Page 1

Before returning this product

to the store of purchase

Contact Dee Zee if you experience the following problems:

•MissingParts

•InstallationProblems/Questions

•WarrantyQuestions

1.800.779.2102

Hoursofoperation:8am-5pmCST,Mon-Friday

Reviewcompletewarrantypolicyandregisteryourproductat:

www.deezee.com

Page 2

Dee Zee Running Board Installation Instructions

Congratulations on your purchase of a quality Dee Zee product. Dee Zee is

recognized as having the highest quality running boards and accessories on

the market today. We have earned this reputation by offering our customers

a product they can be proud to place on their vehicles. Dee Zee meets all

the criteria of manufacturing a custom-fit product which guarantees it to

be the easiest product to install.

Note: Please take time to read all of the instructions before beginning this installation.

War ning! Please check for wiring or other obstr uctions before drilling any holes into

the vehicle. If it is necessar y to drill any holes into the vehicle, Dee Zee recommends

putting a sealant or rust inhibitor around all holes drilled into the body of the vehicle.

War ning! It is the sole responsibility of the vehicle owner to check for tire clearance.

War ning! It is unlawful and dangerous to ride on r unning boards or side box boards

while the vehicle is in motion.

Cleaning Instructions: To maintain the bright finish of your Dee Zee running boards,

clean with a mild deter gent. For our stainless steel products and accessories, the

application of a high grade automotive type wax is recommended.

If you should happen to have any questions with this product or you have an

installation question, please feel fr ee to call us at:

1-800-779-8222

If you would like to find out mor e infor mation on Dee Zee’s products please

feel free to visit our website at:

WWW.DEEZEE.COM

Page 3

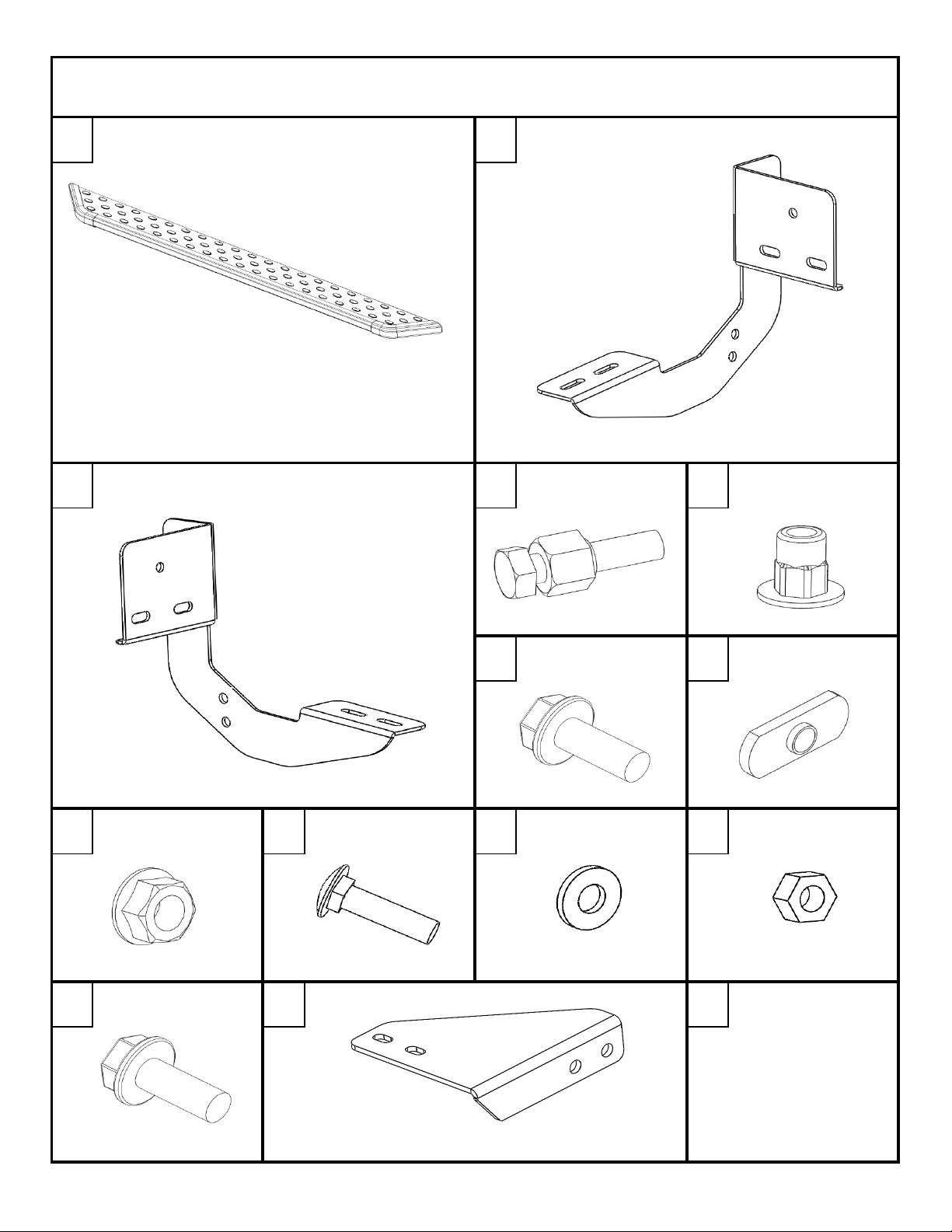

*** BOARD SOLD SEPARATELY

X2

B 1828LP

X3

PN 685

X2

PN 686

X12

B 1828RP

X3

PN 525

X18

PN 835

X6

PN 526

X24

PN 1093

X12

PN 72B

X12

PN 71B

X12

SUPPORT BRACKET

B 2173LP

X3

PN 527

X12

B 2173RP

X3

NXT RUNNING BOARD INSTALLATION INSTRUCTION

NXT RUNNING BOARD INSTALLATION INSTRUCTIONNXT RUNNING BOARD INSTALLATION INSTRUCTION

NXT RUNNING BOARD INSTALLATION INSTRUCTION

DZ 16336 DODGE RAM 2013-CURRENT

DZ 16336 DODGE RAM 2013-CURRENTDZ 16336 DODGE RAM 2013-CURRENT

DZ 16336 DODGE RAM 2013-CURRENT

A B

SIDE STEP TUBE LEFT HAND BRACKET

C D

RIGHT HAND BRACKET

F G

H I J

8mm X 20mm

FLANGE HEAD BOLT

NUTSERT SET TOOL

8mm X 25mm

FLANGE HEAD BOLT

E

K

8mm HEX

NUTSERT

8mm THREADED

PLATE

1/4" NUT1/4" WASHER1/4" CARRIAGE BOLT

L M

DZ 16336 1 of 9 7/10/2013

8mm X 20mm

FLANGE HEAD BOLT

Page 4

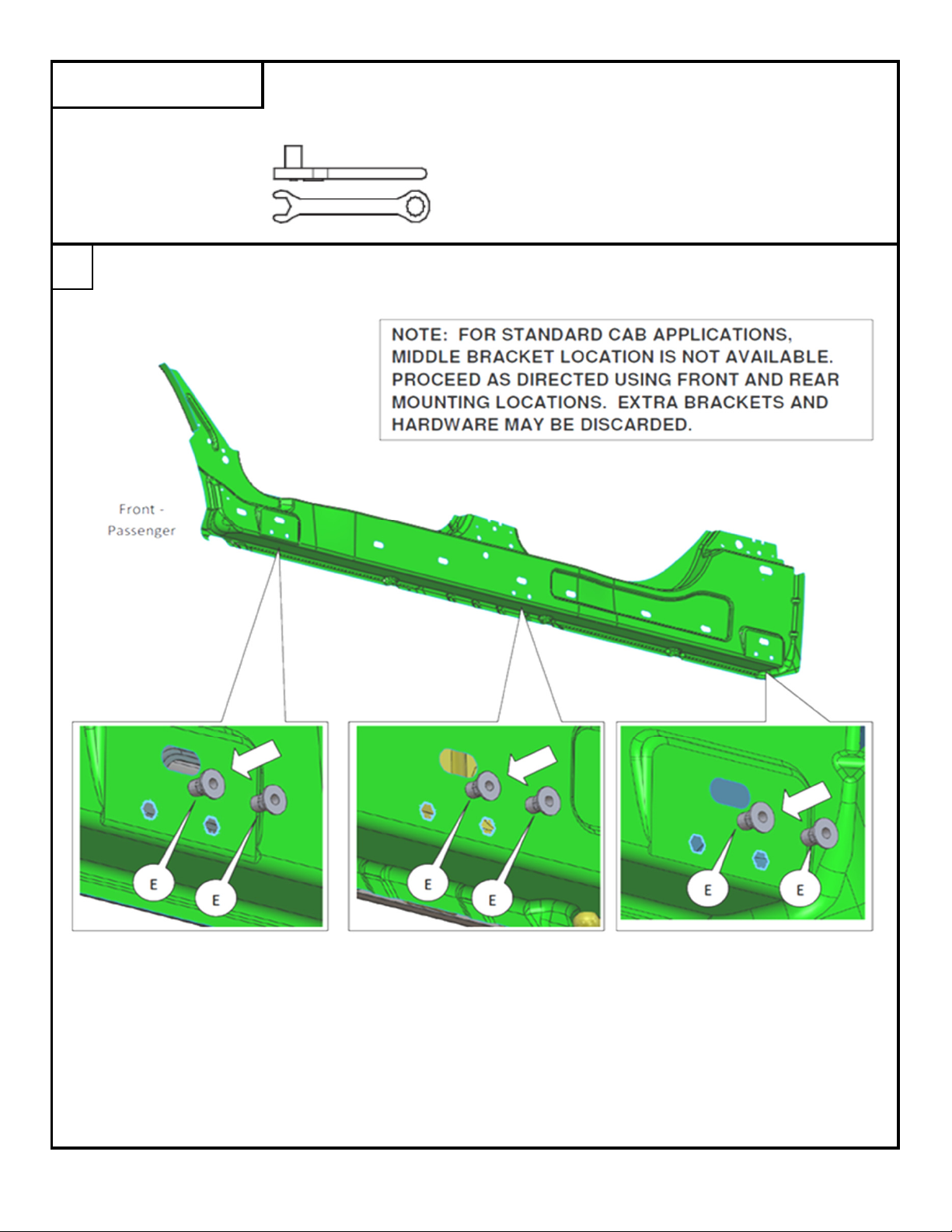

WRENCH/RATCHET

13mm, 15mm, 7/16"

Install the 8mm nutsert [E] as shown below.

The passenger's side is shown. The front of the vehicle is to the left of the picture.

TOOLS REQUIRED

1

DZ 16336 2 of 9 7/10/2013

Page 5

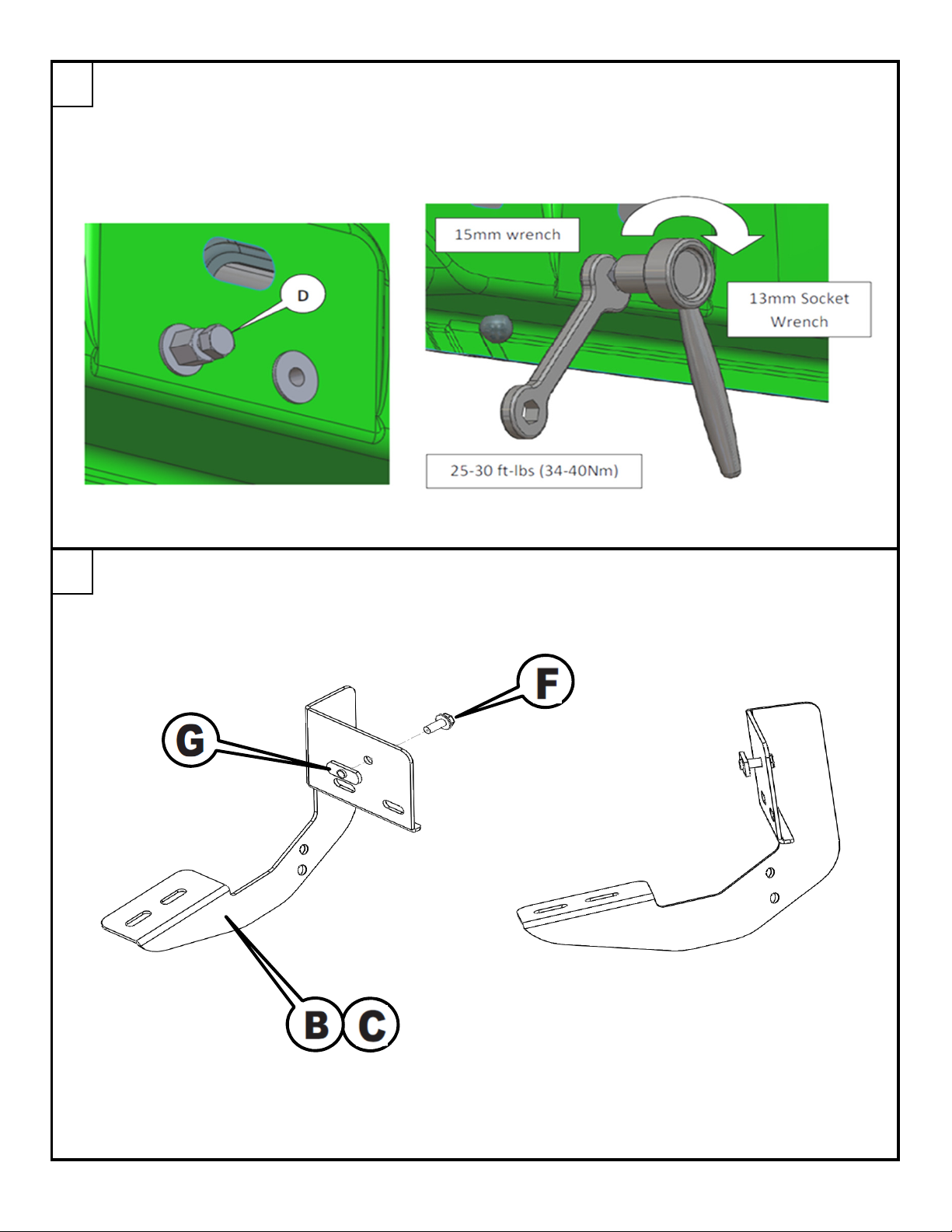

Use the nutsert set tool [D] to crimp the nutserts in the holes.

Hold the nut on the set tool with a 15mm wrench. Tighten the bolt in the set tool with a 13mm

Torque the nutserts to the spcification below to insure they are set correctly.

Put a 8mm x 25mm bolt [F] through the top hole in the braces and thread into the

8mm threaded plate [G] until the bolt starts to come through the threaded plate.

2

socket.

3

DZ 16336 3 of 9 7/10/2013

Page 6

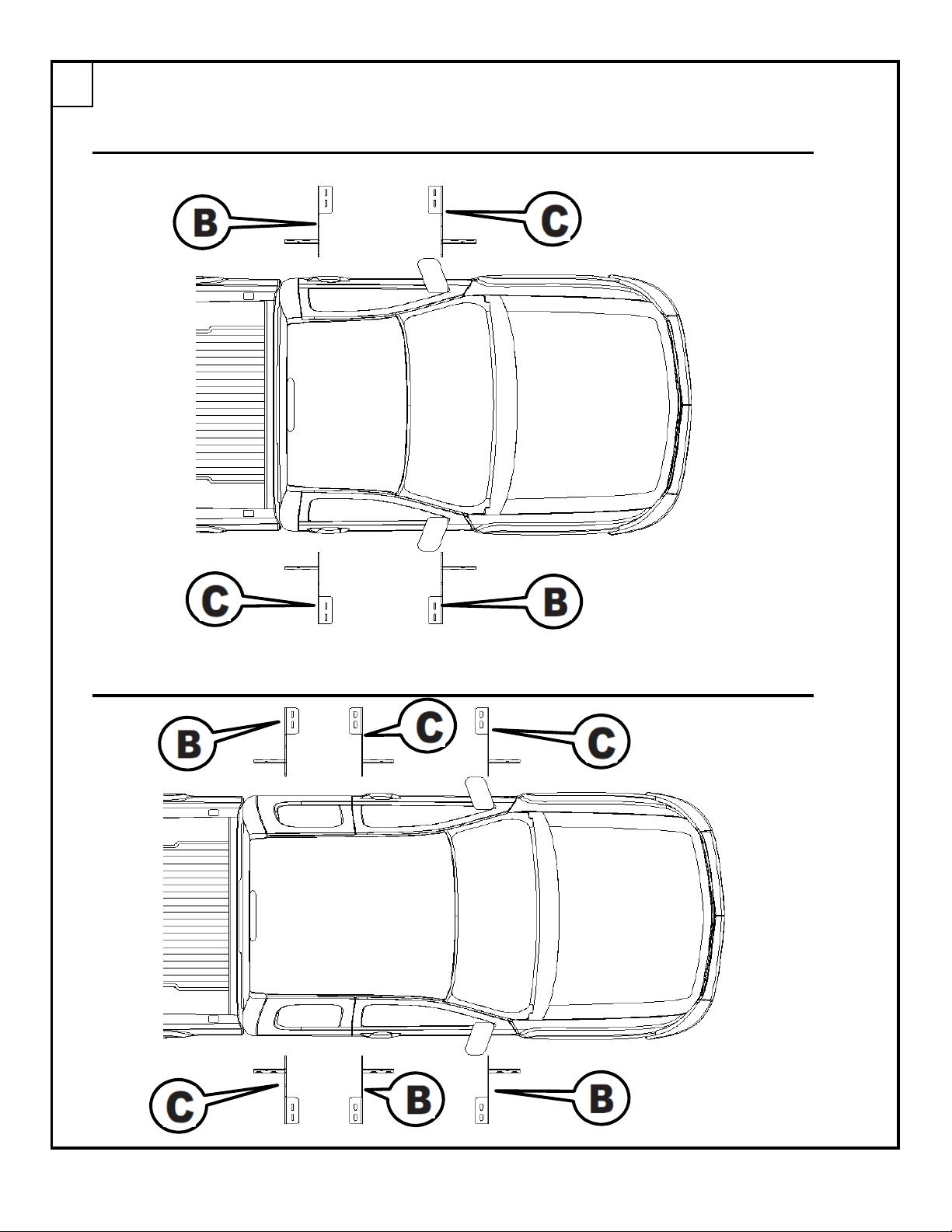

The vehicle cab style will determine which brackets are to be used at the different mounting

locations. Please refer to the cab drawings for bracket configuration.

REGULAR CAB

QUAD CAB

4

DZ 16336 4 of 9 7/10/2013

Page 7

CREW CAB

When the brace is put up to the vehicle mounting location, the threaded plate

must go into the large slot above the nutserts previously installed.

This step continued on the next page.

5

DZ 16336 5 of 9 7/10/2013

Page 8

Thread 2 of the 8mm x 25mm bolts through the slots in the braces into the nutserts.

Only engage the bolts a few threads into the nutserts. Then pushing up on the brace to put tension on the

threaded plate tighten the top until it is snug but not completely tight.

Snug the bottom bolts also.

Using two of the carriage bolts [I], two 1/4" washers [J] and two 1/4" nuts [K], loosely attach the support

bracket [M] to the pinch weld on the truck. The bent flange with two holes in it should be point up.

The support brackets are left hand/right hand. Select the appropriate one for each mounting location.

Do not tighten at this time.

6

7

DZ 16336 6 of 9 7/10/2013

Page 9

Attach the support brace to the main brace using two of the 8mm x 20 mm bolts [L] and two of the 8mm

flange nut [H].

Do not tighten at this time. Repeat the support bracket installation for the other mounting locations.

Align the bolts in the channels on the underside of the running board with the slots in the

mounting braces and loosley attach the board to the brace with the 8mm nuts [H].

Do not completely tighten at this time.

8

9

DZ 16336 7 of 9 7/10/2013

Page 10

Using a 13mm wrench/socket, tighten the bolts that attach the brace to the vehicle. Tighten the top bolt first.

It mat still be necessary to push up on the brace to get this bolt completely tight.

After the bolt with the threaded plate is tightened, tighten the remaining two 8mm bolts.

Using a 7/16" wrench/socket, tighten the carriage bolts attaching the support bracket to the vehicle.

Using a 13mm wrench/socket, tighten the bolts that attach the support bracket to the brace.

Repeat this step for all brace locations.

Once all of the braces have been tighened, adjust the board front/back and in/out to align it

with the vehicle.

10

11

DZ 16336 8 of 9 7/10/2013

Page 11

Once the board location has been set, tighten the nuts holding the board to the braces using

a 13mm socket/wrench.

Make sure all bolts are tightened. Repeat steps for other side.

12

DZ 16336 9 of 9 7/10/2013

Page 12

*** TUBES SOLD SEPARATELY

X2

X3

PN 685

X2

PN 686

X12

X3

PN 525

X18

PN 835

X6

PN 526

X24

PN 1093

X12

PN 72B

X12

PN 71B

X12

SUPPORT BRACKET

BRACE KIT

X12

FROM TUBE

B 2173LP

X3

TUBE BOLT PACK

X12

BOLT PACK

X12

B 2173RP

X3

6" OVAL SIDE STEP INSTALLTION

6" OVAL SIDE STEP INSTALLTION6" OVAL SIDE STEP INSTALLTION

6" OVAL SIDE STEP INSTALLTION

A B

DZ 16336 DODGE RAM 2013-CURRENT

DZ 16336 DODGE RAM 2013-CURRENTDZ 16336 DODGE RAM 2013-CURRENT

DZ 16336 DODGE RAM 2013-CURRENT

SIDE STEP TUBE LEFT HAND BRACKET

C

H I

FLANGE HEAD BOLT

RIGHT HAND BRACKET

1/4" CARRIAGE BOLT

D

NUTSERT SET TOOL

F

8mm X 25mm 8mm THREADED

FLANGE HEAD BOLT

1/4" WASHER8mm X 20mm

J K

E

G

8mm HEX

NUTSERT

PLATE

1/4" NUT

L

8mm X 20mm 8mm U-NUT

FLANGE HEAD BOLT

M N

1 of 9 7/10/2013

Page 13

WRENCH/RATCHET

13mm, 15mm, 7/16"

Install the 8mm nutsert [E] as shown below.

The passenger's side is shown. The front of the vehicle is to the left of the picture.

TOOLS REQUIRED

1

2 of 9 7/10/2013

Page 14

Use the nutsert set tool [D] to crimp the nutserts in the holes.

Hold the nut on the set tool with a 15mm wrench. Tighten the bolt in the set tool with a 13mm

Torque the nutserts to the spcification below to insure they are set correctly.

Put a 8mm x 25mm bolt [F] through the top hole in the braces and thread into the

8mm threaded plate [G] until the bolt starts to come through the threaded plate.

2

socket.

3

3 of 9 7/10/2013

Page 15

The vehicle cab style will determine which brackets are to be used at the different mounting

locations. Please refer to the cab drawings for bracket configuration.

REGULAR CAB

QUAD CAB

4

4 of 9 7/10/2013

Page 16

CREW CAB

When the mount braces is put up to the vehicle mounting location, the threaded plate

must go into the large slot above the nutserts previously installed.

This step continued on the next page.

5

5 of 9 7/10/2013

Page 17

Thread 2 of the 8mm x 25mm bolts through the slots in the braces into the nutserts.

Only engage the bolts a few threads into the nutserts. Then pushing up on the brace to put tension on the

threaded plate tighten the top until it is snug but not completely tight.

Snug the bottom bolts also.

Using two of the carriage bolts [I], two 1/4" washers [J] and two 1/4" nuts [K], loosely attach the support

bracket [N] to the pinch weld on the truck. The bent flange with two holes in it should be point up.

The support brackets are left hand/right hand. Select the appropriate one for each mounting location.

Do not tighten at this time.

7

6 of 9 7/10/2013

Page 18

Attach the support brace to the main brace using two of the 8mm x 20 mm bolts [L] and two of the 8mm

flange nut [H].

Do not tighten at this time. Repeat the support bracket installation for the other mounting locations.

It mat still be necessary to push up on the brace to get this bolt completely tight.

After the bolt with the threaded plate is tightened, tighten the remaining two 8mm bolts.

Using a 7/16" wrench/socket, tighten the carriage bolts attaching the support bracket to the vehicle.

Using a 13mm wrench/socket, tighten the bolts that attach the support bracket to the brace.

Repeat this step for all brace locations.

8

Using a 13mm wrench/socket, tighten the bolts that attach the brace to the vehicle. Tighten the top bolt first.

6

7 of 9 7/10/2013

Page 19

Once the brackets are in place, set the tube on the braces and adjust as necessary front to back.

Look under the tube to determine which sets of slots will be used to attach the tube to the braces.

The passenger side crew cab tube is shown.

Remove the tube and install the 8mm U-nut [M] that was supplied with the tubes into the

slots identified in the previous step.

7

8

8 of 9 7/10/2013

Page 20

Set the tube back on the brackets and slide the U-nuts in the tube slots so that they align

with the mounting slots in the braces. Repeat at all mounting locations.

Attach the tube to the braces using the 8mm x 20mm bolts [L] that were supplied

with the tube step. Tighten bolts with a 13mm wrench or socket. Repeat at all mounting locations.

Make sure all bolts are tightened. Repeat steps for other side.

9

9 of 9 7/10/2013

Loading...

Loading...