Page 1

RO-INTERFACE-ETH

Hardware-Description

2010

Oktober

Page 2

INDEX

1. Introduction 5

1.1. General remarks 5

1.2. Customer satisfaction 5

1.3. Customer response 5

2. Hardware description 7

2.1. Overview screen 7

2.2. Technical data 8

2.3. Plug-in connector of the module 9

2.3.1. Power supply

2.3.2. Ethernet interface

2.4. Buttons of the module 10

2.5. Controll LEDs 11

2.5.1. Definition of LEDs

11

3. Configuring the module 13

3.1. Configuration via DELIB Configuration utility 13

3.2. Configuration via internal web server 17

3.3. Factory settings 18

4. Firmware Update 20

4.1. DEDITEC Flasher 20

4.2. Web interface 21

9

9

5. Restore basic configuration 24

5.1. Restore IP address 24

Index | 2Seite

Page 3

INDEX

5.2. Restore firmware 24

6. Software 26

6.1. Using our products 26

6.1.1. Access via graphical applications

6.1.2. Access via the DELIB driver library

6.1.3. Access via protocol

6.1.4. Access via provided test programs

26

26

26

27

6.2. DELIB driver library 28

6.2.1. Overview

6.2.2. Supported operating systems

6.2.3. Supported programming languages

6.2.4. Installation DELIB driver library

6.2.5. DELIB Configuration Utility

28

30

30

31

33

6.3. Test programs 34

6.3.1. Digital Input-Output Demo

6.3.2. Analog Input-Output Demo

6.3.3. Stepper Demo

34

35

36

7. Appendix 38

7.1. Revisions 38

7.2. Copyrights and trademarks 39

Index | 3Seite

Page 4

Introduction

I

Introduction | Seite 4

Page 5

1. Introduction

1.1. General remarks

First of all, we would like to congratulate you to the purchase of a high quality

DEDITEC product.

Our products are being developed by our engineers according to quality

requirements of high standard. Already during design and development we take

care that our products have -besides quality- a long availability and an optimal

flexibility.

Modular design

The modular design of our products reduces the time and the cost of

development. Therefor we can offer you high quality products at a competitive

price.

Availability

Because of the modular design of our products, we have to redesign only a

module instead of the whole product, in case a specific component is no longer

available.

1.2. Customer satisfaction

Our philosophy: a content customer will come again. Therefor customer

satisfaction is in first place for us.

If by any chance, you are not content with the performance of our product,

please contact us by phone or mail immediately.

We take care of the problem.

1.3. Customer response

Our best products are co-developments together with our customers. Therefor

we are thankful for comments and suggestions.

Introduction | Seite 5

Page 6

Hardware description

II

Hardware description |Seite 6

Page 7

2. Hardware description

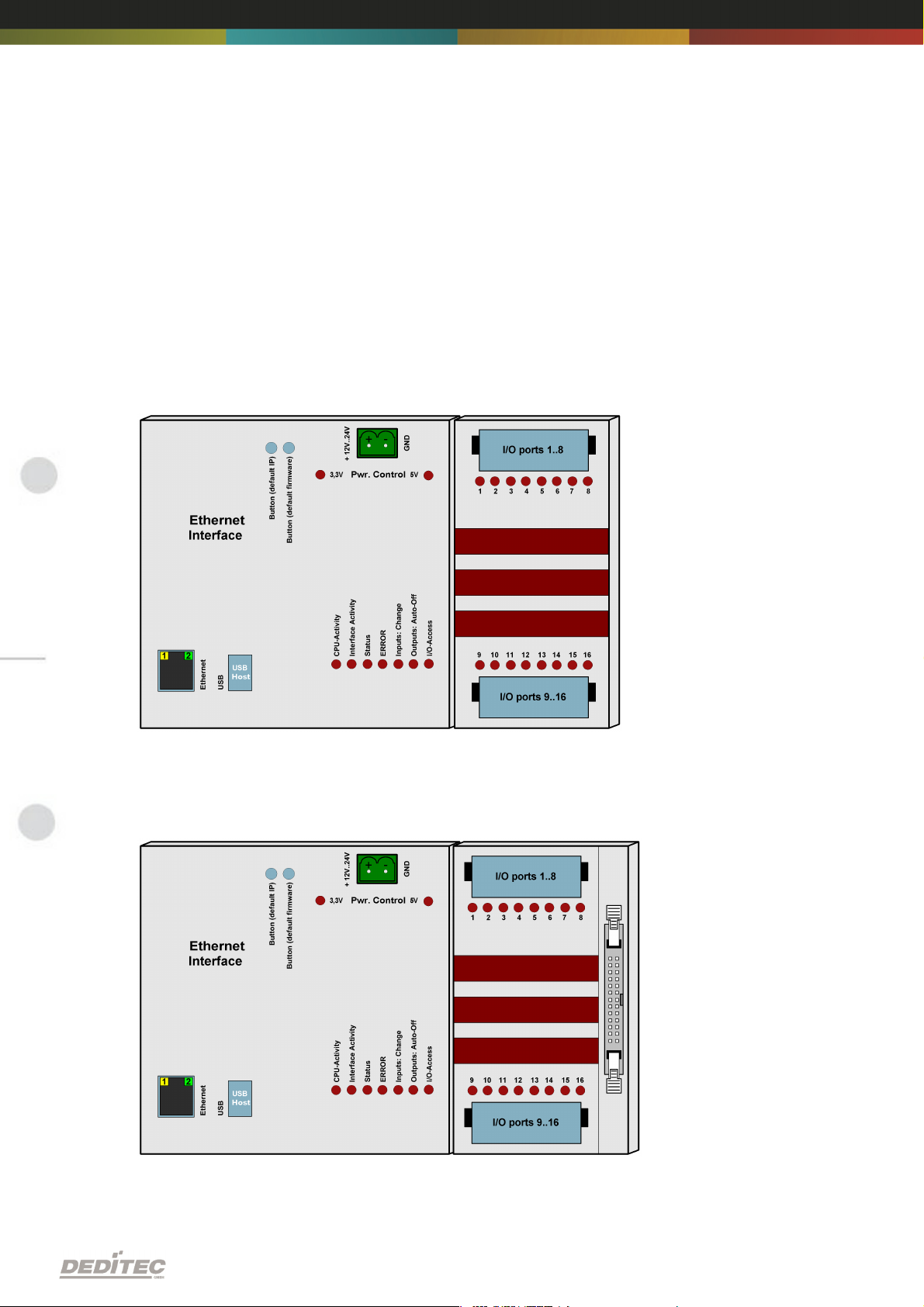

2.1. Overview screen

The figure shows the control module with ethernet interface (left side) combined

with an input/output module (right side).

The figure shows the control module with ethernet interface (left side) combined

with a flexible connector input/output module (right side).

Hardware description |Seite 7

Page 8

2.2. Technical data

Single power supply +7V..+24V DC

10/100 Mbit/sec Ethernet interface

Input/output access over TCP/IP

WEB interface

Configuration over web interface

9 Control LEDs

RJ45 Socket

Timeout feature providing ability to disconnect outputs for safety reasons

Expandable in 16 gradations

Can be combined without any problem to other modules of the RO series

Windows driver library DELIB

Hardware description |Seite 8

Page 9

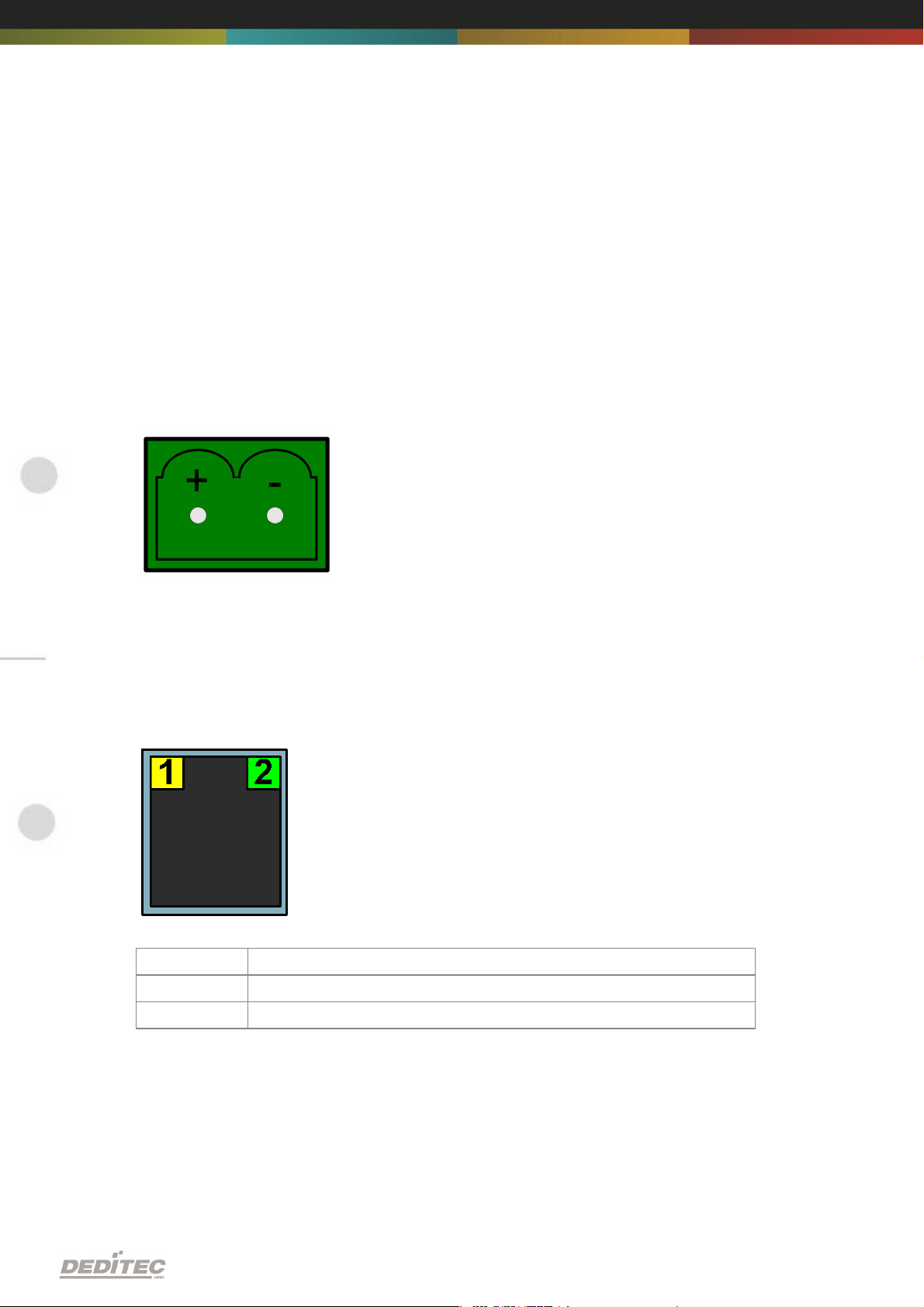

2.3. Plug-in connector of the module

LED

Description

1

Activity

2

10/100 Mbit

2.3.1. Power supply

The input-power-supply-range lies between +7V and +24V DC.The power

supply can be realized with a standard AC/DC adaptor with 1A output current. A

suitable plug-in connector is delivered.

2.3.2. Ethernet interface

The network connection is provided by a RJ45 socket.

Hardware description |Seite 9

Page 10

2.4. Buttons of the module

Left Button:

Reset IP address to default

(see chapter 5.1)

Right Button:

Reset firmware to factory settings.

(see chapter 5.2)

Hardware description |Seite 10

Page 11

2.5. Controll LEDs

LED

Label

Description

above

3,3V

Internal 3,3V power supply

above

5V

Internal 5V power supply

1

CPU Activity

2x flashing + long break. Operating system reports:

Status OK

2

Interface

Activity

Active communication over Ethernet

3

Status

LED is on -> Module is ready

4

ERROR

Error during ethernet-transfer (for details see document

”Serial protocol”)

5

Inputs:

Change

"State change" between 2 read-out cycles detected

6

Outputs: AutoOff

Due to timeout, all outputs are switched-off for safety

reasons

7

I/O Access

CPU-access to the connected I/O modules.

The Ethernet module has a series of control LEDs. They are used for easy visual

indication of various state functions.

While switching the module on, in normal operating mode, the module should

signalize the following sequence:

approx. 20 sec after switching the module on, LED 1 and 2 are flashing briefly.

-> Operating system has been loaded successfully.

Then LED 3 is on permanently and LED 1 is flashing. -> Module is ready.

2.5.1. Definition of LEDs

Hardware description |Seite 11

Page 12

Configuring the module

III

Configuring the module |Seite 12

Page 13

3. Configuring the module

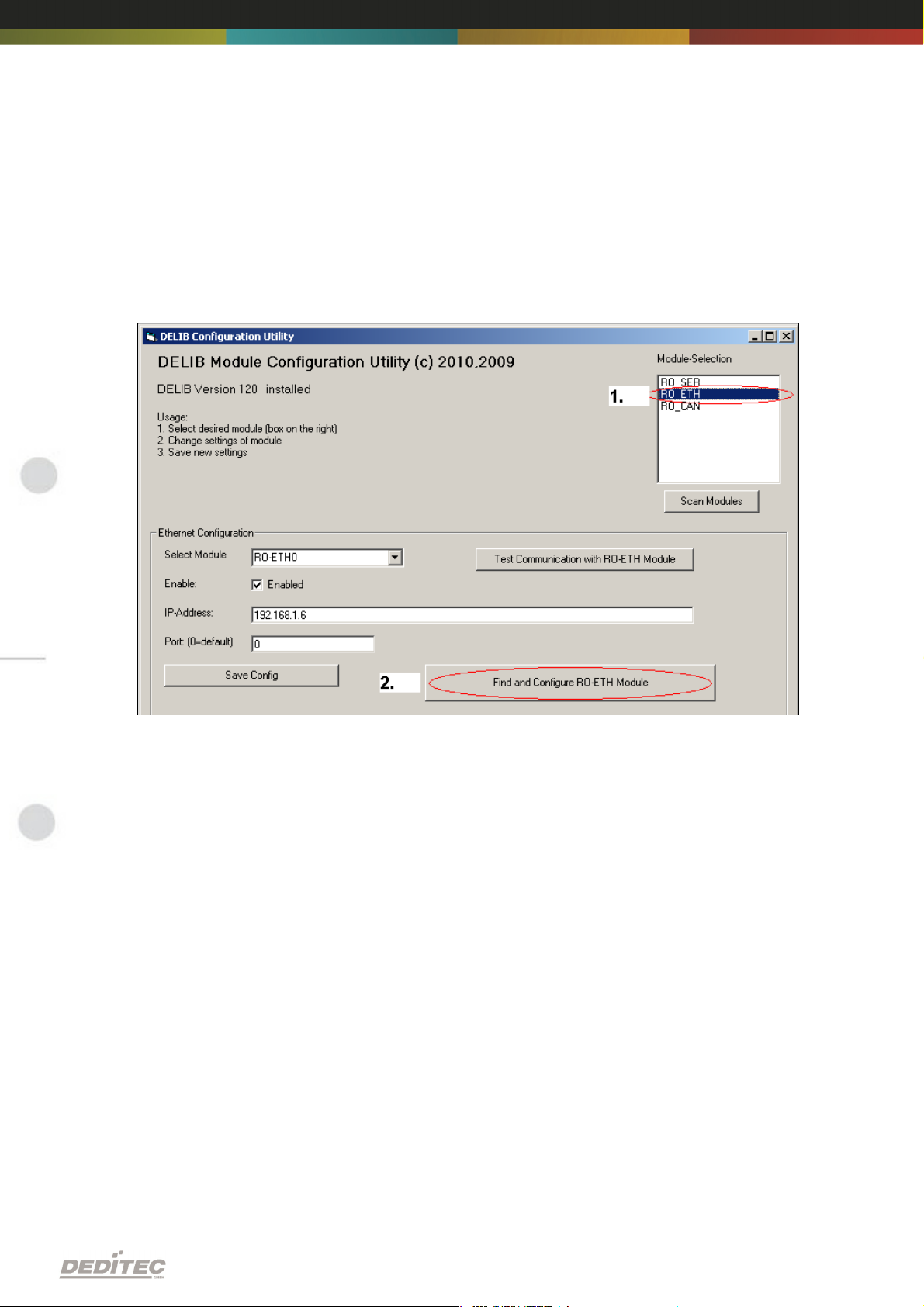

3.1. Configuration via DELIB Configuration utility

This method allows a simple configuration of the product. Following basic

values can be changed.

Module name

IP address

Net mask

Default gateway

DNS server

Additionally with this tool all DEDITEC ethernet devices in the LAN network are

displayed.

The following pages describe how it works...

Configuring the module |Seite 13

Page 14

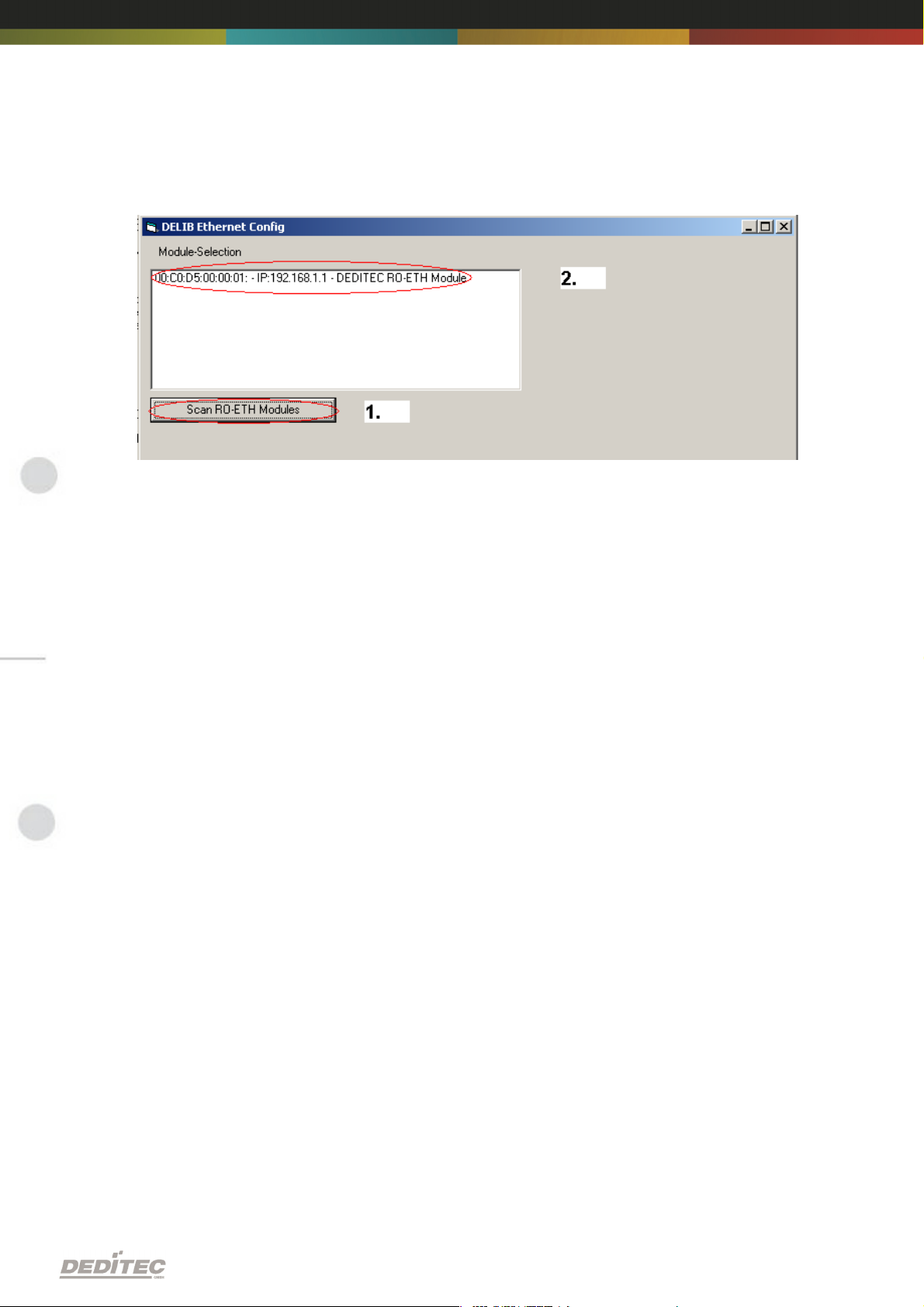

Start DELIB Configuration utility as follows:

Start -> Programs -> DEDITEC -> DELIB -> DELIB Configuration Utility

1.

Module Selection: select RO-ETH

2.

Find and configure RO-ETH Module

Configuring the module |Seite 14

Page 15

1.

Scan RO-ETH modules: So you can find all DEDITEC ETH modules on local

ethernet stream. Therefore we use an ethernet protocol which will not be

routed. Because of that you can configure only modules which are connected

to the bus. The advantage of this method is, that you can find modules which

are not in the same sub net, of which you are configuring.

2.

Click on the module, which you want to configure.

Configuring the module |Seite 15

Page 16

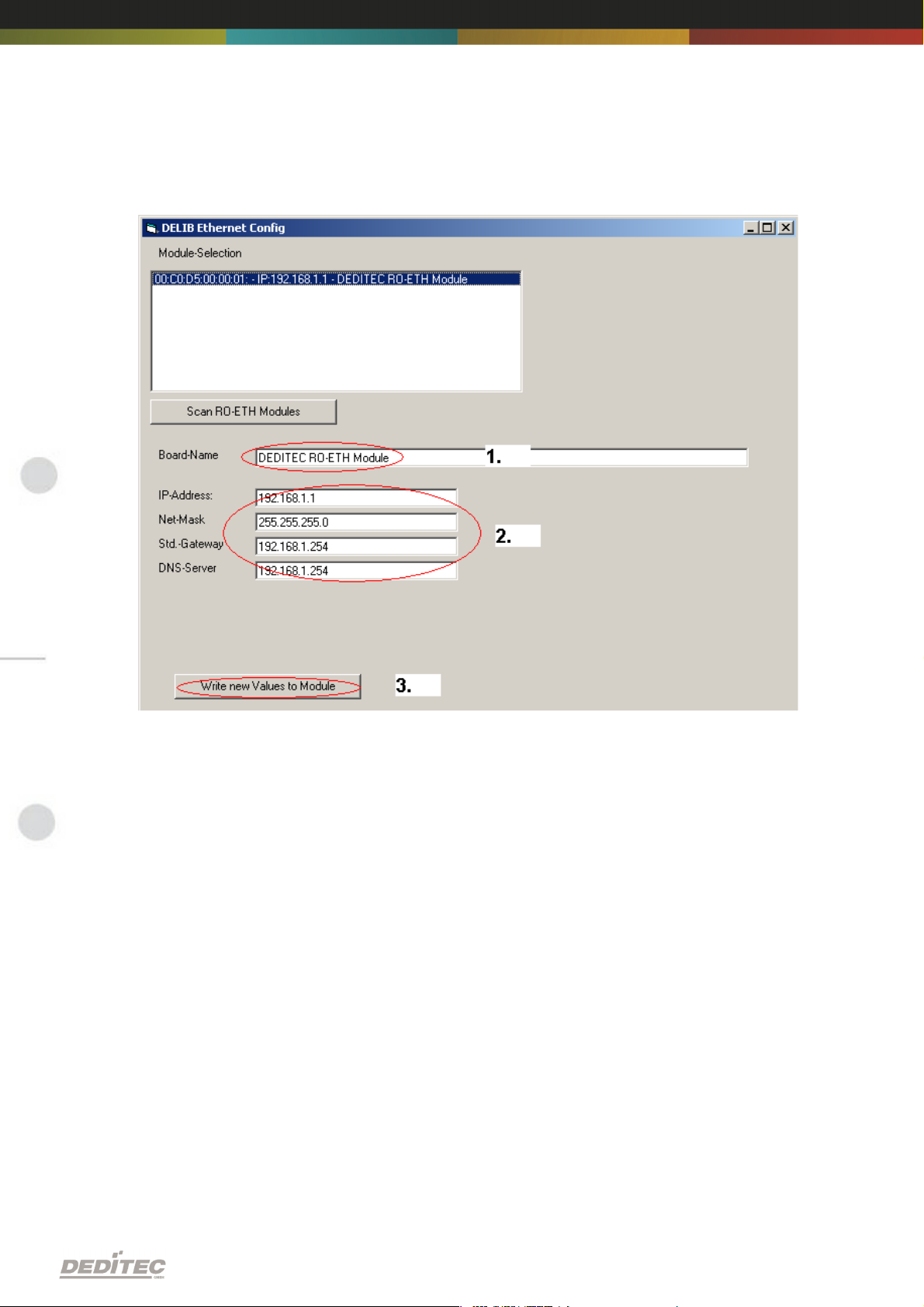

Here you can change the module name according to your wishes

1.

You can change module name, IP address, net mask, default gateway and

DNS server.

2.

Write new Values to Module.

Notice:

At the configuration of the RO-ETH module should be paid attention to the IP

address. It has to be in the same IP segment in which the control PC is. Of

course you must not select an already used IP address.

If the standard IP address of the module is not from the address range of the

network, the module will not be reachable by TCP/IP at the moment. Problems

of accessibility will also occur, if the IP address is already used. However the IP

address and the net mask of the ethernet module are configurable by this utility.

Alternatively you can connect the module to the PC and set the IP address and

the net mask directly. After the accessibility is given, the further configuration is

ensued by a browser via the integrated web server of the ethernet module.

To these belongs ask your system administrator.

Configuring the module |Seite 16

Page 17

3.2. Configuration via internal web server

The RO-ETH module has an own web server by which it can be configured, too.

Configuring the module |Seite 17

Page 18

3.3. Factory settings

The factory settings of the ethernet module include following settings:

IP address: 192.168.1.1

The factory settings can be restored by pushing the left button -> see chapter

5.2

IP address 192.168.1.1

Subnet mask 255.255.255.0

Standard gateway 192.168.1.254

Configuring the module |Seite 18

Page 19

Firmware Update

IV

Firmware Update | Seite 19

Page 20

4. Firmware Update

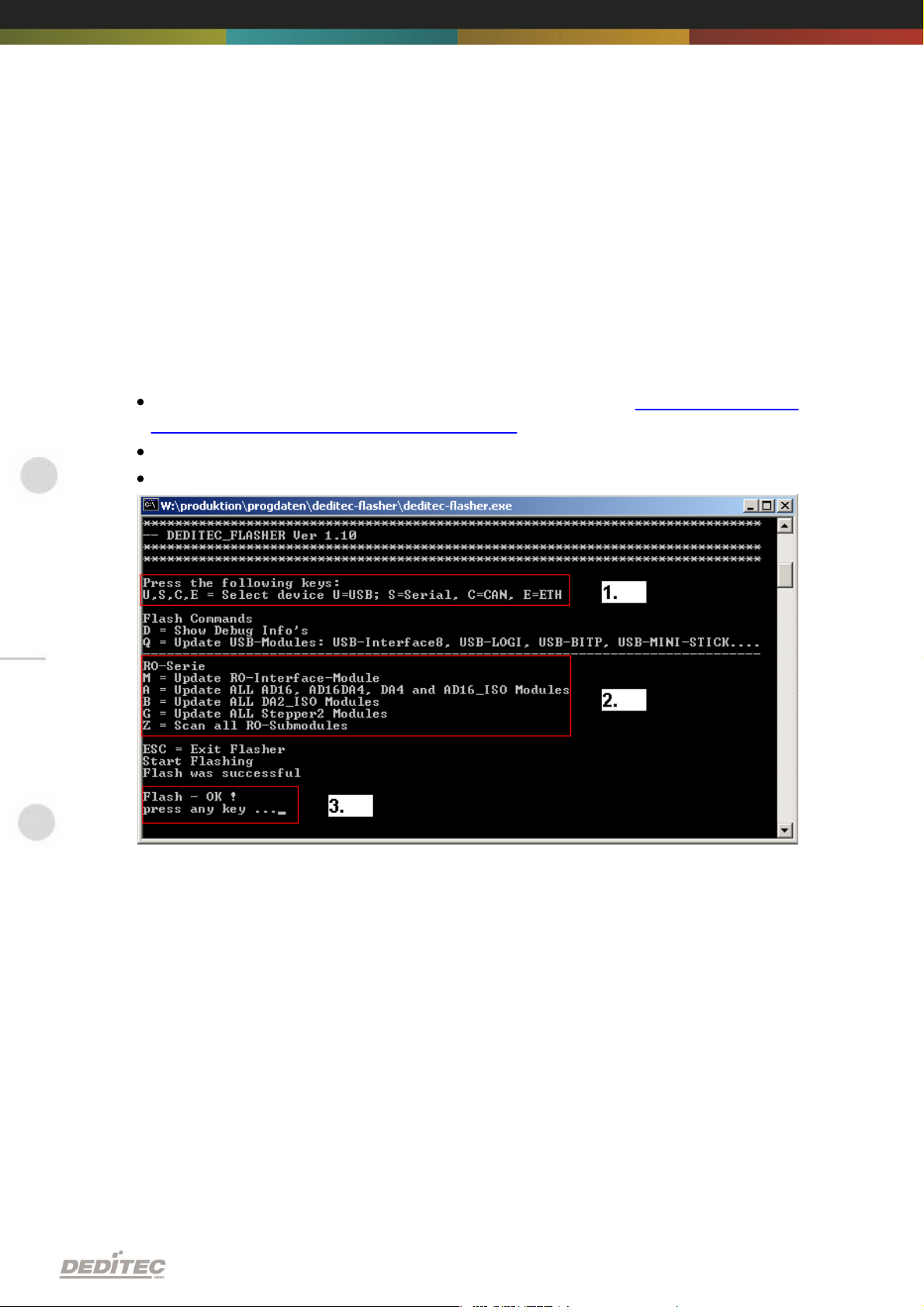

4.1. DEDITEC Flasher

Approach:

Download the latest firmware inclusive software update. http://www.deditec.

de/en/module/software/delib/download.html

Extract all data to one folder

Start the application deditec-flasher.exe

1.

Select the interface. For ethernet press the key "E"

2.

Select the module which you want to update. Press the key "M" for CPU

interface

3.

After successfully flashing , in the prompt appears: Flash OK!

Firmware Update | Seite 20

Page 21

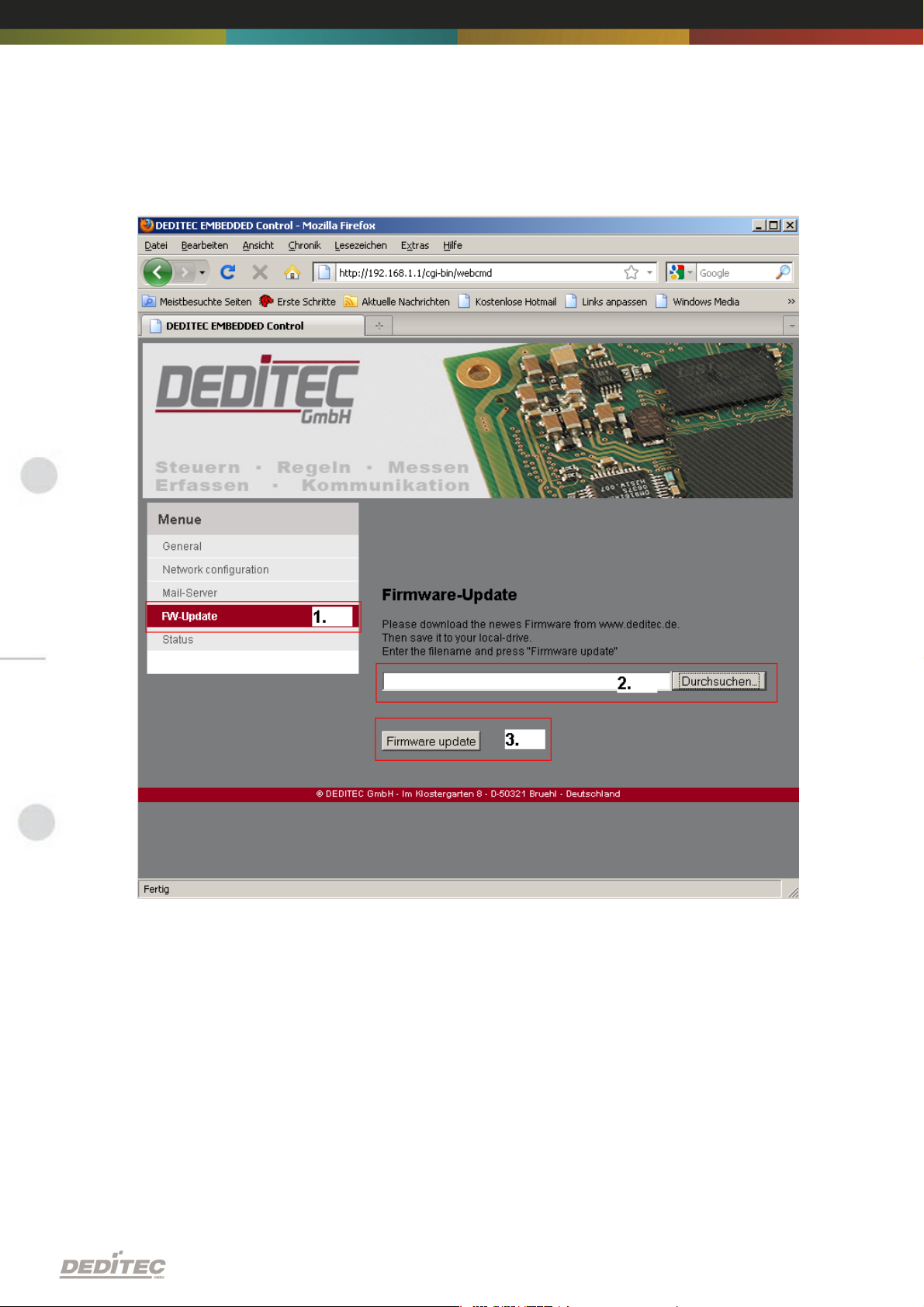

4.2. Web interface

Approach:

1.

Type the IP address of your module in the browser

Firmware Update | Seite 21

Page 22

1.

Click on FW-Update

2.

Select the file “ro_cpu_eth_fw.dfw”

3.

Click on Firmware update

Firmware Update | Seite 22

Page 23

Restore basic configuration

V

Restore basic configuration | Seite 23

Page 24

5. Restore basic configuration

5.1. Restore IP address

The default value of the IP address is: 192.168.1.1

Left Button: Restore IP address to default (192.168.1.1):

To restore the IP address proceed as follow:

Push the button at least 5 sec.

After that, the left LEDs "CPU Activity" and "Interface Activity" should be

flashing four times (confirmation of receipt)

After this, the module has following settings:

IP address 192.168.1.1

Subnet mask 255.255.255.0

Standard gateway 192.168.1.254

5.2. Restore firmware

To restore the firmware to default value proceed as follow:

Right Button: Restore firmware to factory settings

To restore the firmware to factory settings proceed as follow:

Press the button at least 10sec.

After this, the three LED‘s “CPU Activity”, “Interface Activity” and “Status”

should be flashing four times (confirmation of receipt).

After this, the module restarts.

The firmware and configuration of the factory settings are now active again!

Restore basic configuration | Seite 24

Page 25

Software

VI

Software | Seite 25

Page 26

6. Software

6.1. Using our products

6.1.1. Access via graphical applications

We provide driverinterfaces e.g. for LabVIEW and ProfiLab. The DELIB driver

library is the basis, which can be directly activated by ProfiLAB.

For LabVIEW, we provide a simple driver connection with examples!

6.1.2. Access via the DELIB driver library

In the appendix, you can find the complete function reference for the integration

of our API-functions in your software. In addition we provide examples for the

following programming languages:

C

C++

C#

Delphi

VisualBasic

VB.NET

MS-Office

6.1.3. Access via protocol

The protocol for the activation of our products is open source. So you are able

to use our products on systems without Windows or Linux.

Software | Seite 26

Page 27

6.1.4. Access via provided test programs

We provide simple handling test programs for the most important functions of

our products. These will be installed automatically by the installation of the

DELIB driver library.

So you can test directly e.g. relays or you can check the voltage of an A/D

converter.

Software | Seite 27

Page 28

6.2. DELIB driver library

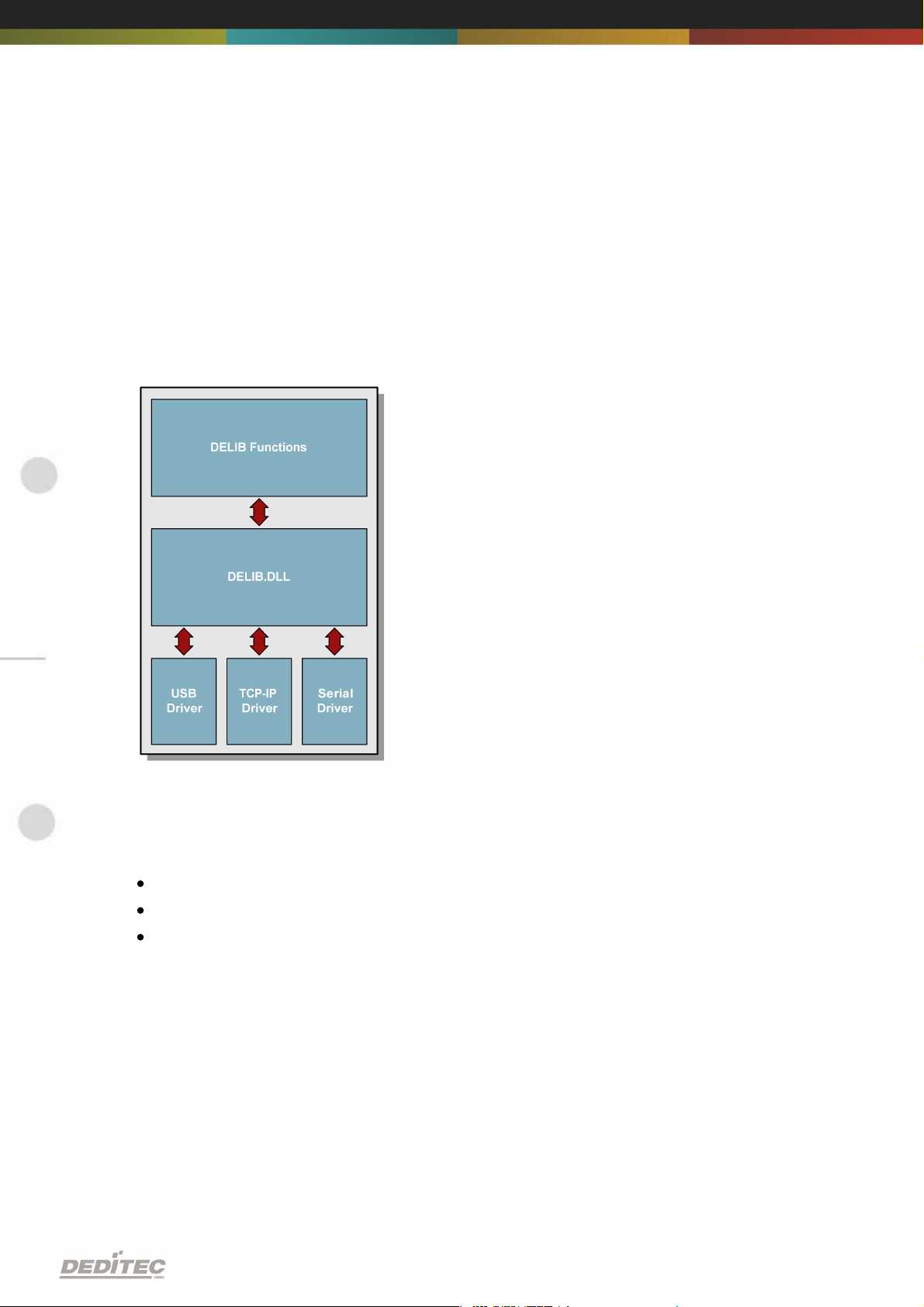

6.2.1. Overview

The following figure explains the structure of the DELIB driver library

The DELIB driver library allows an uniform response of DEDITEC hardware with

particular consideration of the following viewpoints:

Independent of operating system

Independent of programming language

Independent of the product

Program under diverse operating systems

The DELIB driver library allows an uniform response of our products on diverse

operating systems.

We has made sure, that all of our products can be responded by a few

commands.

Whatever which operating system you use. - Therefore the DELIB cares!

Software | Seite 28

Page 29

Program with diverse programming languages

We provide uniform commands to create own applications. This will be solved

by the DELIB driver library.

You choose the programming language!

It can be simply developed applications under C++, C, Visual Basic, Delphi or

LabVIEW®.

Program independent of the interface

Write your application independent of the interface !

Program an apllication for an USB product of us. - Also, it will work with an

ethernet or RS-232 product of us !

SDK-Kit for Programmer

Integrate the DELIB in your application. On demand you receive an installation

script for free, which allows you, to integrate the DELIB installation in your

apllication.

Software | Seite 29

Page 30

6.2.2. Supported operating systems

Our products support the following operating systems:

Windows 2000

Windows XP

Windows Vista

Windows 7

Linux

6.2.3. Supported programming languages

Our products are responsive via the following programming languages:

C

C++

C#

Delphi

VisualBasic

VB.NET

MS-Office

Software | Seite 30

Page 31

6.2.4. Installation DELIB driver library

DELIB stands for DEDITEC Library and contains the necessary libraries for the

modules in the programming languages C, Delphi and Visual Basic.

Insert the DEDITEC driver CD into the drive and start „delib_install.exe“. The

DELIB driver library is also available on http://www.deditec.en/delib

Click on „Install“.

Software | Seite 31

Page 32

The drivers will be installed.

The DELIB driver library is now installed. Press „Close“ to finish the installation.

You can configure your module with the „DELIB Configuration Utility“ (see

next chapter). This is only necessary, if more than one module is present.

Software | Seite 32

Page 33

6.2.5. DELIB Configuration Utility

Start the “DELIB Configuration Utility” as follows:

Start Programs DEDITEC DELIB DELIB Configuration Utility.

The „DELIB Configuration Utility“ is a program to configure and subdivide

identical USB-modules in the system. This is only necessary if more than one

module is present.

Software | Seite 33

Page 34

6.3. Test programs

6.3.1. Digital Input-Output Demo

Start “Digital Input-Output Demo” as follows:

Start Programme DEDITEC DELIB Digital Input-Output Demo.

The screenshot shows a test of the RO-USB-O64-R64. The configuration of the

module (64 inputs and 64 outputs) is shown on the upper left side.

Software | Seite 34

Page 35

6.3.2. Analog Input-Output Demo

Start “Analog Input-Output Demo” as follows:

Start Programme DEDITEC DELIB Analog Input-Output Demo.

The screenshot shows a test of the RO-USB-AD16-DA2_ISO. The configuration

of the module (16 A/D inputs and 2 D/A outputs) is shown on the upper left side.

Software | Seite 35

Page 36

6.3.3. Stepper Demo

Start “Stepper Demo” as follows:

Start Programme DEDITEC DELIB Stepper Demo.

The screenshot shows a test of the RO-USB-STEPPER2. The configuration of

the module (2 Stepper) is shown on the upper left side.

Software | Seite 36

Page 37

Appendix

VII

Appendix | Seite 37

Page 38

7. Appendix

7.1. Revisions

Rev 1.00 First issue

Rev 2.00 Design change

Appendix | Seite 38

Page 39

7.2. Copyrights and trademarks

Linux is registered trade-mark of Linus Torvalds.

Windows CE is registered trade-mark of Microsoft Corporation.

USB is registered trade-mark of USB Implementers Forum Inc.

LabVIEW is registered trade-mark of National Instruments.

Intel is registered trade-mark of Intel Corporation

AMD is registered trade-mark of Advanced Micro Devices, Inc.

Appendix | Seite 39

Page 40

RO-DIGITAL-IN-OUT

Hardware-Description

2010

Oktober

Page 41

INDEX

1. Introduction 6

1.1. General remarks 6

1.2. Customer satisfaction 6

1.3. Customer response 6

2. Hardware description 8

2.1. Opto-coupler inputs 9

2.1.1. Overview screen

2.1.2. Technical data

2.1.3. 16-bit counter

2.1.4. Registering short input pulses

2.1.5. Galvanically decouppled through optocouplers

2.1.6. Plug-in connector on the module

2.1.6.1. Connection wiring

2.1.6.2. Visual control of the inputs

2.1.6.3. Pinout

2.1.7. Variable input voltage range

2.1.7.1. Changing the input voltage

10

11

11

11

12

12

13

13

13

14

2.2. Relay outputs 15

2.2.1. Overview screen

2.2.2. Technical data

2.2.3. Timeout-protection

2.2.4. Plug-in connector on the module

2.2.4.1. Relay-outputs (galvanically decoupled, max.

1A)

2.2.4.2. Connection wiring

2.2.4.3. Visual control of the outputs

2.2.4.4. Pinout

15

16

17

17

17

18

18

18

9

2.3. MOSFET outputs 19

2.3.1. Overview screen

2.3.2. Technical data

2.3.3. Timeout-protection

2.3.4. Plug-in connector on the module

19

20

21

21

Index | 2Seite

Page 42

INDEX

2.3.4.1. Optocoupler-outputs (galvanically isolated,

max. 2A DC)

2.3.4.2. Connection wiring

2.3.4.3. Pinout

3. Software 24

3.1. Using our products 24

21

22

22

3.1.1. Access via graphical applications

3.1.2. Access via the DELIB driver library

3.1.3. Access via protocol

3.1.4. Access via provided test programs

24

24

24

25

3.2. DELIB driver library 26

3.2.1. Overview

3.2.2. Supported operating systems

3.2.3. Supported programming languages

3.2.4. Installation DELIB driver library

3.2.5. DELIB Configuration Utility

26

28

28

29

31

3.3. Test programs 32

3.3.1. Digital Input-Output Demo

32

4. DELIB API reference 34

4.1. Management functions 34

4.1.1. DapiOpenModule

4.1.2. DapiCloseModule

4.2. Error handling 36

34

35

4.2.1. DapiGetLastError

4.2.2. DapiGetLastErrorText

36

37

4.3. Reading Digital inputs 38

4.3.1. DapiDIGet1

4.3.2. DapiDIGet8

4.3.3. DapiDIGet16

4.3.4. DapiDIGet32

4.3.5. DapiDIGet64

4.3.6. DapiDIGetFF32

4.3.7. DapiDIGetCounter

38

39

40

41

42

43

44

Index | 3Seite

Page 43

INDEX

4.4. Setting Digital outputs 45

4.4.1. DapiDOSet1

4.4.2. DapiDOSet8

4.4.3. DapiDOSet16

4.4.4. DapiDOSet32

4.4.5. DapiDOSet64

4.4.6. DapiDOReadback32

4.4.7. DapiDOReadback64

45

46

47

48

49

50

51

4.5. Output timeout management 52

4.5.1. DapiSpecialCMDTimeout

4.5.2. DapiSpecialCMDTimeoutGetStatus

52

53

4.6. Test functions 54

4.6.1. DapiPing

54

4.7. Example program 55

5. Appendix 58

5.1. Revisions 58

5.2. Copyrights and trademarks 59

Index | 4Seite

Page 44

Introduction

I

Introduction | Seite 5

Page 45

1. Introduction

1.1. General remarks

First of all, we would like to congratulate you to the purchase of a high quality

DEDITEC product.

Our products are being developed by our engineers according to quality

requirements of high standard. Already during design and development we take

care that our products have -besides quality- a long availability and an optimal

flexibility.

Modular design

The modular design of our products reduces the time and the cost of

development. Therefor we can offer you high quality products at a competitive

price.

Availability

Because of the modular design of our products, we have to redesign only a

module instead of the whole product, in case a specific component is no longer

available.

1.2. Customer satisfaction

Our philosophy: a content customer will come again. Therefor customer

satisfaction is in first place for us.

If by any chance, you are not content with the performance of our product,

please contact us by phone or mail immediately.

We take care of the problem.

1.3. Customer response

Our best products are co-developments together with our customers. Therefor

we are thankful for comments and suggestions.

Introduction | Seite 6

Page 46

Hardware description

II

Hardware description |Seite 7

Page 47

2. Hardware description

Using the in-/output modules is based on two 16 pol. connectors with each 8

different current circuits. Each state of these (total 16) current circuits is

signalized by a LED. The modules are numbered from left to right (see overview

screen).

Hardware description |Seite 8

Page 48

2.1. Opto-coupler inputs

2.1.1. Overview screen

The figure shows two modules next to each other with corresponding

numbering of the terminal blocks.

The lower figure shows a flexible conntector module with 32 outputs and

corresponding numbered ports. Each outer end of the module has a 26 pol. wire

trap connector. Thus, multiple modules can be connected in series using a

ribbon cable for each connection.

Hardware description |Seite 9

Page 49

2.1.2. Technical data

Variable power supply min. 5V, max. 30V AC

16-bit counter for the first 16 input channels

Pulse-detection between 2 read out cycles, indicated by LED

LED status indication of the inputs

Galvanically isolated using optocouplers

Comfortable connector system with ejection mechanism

Expandable in 16 gradations

Can be combined without any problem to other modules of the RO series

Hardware description |Seite 10

Page 50

2.1.3. 16-bit counter

The first 16 input channels have each a 16 bit counter. Thus, events as light

barriers, turnstiles or push-buttons are counted. Easy logical circuits are

realizable, which may e.g. switch one or several outputs, if a counter reached a

certain amount (set-point is reached). Please refer to the manual ”RO-series” to

implement such logical circuits into software.

2.1.4. Registering short input pulses

Short input pulses between to read-out cycles are registered through an

additional logic and can be separately read-out. A registered pulse on one or

more inputs is signalized by the LED ”Inputs: Change” on the control module.

The LED is extinguishing, if the software-register of the input state change is

read out by the user. For more indformation, see ”Register assignment”.

2.1.5. Galvanically decouppled through optocouplers

AC input optocouplers provide a galvanic isolation of the module towards the

connected equipment. They also provide a safe connection to the module for

reverse currents and high voltage peaks.

Hardware description |Seite 11

Page 51

2.1.6. Plug-in connector on the module

As terminal block, user-friendly terminal strips with locking protection and

ejection mechanism are used. They are reverse-polarity protected and allow

quick replugging. The wire connection itself is realised with a screwless

connector system. A tool is included with each module.

2.1.6.1. Connection wiring

Connecting the wires is to be effected at the ports with the same numbering, for

example: 1a & 1b, 2a & 2b. ...

The optocoupler inputs are suitable for AC voltage. Therefore it is not necessary

to take care of the connection polarity.

The figure shows two terminal blocks with numbered connection ports.

Hardware description |Seite 12

Page 52

2.1.6.2. Visual control of the inputs

Port

Pin

Port

Pin11a & 1b

9

9a & 9b

2

2a & 2b

10

10a & 10b

3

3a & 3b

11

11a & 11b

4

4a & 4b

12

12a & 12b

5

5a & 5b

13

13a & 13b

6

6a & 6b

14

14a & 14b

7

7a & 7b

15

15a & 15b

8

8a & 8b

16

16a & 16b

Input voltage range

5V – 15V

15V – 30V

Resistance value

1K

2K2

The state of each input is directly signalized by a separate LED. This simplifies

to detect and rectify wiring errors, because the signals on the cables are directly

observable.

2.1.6.3. Pinout

2.1.7. Variable input voltage range

The factory-default of the inputs is set to a voltage range of 15V to 30V. This

may be changed to a range of 5V to 15V (even afterward).

Hardware description |Seite 13

Page 53

2.1.7.1. Changing the input voltage

Each terminal block has 8 inputs sudivided in two groups and each group has its

own input voltage range (resulting groups: 1-4, 5-8, 9-12 und 13-16). Each

group‘s input voltage range is defined by a corresponding resistor network.

The following steps describes how to exchange one or more resistor networks.

Notice!

Bevore opening the device, please note the following:

Disconnect the power supply (unplug AC/DC adaptor)!

Do not touch electronic components. They could be destroyed by electrostatic

discharge! If necessary, touch grounded metal casings or radiators.

Remove a module‘s side element. Unscrew the three Phillips screws.

Pull the circuit board together with the front panel sideways out.

Lift the front panel from the module.

Every input module has two single rowed socket terminal strips in which the

resistor networks are plugged in. Please carefully remove the desired resistor

network and replace them it appropriate one.

Assembling the elements in done the reverse order.

Hardware description |Seite 14

Page 54

2.2. Relay outputs

2.2.1. Overview screen

The figure shows two modules next to each other with corresponding

numbering of the terminal blocks.

The lower figure shows a flexible conntector module with 32 outputs and

corresponding numbered ports. Each outer end of the module has a 26 pol. wire

trap connector. Thus, multiple modules can be connected in series using a

ribbon cable for each connection.

Hardware description |Seite 15

Page 55

2.2.2. Technical data

Timeout-protection

LED status indication of the outputs

Galvanically isolated using optocouplers

Comfortable connector system with ejection mechanism

Expandable in 16 gradations

Can be combined without any problem to other modules of the RO series

Max. switching voltage: 36V

Max. switching current: 1A

Max. switching power: 20W

Switching cycles according to the manufacturer: 10 Mio.

Hardware description |Seite 16

Page 56

2.2.3. Timeout-protection

The timeout-protection gives the possibility to switch-off automatically the

outputs on its own to prevent damage. This takes place, if in a predefined time

frame no communication with the module was possible. Reasons could be cable

disruption, PC-crash and more. This way damage control, surcharge of

connected equipment and risk of accidents can be avoided. Switching off the

outputs is indicated by a LED.

2.2.4. Plug-in connector on the module

As terminal block, user-friendly terminal strips with locking protection and

ejection mechanism are used. They are reverse-polarity protected and allow

quick replugging. The wire connection itself is realised with a screwless

connector system. A tool is included with each module.

2.2.4.1. Relay-outputs (galvanically decoupled, max. 1A)

The relays are able to switch voltages up to 36V. The max. current is 1A at a

max. power of 20W.

Additionally, the relays provide a safe electrical isolation of the module to the

connected equipment.

Hardware description |Seite 17

Page 57

2.2.4.2. Connection wiring

Port

Pin

Port

Pin11a & 1b

9

9a & 9b

2

2a & 2b

10

10a & 10b

3

3a & 3b

11

11a & 11b

4

4a & 4b

12

12a & 12b

5

5a & 5b

13

13a & 13b

6

6a & 6b

14

14a & 14b

7

7a & 7b

15

15a & 15b

8

8a & 8b

16

16a & 16b

Connecting the wires is to be effected at the ports with the same numbering, for

example: 1a & 1b, 2a & 2b. ...

It is not necessary to take care to the correct polarity.

2.2.4.3. Visual control of the outputs

The state of each output is directly signalized by a separate LED. This simplifies

to detect and rectify wiring errors, because the signals on the cables are directly

observable.

2.2.4.4. Pinout

Hardware description |Seite 18

Page 58

2.3. MOSFET outputs

2.3.1. Overview screen

The figure shows two modules next to each other with corresponding

numbering of the terminal blocks.

The lower figure shows a flexible conntector module with 32 outputs and

corresponding numbered ports. Each outer end of the module has a 26 pol. wire

trap connector. Thus, multiple modules can be connected in series using a

ribbon cable for each connection.

Hardware description |Seite 19

Page 59

2.3.2. Technical data

Timeout-protection

LED status indication of the outputs

Galvanically isolated using optocouplers

Comfortable connector system with ejection mechanism

Expandable in 16 gradations

Can be combined without any problem to other modules of the RO series

Max. switching voltage: 30V DC

Max. switching current: 2A DC

Max. switching power: 40W

Hardware description |Seite 20

Page 60

2.3.3. Timeout-protection

The timeout-protection gives the possibility to switch-off automatically the

outputs on its own to prevent damage. This takes place, if in a predefined time

frame no communication with the module was possible. Reasons could be cable

disruption, PC-crash and more. This way damage control, surcharge of

connected equipment and risk of accidents can be avoided. Switching off the

outputs is indicated by a LED.

2.3.4. Plug-in connector on the module

As terminal block, user-friendly terminal strips with locking protection and

ejection mechanism are used. They are reverse-polarity protected and allow

quick replugging. The wire connection itself is realised with a screwless

connector system. A tool is included with each module.

2.3.4.1. Optocoupler-outputs (galvanically isolated, max. 2A DC)

Every output is realized using high current optocouplers. Using optocouplers

provides a secure galvanical decoupling of the module-driven equipment to the

module itself.

Pay attention to the optocoupler’s output polarity while wiring (see figure below)!

Hardware description |Seite 21

Page 61

2.3.4.2. Connection wiring

Port

Pin

Port

Pin11a & 1b

9

9a & 9b

2

2a & 2b

10

10a & 10b

3

3a & 3b

11

11a & 11b

4

4a & 4b

12

12a & 12b

5

5a & 5b

13

13a & 13b

6

6a & 6b

14

14a & 14b

7

7a & 7b

15

15a & 15b

8

8a & 8b

16

16a & 16b

Connecting the wires is to be effected at the ports with the same numbering, for

example: 1a & 1b, 2a & 2b, ... Pay attention to the optocoupler’s output polarity

while wiring, else the outputs will get damaged. Connect the positive voltage to

port ”a”, and the switched positive voltage to port ”b”.

2.3.4.3. Pinout

Hardware description |Seite 22

Page 62

Software

III

Software | Seite 23

Page 63

3. Software

3.1. Using our products

3.1.1. Access via graphical applications

We provide driverinterfaces e.g. for LabVIEW and ProfiLab. The DELIB driver

library is the basis, which can be directly activated by ProfiLAB.

For LabVIEW, we provide a simple driver connection with examples!

3.1.2. Access via the DELIB driver library

In the appendix, you can find the complete function reference for the integration

of our API-functions in your software. In addition we provide examples for the

following programming languages:

C

C++

C#

Delphi

VisualBasic

VB.NET

MS-Office

3.1.3. Access via protocol

The protocol for the activation of our products is open source. So you are able

to use our products on systems without Windows or Linux.

Software | Seite 24

Page 64

3.1.4. Access via provided test programs

We provide simple handling test programs for the most important functions of

our products. These will be installed automatically by the installation of the

DELIB driver library.

So you can test directly e.g. relays or you can check the voltage of an A/D

converter.

Software | Seite 25

Page 65

3.2. DELIB driver library

3.2.1. Overview

The following figure explains the structure of the DELIB driver library

The DELIB driver library allows an uniform response of DEDITEC hardware with

particular consideration of the following viewpoints:

Independent of operating system

Independent of programming language

Independent of the product

Program under diverse operating systems

The DELIB driver library allows an uniform response of our products on diverse

operating systems.

We has made sure, that all of our products can be responded by a few

commands.

Whatever which operating system you use. - Therefore the DELIB cares!

Software | Seite 26

Page 66

Program with diverse programming languages

We provide uniform commands to create own applications. This will be solved

by the DELIB driver library.

You choose the programming language!

It can be simply developed applications under C++, C, Visual Basic, Delphi or

LabVIEW®.

Program independent of the interface

Write your application independent of the interface !

Program an apllication for an USB product of us. - Also, it will work with an

ethernet or RS-232 product of us !

SDK-Kit for Programmer

Integrate the DELIB in your application. On demand you receive an installation

script for free, which allows you, to integrate the DELIB installation in your

apllication.

Software | Seite 27

Page 67

3.2.2. Supported operating systems

Our products support the following operating systems:

Windows 2000

Windows XP

Windows Vista

Windows 7

Linux

3.2.3. Supported programming languages

Our products are responsive via the following programming languages:

C

C++

C#

Delphi

VisualBasic

VB.NET

MS-Office

Software | Seite 28

Page 68

3.2.4. Installation DELIB driver library

DELIB stands for DEDITEC Library and contains the necessary libraries for the

modules in the programming languages C, Delphi and Visual Basic.

Insert the DEDITEC driver CD into the drive and start „delib_install.exe“. The

DELIB driver library is also available on http://www.deditec.en/delib

Click on „Install“.

Software | Seite 29

Page 69

The drivers will be installed.

The DELIB driver library is now installed. Press „Close“ to finish the installation.

You can configure your module with the „DELIB Configuration Utility“ (see

next chapter). This is only necessary, if more than one module is present.

Software | Seite 30

Page 70

3.2.5. DELIB Configuration Utility

Start the “DELIB Configuration Utility” as follows:

Start Programs DEDITEC DELIB DELIB Configuration Utility.

The „DELIB Configuration Utility“ is a program to configure and subdivide

identical USB-modules in the system. This is only necessary if more than one

module is present.

Software | Seite 31

Page 71

3.3. Test programs

3.3.1. Digital Input-Output Demo

Start “Digital Input-Output Demo” as follows:

Start Programme DEDITEC DELIB Digital Input-Output Demo.

The screenshot shows a test of the RO-USB-O64-R64. The configuration of the

module (64 inputs and 64 outputs) is shown on the upper left side.

Software | Seite 32

Page 72

DELIB API reference

IV

DELIB API reference | Seite 33

Page 73

4. DELIB API reference

// USB-Modul öffnen

handle = DapiOpenModule(RO_USB1, 0);

printf("handle = %x\n", handle);

if (handle==0)

{

// USB Modul wurde nicht gefunden

printf("Modul konnte nicht geöffnet werden\n");

return;

}

4.1. Management functions

4.1.1. DapiOpenModule

Description

This function opens a particular module.

Definition

ULONG DapiOpenModule(ULONG moduleID, ULONG nr);

Parameters

moduleID=Specifies the module, which is to be opened (see delib.h)

nr=Indicates No of module which is to be opened.

nr=0 -> 1. module

nr=1 -> 2. module

Return value

handle=handle to the corresponding module

handle=0 -> Module was not found

Remarks

The handle returned by this function is needed to identify the module for all

other functions.

Example program

DELIB API reference | Seite 34

Page 74

4.1.2. DapiCloseModule

// Close the module

DapiCloseModule(handle);

Description

This command closes an opened module.

Definition

ULONG DapiCloseModule(ULONG handle);

Parameters

handle=This is the handle of an opened module

Return value

none

Example program

DELIB API reference | Seite 35

Page 75

4.2. Error handling

ULONG error;

error=DapiGetLastError();

if(error==0) return FALSE;

printf("ERROR = %d", error);

4.2.1. DapiGetLastError

Description

This function returns the last registered error.

Definition

ULONG DapiGetLastError();

Parameters

None

Return value

Error code

0=no error. (see delib.h)

Example program

DELIB API reference | Seite 36

Page 76

4.2.2. DapiGetLastErrorText

BOOL IsError ()

{

if (DapiGetLastError () != DAPI_ERR_NONE)

{

unsigned char msg[500];

DapiGetLastErrorText((unsigned char*) msg, sizeof(msg));

printf ("Error Code = %x * Message = %s\n", 0, msg);

return TRUE;

}

return FALSE;

}

Description

This function reads the text of the last registered error.

Definition

extern ULONG __stdcall DapiGetLastErrorText(unsigned char * msg, unsigned long msg_length);

Parameters

msg = text buffer

msg_length = length of the buffer

Example program

DELIB API reference | Seite 37

Page 77

4.3. Reading Digital inputs

4.3.1. DapiDIGet1

Description

This command reads a single digit input.

Definition

ULONG DapiDIGet1(ULONG handle, ULONG ch);

Parameters

handle=This is the handle of an opened module.

ch=Specifies the number of input that is to be read (0 ..).

Return value

State of the input (0 / 1).

DELIB API reference | Seite 38

Page 78

4.3.2. DapiDIGet8

Description

This command reads 8 digital inputs simultaneously.

Definition

ULONG DapiDIGet8(ULONG handle, ULONG ch);

Parameters

handle=This is the handle of an opened module.

ch=Specifies the number of the input, from which it begins to read from (0, 8,

16, 24, 32, ..)

Return value

State of the read inputs.

DELIB API reference | Seite 39

Page 79

4.3.3. DapiDIGet16

Description

This command reads 16 digital inputs simultaneously.

Definition

ULONG DapiDIGet16(ULONG handle, ULONG ch);

Parameters

handle=This is the handle of an opened module.

ch=Specifies the number of the input, from which it begins to read from (0, 16,

32, ..)

Return value

State of the read inputs.

DELIB API reference | Seite 40

Page 80

4.3.4. DapiDIGet32

unsigned long data;

// ---------------------------------------------------// Einen Wert von den Eingängen lesen (Eingang 1-31)

data = (unsigned long) DapiDIGet32(handle, 0);

// Chan Start = 0

printf("Eingang 0-31 : 0x%x\n", data);

printf("Taste für weiter\n");

getch();

// ---------------------------------------------------// Einen Wert von den Eingängen lesen (Eingang 32-64)

data = (unsigned long) DapiDIGet32(handle, 32);

// Chan Start = 32

printf("Eingang 32-64 : 0x%x\n", data);

printf("Taste für weiter\n");

getch();

Description

This command reads 32 digital inputs simultaneously.

Definition

ULONG DapiDIGet32(ULONG handle, ULONG ch);

Parameters

handle=This is the handle of an opened module.

ch=Specifies the number of the input, from which it begins to read from (0, 32,

64, ..)

Return value

State of the read inputs.

Example program

DELIB API reference | Seite 41

Page 81

4.3.5. DapiDIGet64

Description

This command reads 64 digital inputs simultaneously.

Definition

ULONGLONG DapiDIGet64(ULONG handle, ULONG ch);

Parameters

handle=This is the handle of an opened module.

ch=Specifies the number of the input,from which it begins to read from (0, 64, ..)

Return value

State of the read inputs.

DELIB API reference | Seite 42

Page 82

4.3.6. DapiDIGetFF32

Description

This command reads the flip-flops from the inputs and resets them. (Input state

change).

Definition

ULONGLONG DapiDIGet64(ULONG handle, ULONG ch);

Parameters

handle=This is the handle of an opened module .

ch=Specifies the number of the input, from which it begins to read from (0, 32,

..)

Return value

State of 32 input change states

DELIB API reference | Seite 43

Page 83

4.3.7. DapiDIGetCounter

value = DapiDIGetCounter(handle, 0 ,0);

// Reading counter of DI Chan 0

value = DapiDIGetCounter(handle, 1 ,0);

// Reading counter of DI Chan 1

value = DapiDIGetCounter(handle, 8 ,0);

// Reading counter of DI Chan 8

value = DapiDIGetCounter(handle, 0 ,DAPI_CNT_MODE_READ_WITH_RESET);

// Reading AND resetting counter of DI Chan 0

Description

This command reads the counter of a digital input

Definition

ULONG DapiDIGetCounter(handle, ch, par1);

Parameters

handle=This is the handle of an opened module.

ch=Specifies the digital input, from which the counter will be read

par1=0 (Normal counter function)

par1=DAPI_CNT_MODE_READ_WITH_RESET (Reading and resetting the

counter)

Return value

Value of the counter.

Example program

DELIB API reference | Seite 44

Page 84

4.4. Setting Digital outputs

4.4.1. DapiDOSet1

Description

This is the command to set a single output.

Definition

void DapiDOSet1(ULONG handle, ULONG ch, ULONG data);

Parameters

handle=This is the handle of an opened module

ch=Specifies the number of the output to be set to (0 ..)

data=Specifies the data value that is to be written (0 / 1)

Return value

None

DELIB API reference | Seite 45

Page 85

4.4.2. DapiDOSet8

Description

This command sets 8 digital outputs simultaneously.

Definition

void DapiDOSet8(ULONG handle, ULONG ch, ULONG data);

Parameters

handle=This is the handle of an opened module

ch=Specifies the number of the output, from which it begins to write to (0, 8, 16,

24, 32, ..)

data=Specifies the data values, to write to the outputs

Return value

None

DELIB API reference | Seite 46

Page 86

4.4.3. DapiDOSet16

Description

This command sets 16 digital outputs simultaneously.

Definition

void DapiDOSet16(ULONG handle, ULONG ch, ULONG data);

Parameters

handle=This is the handle of an opened module

ch=Specifies the number of the output, from which it begins to write to (0, 16,

32, ..)

data=Specifies the data values, to write to the outputs

Return value

None

DELIB API reference | Seite 47

Page 87

4.4.4. DapiDOSet32

// Einen Wert auf die Ausgänge schreiben

data = 0x0000ff00; // Ausgänge 9-16 werden auf 1 gesetzt

DapiDOSet32(handle, 0, data); // Chan Start = 0

printf("Schreibe auf Ausgänge Daten=0x%x\n", data);

printf("Taste für weiter\n");

getch();

// ---------------------------------------------------// Einen Wert auf die Ausgänge schreiben

data = 0x80000000; // Ausgang 32 wird auf 1 gesetzt

DapiDOSet32(handle, 0, data); // Chan Start = 0

printf("Schreibe auf Ausgänge Daten=0x%x\n", data);

printf("Taste für weiter\n");

getch();

// ---------------------------------------------------// Einen Wert auf die Ausgänge schreiben

data = 0x80000000; // Ausgang 64 wird auf 1 gesetzt

DapiDOSet32(handle, 32, data); // Chan Start = 32

printf("Schreibe auf Ausgänge Daten=0x%x\n", data);

printf("Taste für weiter\n");

getch();

Description

This command sets 32 digital outputs simultaneously.

Definition

void DapiDOSet32(ULONG handle, ULONG ch, ULONG data);

Parameters

handle=This is the handle of an opened module

ch=Specifies the number of the output, from which it begins to write to (0, 32,

64, ..)

data=Specifies the data values, to write to the outputs

Return value

None

Example program

DELIB API reference | Seite 48

Page 88

4.4.5. DapiDOSet64

Description

This command is to set 64 digital outputs.

Definition

void DapiDOSet64(ULONG handle, ULONG ch, ULONG data);

Parameters

handle=This is the handle of an opened module

ch=Specifies the number of the output, from which it begins to write to (0, 64, ..)

data=Specifies the data values, to write to the outputs

Return value

None

DELIB API reference | Seite 49

Page 89

4.4.6. DapiDOReadback32

Description

This command reads back the 32 digital outputs.

Definition

ULONG DapiDOReadback32(ULONG handle, ULONG ch);

Parameters

handle=This is the handle of an opened module

ch=Specifies the number of the input, from which it begins to read from (0, 32,

..)

Return value

Status of 32 outputs.

DELIB API reference | Seite 50

Page 90

4.4.7. DapiDOReadback64

Description

This command reads back the 64 digital outputs.

Definition

ULONGLONG DapiDOReadback64(ULONG handle, ULONG ch);

Parameters

handle=This is the handle of an opened module

ch=Specifies the number of the input, from which it begins to read from (0, 64,

..)

Return value

Status of 64 outputs.

DELIB API reference | Seite 51

Page 91

4.5. Output timeout management

DapiSpecialCommand(handle, DAPI_SPECIAL_CMD_TIMEOUT,

DAPI_SPECIAL_TIMEOUT_SET_VALUE_SEC, 3, 7);

//Die Zeit des Timeouts wird auf 3,7sek gesetzt.

DapiSpecialCommand(handle, DAPI_SPECIAL_CMD_TIMEOUT,

DAPI_SPECIAL_TIMEOUT_ACTIVATE, 0, 0);

//Der Timeout wird aktiviert.

DapiSpecialCommand(handle, DAPI_SPECIAL_CMD_TIMEOUT,

DAPI_SPECIAL_TIMEOUT_DEACTIVATE, 0, 0);

//Der Timeout wird deaktiviert.

4.5.1. DapiSpecialCMDTimeout

Description

This command serves to set the timeout time

Definition

DapiSpecialCommand(handle, DAPI_SPECIAL_CMD_TIMEOUT, cmd, par1, par2);

Parameters

handle=This is the handle of an opened module

Set timeout time

cmd=DAPI_SPECIAL_CMD_TIMEOUT_SET_VALUE_SEC

par1=Seconds [s]

par2=Milliseconds [100ms] (value 6 stands for 600ms)

Activate timeout

cmd=DAPI_SPECIAL_CMD_TIMEOUT_ACTIVATE

Deactivate timeout

cmd=DAPI_SPECIAL_CMD_TIMEOUT_DEACTIVATE

Return value

None

Example program

DELIB API reference | Seite 52

Page 92

4.5.2. DapiSpecialCMDTimeoutGetStatus

status = DapiSpecialCommand(handle, DAPI_SPECIAL_CMD_TIMEOUT,

DAPI_SPECIAL_TIMEOUT_GET_STATUS, 0, 0); //Abfrage des Timeout-Status.

Description

This command reads the timeout status.

Definition

ULONG DapiSpecialCommand(handle, DAPI_SPECIAL_CMD_TIMEOUT,

DAPI_SPECIAL_TIMEOUT_GET_STATUS, 0, 0);

Parameters

handle=This is the handle of an opened module

Return value

Return=0 (timeout is deactivated)

Return=1 (timeout is activated)

Return=2 (timeout has occurred)

Example program

DELIB API reference | Seite 53

Page 93

4.6. Test functions

4.6.1. DapiPing

Description

This command checks the connection of an opened module.

Definition

ULONG DapiPing(ULONG handle, ULONG value);

Parameters

handle=This is the handle of an opened module

value=Given test value to the module

Return value

The given test-value “value“ is also the return value

DELIB API reference | Seite 54

Page 94

4.7. Example program

// ****************************************************************************

// ****************************************************************************

// ****************************************************************************

// ****************************************************************************

// ****************************************************************************

//

// (c) DEDITEC GmbH, 2009

//

// web: http://www.deditec.de

//

// mail: vertrieb@deditec.de

//

//

//

// dtapi_prog_beispiel_input_output.cpp

//

//

// ****************************************************************************

// ****************************************************************************

// ****************************************************************************

// ****************************************************************************

// ****************************************************************************

//

//

// Folgende Bibliotheken beim Linken mit einbinden: delib.lib

// Dies bitte in den Projekteinstellungen (Projekt/Einstellungen/Linker(ObjektBibliothek-Module) .. letzter Eintrag konfigurieren

#include <windows.h>

#include <stdio.h>

#include "conio.h"

#include "delib.h"

// ---------------------------------------------------------------------------// ---------------------------------------------------------------------------// ---------------------------------------------------------------------------// ---------------------------------------------------------------------------// ----------------------------------------------------------------------------

void main(void)

{

unsigned long handle;

unsigned long data;

unsigned long anz;

unsigned long i;

unsigned long chan;

// ---------------------------------------------------// USB-Modul öffnen

handle = DapiOpenModule(USB_Interface8,0);

printf("USB_Interface8 handle = %x\n", handle);

if (handle==0)

{

// USB Modul wurde nicht gefunden

printf("Modul konnte nicht geöffnet werden\n");

printf("TASTE für weiter\n");

getch();

DELIB API reference | Seite 55

Page 95

return;

}

// Zum Testen - ein Ping senden

// ---------------------------------------------------printf("PING\n");

anz=10;

for(i=0;i!=anz;++i)

{

data=DapiPing(handle, i);

if(i==data)

{

// OK

printf(".");

}

else

{

// No answer

printf("E");

}

}

printf("\n");

// ---------------------------------------------------// Einen Wert auf die Ausgänge schreiben

data = 255;

DapiWriteByte(handle, 0, data);

printf("Schreibe auf Adresse=0 daten=0x%x\n", data);

// ---------------------------------------------------// Einen Wert auf die Ausgänge schreiben

data = 255;

DapiWriteByte(handle, 1, data);

printf("Schreibe auf Adresse=0 daten=0x%x\n", data);

// ---------------------------------------------------// Einen Wert auf die Ausgänge schreiben

data = 255;

DapiWriteByte(handle, 2, data);

printf("Schreibe auf Adresse=2 daten=0x%x\n", data);

// ---------------------------------------------------// Einen Wert von den Eingängen lesen

data = (unsigned long) DapiReadByte(handle, 0);

printf("Gelesene Daten = 0x%x\n", data);

// ---------------------------------------------------// Einen A/D Wert lesen

chan=11; // read chan. 11

data = DapiReadWord(handle, 0xff010000 + chan*2);

printf("Adress=%x, ret=%x volt=%f\n", chan, data, ((float) data) / 1024*5);//

Bei 5 Volt Ref

// ---------------------------------------------------// Modul wieder schliessen

DapiCloseModule(handle);

printf("TASTE für weiter\n");

getch();

return ;

}

DELIB API reference | Seite 56

Page 96

Appendix

V

Appendix | Seite 57

Page 97

5. Appendix

5.1. Revisions

Rev 1.00 First issue

Rev 2.00 Design change

Appendix | Seite 58

Page 98

5.2. Copyrights and trademarks

Linux is registered trade-mark of Linus Torvalds.

Windows CE is registered trade-mark of Microsoft Corporation.

USB is registered trade-mark of USB Implementers Forum Inc.

LabVIEW is registered trade-mark of National Instruments.

Intel is registered trade-mark of Intel Corporation

AMD is registered trade-mark of Advanced Micro Devices, Inc.

Appendix | Seite 59

Page 99

RO-Series

Hardware-Description

2010

November

Page 100

INDEX

1. Introduction 10

1.1. General remarks 10

1.2. Customer satisfaction 10

1.3. Customer response 10

2. Hardware description 12

2.1. Ethernet Interface 12

2.1.1. Hardware description

2.1.1.1. Overview screen

2.1.1.2. Technical data

2.1.1.3. Plug-in connector of the module

2.1.1.3.1. Power supply

2.1.1.3.2. Ethernet interface

2.1.1.4. Buttons of the module

2.1.1.5. Controll LEDs

2.1.1.5.1. Definition of LEDs

2.1.2. Restore basic configuration

2.1.2.1. Restore IP address

2.1.2.2. Restore firmware

2.1.3. Firmware Update

2.1.3.1. DEDITEC Flasher

2.1.3.2. Web interface

2.1.4. Configuring the module

2.1.4.1. Configuration via DELIB Configuration utility

2.1.4.2. Configuration via internal web server

2.1.4.3. Factory settings

12

12

14

15

15

15

16

17

17

18

18

18

19

19

20

22

22

26

27

2.2. CAN Interface 28

2.2.1. Hardware description

2.2.1.1. Overview screen

2.2.1.2. Technical data

2.2.1.3. Plug-in connector of the module

2.2.1.3.1. Power supply

2.2.1.3.2. CAN interface

2.2.1.4. Control LEDs

2.2.1.4.1. Definition of LEDs

Index |

28

28

29

30

30

30

31

31

2Seite

Loading...

Loading...