Page 1

Model 100 Series

Ultrasonic Multi-layer

Coating Thickness Gage

Instruction Manual

version 4.0

Page 2

Page 2 100 Series

Page 3

DeFelsko Corporation USA 1999

All Rights Reserved • Patents applied for • Printed in U.S.A.

This manual is copyrighted with all rights reserved and may not be reproduced

or transmitted, in whole or part, by any means, without written permission from

DeFelsko Corporation.

DeFelsko, PosiTector and PosiSoft are

trademarks of DeFelsko Corporation registered

in the U.S. and in other countries. Microsoft.

Windows NT, Windows 95 and Windows 98 are

registered trademarks of Microsoft Corporation.

HP is a registered trademark of Hewlett-Packard

Corporation. Other brand or product names are

trademarks or registered trademarks of their

respective holders.

Every effort has been made to ensure that the information in this manual is

accurate. DeFelsko is not responsible for printing or clerical errors.

01/99

Multi-layer Model 100

••standard •• memory

Gage Serial Number: ______________

Probe (B, C or D): _________________

Probe Serial Number: ______________

Date Purchased: __________________

100 Series Page 3

Page 4

SAFETY, CARE AND MAINTENANCE......................................................................6

QUICK START ......................................................................................................7

PHYSICAL OVERVIEW ..........................................................................................8

Packing List ....................................................................................................8

Gage Description ............................................................................................8

Available Probes............................................................................................. 9

LCD DISPLAY ...................................................................................................10

Status Bar .....................................................................................................10

Menu Bar...................................................................................................... 10

Measurements Area.......................................................................................11

Graphics.......................................................................................................11

Statistics........................................................................................................ 12

Memory......................................................................................................... 13

Sets...............................................................................................................13

OPERATION OVERVIEW...................................................................................... 14

Theory of Operation......................................................................................16

Couplant.......................................................................................................17

Power-up / Power-down................................................................................17

How to take a measurement........................................................................... 18

APPLICATIONS...................................................................................................19

Select an Existing Application........................................................................20

Edit Application Settings ...............................................................................20

Create a New Application ..............................................................................20

Delete an Existing Application....................................................................... 20

RECORDING AND DOWNLOADING MEASUREMENTS............................................. 21

Creating Batches...........................................................................................21

Annotating Batches........................................................................................21

Viewing and Editing Batches.........................................................................22

Charting Batches........................................................................................... 23

Printing......................................................................................................... 23

CALIBRATION AND OPTIMIZATION......................................................................24

Overview.......................................................................................................24

Calibration.................................................................................................... 25

Effects of Temperature.......................................................................................... 25

Calibration Interval ............................................................................................... 26

Optimization .................................................................................................26

Step 1: Select a “Category”....................................................................................26

Step 2: Optimize to a Known Thickness.................................................................27

Plastic Shims .................................................................................................28

Page 4 100 Series

Page 5

ADVANCED FEATURES .......................................................................................29

Zeroing the Probe..........................................................................................29

Restarting the Gage.......................................................................................30

Gage RESET.........................................................................................................30

Gage INITIALIZATION .......................................................................................31

Gates A & B..................................................................................................32

Measurement Units........................................................................................33

System Clock................................................................................................. 33

Language Option........................................................................................... 33

COMMUNICATIONS – (MEMORY OPTION ONLY)....................................................34

Printing......................................................................................................... 34

PosiSoft......................................................................................................... 34

Downloading Measurements As They Are Taken............................................ 34

Serial Communications Configuration...........................................................35

AVAILABLE OPTIONS .........................................................................................35

Memory......................................................................................................... 35

HP IR Printer ................................................................................................35

AC Adapter ................................................................................................... 35

Traceable Standards...................................................................................... 35

MEASURING NOTES ...........................................................................................36

Rough Substrates........................................................................................... 36

Transition Layers .......................................................................................... 36

MAINTENANCE AND TROUBLESHOOTING ............................................................ 37

Battery Management .....................................................................................37

Troubleshooting ............................................................................................ 38

Service..........................................................................................................39

SPECIFICATIONS.................................................................................................39

ASTM............................................................................................................39

Temperature..................................................................................................39

Table 1: Physical Characteristics .................................................................. 40

Table 2: Environmental Characteristics .........................................................40

Table 3: Operational Characteristics.............................................................40

Table 4: Range and Resolution Matrix...........................................................41

SAFETY AND REGULATORY INFORMATION..........................................................42

APPENDIX A - MAKING YOUR OWN CHECK STANDARDS.....................................44

APPENDIX B - SAMPLE HP IR OR SERIAL PRINTOUT ............................................46

WARRANTY.......................................................................................................48

100 Series Page 5

Page 6

Safety, Care and Maintenance

Screen care

• The LCD is protected by a solvent-resistant lens. Be careful not to scratch

this lens. Do not use ink pens or any other sharp object.

• Take care not to break the glass lens. Do not subject the Model 100 to a

strong impact or to extreme temperatures.

• We suggest cleaning the lens only with a soft dry cloth – such as a cloth

made for cleaning eyeglasses.

Cleaning the plastic Gage housing

• Clean the plastic surfaces only with isopropyl alcohol (rubbing alcohol) and

a soft dry cloth. Take care when using other solvents. While the housing is

solvent resistant, the buttons are not.

Cables and ports

• Keep the probe connected to the Gage even during long periods of power-

down.

• Do not use cables that are frayed or otherwise damaged. Hold a cable only

by its connector – the plug, not the cord – when connecting or

disconnecting it.

• Never force a connector into a port if the connector and port do not join

easily. Make sure that the connector matches the port and that it’s properly

aligned and undamaged before you attach it.

Heat, moisture, dust

• Keep the Gage away from extreme heat. Don’t leave it on the dashboard or

in the trunk of a car or near a heater. Heat can damage the screen, the plastic

case and internal parts.

• Don’t leave the Gage where it is extremely dusty, damp or wet. Dust and

moisture can damage the Gage and cause it to malfunction. The Gage is not

waterproof and may not be submerged.

Page 6 100 Series

Page 7

The Model 100 hand-held, electronic Gage uses an ultrasonic technique to nondestructively measure the thickness of coatings on various substrates quickly

and accurately. The probe emits an ultrasonic pulse into the coating. Reflections

from the coating/substrate interface, coating/coating interfaces and other

conditions are picked up by the probe. The travel time is converted into a

thickness value shown on the display. Power is supplied from either two “C”

size Alkaline-Manganese Dioxide batteries or an external power supply.

Quick Start

The Model 100 is always ready to measure. Here are some quick tips:

q Read “How to Take a Measurement” on page 18 to familiarize yourself

with basic Gage

operation.

q Practice measuring the

included plastic shims

as described on page

28 to confirm the Gage

is operating properly

and that the operator is

using it properly.

q If you have a sample of

your coating with a

known thickness, you

may want to adjust the

Gage to this material. Read “Calibration and Adjustment” on page 24 to

how to make the Gage adjustments before taking your measurements.

q Select the Setup Application Setup menu item and adjust values

as necessary (pg.19) for your coating.

q Measure your application.

Remember the “golden rule”:

Calibrate

see pg.24

⇒

Optimize

see pg.26

⇒

Measure

see pg.18

100 Series Page 7

Page 8

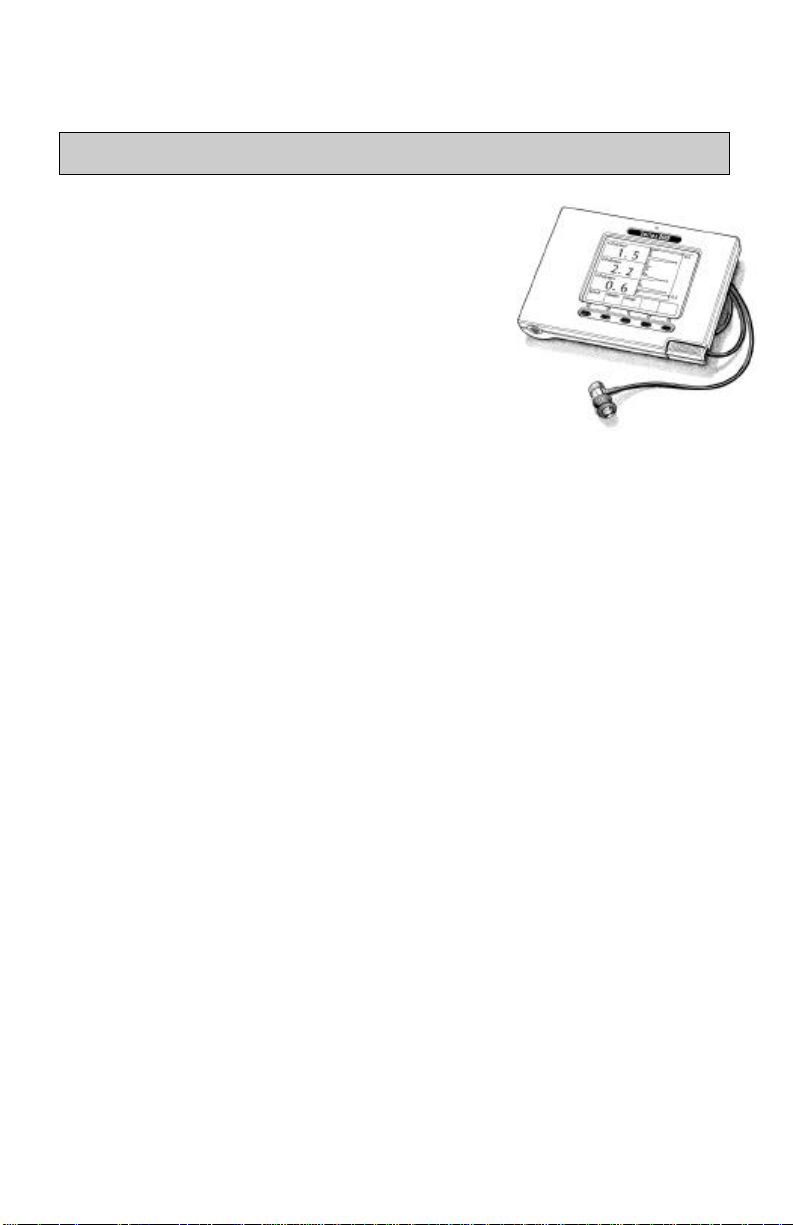

Physical Overview

Packing List

The Model 100 comes complete with:

• one (1) ultrasonic probe, either B, C or D (pg.9)

• Cordura carrying case with shoulder strap

• this instruction booklet

• two (2) “C” alkaline batteries (pg.37)

• wire stand for desktop operation (pg.8)

• precision plastic shim set (pg.28)

• ultrasonic couplant (pg.17)

• Material Safety Data Sheet for couplant

• With the Memory option, PosiSoft software and RS232 serial cable are

included

Gage Description

5 LCD buttons - Soft key functions are displayed in the LCD above each button. Pressing

a button displays available menu choices or moves the black highlight bar

to the next choice. To select, press the OK button.

Speaker - audibly indicates various Gage functions. Volume is not adjustable.

Green LED -low power light emitting diode located above the LCD. Ideal in noisy or

low light environments to confirm a reading has been taken.

Wire Stand - A wire stand is provided to allow for convenient desk top operation.

Press-fit it into the top hole located above the backplate and beside the

batteries. Remove and store it for hand-held operation.

Probe Connect - The probe connector is a locking 9 conductor mini-DIN. Normally the

probe does not need to be disconnected from the Gage.

To disconnect the probe from the Gage pinch the plastic connector firmly

along the hash marks and pull straight out. It can be removed during

power-up or power-down. All settings and readings are maintained.

When reconnecting, ensure the 9 pin DIN connector is properly aligned.

Then push the plastic connector in firmly. The Gage will download probe

identity and enable all applications and calibrations associated with that

probe.

Probe Switches - B and C probes have a convenient sliding switch near the base of the

probe to provide constant pressure during the measuring process. Pushing

this switch down activates the measuring process.

The switch on the D probe is located on top of the probe. Stabilize the

probe on the coating surface before holding this switch down.

Page 8 100 Series

Page 9

AC port - An optional AC adapter can be purchased from your dealer to

supply continuous 7.5 volts DC power from an AC source.

(pg.35)

RS232 Port - An RS232 compatible port is provided via this RJ45 interface

to send stored measurements or measurements-as-they-are-taken

to a serial printer, data collector or computer. Transmission is at

9600 baud, 8 bits, nonparity, 1 stop bit. Active only on Gages

with the Memory option (pg.13).

RESET Button - causes a “soft” or “safe” RESET as described on page 30.

IR Port - sends stored measurements to the optional IR Printer (pg.35).

The IR port is a send-only IR interface and is active only on

Gages with the Memory option (pg.13)

Contrast - adjusts the LCD to compensate for temperature and light

conditions.

Available Probes

Three (3) probes are available for the Model 100. They are interchangeable; one

can be removed and a completely different one installed. The probe type - B, C

or D - and serial number are engraved on the plastic probe connector. The probe

must be disconnected to view this information. The probe letter and serial

number can also be identified by selecting the Admin – About Gage menu

item. As new probes are attached, the Gage records probe type and serial

number to allow quick and easy reconnection at a later time. The probe reading

is independent of the Gage being utilized. The Gage can store calibration data

for up to 5 different probes. This information is cleared with a Gage

INITIALIZATION (pg.31).

Probe Measuring range** Typical uses

B

C

D

**the measuring range depends upon coating properties. See the Range &

Resolution Chart on page 41.

100 Series Page 9

0.3 to 20 mils

8 to 500 microns

2 to 175 mils

50 to 4.5 mm

48 to 350 mils

1 to 8 mm

thin coatings such as paint and urethanes

on wood, glass, plastic, etc.

thick paint or epoxy on concrete and

wood structures

thick, soft attenuative waterproofing

coatings on concrete and wood such as

polyurea and asphaltic neoprene

Page 10

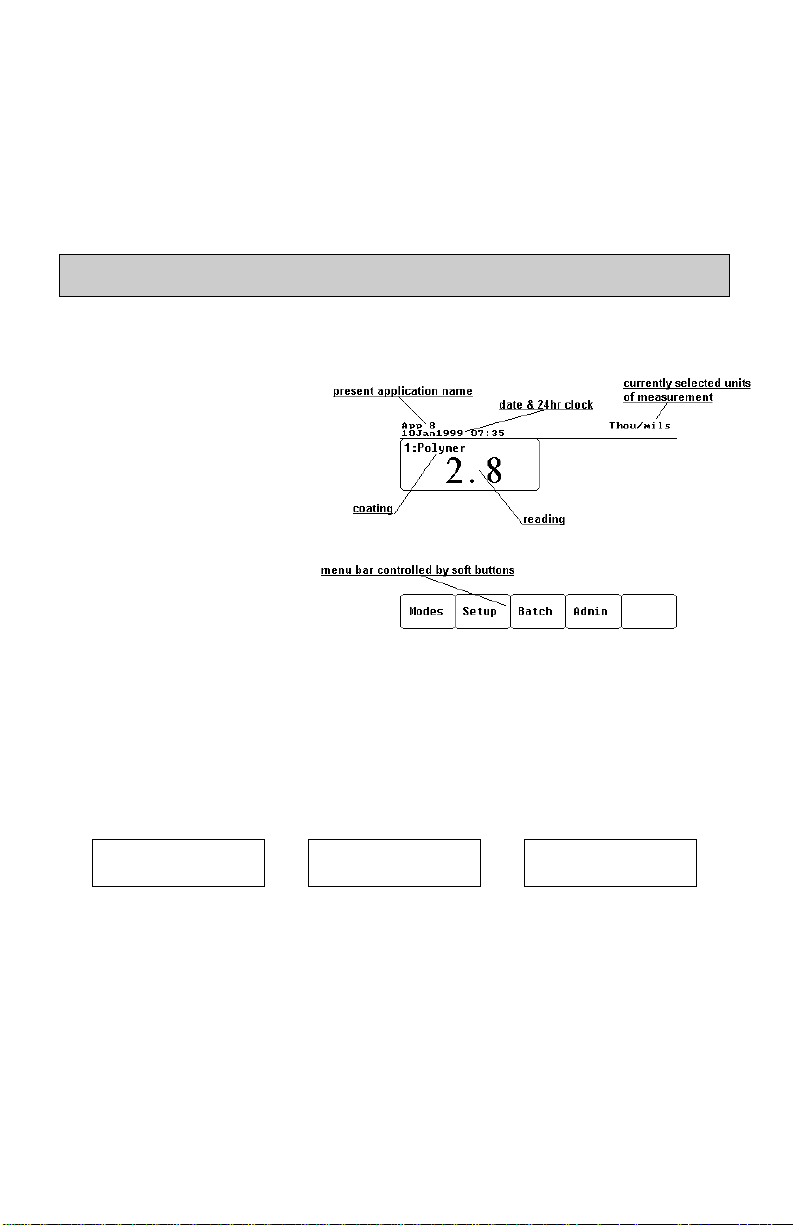

LCD Display

Information is displayed in one of four areas on the LCD: the top STATUS

BAR, the bottom MENU BAR, the left MEASUREMENTS area and the right

STATISTICS/GRAPHICS area.

Status Bar

An area along the top of the LCD is reserved for status information. This

includes the name of the current application (pg.19), the system date and time

(pg.33), the current units of measurement (pg.33), the current batch name and

number of readings. A ticking clock symbol appears occasionally to indicate an

action is being performed, such as a probe measurement.

Menu Bar

Most Gage operations are controlled by the five LCD buttons. When pressed,

each button activates a menu which pops up above that button. (The taking of a

coating thickness measurement is controlled by the probe switch).

These menus appear as follows:

Select

Language

Zero Initialize

Graphics Adjust Delete Change to

ON/OFF Reading Chart Microns

Statistics Gate/Zoom View/Edit Set

ON/OFF † Control Annotate Clock *

Memory Application Select About

ON/OFF * Setup New Gage

Modes Setup Batch* Admin OK

Button 1 Button 2 Button 3 Button 4 Button 5

Probe Print Gage

* - these 3 items are only available with the Memory option.

† - when Memory is ON,

this menu option appears as “Sets ON/OFF”

Page 10 100 Series

Page 11

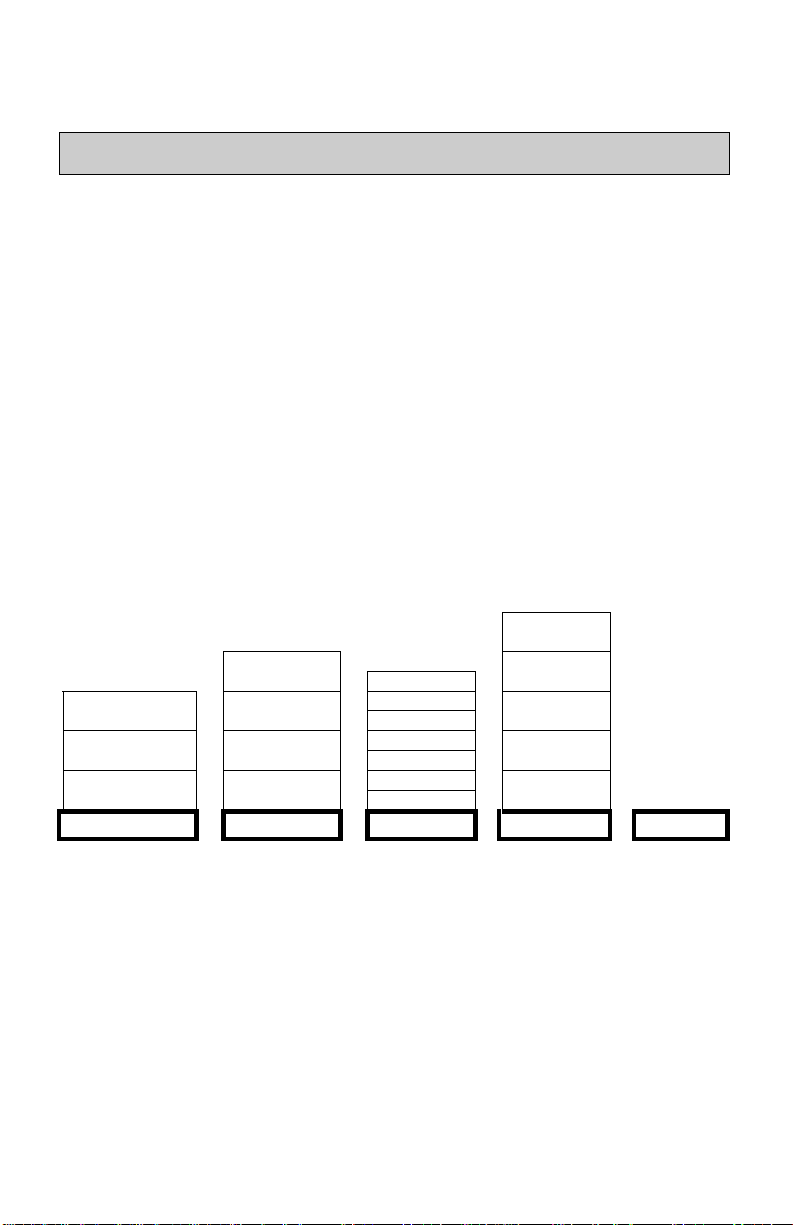

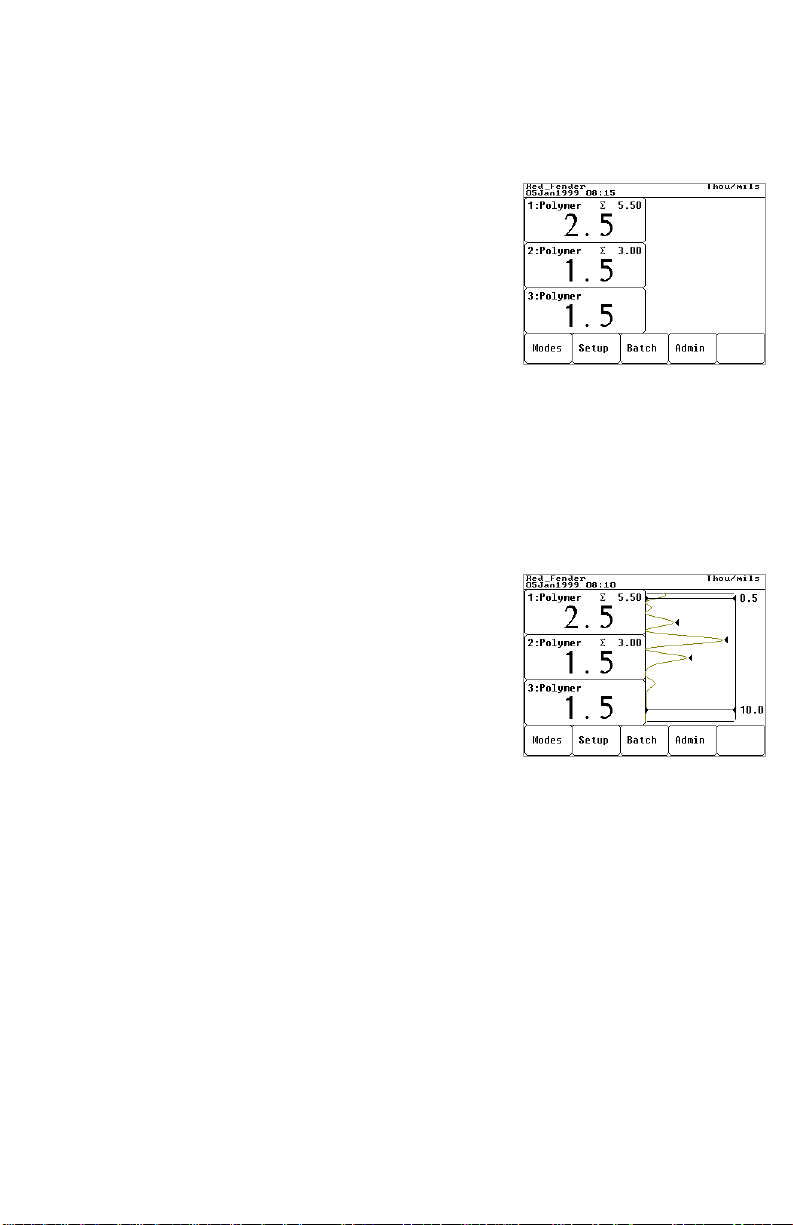

Measurements Area

The left hand side of the screen displays up to five (5) individual coating layers

as set by the Setup qq Application Setup menu option (pg.19). Each layer

is described in its own box.

The number appearing in the top left of each box is

the layer number. The top box, layer 1, represents the

surface layer. The bottom box represents the layer

closest to the substrate. The coating name appears

beside the layer number.

The large number in the center of each box represents

the thickness of that coating layer in the measurement units shown in the Status

Bar. If GRAPHICS MODE is turned on, this value corresponds to the

appropriate triangle arrow.

The cumulative total of the individual layers is displayed in the top right of each

box as subtotaled from the bottom up. Therefore the ∑ value in the top box

represents the total coating thickness.

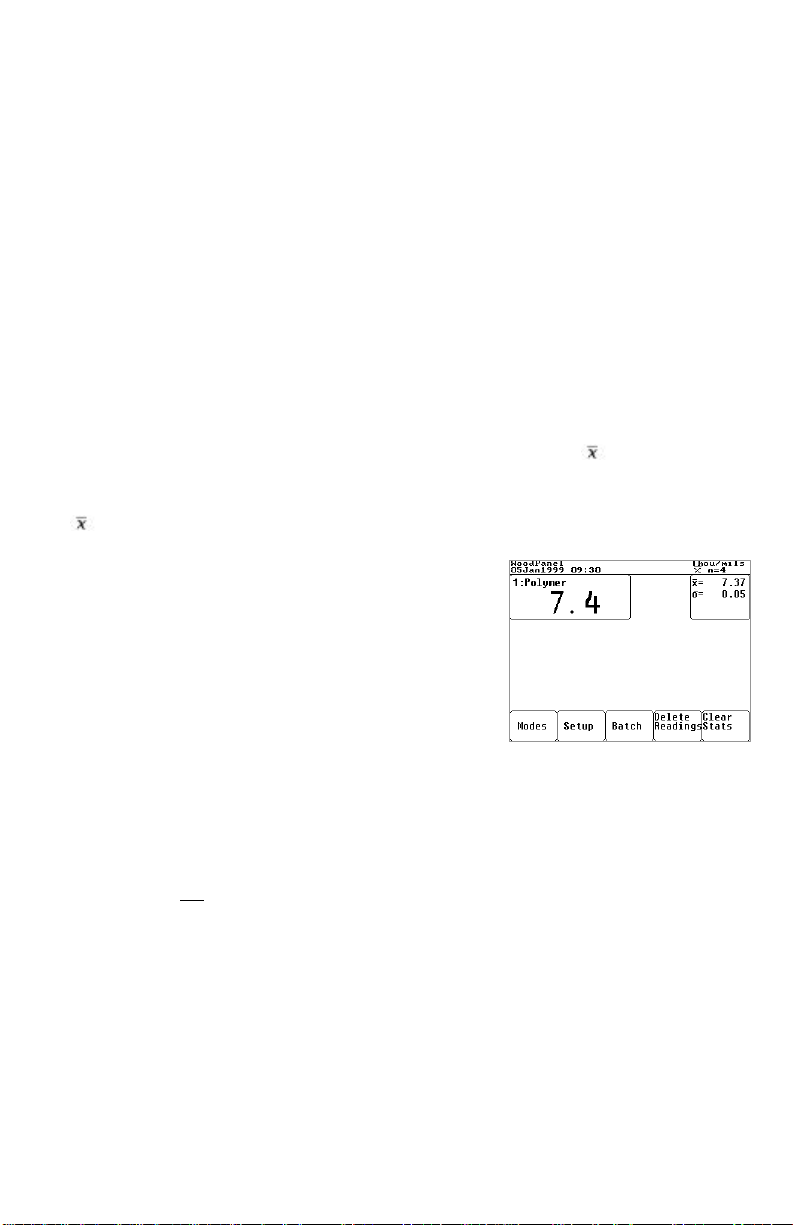

Graphics

The right hand side of the screen can be used to

display a graphical representation of the ultrasonic

echo as it passes through the coating system. It is

controlled by the Modes qq Graphics ON/OFF

menu option.

As the probe switch is depressed and the ultrasonic

pulse travels through the coating system, the pulse

encounters changes in density at the interfaces between coating layers and

between the coating and the substrate.

These interfaces are depicted by a “peak”. The greater the change in density the

higher the peak. The more gradual the change in density, the greater the width of

the peak. For example, two coatings layers made of essentially the same material

and “blended” would result in a low, wide peak. Two materials of very different

density and a well-defined interface would result in a high, narrow peak.

The Model 100 chooses the highest of peaks when trying to determine coating

layer thickness. If the number of layers is set to 3, for example, the 3 highest

peaks between the A & B Gates are selected as the interfaces between these

layers. The peaks that the Gage selected are indicated by black triangle arrows.

100 Series Page 11

Page 12

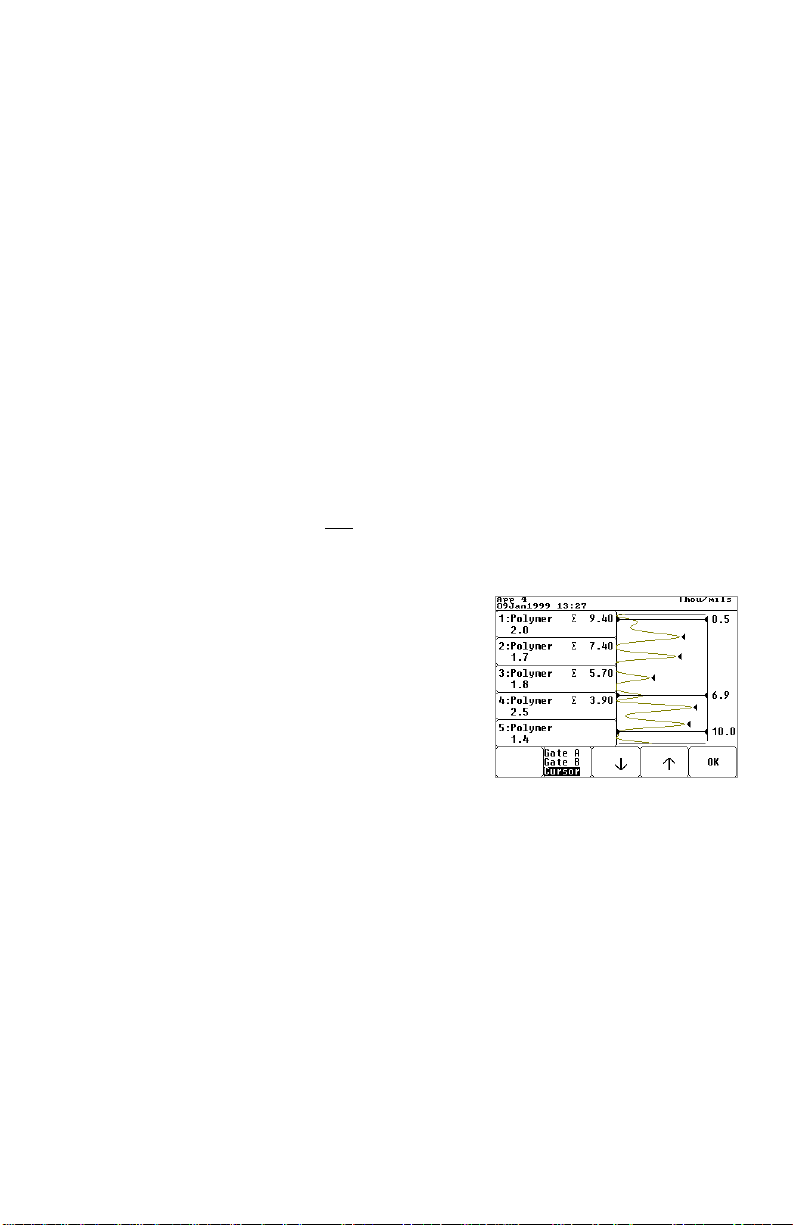

The top (A) and bottom (B) Gate values (pg.32) are displayed as two horizontal

lines at the top and bottom of the graphics area. Their current values are shown

to the right of each line. Gate A, the lower limit, is at the top. Gate B, the upper

limit, is at the bottom. Echoes or peaks (thickness values) outside these Gates

are ignored. GATE values are set and modified using the Setup qq

Application Setup menu option.

This GRAPHICS display can be manipulated with the Setup qq Gate/Zoom

Control menu option. In addition to being able to adjust the GATE values, a

CURSOR can be positioned anywhere between the two GATE values to

estimate other echo values.

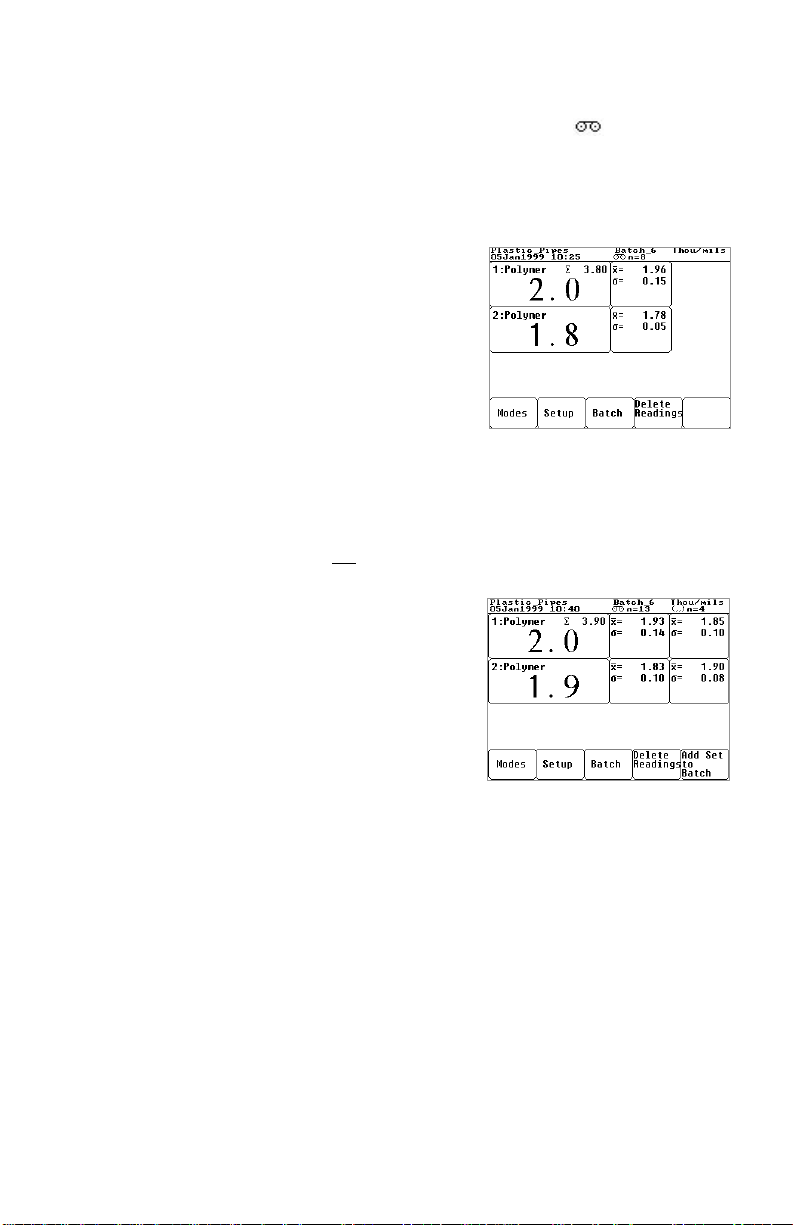

Statistics

When the Modes qq Statistics ON menu item is selected a symbol and a

counter (n=0) appear in the upper right of the display. If the graphics screen is

OFF a box will appear beside every layer box containing the average (mean)

and standard deviation σ values. If the graphics screen is ON statistics

calculations are done in the background.

As each measurement is taken, the readings are

displayed and the counter is increased. An incorrect

reading can be removed by selecting the Delete

Reading menu item before another reading is

taken.

Statistics calculations are erased by selecting

either the Reset Stats or the

Modes qq Statistics OFF menu items.

4 readings taken, last reading is 7.4 mils

Average=7.37mils. Standard Deviation is 0.05

If any layer contains a null result “- - - - -“ then the entire measurement attempt,

although displayed, is not included in the statistical calculations.

Readings are not stored in memory for later downloading.

Page 12 100 Series

Page 13

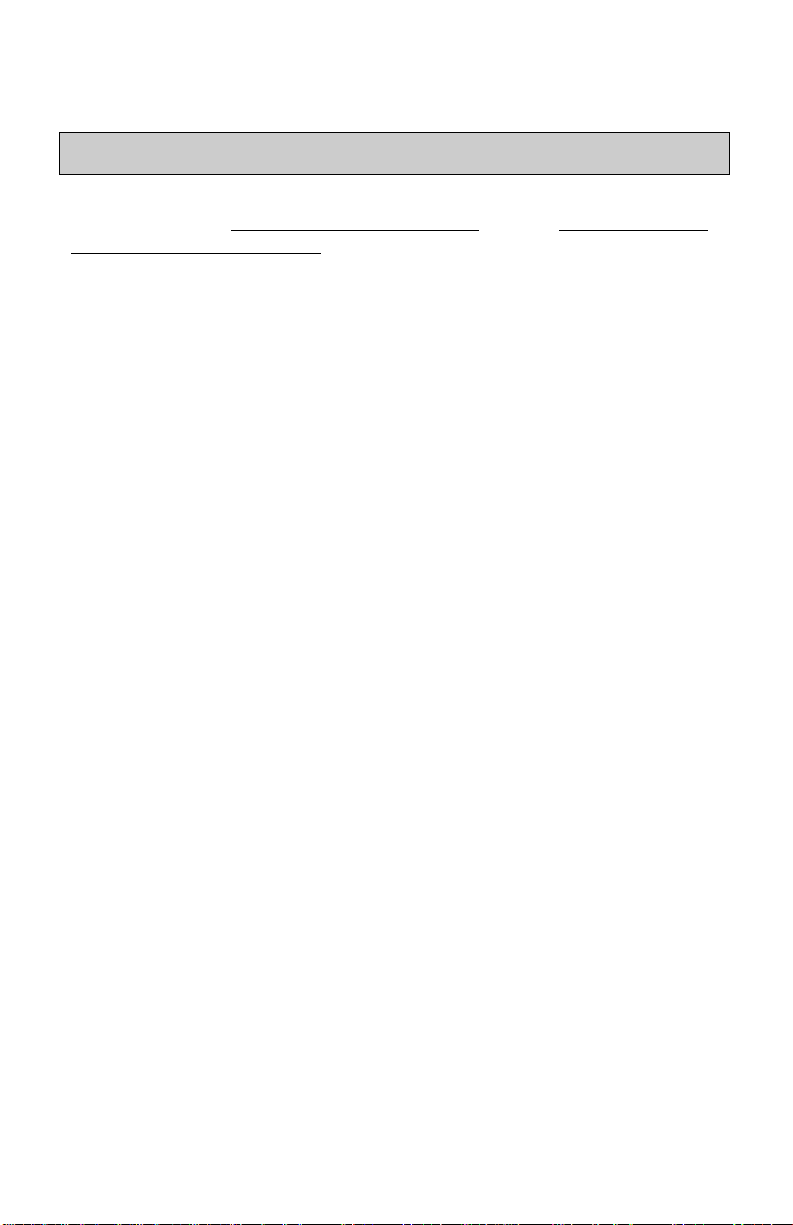

Memory

When the Modes qq Memory ON menu item is selected, a symbol and a

counter (n=0) appears in the upper center of the display. If the graphics screen is

OFF a box will appear beside every layer box containing the average (mean) χ

and standard deviation σ values. If the graphics screen is ON statistics

calculations are done in the background and results are still stored into memory.

As each measurement is taken, the readings are

displayed and the counter is increased. An

incorrect or unwanted reading can be removed

by selecting the Delete Reading menu item

before another reading is taken.

If any layer contains a null result “- - - - -“ then

the entire measurement attempt, although

displayed, is not included in the statistical

calculations and not stored into memory.

This mode is very similar to Statistics mode

8 readings are stored in the application

called Plastic_Pipes. Average of –1st coat

is 1.96mils -2nd coat is 1.78 mils. Total

coating thickness of the last reading is

3.80 mils.

except that measurement results are stored in memory for later downloading.

Sets

The Modes qq Sets ON/OFF menu item is

only visible when Memory mode is ON.

When both Memory and Sets modes are ON

individual measurements ARE NOT STORED.

Instead when the Add Set to Batch menu

item is selected the average, standard deviation

and number of readings are stored in memory.

The memory counter. will be incremented by

one and the sets counter will be reset to 0.

Statistical summaries are calculated for each

batch during printing. This delivers the

13 sets are stored in the application called

Plastic_Pipes. These sets contain only average

and standard deviation values. The average

thickness of coating1 is 1.93 mils. This

represents the average of 13 average values.

Four readings are in the current set which has

not yet been added to the application.

average of a set of average readings as

required by SSPC PA-2 guidelines.

100 Series Page 13

Page 14

Operation Overview

The Model 100 is an ultrasonic coating thickness Gage. As such it shares

characteristics with ultrasonic wall thickness gages and with magnetic and eddy

current coating thickness gages.

Like ultrasonic wall thickness gages, the Model 100 uses a transducer in the

probe to send pulses into the material to be measured and then measures the time

taken by that pulse to return to the probe tip. But unlike an ultrasonic wall

thickness gage the Model 100 is intended not to measure the total thickness of

the part but rather only the surface coating thicknesses. Thickness measurements

are therefore much smaller than those measured by ultrasonic wall thickness

gages. Secondly, the Model 100’s graphical representation of the echo returns

should not be confused with “A” scans presented by some wall thickness gages.

Like magnetic and eddy current coating thickness gages, the Model 100

measures the thickness of applied coatings. Where magnetic and eddy current

coating thickness gages measure the thickness of coatings over metal, the Model

100 is primarily intended to measure the thickness of coatings over non-metals.

It also has the additional capability of being able to measure the individual layer

thickness in a multi-layer coating system during a single measurement attempt.

Another difference: While the substrate plays a major roll in the operating

performance of magnetic and eddy current coating thickness gages, the coating

plays a relatively small roll. The opposite is true with the Model 100 because the

coating is the most important consideration when using the Gage and the

substrate is of relatively minor consequence.

It is always a good idea to verify that the Model 100 is operating properly before

measuring your application. This check makes sure the Gage has not been

damaged or altered in some way, perhaps by a previous user. There are a

number of ways to do this depending upon your requirements.

• calibration ensures measurements are traceable to a national standard

(pg.24)

• measure check standards at your work site (pg.44)

• measure a known thickness of previously measured material

• measure the included plastic shims (pg.28)

Before beginning any job be sure to check the settings found in Setup qq

Application Setup (pg.19) and alter them as necessary.

Page 14 100 Series

Page 15

Once you have checked Gage operation on a known thickness of material and

have modified current Application settings to most closely match your

coating/substrate combination you are ready to measure. Be sure to apply

sufficient couplant to fill voids in the surface and to fully wet the probe tip.

Multiple measurements in the same location may require additional couplant

every so often. Hold the probe steady when measuring and release the probe

switch after hearing the double BEEP. Leaving the Graphics Mode turned on

helps you to understand what the Gage sees and how it arrived at a thickness

measurement.

Never rely on a single measurement. It is important that several measurements

be consistent and repeatable, or as repeatable as your application will allow. If

the coating or substrate is rough or curved, use Statistics Mode to determine the

average of a series of readings. Comparing a series of averaged results will often

provide acceptable repeatability where individual readings might not.

Don’t be too quick to adjust a displayed reading to reflect what you believe the

coating thickness to be. Even though another measurement method might report

a different thickness, it is better to leave the Gage at its default settings and

evaluate repeatability first. The last step in any measurement application is

optimization using the Setup qq Adjust Reading / Adjust Velocity

menu option.

Whenever you run into difficulty, be sure to stop and

measure your Check standards, the plastic shims or

some other part you previously had success measuring.

Once you have made sure you are operating the Gage

correctly and that it is performing properly, return to

your application. Verify the settings found in Setup

Application Setup. Then select Setup qq

Gate/Zoom Control and, between

measurements, change Gate A and B values to observe

the reflected echoes. Use the cursor to measure peaks

not measured by the Gage (measured peaks have a

black triangle beside them).

Gage is set to its maximum 5 coats. The

5 largest peaks are displayed on the

left. However a 6th layer interface exists

at 6.9 mils (from the surface) as

measured by the CURSOR.

To measure properly, the ultrasonic echo must pass completely through the coating(s),

reflect off an acoustically dissimilar material such as the substrate or other coatings, and then

return unimpeded to the probe tip. Sometimes the coating is not homogeneous; it contains

solids or uncured sections that dampen or deflect the echo. Sometimes the interface between

coatings and the substrate is not distinct; the two materials have blended to create a

“transition” layer. Also the material may either be too thin or acoustically too thick or

attenuative to measure with an ultrasonic technique.

100 Series Page 15

Page 16

A visual inspection, such as that obtained by microscopically viewing a crosssectional cut of the material, often reveals useful information about your

application. It may also explain why the Gage behaves the way it does when

measuring your part.

Finally, you are always welcome to contact us at techsale@defelsko.com with

your inquiries. Be sure to include as much information about your application

and about the results obtained from known samples such as the plastic shims as

well as from the unknown material you are trying to measure. Provide us with

the Gage serial number and details about the material you are measuring and the

size and shape of the part. If all else fails you are welcome to send us a sample

of your application for measurement by our lab technicians.

Theory of Operation

The Model 100 uses an ultrasonic pulse echo principle. By transmitting an

ultrasonic pulse into the coating/substrate specimen and determining the time

taken for the pulse to travel to the coating/substrate interface and back to the

transducer, a coating thickness can be calculated.

Layer 1 is 2.5 mils thick. Layer 2 is 1.5 mils thick.

Layer 3 is 1.5 mils thick. Total thickness is 5.5 mils.

The most distinct interface is between layers 2 & 3.

The Gage transmits a high frequency, ultrasonic vibration into the coating using

a single element transducer. The vibration travels through the coating material

until a material with different mechanical properties is encountered, typically the

substrate. The vibration will be partially reflected and transmitted at the

interface between the dissimilar materials. The reflection will propagate back

through the coating and will be detected by the transducer. The transmitted

vibration will continue to travel into the substrate material and will also

experience reflections and transmissions at any material interfaces that are

encountered.

The transducer converts the reflections into an electrical signal which the Gage

digitizes. The digitized echo wave form is then analyzed to determine the exact

propagation time of the vibration.

Page 16 100 Series

Page 17

Since a potentially large number of echoes could occur, the Gage will choose the

strongest echo for use in coating thickness measurements. The assumption is

that the coating/substrate interface will provide the largest distance corrected

echo within the bracketed echo window (as defined by Gates A and B). The

coating thickness is calculated from the measured propagation time and the

velocity of propagation (sound velocity constant, vs) of the coating material. The

velocity of propagation is determined during optimization of the Gage against a

known coating thickness standard (pg.26).

The Model 100 uses deconvolution techniques to filter and enhance closely

spaced digitized echoes. These techniques make it possible to measure thin

coatings and coatings on acoustically similar substrates.

A menu is provided that allows an operator to select from a number of preconfigured coating and substrate classes. Using these class selections, the Model

100 can quickly be optimized to different coating/substrate combinations.

Couplant

Unless the coating is soft, couplant is required by the probe to transmit the

ultrasonic pulse into the coating. Water is an ideal couplant for smooth coatings.

Use the supplied glycol gel for rougher coatings. While it is unlikely that the

couplant will damage the finish or leave a stain on the surface, we suggest

testing the surface by using the couplant on a sample. If testing indicates that

staining has occurred, a small amount of water can be used instead of the

couplant. Consult the enclosed Material Safety Data Sheet and your coating

supplier if you suspect the couplant may damage the coating. Other liquids such

as liquid soap may also be used.

Power-up / Power-down

When any of the LCD buttons is depressed the Model 100 powers-up, performs

a self test and displays the last measurement(s). It then waits for the probe

switch to indicate the beginning of a measurement cycle. To preserve battery life

the Gage automatically powers-down after 2 minutes of inactivity when

operating on battery power or 8 minutes when operating off the optional AC

adapter (pg.35). There is no OFF button. All settings and readings are

maintained during power-down including the last measurement.

100 Series Page 17

Page 18

How to take a measurement

Apply a sufficient amount of couplant to the surface of your part.

After power-up, place the probe FLAT on the surface. Depress the probe switch

and hold the probe steady. While measuring, a “ticking” clock ∅ may

momentarily appear in the top status bar. The time required to take a reading

will vary. When measuring a new application for the first time the Gage may

take up to 5 seconds to acquire a reading. Subsequent readings are faster.

Release the switch when you hear a

double BEEP or see the green light blink.

Measurement results are displayed 1

second later.

A second reading may be taken in the

same spot by simply pressing the probe

switch again, or the probe can be lifted to

a new location before pressing the probe

switch.

During a measurement cycle the probe is excited and a thickness measurement is

derived. The result is simultaneously displayed on the LCD and transmitted out

the RS232 serial port.

When completely finished, wipe the probe clean of couplant and return both

Gage and probe to the protective case. There is no need to disconnect the probe

from the Gage during storage.

There is no “off” switch. The Gage will shut itself off and retain all stored

settings and readings.

Page 18 100 Series

Page 19

Applications

The Model 100 has the unique ability to store various settings for individual jobs

or coating thickness applications. For each, the user may choose to specify:

• the name of the application (memory option only)

• the type of substrate

• the type of coating

• the number of coating layers

• a special optimization setting for each layer

(sound velocity constant)

• Gate A & B settings

• the name of the user, part and batch (memory

option only)

Setting up and specifying applications enables the operator to easily switch

between parts, jobs, work sites and contracts for multiple products and

customers without the need for repeating the setup for each. These unique

“configurations” are stored as applications and can be recalled at any time.

Memory models store measurements in these applications as well.

One default application “App 1”comes preloaded in each Gage and cannot be

deleted. It is restored and reset to factory settings if a Gage INITIALIZATION

is performed (pg.31).

One application must be open at all times, but only one. When the Gage is new

or has been recently initialized, “App 1” is open. To create a new application

the user makes a copy of an existing one, then modifies the “copy”.

Applications are created and edited using the Setup qq Application Setup

menu item. On Gages with the Memory option, existing application names can

also be edited using PosiSoft (pg.34).

When the Setup qq Application Setup menu item is selected, the right

side of the LCD shows a list box of existing applications for the currently

connected probe only. Details on the highlighted application appear on the left

side of the LCD.

100 Series Page 19

Page 20

Select an Existing Application

Use the ↓ ↑ buttons located below the list box to move the highlighter to your

choice. Notice that details on the currently highlighted application appear

immediately in the left side of the LCD. Only applications created for the

currently connected probe are visible. Select the Setup qq Application

Setup qq Select an App menu item. Press the OK button to complete the

selection process. The application is now open to accept changes or stored

readings (memory option only). The name of the current application is listed in

the status bar at the top of the LCD. Memory mode must be turned off before

selecting a new application.

Edit Application Settings

Use the ↓ button located below the application details to move the highlighter to

the setting you wish to change. Some settings cannot be changed once readings

have been recorded in that application.

Create a New Application

New applications are created by simply making a copy of an existing application. First,

select an existing application as described above. Then choose Create a new App. A

new application name with a sequentially higher number will appear in the application list

box. The original application, however, remains as the current, open application.

For example: Four applications exist called App1, App3, App4 & App5. App2 was

previously deleted. App4 is current. When the Create a new App menu choice is

selected, App6 will be created with App4’s settings and App4 will remain current.

A new application is automatically created when a new probe is attached.

Delete an Existing Application

Select the Setup qq Application Setup qq Delete an App menu item.

Use the ↓ ↑ buttons located below the list box to move the highlighter to your

choice. Notice that details on the currently highlighted application appear

immediately in the left side of the LCD. Also note that all applications for all

probes are displayed.

Press the OK button to delete the highlighted application. All stored

measurements, names and settings are deleted and the application name is

removed from the list box. Once deleted this information cannot be recovered.

To exit the delete routine without making any deletion, select <none> from the

application list box and then press the OK button.

Page 20 100 Series

Page 21

Recording and Downloading Measurements

(available only on Gages with the Memory option)

The Model 100 can store measurement results for later downloading to a printer,

datacollector or PC. These values are stored in the currently selected application,

grouped by batch (file). These batches are unique to an individual application

and an application can have many batches.

Creating Batches

• To begin recording measurements into a new file choose the

Batch qq Create New menu option.

• To begin recording measurements into an existing file choose the

Batch qq Select menu option.

• To stop or resume recording, select the Modes qq Memory ON/OFF

menu option

The following symbols appear in the LCD status bar when recording is in

progress:

In this example, Batch_3 has been created but there are currently no recorded

measurements in that batch. The counter (n=0) is incremented every time a new

measurement or average value from a “set” is added to the batch.

New batch names are created sequentially regardless of application. If a batch

name is deleted it is not re-created. This sequencing is only restarted when the

Gage is INITIALIZED (pg.31).

Annotating Batches

Part and user names can be attached to batches.

These names are selected from list boxes created

on a PC using the supplied PosiSoft software

(pg.34) and uploaded into the Gage. These names

appear on printouts and with downloaded

measurements. There are no functions such as

sorting applied to these names. They serve only to

provide additional information and organization.

100 Series Page 21

Page 22

Viewing and Editing Batches

The Batch qq View/Edit screen not only allows the user to view stored

readings but also to delete and modify those readings. It also allows new

measurements to be added without having to return to the main screen.

To delete an existing measurement use the

↓ ↑ buttons to move the highlighter to your

choice and press the Delete key. Notice

that all layers in a multiple layer

measurement are deleted.

Deleted readings can not be recovered,

however they are not actually erased.

They are simply “flagged” as deleted

and can be viewed when downloaded

with PosiSoft. Deleted readings are not

included in statistical calculations.

Note that readings deleted with the

Delete Reading key on the main

screen are completely erased (pg.13).

Existing readings can be changed by

positioning the highlight bar over them and taking another measurement. The

new “modified” result is inserted in its place and identified with the letter “m”.

R = reading. C = coating layer number

Only the second (bottom) layer measurement of 2.1

mils is visible for the 1st reading. The 2nd reading has

an “m” beside it to indicate that the highlight bar

was positioned over it and another reading taken.

The 3rd reading has an “s” to indicate it is the

average result of a “set” of readings. The 4th reading

has been deleted. The highlight bar has been

positioned into the next available field to accept a

new measurement. The average of three layer1

readings is 7.67 mils.

Readings that are the calculated average of a “set” of readings (pg.13) are

identified with a letter “s”.

Additional measurement results can be added to the batch without affecting

existing stored readings by positioning the highlight bar at the bottom of the list

at the next available position (see illustration above) and taking a reading with

the probe.

Page 22 100 Series

Page 23

Charting Batches

The contents of the current batch can be viewed in graphical format by selecting

the Batch qq Chart menu item. A line chart or histogram is available for a

single layer or for all coats.

The batch name is “LabSample”. The application

“PlasticFender” is set to measure two layers. Ten

readings were taken but two were deleted.

Printing

Stored measurements (from one “application” at a time) can be sent formatted to

an infra-red or serial printer and can be captured by a Windows program such as

Windows HyperTerminal or MacTerminal. Measurements are not erased from

memory after being downloaded.

Choose the Batch qq Print menu item and select

the batch names you wish to group into a printout.

Press OK and then select a printer option.

1. Select the IR Printer option to print to the

Hewlett-Packard infra-red printer available

from your dealer. This portable, batteryoperated printer operates without wires, cables or connectors and is handy

for generating rapid, on-site printouts of stored measurements. Turn the

printer on and align it so that the Model 100’s red IR port is pointed at the

printer’s IR port at a distance of 6 inches (25cm) or less.

2. Select the Serial Printer option to print to any serial printer connected to

the Gage using the supplied RS232 cable.

A sample printout can be found in Appendix B. Graphics are

not printed

100 Series Page 23

Page 24

Calibration and Optimization

The Model 100 is factory aligned and does a self check each time it takes a

measurement. Periodically calibrate the Gage against known thickness

calibration standards to verify correct operation and determine if the Gage is

within tolerance.

Calibrate

⇒

Optimize

⇒

Measure

Overview

The operation of an ultrasonic coating thickness Gage is based on the transit time of

an ultrasonic pulse through a coating. The Gage measures this time and multiplies it

by a sound velocity constant for the type of coating material being measured. The

resulting value is displayed on the LCD as thickness.

To obtain optimum accuracy it is necessary to use the correct sound velocity

constant for the material being measured. The Model 100 has internally stored

constants that are set at the factory using NIST or NPL traceable reference materials.

To verify that the Gage is operating correctly make measurements of standards that

have a known thickness and are made of a material with a known sound velocity

constant. This allows you to verify that the Gage can measure accurately.

Calibration is the act of measuring known Thickness Calibration Standards and

verifying that the results are within the tolerance of the Gage. The Gage is calibrated

using the specific sound velocity constant for the reference standard material.

The actual sound velocity in materials often varies significantly from the values

found in published tables. A selection of coatings and substrates are programmed in

at the factory. At times it may be necessary to optimize the Gage to the material

being measured.

Optimization is the act of changing the Gage’s thickness reading or sound velocity

constant to match that of a known sample to compensate for the different velocity of

sound of the material being measured. Optimization does not effect the Calibration

of the Gage.

The Model 100 has an optimization mode (Optimize Reading) to allow for

matching the sound velocity constant used in the Gage to that of the actual material

being measured. To accomplish this, a measurement is made of a known thickness

of the material and the display is adjusted to the correct thickness reading. If a

known thickness is not available, factory settings can be used.

Page 24 100 Series

Page 25

The need to optimize is dependent upon a number of factors. If you are using

standard materials in your coatings and can select from the menu there is

probably no reason to optimize the Gage. On the other hand, if you need very

accurate measurements and are using non-standard materials it is suggested that

you optimize the Gage to your coating material prior to making actual

measurements.

Check standards may be made following the instructions given in Appendix A.

If you already have samples with a known thickness of your coating material

you may optimize the Gage to them. Review the material in Appendix A to

determine if your sample was measured to a sufficient accuracy for valid

optimizations.

Calibration

To calibrate the Model 100 you must have a set of Thickness Calibration

Standards. These Standards should have 3 to 5 values that cover the full range of

the probe being used. These standards must have been measured to an accuracy

that is four times or better than the accuracy of the Gage at the thickness being

measured. For example if the Gage has an accuracy at the measurement point of

±2 microns then the standards have to have been calibrated or verified to an

accuracy of better than or equal to ± 0.5 micron. Thickness Calibration

Standards are available from your dealer for each of the Model 100 probes. They

come complete with a certificate of calibration showing traceability to NIST.

Once you have Thickness Calibration Standards you can calibrate the Gage. Be

sure to use the correct sound velocity constant. Make several readings from each

of the standards. If the average of the readings at each point is within the

tolerance for the Gage for that standard then the Gage is operating properly

within specifications and you are finished the calibration.

If the Gage is not within tolerance, first verify that your standards are good and

then repeat the measurements. If the Gage is still found to be out of tolerance

you may want to try a second set of standards. If after this step the Gage is still

reading out of tolerance you should return it for service. There are no user

alignments available.

EFFECTS OF TEMPERATURE

Variations in temperature change the sound velocity of materials and transducer

delay tips. If measurements will be made in extreme hot or cold temperatures,

prepare and measure your Check Standards (see Appendix A) in the working

environment. The Model 100 should then be optimized using these Check

Standards in the same environment.

100 Series Page 25

Page 26

CALIBRATION INTERVAL

Start with a recommended interval of one year and adjust that interval according

to your individual usage and environment.

Optimization

Thickness measurement error is minimized by ensuring that the Gage has the

correct velocity value for the particular coating system being measured. This is

done by following a 2-step procedure:

1. SELECT A CATEGORY

2. OPTIMIZE TO A KNOWN THICKNESS

Since actual sound velocity in materials often varies significantly from the

values found in published tables, optimization of the Model 100 for velocity is

made by measuring a known thickness of the particular material being measured

and adjusting the displayed result to the actual, known thickness. If a known

thickness is not available, factory settings alone can be used.

The need to optimize is dependant upon a number of factors, not the least of

which is the level of accuracy required. To measure thin coatings for which a

high degree of accuracy is required, such as lacquer on wood with a B probe, for

example, the user may decide that optimization is needed. To measure thick,

rough coatings for which fine accuracy is not critical such as epoxy on concrete

with a C probe, the user may decide that only Step 1 (selection of a category) is

needed. To measure paint on plastic with a B probe and have traceability to a

standard, Steps 1 and 2 must both be performed.

When an adjustment is made to the sound velocity constant, the upper and lower

measuring limits of the probe change. A fast velocity value, such as for metal,

raises both the thinnest and thickest measuring limits of the probe. A slower

velocity value, such as for rubber, lowers both the thinnest and thickest

measuring limits of the probe. Table 4 on page 41 gives some examples.

STEP 1: SELECT A “CATEGORY”

Probes for the Model 100 come pre-adjusted for a variety of coating and

substrate types, or categories.

When a coating category is selected from the Coating

List, a typical sound velocity constant for that

material is used by the Gage. The number of coating

categories available to choose from depends upon the

type of probe that is attached. B probes have only one

category, polymer. The C and D probes have several

categories including polymer, rubber, glass and

metal.

Page 26 100 Series

Page 27

Since the substrate can often affect the return echo, all probes also provide the

user with a selection of substrate categories including concrete, wood, glass,

plastic, metal, ceramic and none to further refine the optimization.

To select these categories choose the Setup

Application Setup menu item. Use the ↓ button

to move the highlighter down to the Substrate:

line. A substrate list box will appear containing the

currently available list of substrates. Use the ↓ ↑

buttons located below the list box to move the

highlighter to your choice.

Now use the leftmost the ↓ button again to move the highlighter down to the

next line Coat 1:Polymer. A coating list box will appear containing the

currently available list of coatings. Use the ↓ ↑ buttons located below the list

box to move the highlighter to your choice. Repeat for each coating layer.

STEP 2: OPTIMIZE TO A KNOWN THICKNESS

It is recommended that a known thickness of your coating be measured with the

Gage to verify the correct sound velocity constant is being used. Make sure your

coating sample is smooth. The thicker your coating “standard” the better. If you

do not have suitable check standards, see Appendix A for instructions in making

a set.

Once you have your Check Standards you are ready to optimize the Gage.

Determine the range of acceptable readings using the thickness value of the

check standard and the accuracy specification of the probe you are using.

Example: You are making a measurement of a check

standard that has been verified to be 20.0 mils

±0.1mils. The Model 100 has an accuracy of ±0.7

mils (±0.1mil + 3% of reading) at this point. The

average of several readings should fall between 19.3

mils and 20.7 mils (20.0 – 0.7 and 20.0 + 0.7 mils).

Note that the check standard has an accuracy of ±0.1

mils and the Gage an accuracy of ±0.7 mils. The

check standard is 7 times more accurate than the

Gage.

Select a coating from the menu that is close to your type of material. Take

several measurements on the check standard. If the average of the readings at

each point is within the tolerance for the Gage then the Gage is operating

properly within specifications and you do not need to optimize the Gage.

100 Series Page 27

Page 28

If the average is not within tolerance, optimize

the displayed value up(+)or down(-) to match

the check standard thickness using the Setup

– Adjust Reading menu option. Measure

and adjust until you are satisfied that the

average of a series of readings equals the check

standard thickness.

Optionally if you know or have previously

recorded a sound velocity constant for this

material it may be adjusted instead of the

thickness value. For example the value for

the polystyrene probe tip is 80 mils per

The thickness value was changed from 1.2 mils

to 1.4 mils. The sound velocity constant changed

from 86 to 100.81 mils/microsecond.

Notice the coating name automatically changed

from “Polymer” to “Polymer1”.

microsecond. The value for the epoxy

coated metal Calibration Standards (pg.35) is 101.56 mils/microsecond. The

value for steel is approximately 250 mils/microsecond.

The Gage is now optimized for your coating. The sound velocity constant for

your material is shown in the upper right corner of the layer box. Normally, the

optimization process does not have to be repeated unless the coating material

changes. However it is a good idea to periodically re-measure the "check

standard".

Plastic Shims

A variety of colored precision plastic shims are included. They provide a quick

operational check of the Gage and help insure the operator is using it properly

by enabling them to practice various measuring techniques. Plastic shims are not

always manufactured with the same material. Therefore it is not important that

the Gage measure their exact thickness, rather readings should be consistent.

To measure shim thickness:

• zero the probe using the Setup qq Zero Probe menu item (pg.29)

• select the default coating “polymer” from the Setup qq Application

Setup menu item (pg.19). Select a substrate category of “none”

• place a shim on any flat, hard surface. Apply couplant on top of the shim

and measure it.

Page 28 100 Series

Page 29

Advanced Features

Zeroing the Probe

The probe must be periodically zeroed using the Setup qq Zero Probe menu

item to compensate for both temperature and probe wear effects. (This is not to

be confused with measuring an uncoated substrate to get a 0.0 reading!) Allow

the probe to reach ambient temperature. Wipe the probe clean of gel.

Temperature changes directly affect Gage measurements by expanding

and contracting the probe’s plastic delay tip. Constant handling and measuring

on a hot surface, for example, will warm the probe. Storage in an outdoor winter

environment will cool and contract the probe tip. The B probe compensates for

temperature automatically during each measurement. But the C and D probes

must be manually compensated using the Setup qq Zero Probe menu item.

This menu item should be selected every hour of measurement for the C and D

probes to compensate for temperature; more often in a changing temperature

environment or when first beginning to measure after an extended power-down.

Probe wear also directly affects Gage measurements but usually in a

less dramatic fashion. Compensation must be made manually for all probes

using the Setup qq Zero Probe menu item. This menu item should be

selected at the beginning of each day to compensate for wear; more often when

measuring on rough coatings.

Occasionally, the message “Probe must be zeroed” will appear when a

new probe is connected or when probe calibration data is lost such as when

“INITIALIZING” the Gage (below).

100 Series Page 29

Page 30

Restarting the Gage

As with any electronic device, harsh temperature, electromagnetic environments

or rough handling may alter the performance of some Gage components causing

the Gage to exhibit unusual behavior.

Two features enable the Gage to recover from many of these disturbances

without the necessity of returning the Gage for service: RESET and

INITIALIZATION. These actions help overcome a lock-up condition or other

erratic Gage behavior. They also help prevent costly service delays.

GAGE RESET

This is a non-destructive action. It simply restarts the internal software program

and does not affect any stored user settings or data.

A Gage RESET is activated by pressing the RESET button (pg.9) on the topside

of the Gage. Use a pen tip or other similar object to push this recessed switch at

any point in the Gage operation. If the Gage is powered-up it will immediately

power-down. If the Gage is powered-down when the switch is pushed it will

stay powered-down. The RESET action occurs when the Gage is next poweredup.

When selected:

• names and settings created by the user for unique coating applications are

not lost

• for Gages with the Memory option, stored measurements and downloaded

user configurations/lists are not lost.

If the RESET is successful, the Gage display should return to the point it left off

when the RESET button was pressed. However, if the RESET was performed to

clear an unusual Gage condition, it is recommended that the Gage be

INITIALIZED at the earliest opportunity.

If the RESET is unsuccessful in restarting normal Gage operations, INITIALIZE

the Gage as described below.

Page 30 100 Series

Page 31

GAGE INITIALIZATION

This is a destructive action. It not only restarts the internal software program,

but it also erases all stored user settings or data and returns the Gage to a known

out-of-the-box condition.

This action:

• performs a Gage RESET as described above

• erases all readings in memory

• erases all stored probe information

• erases all user created or downloaded configurations and list boxes

• turns off Memory, Statistics and Graphics modes

• begins application and batch names at number 1

• erases all applications and restores default App1 (1 coat of “polymer” on

substrate “none”)

• is handy when uncertain what previous changes have been made to the

Gage such as when beginning a new job or taking possession of the Gage

from a previous owner/operator

NOTE: For Gages with the Memory option, stored measurements and

downloaded user configurations/lists are deleted during this

operation. If the user wishes to keep these values, they should

first be downloaded by PosiSoft onto a computer. List box

contents can be re-loaded into the Gage after the

“Initialization” has been successfully performed.

There are two ways to INITIALIZE the Gage. The first is by selecting the

Admin qq Initialize Gage menu item. The second method is to first press

the RESET button and then power-up the Gage by simultaneously pressing and

holding the left-most AND right-most buttons until a BEEP is heard.

100 Series Page 31

Page 32

Gates A & B

Each probe has a measuring range as shown in the chart on page 41. For

example, the C probe can measure polymer coatings in the range of

approximately 2 to 175 mils (50 to 4500 microns). However, there are times

when it is not desired to inspect this full range of thickness.

Gates are used to narrow the range of thickness that the Gage examines. Gate A

sets the minimum thickness limit and Gate B the maximum. These values are

adjusted to:

• increase the resolution of the graphical display

• make the Gage ignore echoes from other sources such as surface echoes and

echoes from within the substrate

• improve the resolution of the displayed measurement results

• reduce the likelihood of the Gage registering other than what the user

intended to measure

There are two ways to adjust the Gates. If the Graphics display is visible, use the

Setup qq Gate/Zoom Control menu item to change the scale of the

display. If the Graphics display is OFF, use the Setup qq Application

Setup menu item to simply adjust their values.

When measuring, the Gage looks for a distinct interface within the two Gate

settings. If the actual thickness is outside this range, incorrect or dashed readings

occur.

Gate A should be high enough to prevent the Gage from reading surface

roughness. Unusually thin readings indicate that the Gate A value may be set too

low.

Gate B should be low enough to prevent total thickness measurements of both

the coating and substrate. If results are twice the expected thickness, lower the

value of Gate B.

Here are some typical setups...

Expected paint thickness Gate A Gate B

20 mils (500µm) on concrete 5 mils 150µm 40 mils 1000µm

2 mils (50µm) on wood 0.5 mils 13µm 10 mils 250µm

Page 32 100 Series

Page 33

Measurement Units

The currently selected units of measurement are displayed in the top right corner

of the LCD status bar. This can be changed from inch to metric or vice versa

using the Admin qq Microns Thou/mils menu item. The displayed

reading(s) and all stored readings are converted.

System Clock

(available only on Gages with the Memory option)

The Model 100 records the date and time as each measurement is stored. This

information is downloaded along with the measurement information. The

current date and time is displayed in the status bar at the top of the LCD and can

be changed using the Admin qq Set Clock menu item.

Language Option

The Model 100 has the ability to display in a variety of languages. Use the

Admin qq Select Language menu item to select your choice. Screen space

limitations have forced some shortening of words. Obscure terms have been left

in English.

100 Series Page 33

Page 34

Communications – (memory option only)

Model 100 “memory” Gages can communicate with other devices such as PC’s,

serial printers and data collectors via either the built-in infra-red port or the

RS232 connector using the supplied serial cable.

Printing

Stored measurements (from one “application” at a time) can be sent formatted to

an infra-red or serial printer and can be captured on a computer using a COM

program such as Windows HyperTerminal or MacTerminal. Measurements are

not erased from memory after being downloaded. See page 23 for full details. A

sample printout can be found in Appendix B.

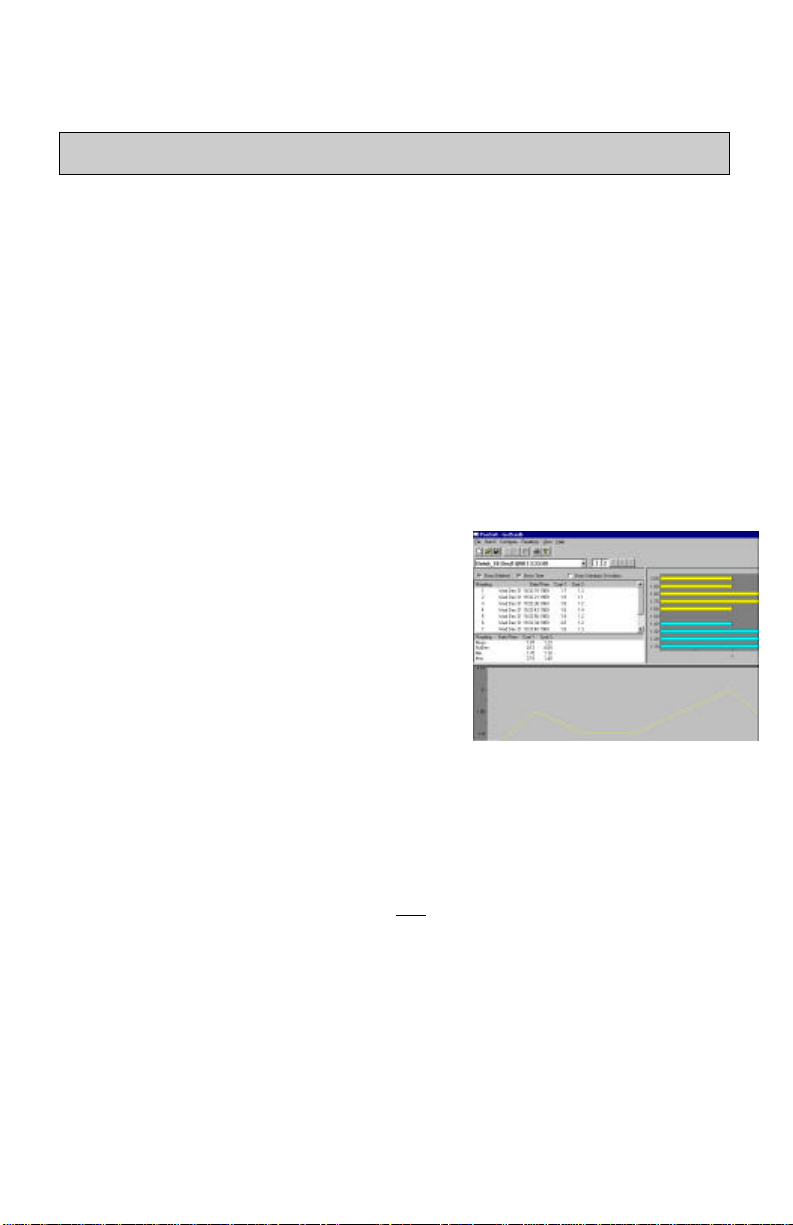

PosiSoft

PosiSoft ™ for Windows is supplied at no additional charge with all Gages with

the memory option. It runs on PC-type computers running Windows95, 98, NT

or higher version and having a COM port.

PosiSoft provides the user with a tool for

monitoring and analyzing a coating thickness

process. When Gage readings are downloaded

to PosiSoft, the results may be saved to

separate files for analysis. PosiSoft quickly

generates Histograms, Control Charts and a

Statistical Summary.

Full operating instructions can be accessed by first installing the software,

starting the program and then selecting the Help qq PosiSoft Help menu

option.

Downloading Measurements As They Are Taken

After each measurement cycle a thickness measurement is derived and the result

is simultaneously displayed on the LCD and transmitted from the RS232 serial

port at 9600 baud, 8 bits, nonparity, 1 stop bit. Output is in the following form

(example):

{STX}2,Polymer,•••••••2.5,Polymer,•••••••1.2,concrete,mils{CR}{LF} where:

STX = ASCII code 02 = ^B concrete = substrate category

2 = number of coats (layers) mils = units

Polymer = coating category CR = ASCII code 13 = ^M

• = space LF = ASCII code 10 = ^J

2.5 =thickness measurement for layer1

Page 34 100 Series

Page 35

Serial Communications Configuration

Existing communication software can be used, providing it can capture data

from a COM port. By selecting "PRINT ?" on the Gage MENU, your computer

will accept the measurements in the printer format.

8 bit words, no parity, 1 stop bit

9600 baud

XON-XOFF handshaking

The supplied serial cable is RJ45 to DB9 F

Pinout Description

2 TXD Transmit data (from Gage)

3 RXD Receive data (from PC or Printer)

5 GROUND

Available Options

Memory

This software feature enables the Gage to record measurements,

basic statistics and annotations by group. These values can be

downloaded to either a printer, data collector or computer.

Additionally, lists of user, part, application and batch names can

be uploaded into the Gage. PosiSoft software is supplied when

the Memory option is ordered.

HP IR Printer

A convenient, portable printer is available for use with Gages

having the Memory option. The Gage transmits data to this

battery operated printer through the infra-red port without

connectors or cables.

AC Adapter

Power normally comes from two ‘C’ alkaline batteries. An AC adapter is

available to supply continuous 7.5 volts DC power from an AC source. This is

handy when doing extensive testing in a lab environment where the Gage will

remain in one location. When the AC adapter is being used, the batteries should

remain in the Gage in case of a power interruption. Do not use any AC adapter

other than the approved model supplied by the manufacturer.

(Model SPU I5A-1-1)

Traceable Standards

Calibration standards are available for each particular probe.

(pg.24). They are ideal for ISO 9000 compliance and for

verifying the operation of your Gage.

100 Series Page 35

Page 36

Measuring Notes

Rough Substrates

In smooth coating/substrate conditions where there is a distinct interface, the

echo is clear and sharp. This results in a repeatable measurement with a sharp,

narrow peak on the graphical display. When the substrate has a surface

consisting of many peaks and valleys, numerous and varied echoes are received

from the interface.

In this occurrence, the Gage received the strongest echo from the

peaks and measured the coating thickness as 25.7 mils. The cursor

has been turned on and located over the 2nd attached peak to

estimate the coating thickness over the valleys as 28.4 mils.

The Model 100 tends to average these reflections and presents them graphically

as a wide peak. Although successive measurements are not repeatable, they

should be close, depending upon the amount of roughness. It is a good idea to

use a statistical average (Modes qq Statistics ON - pg.12) to determine

thickness. When peak and valley depths are consistent, sometimes a “shoulder”,

or attached peak, is visible. This secondary peak can be measured by positioning

the cursor (Setup qq Gate/Zoom Control - pg.32) over it.

Transition Layers

Some coatings “blend” into previous coats or into the substrate. This indistinct

interface produces an echo that is neither clear nor sharp. In these situations it is

difficult to obtain a repeatable measurement. The graphical display shows a

wide peak with a rounded top.

Page 36 100 Series

Page 37

Maintenance and Troubleshooting

Battery Management

The Model 100 obtains power from three potential sources:

• two 1.5v ‘C’ size Alkaline-Manganese Dioxide batteries. If they run low,

the Gage will save all user settings and readings, then power-down.

• an optional AC adapter (pg.35) supplying 7.5 volts DC power. While in use,

two alkaline batteries should remain in the Gage in case of a power

interruption.

• a lithium cell which provides approximately 30 minutes of back-up power

to retain all user settings and readings while the two “C” batteries are

removed. The Gage cannot be operated on this cell.

Power normally comes from the two ‘C’ alkaline batteries. As they become low,

a symbol will appear on the LCD. The Gage can still be used in this

condition but the batteries should be changed at the earliest opportunity. Always

change both batteries at the same time, never just one. Don’t mix old and new

batteries.

If you don’t change the batteries in time, the Gage turns itself off automatically

to save the information in its memory. You can turn the Gage back on once

you’ve replaced the batteries or plugged in the optional power adapter.

The lithium cell will last for more than 10 years of normal to heavy use. It

cannot be replaced by the user. It will retain all user settings and readings while

the Gage is powered-down for a 30 minute period to allow you to replace the old

‘C’ batteries with two new ones. This back-up power retains all user settings and

readings but is not sufficient to operate the Gage. If the 30 minute period is

exceeded, the Gage automatically cuts off power from the lithium cell and will

then experience a power failure. This is the equivalent of a Gage initialization

(pg.31) except that all stored calibration settings and downloaded user

configurations/lists are not lost.

Open the battery door by using your thumb and index finger to turn the door a

quarter turn to the left. Take note of the proper battery orientation when

replacing the batteries (see Gage backplate). If you install the batteries the

wrong way, the batteries may leak and damage the Gage. Leaking batteries may

be hazardous and any damage caused by leaking batteries is not covered by the

warranty.

USE ONLY 1.5v “C” ALKALINE BATTERIES

NOTE: Nickel-cadmium and nickel-metal hydride rechargeable batteries

will work however the low battery symbol may stay on.

100 Series Page 37

Page 38

Troubleshooting

Gage does not turn on

The Gage powers up but

fails to stay on

The screen appears too

light or too dark.

Gage does not yield

accurate or consistent

results

Batteries don’t last as

long as they used to.

Measurements are much

lower than expected

Measurements are much

higher than expected

Gate A and B cannot be

extended to maximum

Readings are not

repeatable (fluctuate)

• make sure each battery’s + and – terminals are

positioned properly and that the batteries are

fresh Alkaline ‘C’ cells

• make sure the probe connector is fully pushed in

• try adjusting the screen contrast

• press the RESET button

Replace batteries. If problem persists return Gage for

service

• adjust the contrast

• adjust your viewing angle

• adjust the surrounding lighting

• make sure the Gage is not too hot or too cold. It is

designed to be used in temperatures between 0

and +40C.

See the Calibration and Gate sections to ensure that

Gage is properly configured for your application.

Check the Gage on traceable standards.

The more you use the communication port for

downloading, the faster the batteries will loose power.

Extensive use of the menu system with the 5 LCD

buttons will also use more power.

Gage may be measuring surface roughness. Raise the

value of Gate A.

Gage may either "doubling" or measuring both

coating and substrate. Lower the value of Gate B.

The user may have optimized the Gage and changed

the sound velocity constants. See the Range and

Resolution Graph on pg.41 for range of each probe.

It is not unusual to get a variety of readings at the

same spot with any coating thickness gage particularly

if the substrate or coating surface is not completely

smooth. The Model 100 is also affected by surface

roughness. However fluctuations in the amount of

pressure applied and the amount of couplant used are

also a factor when measuring very thin coatings. As

long as these variations are within the tolerances of

the Gage there is no cause for concern. If you are

having problems, provide application details.

Page 38 100 Series

Page 39

Service

Before returning the Gage for service, attempt to clear the problem by…

• installing new, “C” alkaline batteries (pg.37), and

• performing a RESET (pg.30), and if still necessary

• performing a Gage INITIALIZATION (pg.31)

to restore factory settings and to return the Gage

to an “out-of-the-box” condition.

For service, ensure the following:

• return Gage, probe and all related material,

including samples if appropriate

• include company name, return address, contact

and fax number

• describe the problem as completely as possible

Specifications

Due to continuous process improvement, specifications are subject to change

without notice.

ASTM

The Model 100 conforms to ASTM D6132 – Standard Test Method for

Nondestructive Measurement of Dry Film Thickness of Applied Organic

Coatings Over Concrete Using an Ultrasonic Gage. The Scope of this Test

Method states, “This test method covers the use of ultrasonic film thickness

gages to measure accurately and nondestructively the dry film thickness of

organic coatings applied over a substrate of dissimilar material”. The Test

Method is available from ASTM in West Conshohocken, Pennsylvania, USA at