. (see pg. 8)

• When a batch is Open, press the Up button to view the

Batch Chart.

(Advanced models only)

9

Page 11

Memory Management

Memory Management

The PosiTector 200 has internal memory storage for recording

measurement data. Stored measurements can be reviewed

on-screen or accessed via computers, tablets and smart phones.

Measurements are date and time-stamped.

Standard models store up to 250 readings in one batch.

Advanced models store 100,000 readings in up to 1,000

batches. “New Batch” closes any currently opened batch and

creates a new batch name using the lowest available number. The

icon appears. New batch names are date stamped when they

are created.

Scroll through display

modes (Advanced only)

Delete last reading

Access the Menu

NOTE:

This Quick Guide summarizes the basic functions

of the Gage. Download the full instruction manual at:

www.defelsko.com/manuals

Accessing Stored Measurements Data

Accessing Stored Measurements Data

PosiSoft solutions for viewing, analyzing and reporting data:

PosiSoft USB Drive - connect the PosiTector to a PC/Mac using

the supplied USB cable to access and print stored readings, graphs,

photos, notes and screen captures. No software or internet

connection required. USB Drive must be selected. (see pg.11)

PosiSoft.net - a free web-based application offering secure

centralized storage of PosiTector readings. Access your data from

any web connected device. Go to: www.PosiSoft.net

PosiSoft Software - Desktop Software for downloading, viewing

and printing your measurement data.

PosiSoft Mobile (Advanced models only) - access readings, graphs,

capture photos and update annotations through WiFi enabled

devices, such as tablets, smart phones and computers.

Create a new batch

(Advanced only)

Restore brightness

after dimming

(Advanced only)

10

Page 12

Connect Menu

Connect Menu

Sync Now

When selected, Gage immediately synchronizes stored

measurement data via USB, Bluetooth or WiFi to PosiSoft.net.

(PosiSoft Desktop Manager and an internet connection are

required when using USB or Bluetooth.)

Auto SYNC

Allows the Gage to automatically synchronize with PosiSoft.net

when initially connected to the internet via a PC running PosiSoft

Desktop Manager or a local WiFi network.

Additional measurements added to memory while connected are

synchronized only when the USB cable is disconnected, then

reconnected or when the Sync Now option is selected.

USB Drive

The Gage uses a USB mass storage device class which provides

a simple interface to retrieve data in a manner similar to USB flash

drives, cameras or digital audio players.

NOTE:

When connected, power is supplied through the USB

cable. The batteries are not used and the body will not

automatically power down. If rechargeable (NiMH) batteries are

installed, the Gage will trickle charge the batteries.

Bluetooth

Allows individual readings to be sent to a computer, printer or

compatible device as they are taken using Bluetooth wireless

technology. See www.defelsko.com/bluetooth

WiFi

Allows wireless communication with devices such as tablets,

smart phones and computers connected to your local wireless

network or portable mobile hot spot. See www.defelsko.com/WiFi

(Advanced models only)

(Advanced models only)

Updates

Determines if a software update is available for your Gage.

See www.defelsko.com/update

WARNING:

update. (see pg. 7)

The Gage may perform a Hard Reset after an

11

Page 13

Returning for Service

Returning for Service

Before returning the Gage for service…

1.Install new or newly recharged batteries in the proper alignment

as shown within battery compartment.

2.Examine the probe tip for dirt or damage.

3.Perform a Hard Reset (pg. 7) and a Zero (pg. 5).

4.Place a plastic shim onto a hard surface (i.e. glass) and attempt

a measurement. (pg. 3)

If you must return the Gage for service, describe the problem fully

and include measurement results, if any. Be sure to also include

the probe, your company name, company contact, telephone

number and fax number or email address.

Website: www.defelsko.com/support

Limited Warranty, Sole Remedy

Limited Warranty, Sole Remedy

and Limited Liability

and Limited Liability

DeFelsko's sole warranty, remedy, and liability are the express

limited warranty, remedy, and limited liability that are set forth on

its website: www.defelsko.com/terms

www.defelsko.com

© DeFelsko Corporation USA 2012

This manual is copyrighted with all rights reserved and may not be reproduced or transmitted, in whole

or part, by any means, without written permission from DeFelsko Corporation.

DeFelsko and PosiTector are trademarks of DeFelsko Corporation registered in the U.S. and in other

countries. Other brand or product names are trademarks or registered trademarks of their respective

holders.

Every effort has been made to ensure that the information in this manual is accurate. DeFelsko is not

responsible for printing or clerical errors.

All Rights Reserved

12

Page 14

Guia rápida v. 3.0

Ultrasonic Coating Thickness Gage

Estándar y

Avanzado

Page 15

Introducción

Introducción

El PosiTector 200 es un medidor de espesor de recubrimientos

portátil que utiliza un principio ultrasónico no destructivo para

medir el espesor de recubrimientos en una amplia variedad de

sustratos. Consta de un cuerpo (Standard o Advanced) y una

sonda (consulte Sondas Pág. 2).

Esta guía rápida es un resumen de las funciones básicas del

medidor. Descargue el manual de instrucciones completo en:

www.defelsko.com/manuals

Inicio Rápido

Inicio Rápido

El PosiTector 200 se encenderá al pulsar el botón central

Para ahorrar energía, el equipo se apagará tras unos 5 minutos

de inactividad. Se conservarán todas las configuraciones.

1. Retire el tapón protector de goma de la sonda.

2. Encienda el medidor pulsando el botón central .

3. Ajuste a cero la sonda. (consulte Pág. 5)

4. Ajuste a un espesor conocido de ser necesario. (

5. Mida la pieza. (consulte Pág. 4)

Menú de Operación

Menú de Operación

Las funciones del medidor se controlan con un menú. Para acceder al menú encienda el medidor y pulse el botón central.

consulte Pág. 6)

Botón central

Arriba

Centro

Abajo

El botón central está a desnivel intencionalmente

NOTA:

para ayudar a evitar apagar de manera involuntaria el

medidor.

Para desplazarse utilice los botones Arriba y

Abajo y para SELECCIONAR.

Seleccione Salir para salir de cualquier menú.

1

Page 16

Sondas

Sondas

P

a

r

a

s

e

p

a

r

a

r

l

a

s

o

n

d

a

d

e

l

c

u

e

r

p

o

,

a

p

a

g

u

e

e

l

e

q

u

i

p

o

d

e

s

l

i

c

e

l

a

b

a

s

e

d

e

p

l

á

s

t

i

c

o

d

e

l

c

o

n

e

c

t

o

r

d

e

l

a

e

l

p

l

a

n

o

h

o

r

i

z

o

n

t

a

l

(

e

n

l

a

d

i

r

e

c

c

i

ó

f

l

e

c

h

a

)

,

s

e

p

a

r

á

n

d

o

l

a

d

e

l

c

u

c

o

n

e

c

t

a

r

u

n

a

n

u

e

v

C

u

a

n

d

o

s

e

e

n

c

a

u

t

o

m

á

t

i

c

r

e

Están disponibles sondas PosiTector 200 para medir una amplia

variedad de aplicaciones de espesor de recubrimiento.

NOTA:

de polímero.

Adicionalmente, el PosiTector acepta otros tipos de sonda

incluyendo sondas magnéticas y sondas por corrientes de

Foucault para medir espesores de recubrimiento, sonda para

obtener perfil de superficie, ultrasónicas para espesores de pared

y ambientales.

Para obtener la información más reciente sobre la compatibilidad

de la sonda consulte www.defelsko.com/probes

a

a

l

i

z

a

u

n

a

Sonda B - 13 a 1000 micras (0,5 a 40 milésimas)

Ideal para revestimientos de polímero en madera, plástico,

composite, etc.

Sonda C - 50 a 3800 micras (2 a 150 milésimas)

Ideal para recubrimientos más gruesos de hormigón, fibra de

vidrio, etc.

Sonda D - 50 a 7600 micras (2 to 300 milésimas)

Ideal para revestimientos gruesos y suaves (atenuantes)

como la poliurea

Los rangos anteriores solo aplican para revestimientos

i

m

e

n

t

e

e

a

u

t

o

-

v

e

e

a

s

o

n

d

a

.

e

n

d

e

,

e

l

m

o

d

e

l

o

r

i

f

i

c

a

c

i

ó

n

n

r

p

o

.

I

n

v

i

e

l

P

o

s

i

T

d

e

s

o

n

d

a

.

i

n

d

i

c

a

d

r

t

a

l

o

s

p

a

e

c

t

o

r

d

e

s

t

á

c

o

y

s

o

n

d

a

e

n

a

p

o

r

l

a

s

o

s

p

a

r

a

e

t

e

r

m

i

n

a

n

e

c

t

a

d

a

y

2

Page 17

Acoplante

Acoplante

El acoplante es necesario para propagar el ultrasonido en el

recubrimiento. El agua es un buen acoplante para revestimientos

lisos. Utilice el gel de glicol suministrado para revestimientos más

ásperos. Si bien es improbable que el acoplador dañe el acabado

o deje mancha en la superficie, le sugerimos que realice una

prueba sobre una muestra. Si la prueba indica daño en la

superficie, puede utilizar una pequeña cantidad de agua en lugar

del acoplante. Consulte la hoja de datos de seguridad del material

disponible en nuestro sitio Web. Contacte a su proveedor de

recubrimiento si sospecha que el acoplante puede dañar el

revestimiento. También pueden utilizarse otros líquidos como el

jabón líquido.

PosiTector 200 - Fundamento de Operación

Las sondas PosiTector 200 emiten un pulso de sonido de alta

frecuencia que viaja por el revestimiento a través de un gel

acoplante y se refleja en CUALQUIER superficie que tenga

densidad diferente. Las lecturas de espesor de recubrimiento se

obtienen midiendo el tiempo que necesita la señal ultrasónica para

propagarse desde la sonda a la superficie de recubrimiento o

sustrato y regresar. El tiempo de transmisión se divide en dos y

se multiplica por la velocidad del sonido en el recubrimiento y así

obtener el espesor del recubrimiento.

El PosiTector 200

interpreta el "eco"

mayor dentro del

rango seleccionado

como econ del

recubrimiento/recubri

miento

o eco de

recubrimiento/

sustrato.

nto 1

ie

brim

u

Rec

Recubrimiento 2

Substrato

Sonda

Acoplante

3

Page 18

Cómo Medir

Cómo Medir

1. Retire la tapa de protección de la sonda.

2. Encienda el medidor pulsando el botón central .

3. Aplique el acoplante (véase Pág. 3) a la

superficie de la pieza.

4. Coloque la sonda PERPENDICULAR sobre

la superficie y presione hacia abajo.

5. Levante la sonda cuando oiga un doble

pitido, O deje la sonda en la superficie en la misma posición para

mediciones continuas.

6. Cuando haya terminado completamente, limpie la sonda de

acoplante y coloque de nuevo el medidor en la bolsa protectora.

No requiere separar la sonda del PosiTector para almacenar.

Calibración, Verificación y Ajuste

Calibración, Verificación y Ajuste

Para garantizar la mayor exactitud, siga estos tres pasos...

1.Calibración - realizada por el fabricante o por un laboratorio

cualificado. Todas las sondas incluyen Certificado de

Calibración.

2.Verificación de precisión - es realizada por el usuario

midiendo sobre patrones de referencia de espesor como las

laminillas de plástico incluidas o los patrones de espesor de

recubrimiento opcionales.

3.Adjuste - a un espesor conocido.

Calibración

La calibración es el proceso controlado y documentado de

medición de patrones de calibración trazables y la verificación de

los resultados para confirmar que estos se encuentran dentro del

nivel de precisión establecido del medidor. El proceso de

calibración generalmente lo realiza el fabricante del medidor o un

laboratorio de calibración certificado en un entorno controlado y

siguiendo un proceso documentado.

4

Page 19

Verificación

El proceso de verificación es una comprobación de la exactitud

realizada por el usuario, para lo cual utiliza galgas patrón de

espesores conocidos. Una verificación exitosa implica que el

equipo mida dentro de la exactitud combinada del medidor y de

las galgas patrón.

Adjuste

El ajuste, o ajuste de calibración, es la operación que consiste en

hacer corresponder las medidas de espesor del instrumento con

una muestra de referencia conocida, con el fin de mejorar la

precisión del instrumento sobre un revestimiento específico.

Vea Espesor Pág. 6.

Menú de Ajustes Cal

Menú de Ajustes Cal

Zer

o

La sonda deberá ajustarse a cero periódicamente utilizando la

opción de menú Zero para compensar las temperaturas extremas

y los efectos de desgaste de la sonda. Antes de utilizarla espere a

que la sonda alcance la temperatura ambiente. Deberá limpiar el

acoplante presente en la sonda. El icono aparecerá tras

ajustar a Zero la sonda.

En casos que requieran mediciones en dos ambientes con

temperaturas frías o calientes extremas se recomienda ajustar la

sonda a Zero dentro del entorno de trabajo. En caso de

mediciones sobre sustratos ásperos, se recomienda ajustar la

sonda a Zero periódicamente para compensar el desgaste.

Set Range

El rango de medición de cada sonda puede modificarse

dependiendo de la aplicación específica o el rango de espesor

esperado del sistema de recubrimiento.

Para la mayoría de las aplicaciones no necesitará ajustar los

valores de intervalo por defecto. Pero algunas condiciones como

la aspereza de la superficie pueden causar que el instrumento

muestre lecturas no repetibles o muy bajas. En este caso podrá

aumentarse el intervalo inferior para que el instrumento muestre

sólo las lecturas que superan el valor inferior establecido por el

usuario.

5

Page 20

Para ajustar los valores de intervalo de conjunto (Set Range)...

1. Seleccione o .

2. Utilice los botones (-) (+) para aumentar o reducir el valor

mostrado.

IMPORTANTE:

largos dentro del rango seleccionado como el eco de

recubrimiento/recubrimiento o revestimiento/sustrato. Si el espesor del

recubrimiento está fuera del rango elegido, obtendrá medidas incorrectas o

una línea pausada.

El PosiTector 200 interpreta el "eco" o los "ecos" más

Esta es la configuración típica del Rango…

Espesor esperado de pintura Lo Hi

500 µm (20 mils) en concreto 130 µm (5 mils) 1000 µm (40 mils)

50 µm (2 mils) en madera 25 µm (1 mil) 250 µm (10 mils)

Espesor

El PosiTector 200 mide la mayoría de revestimientos de polímero

con precisión sin requerir ningún ajuste.

Para determinar si es necesario realizar ajustes, seleccione una

muestra de recubrimiento de espesor conocido cuya composición

sea lo más parecida a la composición del recubrimiento en la

aplicación prevista. Para obtener mejores resultados, el espesor

de la muestra deberá ser igual o ligeramente mayor que el mayor

espesor esperado de la pieza que va a medirse.

Mida la muestra. Si la media de una serie de mediciones en la

muestra no está cerca del espesor conocido:

1. Seleccione la opción de menú Espesor.

2. Utilice (-) or (+) para incrementar o reducir el espesor de

medición mostrado para hacer coincidir con el espesor de la

muestra.

3. Para modelos Avanzados con selección de múltiples capas,

utilice el botón de desplazamiento hacia Abajo para seleccionar

la siguiente capa y ajustar según sea necesario.

4. Para guardar los ajustes, utilice el botón de desplazamiento

Abajo para resaltar. OK y pulse el botón central .

6

Page 21

Poliurea

(sólo sondas PosiTector 200 D)

Cuando está activada, el medidor carga un ajuste de calibración

preprogramado optimizado para la medición de recubrimientos

de poliurea.

Fijar Cal

Cuando está activado, el icono aparecerá y las configuraciones

de calibración actuales se "bloquearán" para evitar su

modificación.

Cal Reset

Devuelve al medidor la calibración y los rangos establecidos por

el fabricante. El icono aparecerá en la pantalla.

Menú de Establecer

Menú de Establecer

Reinicio

Reset (reinicio parcial) devolverá la configuración de fábrica y

restablecerá en el equipo una condición conocida. Ocurrirá lo

siguiente:

- Se borrarán todas las series, mediciones almacenadas,

imágenes, nombres de serie y capturas de pantalla.

- Todas las configuraciones de rango y ajustes de calibración se

borrarán y el medidor volverá a los ajustes de fábrica.

- Las configuraciones del menú serán de nuevo las siguientes:

Memoria = OFF

Gráficos = ON

Fijar Cal = OFF

Bluetooth = OFF

Display = None

Capas (Layers) = 1

Layer Name = Layer 1

Layer Color = blue

Puede reiniciar el equipo de manera más completa (Hard Reset)

apagando el equipo, esperando varios segundos y pulsando

simultáneamente los botones central y (+) hasta que

aparezca el símbolo Reset . Esto restablecerá el equipo a su

condición conocida de fábrica.

7

Page 22

Realiza la misma función que el Reinicio y además:

- Borrará la información de la conexión Bluetooth.

- Las configuraciones del menú serán de nuevo las siguientes:

Units = microns

Voltear LCD = Normal

Invertir LCD = OFF

Idioma = English

La fecha, hora y WiFi no se modificarán por ningún tipo de

NOTA:

Reinicio (Reset).

Tipo de batería = Alkaline

Backlight = Normal

USB Drive = ON

Auto Sync = OFF

Batería

Selecciona el tipo de baterías utilizadas en el medidor entre

"Alcalina", "Litio" o "NiMH" (Níquel - metal híbrido recargable). Si

se ha seleccionado NiMH el medidor cargará las baterías poco a

poco cada vez que esté conectado por USB a un PC o a un

cargador opcional CA. El indicador de estado de batería se

calibrará según el tipo de pila seleccionado. No habrá daños si el

tipo de batería seleccionado es erróneo

NOTA:

DeFelsko recomienda el empleo de pilas recargables tipo

eneloop (NiMH).

Gráficos

(solo para modelos Advanced)

Si se selecciona, el medidor mostrará

una representación gráfica de la

propagación del impulso ultrasónico a

través del sistema de recubrimiento.

Cuando la sonda es apoyada y el

impulso ultrasónico que atraviesa el

sistema de revestimiento. El impulso

encuentra cambios en la densidad en

las interfaces de las diferentes capas de

recubrimiento y en la interfaz del

recubrimiento y el sustrato.

8

Page 23

Estas interfaces se representan con un "pico". A mayor cambio de

densidad, mayor pico. Cuanto más gradual sea el cambio de

densidad, mayor será la amplitud del pico. Por ejemplo, dos capas

de recubrimiento compuestas esencialmente por el mismo

material y "mezcladas" darían como resultado un pico amplio y de

poca altura. Dos materiales de densidad muy diferente y una

interfaz bien definida darían como resultado un pico alto y

estrecho.

El PosiTector 200 elegirá el pico (una sola capa) o picos (sistema

multicapa) más altos dentro del intervalo establecido. Por ejemplo,

si el número de capas se establece en 3, los tres picos más altos

deberían identificarse con pequeños triángulos rojos. Los valores

de pico también se muestran en formato numérico como

mediciones de espesor.

NOTA:

A la pantalla Gráficos también se puede acceder mediante

la opción de menú configurar rango (Set Range).

Utilice los botones Arriba (a la izquierda) y Abajo (a la derecha)

para resaltar los iconos en la pantalla de gráficos.

Zoom - amplía la forma de onda de los picos mostrados para

mayor visibilidad. Pulsando repetidamente el botón (+) o (-) podrá

aumentar o disminuir el zoom.

(-) or (+) para ajustar el rango de medición Lo o Hi del medidor.

(consulte Pág. 5).

Utilice los botones (-) (+) para mover la línea verde de cursor hacia

izquierda o derecha sobre la forma de onda. Se mostrará el valor

de espesor en la parte superior derecha de la línea de cursor.

Esta característica es particularmente útil en aplicaciones

multicapa donde hay más de 3 capas distintas.

Intervalo de conjunto (Set Range) - Pulse los botones

Cursor - permite diferentes análisis de la onda mostrada.

9

Page 24

Captura de Pantalla - Pulse para capturar y guardar

una copia de la imagen de la pantalla actual. Se almacenarán las

10 últimas capturas y podrá acceder a ellas cuando se conecte a

un ordenador. (vea PosiSoft USB Drive Pág. 11)

Atajo:

simultánea para capturar cualquier pantalla.

el botón arriba para volver a la pantalla de gráficos.

Pulse y mantenga los botones (-) (+) de manera

Menú - Pulse para acceder al menú principal del medidor.

Salir - Pulse para cerrar la pantalla de gráficos. Pulse

Capas

Los modelos avanzados de PosiTector 200 son capaces de

mostrar hasta 3 espesores de capa individual en formato

numérico en un sistema multicapa.

Seleccione la opción de menú de Capas (Layers) para:

- Elegir hasta 3 valores de espesor de capa individual

- Modifique los nombres de las capas y los colores del gráfico para

las series.

NOTAS:

Antes de configurar el instrumento para la medición de un sistema

de capas múltiples, se recomienda realizar primero una medición

configurándolo para una sola capa e interpretar los resultados

utilizando la opción Gráficos (vea Pág. 8)

Mientras una serie está abierta (Abrir), pulse el botón de Arriba

para ver el gráfico de dicha serie.

(sólo modelos Advanced)

10

Page 25

Gestión de Memoria

Gestión de Memoria

El PosiTector 200 tiene memoria interna que le permite mantener

un registro con los datos de la medición. Las mediciones

almacenadas pueden consultarse en pantalla o accederse por

medio de computadores, tabletas y smartphones. Las mediciones

incluyen etiquetas con fecha y hora.

Los modelos Standard almacenan hasta 250 lecturas en una serie.

Los modelos Advanced almacenan 100.000 lecturas en hasta 1.000

series. La función "New Batch" cierra cualquier serie abierta y crea un

nuevo nombre de serie con el número siguiente más bajo. Aparecerá el

icono . Los nombres de series nuevas quedarán registrados con la

fecha en que se crearon.

Desplazamiento por los

modos de visualización

(sólo Advanced)

Eliminar última lectura

Acceso al menú

NOTA:

Esta Guía rápida resume las funciones básicas del medidor.

Descargue el manual de instrucciones en: www.defelsko.com/manuals

Acce so a los Dat os Almacena dos de M ediciones

Acce so a los Dat os Almacena dos de M ediciones

Crear una nueva serie

(sólo Advanced)

Restauración del brillo

si se ha oscurecido

(sólo Advanced)

Soluciones para la visualización, análisis y reporte de datos:

PosiSoft USB Drive - Conecte el PosiTector a un PC o Mac con

el cable USB suministrado para acceder e imprimir las lecturas

almacenadas, gráficos, fotos, notas y capturas de pantalla. No se

requiere conexión a internet ni software especializado. Vea USB

Drive Pág. 12.

PosiSoft.net - aplicación web gratuita que ofrece un

almacenamiento seguro y centralizado de las lecturas del

PosiTector. Acceda a sus lecturas desde cualquier dispositivo

conectado a internet. Visite: www.PosiSoft.net

PosiSoft Software - Aplicación desktop para descargar, ver e

imprimir sus datos de medición.

PosiSoft Mobile

(sólo modelos Advanced) - acceda a lecturas, gráficos,

capture fotos y actualice anotaciones a través de dispositivos

habilitados para WiFi, tales como tablets, smartphones y

ordenadores.

11

Page 26

Menú Conectar

Menú Conectar

Sincroniza ya

Cuando se selecciona, el medidor sincronizará inmediatamente a

través de USB, Bluetooth o WiFi los datos de medición

almacenados para PosiSoft.net. (se requiere PosiSoft Desktop

Manager y una conexión a Internet cuando utilice USB o

Bluetooth.)

Auto SINCR

Permite al medidor sincronizar automáticamente con PosiSoft.net

cuando esté conectado a Internet a través de un PC con PosiSoft

Desktop Manager o una red WiFi local.

Sólo se sincronizarán las mediciones adicionales añadidas a la

memoria durante la conexión cuando el cable USB esté desconectado y se reconecte o cuando Sync Now esté seleccionado.

USB Drive

El medidor utiliza un dispositivo de almacenamiento masivo USB

que proporciona una interfaz sencilla para recuperar los datos de

manera semejante a un USB Flash, una cámara o un reproductor

digital de audio.

NOTA:

Cuando el USB está conectado, la alimentación de

energía se obtiene a través del cable. Las baterías no estarán en

uso y la base no se apagará automáticamente. Si dispone de

baterías recargables (NiMH), el medidor las cargará poco a poco.

Bluetooth

Permite enviar lecturas individuales a un ordenador, impresora o

dispositivo compatible con tecnología Bluetooth. Consulte

www.defelsko.com/bluetooth

WiFi

Permite la conexión inalámbrica con dispositivos como tabletas,

smartphones y ordenadores conectados a su red inalámbrica o

sistemas móviles. Consulte www.defelsko.com/WiFi

Actualizar

Determina si hay actualizaciones disponibles de software para su

medidor. Consulte www.defelsko.com/update

ADVERTENCIA:

una actualización (vea Pág. 7)

(sólo modelos Advanced)

(sólo modelos Advanced)

El medidor podrá reiniciarse (Hard Reset) tras

12

Page 27

Devolución Para Reparaciones

Devolución Para Reparaciones

Antes de devolver el medidor para reparaciones…

1.Ponga baterías nuevas o recién recargadas en el

compartimento de las baterías según instrucciones.

2.Examine la punta de la sonda por si está sucia o dañada.

3.Reinicie (Hard Reset) (Pág. 7) y un ajuste Zero (Pág. 5).

4.Coloque una galga de plástico en una superficie dura

(p.ej. cristal) y realice una medición. (Pág. 4)

Si debe devolver el medidor para reparaciones, describa el

problema con detalle e incluya los resultados de medición, si los

tiene. Asegúrese también de incluir la sonda, el nombre de su

empresa, el nombre de la persona de contacto, sus números de

teléfono y de fax o su dirección de correo electrónico.

Página Web: www.defelsko.com/support

Garantía Limitada, Solución Unica y

Garantía Limitada, Solución Unica y

Obligación

Obligación

La garantía única de DeFelsko, la solución, y la obligación son

la garantía limitada expresa, la solución y la obligación limitada

expuestas en su sitio web: www.defelsko.com/terms

www.defelsko.com

© DeFelsko Corporation USA 2012

Este manual está protegido por copyright. Todos los derechos de este manual están reservados y no

podrá ser parcial o totalmente reproducido o transmitido por ningún medio sin el consentimiento previo

por escrito de DeFelsko Corporation.

DeFelsko y PosiTector son marcas comerciales de DeFelsko Corporation registradas en los EE.UU. y

en otros países. Otras marcas o nombres de productos son marcas comerciales o registradas de sus

propietarios respectivos.

Se han tomado todas las precauciones posibles para asegurar la precisión de toda la información contenida en este manual. DeFelsko no aceptará responsabilidad por errores tipográficos o de impresión.

Reservados todos los derechos

13

Page 28

Kurzanleitung v. 3.0

Ultrasonic Coating Thickness Gage

Standard

und

Advanced

Page 29

Einführung

Einführung

Das PosiTector 200 ist ein handliches Schichtdickenmessgerät,

das zerstörungsfrei mittels Ultraschall die Beschichtungsdicke auf

unterschiedlichen Untergründen messen kann. Es besteht aus

einer Grundeinheit (Standard oder Advanced) und einer Sonde

(siehe Sonden S. 2).

Diese Kurzanleitung fasst die Grundfunktionen des Gerätes

zusammen. Die vollständige Bedienungsanleitung können Sie

unter: www.defelsko.com/manuals herunterladen

Schnellstart

Schnellstart

Das PosiTector 200 schaltet sich durch Drücken der mittleren

Navigationstaste ein. Um die Lebensdauer der Batterien zu

verlängern, schaltet sich das Gerät nach etwa 5 Minuten

automatisch aus. Alle Einstellungen bleiben erhalten.

1. Entfernen Sie die Gummischutzkappe von der Sonde.

2. Schalten Sie das Messgerät ein, indem Sie die mittlere

Navigationstaste drücken.

3. Setzen Sie die Sonde auf Null. (siehe S. 5)

4. Falls nötig, auf eine bekannte Dicke einstellen. (siehe S. 6)

5. Messen Sie das Werkstück. (siehe S. 4)

Menü Betrieb

Menü Betrieb

Die Funktionen des Messgeräts sind menügesteuert. Um auf das

Menü zuzugreifen, schalten Sie das Messgerät ein und drücken

anschließend die mittlere Navigationstaste.

Navigationstaste

Nach

oben

Mitte

Nach

unten

HINWEIS:

um ein unabsichtliches Einschalten des Messgeräts zu

verhindern.

Die mittlere Taste ist beabsichtigt eingelassen,

Navigieren Sie mit den Tasten Nach oben

oder Nach unten zum gewünschten

Menüpunkt und bestätigen diesen zur

Auswahl mit der mittleren Taste.

Wählen Sie Beenden innerhalb eines beliebigen Menüs, um dieses zu verlassen

1

Page 30

Sonden

Sonden

U

m

e

i

n

e

S

o

n

d

e

v

o

m

G

r

u

n

d

g

e

r

ä

t

z

u

e

n

t

f

e

r

n

e

n

,

s

c

h

a

l

t

e

S

i

e

d

a

s

I

n

s

t

r

u

m

e

n

t

a

u

s

u

n

d

z

i

e

h

e

n

d

e

n

S

o

n

d

e

n

a

n

s

c

h

l

u

s

s

h

o

r

i

z

o

n

t

a

l

(

i

n

G

r

u

n

d

g

e

r

ä

t

a

b

.

S

c

h

r

i

t

t

e

i

w

i

e

d

e

r

h

o

l

e

n

,

u

m

e

N

a

c

h

d

e

m

E

i

n

s

a

u

t

o

m

a

t

i

e

Folgende Sonden zum PosiTector 200 stehen zur Verfügung, um

eine breite Vielfalt an Schichtdickenanwendungen zu messen.

Außerdem können am PosiTector weitere Sondentypen

angeschlossen werden, z.B.; Magnet- und WirbelstromSchichtdicken-, Oberflächenprofil-, Taupunkt- und

Umgebungstemperatur- sowie Ultraschall-Wanddickensonden.

Die aktuellsten Informationen zur Austauschbarkeit von Sonden

finden Sie unter: www.defelsko.com/probes

s

i

n

e

n

S

e

Sonde B - 13 bis 1000 Mikron (0,5 bis 40 mils)

Ideal für Polymerbeschichtungen auf Holz, Kunststoff,

Verbundstoffen

Sonde C - 50 bis 3800 Mikron (2 bis 150 mils)

Ideal für dickere Beschichtungen auf Beton, Fiberglas usw.

Sonde D - 50 bis 7600 Mikron (2 bis 300 mils)

Ideal für dicke, weiche (dämpfende) Beschichtungen wie

Polyharnstoff

NOTE:

c

c

h

d

e

n

a

l

b

Bereichsgrenzwerte gelten nur für

n

s

t

t

e

s

t

d

u

Polymerbeschichtungen.

n

i

n

e

n

e

u

e

h

a

l

t

e

n

i

d

g

e

s

c

h

l

o

r

c

h

.

P

u

m

g

e

k

e

S

o

n

d

e

a

e

n

t

i

f

i

z

i

e

s

s

e

n

e

n

S

K

f

e

i

l

r

i

c

h

t

u

h

r

t

e

r

R

n

r

e

z

u

b

r

i

n

g

e

t

d

a

s

P

o

n

d

e

n

t

y

p

n

u

n

s

t

s

t

o

f

f

n

i

o

-

g

)

v

o

m

h

e

n

f

o

l

g

e

n

.

s

i

T

e

c

t

o

r

u

n

d

f

ü

h

r

t

2

Page 31

Koppelmittel

Koppelmittel

Das Koppelmittel ist erforderlich, um den Ultraschall in die

Beschichtung zu übertragen. Wasser ist ein gutes Koppelmittel für

glatte Beschichtungen. Verwenden Sie das mitgelieferte Glycolgel

für rauere Beschichtungsoberflächen. Es ist zwar

unwahrscheinlich, dass das Koppelmittel die Beschichtung

beschädigt oder einen Flecken auf der Oberfläche hinterlässt;

dennoch empfehlen wir, die Oberfläche auf Resistenz zu testen,

bevor man das Koppelmittel an einer Probe verwendet. Wenn der

Test eine Verfärbung ergibt, kann z.B. eine kleine Menge Wasser

anstatt des Koppelmittels verwendet werden. Sehen Sie im

Materialsicherheitsdatenblatt nach, welches auf unserer Website

zur Verfügung steht, und wenden Sie sich an Ihren

Beschichtungsanbieter, wenn Sie den Verdacht haben, dass das

Koppelmittel möglicherweise die Beschichtung beschädigt.

Andere Flüssigkeiten wie flüssige Seife können auch verwendet

werden.

PosiTector 200 - Theorie des Betriebes

Die Sonden des PosiTector 200 übertragen einen HochfrequenzSchallimpuls durch das Koppelmittel in die Beschichtung. Diese

werden an jeder Grenzfläche mit unterschiedlicher Dichte

reflektiert. Man erhält den Wert der Schichtdicke, indem man die

Zeit misst, die das Ultraschallsignal benötigt, um von der Sonde

und z.B. der Grenzfläche zwischen Beschichtung und Untergrund

und zurück zu durchlaufen. Die ermittelte Laufzeit wird während

dieses Vorgangs durch zwei geteilt und mit der spezifischen

Materiallaufzeit der Beschichtung multipliziert, um die Schichtdicke

zu ermitteln.

Sonde

Beschichtung 1

Beschichtung 2

Untergrund

Koppelmittel

Der PosiTector 200

interpretiert das

größte "Echo"

innerhalb der

Grenzen als Echo

zwischen

Beschichtung/

Beschichtung

oder Beschichtung/

Untergrund.

3

Page 32

Wie Misst Man

Wie Misst Man

1. Entfernen Sie die Gummischutzkappe von der Sonde.

2. Schalten Sie das Messgerät ein, indem Sie die mittlere

Navigationstaste drücken.

3. Tragen Sie Koppelmittel (siehe S. 3) auf die

Oberfläche des Werkstücks auf.

4. Setzen Sie die Sonde FLACH auf die

Oberfläche und drücken Sie sie herunter.

5. Heben Sie die Sonde an, wenn Sie einen doppelten PIEPTON

hören - ODER - lassen Sie die Sonde auf der Oberfläche an

derselben Stelle, um fortlaufende Messungen durchzuführen.

6. Wenn Sie mit Ihren Messungen fertig sind, reinigen Sie die

Sonde vom Koppelmittel und legen Sie das Messgerät und die

Sonde wieder in die Schutzhülle. Es ist nicht notwendig, die

Sonde während der Lagerung vom PosiTector abzutrennen.

Calibration, Verification and Adjustment

Calibration, Verification and Adjustment

Drei Schritte sichern die größte Genauigkeit...

1.Kalibrierung - erfolgt typischerweise durch den Hersteller oder

ein qualifiziertes Labor. Alle Sonden werden mit einem

Kalibrierzertifikat geliefert.

2.Überprüfung der Genauigkeit - wird vom Benutzer anhand

bekannter Referenznormalen wie z.B. der beigefügten

Kunststofffolien oder optionaler Schichtdickennormale

durchgeführt.

3.Einstellung - auf eine bekannte Dicke.

Kalibrierung

Kalibrierung ist das kontrollierte und dokumentierte Verfahren

einer Messung mittels rückführbarer Kalibrierungsstandards und

der Überprüfung, dass die Messresultate innerhalb der

angegebenen Genauigkeit des Messgeräts liegen. Kalibrierungen

werden typischerweise vom Hersteller des Messgeräts oder von

einem zugelassenen Kalibrierlabor in einer kontrollierten

Umgebung unter Verwendung eines dokumentierten Verfahrens

durchgeführt.

4

Page 33

Überprüfung

Die Überprüfung ist eine Genauigkeitskontrolle, die vom Benutzer

unter Verwendung bekannter Referenznormale durchgeführt wird.

Eine erfolgreiche Überprüfung erfordert, dass das Messgerät

innerhalb der kombinierten Genauigkeit des Messgeräts und der

Referenznormale liegt.

Einstellung

Einstellung oder Kalibrierungseinstellung ist das Anpassen der

abgelesenen Dickenmessungen des Messgeräts, so dass diese

denjenigen einer bekannten Referenzprobe entsprechen, um die

Genauigkeit eines Messgeräts auf einer bestimmten

Beschichtung zu verbessern. Siehe Dicke S. 6.

Kalibrierungseinstellungsmenü

Kalibrierungseinstellungsmenü

Null-Punkt

Die Sonde muss mit der Menüoption Null von Zeit zu Zeit auf Null

gesetzt werden, um sowohl extreme Temperaturunterschiede als

auch Sondenverschleißeffekte auszugleichen. Lassen Sie die

Sonde vor Gebrauch die Umgebungstemperatur erreichen.

Reinigen Sie die Sonde von Koppelmittel. Das Symbol

erscheint, nachdem die Sonde auf Null gesetzt wurde.

Wenn Messungen bei extrem heißen oder kalten Temperaturen

durchgeführt werden, wird empfohlen, die Sonde in der

Arbeitsumgebung auf Null zu setzen. Wenn Messungen auf rauem

Untergrund durchgeführt werden, wird empfohlen, die Sonde

periodisch auf Null zu setzen, um einen Verschleiß zu

kompensieren.

Set Range

Der Messbereich jeder Sonde kann je nach spezifischer

Anwendung oder dem erwarteten Dickenbereich des

Beschichtungssystems verändert werden.

Für die meisten Anwendungen müssen die Standardbereichswerte

nicht eingestellt werden. Aber einige Bedingungen, wie

Oberflächenrauheit, können dazu führen, dass das Messgerät

sehr niedrige oder nicht reproduzierbare Messwerte anzeigt. In

diesem Fall kann der niedrige Bereich erhöht werden, um das

Messgerät zu veranlassen, nur Messwerte über dem vom

Benutzer eingestellten Lo-Wert anzuzeigen.

5

Page 34

Um die Werte unter Bereich einstellen anzupassen (Set Range)...

1. Wählen Sie oder .

2. Verwenden Sie die Tasten (-) oder (+), um den angezeigten

Wert zu verringern oder zu erhöhen.

WICHTIG:

Der PosiTector 200 interpretiert das größte "Echo"

innerhalb des ausgewählten Bereichs als Echo zwischen

Beschichtung/Beschichtung oder Beschichtung/Untergrund.

Wenn die Schichtdicke außerhalb dieses Bereichs liegt, kann es

zur falschen oder gestrichelten, nicht gültigen Messung kommen.

Hier sind einige typische Bereichseinstellungen...

Erwartete Schichtdicke Lo Hi

500 µm (20 mils) auf Beton 130µm (5 mils) 1000µm (40 mils)

50 µm (2 mils) auf Holz 25µm (1 mil) 250µm (10 mils)

Dicke

Der PosiTector 200 misst die meisten Polymerbeschichtungen

standardmäßig genau, ohne dass eine Einstellung erforderlich ist.

Um zu bestimmen, ob eine Einstellung notwendig ist, wählen Sie

ein Beschichtungsmuster bekannter Dicke, das in der

Zusammensetzung der beabsichtigten Anwendung so nahe wie

möglich kommt. Um die besten Ergebnisse zu erzielen, sollte die

Dicke der Probe gleich oder ein wenig größer sein als die höchste

zu erwartende Dicke der zu messenden Beschichtung.

Messen Sie die beschichtete Probe. Wenn der Durchschnitt aus

einer Reihe von Messungen an der Probe mit der bekannten

Dicke stark abweichen...

1. Wählen Sie die Menüoption Dicke.

2. Verwenden Sie (-) oder (+), um den angezeigten Messwert zu

vermindern oder zu erhöhen, so dass er der bekannten Dicke

der Probe entspricht.

3. Wenn bei den Advanced-Modellen mehrere Schichten

ausgewählt wurden, verwenden Sie die Navigationstaste Nach

unten, um die nächste Schicht auszuwählen und nach Bedarf

einzustellen.

4. Um die Einstellungen zu speichern, verwenden Sie die

Navigationstaste Nach unten, um OK zu markieren, und

drücken Sie anschließend die mittlere Navigationstaste.

6

Page 35

Polyharnstoff

(PosiTector 200 nur Sonden D)

Wenn dies markiert ist, lädt das Messgerät eine

vorprogrammierte Kalibrierungseinstellung, die für die Messung

von Polyharnstoff-Beschichtungen optimiert ist.

Sperren

Wenn dies markiert ist, erscheint das Symbol , und die aktuelle

Kalibrierungseinstellung wird „gesperrt“, um weitere Einstellungen

durch den Benutzer zu verhindern.

Cal Reset

Stellt das Messgerät wieder auf die werksseitigen Kalibrierungsund Bereichseinstellungen zurück. Das Symbol erscheint auf

der Anzeige.

Menü Setup

Menü Setup

Reset

Reset (soft reset) stellt die Werkseinstellungen wieder her und

setzt das Messgerät auf einen bekannten Zustand zurück.

Folgendes passiert:

- Alle Blöcke, gespeicherten Messungen, Abbildungen,

Blocknamen und Bildschirmkopien werden gelöscht.

- Alle Kalibrierungs- und Bereichseinstellungen werden entfernt

und auf die Werkseinstellungen des Messgeräts zurückgesetzt.

- Die Menüeinstellungen werden wie folgt zurückgesetzt:

Speicher = AUS

Grafik = EIN

Sperren = AUS

Bluetooth = AUS

Anzeige = Keine

Schichten (Layers) = 1

Layer Name = Layer 1

Layer Color = blue

Führen Sie ein noch gründlicheres Hard Reset durch, indem Sie

das Gerät ausschalten, einige Sekunden warten, dann gleichzeitig

die beiden Tasten Mitte und (+) solange drücken, bis das

Symbol Zurücksetzen (Reset) erscheint. Dies setzt das Gerät

auf den bekannten originalen Werkszustand zurück. Es führt

dieselben Funktionen durch wie im Menü Reset, mit folgenden

Zusätzen:

- Die Bluetooth-Kopplungsinformationen werden gelöscht.

7

Page 36

- Die Menüeinstellungen werden wie folgt zurückgesetzt:

Einheiten = microns

Flip-Anzeige = Normal

Weiß auf Schwarz = OFF

Sprache = English

Batterie Typ = Alkali

Hintergrundbeleuchtung = Normal

USB-Laufwerk = EIN

Auto Sync = AUS

HINWEIS:

Datum, Uhrzeit und WiFi werden von beiden Reset

Funktionen nicht beeinflusst.

Batterie Typ

Mit dieser Funktion wählen Sie den im Messgerät verwendeten

Batterietyp aus: „Alkali“, „Lithium“ oder „NiMH“ (NickelMetallhydrid wieder aufladbar). Wenn NiMH gewählt wird, lädt das

Gerät die Batterien auf, während es über USB an einen PC oder

ein optionales Wechselstrom-Ladegerät angeschlossen ist. Das

Batteriezustandsanzeigesymbol wird für den gewählten

Batterietyp kalibriert. Es entsteht kein Schaden, wenn der falsche

Batterietyp ausgewählt wird.

HINWEIS:

DeFelsko empfiehlt die Verwendung wieder auflad-

barer Batterien des Typs eneloop (NiMH).

Grafik

(Advanced models only)

Wenn dies gewählt wird, zeigt das

Messgerät eine grafische Darstellung

des Ultraschallimpulses an, während er

durch das Beschichtungssystem läuft.

Sobald die Sonde niedergedrückt wird

und der Ultraschallimpuls durch das

Beschichtungssystem läuft, trifft der

Impuls auf Änderungen der Dichte an

den Übergängen zwischen den Lagen

der Beschichtung und zwischen der

Beschichtung und dem Untergrund.

8

Page 37

Diese Übergänge werden als "Spitze" dargestellt. Je größer die

Dichteänderung, desto höher die Spitze. Je größer die Änderung

der Dichte schrittweise verläuft, desto breiter ist die Spitze. Zum

Beispiel führen zwei Schichten, die im Wesentlichen aus

demselben Material bestehen und "vermischt" werden, zu einer

flachen, breiten Spitze. Zwei Materialien mit sehr unterschiedlicher

Dichte und mit einer klar definierten Grenzfläche würden zu einer

hohen, schmalen Spitze führen.

Der PosiTector 200 wählt die höchste Spitze (einlagig) oder die

höchsten Spitzen (mehrlagig) innerhalb des eingestellten

Bereichs. Wenn zum Beispiel die Anzahl der Schichten auf 3

eingestellt ist, werden die drei höchsten Spitzen mit kleinen roten

Dreiecken gekennzeichnet. Die Spitzenwerte werden auch digital

als Dickenmessungen angezeigt.

HINWEIS:

Bereich einstellen zugegriffen werden.

Verwenden Sie die Navigationstasten Nach oben (nach links

verschieben) und Nach unten (nach rechts verschieben), um

Symbole auf der Grafikanzeige zu markieren.

der angezeigten Spitzen, um für eine bessere Sicht zu sorgen.

Durch wiederholtes Drücken der Taste (+) oder (-) wird die

Vergrößerung erhöht oder verringert.

Tasten (-) oder (+), um den Messbereich Lo oder Hi des

Messgeräts einzustellen (siehe S. 5)

angezeigten „Spitze“ durchzuführen. Verwenden Sie die Tasten (-)

oder (+), um die grüne Cursorlinie links oder rechts über die

Wellenform zu schieben. Der Dickenmesswert wird oben rechts

von der Cursorlinie angezeigt. Diese Eigenschaft ist besonders

nützlich bei Mehrschichtanwendungen, bei denen es mehr als 3

verschiedene Schichten gibt.

Auf die Grafikanzeige kann auch mit der Menüoption

Vergrößern - Vergrößert den Ansichtsbereich der Wellenform

Bereich einstellen (Set Range) - Drücken Sie die

.

Cursor - Der Cursor ermöglicht es, eine weitere Analyse einer

9

Page 38

Bildschirmkopie - Drücken Sie , um eine Bildkopie der

aktuellen Anzeige aufzunehmen und zu speichern. Die letzten 10

Bildschirmkopien werden im Speicher gesichert, und es kann über

einen bestehenden Computeranschluss darauf zugegriffen werden (siehe PosiSoft USB Drive S. 11)

Shortcut:

ichzeitig, um einen Bildschirm aufzunehmen.

des Messgeräts zuzugreifen.

zu schließen. Drücken Sie die Taste Nach oben, um zur

Grafikanzeige zurückzukehren.

Drücken und halten Sie die Tasten (-) oder (+) gle-

Menü - Drücken Sie , um auf das Hauptmenü

Beenden - Drücken Sie , um die Grafikanzeige

Schichten

Die Advanced-modelle des PosiTector 200 können bis zu 3

einzelne Schichtdicken in einem Mehrschichtsystem digital

anzeigen.

Wählen Sie die Menüoption Schichten, um:

- Bis zu 3 einzelne Schichtdickenwerte zu wählen

- Schichtnamen und Blockdiagrammfarben zu bearbeiten

HINWEISE:

• Bevor Sie das Messgerät zur Mehrschichtmessung einstellen

wird empfohlen, dass Sie zuerst Messungen im Einschichtmodus

vornehmen und die Ergebnisse mit der Option Grafik

interpretieren (siehe S. 8)

• Wenn ein Block Oeffnen ist, drücken Sie die Taste Nach oben,

um das Blockdiagramm anzusehen.

Der PosiTector 200 hat einen internen Speicher zur Aufzeichnung

von Messdaten. Gespeicherte Messungen können am Bildschirm

angesehen werden oder es kann über Computer, Tablets und

Smartphones darauf zugegriffen werden. Die Messungen erhalten

einen Datums- und Zeitstempel.

(nur Advanced-Modelle)

Speicherverwaltung

Speicherverwaltung

Standardmodelle speichern bis zu 250 Messungen in einem Block.

10

Page 39

Advanced-Modelle speichern 100.000 Messungen in bis zu 1000

Blöcken. „Neuer Block“ schließt einen aktuell geöffneten Block und erzeugt

einen neuen Blocknamen unter Verwendung der niedrigsten zur Verfügung

stehenden Nummer. Das Symbol erscheint. Neue Blocknamen erhalten

einen Datumsstempel, wenn sie erstellt werden.

Durch Anzeigemodi

scrollen (nur Advanced)

Letzte Messung löschen

Auf das Menü zugreifen

HINWEIS:

zusammen. Die vollständige Bedienungsanleitung können Sie unter:

www.defelsko.com/manuals herunterladen

Diese Kurzanleitung fasst die Grundfunktionen des Gerätes

Zugriff auf gespeicherte Messdaten

Zugriff auf gespeicherte Messdaten

Einen neuen Block

erstellen (nur Advanced)

Helligkeit wiederherstellen nach dem

Abdunkeln (nur

Advanced)

PosiSoft-Lösungen zur Ansicht, Analyse, Verarbeitung der Daten:

PosiSoft USB Drive - schließen Sie den PosiTector mit dem

mitgelieferten USB-Kabel an einen PC oder Mac an, um auf

gespeicherte Messungen, Schaubilder, Fotos, Notizen und

Bildschirmkopien zuzugreifen und diese auszudrucken. Keine

Software oder Internetverbindung ist hierfür erforderlich. Siehe USB

Drive S.12.

PosiSoft.net - eine kostenlose webbasierte Anwendung, die eine

sichere zentralisierte Speicherung von PosiTector - Messungen

bietet. Greifen Sie von einem beliebigen mit dem Web verbundenen

Gerät auf Ihre Daten zu. Gehen Sie auf: www.PosiSoft.net

PosiSoft Software - Desktop-Software zum Herunterladen,

Ansehen und Ausdrucken Ihrer Messdaten.

PosiSoft Mobile (nur Advanced-Modelle) - greifen Sie über mit WiFi

ausgestatteten Geräten wie Tablets, Smartphones und Computer

auf Messungen, Schaubilder, Bildschirmkopien zu und aktualisieren

Sie Anmerkungen.

Connect Menu

Connect Menu

Synchro

Wenn dies gewählt wird, synchronisiert das Messgerät sofort

gespeicherte Messdaten über USB, Bluetooth oder WiFi an

PosiSoft.net. (Der PosiSoft-Desktop-Manager und ein Internetanschluss

sind erforderlich, wenn USB oder Bluetooth verwendet werden.)

11

Page 40

Auto SYNC

Ermöglicht die automatische Synchronisierung des Messgerätes

mit PosiSoft.net, wenn ein Anschluss ans Internet über einen PC

besteht, auf dem der PosiSoft-Desktop-Manager oder ein lokales

WiFi Netzwerk läuft.

Zusätzliche Messwerte, die dem Speicher hinzugefügt werden,

während der Anschluss besteht, werden erst synchronisiert, wenn

das USB-Kabel abgetrennt und dann erneut angeschlossen wird

oder wenn die Option Sync Now gewählt wird.

USB Drive

Das Messgerät verwendet das USB-MassenspeichergeräteFormat, das eine einfache Schnittstelle bietet, um Daten in

ähnlicher Weise abzurufen wie es bei USB-Flashlaufwerken,

Kameras oder digitalen Audioplayern der Fall ist.

HINWEIS:

Wenn ein Anschluss besteht, wird Strom über das

USB-Kabel zugeführt. Die Batterien werden nicht genutzt und das

Gerät schaltet sich nicht automatisch aus. Wenn wieder

aufladbare (NiMH) Batterien installiert werden, lädt das Gerät die

Batterien während der Verbindung auf.

Bluetooth

(nur Advanced-Modelle)

Ermöglicht, an einen Computer, Drucker oder ein kompatibles

Gerät einzelne Messungen zu senden, während sie mit der

Bluetooth-Kabellostechnik erfasst werden. Siehe

www.defelsko.com/bluetooth

WiFi

(nur Advanced-Modelle)

Ermöglicht kabellose Kommunikation mit Geräten wie Tablets,

Smartphones und Computer, die an Ihr lokales, kabelloses

Netzwerk oder an einen Hotspot für tragbare Mobilgeräte

angeschlossen sind. Siehe www.defelsko.com/WiFi

Updates

Bestimmt, ob eine Softwareaktualisierung für Ihr Messgerät

vorhanden ist. Siehe www.defelsko.com/update

WARNUNG:

Das Messgerät kann nach einer Aktualisierung ein

Hard Reset durchführen. (siehe S. 7)

12

Page 41

Rücksendung zur Reparatur

Rücksendung zur Reparatur

Bevor Sie das Gerät zur Reparatur einsenden...

1.Setzen Sie neue oder neu aufgeladene Batterien in der richtigen

Richtung (Polung) wie an der Batterieklappe vorgeschrieben

ein.

2.Prüfen Sie die Sondenspitze auf Verschmutzung oder

Beschädigung.

3.Führen Sie ein Hard Reset (S. 7) und eine Nullstellung (S. 5)

durch.

4.Legen Sie eine Kunststofffolie auf eine harte Oberfläche

(z. B. Glas) und führen Sie eine Messung aus. (S. 4)

Falls Sie das Gerät zur Reparatur einschicken müssen,

beschreiben Sie das Problem vollständig und fügen Sie

Messergebnisse bei, falls vorhanden. Achten Sie darauf, das auch

die Sonde, den Namen Ihrer Firma, den Namen der

Kontaktperson Ihrer Firma, Telefon- und Faxnummer oder E-MailAdresse beizufügen. Website: www.defelsko.com/support

Begrenzte Garantie, alleinige Abhilfe

Begrenzte Garantie, alleinige Abhilfe

und beschränkte Haftung

und beschränkte Haftung

Die alleinige Garantie, Abhilfe und Haftung der Firma DeFelsko

sind ausdrücklich auf die Garantieleistung, Abhilfe und

beschränkte Haftung begrenzt, so wie es auf ihrer Website

dargelegt ist: www.defelsko.com/terms

www.defelsko.com

Dieses Handbuch ist urheberrechtlich geschützt, und alle Rechte sind vorbehalten. Es darf ohne

schriftliche Genehmigung der DeFelsko Corporation weder insgesamt noch in Teilen in irgendeiner Weise

vervielfältigt oder weitergegeben werden.

DeFelsko und PosiTector sind in den USA und anderen Ländern eingetragene Warenzeichen der

DeFelsko Corporation. Alle anderen Marken- oder Produktnamen sind Marken oder eingetragene Marken

der jeweiligen Besitzer.

Die in dieser Betriebsanleitung enthaltenen Informationen wurden nach bestem Wissen und Gewissen

zusammengestellt. Für Druck- oder Bearbeitungsfehler übernimmt DeFelsko keine Verantwortung.

© DeFelsko Corporation USA 2012

13

Page 42

Guide d’utilisation v. 3.0

Ultrasonic Coating Thickness Gage

Standard

et

Advanced

Page 43

Introduction

Introduction

Le PosiTector 200 est un mesureur d'épaisseur de revêtement

portable qui utilise un principe ultrasonique non destructif pour

mesurer l'épaisseur des revêtements sur un vaste panel de

supports. Il se compose d'un corps (standard ou avancé) et d’une

sonde. (voir Sondes en page 2)

Ce guide rapide résume les fonctions de base de l'instrument.

Téléchargez la notice d'instructions complète à l’adresse

www.defelsko.com/manuals

Démarrage Rapide

Démarrage Rapide

Le PosiTector 200 est mis sous tension au moyen du bouton de

navigation central . Pour préserver la durée de vie de la

batterie, l’instrument est mis hors tension après environ 5 minutes

d'inactivité. Tous les paramètres sont conservés.

1. Enlever le capuchon de protection en caoutchouc de la sonde.

2. Mettre l'instrument sous tension en appuyant sur le bouton de

navigation central .

3. Mettre la sonde à Zéro. (voir la page 5)

4. Ajuster à une épaisseur connue, si nécessaire. (voir la page 6)

5. Mesurer la pièce. (voir la page 4)

Utilisation du Menu

Utilisation du Menu

Les fonctions de l'instrument sont contrôlées via un menu. Pour

accéder à ce menu, mettre l'instrument sous tension, puis presser

le bouton de navigation central.

Bouton de navigation

Haut

Centre

Bas

RQE:

Le bouton est volontairement noyé pour éviter

toute mise sous tension accidentelle de l’instrument.

Pour naviguer, presser les boutons Haut et

Bas pour défiler et sur pour

SÉLECTIONNER.

Sélectionner Sortie (Exit) pour sortir du

menu.

1

Page 44

Sondes

Sondes

P

o

u

r

d

é

c

o

n

n

e

c

t

e

r

u

n

e

s

o

n

d

e

d

u

c

o

r

p

s

,

m

e

t

t

r

l

’

i

n

s

t

r

u

m

e

n

t

h

o

r

s

t

e

n

s

i

o

n

e

t

f

a

i

r

e

g

l

i

s

s

e

r

l

e

c

d

e

s

o

n

d

e

e

n

p

l

a

s

t

i

q

u

e

h

o

r

i

z

o

n

t

a

l

e

m

l

a

f

l

è

c

h

e

)

h

o

r

s

d

u

c

o

r

p

s

.

I

n

u

n

e

n

o

u

v

e

l

l

e

s

o

n

d

e

U

n

e

f

o

i

s

s

o

u

s

t

a

u

t

o

m

a

t

i

q

e

x

Des sondes PosiTector 200 sont disponibles pour un vaste panel

d'applications de mesure d'épaisseur de revêtement.

RQE:

polymères uniquement.

Le PosiTector accepte, en outre, un grand nombre de types de

sondes différentes, y compris des sondes de mesure d'épaisseur

de revêtement à courant de Foucault et induction magnétique, à

profil de rugosité de surface, de Température et d’Hygrométrie

ainsi que des sondes à ultrasons pour mesurer l'épaisseur des

parois.

Pour les dernières informations sur l'interchangeabilité des

sondes, consulter le lien www.defelsko.com/probe

u

é

c

u

t

e

u