Page 1

DeeZeeRunningBoardInstallationInstructions

CongratulationsonyourpurchaseofaqualityDeeZeeproduct.DeeZeeis

recognizedashavingthehighestqualityrunningboardsandaccessorieson

themarkettoday.Wehaveearnedthisreputationbyofferingourcustomers

aproducttheycanbeproudtoplaceontheirvehicles.DeeZeemeetsall

thecriteriaofmanufacturingacustom-fitproductwhichguaranteesitto

betheeasiestproducttoinstall.

Note:Pleasetaketimetoreadalloftheinstructionsbeforebeginningthisinstallation.

Warning!Pleasecheckforwiringorotherobstructionsbeforedrillinganyholesinto

thevehicle.Ifitisnecessarytodrillanyholesintothevehicle,DeeZeerecommends

puttingasealantorrustinhibitoraroundallholesdrilledintothebodyofthevehicle.

Warning!Itisthesoleresponsibilityofthevehicleownertocheckfortireclearance.

Warning!Itisunlawfulanddangeroustorideonrunningboardsorsideboxboards

whilethevehicleisinmotion.

CleaningInstructions:TomaintainthebrightfinishofyourDeeZeerunningboards,

cleanwithamilddetergent.Forourstainlesssteelproductsandaccessories,the

applicationofahighgradeautomotivetypewaxisrecommended.

Ifyoushouldhappentohaveanyquestionswiththisproductoryouhavean

installationquestion,pleasefeelfreetocallusat:

1-800-779-8222

IfyouwouldliketofindoutmoreinformationonDeeZee’sproductsplease

feelfreetovisitourwebsiteat:

WWW.DEEZEE.COM

DZ1020.PDF12/09/02

Page 2

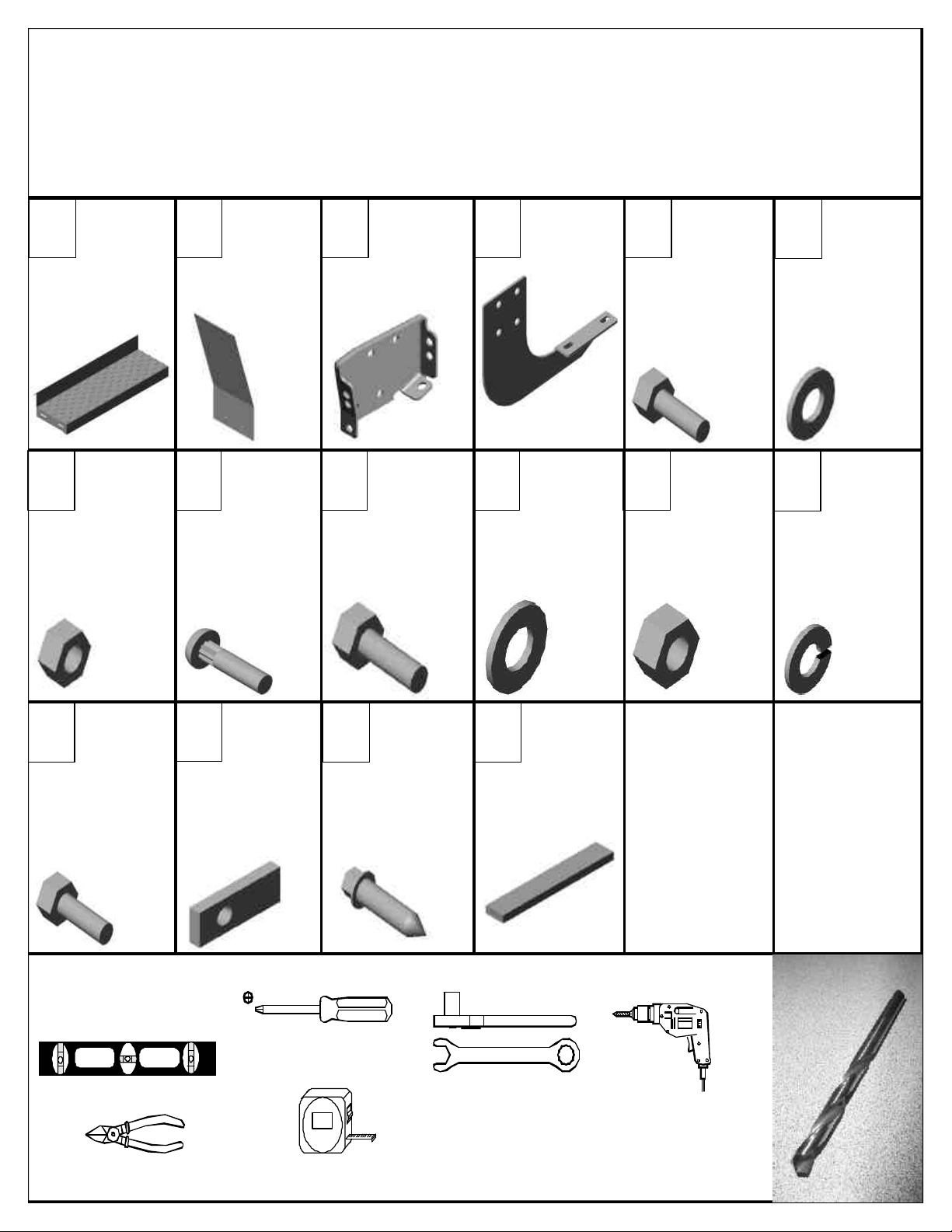

DeeZeeBritetreadRunningBoardInstallationInstruction

DZ1020

(1988-1998)ChevyExtendedCabPickup

Britetread

Running

A

Board

X2 X6

G I

1/4“HexNut

1/4x1”Ribneck

CarriageHead

Bolt

Britetread

Mudflap

B

H

C D

X2

3/8x1“Hex

HeadBolt

Rocker

Panel

Bracket

E

1/4x3/4”

HexHead

Bolt

Running

Board

Bracket

X6

J K

5/16“FlatWasher 3/8“HexNut

X4

3/8"Lock

Washer

F

L

1/4“Flat

Washer

X26

X22 X12

M

3/8x11/4”Hex

HeadBolt

ToolsRequired:

OutilsNécessaires:

Level

Tin-snips

N

3/8“Offset

ThreadedPlate

X6

X18

O

1/4x1”Sheet

MetalScrew

X6

PhillipsHead

Screwdriver

TapeMeasure

P

FoamTape

X4

Ratchet/Wrench

Sizes:3/8“

7/16“

9/16"

X30

1EA.

Drill

X12

X18

1/4”Needed

3/16”Needed

Page 3

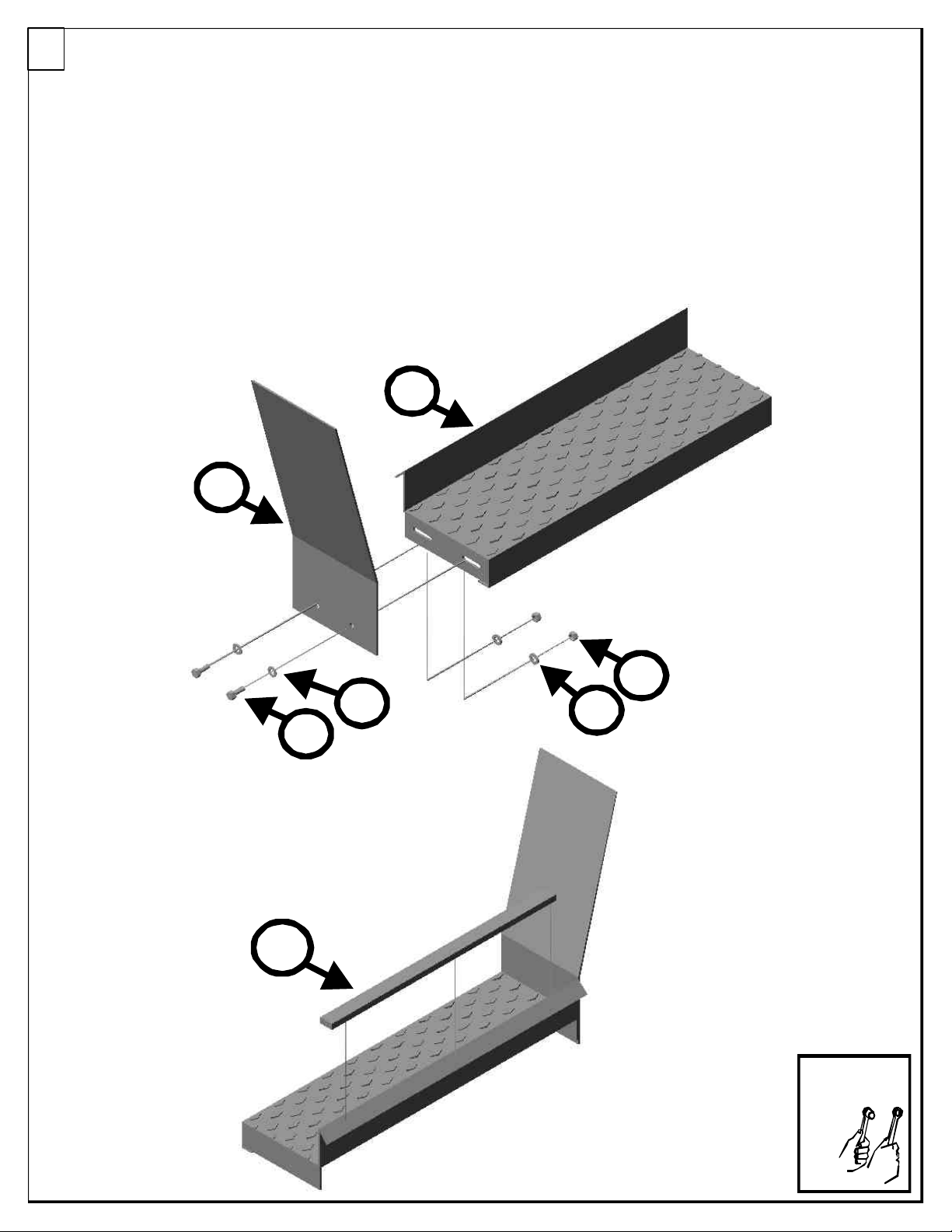

1

Securebritetreadmudflap(B)tobritetreadrunningboard(A)using1/4x3/4”hexheadbolts(E),

1/4”flatwashers(F),and1/4”hexnuts(G).Tightenintoplaceusinga7/16”wrench/orsocket.

Placefoamgasket(P)ontothebacklipofbritetreadrunningboard(A)andtrimflushwiththe

britetreadmudflap(B)andtheendofbritetreadrunningboard(A).

Asegureelmudflapdelbritetread(b)alatarjetacorrientedelbritetread(a)usandolospernosdel

apistadelatuercahexagonalde1/4delx3/4"(e),lasarandelasdel1/4"(f),ylastuercas1/4"de

tuercahexagonalplanas(g).Aprieteenlugarusandounallavedel7/16"/oelsocket.Coloquela

juntadeespuma(p)sobreelbacklipdelatarjetacorrientedelbritetread(a)ycortearasdel

mudflapdelbritetread(b)ydelextremodelatarjetacorrientedelbritetread(a).

A

B

P

E

F

G

F

Britetread

RunningBoard

7/16“Wrench

orSocket

Page 4

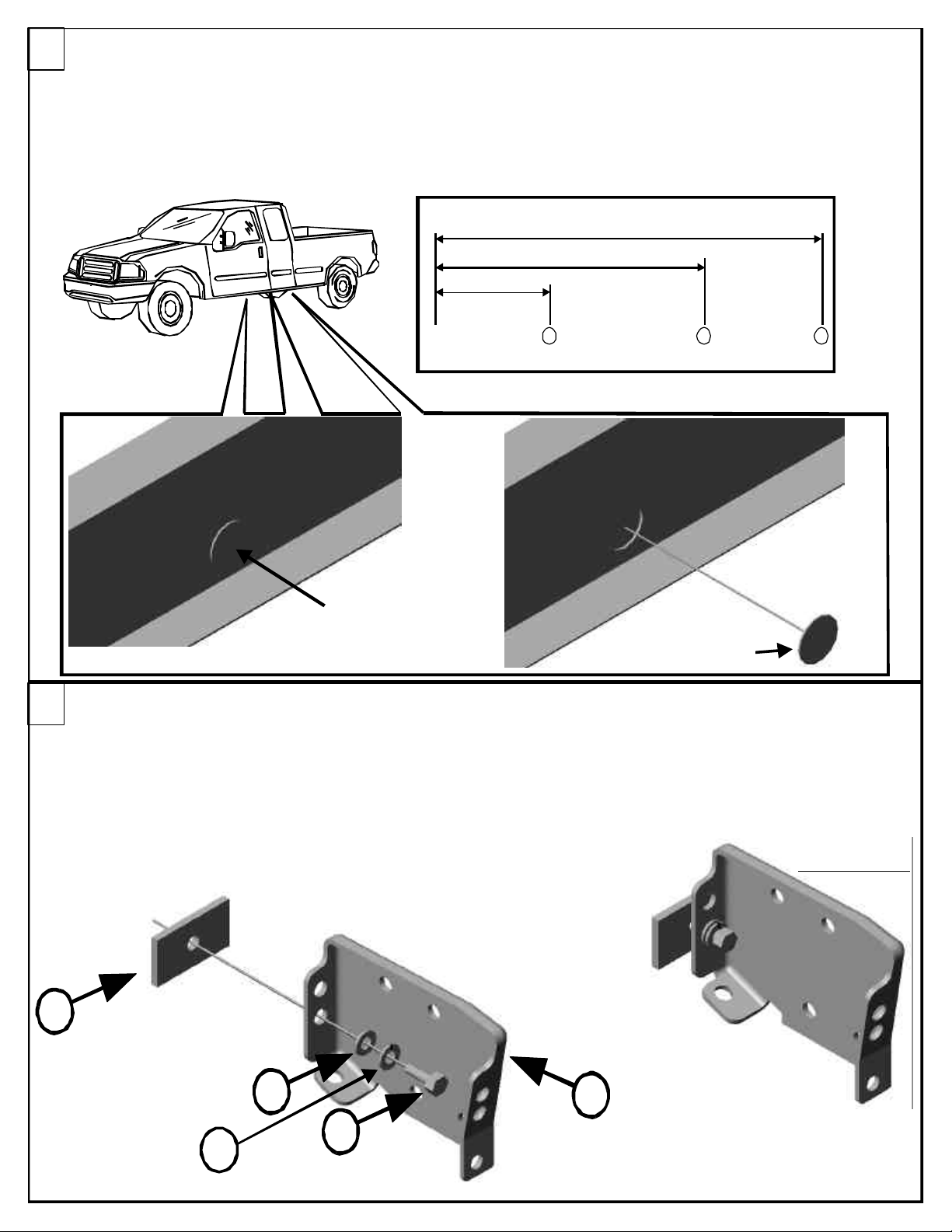

Locatetheplasticplugscoveringtheexistingholesinthevehiclerockerpanelatthelocationsshownbelow.Remove

2

themfromthevehicle.

Localisezlesprisesdeplastiquecouvrantlestrousexistantsdanslepanneaudeculbuteurdevéhiculeaux

emplacementsmontrésci-dessous.Retirez-lesduvéhicule.

ApproximateHoleLocationsonVehicle

733/8”

381/8”

15”

Frontof

Rocker

Panel

Plastic

Plug

Plastic

Plug

3

Placea3/8x11/4”hexheadbolt(M),3/8”lockwasher(L),and5/16”flatwasher(J)throughrockerpanelbracket(C)as

shownbelow.Threada3/8”largethreadedplate(N)ontothe3/8x11/4”hexheadbolt(M)acoupleofturns.

Placezdes3/8x11/4"boulonsprincipauxd'hexa(m),unerondelledefreinagede3/8"(l),etunerondelleplatede5/16"(j)

parlaparenthèsedepanneaudeculbuteur(c)commemontréci-dessous.

Assembled

N

L

J

C

M

Page 5

Usingthedrawingsbelowasaguide,placethethreadedplateonthebraceassemblyintotheexistingholesinthe

4

vehiclepanel.Thebraceassemblyshouldbesnugagainstthebottomoftherockerpanelonthevehicle.Nowtighten

the3/8x11/4”hexheadboltonthebraceassemblyuntilsnugusinga9/16”wrench/orsocket.

Enutilisantlesschémasci-dessouscommeguide,placezleplatfiletésurlecroisillondanslestrousexistantsdansle

panneaudevéhicule.Lecroisillondevraitêtreconfortablecontrelebasdupanneaudeculbuteursurlevéhicule.Serrez

maintenantle3/8x11/4”;boulon principald'hexaducroisillonjusqu'àutiliserdouillettementun9/16”;clé/ouplot.

VehicleRocker

Panel

Brace

Assembly

Brace

Assembly

Brace

Assembly

Brace

Assembly

VehicleRocker

Panel

Brace

Assembly

Brace

Assembly

3/8x11/4”Hex

HeadBolt

Brace

Assembly

9/16“Wrench

orSocket

Page 6

Usingthebottomholeintheflangeonrockerpanelbracket(C)asaguide,drilla1/4”holethroughthe

5

vehiclerockerpanel.Securethebottomflangeonrockerpanelbracket(C)tothevehiclerockerpanel

using1/4x1”ribneckcarriageheadbolt(H),1/4”flatwasher(F),and1/4”hexnut(G)asshownbelow.

Tightenintoplaceusinga7/16”wrench/orsocket.

Drillwitha

1/4”drillbit

Enutilisantletrouinférieurdanslabridesurlaparenthèsedepanneaudeculbuteur(c)commeguide,

forezun1/4”;trouparlepanneaudeculbuteurdevéhicule.Fixezlabrideinférieuresurlaparenthèsede

panneaudeculbuteur(c)aupanneaudeculbuteurdevéhiculeenutilisant1/4x1”;boulondetêtede

chariotderibneck(h),1/4”;rondelleplate(f),et1/4”;écroud'hexa(G)commemontréci-dessous.Serrez

dansl'endroitenutilisantun7/16”;arrachez/ouplot.

VehicleRocker

Panel

C

7/16“Wrench

orSocket

Drillwitha

1/4”drillbit

VehicleRocker

Panel

G

F

C

H

Page 7

6

Usingthedrawingbelowasaguide,placerunningboardbracket(D)uptorockerpanelbracket(C).Securethe

rear-bottom

5/16"flatwashers(J),3/8"lockwasher(L),and3/8"hexnut(K).

Enutilisantleschémaci-dessouscommeguide,placezlaparenthèsecourantedepanneau(d)jusqu'àlaparenthèsede

panneaudeculbuteur(c).Fixezletroud'arrière-basdanslaparenthèsecourantedepanneau(d)autroudansla

parenthèsedepanneaudeculbuteur(c)àl'aideduboulondetêted'hexade3/8xde1"(i),desrondellesplatesde5/16"

(j),delarondelledefreinagede3/8"(l),etdel'écroud'hexade3/8"(k).Note:Voirlesdessinsci-dessouspour

l'identificationcorrectedetrou.

holeinrunningboardbracket(D)totheholeintherockerpanelbracket(C)using3/8x1"hexheadbolt(I),

Note:Seedrawingsbelowforcorrectholeidentification.

I

Vehicle

Rocker

Panel

C

J

D

J

KL

KK

CorrectHoleLocations

CorrectHoleLocations

Page 8

7

Rotatethebraceassemblytotheuprightpositionandsecureitintoplaceusinga3/8x1"hexheadbolt(I),3/8"lock

washer(L),5/16"flatwashers(J),and3/8"hexnuts(K)asshownbelow.

Tournezlecroisillonjusquàlapositiondroiteetfixez-ledansl'endroitàl'aided'unboulondetêted'hexade3/8xde1"

(i),delarondelledefreinagede3/8"(l),desrondellesplatesde5/16"(j),etdesécrousd'hexade3/8"(k)commemontré

ci-dessous.

I

J

Rotate

K

L

J

C

D

9/16and7/16“

Wrenchor

Socket

Page 9

8

Placebritetreadrunningboard(A)uptotherunningboardbrackets(D)asshownbelow.Slidethebritetreadrunning

boarduptotherockerpanelsothatitisflushwiththevehiclerockerpanel.

Placezlepanneaucourantdebritetread(a)jusqu'auxparenthèsesdepanneaudefonctionnement(d)commemontré

ci-dessous.Glissezlepanneaucourantdebritetreadjusqu'aupanneaudeculbuteurdesortequ'ilsoitaffleurantdu

panneaudeculbuteurdevéhicule.

BritetreadRunning

Board

RockerPanel

Bracket

RunningBoard

Bracket

SideViewofrockerpanelbracket

andbritetreadrunningboardassembly.

RockerPanel

Bracket

Vehicle

Rocker

Panel

BritetreadRunning

Board

RunningBoard

Bracket

Page 10

9

Usingthebottomholesintherunningboardbracket(D)asaguide,drill1/4”holesthroughthebritetread

runningboard.Securetherunningboardbracket(D)tothebritetreadrunningboardusing1/4x1”

ribneckcarriageheadbolts(H),1/4”flatwashers(F),and1/4”hexnuts(G).Tightenintoplaceusinga

7/16”wrench/orsocket.

Drillwitha

1/4”drillbit

Enutilisantlestrousdebasdanslepanneaucourantencadrez(d)commeguide,forentdestrousde

1/4"parlepanneaucourantdebritetread.Fixezlaparenthèsecourantedepanneau(d)aupanneau

courantdebritetreadenutilisantlesboulonsdetêtedechariotde ribneckde1/4xde1"(h),les

rondellesde1/4"(f),etlesécrous1/4"d'hexaplats(g).Serrezdansl'endroitàl'aided'unecléde7/16"/ou

duplot.

Britetread

D

Running

7/16“Wrench

orSocket

H

Drillwitha

1/4”Drillbit

Board

Britetread

Running

Board

D

F

G

Page 11

10

Drilltwoholesthroughthebritetreadmudflapandthesheetmetalofthevehicle

wheelwellopening.Securethebritetreadmudflaptothevehiclewheelwell

openingusing1/4x1”sheetmetalscrews(O).Tightenintoplaceusinga3/8”

wrench/orsocket.

Drillwitha

3/16”drillbit

Forezdeuxtrousparlemudflapdebritetreadetlemétaldefeuilledel'ouverture

desoutedetraindevéhicule.Fixezlemudflapdebritetreadàl'ouverturedesoute

detraindevéhiculeàl'aidedesvisenmétaldefeuillede1/4xde1"(o).Serrezdans

l'endroitàl'aided'unecléde3/8"/ouduplot.

Britetread

Mudflap

3/8“Wrench

orSocket

Britetread

Mudflap

O

O

Loading...

Loading...