Page 1

Before returning this product

to the store of purchase

Contact Dee Zee if you experience the following problems:

•MissingParts

•InstallationProblems/Questions

•WarrantyQuestions

1.800.779.2102

Hoursofoperation:8am-5pmCST,Mon-Friday

Reviewcompletewarrantypolicyandregisteryourproductat:

www.deezee.com

Page 2

Dee Zee Running Board Installation Instructions

Congratulations on your purchase of a quality Dee Zee product. Dee Zee is

recognized as having the highest quality running boards and accessories on

the market today. We have earned this reputation by offering our customers

a product they can be proud to place on their vehicles. Dee Zee meets all

the criteria of manufacturing a custom-fit product which guarantees it to

be the easiest product to install.

Note: Please take time to read all of the instructions before beginning this installation.

War ning! Please check for wiring or other obstr uctions before drilling any holes into

the vehicle. If it is necessar y to drill any holes into the vehicle, Dee Zee recommends

putting a sealant or rust inhibitor around all holes drilled into the body of the vehicle.

War ning! It is the sole responsibility of the vehicle owner to check for tire clearance.

War ning! It is unlawful and dangerous to ride on r unning boards or side box boards

while the vehicle is in motion.

Cleaning Instructions: To maintain the bright finish of your Dee Zee running boards,

clean with a mild deter gent. For our stainless steel products and accessories, the

application of a high grade automotive type wax is recommended.

If you should happen to have any questions with this product or you have an

installation question, please feel fr ee to call us at:

1-800-779-8222

If you would like to find out mor e infor mation on Dee Zee’s products please

feel free to visit our website at:

WWW.DEEZEE.COM

Page 3

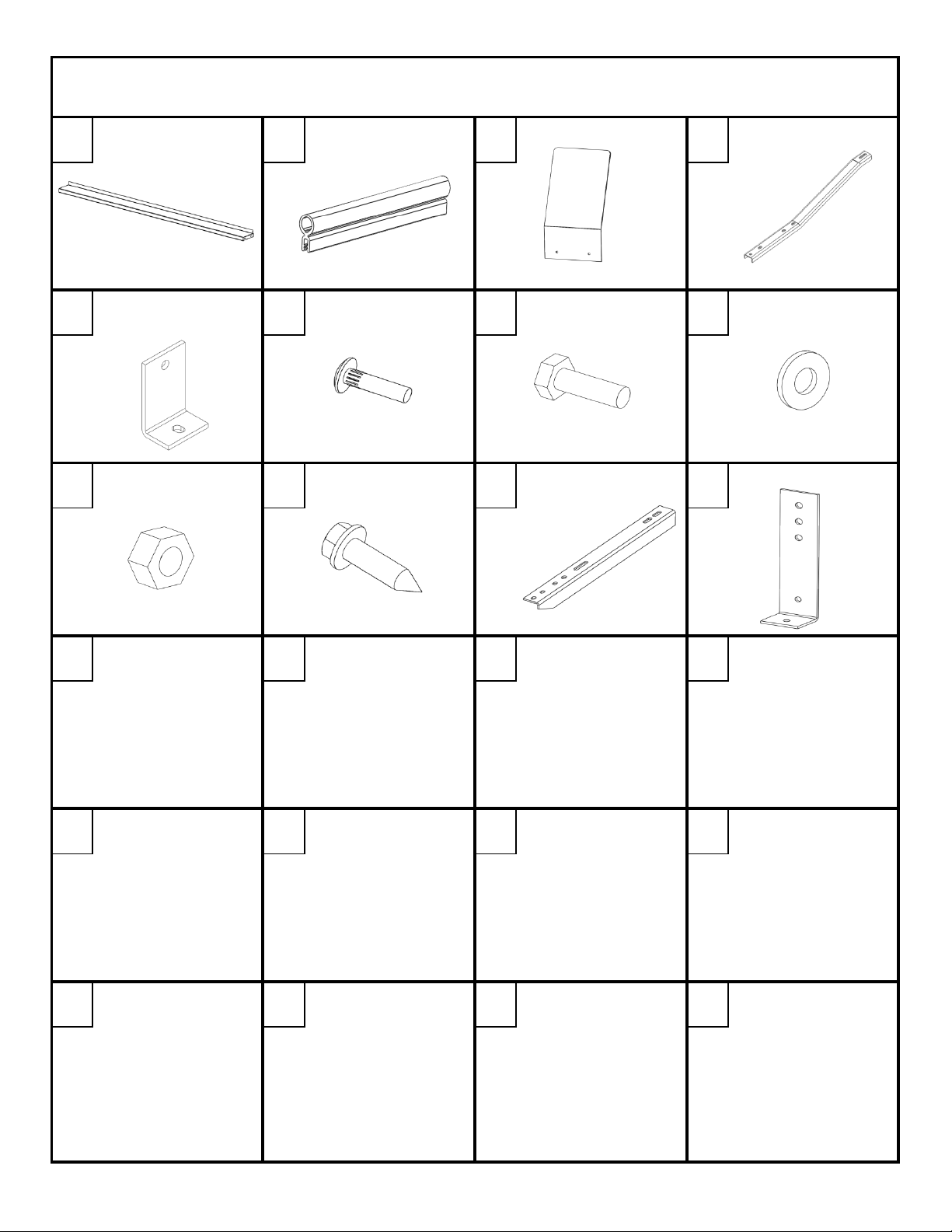

BD 2044W

X2

GSK-41

17 FT.

FP0300

X4

B 1988

X2

BRACKET

B 81FX

X6

PN 87

X18

PN 70

X18

PN 72

X54

PN 71

X36

PN 97

X18

B 1984P

X4

B4570

X4

Dee Zee Brite Tread Board Installation Instruction

DZ 2044 Ford 138" WB Van

A B C D

PN 71

X36

PN 97

X18

B 1984P

X4

B4570

X4

BT BOARD RUBBER TRIM MUD FLAP CHANNEL BRACE

E F G H

ROCKER PANEL

I

1/4" HEX NUT SHEET

J K

1/4 X 1" RIBNECK 1/4 X 3/4" HEX

CARRIAGE BOLT

METAL SCREW

HEAD BOLT

ANGLE BRACE FRAME BRACKET

L

1/4" FLAT WASHER

DZ 2044 1 OF 10 8/14/2012

Page 4

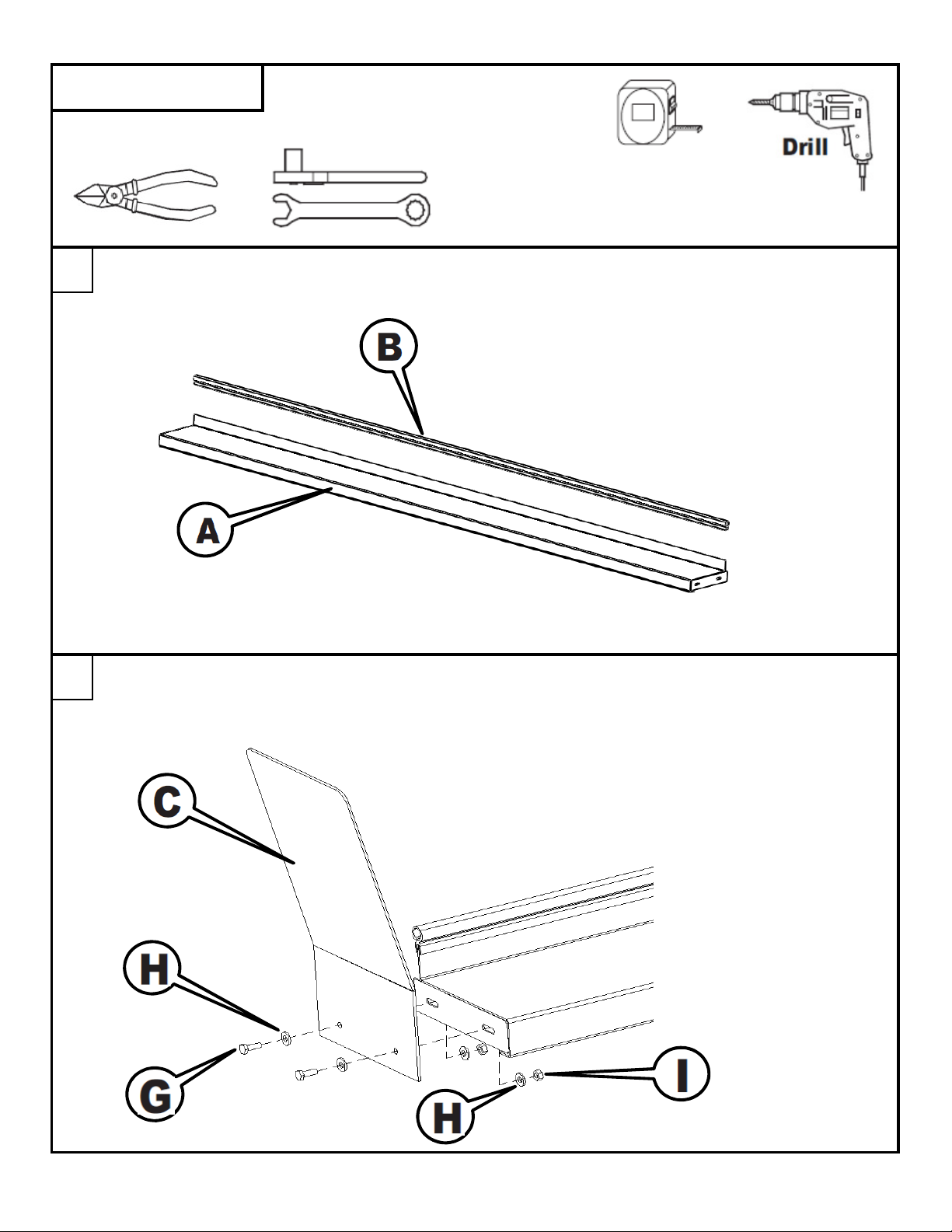

WRENCH/RATCHET

3/8", 7/16"

TAPE

MEASURE

TIN SNIPS

CLAMP

3/16" DRILL BIT

1/4" DRILL BIT

Place the rubber trim onto the back lip of the running board. Cut the trim to length using tin snips.

TOOLS REQUIRED

Attach the mud flap [C] to both ends end of the running board using

the 1/4" x 3/4" hex head bolt [G], the 1/4" flat washer [H], and the 1/4" hex nut [I].

Snug the flap to the board, but do not completely tighten at this time.

1

2

DZ 2044 2 OF 10 8/14/2012

Page 5

Measure back from the front wheel well and mark the lower rocker panel at 18", 41" and 68".

This will be the approximate location for the rocker panel bracket [E].

Make sure there is nothing on the bottom of the frame at these location that would obstruct the

channel / angle brace from being installed in the later steps. If there is an obstruction, move the rocker

panel bracket to the front/rear as needed.

3

The bottom of the mounting bracket should be 1" below the bottom of the pinch weld.

Mark the hole location in the vertical long leg of the mounting bracket .

Remove the bracket and drill a 1/4" hole through the pinch weld.

Repeat this for each bracket location.

4

POINTING TOWARDS

THE FRAME

DZ 2044 3 OF 10 8/14/2012

Page 6

Attach the rocker brackets [E] to the rocker panel with a ribneck carriage bolt [F],

washer [H], and nut [I].

Repeat this for each bracket location.

5

Once the rocker panel brackets are installed, attach the channel brace to the bottom of the FRONT bracket

through the slot shown in the channel brace using a hex head bolt [G], washer [H], and a nut [I].

Tighten with a 7/16" socket/wrench.

6

DZ 2044 4 OF 10 8/14/2012

Page 7

Drill a 3/16" hole through the slot in the back of brace into the bottom of the frame.

Attach the channel brace to the frame using a sheet metal screw [J] with a 3/8" socket.

7

DZ 2044 5 OF 10 8/14/2012

Page 8

Attach the angle brace [K] to the bottom of the MIDDLE and REAR mounting bracket

through the slot shown in the anglel brace using a hex head bolt [G], washer [H], and a nut [I].

Tighten with a 7/16" socket/wrench.

Attach the frame brace [L] to the bottom of the middle and rear angle brace

through the slot shown in the angle brace using a hex head bolt [G], washer [H], and a nut [I].

With the frame brace held up against the frame, tighten the hardware with a 7/16" socket/wrench.

8

9

DZ 2044 6 OF 10 8/14/2012

Page 9

Use a level to set the angle brace parallel to the ground. Clamp the frame brace [L] in place.

Drill two 3/16" holes into the frame through the holes in the frame brace.

Use whichever two holes best fit to the frame

10

Attach the frame brace to the frame using two sheet metal screws [J] with a 3/8" socket.

HOLES

11

12

DZ 2044 7 OF 10 8/14/2012

Page 10

Place the running board on the angle braces. Adjust the angle braces as needed to insure that the

holes can be drill through the board to attach it to the braces.

The bolts holding the angle brace to the mounting bracket and frame bracket will have to be loosened

to adjust the brace. Once the brace location is set, re-titghten the bolts.

ADJUST BRACE AS NEEDED

Adjust the board to make sure the flap is up against the inner portion of the wheel well.

Then adjust the board in/out to make sure it is straight with the vehicle and that the gasket

on the backlip is in contact with the rocker panel.

Once the board location is set, clamp the running board to the angle braces.

13

CLAMP

BOARD TO

14

BRACE

DZ 2044 8 OF 10 8/14/2012

Page 11

Drill 1/4" holes up through the board using the holes shown below.

For the middle and rear location, drill through either the 1st and 3rd slot, or the 2nd and 4th slot.

15

Attach the running board to the angle brace using the 1/4" x 1" ribneck carriage bolt [F],

1/4" flat washer [H], and 1/4" hex nut [I]. Tighten using a 7/16" wrench or deep well socket.

Repeat at each brace location.

16

3rd

4th

1st

2nd

DZ 2044 9 OF 10 8/14/2012

Page 12

Pressing the flap up against the wheel well, drill two 3/16" holes through the hole in the mud flap

into the sheet metal of the wheel well. Repeat for the rear of the board.

Attach the mud flap to the wheel well using two sheet metal screws [K] with a 3/8" socket.

Repeat for the rear of the board.

17

Check all hardware to make sure it has been tightened.

Repeat the assembly steps for the other side of the vehicle.

18

DZ 2044 10 OF 10 8/14/2012

Loading...

Loading...