Page 1

PosiTector 200

INSTRUCTION MANUAL v. 2.0

Simple. Durable. Accurate.

Ultrasonic Coating

Thickness Gage

Standard

and

Advanced

Page 2

2

Introduction

Introduction

Power-up / Power-down

Power-up / Power-down

The PosiTector 200 powers-up when any button is

pressed. To preserve battery life, the Gage powersdown after approximately 3 minutes of no activity. All

settings are retained.

Throughout this manual, the symbol

indicates more information about the particular topic

or feature is available on our website.

Go to: www.defelsko.com/manuals

NOTE:

The PosiTector 200 is a hand-held Coating

Thickness Gage that uses a non-destructive

ultrasonic principle to measure coating thickness on

a wide variety of substrates.

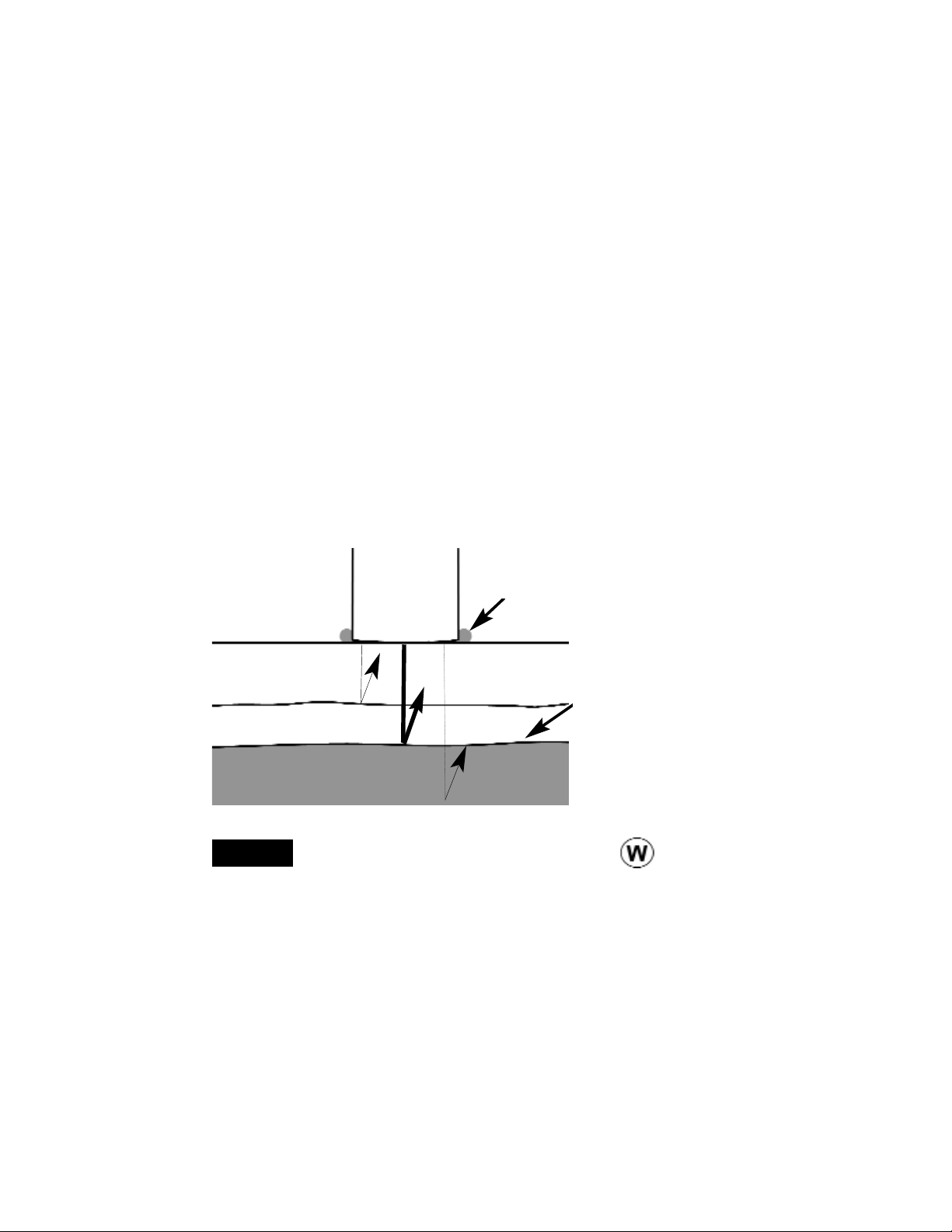

The PosiTector 200 probe emits a high frequency

sound pulse that travels into the coating via a

coupling gel and reflects from ANY surface that is

different in density. Coating thickness readings are

obtained by measuring the time taken for the

ultrasonic signal to propagate from the probe to the

coating/substrate interface and back. The travel time

is divided by two and multiplied by the velocity of

sound in the coating to obtain the thickness of the

coating.

Couplant

Probe

Coating 1

Substrate

Coating 2

The PosiTector 200

interprets the largest

“echo” within the

Gates as the

coating/substrate

echo.

Page 3

3

Certification

All probes or gages are shipped with a Certificate of

Calibration. For organizations with re-certification

requirements, gages may be returned at regular

intervals for calibration. DeFelsko recommends that

customers establish gage calibration intervals based

upon their own experience and work environment.

Based on our product knowledge, data and

customer feedback, a one year calibration interval

from either the date of calibration, date of purchase,

or date of receipt is a typical starting point.

Operation Overview

Operation Overview

1. Turn the Gage ON (see Power-Up pg.2)

2. ZERO the probe (see pg.5)

3. ADJUST to a known thickness, if necessary

(see pg.8)

4. MEASURE the part (see pg.5)

Couplant

Couplant

Couplant is required to propagate ultrasound into the

coating. Water is a good couplant for smooth

coatings. Use the supplied glycol gel for rougher

coatings. While it is unlikely that the couplant will

damage the finish or leave a stain on the surface, we

suggest testing the surface by using the couplant on

a sample. If testing indicates that staining has

occurred, a small amount of water can be used

instead of couplant. Consult the Material Safety Data

Sheet available on our website and your coating

supplier if you suspect the couplant may damage the

coating. Other liquids such as liquid soap may also

be used.

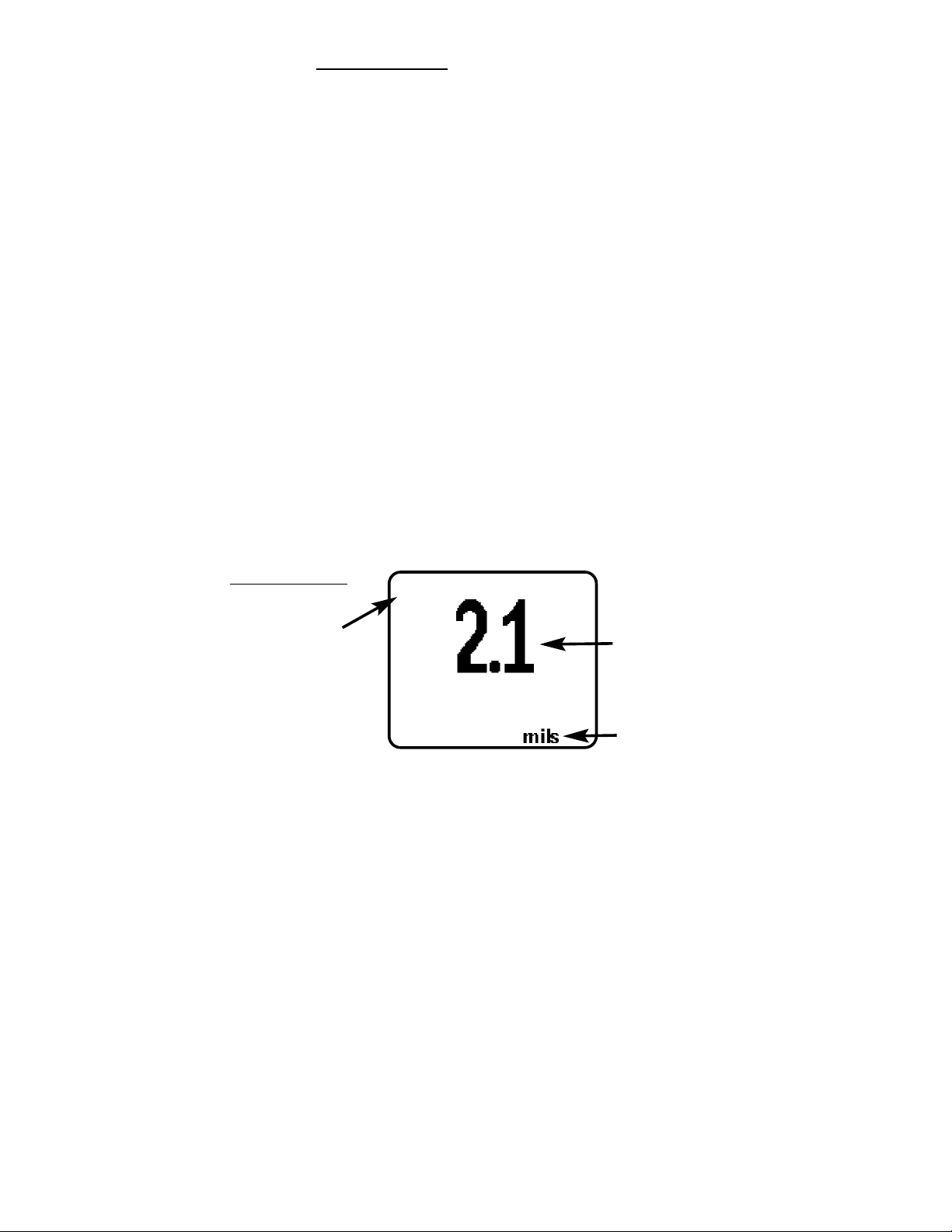

Typical Display:

Unit of

Measurement

Indicates Gage is

in single layer

mode (Advanced

models only)

1

Current

Measurement

Page 4

4

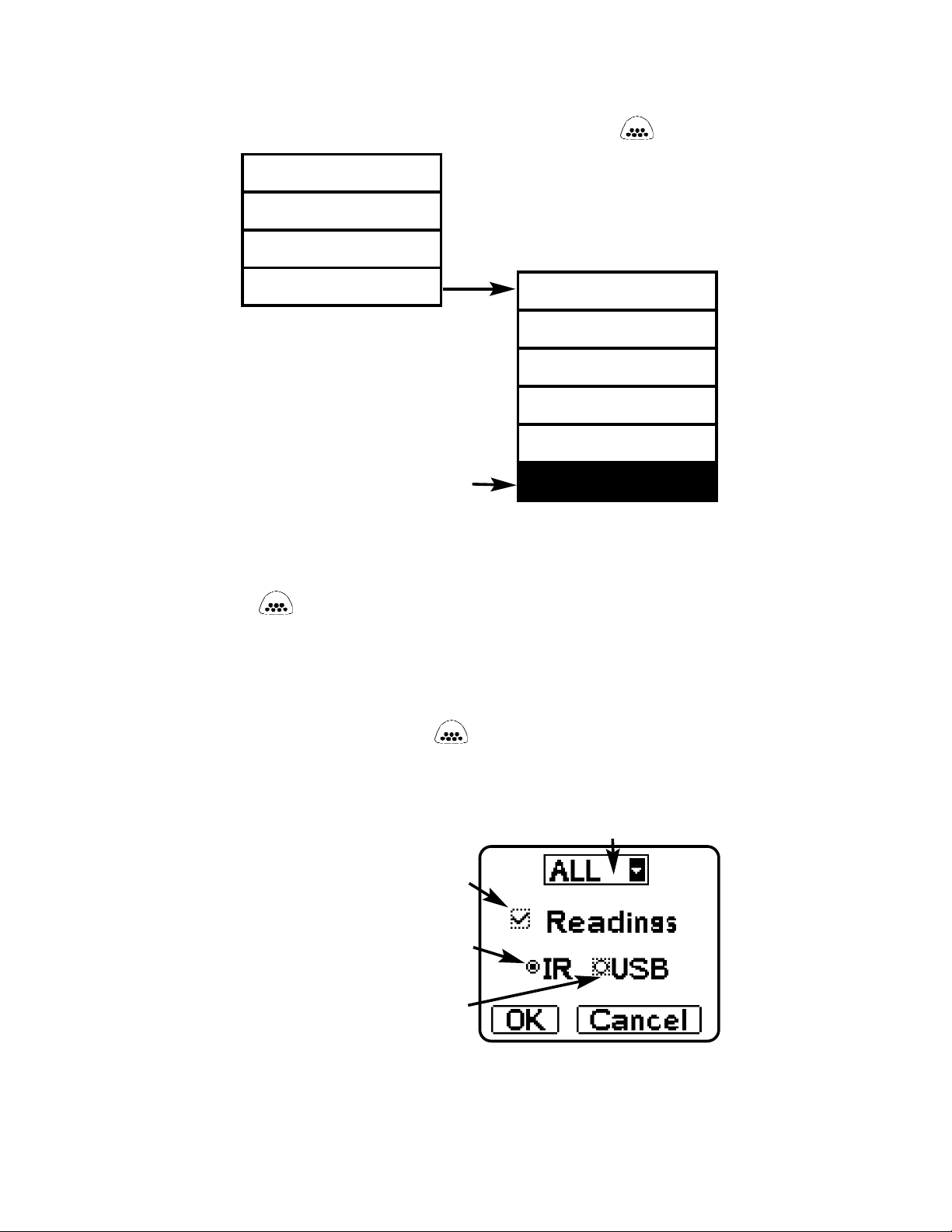

Menu Operation

Menu Operation

Current selection is displayed

with darkened background

Gage functions are menu controlled. To access the

Menu, turn the Gage on, then press the button.

To navigate, press (-) to scroll DOWN, (+) to scroll UP

and to SELECT. Press both (-)(+) buttons at any

time to exit any menu or select Exit from the Menu.

List boxes have a down arrow on the right-hand side.

Use the (-) and (+) buttons until your desired choice

appears, then press to select this choice and

move focus onto the next item.

Memory

Zero

Cal Settings

Setup

Reset

Graphics*

Gage Info

Units

Set Clock

Language

“Focus” is currently at this

unselected (empty) Radio button

“Radio” buttons. Only one

can be selected at a time.

“List“ box

a “tick” indicates this square

box has been selected

Graphics on Advanced

models only

*

Page 5

5

1. Apply couplant to the surface of your part.

2. After power-up, place the probe FLAT on the

surface and press down.

3. Lift the probe when you hear a

double BEEP or see the green indicator light blink. Measurement result

is displayed on the LCD.

A second reading may be taken at the same spot by

continuing to hold the probe down on the surface.

4. When completely finished, wipe the probe clean

of couplant then return both Gage and probe to the

protective case. There is no need to disconnect the

probe from the Gage during storage.

How to Measure

How to Measure

Zero Menu Option

Zero Menu Option

Zero

The probe must be periodically zeroed using the

ZERO menu option to compensate for both extreme

temperature and probe wear effects. Before using,

allow the probe to reach ambient temperature. Wipe

the probe clean of couplant.

If measurements will be made in extreme hot or cold

temperatures, it is recommended to ZERO the probe

in the working environment.

If measurements will be made on rough substrates

,

it is recommended to periodically ZERO the probe to

compensate for wear.

Page 6

6

Set Gates Option

Set Gates Option

Set Gates

Standard Model

Advanced Model

Each probe has a measuring range as shown on

page 19. For example the C probe can measure

coatings in the range of 50 to 3800 microns (2 to

150 mils).

Gates are used to narrow the range of thickness that

the Gage examines. Gate A sets the minimum

thickness limit and Gate B the maximum.

For most applications the default Gate values do not

have to be adjusted. But some conditions may exist

in the user's application that cause the Gage to

display very low or non-repeatable readings. These

conditions include…

·rough or textured coatings

·hard (dense) coatings

·coatings applied in multiple layers

·coatings applied on a very thin, hard substrate

Important: When measuring, the Gage finds the

most distinct interface within the two Gate settings. If

the coating thickness is outside this range, incorrect

or dashed readings may occur. The PosiTector 200

interprets the largest “echo” or echoes within the

gates as the coating/substrate echo.

Page 7

7

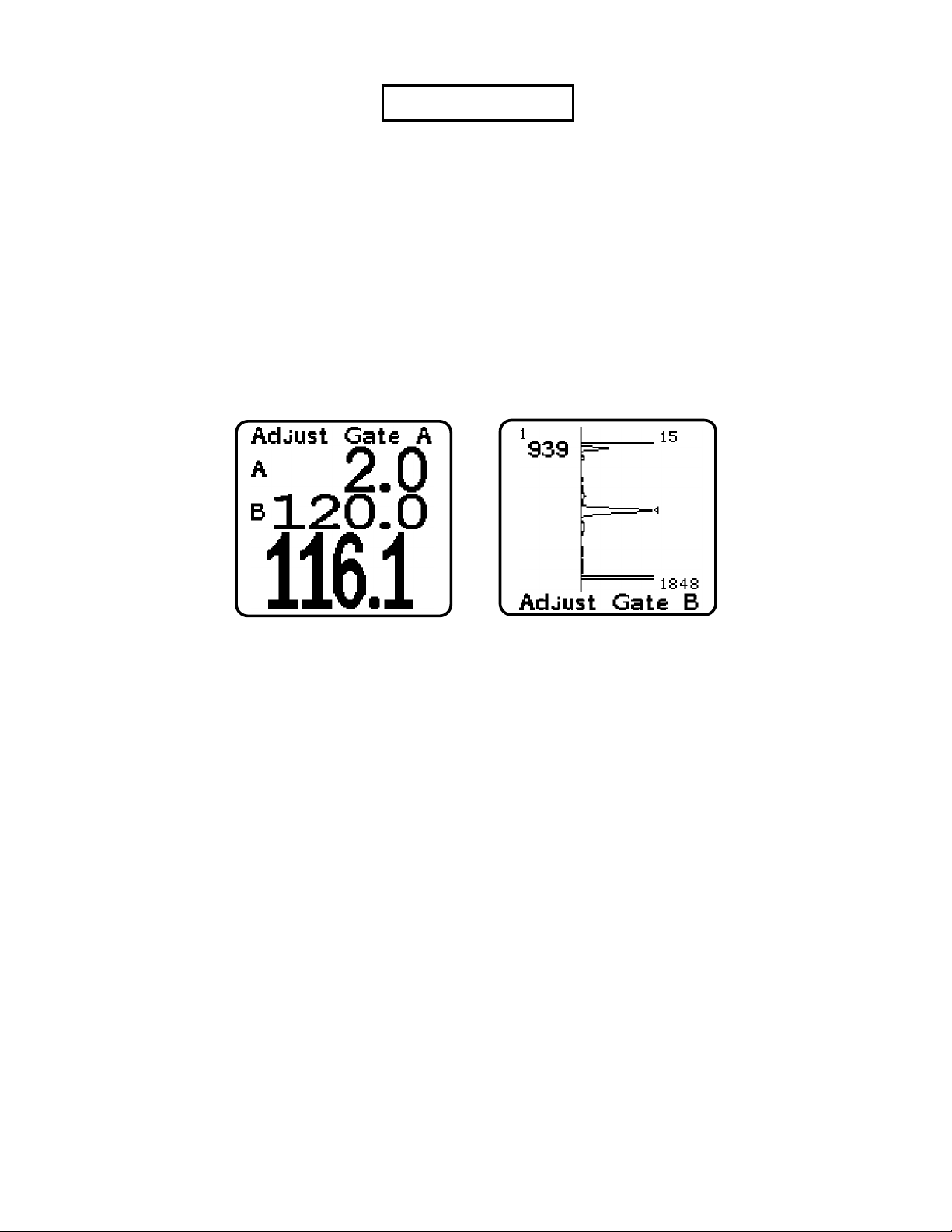

To make adjustments:

1. Measure the coated part.

2. Select the Set Gates menu option.

3. Gate A can be changed first. Adjust the value

down (-) or up (+).

Press to accept the value and to move to

Gate B.

4. Gate B can now be changed. Adjust the value

down (-) or up (+).

5. Press to accept the value. Standard models

will exit.

6. Advanced models will display a Cursor which

allows analysis of the peaks displayed in the

Graph. Adjust the Cursor down (-) or up (+).

Press to accept Gate values and exit.

Use the Cursor to measure

multi-layer coating systems with

more than 3 distinct layers.

NOTE:

Here are some typical Gate settings...

Expected paint thickness Gate A Gate B

500um (20 mils) on concrete 130µm (5 mils) 1000µm (40 mils)

50µm (2 mils) on wood 25µm (1 mil) 250µm (10 mils)

The displayed thickness reading may

change when Gate values are adjusted. The new

thickness value represents the distance to the

"loudest" interface within the new A/B Gate values

(see pg.2). This handy feature makes it easy to

ignore other measurements such as surface

roughness.

For additional help with Gates see Application

Notes (pg.15)

NOTE:

Page 8

8

Adj Thickness

Adjust Thickness Option

Adjust Thickness Option

Select a reference standard of material as close as

possible in composition to the intended application.

For best results, the thickness of the reference standard should be equal to or slightly greater than the

thickness of the coating to be measured.

1. Apply a drop of couplant onto the reference standard.

2. Measure the reference standard.

3. Lift the probe. Select the Adj Thickness menu

option.

4. Adjust the display down (-) or up (+) to the

reference standard thickness.

5. Press to store the adjustment. Standard

models will exit.

6. Advanced models with more than 1 layer selected

will continue to the next layer. Adjust the thickness

(step 4) and store the adjustment by pressing .

When all layers have been adjusted, the gage will

exit the Adj Thickness option.

Note: A Reset (pg.11) will restore factory settings.

Page 9

9

Memory Mode

Memory Mode

The PosiTector 200 can record 10,000

measurements in up to 1000 groups (batches) for

on-screen statistical purposes, for printing to an

optional IR printer, or for downloading to a personal

computer using optional PosiSoft software and USB

cable.

-closes any currently opened batch and creates a

new batch name using the next higher number. For

example, if only Batch 1 and Batch 3 exist, then Batch

4 would be created and made the current batch.

Statistics are displayed and each measurement will

now be simultaneously shown on the display and

stored into this new batch. On screen statistics are

immediately updated with each measurement. New

batch names are date stamped at the time they are

created.

When a batch is open, create a new batch

by pressing (+)

Memory

Open

New Batch

Shortcut:

-selects a previously created batch name to open

and make current. If it contains measurements, onscreen statistics will immediately reflect values

calculated from this batch.

Mean

(average)

Standard

Deviation

No. of

measurements

Max and Min

measurement

Current

Batch

Last

reading

Page 10

10

Print

-prints all stored measurements to the optional IR

printer or to a PC’s default Windows printer via the

optional USB cable and PosiSoft software. Press

(-)(+) simultaneously to cancel printing.

Downloading Measurement

s Stored in Memory

Measurements stored in the Gage's memory (in

batches) can be downloaded to a computer using

optional PosiSoft software and USB cable.

Measurements are not erased from memory after

downloading.

PosiSoft® allows entry of notes and annotations,

prints histograms and basic charts, manages data,

and readings can be exported to a document or

spreadsheet.

Remove the last reading from the current open batch

by pressing (-).

NOTE:

View

Delete

-removes a batch completely from memory. The

name is deleted and all measurements are erased.

-lists all readings on the display from the current or

most recently used batch. It begins by showing the

last 10 measurement values. Scroll using the (-) or

(+) buttons. Hold for 1 second to scroll a page at a

time.

To change or delete a value, scroll to that value

(align the “+” symbol beside it) then either take

another measurement to change it, or press to

delete it or exit. Statistics are updated.

Close

-stops the recording process, closes the current

batch, and removes the statistics from the display.

Page 11

11

Graphics

Advanced models only

Reset restores factory settings and returns

the Gage to a known, out-of-the-box

condition. It is handy when you want to “start all over”

The following occurs:

- all batches are closed and stored measurements

are erased.

- calibration adjustments are cleared and returned

to the Gage’s factory calibration settings.

- Gates are returned to default settings.

- menu setting are returned to the following:

Memory = OFF

Graphics = OFF

(Advanced models only)

A more thorough Reset can be performed by holding

the (+) button when the Gage is powered down until

the Reset symbol appears. It performs the same

function as a menu Reset with addition of Units =

microns, and Language = English.

Setup Menu

Setup Menu

Setup

Reset

The right hand side of the screen

can be used to display a graphical

representation of the ultrasonic

pulse as it passes through the

coating system.

Press the (+) to toggle Graphics On/Off

(shortcut is active when Memory is off)

As the probe is depressed and the ultrasonic pulse

travels through the coating system, the pulse

encounters changes in density at the interfaces

Shortcut:

Page 12

This menu button converts the display and all stored

readings from mils to microns or vice versa.

12

Units

between coating layers and between the coating and

the substrate.

These interfaces are depicted by a "peak". The

greater the change in density the higher the peak.

The more gradual the change in density, the greater

the width of the peak. For example, two coatings

layers made of essentially the same material and

"blended" would result in a low, wide peak. Two

materials of very different density and a well-defined

interface would result in a high, narrow peak.

The PosiTector 200 Advanced chooses the highest

of peaks when trying to determine coating layer

thickness. For example, if the number of layers is set

to 3, the 3 highest peaks between the A & B Gates

are selected as the interfaces between these layers.

The peaks that the Gage selected are indicated by

black triangle arrows.

The top (A) and bottom (B) Gate values (pg.6) are

displayed as two horizontal lines at the top and

bottom of the graphics area. Their current values are

shown to the right of each line. Gate A, the minimum

limit, is at the top. Gate B, the maximum limit, is at

the bottom. Echoes or peaks (thickness values)

outside these Gates are ignored. Gate values are set

and modified using the Set Gates menu option.

This Graphics display can be manipulated with the

Set Gates menu option. In addition to being able to

adjust the Gate values, a Cursor can be positioned

anywhere between the two Gate values to

investigate other peaks.

Page 13

13

Set Clock

All batches are date-stamped when created, and all

measurements are time-stamped (24 hour format)

when stored into these batches. It is therefore important to keep both the date and time current using this

menu button. Alternatively, the date and time can be

automatically updated when the gage is connected

to PosiSoft using the Gage Utilities -> Set Clock function in PosiSoft.

Layers

Measuring Multiple Layers

Measuring Multiple Layers

Advanced models only

Advanced models of the PosiTector 200 are

capable of numerically displaying up to 3 individual

layer thicknesses in a multi-layer system.

To setup the Gage for multi-layer coatings:

1. Select Layers from the Cal Settings menu.

2. Select the number of layers using the

(-) and (+) buttons.

Press to accept the value.

Couplant

Probe

Layer 1

Substrate

Layer 2

Layer 3

Total thickness

Before setting up the Gage for multi-layer

measurement, it is recommended that you first take

measurements in single layer mode and interpret the

results using the Graphics option (see pg.11)

NOTE:

Page 14

14

Calibration

Calibration is the controlled and documented

process of measuring traceable calibration

standards and verifying that the results are within the

stated accuracy of the Gage. Calibrations are

typically performed by the Gage manufacturer or by

a certified calibration laboratory in a controlled

environment using a documented process.

V

erification

Verification is an accuracy check performed by the

user using known reference standards. A successful

verification requires the Gage to read within the

combined accuracy of the Gage and the reference

standards.

Adjustment

Adjustment, or Calibration Adjustment, is the act of

aligning the Gage's thickness readings to match that

of a known reference sample in order to improve the

accuracy of the gage on a specific coating. (pg.8)

Calibration, V

Calibration, V

erification and

erification and

Adjustment

Adjustment

Three steps ensure best accuracy…

1. Calibration - typically done by the manufacturer

or a qualified lab

2. Verification of Accuracy - as done by the user

3. Adjustment - to a known thickness

AAvailable Options

vailable Options

A variety of accessories are available to help you get

the most from your PosiTector 200 coating

thickness gage.

Page 15

15

The PosiTector 200 probe emits a high frequency

sound pulse that travels into the coating via a

coupling gel and reflects from ANY surface that is

different in density. Coating thickness readings are

obtained by measuring the time taken for the

ultrasonic signal to propagate from the probe to the

coating/substrate interface and back. The travel time

is divided by two and multiplied by the velocity of

sound in the coating to obtain the thickness of the

coating. The strength of the reflected signal from the

coating/substrate interface determines the ability of

the instrument to measure the thickness of the

coating. Since most applications are not

homogeneous the gage will "hear" many echoes

when placed on a coating/substrate. The instrument

"hears" ALL reflections within the measurement

Application Notes

Application Notes

The PosiTector 200 uses an ultrasonic principle to

measure coating thickness of most coatings on most

substrates. An ultrasonic signal is a very high

frequency sound wave. Like the echoes you hear

when you shout in a large hall or canyon the

PosiTector 200 listens for echoes from acoustic

boundaries within your application.

The PosiTector 200 is factory calibrated. But in

order for it to take accurate thickness measurements

of a particular material it might be necessary to

adjust the gage for that material. To determine if an

adjustment is necessary for your application,

measure a sample of known thickness of the coating

material to be measured. If the average of a series

of measurements is not close to the expected

thickness, adjust to the expected thickness.

Samples should be flat, smooth and as thick or

thicker than the maximum expected thickness of the

piece to be tested.

Page 16

16

#2

#1

Coating

Substrate

Probe

Couplant

Measurement of dense (hard) coatings.

A significant echo occurs at the probe/coating

interface. The relative strength of this echo

compared to the coating/substrate echo requires that

Gate A be increased.

Measurement of total thickness in multi-layer

coating applications.

Multiple coating/coating/substrate interfaces may

generate several echoes. The user may need to

adjust Gates to ignore echoes from coating/coating

interfaces.

limits of the gage and assumes the largest “echo” is

the coating/substrate echo (single coating

applications only). Adjustable measurement Gates

have been provided for the user to force the

instrument to ignore echoes from unwanted

boundaries within the sample. Several examples

below help to illustrate the use of Gates for specific

applications.

Measurement of coatings with rough surfaces.

When rough coatings are measured, the gage

typically identifies the thickness from the top of the

coating peaks down to the substrate (#1). Couplant

fills the voids between the probe and the coating (#2)

creating an additional interface. If echoes from the

couplant/coating interface (#2) are stronger than the

coating/substrate interface (#1), an adjustment

(increase) of Gate A may be required for the gage to

display the weaker (#1) echo.

Page 17

TTroubleshooting

roubleshooting

Gage does not turn on

Make sure the + and - battery terminals are positioned properly and that fresh Alkaline batteries are

being used.

Gage powers up but fails to st

ay on

Replace batteries with fresh Alkaline batteries. If

problem persists return Gage for service.

Gage readings are much lower than expected

Gage may be measuring surface roughness. Raise

the value of Gate A. See pg.6

Gage readings are much higher than expected

Gage may be measuring both the coating and

substrate. Lower the value of Gate B. See pg.6

Gage does not yield accurate or consistent

results

See the Set Gates (pg.6) and Adjustment (pg.8)

sections to ensure the gage has been optimized for

your application. Check the Gage on traceable

standards.

Gage displays an error message while attempt

-

ing probe ZERO

Make sure to hold the probe

in the air and ensure the

probe is free of couplant. If

problem persists, note the

error message and contact our technical support

department.

17

ZERO FAILED 1

OK

Page 18

18

Returning for Service

Returning for Service

Before returning the Gage for service…

1.Install new Alkaline batteries in the proper

alignment as shown within battery compartment.

2.Examine the probe tip for dirt or damage.

3.Perform a Reset (pg.11) and a Zero (pg.5)

4.Place a plastic shim onto a hard surface (i.e. glass)

and attempt a measurement. (see pg.5)

If you must return the Gage for service, describe the

problem fully and include measurement results, if

any. Be sure to also include the gage, probe, your

company name, company contact, telephone

number and fax number or email address.

Website: www.defelsko.com/support

Changing The Batteries

Changing The Batteries

The battery icon displays a full bar with fresh

alkaline batteries installed. As the batteries weaken,

the bar will be reduced. When the battery icon is low

, the Gage can still be used, but the batteries

should be changed at the earliest opportunity. USE

ONLY “AAA” ALKALINE BATTERIES. Nickel-cadmium and

nickel-metal hydride rechargeable batteries will work

but the Gage may appear to have weak batteries.

To retain all user settings and stored memory readings, only replace the batteries after the Gage has

automatically powered-down.

TTechnical Dat

echnical Dataa

Conforms to: ASTM D6132 and ISO 2808

Gage body dimensions:

(146 x 64 x 31 mm) 5.75" x 2.5" x 1.2"

Temperature Range: 0 to 40°C (+32° to +104°F)

Page 19

19

WWarranty

arranty

DeFelsko fully warrants its products against defects

in workmanship or materials under normal use for a

period of two years

from date of purchase. In the

event that an instrument is believed to be defective,

return the product with proof of purchase to your

dealer. If upon DeFelsko’s inspection of the

instrument, it is determined in our sole discretion that

the returned instrument is defective as to

workmanship or material, the instrument will be

repaired or replaced at DeFelsko’s sole option.

In no event shall DeFelsko be liable for any indirect,

special, incidental or consequential damages.

The warranty is voided if the Instrument has been

opened.

Data subject to change without notice.

Probe Measuring Range*

B 13 - 1000 microns (0.5 - 40 mils)

C 50 - 3800 microns (2 - 150 mils)

*Range limits apply to polymer coatings only.

Accuracy: ± (2 microns + 3% of reading)

± (0.1 mils + 3% of reading)

Page 20

www.defelsko.com

© DeFelsko Corporation USA 2006

All Rights Reserved

This manual is copyrighted with all rights reserved and may not be reproduced or

transmitted, in whole or part, by any means, without written permission from

DeFelsko Corporation.

DeFelsko, PosiTector and PosiSoft are trademarks of DeFelsko Corporation registered in the U.S. and in other countries. Other brand or product names are trademarks or registered trademarks of their respective holders.

Every effort has been made to ensure that the information in this manual is accurate. DeFelsko is not responsible for printing or clerical errors.

Loading...

Loading...