Page 1

Before returning this product

DZ 2041

to the store of purchase

Contact Dee Zee if you experience the following problems:

•MissingParts

•InstallationProblems/Questions

•WarrantyQuestions

1.800.779.2102

Hoursofoperation:8am-5pmCST,Mon-Friday

Reviewcompletewarrantypolicyandregisteryourproductat:

www.deezee.com

Page 2

Dee Zee Running Board Installation Instructions

Congratulations on your purchase of a quality Dee Zee product. Dee Zee is

recognized as having the highest quality running boards and accessories on

the market today. We have earned this reputation by offering our customers

a product they can be proud to place on their vehicles. Dee Zee meets all

the criteria of manufacturing a custom-fit product which guarantees it to

be the easiest product to install.

Note: Please take time to read all of the instructions before beginning this installation.

Warning! Please check for wiring or other obstructions before drilling any holes into

the vehicle. If it is necessary to drill any holes into the vehicle, Dee Zee recommends

putting a sealant or rust inhibitor around all holes drilled into the body of the vehicle.

Warning! It is the sole responsibility of the vehicle owner to check for tire clearance.

Warning! It is unlawful and dangerous to ride on running boards or side box boards

while the vehicle is in motion.

Cleaning Instructions: To maintain the bright finish of your Dee Zee running boards,

clean with a mild detergent. For our stainless steel products and accessories, the

application of a high grade automotive type wax is recommended.

If you should happen to have any questions with this product or you have an

installation question, please feel free to call us at:

1-800-779-8222

If you would like to find out more information on Dee Zee’s products please

feel free to visit our website at:

WWW.DEEZEE.COM

DZ 2041.PDF 10/30/03

Page 3

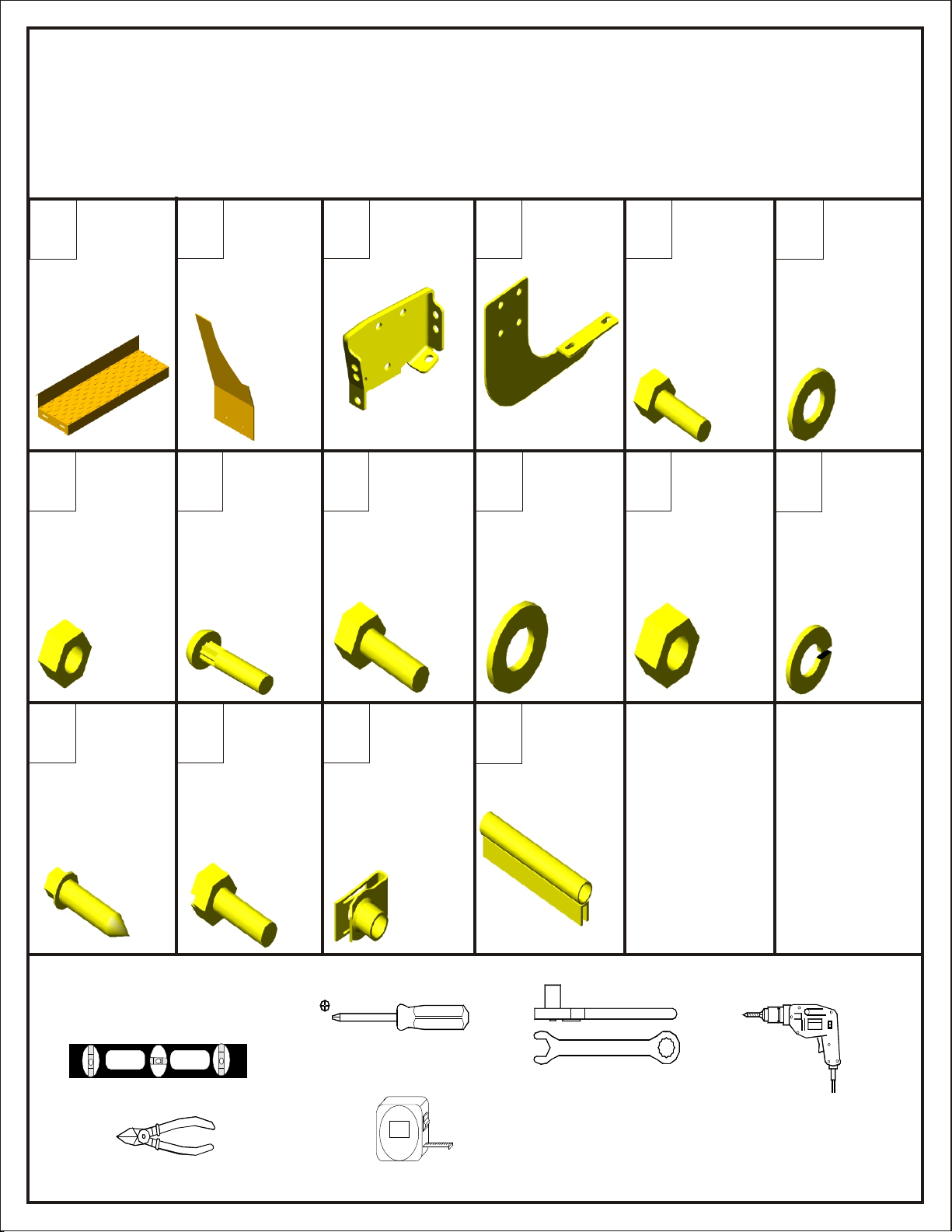

Dee Zee Britetread Running Board Installation Instruction

DZ 2041

(2004 - Current) Ford F150 Super Cab Pickup

Britetread

Running

A

Board

G

1/4“ Hex Nut

Britetread

Mudflap

B

X2

H

1/4 x 1” Ribneck

Carriage Head

Bolt

Rocker

Panel

C D

Bracket

X2

I

3/8 x 1“ Hex

Head Bolt

Running

Board

Bracket

X6

J

5/16“ Flat Washer

E

X6

K

3/8“ Hex Nut

1/4 x 3/4”

Hex Head

Bolt

X4

1/4“ Flat

Washer

F

L

3/8" Lock

Washer

X20

X16

M

1/4 x 1” Sheet

Metal Screw

To o ls Re qu i r ed :

Outils Nécessaires:

Tin-snips

N

8mm x 25mm

Hex Head Bolt

X4

Level

X12

X12

P

8mm U-Clip

Phillips Head

Screwdriver

Tape Measure

X12

X12

Q

Bulb-Seal

Gasket

Ratchet / Wrench

Sizes: 3/8“

7/16“

13mm

X24

14 ft.

9/16"

X12

Drill

1/4” Drill Bit

3/16” Drill Bit

X12

Page 4

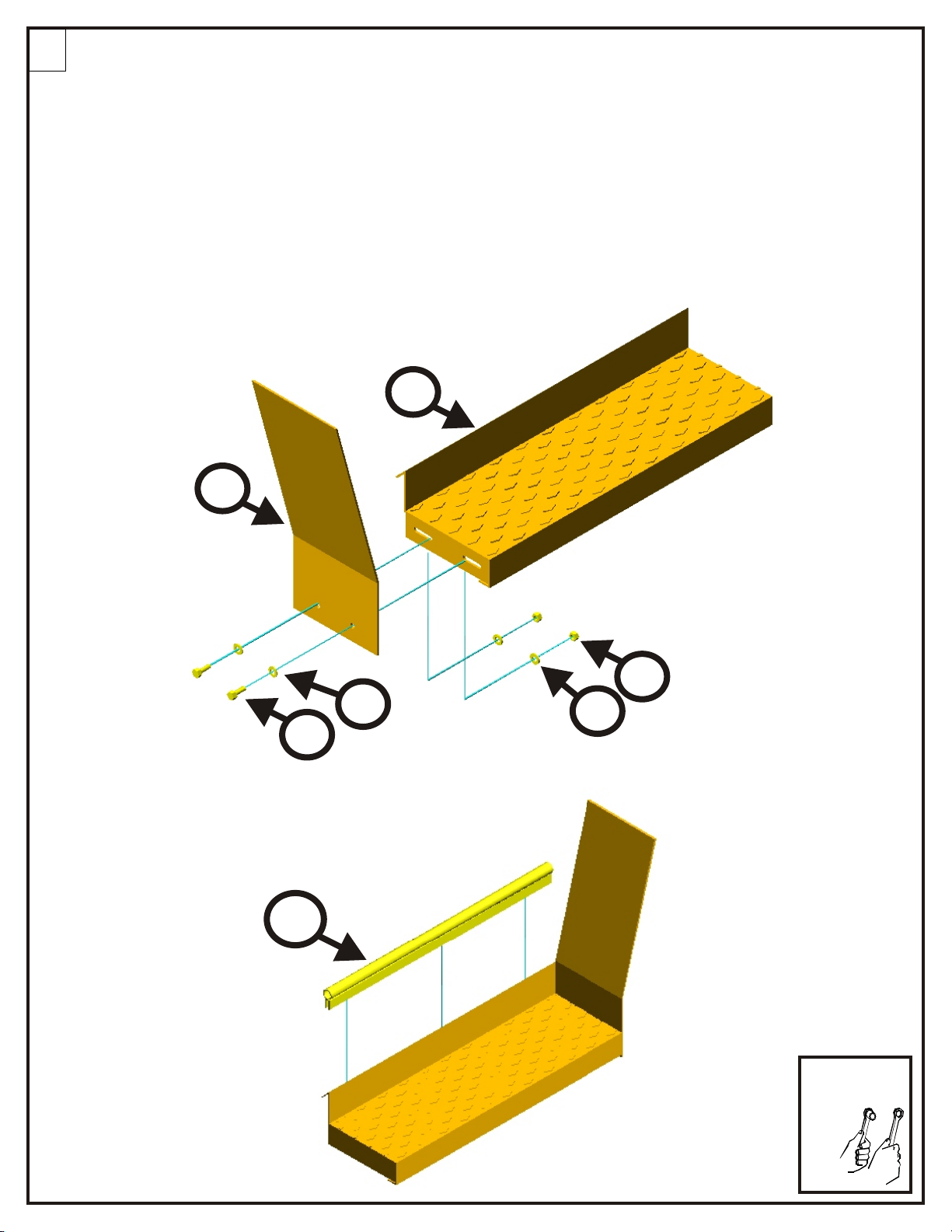

1

Secure britetread mudflap (B) to britetread running board (A) using 1/4 x 3/4” hex head bolts (E),

1/4” flat washers (F), and 1/4” hex nuts (G). Tighten into place using a 7/16” wrench / or socket.

Place bulb-seal gasket (Q) onto the backlip of britetread running board (A) and trim flush with the

britetread mudflap (B) and the end of britetread running board (A).

Fixez le mudflap de britetread (b) au panneau courant de britetread (a) en utilisant les boulons de

tête d'hexa de 1/4 x de 3/4"(e), les rondelles de 1/4" (f), et les écrous 1/4"d'hexa plats (g). Serrez

dans l'endroit à l'aide d'une clé de 7/16"/ou du plot. Placez la garniture d'ampoule-joint (q) sur le

backlip du panneau courant de britetread (a) et équilibrez à affleurement du mudflap de britetread

(b) et de l'extrémité du panneau courant de britetread (a).

A

B

E

Q

F

G

F

Britetread

Running Board

7/16“ Wrench

or Socket

Page 5

2

You will need to remove the black tape from the rocker panel and then place an 8mm u-clip (P) into the hole locations

shown below.

P

Approximate Hole Locations on Vehicle

64 1/4”

36 ½”

19 3/4”

Front of

Rocker

Panel

Existing

Hole

Location

Existing

Hole

Location

Existing

Hole

Location

Page 6

3

Slide 8mm u-clip (P) onto the rocker panel bracket (C) as shown below. Make sure that the hole in 8mm u-clip (O) is

aligned with the hole in rocker panel bracket (C).

Diapositive l'u-agrafe de 8mm (p) sur la parenthèse de panneau de culbuteur (c) comme montré ci-dessous. Assurez-vous

que le trou dans l'u-agrafe de 8mm (o) est aligné avec le trou dans la parenthèse de panneau de culbuteur (c).

C

P

Brace

Assembly

Page 7

4

Front and Rear Brace Installation

Place the rocker panel bracket (C) up to the vehicle rocker panel and u-clip (p) and secure into place

using an 8mm x 30mm flange head bolt (N) as shown below.

Placez la parenthèse de panneau de culbuteur (c) jusqu'au panneau de culbuteur de véhicule et

à l'u-agrafe (p) et la fixez dans l'endroit à l'aide d'un boulon de tête de bride de 8mm x de 30mm (n)

comme montré ci-dessous.

13mm Wrench

or Socket

C

P

N

Brace Assembly

Installed

C

Page 8

5 Front and Rear Brace Installation

Secure the 8mm u-clip in the bottom flange on rocker panel bracket (C) to the rocker panel using 8mm

x 25mm flange head bolt (N).

Asegure el u-clip de 8m m en el reborde inferior en el soporte del panel del eje de balancín (c) al panel

del eje de balancín usando el perno de la cabeza del reborde de 8m m x de 25m m (n).

Vehicle Rocker

Panel

13mm Wrench

or Socket

N

C

Brace Assembly

Installed

C

Page 9

6

Using the drawing below as a guide, place running board bracket (D) up to rocker panel bracket (C). Secure the

rear-top hole in running board bracket (D) to the hole in the rocker panel bracket (C) using 3/8 x 1" hex head bolt (I),

5/16" flat washers (J), 3/8" lock washer (L), and 3/8" hex nut (K). Note: See drawings below for correct hole identification.

I

Vehicle

Rocker

Panel

E

J

D

J

KL

KK

Correct Hole Locations

Correct Hole Locations

Page 10

7

Rotate the running board bracket (D) to the upright position and secure it into place using a 3/8 x 1" hex head bolt (I), 3/8"

lock washer (L), 3/8" flat washers (J), and 3/8" hex nuts (K) as shown below.

Rote el soporte corriente del tablero (d) a la posición vertical y asegúrelo en lugar usando un perno de la cabeza de

la tuerca hexagonal de 3/8 del x 1"(i), la arandela de cerradura del 3/8" (l), las arandelas planas del 3/8"(j), y las tuercas

de tuerca hexagonal del 3/8" (k) según lo demostrado abajo.

I

K

J

C

J

L

D

Rotate

9/16 and 7/16“

Wrench or

Socket

Page 11

8

Place britetread running board (A) up to the running board brackets (D) as shown below. Slide the britetread running

board up to the rocker panel so that it is flush with the vehicle rocker panel.

Placez le panneau courant de britetread (a) jusqu'aux parenthèses de panneau de fonctionnement (d) comme montré

ci-dessous. Glissez le panneau courant de britetread jusqu'au panneau de culbuteur de sorte qu'il soit affleurant du

panneau de culbuteur de véhicule.

Rocker Panel

Bracket

Running Board

Bracket

Britetread Running

Board

Side View of rocker panel bracket

and britetread running board assembly.

Britetread Running

Vehicle

Rocker

Panel

Rocker Panel

Bracket

Board

Running Board

Bracket

Page 12

9

Using the bottom holes in the running board bracket (D) as a guide, drill 1/4” holes through the britetread

running board. Secure the running board bracket (D) to the britetread running board using 1/4 x 1”

ribneck carriage head bolts (H), 1/4” flat washers (F), and 1/4” hex nuts (G). Tighten into place using a

7/16” wrench / or socket.

Drill with a

1/4” drillbit

En utilisant les trous de bas dans le panneau courant encadrez (d) comme guide, forent des trous de

1/4"par le panneau courant de britetread. Fixez la parenthèse courante de panneau (d) au panneau

courant de britetread en utilisant les boulons de tête de chariot de ribneck de 1/4 x de 1"(h), les

rondelles de 1/4" (f), et les écrous 1/4"d'hexa plats (g). Serrez dans l'endroit à l'aide d'une clé de 7/16"/ou

du plot.

Britetread

D

Running

7/16“ Wrench

or Socket

E

Drill with a

1/4” Drillbit

Board

Britetread

Running

Board

D

F

G

Page 13

10

Drill two holes through the britetread mudflap and the sheet metal of the vehicle

wheel well opening. Secure the britetread mudflap to the vehicle wheel well

opening using 1/4 x 1” sheet metal screws (M). Tighten into place using a 3/8”

wrench / or socket.

Drill with a

3/16” drillbit

Forez deux trous par le mudflap de britetread et le métal de feuille de l'ouverture

de soute de train de véhicule. Fixez le mudflap de britetread à l'ouverture de soute

de train de véhicule à l'aide des vis en métal de feuille de 1/4 x de 1"(mj). Serrez dans

l'endroit à l'aide d'une clé de 3/8"/ou du plot.

Britetread

Mudflap

3/8“ Wrench

or Socket

Britetread

Mudflap

M

M

Loading...

Loading...