Page 1

Before returning this product

DZ 1030

to the store of purchase

Contact Dee Zee if you experience the following problems:

•MissingParts

•InstallationProblems/Questions

•WarrantyQuestions

1.800.779.2102

Hoursofoperation:8am-5pmCST,Mon-Friday

Reviewcompletewarrantypolicyandregisteryourproductat:

www.deezee.com

Page 2

Dee Zee Running Board Installation Instructions

Congratulations on your purchase of a quality Dee Zee product. Dee Zee is

recognized as having the highest quality running boards and accessories on

the market today. We have earned this reputation by offering our customers

a product they can be proud to place on their vehicles. Dee Zee meets all

the criteria of manufacturing a custom-fit product which guarantees it to

be the easiest product to install.

Note: Please take time to read all of the instructions before beginning this installation.

Warning! Please check for wiring or other obstructions before drilling any holes into

the vehicle. If it is necessary to drill any holes into the vehicle, Dee Zee recommends

putting a sealant or rust inhibitor around all holes drilled into the body of the vehicle.

Warning! It is the sole responsibility of the vehicle owner to check for tire clearance.

Warning! It is unlawful and dangerous to ride on running boards or side box boards

while the vehicle is in motion.

Cleaning Instructions: To maintain the bright finish of your Dee Zee running boards,

clean with a mild detergent. For our stainless steel products and accessories, the

application of a high grade automotive type wax is recommended.

If you should happen to have any questions with this product or you have an

installation question, please feel free to call us at:

1-800-779-8222

If you would like to find out more information on Dee Zee’s products please

feel free to visit our website at:

WWW.DEEZEE.COM

DZ 1030.PDF 06/02/99

Page 3

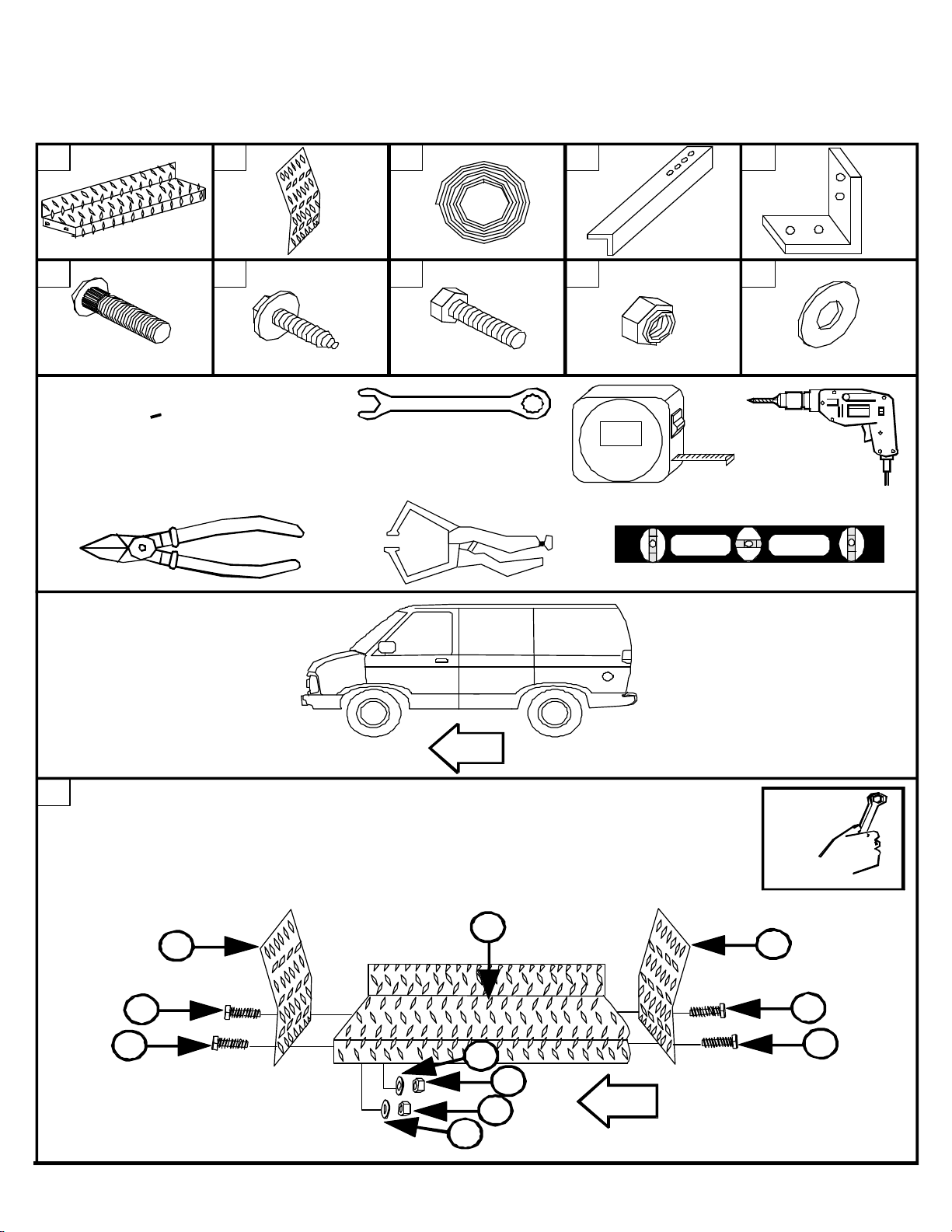

DEE ZEE Running Boards

DZ 1030

96-99 Chevy / GMC Full Size 135" WB Van

A

M

X12

B ED

X2 X4

N P

Tools Required:

Outils Necessaires:

C

X2 X6

1/4“ x 1”1/4“ x 1”

X12

1/4“ x 3/4”

7/16“

3/8“

X42

S T

X54 X54

3/16“

1/4“

X6

1/4“1/4“

1

Place a britetread mudflap (B) onto each end of britetread running

board (A). Attach the britetread mudflap (B) to the britetread

running board (A) using 1/4 x 3/4“ hex head bolt (P), 1/4” flat

washer (T), and 1/4“ hex nut (S).

7/16“

A

B

P

P

P

B

P

T

S

S

T

DZ1030.PDF 06/02/99 PAGE 2

Page 4

2

Clean the backlip of britetread running board (A) using

a clean cloth.

3

Place foam gasket (C) onto the backlip of britetread running board (A).

C

4

Trim foam gasket (C) so that it is flush with

the ends of britetread running board (A).

C

C

5

Place britetread running board (A) up to the vehicle.

C

A

DZ1030.PDF 06/02/99 PAGE 3

A

Page 5

6

A

Drill five 1/4“ holes through

the backlip of the britetread

running board (A) as shown.

Secure britetread running board (A) into

7

place by using 1/4 x 3/4“ hex head bolts (P),

1/4“ flat washers (T), and 1/4” hex nuts (S).

S

T

7/16“

A

P

Level out the britetread running board (A) and then drill three 3/16“ holes through

8

each mudflap on the britetread running board (A). Secure into place using three

1/4 x 1“ sheet metal screws (N).

3/16“

9

D

D

D

Place angle braces (D) in the

locations shown to the right.

3/8“

N

P

A

D

17 1/2“

50 1/2“

82 1/2“

DZ1030.PDF 06/02/99 PAGE 4

A

Page 6

10

D

Drill two 1/4“ holes up through the bottom of britetread

running board (A) at each angle brace (D) location, using the

holes in angle brace (D) as a guide.

11

Secure angle brace (D) to the britetread running board (A) using 1/4 x 1“ ribneck

carriage head bolts (M), 1/4“ flat washers (T), and 1/4” hex nuts (S).

D

7/16“

12a

Place mounting brackets (E) up to the vehicle

frame and angle braces (D) as shown. Drill two

1/4“ holes through the frame, using the

mounting bracket (E) as a guide.

Note: Repeat this process for all of

the angle brace placements.

E

T

M

T

SS

D

12b

T

7/16“

P

S

E

Secure each mounting bracket (E)

into place using 1/4 x 3/4“ hex head bolts (P),

1/4” flat washers (T), and 1/4“ hex nuts (S).

Note: Repeat this process for all of the angle

brace placements.

DZ1030.PDF 06/02/99 PAGE 5

D

Page 7

13

Drill two 1/4“ holes through angle brace (D), using mounting brace (E)

as a guide. Note: Repeat this process for each angle brace (D) location.

E

D

14

7/16“

Place 1/4 x 3/4“ hex head bolts (P) through mounting bracket (E) and angle brace

(D). Secure into place using 1/4“ flat washer (T) and 1/4“ hex nut (S).

Note: Repeat this process for each

mounting bracket (E) location.

P

D

E

T

S

DZ1030.PDF 06/02/99 PAGE 6

Loading...

Loading...