Page 1

Export

C003182-B

KALIKO

Thermodynamic water heater

TWH 200E

TWH 300E

TWH 300EH

EN

Installation and

Service Manual

300026515-001-03

Page 2

Declaration of conformity

The device complies with the standard type described in the EG

declaration of conformity. It was manufactured and commissioned in

accordance with European directives.

The original declaration of conformity is available from the

manufacturer.

Page 3

Contents

1 Introduction ................................................................................................6

1.1 Symbols used .......................................................6

1.2 Abbreviations ........................................................6

1.3 General ..................................................................7

1.3.1 Manufacturer’s liability .............................................7

1.3.2 Installer’s liability .....................................................7

1.4 Homologations ......................................................7

1.4.1 Certifications ...........................................................7

1.4.2 Directive 97/23/EC ..................................................8

1.4.3 Factory test .............................................................8

2 Safety instructions and recommendations ..............................................9

2.1 Safety instructions ...............................................9

2.2 Recommendations ................................................9

2.3 Safety data sheet: R-134a refrigerant ...............10

2.3.1 Product identification .............................................10

2.3.2 Hazard identification ..............................................10

2.3.3 Composition / Information on the ingredients ........10

2.3.4 First aid .................................................................10

2.3.5 Fire prevention measures .....................................10

2.3.6 In the event of accidental spillage .........................11

2.3.7 Handling ................................................................11

2.3.8 Personal protection ...............................................11

2.3.9 Considerations on disposal ...................................12

2.3.10 Regulations ...........................................................12

3 Technical description ..............................................................................13

3.1 General description ............................................13

3.2 Main parts ............................................................14

3.3 Operating principle .............................................14

3.4 Technical specifications ....................................15

03/02/2014 - 300026515-001-03

3.4.1 Characteristics of the appliance ............................15

3.4.2 Heating time of the DHW tank depending on the air

temperature ...........................................................16

3.4.3 Max domestic hot water set point reached by the heat

pump depending on the air temperature ...............16

1

Page 4

Contents

4 Installation ................................................................................................17

4.1 Regulations governing installation ...................17

4.2 Package list .........................................................17

4.2.1 Standard delivery ..................................................17

4.2.2 Accessories ...........................................................17

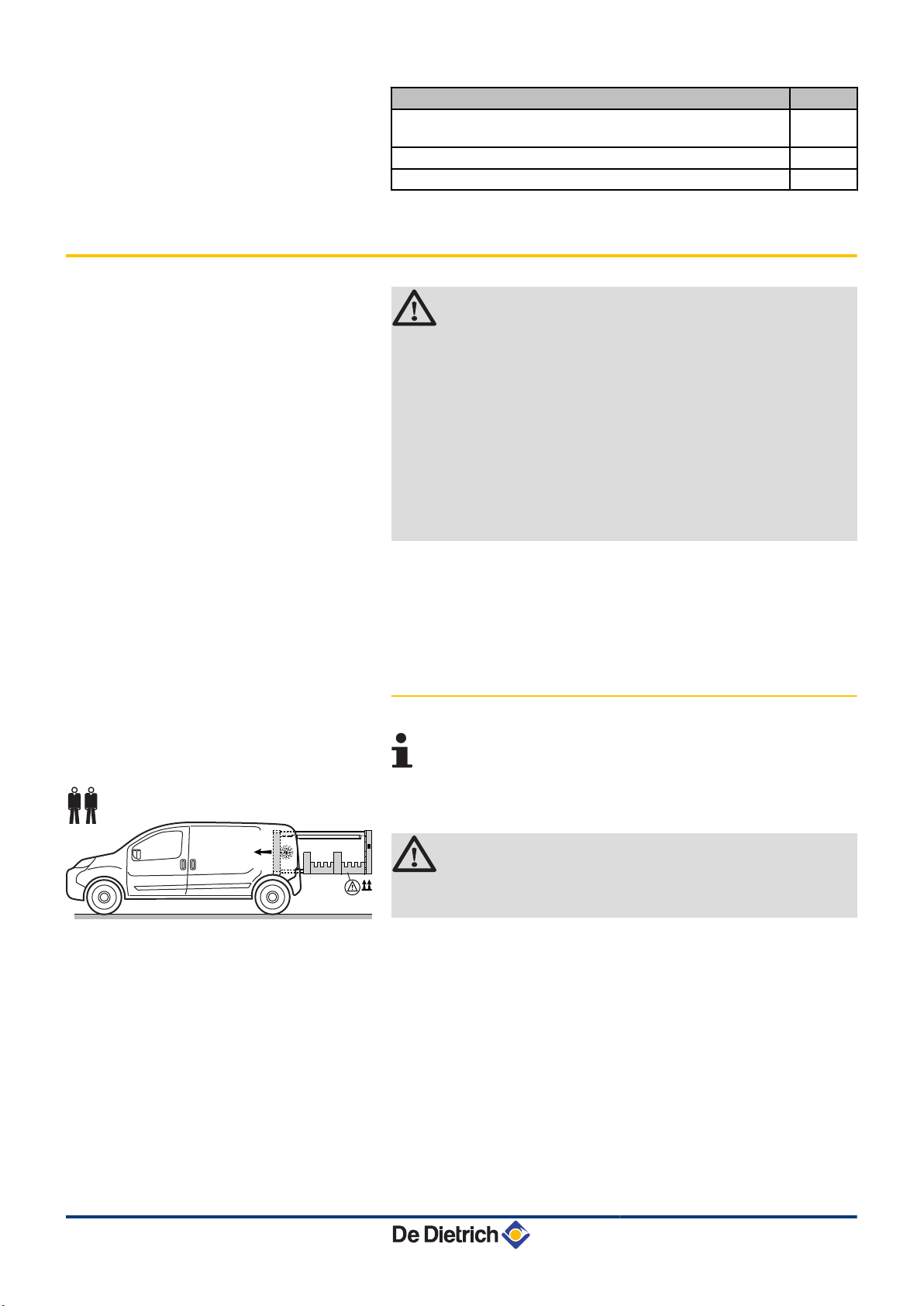

4.3 Storage and transport ........................................18

4.3.1 Transport ...............................................................18

4.4 Choice of the location ........................................19

4.4.1 Type plate .............................................................19

4.4.2 Positioning of the appliance ..................................19

4.4.3 Main dimensions ...................................................23

4.5 Positioning the appliance ..................................25

4.5.1 Unpacking the appliance .......................................25

4.5.2 Positioning the appliance ......................................25

4.5.3 Levelling ................................................................26

4.6 Hydraulic connections .......................................26

4.6.1 Connecting the calorifer to the domestic water circuit

(secondary circuit) .................................................26

4.6.2 Connection to a boiler (Version EH) ......................28

4.6.3 Connection to solar collectors (Version EH) .........30

4.7 Condensates discharge .....................................32

4.8 Installing the control system in the living

room .....................................................................32

4.8.1 Choose a location .................................................32

4.8.2 Operations to be carried out on the thermodynamic

DHW tank ..............................................................33

4.8.3 Installing the control system in the living

room ......................................................................34

4.9 Electrical connections ........................................35

4.9.1 Recommendations ................................................35

4.9.2 Connecting the hydraulic back-up (Version

EH) ........................................................................35

4.9.3 Access to the connection terminal HP/HC ............36

4.9.4 Connection with HP/HC signal connected ............37

4.9.5 Connection with timer programming .....................39

4.9.6 Connection with timer programming and photovoltaic

signal .....................................................................40

4.10 Electrical principle diagram ...............................41

4.11 Filling the thermodynamic DHW tank ...............42

5 Commissioning ........................................................................................43

5.1 Control panel .......................................................43

5.1.1 Description of the keys ..........................................43

5.1.2 Description of the display ......................................43

03/02/2014 - 300026515-001-03

2

Page 5

5.1.3 Browsing in the menus ..........................................45

5.2 Check points before commissioning ................45

5.3 Putting the appliance into operation ................46

5.3.1 Commissioning ......................................................46

5.4 Checks and adjustments after

commissioning ...................................................46

5.5 Choosing the operating mode ...........................46

5.6 Reading out measured values ...........................47

5.6.1 Measurements menu ............................................47

5.6.2 Counters ................................................................47

5.7 Modifying the installer parameters ...................49

5.7.1 Access to parameters ...........................................49

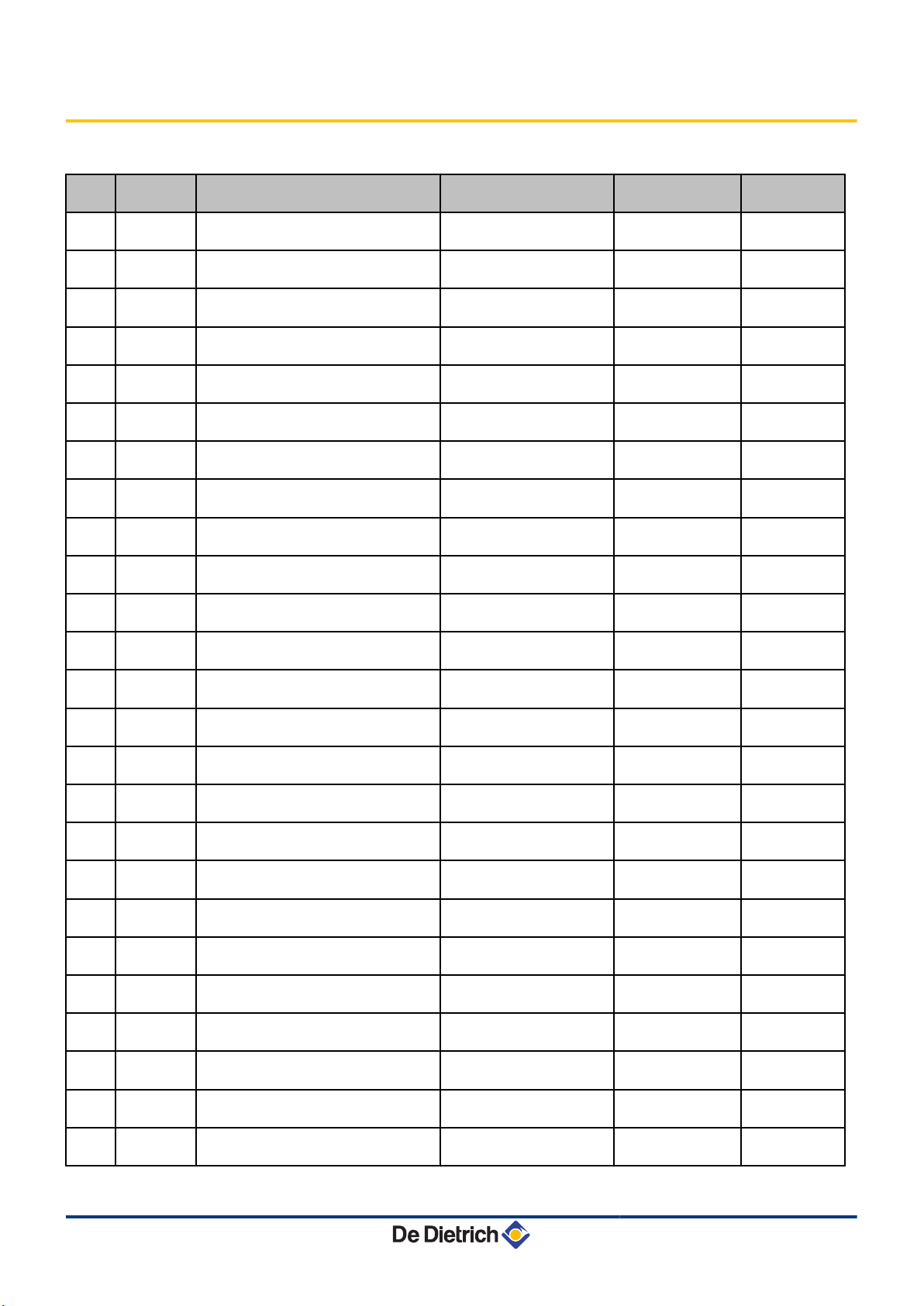

5.7.2 List of the parameters ...........................................50

5.7.3 Control system sequence ......................................51

5.7.4 Return to the factory settings ................................51

6 Switching off the appliance .....................................................................53

6.1 Installation shutdown .........................................53

6.2 Antifreeze protection ..........................................53

7 Checking and maintenance .....................................................................54

7.1 General instructions ...........................................54

7.2 Maintenance operations to be performed ........55

7.2.1 Refrigerant circuit ..................................................55

7.2.2 Hydraulic circuit .....................................................55

7.2.3 Aeraulics ...............................................................55

7.2.4 Impressed current anode ......................................55

7.2.5 Checking the safety valve or unit ..........................55

7.2.6 Descaling ..............................................................56

7.2.7 Cleaning the condensates discharge duct ............56

7.3 Accessing the bottom inspection trap .............57

7.4 Maintenance form ...............................................58

8 Troubleshooting .......................................................................................59

03/02/2014 - 300026515-001-03

8.1 Messages (Code type bxx or Exx) .....................59

8.1.1 Messages (type code bXX) ..............................59

8.1.2 Messages (type code EXX) ..............................61

8.2 Message and error history .................................62

8.2.1 Err error display ....................................................63

8.2.2 bL blockage display ...............................................63

8.2.3 Reset error and blockage history ..........................63

3

Page 6

Contents

9 Spare parts ................................................................................................64

9.1 General ................................................................64

9.2 Spare parts ..........................................................64

9.2.1 Heat pump .............................................................64

9.2.2 DHW tank ..............................................................66

03/02/2014 - 300026515-001-03

4

Page 7

03/02/2014 - 300026515-001-03

5

Page 8

1. Introduction

1 Introduction

1.1 Symbols used

TWH 200E TWH 300E TWH 300EH

In these instructions, various danger levels are employed to draw the

user’s attention to particular information. In so doing, we wish to

safeguard the user’s safety, obviate hazards and guarantee correct

operation of the appliance.

DANGER

Risk of a dangerous situation causing serious physical

injury.

WARNING

Risk of a dangerous situation causing slight physical

injury.

1.2 Abbreviations

CAUTION

Risk of material damage.

Signals important information.

¼Signals a referral to other instructions or other pages in the

instructions.

Before installing and commissioning the device, read

carefully the instruction manuals provided.

4 HP: Heat pump

4 DHW: Domestic hot water

4 LP: Low pressure

4 HP: High pressure

4 CFC: Chlorofluorocarbon

4 Qpr: Static losses (Thermal losses from the DHW tank when it is

off for 24 hours)

4 COP: Performance coefficient

4 HP/HC: Peak hours / Off-peak hours

6

03/02/2014 - 300026515-001-03

Page 9

TWH 200E TWH 300E TWH 300EH

1.3 General

1. Introduction

1.3.1. Manufacturer’s liability

Our products are manufactured in compliance with the requirements

of the various applicable European Directives. They are therefore

delivered with [ marking and all relevant documentation.

In the interest of customers, we are continuously endeavouring to

make improvements in product quality. All the specifications stated in

this document are therefore subject to change without notice.

Our liability as the manufacturer may not be invoked in the following

cases:

4 Failure to abide by the instructions on using the appliance.

4 Faulty or insufficient maintenance of the appliance.

4 Failure to abide by the instructions on installing the appliance.

1.4 Homologations

1.3.2. Installer’s liability

The installer is responsible for the installation and inital start up of the

appliance. The installer must respect the following instructions:

4 Read and follow the instructions given in the manuals provided

with the appliance.

4 Carry out installation in compliance with the prevailing legislation

and standards.

4 Perform the initial start up and carry out any checks necessary.

4 Explain the installation to the user.

4 If a maintenance is necessary, warn the user of the obligation to

check the appliance and maintain it in good working order.

4 Give all the instruction manuals to the user.

1.4.1. Certifications

03/02/2014 - 300026515-001-03

Electrical compliance / Marking CE

n

This product complies to the requirements to the european directives

and following standards:

4 2006/95/EC Low Voltage Directive

Reference Standard: EN 60.335.1.

4 2004/108/EC Electromagnetic Compatibility Directive

7

Page 10

1. Introduction TWH 200E TWH 300E TWH 300EH

Reference Standard: EN 50.081.1 / EN 50.082.1 / EN 55.014.

1.4.2. Directive 97/23/EC

This product conforms to the requirements of european directive 97 /

23 / EC, article 3, paragraph 3, on pressure equipment.

1.4.3. Factory test

Before leaving the factory, each appliance is tested for the following:

4 Water tightness

4 Air tightness

4 Electrical safety.

8

03/02/2014 - 300026515-001-03

Page 11

TWH 200E TWH 300E TWH 300EH 2. Safety instructions and recommendations

2 Safety instructions and

recommendations

2.1 Safety instructions

DANGER

If smoke is released or in case of refrigerant leak:

1. Do not use a naked flame, do not smoke, do not

operate electrical contacts or switches ( doorbell,

light, motor, lift, etc..).

2. Open the windows.

3. Switch the appliance off.

4. Avoid contact with the refrigerant. Danger of frost

injuries.

5. Trace possible leaks and seal them immediately.

2.2 Recommendations

WARNING

Depending on the settings of the appliance:

4 Do not touch the refrigeration connection pipes with

your bare hands while the appliance is running. Risk

of being burnt.

CAUTION

4 Do not neglect to service the appliance.

4 In order to limit the risk of being scalded, the

installation of a thermostatic mixing valve on the

domestic hot water flow piping is compulsory.

WARNING

Only certified professionals having received adequate

training are permitted to work on the appliance and the

installation.

03/02/2014 - 300026515-001-03

WARNING

Before any work, switch off the mains supply to the

appliance.

9

Page 12

2. Safety instructions and recommendations

2.3 Safety data sheet: R-134a refrigerant

2.3.1. Product identification

4 Refrigerant name: R-134a

2.3.2. Hazard identification

4 Effects harmful to health:

- The vapours are heavier than air and may lead to asphyxia

owing to reduced oxygen levels.

- Liquefied gas: Contact with the liquid may cause serious frost

and eye injuries.

4 Product classification: This product is not classified as a

"hazardous preparation" according to European Union

regulations.

TWH 200E TWH 300E TWH 300EH

2.3.3. Composition / Information on the

ingredients

4 Chemical nature: 1,1,1,2-Tetrafluoroethane R-134a.

4 Ingredients that may lead to hazardous situations:

Substance name

1,1,1,2-Tetrafluoroethane R-134a 100 % 811-97-2 212-377-0

Concentration CAS number CE number Classification GWP

2.3.4. First aid

4 If inhaled: Evacuate the subject from the contaminated area and

take him into the open air.

If feeling unwell: Call a doctor.

4 In the event of contact with the skin: Treat frost injuries as

burns. Rinse in abundant water, do not remove clothing (risk of

adhesion to the skin).

If skin burns appear, call a doctor immediately.

4 In the event of contact with the eyes: Rinse immediately in

water, holding the eyelids well apart (at least 15 minutes).

Consult an ophthalmologist immediately.

1300

10

2.3.5. Fire prevention measures

4 Appropriate extinguishing agents: All extinguishing agents can be

used.

03/02/2014 - 300026515-001-03

Page 13

TWH 200E TWH 300E TWH 300EH

2. Safety instructions and recommendations

4 Inappropriate extinguishing agents: None to our knowledge. In the

event of fire nearby, use the appropriate extinguishing agents.

4 Specific hazards:

- Rise in pressure.

In the presence of air, an inflammable mixture may form under

certain temperature and pressure conditions

- Toxic and corrosive vapours may be released by the effect of

the heat.

4 Special intervention methods: Cool the volumes exposed to heat

with water spray.

4 Protection of the firemen:

- Full facepiece self-contained breathing apparatus

- Complete body protection.

2.3.6. In the event of accidental spillage

4 Individual precautions:

- Avoid contact with the skin and eyes

- Do not intervene without appropriate protective equipment

- Do not inhale the vapours

- Evacuate the hazardous area

- Stop the leakage

- Eradicate all sources of ignition

- Ventilate the spillage area mechanically (Risk of asphyxia).

4 Cleaning / Decontamination: Allow residual product to evaporate.

2.3.7. Handling

4 Technical measures: Ventilation.

4 Precautions to be taken:

- No smoking

- Prevent the accumulation of electrostatic charges

- Work in a well ventilated place.

2.3.8. Personal protection

4 Respiratory protection:

- If insufficient ventilation: AX type cartridge mask

- In confined spaces: Full facepiece self-contained breathing

apparatus.

4 Hand protection: Protective gloves in leather or nitrile rubber.

4 Eye protection: Safety glasses with side protection.

4 Skin protection: Clothing made mostly of cotton.

4 Industrial hygiene: Do not drink, eat or smoke at the place of work.

03/02/2014 - 300026515-001-03

11

Page 14

2. Safety instructions and recommendations TWH 200E TWH 300E TWH 300EH

2.3.9. Considerations on disposal

4 Product waste: Consult the manufacturer or the supplier for

information on recovery or recycling.

4 Soiled packaging: Reuse or recycle after decontamination.

Destroy in authorised installations.

WARNING

Disposal must be done in compliance with prevailing local

and national regulations.

2.3.10. Regulations

4 EC Regulation 842/2006: Fluorinated greenhouse gases under

the Kyoto Protocol.

12

03/02/2014 - 300026515-001-03

Page 15

TWH 200E TWH 300E TWH 300EH 3. Technical description

3 Technical description

3.1 General description

The DHW tanks in the TWH range have the following characteristics:

4 Floor-standing thermodynamic storage DHW tank

4 Thermodynamic unit extracting energy from unheated ambient air

or outside air

4 Control panel with display of the volume of water heated and

hourly programming

4 Heat exchanger for connection to a boiler or a solar circuit (Version

EH)

4 Steatite electrical resistor 2.4 kW

4 Enamelled tank protected by impressed current anode

4 Very thick insulation (0% CFCs)

The thermodynamic water heater is a hot water tank that can be

heated by:

4 The Heat Pump (up to 65°C)

4 The electric heating resistance (Electrical back-up - AUTO and

Boost mode) (up to 70°C)

4 The additional heat exchanger (Version EH)

03/02/2014 - 300026515-001-03

13

Page 16

C003185-F

5

6

10

2

1

3

4

15

16

13

12

14

17

11

19

18

8

7

9

3. Technical description

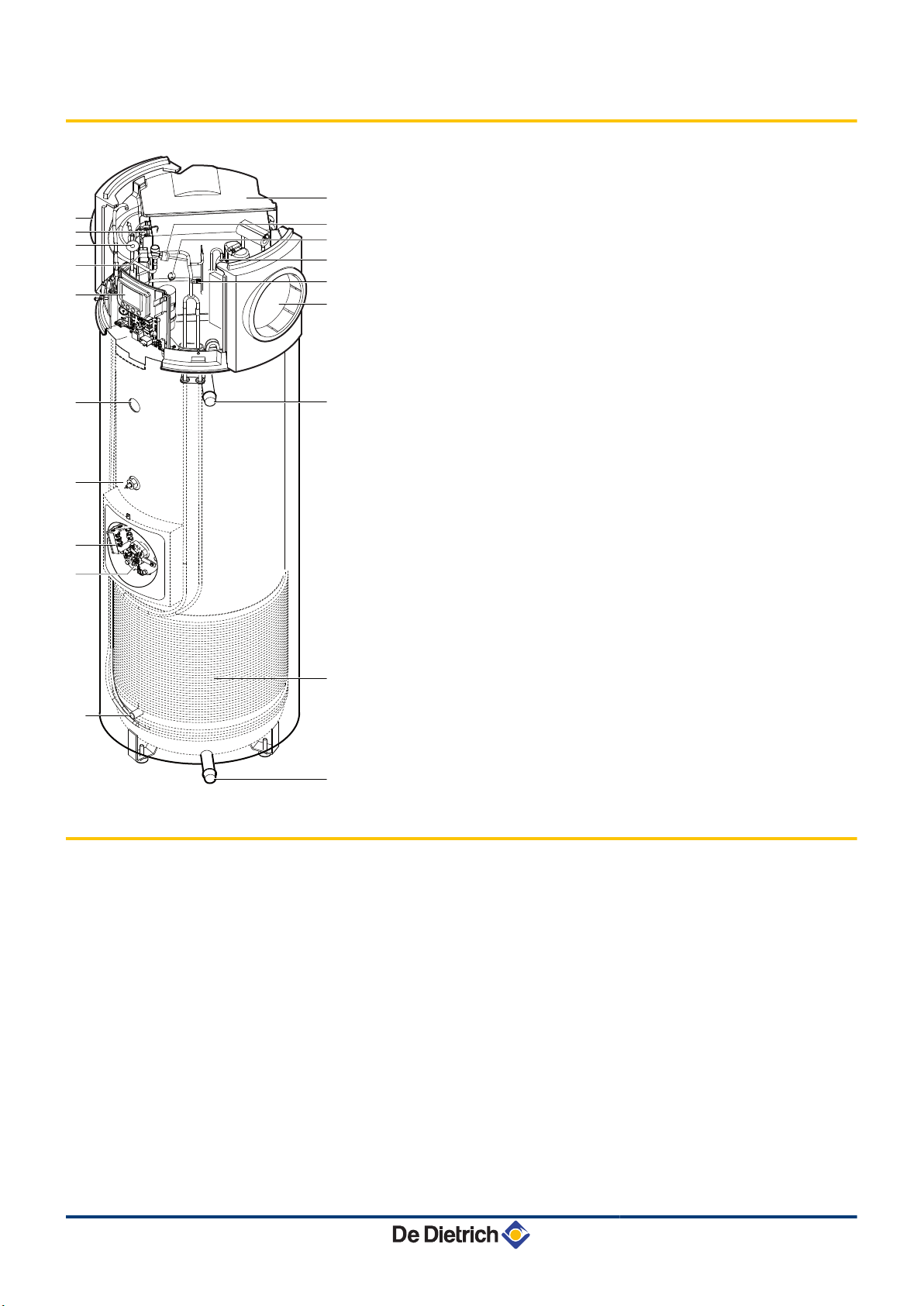

3.2 Main parts

TWH 200E TWH 300E TWH 300EH

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

Fan

Evaporator

Expansion valve

Solenoid valve for defrosting

Regulation

temperature sensor

Impressed current anode

Safety thermostat

Steatite electrical resistor

temperature sensor

Air conduits

High pressure (HP) pressure switch

Low pressure (LP) pressure switch

Compressor

Pressure measurement point - High pressure (HP)

Ventilation grid

Domestic hot water outlet

18

19

Condenser

Cold water inlet

3.3 Operating principle

The thermodynamic DHW tank uses unheated ambient air or outside

air to prepare DHW.

The refrigerant circuit is a closed circuit in which the R-134a

refrigerant plays the role of an energy carrier.

The heat from the intake air is transferred to the refrigerant in the

finned heat exchanger at a low evaporation temperature.

The refrigerant is sucked in by a compressor in vapour form, which

raises it to a higher pressure and temperature and sends it to the

condenser. In the condenser, the heat extracted in the evaporator and

some of the energy absorbed by the compressor are released into

the water.

14

03/02/2014 - 300026515-001-03

Page 17

C003625-D

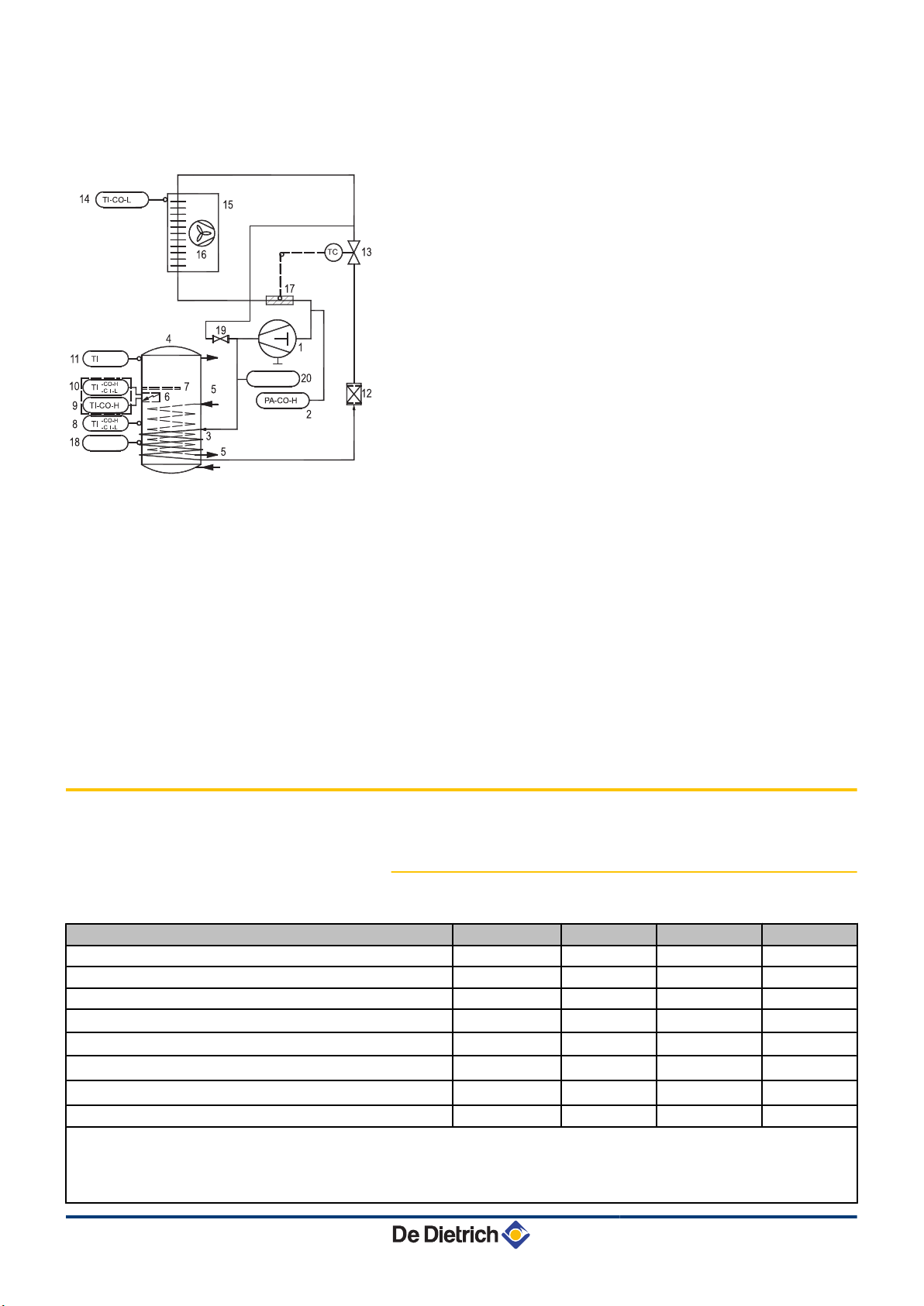

TWH 200E TWH 300E TWH 300EH 3. Technical description

The refrigerant is depressurised in the thermostatic expansion valve

and is cooled. The refrigerant can again extract the heat contained in

the inlet air into the evaporator.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Compressor

Low pressure (LP) pressure switch

Condenser

Domestic hot water tank

Heat exchanger (Version EH)

Steatite electrical resistor

Impressed current anode

Temperature regulator (HP)

Limiting thermostat

Temperature regulator (Electric heating

resistance)

Sensor tube

Filter-drier

Thermostatic expansion valve

Ambient air thermostat

Evaporator

Fan

17

18

19

20

Expansion valve bulb

Sensor tube

Solenoid valve for defrosting

High pressure (HP) pressure switch

3.4 Technical specifications

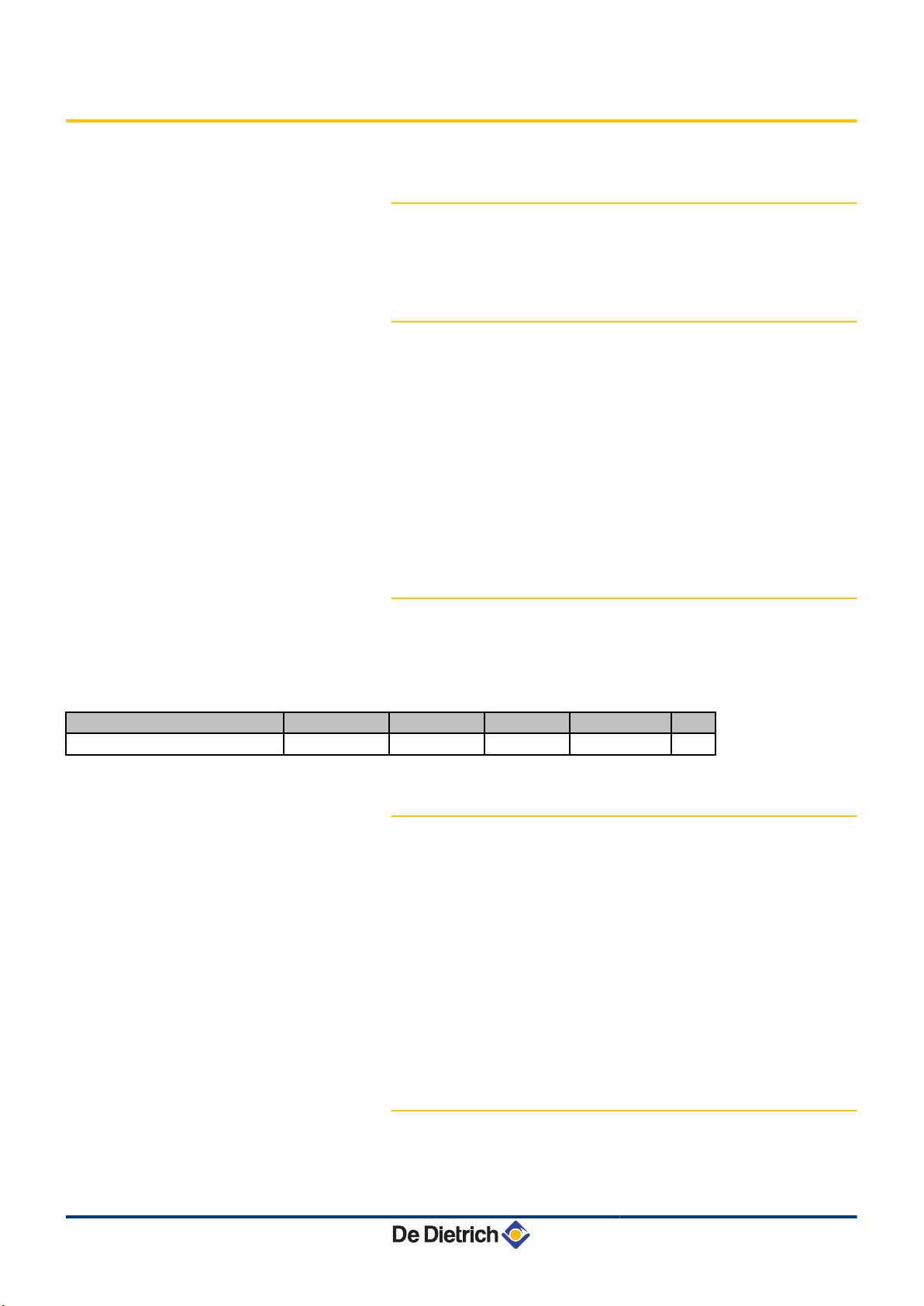

3.4.1. Characteristics of the appliance

Model

Capacity litres 270 265 215

Output (HP) -Air temperature = 15°C W 1700 1700 1700

Absorbed electrical power (HP) W 500 500 500

(1)

COP

(2)

COP

Air flow rate - maximum

Nominal air flow rate (DP = 25 Pa)

Electrical resistor output W 2400 2400 2400

(1) Value obtained at an air temperature of 15°C and a relative humidity of 70%. Water inlet temperature at 15°C in accordance with EN255-3.

(2) Value obtained with an air temperature of 7 and a water inlet at 10 °C, as per EN16147 based on Specification LCIE N°103-15/B:2011

(3) Domestic cold water input at 10°C - Primary inlet temperature at 80°C

(4) Output: 34.1 kW

(5) The installation of suction and backflow conduits on the heat pump lessens its performance

(2)

m3/h

m3/h

TWH 300 E TWH 300 EH TWH 200 E

3.7 3.6 3.5

2.94 2.75 2.90

385 385 385

320 320 320

03/02/2014 - 300026515-001-03

15

Page 18

0

2

4

6

8

10

12

14

16

18

20

-5 0 5 10 15 20 25 30 35

Y

X

B

A

C003447-A

C003483-B

51°

-5 0 5 7 10 X

55°

65°

Y

3. Technical description TWH 200E TWH 300E TWH 300EH

Model

TWH 300 E TWH 300 EH TWH 200 E

Operating pressure bar (MPa) 10 10 10

Power supply voltage V 230 230 230

Circuit breaker A 16 16 16

Exchanger surface

Continuous output DT = 35 K

Flow rate over 10 minutes with DT = 30 K

Heating time (15-51 °C)

(1)

Qpr

(1)

V40

(2)

Vmax

(2)

Pes

(3) (4)

(3)

(1)

Maximum length of the air connection Diameter 160 mm

(5)

2

m

- 1.00 -

litres per hour - 955.6 -

l/10 mm - 420 -

Hours 7 7 5

kWh/24h 0.67 0.75 0.73

litres 357 358 240

litres 388 383 281.9

W 34 36 30

m 25 25 25

R134a refrigerant kg 1.45 1.45 1.45

Weight (empty) kg 105 123 92

(1) Value obtained at an air temperature of 15°C and a relative humidity of 70%. Water inlet temperature at 15°C in accordance with EN255-3.

(2) Value obtained with an air temperature of 7 and a water inlet at 10 °C, as per EN16147 based on Specification LCIE N°103-15/B:2011

(3) Domestic cold water input at 10°C - Primary inlet temperature at 80°C

(4) Output: 34.1 kW

(5) The installation of suction and backflow conduits on the heat pump lessens its performance

3.4.2. Heating time of the DHW tank depending on

the air temperature

Scenario for complete heating of the DHW tank

A

B

Y

X

Heating time for a set point of 51°C

Heating time for a set point of 62°C

Heating time (Hours)

Air temperature (°C)

3.4.3. Max domestic hot water set point reached

by the heat pump depending on the air

temperature

Y

Max domestic hot water temperature (°C)

16

X

Air temperature (°C)

03/02/2014 - 300026515-001-03

Page 19

TWH 200E TWH 300E TWH 300EH 4. Installation

4 Installation

4.1 Regulations governing installation

CAUTION

Installation and maintenance of the appliance must be

done by a qualified professional in accordance with

prevailing statutory texts and codes of practice.

4.2 Package list

4.2.1. Standard delivery

The delivery includes:

4 The thermodynamic DHW tank x1

4 Dielectric connection (delivered in the instructions bag for the

DHW tank) (2x)

4 Lip gasket (2x)

4 Condensate evacuation hose (1x)

4 Instructions + Kyoto Protocol sticker (1x)

4 Hose holding clip (1x)

4 The user instructions

4 The installation and maintenance instructions

4.2.2. Accessories

Accessories

Galvanised 90° elbow (Diameter 160 mm) EH 77

Adapter sleeve (Diameter 160 mm) EH 205

Insulated flexible duct (Diameter 160 mm - Length 3 m) EH 206

Set of 2 retaining clamps (Diameter 160 mm) EH 207

Passing through walls (Diameter 160 mm) + Closing plate EH 208

Outside grid (Diameter 160 mm) (aluminium) EH 209

PPE duct (Diameter 160 mm - Length 2x1 m) + 2 sleeves EH 272

290° elbows (PPE) (Diameter 160 mm) + 2 sleeves EH 273

2 sleeves PPE (Diameter 160 mm) EH 274

Roof outlet Black (Diameter 160 mm) EH 275

Tightness bed plate for flat roof (Diameter 160 mm) EH 276

package

03/02/2014 - 300026515-001-03

17

Page 20

C003496-B

4. Installation TWH 200E TWH 300E TWH 300EH

Accessories package

Tightness bed plate for sloping roof 25 to 45° (Diameter 160

mm)

Reduced elbow kit EH 434

Connection kit for safety unit ER 208

EH 277

4.3 Storage and transport

CAUTION

4 Have 2 people available.

4 Use a 3-wheel hand truck.

4 Handle the appliance with gloves.

4 The appliance cover cannot be used for transport

operations. The cover is not capable of withstanding

heavy weights.

4 Model 300 : Allow a minimum room height of

approximately 2.15 m

Model 200 : Allow a minimum room height of

approximately 1.84 m.

4 The thermodynamic DHW tank must be stored and transported in

its packaging and not filled with water.

4 Ambient transport and storage temperatures admissible: from

-20 to +60°C.

4.3.1. Transport

We recommend shipping the appliance vertically.

It is possible to ship the appliance horizontally over short

distances but only on its back.

CAUTION

The appliance must never be stacked or laid on another

side; it may otherwise malfunction or break down.

18

03/02/2014 - 300026515-001-03

Page 21

C003192-D

TWH 200E TWH 300E TWH 300EH

4.4 Choice of the location

4. Installation

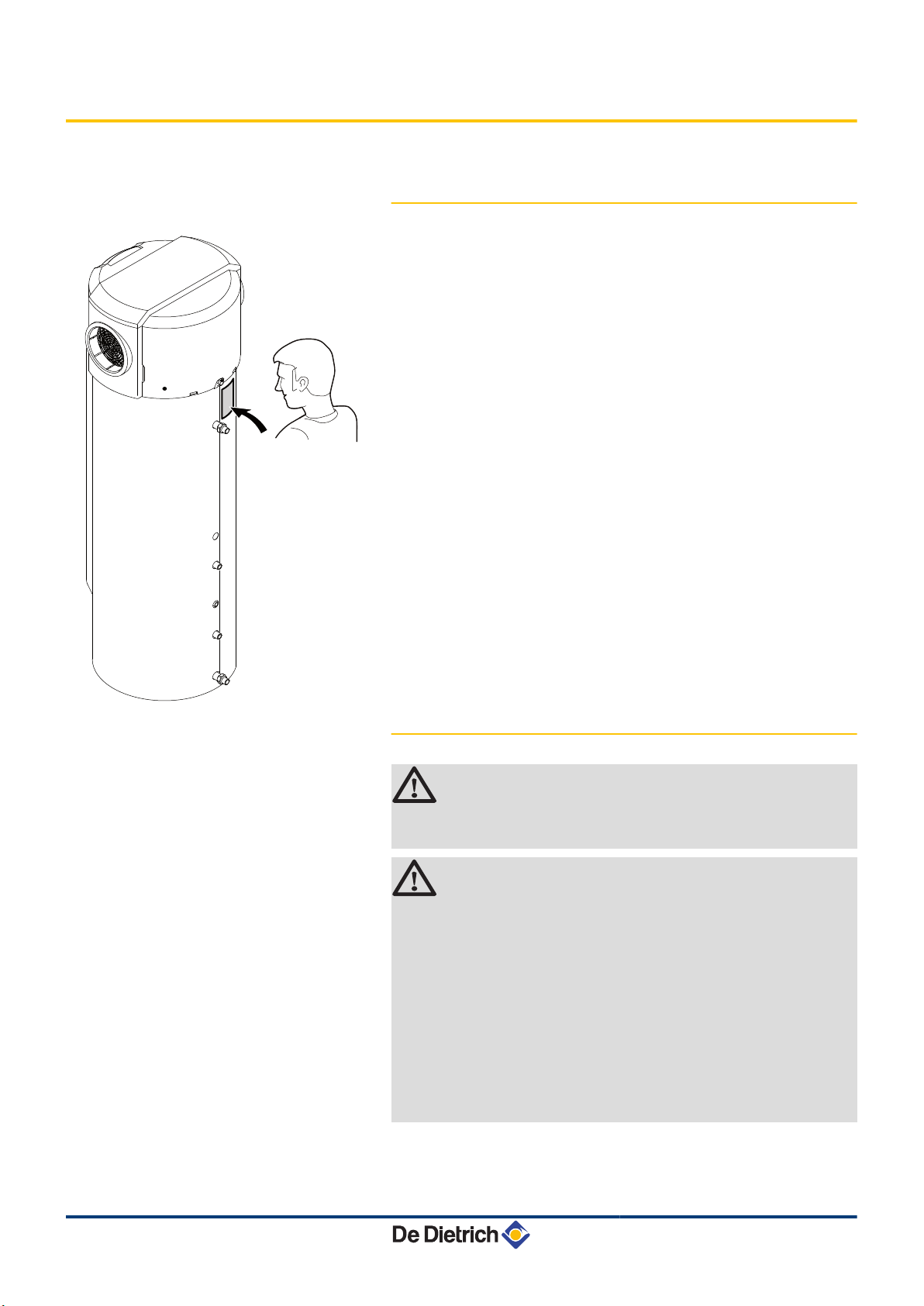

4.4.1. Type plate

4 The type plate must be accessible at all times.

4 The type plate identifies the product and provides the following

information:

- Appliance type

- Manufacturing date (Year - Week)

- Serial number.

4.4.2. Positioning of the appliance

CAUTION

When installing the appliance, respect the IP21

environmental rating.

CAUTION

4 Do not install the thermodynamic water heater in

premises exposed to gas, vapours or dust. Do not

install the thermodynamic DHW tank in an

atmosphere which is chlorinated (swimming pool) or

fluorinated (aerosols, detergents, solvents, etc.).

4 The air taken in must in no event be dusty.

4 Adequate thermal insulation in relation to adjacent

living spaces is recommended.

4 Temperature of the ambient air or of the air taken in

by the heat pump for optimum running: from 10 to

35°C.

Install the appliance in a dry, frost-free room at a minimum

4

temperature of 7°C.

4 Install the appliance on a flat, solid surface.

03/02/2014 - 300026515-001-03

19

Page 22

C004021-A

C004020-A

C004019-A

A

C004022-A

C004023-A

B

4. Installation TWH 200E TWH 300E TWH 300EH

4 Install the appliance on a base frame. The base frame must at all

times present sufficient resistance to the load.

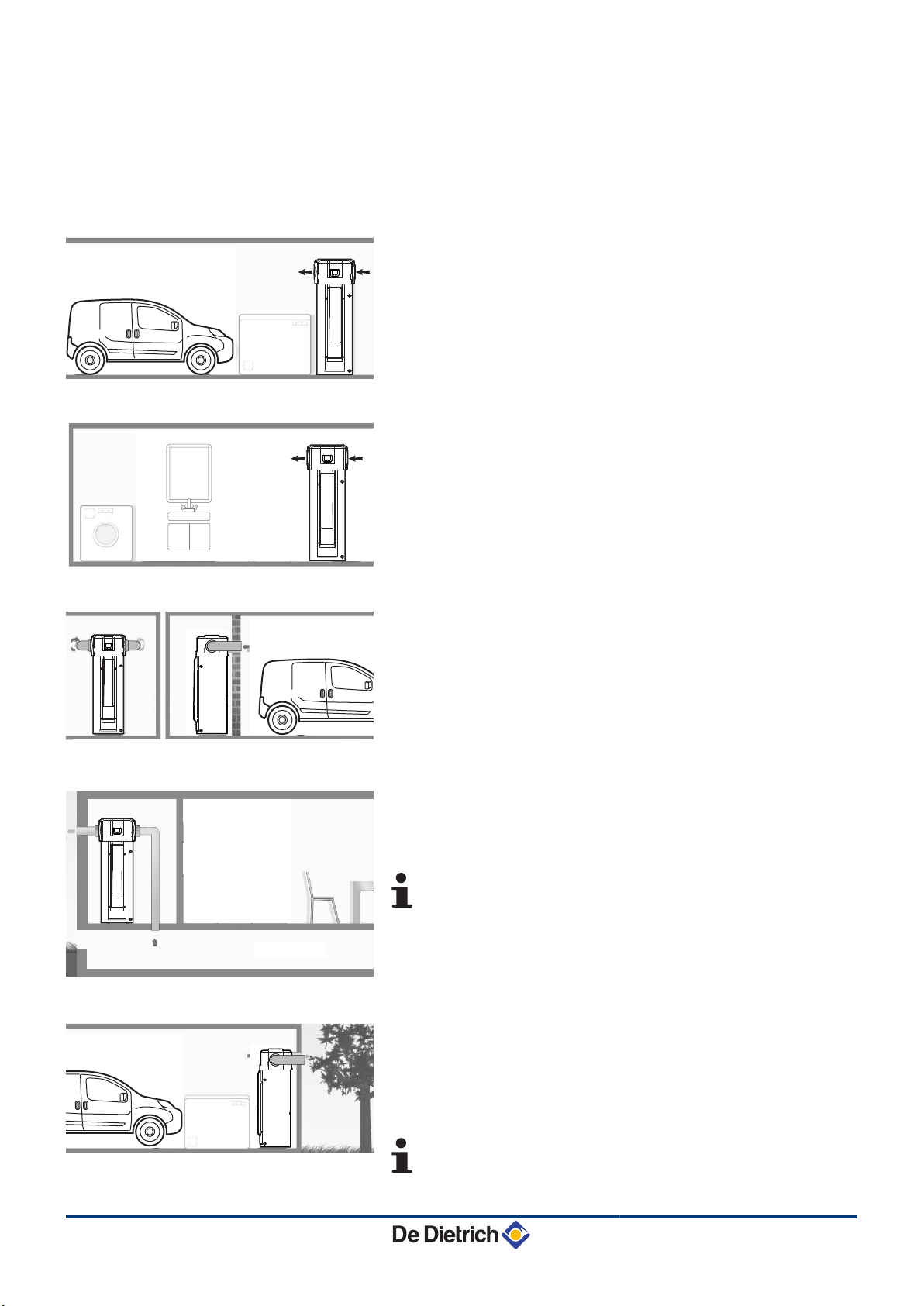

Advised positions

n

Garage:

4 Unheated room.

4 Enables recovery of the free energy released by your vehicle’s

engine when switched off after use or by household appliances in

operation.

Laundry room:

4 Unheated room.

4 Enables the dehumidification of the room and recovery of the

energy wasted by washing and drying machines.

Habitable room:

4 Can obtain free heat from the garage.

Via crawl space:

4 Connection to the crawl space is possible if the volume is greater

than 30 m3.

4 The crawl space must be frost-free (temperature > 1°C).

If the crawl space is poorly insulated, thermal losses from

the home will be greater.

Via outside air:

4 Connection to the outside air may lead to overconsumption of

electricity if the outside air temperature falls outside the operating

range.

4 Minimum distance to be observed for the ducts if intake and

backflow are done on the same façade: 700 mm.

20

Risk of discomfort in the Eco operating mode.

03/02/2014 - 300026515-001-03

Page 23

C003481-C

690

300

1100

1100 mini

0 160

C004734-A

0 160 / 200

800 mini

800

826

598

C003188-F

V > 30m

3

150

150

min.

400

min.

400

690

A

0 600

TWH 200E TWH 300E TWH 300EH

4. Installation

Cupboard:

4 With EH77 or EH273: 1100 mm x 1100 mm - Ducted version. Be

sure to make the aeraulic connections absolutely leakproof in

order to prevent the cupboard from losing heat.

We strongly recommend installing the control system in the

living room.

4 With EH434 (Reduced elbow kit): 800 mm x 800 mm - Ducted

version. Be sure to make the aeraulic connections absolutely

leakproof in order to prevent the cupboard from losing heat.

We strongly recommend installing the control system in the

living room.

A (mm) 1690 2000 2000

TWH 200E TWH 300E TWH 300EH

4 To ensure adequate access and facilitate maintenance, allow

sufficient space around the appliance.

4 Model 200: Allow a minimum distance of 0.4 m at both sides of the

appliance and a minimum room height of around 1.84 m for

operation without air ducts.

4 Model 300: Allow a minimum distance of 0.4 m at both sides of the

appliance and a minimum room height of around 2.15 m for

operation without air ducts.

03/02/2014 - 300026515-001-03

21

Page 24

4. Installation TWH 200E TWH 300E TWH 300EH

Pipe length

n

CAUTION

Do not use accessories that may cause considerable

pressure drops (extraction grid with mosquito screen,

partially extended flexible duct, etc.). Pressure drops from

accessories must be lower than or equal to the static

pressure of the fan (50 Pa). If the pressure drops are

greater, the performance of the appliance will be impaired

and the loading times increased.

Maximum length of the air connection m

diameter 160 mm 25

Accessories package Equivalent length in m

Galvanised 90° elbow (Diameter 160 mm) EH77 1.0

Adapter sleeve (Diameter 160 mm) EH205 1.5

Insulated flexible duct (Diameter 160 mm - Length 3 m) EH206 3.0

Passing through walls (Diameter 160 mm) + Closing plate EH208 7.0

Outside grid (Diameter 160 mm) (aluminium) EH209 8.0

PPE duct (Diameter 160 mm - Length 2x1 m) + 2 sleeves EH272 0.2

290° elbows (PPE) (Diameter 160 mm) + 2 sleeves EH273 0.2

Roof outlet Black (Diameter 160 mm) EH275 2.0

Reduced elbow kit EH434 6.0

22

03/02/2014 - 300026515-001-03

Page 25

C003183-E

50°

A

690

90

B

1025

810

4

(1)

3

1

2

4

TWH 200E TWH 300E TWH 300EH 4. Installation

4.4.3. Main dimensions

TWH 200E - TWH 300E

n

03/02/2014 - 300026515-001-03

A

Z

E

R

(1)

TWH 200E TWH 300E

A 1690 2000

B 974 1287

Impressed current anode

Steatite electrical resistor 2.4 kW

Domestic hot water outlet G 3/4"

Domestic cold water inlet G 3/4"

Adjustable feet

¼See chapter "Positioning the appliance", page

25

23

Page 26

C003476-B

90

690

810

300

455

658

1375

2000

1025

4

(1)

1

2

3

4

5

6

7

4. Installation TWH 200E TWH 300E TWH 300EH

TWH 300EH

n

24

A

Z

E

R

T

Y

U

(1)

Impressed current anode

Steatite electrical resistor 2.4 kW

Secondary domestic hot water flow G 3/4"

Solar exchanger or boiler inlet G 3/4"

Sensor tube for solar or boiler sensor G 3/4"

Solar exchanger or boiler outlet G 3/4"

Domestic cold water inlet G 3/4"

Adjustable feet

¼See chapter "Positioning the appliance", page

25

03/02/2014 - 300026515-001-03

Page 27

M003102-A

1

2

3

4

5

6

7

8

TWH 200E TWH 300E TWH 300EH 4. Installation

4.5 Positioning the appliance

4.5.1. Unpacking the appliance

CAUTION

Remove all packaging materials. Check that the contents

are intact. If you notice a defect, do not use the appliance

and contact the supplier.

1. Remove the retaining screw from the fan grille.

2. Turn the grille anticlockwise.

3. Remove the fan grille.

4. Unscrew the 2 screws from the compressor support part.

5. Remove the compressor support part and discard it.

6. Put the grille back in place.

7. Turn the grille clockwise to fit it back into its housing.

8. Put the retaining screws in place.

4.5.2. Positioning the appliance

¼Refer to the instructions affixed to the packaging of the

appliance

CAUTION

After positioning the appliance, wait one hour before

starting it up.

03/02/2014 - 300026515-001-03

25

Page 28

C003187-E

B

21

(1)

19

3°

4. Installation

4.6 Hydraulic connections

TWH 200E TWH 300E TWH 300EH

4.5.3. Levelling

To improve condensates evacuation, we recommend tilting

the appliance slightly backwards.

1. Level the appliance using the adjustable feet.

(1) Adjustable feet, Basic dimension 4 mm

Can be adjusted from 4 mm to 21 mm

CAUTION

Before making the hydraulic connections, it is essential to

rinse the circuit to get rid of any particles that may damage

certain units (safety valve, pumps, valves, etc.).

If rinsing has to be done using an aggressive product,

neutralise the rinsing water before disposing of it in the

waste water network.

Using hoses which are too short or too rigid encourages

the transmission of vibrations and the production of noises.

Version EH: Make all the hydraulic connections for the DHW tank

using flexible pipes.

4.6.1. Connecting the calorifer to the domestic

water circuit (secondary circuit)

When making the connections, it is imperative that the standards and

corresponding local directives are respected.

Specific precautions

n

Before making the connection, rinse the drinking water inlet

26

pipes in order not to introduce metal or other particles into the

appliance’s tank.

03/02/2014 - 300026515-001-03

Page 29

TWH 200E TWH 300E TWH 300EH

4. Installation

CAUTION

Do not connect the domestic hot water connection directly

to copper pipes in order to prevent galvanic couples in iron/

copper (risk of corrosion). It is compulsory to fit the

domestic hot water connection with a dielectric

connection (Supplied).

Safety valve or safety unit

n

CAUTION

In accordance with safety rules, a safety unit calibrated to

7 bar must be mounted on the DHW tank’s domestic cold

water inlet.

4 Integrate the safety valve in the cold water circuit.

4 Install the safety valve close to the calorifer in a place which is

easy to access.

Size

n

4 The diameter of the safety unit and its connection to the calorifer

must be at least equal to the diameter of the domestic cold water

inlet on the calorifer.

4 There must be no cut-off element between the valve or the safety

unit and the domestic hot water calorifer.

4 The outlet pipe in the valve or safety assembly must not be

blocked.

To avoid restricting the flow of water in the event of overpressure:

4 The safety device drain pipe must have a uniform and sufficient

gradient and its diameter must be at least equal to that of the outlet

opening of the safety device (to prevent the flow of water being

hindered if the pressure is too high).

4 The cross section of the discharge pipe from the safety unit must

be at least equal to the cross section of the opening of the safety

unit outlet.

Isolating valves

n

03/02/2014 - 300026515-001-03

Hydraulically isolate the primary and secondary circuits using stop

valves to facilitate maintenance operations on the unit. The valves

make it possible to carry out maintenance on the calorifer and its

components without draining the entire installation.

These valves are also used to isolate the calorifer unit when

conducting a pressurised check on the leak tightness of the

installation if the test pressure is greater than the admissible operating

pressure.

27

Page 30

4. Installation TWH 200E TWH 300E TWH 300EH

CAUTION

If the mains pipes are made of copper, fit a sleeve made

of steel, cast iron or any other insulating material between

the tank’s hot water outlet and the pipes to prevent

corrosion to the connection.

Connecting the domestic cold water

n

Make the connection to the cold water supply according to the

hydraulic installation diagram.

Install a water drain in the boiler room and a funnel-siphon for the

safety unit.

The components used for the connection to the cold water supply

must comply with the prevailing standards and regulations in the

country concerned. Fit a one-way valve to the domestic cold water

circuit.

Pressure reducer

n

If the mains pressure exceeds 80% of the calibration of the valve or

safety unit (e.g. 5,5 bar (0,55 MPa) for a safety unit calibrated to 7 bar

(0,7 MPa)), a pressure reducer must be installed upstream of the

appliance. Install the pressure reducer downstream the water meter

in such a way as to ensure the same pressure in all of the installation

pipes.

Measures to take to prevent hot water flow return

n

Fit a one-way valve to the domestic cold water circuit.

4.6.2. Connection to a boiler (Version EH)

CAUTION

Before making the water connections of the heating circuit

and domestic hot water tank heat exchanger, it is

imperative to rinse the circuits to remove any particles

which might damage the components (safety valve,

pumps, valves, ...).

28

03/02/2014 - 300026515-001-03

Page 31

C003613-B

TWH 200E TWH 300E TWH 300EH 4. Installation

A

1

2

3

4

7

9

11

16

17

18

21

22

24

25

26

27

Boiler

Heating flow

Heating return

Safety valve

Pressure gauge

Automatic air vent

Isolating valve

Heating pump

Expansion vessel

Drain cock

Filling the heating circuit

Outside sensor

Boiler sensor

DHW calorifier exchanger primary inlet

DHW calorifier heat exchanger primary outlet

DHW pump

Non-return valve

03/02/2014 - 300026515-001-03

28

Domestic cold water inlet

29

Page 32

C003612-A

4. Installation TWH 200E TWH 300E TWH 300EH

29

30

33

50

51

52

Pressure reducer

Safety unit

DHW sensor

Disconnector

Thermostatic valve

Differential valve (only with module fitted with a 3-speed

pump)

57

90

Domestic hot water outlet

Anti-thermosiphon loop

4.6.3. Connection to solar collectors (Version

EH)

CAUTION

Limit the domestic hot water temperature to 60°C.

30

4

Pressure gauge

03/02/2014 - 300026515-001-03

Page 33

TWH 200E TWH 300E TWH 300EH 4. Installation

27

28

29

30

57

61

79

80

84

85

87

88

89

90

109

112a

112b

Non-return valve

Domestic cold water inlet

Pressure reducer

Safety unit

Domestic hot water outlet

Thermometer

Primary solar exchanger outlet on the DHW calorifier

Primary solar exchanger inlet on the DHW calorifier

Stop valve with releasable non-return valve

Primary solar circuit pump

Safety valve calibrated at 6 bar

Solar expansion vessel

Heat transfer fluid container

Anti-thermosiphon loop (= 10 x Pipe diameter)

Domestic hot water thermostatic mixing valve

Solar sensor probe

Solar DHW sensor

114

126

129

130

131

132

Primary solar circuit filling and draining device

Solar regulator

Insulation

Manual bleed degasser

Solar collectors

Complete solar station with solar regulator

03/02/2014 - 300026515-001-03

31

Page 34

1

C003656-B

min. 200

4. Installation

4.7 Condensates discharge

TWH 200E TWH 300E TWH 300EH

1. Mount a siphon in the condensates discharge pipe.

CAUTION

If there is no siphon, problems with condensates

discharge may arise when the compressor is running.

2. Mount the flow collector.

3. Fit the clamp to the flow header.

4.8 Installing the control system in the living room

The control system is mounted as standard on the heat pump. It is

possible to install the control system in the living room for greater

comfort.

4 The user can remotely control programming of DHW production.

4 The user is informed directly if the installation malfunctions in any

way.

4.8.1. Choose a location

Install the control system against an internal wall around 1.5 metres

from the floor in the carefully chosen pilot room.

Locations in the room that are not recommanded:

4 Encased

4 Exposed to solar radiation.

32

03/02/2014 - 300026515-001-03

Page 35

C003254-C

1

1

2

6

4

3

5

C003329-D

7

C003408-D

TWH 200E TWH 300E TWH 300EH 4. Installation

4.8.2. Operations to be carried out on the

thermodynamic DHW tank

1. Unscrew the 2 screws.

2. Remove the front cover.

3. Separate the control system command module from its base.

4. Disconnect the command module (2 wires).

5. Unscrew the 2 fastening wires on the base.

6. Remove the wire and discard it.

7. Unscrew the 2 fastening screws on the base of the control panel

and remove the base.

03/02/2014 - 300026515-001-03

33

Page 36

C003330-D

8

C003334-G

10

13

9

10

1

2

3

6

C003331-A

4. Installation TWH 200E TWH 300E TWH 300EH

8. Connect the 2 wires for connecting the command module at the

appliance end (not supplied).

9. Replace the front cover.

10.Tighten the 2 screws.

4.8.3. Installing the control system in the living

room

1. Drill 2 holes with a Ø of 6 mm.

2. Put the plugs in place.

3. Attach the wall support.

34

03/02/2014 - 300026515-001-03

Page 37

4

5

C003407-D

TWH 200E TWH 300E TWH 300EH

4.9 Electrical connections

4. Installation

4. Connect the 2 wires on the command module.

5. Put the control system module in place.

4.9.1. Recommendations

WARNING

4 Only qualified professionals may carry out electrical

connections, always with the power off.

4 Do not connect the power supply directly to the HP/

HC contact.

The earthing shall comply with local standards.

Power the appliance with a circuit that includes a 16 A omnipolar

circuit breaker, D curve type, with a gap of more than 3 mm.

The DHW tank is delivered with a 3G cable. If the power cable is

damaged, it must be replaced by the manufacturer, its after sales

service or persons with similar qualifications in order to obviate any

danger.

The electricity supply is connected to the mains by connection cable

(~230 V, 50 Hz) and electrical plug.

The HP/HC connection is made on the terminal block.

4.9.2. Connecting the hydraulic back-up (Version

EH)

1. Remove the front cover.

See chapter "Installing the control system in the living

¼

room", page 32

03/02/2014 - 300026515-001-03

35

Page 38

C003618-B

Backup

C003254-C

1

1

2

4. Installation TWH 200E TWH 300E TWH 300EH

2. Access to the PCB.

3. Connect the boiler back-up connector (boiler back-up). To set the

boiler inlet, refer to the boiler instruction manual.

4.9.3. Access to the connection terminal HP/HC

1. Unscrew the 2 screws.

2. Remove the front cover.

36

03/02/2014 - 300026515-001-03

Page 39

C003335-A

HP/HC 230V

C003335-B

C003617-E

A

A

B

C1 C2

538 kW/h

1

1

A1

A2

0

Auto

0

15 / 45 A

500 mA

TEST

16 A40 A 2 A

30

mA

L

N

X11-2 HP/H

X11-1 LINE

C

1 2

3 4 4

TWH 200E TWH 300E TWH 300EH 4. Installation

3. Access to the PCB.

4. Make the electrical connection using cable with a cross section of

1,5 mm2.

4.9.4. Connection with HP/HC signal connected

Shunt connection with HP/HC relay (Dry contact in the

n

heat pump)

03/02/2014 - 300026515-001-03

1

Meter

37

Page 40

C1 C2

538 kW/h

1

0

15 / 45 A

500 mA

TEST

16 A40

C003616-D

A 2 A

30

mA

L

N

X11-2 HP/H

X11-1 LINE

C

L

N

X11-2 HP/HC

X11-1 LINE

A

1 2

3 4 4

4. Installation

TWH 200E TWH 300E TWH 300EH

2

3

4

A

B

Connection circuit breaker

AC type differential switch

Circuit breaker

Power cable 1,5 mm

Shunt 1,5 mm

2

2

4 Set parameter P04 to 2.

4 The heat pump and additional heating are not permitted to operate

in Peak Hours

4 Rapid Boost heating at one touch

4 The 2 signal wires must be routed as far as the appliance’s box

Connection to the meter with direct HP/HC contact (Dry

n

contact or voltage in the heat pump)

38

1

2

3

4

A

Meter

Connection circuit breaker

AC type differential switch

Circuit breaker

Power cable 1,5 mm

2

4 Set parameter P04 to 2.

4 The heat pump and additional heating are not permitted to operate

in Peak Hours

4 Rapid Boost heating at one touch

03/02/2014 - 300026515-001-03

Page 41

C1 C2

538 kW/h

1

0

15 / 45 A

500 mA

TEST

16 A40

C003615-D

A 2 A

30

mA

L

N

1 2

3 4 4

TWH 200E TWH 300E TWH 300EH 4. Installation

4 The 2 signal wires must be routed as far as the appliance’s box

4.9.5. Connection with timer programming

1

2

3

4

Meter

Connection circuit breaker

AC type differential switch

Circuit breaker

4 Easy to install

4 Opt for hourly programming to take advantage of the HP/HC tariff

03/02/2014 - 300026515-001-03

39

Page 42

C004218-B

A

TEST

16 A40 A 2 A

30

mA

L

N

X11-2 HP/H

PV-S

DC AC

X11-1 LINE

C

3

5

6

4 4

4. Installation TWH 200E TWH 300E TWH 300EH

4.9.6. Connection with timer programming and

photovoltaic signal

3

AC type differential switch

4

Circuit breaker

5

Photovoltaic panel

6

Inverter

A

Power cable 1,5 mm

4The heat pump and electrical

backup are allowed to operate

depending on the time program.

4The heat pump will start to heat

at the temperature of 62 °C

(parameter P07) when the

photovoltaic signal is actif.

4If the photovoltaic signal is actif

when the contact is open, set

the parameter P04 on 3.

4If the photovoltaic signal is actif

when the contact is closed, set

the parameter P04 on 4.

2

40

03/02/2014 - 300026515-001-03

Page 43

3

3

4

PCU-195

2

θ

°C

1

2

1

2

X8

1

5 4

4

1

2

6

1

2

3

1 2

2

1

2

3

X-HC

1

2

1

X7

2

θ

°C

2

2

1

1

1

2

X3

1

X1

1

2

θ

°C

2

1

2

X4

1

θ

°C

2

1

2

X2

1

3

X5

5

6

2

θ

°C

1

2

1

1

2

4

P

COM

NC NO

L

SPL1

N

1

2

3

4

1

X-B1

1

2

R5R4R3R1R2

S1 S2 S3 TA

S4 S5

P

TS

X6

1

2

2 4

R6

2

5

1 23

KLIXON

HP

ALIMENTATION 230 V

SPC003402-B

TWH 200E TWH 300E TWH 300EH 4. Installation

4.10 Electrical principle diagram

03/02/2014 - 300026515-001-03

Control panel

Fan

Solenoid valve for defrosting

Compressor

Condenser

Electric heating resistance

41

A

Z

E

R

T

Y

Page 44

C003409-A

4. Installation TWH 200E TWH 300E TWH 300EH

*

L

N

P

R1 - R6

S4

S5

SPL1

TA

TS

X1

X2-S3

X3-S2

X4-S1

X5

X6

X7

Earth

Live

Neutral

Pressure switch

Relay

Evaporator sensor

Room sensor

Splice

Impressed current anode

Safety thermostat

Connecting the impressed current anode

Bottom DHW temperature sensor

Middle DHW temperature sensor

Top DHW temperature sensor

Room sensor, Evaporator, Pressure switch

Control panel connection

Hydraulic back-up command terminal board

X8

X-B1

X-HC

Command terminal board

Electrical back-up command terminal board

Pricing information input (HP-HC).

Allows authorisation of domestic hot water production

depending on the setting of the HP/HC input

4.11 Filling the thermodynamic DHW tank

1. Open a hot water tap.

2. Open the cold water tap located on the safety unit. Ensure that the

drainage valve on the unit is closed.

3. When the water overflows through the hot water tap, the appliance

is full. Close the hot water tap.

42

03/02/2014 - 300026515-001-03

Page 45

C003197-B

MENUMODE

C003186-H

1

2

3

4

5

6

7

1

4

3

4

1

2

MENUMODE

TWH 200E TWH 300E TWH 300EH 5. Commissioning

5 Commissioning

5.1 Control panel

5.1.1. Description of the keys

( - )

MODE

MENU

Browse keys

Operating mode selection key

Key to access the various menus

5.1.2. Description of the display

!

J

!

K

88[8

8

Quantity of domestic hot water available (depending on

the set point input)

Parameter settings

Alarm

Comfort period active or Clock programming

Display of the date (day:month) or the time (hour:minutes)

depending on the selected menu

03/02/2014 - 300026515-001-03

1 2 3 4 5

6 7

888

L

X

(

)

B

V

M

%

W

> C

Display of the day of the week (1=Monday, 2=Tuesday,

etc.)

Digital display

Number of baths available (40 °C)

Quantity of water (litres)

Reduces set values

Increases set values

Confirm key

Reset the control system after a breakdown

Automatic mode or Comfort mode

Eco mode

Boost mode

Holiday mode

43

Page 46

C003487-B

C003484-B

C003485-B

C003486-A

C003493-A

1

4

3

4

1

2

5. Commissioning

TWH 200E TWH 300E TWH 300EH

Display Domestic hot water

production

Heat pump The 2 segments of the tank flash simultaneously when domestic hot water production

Electrical back-up The right-hand segment of the tank flashes when domestic hot water production is

Hydraulic additional heating The left-hand segment of the tank flashes when domestic hot water production is

Heat pump + Electrical backup + Hydraulic additional

heating

M + W

% + W

> C

Boost function active via the HP/HC inlet

Boost function active via the HP/HC inlet

Boost function active via the HP/HC inlet

+ W

DHW production mode indicator

n

The main display indicates the domestic hot water production mode.

Description

is handled by the heat pump

handled by electrical back-up

handled by hydraulic back-up (Version EH)

The 2 segments of the tank flash alternately when domestic hot water production is

handled by the heat pump, by electrical back-up and by hydraulic backup (EH version)

Indicator of the water volume available

n

When producing domestic hot water, the display indicates the number

of baths available and the level to which the tank is filled (quantity of

hot water available).

4 The number of baths is calcuated based on a domestic hot water

temperature of 40°C.

4 The level to which the tank is filled is calculated according to the

set point temperature.

4 Set the 2 parameters, P18 and P19, according to the

appliance model.

¼See chapter: "Modifying the installer parameters", page

49

44

03/02/2014 - 300026515-001-03

Page 47

C003203-D

1x

3

1

4

3

4

1

2

MENUMODE

C003204-B

1x

2x

3x

.

.

.

1

4

3

4

1

2

MENUMODE

TWH 200E TWH 300E TWH 300EH

5. Commissioning

5.1.3. Browsing in the menus

1. Press the MENU key. The SE nS 1 menu is displayed

(Temperature measurement).

2. Use the ( and ) keys to scroll through the menus (See table

below).

3. To access the selected menu, press the MODE key (B).

4. To go back to the previous display, press the key MENU.

5. To go back ty the main display, press once key MENU.

Accessing the menu

1x MENU SE nS

1x )

2x )

3x )

4x )

5x )

6x )

Menu Description See chapter

1

CL OC

2

Pr oG

3

Co un

4

PA rA

5

Er bL

6

Co dE

7

Measurements menu

Setting the time and the date

Modify an hourly programme

Meters

Setting parameters

Failure history

Installer parameters

¼ "Reading out measured values", page 47

¼Refer to the user instructions

¼Refer to the user instructions

¼ "Counters", page 47

¼ "Reading out measured values", page 47

¼ "Message and error history", page 62

¼ "Modifying the installer parameters", page 49

5.2 Check points before commissioning

4 Check that the thermodynamic DHW tank is full of water.

4 Check the seals.

4 Check that the safety devices are operating correctly.

4 Check the operating mode.

03/02/2014 - 300026515-001-03

45

Page 48

C003493-A

1

4

3

4

1

2

5. Commissioning

5.3 Putting the appliance into operation

5.3.1. Commissioning

CAUTION

Initial commissioning must be done by a qualified

professional.

Carry out the commissioning operations in the following order:

1. Connect to the mains.

2. Check that no error codes or messages are shown on the display.

The domestic hot water set point temperature is set to 55°C in

comfort mode.

3. Select the Boost operating mode.

See chapter: "Choosing the operating mode", page 46

¼

4. The compressor starts up after 120 seconds if DHW production is

required.

TWH 200E TWH 300E TWH 300EH

5.4 Checks and adjustments after commissioning

4 Check the leak tightness of the connections.

4 Check the temperature of the 3 DHW temperature sensors to

ensure that the appliance operates correctly.

If the readout values are incorrect, check the positioning of the

sensors in the sensor tube.

4 A few days after start up of the appliance, a visual inspection must

be made to check for any leaks in the water system or any

blockages in the condensates runoff.

5.5 Choosing the operating mode

The operating mode is shown on the main display.

1. To change the operating mode, press the MODE key several times

until the symbol corresponding to the desired operating mode

appears on the display.

46

03/02/2014 - 300026515-001-03

Page 49

C003206-D

1x

2x

3x

.

.

.

1

4

3

4

1

2

MENUMODE

TWH 200E TWH 300E TWH 300EH

5. Commissioning

Display Operating

Description

mode

M

Automatic or

Comfort

Comfort programme activated

Domestic hot water production is handled by the heat pump and by electrical back-up if necessary

(+ Hydraulic back-up for EH version).

If domestic hot water production is not satisfied by the compressor after a modifiable time delay

(factory setting: 5 hours - Parameter P23), the back-ups start up.

%

Eco Reduced programme activated.

Domestic hot water production is handled by the heat pump alone.

After the compressor stops, the displayed quantity of domestic hot water available may not be

complete (!).

W

Boost

Forced operating activated

Domestic hot water production is handled simultaneously by the heat pump and the electrical backup for a modifiable period (factory setting: 6 hours).

> days

Vacation

Holiday period

Shutting down domestic hot water production.

The domestic hot water temperature is kept at 10°C.

5.6 Reading out measured values

5.6.1. Measurements menu

1. Press once the MENU key. The SE nS 1 menu is displayed.

2. Press the MODEB key to go to the Measurements menu. The SE

01 menu is displayed.

3. Use the ( and ) keys to switch from one measurement to

another.

Parameters

SE 01

SE 02

SE 03

SE 04

SE 05

SE 06

St Su

SP 1

SP 2

5.6.2. Counters

Displaying the counters

n

Description Unit

Top DHW temperature sensor °C

Middle DHW temperature sensor °C

Bottom DHW temperature sensor °C

Room sensor °C

Evaporator temperature sensor °C

Electricity tariff:

4 HP1: Peak hours

4 HC0: Off-peak hours

Operating status / sub-status of the control system

sequence

Back-up setpoint °C

Compressor setpoint °C

03/02/2014 - 300026515-001-03

1. Press once the MENU key. The SE nS 1 menu is displayed.

47

Page 50

C004186-A

1

4

3

4

1

2

MENUMODE

C003210-C

1

1

4

3

4

1

2

MENUMODE

C004186-A

1

4

3

4

1

2

MENUMODE

C003210-C

1

1

4

3

4

1

2

MENUMODE

5. Commissioning

TWH 200E TWH 300E TWH 300EH

2. Press the ) key 3 times. The Co un 4 menu is displayed.

3. Press the MODE B key to go to the Counters menu. The number

of the counter is shown to the right of the display.

4. Use the ( and ) keys to switch from one counter to another (See

table below).

5. To exit this menu, press the MODE B key.

6. To go back to the main display, press the MENU button.

Meter

Description Unit

1 Total electric energy input for DHW production kWh

2 Electric energy input by the compressor in the last 24 hours

kWh

The counter is reset at 00:00 hours every day

3 Electric energy input by the electrical back-up in the last 24 hours

kWh

The counter is reset at 00:00 hours every day

4 Number of hours operation of the hydraulic backup h

5 Number of hours powered up h

6 Instantaneous output W

Resetting the counters

n

1. Press once the MENU key. The SE nS 1 menu is displayed.

2. Press the ) key 3 times. The Co un 4 menu is displayed.

3. Press the MODE B key to go to the Counters menu. The number

of the counter is shown to the right of the display.

48

4. Use the ( and ) keys to switch from one counter to another.

5. Press the

key to reset the meter displayed to zero.

V

03/02/2014 - 300026515-001-03

Page 51

C004187-A

1

4

3

4

1

2

MENUMODE

C003203-D

1x

3

1

4

3

4

1

2

MENUMODE

C004192-A

1

4

3

4

1

2

MENUMODE

C003307-A

1

4

3

4

1

2

MENUMODE

TWH 200E TWH 300E TWH 300EH

6. Confirm using key MODE B.

7. To exit this menu, press the MODE B key.

8. To go back to the main display, press the MENU button.

5.7 Modifying the installer parameters

CAUTION

Modification of the factory settings may be detrimental to

the functioning of the appliance.

5.7.1. Access to parameters

To prevent input errors, access to this menu requires the use of the

access code 012.

5. Commissioning

1. Press once the MENU key. The SE nS 1 menu is displayed.

2. Press the ) key 6 times. The Co dE menu is displayed.

3. Enter the access code

012

4. Press the MODE B-key for the menu. The parameter

using the ( or ) keys.

P1

displays.

5. Scroll through the parameters using the ( or ) key.

6. To modify a parameter, press the MODE B key. The parameter

value flashes.

7. Set the desired value using the ( or ) key.

8. Confirm using key MODE B.

03/02/2014 - 300026515-001-03

49

Page 52

5. Commissioning TWH 200E TWH 300E TWH 300EH

5.7.2. List of the parameters

Parameters Description Adjustment range Factory

setting

P 01

P 02

P 04

P 06

DHW setpoint in Auto mode 40 to 70 °C 55 °C

DHW set point in Eco mode 40 to 65 °C 55 °C

Choice of mode for the DHW Comfort period:

4 0 = Use the time programs.

4 1 = Use the electricity tariff information input. Tells you whether or not

domestic hot water production is permitted (HP1 = not permitted => Contact

closed, HC0 = permitted => Contact open).

4 2 = Use the electricity tariff information input. Tells you whether or not

domestic hot water production is permitted (HP1 = not permitted => Contact

open, HC0 = permitted => Contact closed).

4 3 = Use the time programs. The status of the electricity tariff information

input is used to activate the Boost function with compressor only (HP1 =

Boost deactivated => Contact closed, HC0 = Boost activated => Contact

open).

4 4 = The status of the electricity tariff information input is used to activate

the Boost function with compressor only (HP1 = Boost activated => Contact

open, HC0 = Boost deactivated => Contact closed).

4 5 = The status of the electricity tariff information input is used to activate

the Boost function with compressor and back-up (HP1 = Boost deactivated

=> Contact closed, HC0 = Boost activated => Contact open).

4 6 = The status of the electricity tariff information input is used to activate

the Boost function with compressor and back-up (HP1 = Boost activated

=> Contact open, HC0 = Boost deactivated => Contact closed).

Automatic switch to summer time (last Sunday in March) and winter time (last

Sunday in October):

0 - 6 0

0 - 1 1

P 07

P 17

P 18

P 19

P 20

P 21

P 22

P 23

P 24

P 25

4 0 = Function not active (for countries where the time change is done on

other dates or is not in use)

4 1 = Function active

DHW setpoint in Boost mode 40 to 70 °C 62 °C

Protection by impressed current anode

4 0 = Deactivation

4 1 = Activation

Water volume contained in the DHW tank (x 10 l) 6 - 255 27

Water volume for one bath (l) 10 - 255 120

Maximum duration of the Boost mode (h) 1 - 10 6

Measurement unit

4 0 = °C

4 1 = °F

Back-up type

4 0 = None

4 1 = Electrical back-up

4 2 = Hydraulic additional heating

Time delay for starting the electrical or hydraulic back-up in Automatic mode

(Hours)

Compressor start-up time (seconds) 60 - 255 120

Management of the fans in domestic hot water production mode

0 - 1 1

0 - 1 0

0 - 2 1

0 - 10 5

0 - 2 0

50

4 0 = Automatic

4 1 = Average speed of fan rotation

4 2 = Maximum speed of fan rotation

03/02/2014 - 300026515-001-03

Page 53

C003495-B

3

1

4

3

4

1

2

MENUMODE

TWH 200E TWH 300E TWH 300EH

5. Commissioning

Parameters Description Adjustment range Factory

setting

P 26

Antilegionella function. The tank is overheated every Saturday from 1 o’clock to

0 - 1 0

6 o’clock (65 °C).

4 0 = Off

4 1 = Activated outside holiday periods

4 2 = Always activated

P 27

Compressor cut-off hysteresis in relation to the set point for the bottom domestic

5 - 15 10

hot water temperature sensor (only in Auto or Boost mode)

P 28

Maximum DHW temperature (bottom sensor) for compressor cut-off (°C) (only

35 - 50 45

in Auto or Boost mode)

P 29

P 30

P 31

Minimum duration of compressor operation (minutes) 3 - 10 3

Anti-short-cycle period between 2 compressor start-ups (minutes) 5 - 10 5

Hydraulic additional heating

0 - 1 0

4 0 = contact R6 closed if there is an additional hydraulic heating request

4 1 = contact R6 opened if there is an additional hydraulic heating request

P 32

DHW setpoint used for the antilegionella function 55 to 70 °C 65 °C

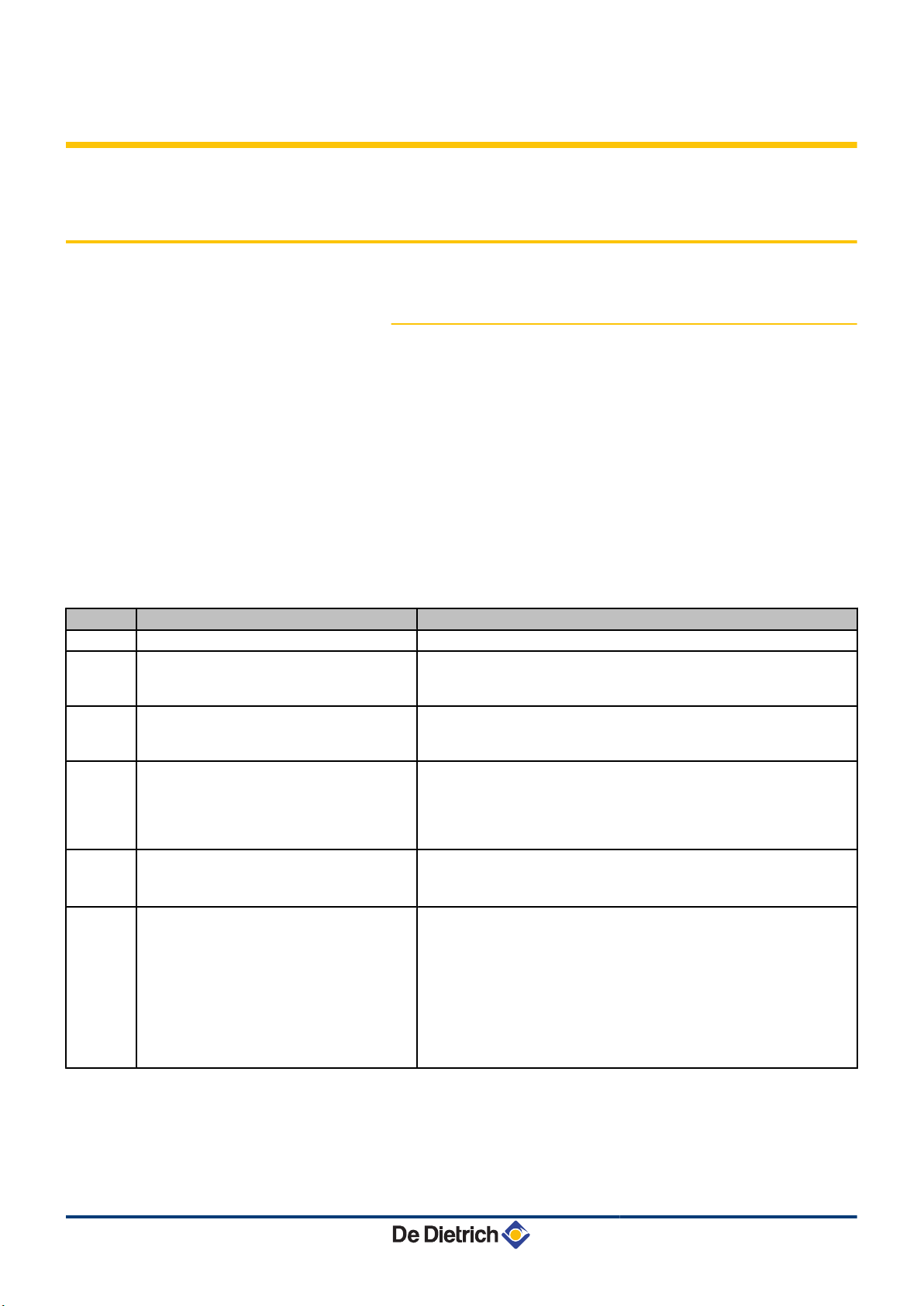

5.7.3. Control system sequence

Control system sequence

Status Sub-status Operation

0 0 Appliance off

7 Compressor post-operation

1 1 Anti-short cycle activated

2 Wait for the start-up condition for domestic hot water production

3 Start-up of the fan and the defrosting valve

2 5 Compressor starts

6 Defrosting

3 1 Anti-short cycle activated

4 Additional heating starts

7 Compressor post-operation

4 5 Compressor starts

6 Defrosting

9 -- Blockage state

5.7.4. Return to the factory settings

1. Press the ( and ) keys simultaneously for 5 seconds. The

rSt menu is displayed.

03/02/2014 - 300026515-001-03

51

Page 54

C004193-A

1

4

3

4

1

2

MENUMODE

5. Commissioning TWH 200E TWH 300E TWH 300EH

2. Press the MODE B key to carry out a TOTAL RESET of all

parameters.

52

03/02/2014 - 300026515-001-03

Page 55

TWH 200E TWH 300E TWH 300EH 6. Switching off the appliance

6 Switching off the appliance

6.1 Installation shutdown

CAUTION

Try to avoid switching off the appliance in order to maintain

protection against corrosion. The appliance’s frost

protection continues to be activated.

6.2 Antifreeze protection

In the event of extended absence (holiday), programme the

corresponding number of days. The temperature of the water in the

tank is maintained at 10°C.

¼Refer to the user instructions.

03/02/2014 - 300026515-001-03

53

Page 56

7. Checking and maintenance TWH 200E TWH 300E TWH 300EH

7 Checking and maintenance

7.1 General instructions

CAUTION

Installation and maintenance of the appliance must be

done by a qualified professional in accordance with

prevailing statutory texts and codes of practice.

CAUTION

Before working on the appliance, ensure that it is switched

off and safe.

CAUTION

Check the discharge on the compressor condenser for

single phase voltages.

CAUTION

Before working on the cooling circuit, switch off the

appliance and wait a few minutes. Some equipment such

as the compressor and the pipes can reach temperatures

higher than 100°C and high pressures, which may cause

serious burns.

When the appliance is switched off, the fan continues to

run by inertia for around one minute.

Maintenance operations are important for the following reasons:

4 To guarantee optimum performance

4 To extend the life of the equipment

4 To provide an installation which offers the customer optimum

comfort over time.

CAUTION

At no time allow water to get into the control

components. Before starting cleaning, disconnect the

mains power plug or switch off the appliance.

54

03/02/2014 - 300026515-001-03

Page 57

TWH 200E TWH 300E TWH 300EH

7.2 Maintenance operations to be performed

7.2.1. Refrigerant circuit

No maintenance is required on the refrigerant circuit in the

thermodynamic water heater.

7.2.2. Hydraulic circuit

Check the watertightness of the water connections.

7.2.3. Aeraulics

Cleaning the evaporator

n

7. Checking and maintenance

DANGER

Risk of injury on the sharp-edged fins.

CAUTION

Do not distort or damage the fins.

4 Clean the evaporator at regular intervals using a soft-haired brush.

4 Carefully realign the fins using a suitable comb if they are bent.

Cleaning the fan

n

Check the cleanliness of the fan 1 time per year. Clogging by dust

and other particles impairs the heat pump’s performance.

7.2.4. Impressed current anode

No maintenance operations are required on an impressed current

anode.

The appliance’s control panel must be switched on to

ensure operation of the impressed current anode.

03/02/2014 - 300026515-001-03

7.2.5. Checking the safety valve or unit

Operate the safety valve or unit at least 1 time per month to check

that it is running correctly. This check provides forewarning of any

occurrences of excess pressure that may damage the domestic hot

water calorifier.

55

Page 58

C003214-E

7. Checking and maintenance TWH 200E TWH 300E TWH 300EH

WARNING

Failure to comply with this maintenance rule may cause

deterioration of the DHW tank and the cancellation of the

guarantee.

7.2.6. Descaling

Use a new leak tight seal on the inspection trap.

In hard water regions, it is advisable to ask the fitter to descale the

DHW tank exchanger once a year in order to maintain its level of

performance.

1. Turn off the domestic cold water inlet.

2. Drain the calorifier.

3. Open a hot water tap.

4. Open the valve on the safety unit.

5. Remove the insulation from the inspection hatch.

6. Pull out the DHW sensor.

7. Remove the inspection trap (13 mm spanner).

8. Remove the 2 bulbs from the safety thermostat.

9. Remove the limescale deposited in the tank in the form of sludge

or strips. Keep the limescale on the wall of the tank: it provides

effective protection against corrosion and enhances the insulation

of the DHW tank.

10.Then replace all the parts in reverse order.

Each time it is opened, the lip gasket must be replaced to

guarantee tightness. Place the positioning lug on the

gasket toward the outside of the tank.

11.After each intervention, ensure that the installation is watertight.

The screws retaining the visit trap must be tightened to

6 N·m +1/-0. Use a torque wrench.

7.2.7. Cleaning the condensates discharge duct

Check the cleanliness of the condensates discharge pipe. An

obstruction by dust may cause poor condensates flow or even a risk

of excessive accumulation of water.

DANGER

Risk of the heat pump malfunctioning.

56

03/02/2014 - 300026515-001-03

Page 59

85°

1

C003190-B

TWH 200E TWH 300E TWH 300EH 7. Checking and maintenance

7.3 Accessing the bottom inspection trap

Have a lip gasket and a retainer ring on hand for the

inspection hatch.

1. Disconnect the mains supply.

2. Drain the calorifier.

3. Open a hot water tap.

4. Open the valve on the safety unit.

5. Set the appliance to repair position

6. Check the extent of scaling in the tank and on the exchanger.

Keep the limescale on the wall of the tank: it provides effective

protection against corrosion and enhances the insulation of the

DHW tank.

Remove limescale deposits from the bottom of the tank.