Page 1

Instruction Manual v.1.2

Shore Hardness Durometer

Page 2

Page 3

Do not place the indentor on hard materials such

as steel or glass. Doing so may damage the indentor and cause the

probe to read out of tolerance. Replace the rubber cap to protect the

indentor and presser foot when not in use.

Damage to the indentor caused by measuring on hard materials is

not covered by DeFelsko’s warranty.

1

Introduction

Introduction

The PosiTector Shore Hardness Durometer (SHD) is a hand-held

electronic instrument that measures the indentation hardness of

non-metallic materials. It consists of a PosiTector body (Standard or

Advanced) and an interchangeable probe (SHD-A or SHD-D).

This Quick Guide summarizes the basic functions of the gage.

Download the full instruction manual at www.defelsko.com/manuals

Quick Start

Quick Start

The PosiTector SHD powers-up when the center navigation

button is pressed. To preserve battery life, the Gage powers

down after approximately 5 minutes of no activity. All settings are

retained.

1. Remove the protective rubber cap from the probe.

2. Power-up the Gage by pressing the center navigation button .

Ensure the probe indentor (pg. 2) is not in contact with any

surface.

3. Measure

a) Press the probe down onto the material to be measured until the

presser foot is in full, flat contact with the surface. HOLD STEADY

against the surface.

b) The Gage will emit a single BEEP and display a ▼ symbol

indicating a reading is being taken. The test timer will begin

counting down (see Test Time, pg. 5). When the timer reaches 0s,

the Gage will BEEP twice and display the measurement value.

4. Lift the probe from the surface between readings.

IMPORTANT:

Verify accuracy (pg. 3) on test blocks at the beginning and the

end of each shift, or if the gage is dropped or suspected of giving

erroneous readings.

Page 4

2

Probes

Probes

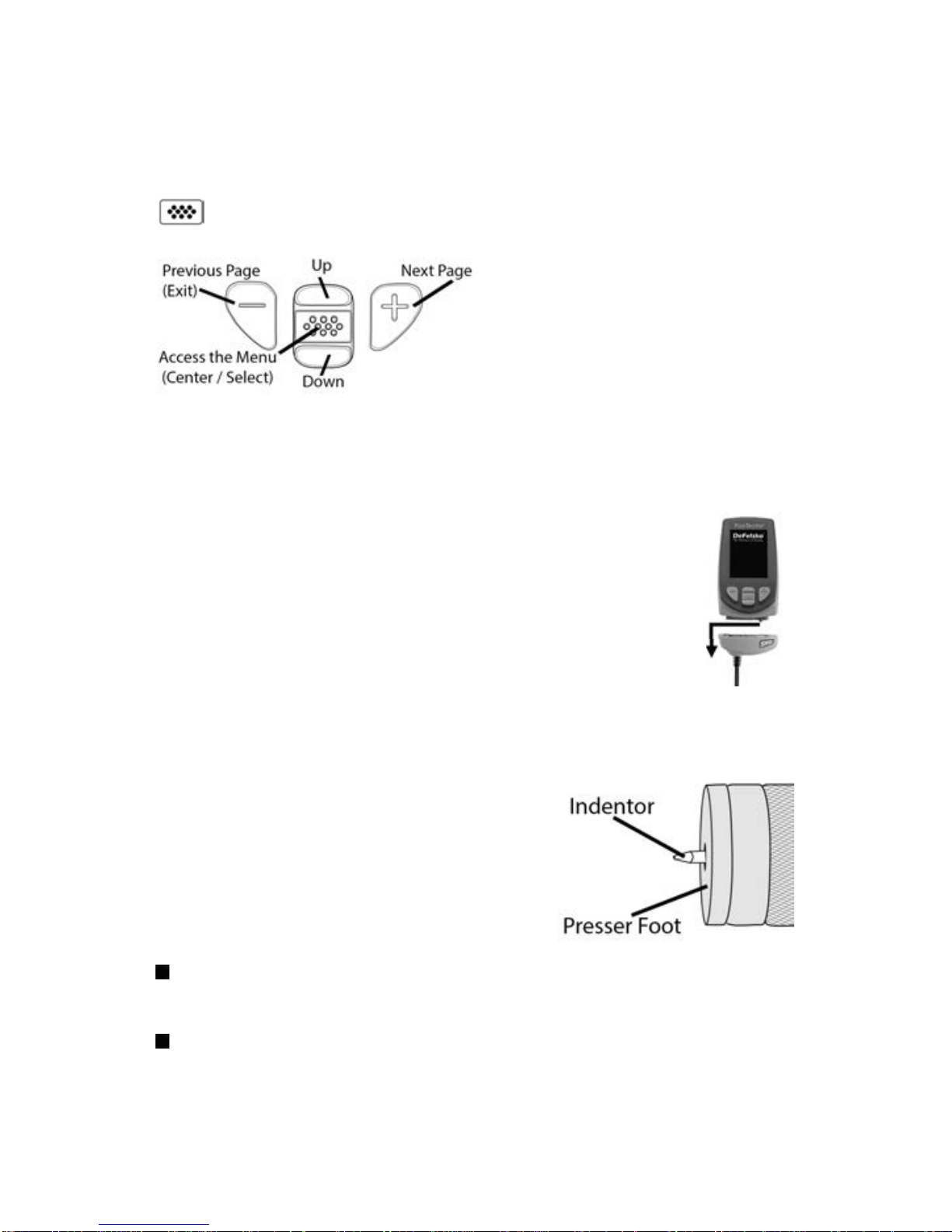

When powered-up, the PosiTector automatically determines which

probe is attached and does a self-check.

To disconnect a probe from a body, slide the plastic probe

connector horizontally (in the direction of the arrow) away

from the body. Reverse these steps to attach a different

probe. It is not necessary to power-down the Gage when

switching probes.

The PosiTector gage body accepts a wide variety of

probe types including magnetic, eddy-current and ultrasonic

coating thickness, surface profile, environmental, hardness,

salt contamination and ultrasonic wall thickness probes.

See www.defelsko.com/probes

The PosiTector SHD probe consists of

an indentor, calibrated spring and a

presser foot.

Two probe models are available for

measuring on a variety of materials:

PosiTector SHD-A (Shore A)

soft rubber, elastomers, neoprene, silicone, etc.

PosiTector SHD-D (Shore D)

hard rubber, epoxies, hard plastics, PVC, acrylic, etc.

To navigate, use the Up and Down buttons to scroll vertically and

to SELECT.

Press the (+) button to switch

pages in a multipage menu.

Press the (-) button to return to

the previous menu or page.

Select Exit to exit from any menu.

Menu Operation

Menu Operation

Gage functions are menu controlled. To access the Menu, power-up

the gage, then press the center navigation button.

Page 5

3

Calibration, Verification and Adjustment

Calibration, Verification and Adjustment

Three steps ensure best accuracy…

1. Calibration - typically performed by the manufacturer. All probes

include a Certificate of Calibration.

2. Verification of Accuracy - typically performed by the user on

known reference standards such as the included test block.

3. Adjustment - to a known hardness

Calibration

Calibration is the high-level, controlled and documented process of

measuring traceable calibration standards over the full operating

range of the probe, and verifying that the results are within the stated

accuracy of the probe. Calibrations are performed by the

manufacturer, their authorized agent, or by an accredited calibration

laboratory in a controlled environment using a documented process.

Verification

Verification is an accuracy check performed by the user on known

reference standards. A successful verification requires the Gage to

read within the combined accuracy of the probe and the test blocks.

Instrument operation may be verified with the included test block.

Place the test block on a flat, hard surface and take three to five

readings. The measurement points should be at least 6mm (0.24”)

apart. If the average of those readings is outside than the combined

accuracy of the test block and gage, the gage may require service.

Some causes for the gage to not read properly are the indentor

being damaged, incorrect pressure being applied to the test block or

temperatures beyond normal conditions.

Verify accuracy at the beginning and the end of each work shift.

During the work shift, if the Gage is dropped or suspected of giving

erroneous readings, its accuracy should be re-verified.

Adjustment

Adjustment, or Calibration Adjustment, is the act of aligning the

Gage’s readings to match that of a known reference in order to

improve accuracy of a gage on a specific material. (see 1 Pt Adjust,

pg. 4)

Page 6

Reset (menu reset) restores factory settings and returns the

Gage to a known condition. The following occurs:

- All batches, stored measurements, batch names and screen

captures are erased.

- Calibration adjustments are returned to factory settings.

- Menu settings are returned to the following:

Reset

Memory = OFF

Auto Sub-Batch = OFF

Statistics = OFF

Hi Lo Alarm = OFF

Hi Res = OFF

Bluetooth & Stream = OFF

WiFi & Access Point = OFF

Auto Ignore 20/90 = OFF

Auto Dim = ON

Setup Menu

Setup Menu

4

Cal Reset

Restores the gage back to factory calibration and range settings.

The icon will appear on the display.

Cal Settings Menu

Cal Settings Menu

Adjusts the Gage to a known material hardness.

Step 1: Select 1 Pt Adjust from the Cal Settings menu.

Step 2: Press the (+) button to select the number of readings to

be used to obtain an average, typically 3 to 10 readings. The

greater the variation between readings, the more readings should

be taken to obtain an average.

Step 3: Repeatedly measure the known hardness sample using

the on-screen green arrows as a guide. After the final reading,

the Gage will calculate and display an average measurement

value of all readings taken on the sample. If the expected

hardness value is not obtained (within tolerance), adjust the

displayed value up (+) or down (-) to the known hardness value

and press to enter the value.

1 Pt Adjust

0

Page 7

5

Perform a more thorough Hard Reset as follows:

Power down the Gage and wait 5 seconds.1

Simultaneously press and hold the (+) and center2

buttons until the Reset symbol appears.

This returns the Gage to a known, “out-of-the-box” condition.

It performs the same function as a menu Reset with the addition of:

Date, Time and WiFi settings are not affected by either Reset.

Bluetooth Smart = OFF

Test Time = 1 second

Sound = ON

Backlight = Normal

Flip Display = Normal

Auto Sync .net = ON

USB Drive= ON

Language = English

Battery Type = Alkaline

- Bluetooth Pairing info is cleared.

- Menu settings are returned to the following status:

NOTE:

Auto Ign. 20/90

Test Time

The PosiTector SHD has an on-screen timer to measure the

hardness of a material after a given period of time as defined by

international standards, typically 1, 3 or 15 seconds.

Use the (-) and (+) buttons to adjust the test duration. When

taking a reading, the timer starts automatically once the presser

foot is on the surface and the ▼ symbol appears on the display.

According to most international standards, readings below 20

and above 90 are not considered reliable. When enabled,

measurement results outside 20/90 will emit a low tone and will

not be included in Memory or Statistics.

If values above 90 Shore A are measured, the

PosiTector SHD-D probe should be used. If values below 20

Shore D are measured, use the PosiTector SHD-A probe.

NOTE:

(Auto Ignore)

Page 8

6

Advanced models store 100,000 readings in up to 1,000

batches. “New Batch” closes any currently opened batch and

creates a new batch name using the lowest available number.

New batch names are date-stamped when they are created.

The PosiTector has internal memory storage for recording

measurement data. Stored measurements can be reviewed onscreen or accessed via computers, tablets and smart phones. All

stored measurements are date and time-stamped.

Standard models store up to 250 readings in one batch.

Memory Management

Memory Management

Selects the type of batteries used in the Gage from a choice of

“Alkaline”, “Lithium” or “NiMH” (nickel-metal hydride rechargeable).

If “NiMH” is selected, the Gage will trickle charge the batteries while

connected via USB to a PC or optional AC power supply (USBAC).

The battery state indicator symbol is calibrated for the selected

battery type. No damage will occur if the battery type used in the

Gage does not match the selected battery type.

Battery Type

Statistics Mode

Statistics Mode

A statistical summary will appear on the display. Remove the

last reading by pressing the (-) button. Press (+) to clear

statistics.

Statistics

HiLo Alarm

Allows Gage to visibly and audibly alert the user when readings

exceed user-specified limits.

The symbol appears when the Gage is set to store measurement

data.

Average

Maximum Value

Standard Deviation

Minimum Value

Page 9

7

Accessing Stored Measurement Data

Accessing Stored Measurement Data

DeFelsko offers the following free solutions for viewing, analyzing

and reporting data:

PosiSoft USB Drive - Connect the Gage to a PC/Mac using the

supplied USB cable. View and print readings and graphs using

universal PC/Mac web browsers or file explorers. No software or

internet connection required. USB Drive must be selected in the

Gage’s “Connect > USB” menu (pg. 8).

PosiSoft Desktop - Powerful desktop software (PC/Mac) for

downloading, viewing, printing and storing measurement data.

Includes a customizable, templated PDF Report Generator. No

internet connection required.

PosiSoft.net - Web-based application offering secure, centralized

storage of measurement data. Access your data from any webconnected device.

PosiTector App - (

Advanced models only, serial numbers 784000+)

App for compatible iOS and Android smart devices. Permits users

to create, save and share professional PDF reports. Add images

and notes using the smart device’s camera and keyboard.

For more information on our PosiSoft solutions, see:

www.defelsko.com/posisoft

Screen Capture

Press both the (-) and (+) buttons at any time to capture and save

an image copy of the current display. The last 10 screen captures

are stored in memory and can be accessed when connected to a

computer (see PosiSoft USB Drive).

This option will automatically create a new sub-batch after the

required number of readings are stored in the current sub-batch.

Use the (-) and (+) buttons to set the number of readings to store

in each sub-batch, then select New to open the first sub-batch.

Auto Sub-Batch

(Advanced models only)

Page 10

8

The above WiFi, USB and Bluetooth menus contain a

Sync .net Now option. When selected, the Gage immediately

synchronizes stored measurement data via its respective

communication method (internet connection required). Alternatively,

select Auto Sync .net from within the USB connect menu to

automatically synchroniz e upon connection to a PC. Additional

measurements added to memory while connected are synchronized

only when the USB cable is disconnected and reconnected, or when

the Sync .net Now option is selected. WiFi connected gages

automatically attempt synchronization upon power-up.

Sync .net Now

Connect Menu

Connect Menu

When USB Drive is checked , the PosiTector gage uses a

USB mass storage device class which provides users with a

simple interface to retrieve stored data in a manner similar to

USB flash drives, digital cameras and digital audio players.

USB Drive is also required to import stored measurements into

PosiSoft Desktop software.

When connected, power is supplied through the USB

cable. The batteries are not used and the body will not

automatically power down. If rechargeable (NiMH) batteries are

installed, the instrument will trickle charge the batteries.

Allows individual readings to be sent to a computer, printer or

compatible device as they are taken using Bluetooth wireless

technology. See www.defelsko.com/bluetooth

Bluetooth

(Advanced models only)

Allows connection to your local wireless network or mobile hot

spot. Ideal for using your network’s internet connection for

synchronizing stored measurements with PosiSoft.net (pg. 7).

See www.defelsko.com/wifi

WiFi

(Advanced models only)

NOTE:

USB

When enabled and connected to a computer, the PosiTector will be

recognized as a Keyboard. Readings are sent to the computer as

they are taken, emulating keystrokes, followed by a carriage return.

Keyboard

(Advanced models only,

serial numbers 784000 and greater)

Page 11

9

Sync Batches

Select batches to flag them for synchronization to the

PosiTector App. New batches created while Bluetooth Smart is

enabled are automatically selected.

With Bluetooth Smart enabled, select Sync Batches to transfer

selected batches to the PosiTector App. Only readings and

batches that have yet to be synchronized with any smart device

are synchronized automatically.

The Gage will perform a Hard Reset after an

update (pg. 5). All stored measurements will be erased from

memory.

Updates

Determine if a software update is available for your Gage.

See www.defelsko.com/update

WARNING:

When Enabled , allows communication with a smart device

running the PosiTector App (see Accessing Stored Measurement

Data, pg. 7) via auto-pairing Bluetooth Smart (BLE) wireless

technology.

Bluetooth Smart

(Advanced models only, serial numbers 784000 and greater)

PosiSoft Desktop is required when using USB

connections to synchronize measurements with PosiSoft.net.

NOTE:

Send Batches

Transfers selected batches to the PosiTector App (useful

when switching between devices).

The send batches option is visible in the menu when the Gage is

connected to a smart device running the PosiTector App.

If Bluetooth Smart is disabled, data from batches

selected in the Sync Batches menu are held in a queue until

communication with the PosiTector App is re-established.

NOTE:

Page 12

10

www.defelsko.com

© DeFelsko Corporation USA 2018

All Rights Reserved

This manual is copyrighted with all rights reserved and may not be reproduced or transmitted, in whole

or part, by any means, without written permission from DeFelsko Corporation.

DeFelsko, PosiTector and PosiSoft are trademarks of DeFelsko Corporation registered in the U.S. and

in other countries. Other brand or product names are trademarks or registered trademarks of their

respective holders.

Every effort has been made to ensure that the information in this manual is accurate. DeFelsko is not

responsible for printing or clerical errors.

Limited Warranty, Sole Remedy

Limited Warranty, Sole Remedy

and Limited Liability

and Limited Liability

DeFelsko's sole warranty, remedy, and liability are the express

limited warranty, remedy, and limited liability that are set forth on

its website: www.defelsko.com/terms

Returning for Service

Returning for Service

Before returning the Gage for service…

1.Install new or newly recharged batteries in the proper

alignment as shown within battery compartment.

2.Examine the indentor tip and presser foot for dirt or damage.

3.Perform a Hard Reset. (pg. 5)

4.Attempt a measurement on the supplied test block.

(see Verification, pg. 3)

5. If issue is not resolved, Update your PosiTector gage body

(pg. 9) and re-attempt measurements.

IMPORTANT:

If you must return the Gage for service, please fill out and

include the Service Form located at www.defelsko.com/support

with the Gage. Be sure to also include the probe, your company

name, company contact, telephone number and fax number or

email address.

Page 13

Durómetro de Escala Shore

Guía Rápida v.1.1

Page 14

Compruebe la precisión (pág. 3) en patrones de referencia al

principio y al final de cada turno, si el medidor se cae o si sospecha

que las lecturas son erróneas.

No coloque la punta de la sonda en materiales

duros como el acero o el vidrio. Si lo hace podría dañarla y hacer

que las lecturas de la sonda estén fuera de tolerancia. Vuelva a

colocar la tapa de goma para proteger la punta y el soporte de

presion cuando no esté en uso. Los daños a la punta de la sonda

causados por hacer medición en materiales duros no están cubiertos

por la garantía del DeFelsko.

1

Introducción

El PosiTector Durómetro de Escala Shore (SHD) es un instrumento

electrónico portátil que mide la dureza de materiales no metálicos.

Está formado por un cuerpo de PosiTector (Standard o Advanced) y

una sonda intercambiable (SHD-A o SHD-D).

Esta guía rápida recoge las funciones básicas del dispositivo.

Descargue el manual completo de instrucciones en

www.defelsko.com/manuals

Inicio rápido

El PosiTector SHD se enciende al pulsar el botón central .

Para ahorrar energía el equipo se apagará tras unos 5 minutos

de inactividad. Se conservarán todas las configuraciones.

1. Retire el tapón protector de goma de la sonda.

2. Encienda el medidor pulsando el botón central .

Asegúrese de que la punta de la sonda (pág. 2) no está en

contacto con ninguna superficie.

3. Medición

a) Presione la sonda hacia abajo sobre el material que desea

medir hasta que el soporte de presión quede totalmente plano y

en completo contacto con la superficie. Manténgalo estable contra

la superficie.

b) El medidor emitirá un pitido y mostrará el símbolo que indica

que se está realizando una lectura. El temporizador de prueba

comenzará la cuenta atrás (consulte Tiempo de prueba, pág. 5).

Cuando el temporizador alcance 0 seg., el medidor sonará dos

veces y mostrará el valor de la medida.

4. Levante la sonda de la superficie antes de continuar con la

siguiente medición.

IMPORTANTE:

Page 15

2

Sonda

Una vez encendido, el PosiTector determinará automáticamente el

tipo de sonda conectado y realizará una comprobación

automática.

Para desconectar una sonda de la base del PosiTector

deslíce el conector de la sonda de plástico

horizontalmente (en la dirección de la flecha) separándola

de la base PosiTector. Invierta los pasos para conectar

una sonda diferente. No es necesario apagar el medidor

cuando se cambia la sonda.

La base del medidor PosiTector acepta

una amplia variedad de tipos de sonda

incluyendo las necesarias para medir

espesor de recubrimientos tipo

magnético, de corrientes de Foucault y

de ultrasonido; sondas para perfiles de

superficie, ambiental, dureza Shore y

sondas de espesor de pared por

ultrasonidos. Consulte www.defelsko.com/probes

La sonda PosiTector SHD consta de una punta, un muelle calibrado

y un pisador. Existen dos modelos de sonda para medir diferentes

materiales:

n PosiTector SHD-A (Tipo A) - goma blanda, elastómeros,

neopreno, silicona, etc.

n PosiTector SHD-D (Tipo D) - goma dura, epoxy, plástico rígido,

PVC, acrílico, etc.

Para desplazarse utilice los botones Arriba y Abajo y

para SELECCIONAR.

Presione el botón (+) para

cambiar de página en el menú

formado de varias páginas.

Presione el botón (-) para

regresar al menú o página

anterior.

Seleccione Salir para cerrar el menú del medidor.

Menú Operation

Las funciones del medidor se controlan con un menú. Para acceder

al menú encienda el medidor y pulse el botón central.

Page 16

3

Calibración, Comprobación y Ajuste

Para garantizar la mayor precisión siga estos tres pasos...

1. Calibración - habitualmente realizada por el fabricante. Todas las

sondas incluyen certificado de calibración.

2. Comprobación - normalmente realizada por el usuario con los

patrones de referencia conocidos como el bloque de prueba

suministrado.

3. Ajuste - a un espesor conocido

Calibración - La calibración es el proceso de medición de alto nivel,

controlado y documentado de estándares de calibración con

trazabilidad en todo el rango de operación de la sonda, con la

comprobación de que los resultados están dentro de la precisión

declarada de la sonda. El fabricante, su agente autorizado o un

laboratorio de calibración acreditado llevarán a cabo las calibraciones

en un ambiente controlado y con un proceso documentado.

Comprobación - La comprobación que es una verificación de

precisión hecha por el usuario midiendo en materiales de referencia

con valores de dureza conocidos. Una comprobación exitosa implica

que el equipo mida dentro de las tolerancias de precisión

combinadas del medidor y las galgas patrón.

Puede comprobar el funcionamiento del dispositivo con el bloque de

prueba incluido. Coloque el bloque de prueba sobre una superficie

plana, dura y realice de tres a cinco lecturas. Los puntos de

medición deberán tener al menos 6 mm (0,24 ") de separación. Si el

promedio de esas lecturas se encuentra fuera de la precisión

combinada del bloque de prueba y galga puede ser que el medidor

requiera reparación. Algunas de las causas para que el medidor no

lea correctamente son daños en la punta, presión incorrecta aplicada

al bloque de prueba o temperaturas que no se consideren

condiciones normales.

Compruebe la precisión al principio y al final de cada turno laboral.

Si durante un turno de trabajo el instrumento se cae o se sospecha

que las lecturas son erróneas, deberá comprobar su precisión

nuevamente.

Ajuste

- El ajuste o ajuste de calibración es la operación que alinea

las lecturas del medidor con una muestra de referencia conocida con

el fin de mejorar su precisión sobre un material específico. (consulte

Ajuste 1 punto, pág. 4)

Page 17

Reset (menú reset) restaura la configuración de fábrica y

devuelve el dispositivo a una condición conocida. Ocurrirá lo

siguiente:

- Todas las series, mediciones almacenadas y nombres de

series se borrarán.

- Los ajustes de calibración volverán a los valores de fábrica.

- Las configuraciones del menú serán de nuevo las siguientes:

Reset

Memoria = OFF

Subseries Auto = OFF

Estadísticas = OFF

Alarma HiLo = OFF

Alta Resolución = OFF

Bluetooth y Stream = OFF

WiFi y Punto de Acceso = OFF

Ignorar Auto 20/90 = OFF

Auto Dim = ON

Lectura Cont. = OFF

Menú Configuración (Setup)

4

Restablecer Cal

Restaura la calibración de fábrica del medidor. El icono

aparecerá en la pantalla.

Menú Cal Settings

Ajusta el medidor a un material de dureza conocida.

Paso 1: Seleccione la opción 1 Punto del menú Cal Settings.

Paso 2: Pulse el botón (+) para seleccionar el número de

lecturas de las que se obtendrá el promedio, generalmente entre

3 y 10. Cuanto mayor sea la variación entre lecturas, más

lecturas deberá tomar para obtener un buen promedio.

Paso 3: Realice mediciones repetidas en la muestra de dureza

conocida usando las flechas verdes que aparecen en pantalla

como guía. Después de la lectura final, el medidor calculará y

mostrará un valor medio de las mediciones de todas las lecturas

tomadas en la muestra. Si no se obtiene el valor de dureza

esperado (dentro de la tolerancia), ajuste el valor que se muestra

en pantalla usando la tecla (+) arriba o (-) abajo hasta igualar la

lectura con el valor de dureza conocido. Pulse para

introducir el valor.

Ajuste 1 punto

0

Page 18

5

Realice un Reinicio completo de esta manera:

1. Apague el dispositivo y espere 5 segundos.

2. Pulse simultáneamente los botones (+) y el central

hasta que el símbolo de reinicio aparezca.

Esto restablecerá el medidor a su condición conocida de fábrica.

Realiza la misma función que el Reinicio y además:

La hora y la fecha y la configuración de WiFi no se

verán afectadas por ningún Reinicio.

Bluetooth Smart = OFF

Tiempo de Prueba = 1 segundo

Sonido = ON

Retroiluminación = Normal

Volteo Pantalla = Normal

Auto Sync .net = ON

USB Drive= ON

Idioma = Inglés

Tipo de Batería = Alcalina

- La información de conexión Bluetooth se borrará.

- Las configuraciones del menú serán de nuevo las siguientes:

NOTA:

Auto Ign. 20/90

Tiempo de Prueba

El PosiTector SHD tiene un temporizador en la pantalla para medir

la dureza de un material después de un período determinado de

tiempo tal como se define en las normas internacionales, típicamente

1, 3 o 15 segundos. Utilice los botones (-) y (+) para ajustar la

duración de la prueba. Cuando realice una lectura, el temporizador

se iniciará automáticamente una vez que el pisador quede en la

superficie y aparecerá en la pantalla el símbolo .

Según la mayoría de las normas internacionales, las lecturas por

debajo de 20 y por encima de 90 no se consideran fiables. Cuando

está activado, los resultados de medición fuera de 20/90 emitirán un

tono grave y no se incluirán en Memoria o Estadísticas.

Si se miden valores superiores a 90 Shore A, deberá utilizar

la sonda del PosiTector SHD-D. Si se miden valores por debajo de

20 Shore D, utilice la sonda del PosiTector SHD-A.

NOTA:

(Ignorar Auto)

Lectura Cont.

Cuando se activa esta función, el instrumento desplegará las lecturas

de la sonda de manera continua. Es ideal cuando el temporizador de

prueba no es requerido o cuando se realiza la verificación de

calibración. La función de Lectura Continua no esta disponible

cuando los modos Memoria, Estadística o alarma HI/LO se

encuentran activadas.

(Lectura Continua)

Page 19

6

Modelos Advanced almacenan 100.000 lecturas en hasta 1.000

series. "Lote Nuevo" cierra cualquier serie abierta y crea un

nuevo nombre de serie con el número más bajo disponible. Los

nombres de series nuevas quedarán registrados con la fecha en

que se crearon.

El PosiTector SHD dispone de memoria de almacenamiento

interna para registro de datos de mediciones. Podrá revisar las

mediciones almacenadas en pan

talla o

acceder a ellas mediante

ordenadores, tablets y smartphones. Todas las mediciones

almacenadas incluyen fecha y hora.

Modelos Standard almacenan 250 lecturas en una sola serie.

Gestión de memoria

Selecciona el tipo de baterías utilizadas en el medidor entre

"Alcalina""Litio" o "NiMH" (Níquel - metal híbrido recargable). Si se ha

seleccionado NiMH el medidor cargará las baterías poco a poco si

está conectado por USB a un PC o a un cargador de red (USBCA).

El símbolo indicador de estado de batería se calibrará según el tipo

de pila seleccionado. No se producirá ningún daño si el tipo de

batería del medidor no coincide con el tipo de batería seleccionado.

Tipo de batería

Modo Estadísticas

En la pantalla aparecerá un resumen de las estadísticas.

Elimine la última lectura del resumen presionando el botón (-).

Pulse (+) para borrar las estadísticas.

Estadísticas

x

Alarma HiLo

El medidor alertará visual y acústicamente al usuario cuando las

mediciones excedan los límites que haya especificado.

El símbolo aparecerá cuando el medidor esté configurado para

almacenar los datos de medición.

Media

Valor máximo

Desviación estándar

Valor mínimo

(Límites)

Page 20

7

Acceso a los datos de mediciones almacenados

DeFelsko ofrece las siguientes soluciones libres para la

visualización, análisis y presentación de datos:

PosiSoft USB Drive - Conecta el calibrador a un PC / Mac

mediante el cable USB suministrado. Vea e imprima lecturas y

gráficos utilizando navegadores web o exploradores de archivos

para PC / Mac. No se requiere conexión a internet ni software

especializado. Deberá seleccionar USB Drive en el menú del

dispositivo "Connectar > USB" (pág. 8).

PosiSoft Desktop - Potente software de usuario (PC / Mac) para

descargar, ver, imprimir y almacenar datos de medición. Incluye

un generador de informes PDF personalizable con plantilla. No

requiere conexión a Internet.

PosiSoft.net - Aplicación basada en Web que ofrece un

almacenamiento seguro y centralizado de los datos de medición.

Acceda a sus datos desde cualquier dispositivo conectado a

Internet.

PosiTector App - (

Modelos Advanced, números de serie 784000+)

Aplicación para compatible con dispositivos iOS y Android.

Permite a los usuarios crear, guardar y compartir informes

profesionales en PDF. Añade imágenes y notas con la cámara y

el teclado del dispositivo.

Para más información de los soluciones de PosiSoft, consulte:

www.defelsko.com/posisoft

Screen Capture - Pulse simultáneamente los botones (-) y (+) en

cualquier momento para copiar y guardar una imagen de la pantalla

actual. Las últimas 10 impresiones de pantalla están almacenadas

en memoria y podrá acceder a ellas cuando esté conectado a un

ordenador (consulte PosiSoft USB Drive).

Esta opción creará automáticamente una nueva subserie después

de que el número necesario de lecturas se almacenen en la

subserie actual. Utilice los botones (-) y (+) para establecer el

número de lecturas que desea almacenar en cada subserie y a

continuación seleccione Nuevo para abrir la primera subserie.

Auto Sub-Lote

(Sólo modelos Advanced)

Page 21

8

Los menús anteriores de WiFi, USB y Bluetooth contienen una

opción de Sync .net Now. Cuando está seleccionada, el

dispositivo sincroniza inmediatamente los datos de medición

almacenados a través de su método de comunicación respectivo

(requerida conexión a internet).

Como alternativa seleccione Auto Sync .net con la conexión

USB para sincronizar automáticamente con un PC. Sólo se

sincronizarán las mediciones adicionales añadidas a la memoria

durante la conexión cuando el cable USB esté desconectado y

se conecte de nuevo o cuando Sync .net Now esté

seleccionado. Los medidores conectados por WiFi realizarán

una sincronización automática cuando se conecten.

Sync .net Now

Menú Connect

Cuando está USB Drive comprobado , el medidor PosiTector

utiliza una clase de dispositivo de almacenamiento masivo USB

que proporciona a los usuarios con una interfaz sencilla para

recuperar los datos almacenados de una manera similar a

unidades flash USB, cámaras digitales y reproductores de audio

digital. El USB Drive también es necesario para importar las

mediciones guardadas con la aplicación PosiSoft Desktop.

Cuando está conectado, la alimentación se obtiene a

través del cable USB. Las baterías no estarán en uso y la base

no se apagará automáticamente. Si dispone de baterías

recargables (NiMH), el equipo las cargará poco a poco.

Permite enviar lecturas individuales a un ordenador o dispositivo

compatible con tecnología Bluetooth. Consulte

www.defelsko.com/bluetooth

Bluetooth

(sólo modelos Advanced)

Permite la conexión a su red inalámbrica local o punto de

acceso. Ideal para el uso de su conexión a internet y sincronizar

las mediciones almacenadas con PosiSoft.net (pág. 7).

Consulte www.defelsko.com/WiFi

WiFi

(Sólo modelos Advanced)

NOTA:

USB

Page 22

9

Sync Batches

Seleccione series para marcarlas para su sincronización con

la App PosiTector. Las nuevas series creadas con el Bluetooth

Smart activado se seleccionarán automáticamente.

Con Bluetooth Smart activado, seleccione Sync Batches para

transferir a la App de PosiTector las series seleccionadas.

Sólo se sincronizarán automáticamente las lecturas y series que

aún tienen que sincronizarse con cualquier dispositivo

inteligente.

Tel medidor puede realizar un Reinicio

completo (pág. 5) tras una actualización. Todas las mediciones

guardadas se borrarán de la memoria.

Actualizar

Determina si hay actualizaciones disponibles de software para su

medidor. Consulte www.defelsko.com/update

ADVERTENCIA:

Si está Activado , comunicará con dispositivos que ejecuten

la App PosiTector (consulte Acceso a datos de mediciones

almacenados) mediante conexión automática Bluetooth Smart (BLE).

Bluetooth Smart

(sólo modelos Advanced con número de serie 784000+

El PosiSoft Desktop será necesario cuando se

empleen conexiones USB para sincronizar mediciones con

PosiSoft.net.

NOTA:

Send Batches

Transfiere las series seleccionadas a la App PosiTector (útil

cuando se trabaja con varios dispositivos).

La opción Send Batches podrá verse en el menú cuando el

medidor esté conectado a un dispositivo que tenga installada la

App PosiTector

Si Bluetooth Smart está desactivado, los datos de las

series seleccionadas en el menú Sync Batches se incluirán en

una cola hasta que la comunicación con la App PosiTector se

restablezca.

NOTA:

Page 23

10

www.defelsko.com

© DeFelsko Corporation USA 2017

Reservados todos los derechos.

Este manual está protegido por copyright. Todos los derechos de este manual están reservados y no

podrá ser parcial o totalmente reproducido o transmitido por ningún medio sin el consentimiento previo

por escrito de DeFelsko Corporation.

DeFelsko, PosiTector y PosiSoft son marcas comerciales de DeFelsko Corporation registradas en los

EE.UU. y en otros países. Otras marcas o nombres de productos son marcas comerciales o registradas

de sus propietarios respectivos.

Se han tomado todas las precauciones posibles para asegurar la precisión de toda la información contenida en este manual. DeFelsko no aceptará responsabilidad por errores tipográficos o de impresión.

Garantía limitada, solución única y obligación

limitada

La garantía única de DeFelsko, la solución, y la obligación son la

garantía limitada expresa, la solución y la obligación limitada

expuestas en su sitio web: www.defelsko.com/terms

Devolución para reparaciones

Antes de devolver el medidor para reparaciones…

1. Ponga baterías nuevas o recién recargadas en el compartimento

de las baterías según instrucciones.

2. Examine si hay suciedad o daños en el pisador y la punta de la

sonda.

3. Realice un Reinicio completo. (pág. 5)

4. Realice una medición con el bloque de prueba suministrado

(consulte Comprobación, pág. 3)

5. Si el problema no se resuelve, Actualice su base PosiTector

(pág. 9) y vuelva a intentarlo.

IMPORTANTE:

Si debe devolver el medidor para reparaciones, describa el problema

con detalle e incluya los resultados de medición, si los tiene.

Asegúrese también de incluir la sonda, el nombre de su empresa, el

nombre de la persona de contacto, sus números de teléfono y de fax

o su dirección de correo electrónico.

Website: www.defelsko.com/support

.

Page 24

Page 25

Kurzanleitung v.1.1

Shore-Härtemesser

Page 26

1

Platzieren Sie die Auflagefläche der Sonde nicht auf

harten Materialien wie Stahl oder Glas. Dies kann den Eindringkörper

beschädigen und dazu führen, dass die Sonde Messungen außerhalb des

Toleranzbereichs vornimmt. Bringen Sie die Gummikappe zum Schutz des

Eindringkörpers und der Auflagefläche wieder an, wenn diese nicht

verwendet werden. Eine Beschädigung am Eindringkörper, die durch

Messen auf harten Materialien verursacht wird, ist nicht durch die

Garantie von DeFelsko abgedeckt.

Einleitung

Der PosiTector-Shore-Härtemesser (SHD) ist ein elektronisches

Handinstrument, das die Härte nichtmetallischer Stoffe misst. Er besteht

aus einem PosiTector-Grundgerät (Standard oder Advanced) und einer

austauschbaren Sonde (SHD-A oder SHD-D).

Diese Schnellanleitung fasst die Grundfunktionen des Instruments

zusammen. Laden Sie die vollständige Anleitung auf:

www.defelsko.com/manuals

herunter (nur in Englisch)

Schnellstart

Der PosiTector SHD schaltet sich ein, wenn die zentrale Steuertaste

gedrückt wird. Um die Lebensdauer der Batterie zu schonen, schaltet sich

das Instrument nach etwa 5 Minuten Nichtbenutzung aus. Alle

Einstellungen bleiben erhalten.

1. Entfernen Sie die Gummischutzkappe von der Sonde.

2. Schalten Sie das Messgerät ein, indem Sie die zentrale Steuertaste

drücken. Stellen Sie sicher, dass die Auflagefläche (S. 2) nicht in

Kontakt mit der Oberfläche ist.

3. Messen

a) Drücken Sie die Sonde auf das zu messende Material herunter, bis

der Sondenfuß sich vollständig und flach auf der Oberfläche befindet.

HALTEN SIE IHN GLEICHMÄSSIG gedrückt auf der Oberfläche.

b) Das Messgerät sendet einen einzigen Piepton aus und zeigt ein

Symbol an, das darauf hinweist, dass eine Messung vorgenommen

wird. Die vorgewählte Zeit (Timer) beginnt herunterzuzählen (siehe

Testzeit, S. 5). Wenn der Timer 0 s erreicht, piept das Messgerät

zweimal und zeigt den Messwert an.

4. Heben Sie die Sonde zwischen den Messungen von der Oberfläche

ab.

WICHTIG:

Überprüfen Sie die Genauigkeit (S. 3) auf dem Testblock am Anfang und

am Ende jedes Arbeitstages und ob das Messgerät hingefallen ist oder der

Verdacht besteht, dass es falsche Messungen anzeigt.

Page 27

2

Sonde

Wenn er eingeschaltet ist, erkennt der PosiTector automatisch, welche

Sonde angeschlossen ist, und führt einen Selbsttest durch.

Um eine Sonde vom Grundgerät zu entfernen, schieben Sie

die Sondeneinheit in Pfeilrichtung (s. Rückseite) nach links

weg vom Gehäuse. Führen Sie diese Schritte umgekehrt aus,

um eine andere Sonde anzuschließen. Es ist nicht notwendig,

das Messgerät abzuschalten, wenn die Sonden ausgetauscht

werden.

An das PosiTector-Grundgerät kann eine Vielzahl von Sonden

angeschlossen werden, einschließlich magnetischer, Wirbelstrom- und

Ultraschall-Schichtdicken-, Oberflächenprofil-, Umwelt-, Shore-Härte- und

Ultraschall-Wanddickensonden. Siehe

www.defelsko.com/probes

Die PosiTector SHD-Sonde besteht aus

einem Eindringkörper, einer kalibrierten

Feder und einer Sonde mit Auflagefläche.

Zwei Sondenmodelle sind verfügbar:

PosiTector SHD-A (Typ A)

Weichgummi, Elastomere, Neopren, Silikon usw.

PosiTector SHD-D (Typ D)

Hartgummi, Epoxide, harte Kunststoffe, PVC, Acryl usw.

Verwenden Sie zur Navigation die Tasten Auf und Ab, um vertikal zu

scrollen und um AUSZUWÄHLEN.

Drücken Sie die Taste (+), um in

einem mehrseitigen Menü die

Seiten zu wechseln.

Drücken Sie die Taste (-), um zur

vorherigen Seite zurückzukehren.

Wählen Sie Zurück, um das Messgerätemenü zu schließen.

Menü

Die Funktionen des Messgeräts sind menügesteuert. Um auf das Menü

zuzugreifen, schalten Sie das Messgerät ein und drücken Sie dann die

zentrale Steuertaste.

Page 28

3

Kalibrierung, Überprüfung & Einstellung

Drei Schritte stellen die größte Genauigkeit sicher…

1.Kalibrierung - typischerweise vom Hersteller durchgeführt. Alle

Sonden werden mit Kalibrierzertifikat geliefert.

2.Überprüfung - typischerweise vom Benutzer auf bekannten

Referenzstandards durchgeführt, wie etwa dem beigefügten Testblock.

3.Einstellung - auf eine bekannte Dicke

Kalibrierung

Kalibrierung ist der qualifizierte, kontrollierte und dokumentierte Prozess,

rückführbare Kalibrierungsnormen über den gesamten Betriebsbereich der

Sonde zu messen und sicherzustellen, dass die Ergebnisse innerhalb der

angegebenen Genauigkeit der Sonde liegen. Kalibrierungen werden vom

Hersteller, ihrem zugelassenen Vertreter oder von einem zugelassenen

Kalibrierungslabor in einer kontrollierten Umgebung unter Verwendung

eines dokumentierten Verfahrens durchgeführt.

Überprüfung

Die Überprüfung ist eine Kontrolle der Genauigkeit, die vom Benutzer

unter Verwendung bekannter Referenznormalen durchgeführt wird. Eine

erfolgreiche Überprüfung erfordert, dass das Messgerät innerhalb der

kombinierten Genauigkeit des Messgeräts und der Referenznormalen

misst.

Das Instrument kann mit dem beigefügten Testblock überprüft werden.

Stellen Sie den Testblock auf eine flache, harte Fläche und nehmen Sie

drei bis fünf Messungen vor. Die Messpunkte sollten mindestens 6 mm

(0,24”) auseinander liegen. Wenn der Durchschnitt dieser Messungen

außerhalb der kombinierten Genauigkeit des Testblocks und Messgeräts

liegt, ist evtl. eine Wartung des Messgerätes erforderlich. Einige

Ursachen dafür, dass das Messgerät nicht ordnungsgemäß misst, sind,

dass die Spitze beschädigt ist, dass ein falscher Druck auf den Testblock

ausgeübt wird oder dass die Temperaturen jenseits normaler

Bedingungen liegen.

Überprüfen Sie die Genauigkeit am Anfang und am Ende jeder

Arbeitsschicht. Wenn während der Arbeitsschicht das Messgerät

fallengelassen wird oder der Verdacht besteht, dass es falsche

Messungen anzeigt, sollte seine Genauigkeit erneut überprüft werden.

Einstellung

Einstellung oder Kalibrierungseinstellung ist der Abgleich der Messungen

des Messgeräts mit einer bekannten Bezugsgröße, um die Genauigkeit

eines Messgeräts bei einem bestimmten Material zu verbessern.

(Siehe 1-Punkt, S. 4)

Page 29

Menü Zurücksetzen (Reset) stellt die Werkseinstellungen wieder her und

setzt das Instrument auf den werkseitigen Zustand zurück. Folgendes

passiert:

- Alle Blöcke, gespeicherten Messungen, Bilder und Blocknamen werden

gelöscht.

- Die Kalibrierungseinstellungen werden auf die Werkseinstellungen

zurückgesetzt.

- Die Menüeinstellungen werden auf Folgendes zurückgesetzt:

Reset

Speicher = AUS

Auto-Untergruppe = AUS

Statistik = AUS

MinMax-Alarm = AUS

Hochauflösung = AUS

Bluetooth & Stream = AUS

WiFi & Accesspoint = AUS

Auto-Ignorieren 20/90 = AUS

Auto-Dim = AN

Kontin. Messen = AUS

Setup-Menü

4

Kal Reset

Setzt das Messgerät zurück auf die Werkskalibrierung. Das Symbol

erscheint auf der Anzeige.

Menü Kalibrierung

Stellt das Messgerät auf eine bekannte Materialhärte ein.

Schritt 1:Wählen Sie 1-Punkt aus dem Menü Kalibrierung

Schritt 2: Drücken Sie die Taste (+), um die Zahl der Messungen zu

wählen, die verwendet werden sollen, um einen Durchschnitt zu erhalten,

typischerweise 3 bis 10 Messungen. Je größer die Abweichung zwischen

den Messungen ist, desto mehr Messungen sollten vorgenommen werden,

um einen Durchschnitt zu erhalten.

Schritt 3: Messen Sie wiederholt das Muster mit der bekannten Härte,

indem Sie die grünen Pfeile am Bildschirm als Richtlinie verwenden. Nach

der letzten Messung berechnet das Messgerät einen durchschnittlichen

Messwert aller an dem Muster vorgenommenen Messungen und zeigt

diesen an. Wenn der erwartete Härtewert nicht erreicht wird (innerhalb der

Toleranz), stellen Sie den angezeigten Wert mit (+) oder (-) auf den

bekannten Härtewert ein und drücken Sie , um den Wert

einzugeben.

1-Punkt

0

Page 30

Wenn Werte über 90 Shore A gemessen werden, sollte die

Sonde PosiTector SHD-D verwendet werden. Wenn Werte unter 20 Shore

D gemessen werden, verwenden Sie die Sonde PosiTector SHD-A.

Sonden der PosiTector SHD-Serie zeigen keine Messwerte unter 5 an.

5

Führen Sie einen vollständigen Hard Reset wie folgt durch:

Schalten Sie das Messgerät ab und warten Sie 5 Sekunden.1

Halten Sie die Taste (+) und die zentrale Taste gleichzeitig2

gedrückt, bis das Rücksetzsymbol erscheint.

Dies setzt das Messgerät auf einen bekannten Originalzustand zurück. Der

Hard Reset unterscheidet sich vom Reset wie folgt:

Datum, Uhrzeit, WiFi-Einrichtung sind von keinem Reset betroffen.

Bluetooth Smart = AUS

Timer = 1 Sekunde

Ton = AN

Hintergrundbeleuchtungacklight = Normal

LCD drehen = Normal

Auto Sync .net = AN

USB-Drive = AN

Sprache = Englisch

Batterietyp = Alkali

- Die Bluetooth-Kopplung wird gelöscht.

- Die Menüeinstellungen werden wie folgt zurückgesetzt:

HINWEIS:

Testzeit

Der PosiTector SHD hat eine Timerfunktion, um die Härte eines Materials

innerhalb eines bestimmten Zeitraums zu messen, wie von internationalen

Normen festgelegt, typischerweise 1, 3 oder 15 Sekunden. Verwenden Sie

die Tasten (-) und (+), um die Testdauer einzustellen. Wenn eine Messung

vorgenommen wird, startet der Timer automatisch, sobald der Sondenfuß

sich auf der Oberfläche befindet und das Symbol ▼ in der Anzeige

erscheint.

Auto Ign. 20/90

Nach den meisten internationalen Normen werden Messungen unter 20

und über 90 nicht als zuverlässig erachtet. Wenn dieser Menüpunkt

ausgewählt ist, ertönt ein tieferer Ton bei Messungen außerhalb des

Bereichs 20-90 und diese Messungen werden nicht in den Speicher oder

die Statistik aufgenommen.

HINWEIS:

(Auto-Ignorieren)

Wenn diese Funktion eingeschaltet ist, zeigt das Messgerät kontinuierlich

Messwerte der Sonde an.

Dies ist ideal, wenn keine bestimmte Testdauer nicht festgelegt oder eine

Überprüfung einer Kalibrierung durchgeführt wird.

Die Funktion ist nicht verfügbar, wenn die Funktionen Speicher, Statistik

und MinMax-Alarm eingeschaltet sind.

Kontin. Messen

(Kontinuierliche Messung)

Page 31

6

Advanced Modelle speichern 100.000 Messungen in bis zu 1000 Blöcken.

Die Auswahl „Neuer Block“ schließt einen aktuell geöffneten Block und

erzeugt einen neuen Blocknamen unter Verwendung der niedrigsten

verfügbaren Nummer. Neue Blocknamen werden mit Datum versehen,

wenn sie erstellt werden.

Der PosiTector SHD hat einen internen Speicher zur Aufzeichnung von

Messdaten. Gespeicherte Messwerte können am Bildschirm durchgesehen

werden, oder es kann auf diese über Computer, Tablets und Smartphones

zugegriffen werden. Alle gespeicherten Messwerte werden mit Datum und

Uhrzeit versehen.

Standard Modelle speichern 250 Messungen in einem Block.

Speicher-Menü

Statistikmodus

Eine statistische Zusammenfassung erscheint in der Anzeige. Entfernen

Sie die letzte Messung aus der Zusammenfassung, indem Sie die Taste

(-) drücken. Drücken Sie (+), um die Statistik zu löschen.

Statistik

MinMax-Alarm

Das Messgerät warnt den Benutzer sichtbar und hörbar, falls die

Messwerte die vom Benutzer angegebenen Grenzwerte überschreiten.

Das Symbol erscheint, wenn die Speicherfunktion eingeschaltet ist.

Mittelwert

Maximalwert

Standardabweichung

Minimalwert

(HiLo Alarm)

Wählt den im Messgerät verwendeten Batterietyp aus „Alkali“, „Lithium“ oder

„NiMH“ (Nickel-Metall-Hydrid, wiederaufladbar). Wenn „NiMH“ gewählt wird,

lädt das Messgerät die Batterien sehr langsam, während es über USB an

einen PC oder ein optionales Wechselstrom-Ladegerät angeschlossen ist

(USBAC). Das Batteriezustandsanzeigesymbol wird für den gewählten

Batterietyp kalibriert. Es tritt kein Schaden ein, wenn der im Messgerät

verwendete Batterietyp nicht mit dem gewählten Batterietyp übereinstimmt.

Batterietyp

Page 32

7

Zugriff auf gespeicherte Messdaten

DeFelsko bietet folgende kostenlose Lösungen zur Ansicht, Analyse und

Verarbeitung von Daten an:

PosiSoft USB Drive - Schließen Sie das Messgerät mit dem mitgelieferten

USB-Kabel an einen PC/Mac an. Betrachten Sie Messungen und Graphen

mit beliebigen Webbrowsern oder Dateimanagern und drucken Sie sie aus.

Keine Software und keine Internetverbidung erforderlich. USB-Drive muss

im Menü „Verbindung -> USB“ des Messgerätes ausgewählt werden (S.8).

PosiSoft Desktop - Leistungsfähige Desktop-Software (PC/Mac) zum

Herunterladen, Ansehen, Drucken und Speichern von Messdaten. Enthält

einen anpassungsfähigen, mit Vorlagen ausgestatteten PDFBerichtsgenerator. Keine Internetverbidung erforderlich.

PosiSoft.net - Webbasierte Anwendung, die eine sichere zentrale

Speicherung von Messdaten bietet. Greifen Sie von jedem mit dem Web

verbundenen Gerät auf Ihre Daten zu.

PosiTector App - (Nur Advanced Modelle, Seriennummern 784000+) App

für kompatible iOS- und Android-Smart-Geräte. Ermöglicht den Benutzern,

professionelle PDF-Berichte zu erstellen, zu speichern und mit anderen zu

teilen. Fügen Sie mit der Kamera und Tastatur eines Smartphones/Tablets

Fotos und Anmerkungen hinzu.

Weitere Informationen zu PosiSoft-Lösungen, siehe:

www.defelsko.com/posisoft

Diese Option erstellt automatisch einen neue Untergruppe, nachdem die

erforderliche Anzahl von Messungen in der aktuellen Untergruppe

gespeichert wurde. Verwenden Sie die Tasten (-) und (+), um die Anzahl

der Messungen einzustellen, die in jeder Untergruppe gespeichert werden

soll, und wählen Sie dann Neu, um die erste Untergruppe zu öffnen.

Auto-Unt.gr

(Nur Advanced Modelle)

(Auto-Untergruppe)

Bildschirmkopie

Drücken Sie beide Tasten (-) und (+) jederzeit, um eine Bildkopie der

aktuellen Anzeige zu erfassen und zu speichern. Die letzten 10

Bildschirmkopien werden im Speicher gespeichert, und es kann darauf

zugegriffen werden, wenn ein Computeranschluss besteht (siehe PosiSoftUSB-Drive).

Page 33

8

Die Menüpunkte WiFi, USB und Bluetooth enthalten eine Option Sync

.net Now. Wenn diese gewählt wird, synchronisiert das Messgerät sofort

gespeicherte Messdaten über die jeweilige ausgewählte Verbindung

(Internetverbindung erforderlich).

Wählen Sie alternativ Auto Sync .net aus dem USB-Menü, um

automatisch beim Anschluss an einen PC zu synchronisieren. Zusätzliche

Messwerte, die dem Speicher hinzugefügt werden, während der Anschluss

besteht, werden erst synchronisiert, wenn das USB-Kabel abgetrennt und

dann neu angeschlossen wird oder wenn die Option Sync .net Now

gewählt wird. Über WiFi angeschlossene Messwerte versuchen

automatisch beim Einschalten eine Synchronisation.

Sync .net Now

USB-Drive : Wenn dies ausgewählt ist, fungiert das PosiTector-

Messgerät als USB-Massenspeicher, das den Benutzern eine einfache

Schnittstelle bietet, um auf gespeicherte Daten zuzugreifen, ähnlich wie

bei USB-Flashlaufwerken, Digitalkameras und USB-Sticks. USB-Drive ist

auch erforderlich, um gespeicherte Messwerte in die PosiSoft-DesktopSoftware zu importieren.

Beim Anschluss wird der Strom über das USB-Kabel

bereitgestellt. Die Batterien werden nicht verwendet und das Gerät

schaltet sich nicht automatisch aus. Wenn wiederaufladbare (NiMH)

Batterien verwendet werden, lädt das Instrument die Batterien nur

langsam auf.

Damit können Einzelmesswerte während der Messung an einen

Computer oder ein anderes kompatibles Gerät gesendet werden.

Siehe: www.defelsko.com/bluetooth

(in englischer Sprache)

Bluetooth

(Nur Advanced Modelle)

USB

Der PosiSoft-Desktop ist erforderlich, wenn USB

Verbindungen verwendet werden, um Messwerte mit PosiSoft.net zu

synchronisieren.

HINWEIS:

HINWEIS:

Menü Verbindung

Ermöglicht einen Anschluss an Ihr lokales kabelloses Netzwerk oder

einen mobilen Hotspot. Ideal für die Verwendung der Internetverbindung

Ihres Netzwerks zur Synchronisierung gespeicherter Messwerte mit

PosiSoft.net (S. 7). Siehe www.defelsko.com/wifi

WiFi

(Nur Advanced Modelle)

Page 34

9

Bloecke sync

Wählen Sie Block aus, um sie für die Synchronisation mit der

PosiTector-App zu markieren. Neue Blöcke, die erstellt werden, während

Bluetooth Smart eingeschaltet ist, werden automatisch ausgewählt.

Wenn Bluetooth Smart eingeschaltet ist, wählen Sie Bloecke sync, um

die ausgewählten Blöcke an die PosiTector-App zu übertragen. Nur

Messungen und Blöcke, die noch mit einem Smart-Gerät synchronisiert

werden müssen, automatisch synchronisiert werden.

Das Messgerät führt nach einer Aktualisierung einen

Hard Reset (S. 5) durch. Alle gespeicherten Messwerte werden aus dem

Speicher gelöscht.

Updates

Ob eine Softwareaktualisierung für Ihr Messgerät vorhanden ist, erfahren

Sie unter: www.defelsko.com/update

WARNUNG:

Wenn dies eingeschaltet ist, ermöglicht es die Kommunikation über

Bluetooth (BLE) mit einem Smartphone/Tablet, das die PosiTector-App

ausführt (siehe Zugriff auf gespeicherte Messdaten, S. 7).

Bluetooth Smart

(Nur Advanced Modelle mit

Seriennummern 784000 und höher)

Bloecke senden

Überträgt ausgewählte Blöcke an die PosiTector App (nützlich bei

Wechsel zwischen Geräten).

Die Option Bloecke senden ist im Menü sichtbar, wenn das Messgerät mit

einem Smartphone / Tablet verbunden ist, auf dem die PosiTector App

ausgeführt wird.

Wenn Bluetooth Smart ausgeschaltet ist, werden Daten

aus Blöcken, die im Menü Blöcke sync ausgewählt wurden, in einer

Warteschlange gehalten, bis die Kommunikation mit der PosiTector-App

wiederhergestellt ist.

HINWEIS:

(Blöcke synchronisieren)

Page 35

10

www.defelsko.com

© DeFelsko Corporation USA 2016

Alle Rechte vorbehalten

Dieses Handbuch ist urheberrechtlich geschützt, und alle Rechte sind vorbehalten. Es darf ohne

schriftliche Genehmigung der DeFelsko Corporation weder insgesamt noch in Teilen in irgendeiner Weise

vervielfältigt oder weitergegeben werden.

DeFelsko, PosiTector und PosiSoft sind in den USA und anderen Ländern eingetragene Warenzeichen

der DeFelsko Corporation. Alle anderen Marken- oder Produktnamen sind Marken oder eingetragene

Marken der jeweiligen Besitzer.

Die in dieser Betriebsanleitung enthaltenen Informationen wurden nach bestem Wissen und Gewissen

zusammengestellt. Für Druck- oder Bearbeitungsfehler übernimmt DeFelsko keine Verantwortung.

Begrenzte Garantie, einziges Rechtsmittel und

beschränkte Haftung

Die ausdrücklich begrenzte Garantie, das einzige Rechtsmittel und die

beschränkte Haftung von DeFelsko sind auf der folgenden Website

dargelegt: www.defelsko.com/terms (in englischer Sprache)

Einsenden zur Reparatur

Bevor Sie das Messgerät zur Reparatur einsenden…

1. Setzen Sie neue oder neu aufgeladene Batterien in der richtigen

Polung ein, wie im Batteriefach gezeigt.

2. Untersuchen Sie Eindringkörper und die Auflagefläche auf Schmutz

oder Beschädigungen.

3. Führen Sie einen Hard Reset durch. (S. 5)

4. Versuchen Sie eine Messung am mitgelieferten Testblock.

(siehe Überprüfung, S. 3)

5. Wenn das Problem nicht gelöst ist, aktualisieren (Updates) Sie die

Software Ihres PosiTector-Messgeräts (S. 9) und versuchen Sie die

Messungen erneut.

WICHTIG:

Falls Sie das Gerät zur Reparatur einschicken müssen, beschreiben Sie

das Problem vollständig und fügen Sie Messergebnisse bei, falls

vorhanden. Achten Sie darauf, unbedingt auch die Sonde, den Namen

Ihrer Firma, den Namen der Kontaktperson in Ihrer Firma, Telefon- und

Faxnummer oder E-Mail-Adresse beizufügen.

Page 36

Guide d’ utilisation v.1.1

Duromètre Dureté Shore

Page 37

Vérifier l'exactitude (voir la page 5) concernant les étalons de

référence au début et à la fin de chaque journée de travail, ou si

l’instrument est tombé ou que l’on soupçonne d’obtenir des lectures

erronées.

Ne pas placer le pénétrateur sur des matériaux durs

tels que l'acier ou le verre. Cela pourrait endommager le pénétrateur

et provoquer une lecture hors plage de la sonde. Remettre le

capuchon en caoutchouc en place pour protéger le pénétrateur et le

pied lorsqu'ils ne sont pas utilisés. Les dommages causés au

pénétrateur par des mesures réalisées sur des matériaux durs ne sont

pas couverts par la garantie DeFelsko.

1

Introduction

Introduction

Le duromètre Shore PosiTector (SHD) est un instrument électronique

portable qui mesure la dureté des matériaux non-métalliques. Il se

compose du corps d’instrument PosiTector (standard ou avancé) et

d’une sonde interchangeable (SHD-A ou SHD-D).

Ce guide rapide résume les fonctions de base de l'instrument.

Téléchargez la notice d'instructions complète à l'adresse:

www.defelsko.com/manuals

Démarrage rapide

Démarrage rapide

Le PosiTector SHD est mis sous tension au moyen du bouton de

navigation central . Pour préserver la durée de vie de la batterie,

l’instrument est mis hors tension après environ 5 minutes d'inactivité.

Tous les paramètres sont conservés.

1.Enlever le capuchon de protection en caoutchouc de la sonde.

2.Mettre l'instrument sous tension en appuyant sur le bouton de

navigation central . Veiller à ce que la pénétrateur de la

sonde (page 2) ne soit pas en contact avec une surface

quelconque.

3. Mesure

a) Appuyer la sonde sur le matériau à mesurer jusqu'à ce que le

pied soit en parfait contact plan avec la surface. MAINTENIR LA

SONDE IMMOBILE contre la surface.

b) L’instrument émet un BIP et affiche un symbole ▼ indique

qu'une mesure est prise. La minuterie d'essai démarre le compte

à rebours (voir la section Durée de test en page 5). Lorsque la

minuterie atteint 0s, l'instrument émet deux BIPS et affiche la

valeur mesurée.

4. Soulever la sonde de la surface entre les mesures.

IMPORTANT:

Page 38

2

Sonde

Sonde

Une fois sous tension, le PosiTector détermine automatiquement le

type de sonde raccordée puis il exécute un auto-contrôle.

Pour déconnecter une sonde de l'instrument, faire glisser le

connecteur de sonde en plastique horizontalement (en direction de la

flèche) hors du corps. Inverser ces étapes pour monter une nouvelle

sonde. Il ne faut pas mettre l'instrument sous tension lors de la

commutation des sondes.

En outre, le PosiTector accepte un grand nombre de types de sondes

différents, y compris des sondes de mesure d'épaisseur de

revêtement à courant de Foucault et magnétiques, à profil de surface,

environnementales, de mesure de dureté shore ainsi que des sondes

de mesure d'épaisseur de paroi à ultrasons. Consultez le lien à

l'adresse www.defelsko.com/probes

La sonde PosiTector SHD se compose d'un pénétrateur, d'un

ressort calibré et d'un pied presseur.

Deux modèles de sondes sont

disponibles pour mesurer une grande

variété de matériaux:

PosiTector SHD-A (Type A) –

caoutchouc mou, élastomères, néoprène,

silicone, etc.

PosiTector SHD-D (Type D) –

caoutchouc dur, époxydes, plastiques durs, PVC, acrylique, etc.

Pour naviguer, presser les flèches Haut et Down pour défiler et

sur à pour SÉLECTIONNER.

Appuyer sur le bouton (+) pour changer de page dans un menu multipage.

Appuyer sur le bouton (-) pour retourner au menu ou à la page précédente.

Sélectionner Quitter pour fermer le menu Instrument.

Utilisation du menu

Utilisation du menu

Les fonctions de l'instrument sont contrôlées via un menu. Pour

accéder à ce menu, mettre l'instrument sous tension, puis presser le

bouton de navigation central.

Page 39

Étalonnage, vérification et ajustement

Étalonnage, vérification et ajustement

Ces étapes assurent une meilleure précision…

1.Étalonnage - généralement réalisé par le fabricant. Toutes les

sondes sont fournies avec certificat d'étalonnage

2.Vérification - Généralement effectuée par l'utilisateur sur des

étalons de référence connus tels que le bloc de test inclus.

3. Ajustement - à une dureté connue

Étalonnage

L'étalonnage est le processus contrôlé et documenté de haut niveau

visant à mesurer des étalons d'étalonnage traçables sur la pleine

plage de service de la sonde, pour ensuite vérifier que les résultats se

situent bien dans la fourchette d'exactitude établie. Les étalonnages

sont généralement effectués par le fabricant de l’instrument, un agent

autorisé ou par un laboratoire d'étalonnage certifié, en environnement

contrôlé et par le biais d'un processus documenté.

Vérification

La vérification est un contrôle de précision réalisé par l'utilisateur au

moyen d’étalons de référence connus. Une vérification réussie

nécessite que l’instrument indique une valeur correspondant à sa

fourchette d’exactitude combinée à celle des étalons de référence.

Le fonctionnement de l'instrument peut être vérifié avec le bloc de test

inclus. Placer le bloc de test sur une surface plane et dure, puis

prendre trois à cinq mesures. Les points de mesure doivent être

éloignés d'au moins 6 mm. Si la moyenne de ces mesures est en

dehors de la plage d’exactitude combinée du bloc de test et de

l’instrument, la sonde peut nécessiter une intervention de service. Les

causes d’erreur de lecture des sondes sont un endommagement de la

pointe, une pression incorrectement appliquée sur le bloc de test ou

des températures au-delà des conditions normales.

Vérifier l'exactitude au début et à la fin de chaque journée de travail.

Pendant la journée de travail, si l’instrument a chuté ou que l’on

soupçonne des mesures erronées, l’exactitude soit être revérifiée.

Ajustement

L'ajustement ou l'ajustement d'étalonnage est le fait d'aligner les

mesures de l'instrument pour correspondre avec celles d'un étalon de

référence connu de sorte à améliorer l'exactitude d'un instrument sur

un matériau spécifique. (Voir le menu 1 Pt Adjust, page 4)

3

Page 40

Réinitialisation (Menu de réinitialisation) permet de restaurer les

paramètres d'usine et retourner l'instrument dans un état connu. Les

événements suivants surviennent:

- Tous les lots, les mesures enregistrées et les noms de lots sont

effacés.

- Les ajustements de calibration sont retournés aux réglages d'usine.

- Les réglages du menu sont retournés comme suit:

Reset

Mémoire = OFF

Sous-lot Auto = OFF

Statistiques = OFF

Alarme Haute/Basse = OFF

Res. Élevée = OFF

Bluetooth et Flux = OFF

WiFi et Point d'accès = OFF

Auto Ignorer 20/90 = OFF

Lumin. Auto = ON

Cont. Reading = OFF

Menu d'installation

Menu d'installation

4

Cal Reset

Restaure l'instrument à la calibration d'usine. L'icône va apparaître

sur l'écran.

Menu des paramètres d'étalonnage

Menu des paramètres d'étalonnage

Ajuste l'instrument à une dureté de matériau connue.

Étape 1: Sélectionner 1 Pt Adjust dans le menu Cal Settings

(Paramètres d'étalonnage)

Étape 2: Appuyer sur le bouton (+) pour sélectionner le nombre de

mesures à utiliser pour obtenir une moyenne, habituellement de 3 à 10

mesures. Plus l’écart entre les mesures est importants, plus il faut

prendre de mesures pour obtenir une moyenne.

Étape 3: Mesurer à plusieurs reprises l'échantillon de dureté connue en

utilisant les flèches vertes à l'écran comme guide. Après la mesure

finale, l’instrument calcule et affiche une valeur de mesure moyenne de

toutes les valeurs prises sur l'échantillon. Si la valeur de dureté

attendue n’est pas obtenue (dans les tolérances), ajuster la valeur

affichée vers le haut (+) ou le bas (-) à la valeur de dureté connue et

appuyer sur pour entrer la valeur.

1 Pt Adjust

0

Page 41

5

Exécuter une réinitialisation plus complète comme suit :

1) Mettre l’instrument hors tension et attendre 5 secondes.

2) Appuyer simultanément sur les deux boutons (+) et central

jusqu'à ce que le symbole de réinitialisation apparaisse.

Cela réinitialise l'instrument dans un état connu après déballage. La

même fonction que la réinitialisation du menu est effectuée avec en

plus:

L'heure, la date, la configuration WiFi ne sont pas

affectés par la réinitialisation.

Bluetooth Smart = OFF

Temps Test = 1 seconde

Son = ON

Rétroéclairage = Normal

Affichage inversé = Normal

Auto Sync .net = ON

Lecteur USB = ON

Langue = Anglais

Type de pile = alcaline

- Les informations de couplage Bluetooth sont effacées.

- Les réglages du menu sont retournés comme suit:

REMARQUE:

Auto Ig. 20/90

Test retard

Le PosiTector SHD utilise une minuterie à l'écran pour mesurer la

dureté d'un matériau après une période de temps donnée telle que

définie par les normes internationales. Le retard est habituellement de

1, 3 ou 15 secondes. Utiliser les boutons (-) et (+) pour ajuster la durée

du test. Lorsque l’on prend une mesure, la minuterie démarre

automatiquement dès que le pied est sur la surface et le symbole ▼

apparaît sur l'écran.

Selon la plupart des normes internationales, les mesures inférieures à

20 et supérieures à 90 ne sont pas considérées comme fiables.

Lorsque cette fonction est activée, les résultats de mesure en dehors

de la plage 20 à 90 émettent une faible tonalité et ne seront pas

incluses dans la Mémoire ou les Statistiques.

Si des valeurs supérieures à 90 Shore A sont

mesurées, la sonde PosiTector SHD-D doit être utilisée. Si des

valeurs inférieures à 20 Shore D sont mesurées, utiliser la sonde

PosiTector SHD-A.

REMARQUE:

(Auto Ignore)

Page 42

Alarme HiLo

6

Modèles avancés stockent 100 000 mesures dans une maximum de

1 000 lots. « Un nouveau lot » ferme tout lot actuellement ouvert et crée

un nom nouveau lot en utilisant le plus petit numéro disponible. Les

nouveaux lots sont horodatés au moment de leur création.

Le PosiTector SHD peut enregistrer mesures dans sa mémoire de

stockage interne. Les valeurs stockées peuvent être examinées à

l'écran ou sont accessibles via des PC, des tablettes PC et des smart

phones. Les mesures enregistrées sont horodatées.

Modèles standard stockent jusqu'à 250 mesures dans un seullot.

Gestion de la mémoire

Gestion de la mémoire

Sélectionne le type de piles utilisées dans l’instrument parmi «

Alcaline », « Lithium » ou « NiMH » (piles rechargeables de

technologie Nickel-Métal Hydrure). Si l’option « NiMH » est

sélectionnée, l'instrument v

a même recharger les piles en étant

connecté via USB à un PC ou à un chargeur CA optionnel. L'icône

d’indicateur d'état de la batterie est étalonné selon le type de pile

choisie. Aucun dommage ne se produit si le type de batterie utilisé

dans l’instrument ne correspond pas au type de batterie sélectionné.

Type de pile

Mode statistique

Mode statistique

Un résumé statistique apparaît à l'écran. Supprimer la dernière

mesure du récapitulatif en appuyant sur le bouton (-). Appuyez sur

(+) pour effacer les statistiques.

Statistique

x

Permet à l'instrument d'alerter de manière audible et visuellel'utilisateur lorsque les mesures dépassent les limites qu'il aura préalablement

déterminées.

Le symbole apparaît lorsque l’instrument est réglé pour stocker

les valeurs de mesure.

Moyenne

Valeur Maxi

Déviation standard

Valeur min

Page 43

7

Accès aux valeurs de mesure enregistrées

Accès aux valeurs de mesure enregistrées

DeFelsko offre les solutions gratuites suivantes pour la visualisation,

l'analyse et la communication des données:

PosiSoft USB Drive – Brancher l’instrument à un PC / Mac à l'aide du

câble USB fourni. Afficher et imprimer des valeurs et des graphiques de

mesure à l'aide des navigateurs Internet ou les explorateurs de fichiers

PC / Mac universels. Aucun logiciel ni aucune connexion Internet n'est

requise. USB Drive doit être sélectionnée dans le menu « Connecter

> USB » de l'instrument (page 8).

PosiSoft Desktop – Logiciel de bureau puissant (PC/MAC) pour le

téléchargement, la visualisation, l'impression et le stockage de vos

données de mesure. Comprend un générateur de rapport PDF configuré

et personnalisable. Aucune connexion Internet n'est requise.

PosiSoft.net – Application Web offrant un stockage sécurisé et

centralisé des valeurs de mesure. Accédez à vos données à partir d'un

périphérique connecté à Internet.

PosiTector App – (Modèles avancés uniquement, numéros de série

784000 et supérieurs)App pour périphériques intelligents Android et iOS

compatibles. Permet aux utilisateurs de créer, enregistrer et partager

des rapports PDF professionnels. Ajouter des images et des notes en

utilisant l'appareil photo et le clavier du périphérique intelligent.

Pour plus d'informations, consultez le lien à l'adresse

www.defelsko.com/posisoft

Appuyez sur les boutons (-) et (+) à tout moment pour capturer et

enregistrer une copie de l'image de l'écran actuel. Les 10 dernières

captures d'écran sont enregistrées dans la mémoire et il est possible

d'y accéder lorsque l'instrument est connecté à un ordinateur (voir le

paragraphe PosiSoft USB Drive).

Cette option crée automatiquement un nouveau sous-lot dès que le

nombre requis de mesures a été enregistré dans le sous-lot en cours.

Utiliser les boutons (-) et (+) pour définir le nombre de mesures à

enregistrer dans chaque sous-lot, puis sélectionner Nouveau pour

ouvrir le premier sous-lot.

Auto Sub-Batch

(Modèles avancés uniquement)

Capture d'écran

Page 44

8

Les menus WiFi, USB et Bluetooth ci-dessus contiennent une option

Sync .net Now. Une fois sélectionné, l’instrument synchronise

immédiatement les valeurs de mesure stockées via sa méthode de

communication respective (connexion Internet requise).

Sinon, sélectionner Auto Sync .net à partir du menu de connexion

USB pour synchroniser automatiquement la connexion avec un PC.

Les valeurs de mesure supplémentaires ajoutées dans la mémoire

durant la connexion sont uniquement synchronisées lorsque le câble

USB est débranché ou lorsque l'option Sync .net Now est

sélectionnée. Les instruments connectés au WiFi tentent de se

synchroniser automatiquement à la mise sous tension.

Sync .net Now

Menu de connexion

Menu de connexion

USB Drive: Lorsque la case est cochée, l’instrument PosiTector utilise

une catégorie de périphérique de stockage de masse USB qui offre

aux utilisateurs une interface simple pour récupérer les données

stockées d'une manière similaire aux lecteurs USB flash, appareils

photo numériques et lecteurs audio numériques. USB Drive est

également requise pour importer les valeurs de mesure enregistrées

dans le logiciel PosiSoft Desktop.

Une fois connecté, l'alimentation électrique est fournie

via le câble USB. Les piles ne sont pas utilisées et l’instrument n’est

pas mis automatiquement hors tension. L’instrument se comporte

comme un chargeur de batterie lorsque des piles rechargeables

(NiMH) sont installées.

Cette fonctionnalité permet de transmettre des valeurs de mesure

individuelles vers un ordinateur ou un périphérique compatible grâce à

l’utilisation de la technologie sans fil Bluetooth.

Voir www.defelsko.com/bluetooth

Bluetooth

(modèle avancé uniquement)

Permet une connexion à votre réseau local sans fil ou à un Hot Spot

mobile. Idéal pour utiliser la connexion Internet de votre réseau et ainsi

synchroniser les valeurs enregistrées avec le PosiSoft.net.

Voir www.defelsko.com/wifi

WiFi

(Modèles avancés uniquement)

REMARQUE:

USB

Page 45

9

Sync Batches

Sélectionner les lots afin de les signaler pour une synchronisation

avec l'App PosiTector. Les nouveaux lots créés tandis que le Bluetooth

Smart est activé sont automatiquement sélectionnés.

Avec le Bluetooth Smart activé, sélectionner Sync Batches pour

transférer les lots sélectionnés vers l'App PosiTector. Seuls les

mesures et les lots qui doivent encore être synchronisés avec un

dispositif intelligent sont synchronisés automatiquement.

Il est possible de réaliser une réinitialisation

complète de l'instrument après une mise à jour. Toutes les valeurs

enregistrées seront effacées de la mémoire.

Updates

Cette option détermine si une mise à jour logicielle est disponible pour

votre instrument.

Consultez le lien à l'adresse www.defelsko.com/update

ATTENTION:

Lorsque Activé , cette fonction permet la communication avec un

dispositif intelligent exécutant l'App PosiTector (voir Accès aux valeurs

de mesure enregistrées) via la technologique d'auto-appairage sans fil

Bluetooth Smart (BLE).

Bluetooth Smart

(Modèles avancés avec numéros de série 784000 et

supérieurs uniquement)

PosiSoft Desktop est nécessaire lors de l'utilisation

des connexions USB pour synchroniser les données avec l’application

PosiSoft.net.

REMARQUE:

Send Batches

Transferts de lots sélectionnés à l'App PosiTector (utile en cas de

commutation entre dispositifs).

L'option Envoyer les lots est visible dans le menu lorsque l’instrument

est connecté à un dispositif intelligent exécutant l’App PosiTector.

Si la fonction Bluetooth Smart est désactivée, les

données provenant des lots sélectionnés dans le menu Sync Batches

sont maintenus en file d'attente jusqu'à ce que la communication avec

l'App PosiTector soit rétablie.

REMARQUE:

Page 46

10

www.defelsko.com

© DeFelsko Corporation États-Unis 2016

Tous droits réservés

Le présent manuel est protégé par des droits de propriété intellectuelle. Tous droits réservés. Toute reproduction ou transmission intégrale ou partielle, de quelque manière que ce soit sans l'autorisation écrite de

DeFelsko Corporation est interdite.

DeFelsko, PosiTector et PosiSoft sont des marques déposées par DeFelsko Corporation aux États-Unis

et dans d'autres pays. Les autres marques et les autres noms de produits sont des marques, déposées

ou non, qui appartiennent à leurs propriétaires respectifs.