Page 1

DIETRISOL

Solar domestic hot water tanks

TRIO DT 250 - TRIO DT 350

EN

M000854

User Guide

300028005-001-03

Page 2

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.1 Symbols and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.2 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.2.1 Manufacturer's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2.2 Installer's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.2.3 User's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.2.4 Compliance of design and manufacture. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.2.5 Electrical compliance / Marking 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2 Safety instructions and recommendations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.1 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.2 Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

3 Technical description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

3.1 Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

3.2 Main parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

4 Setting the DHW calorifier outlet temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4.1 Programming and setting the electrical back-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4.2 Setting the thermostatic mixing valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

5 Diemasol B solar regulator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

5.1 General description of how the unit operates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

5.2 Start-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

5.3 Adjustment keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

5.4 LED message code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

5.5 Measured values and adjustment parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

6 Checking and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

6.1 Solar installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

6.2 Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

6.2.1 Magnesium anodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

6.2.2 Safety valve or safety unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

6.2.3 Descaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

6.2.4 Casing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

6.2.5 Vent device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

6.3 Solar circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Warranty certificate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

2

TRIO DT 250 - TRIO DT 350 17/10/12 - 300028005-001-03

Page 3

1Introduction

1.1 Symbols and abbreviations

In these instructions, various markings and pictograms are used to

draw your attention to particular information. In so doing, De Dietrich

Thermique S.A.S wishes to safeguard the user's safety, obviate

hazards and guarantee correct operation of the appliance.

Danger

Risk of a dangerous situation causing serious physical

injury.

Warning

Risk of a dangerous situation causing slight physical

injury.

1.2 General

Congratulations on choosing a De Dietrich product, a product of

quality. We strongly recommend that you read the following

instructions in order to guarantee the optimal operation of your

appliance. We are sure that you will not be disappointed and that it

will satisfy all of your expectations.

1.2.1 Manufacturer's liability

Our products are manufactured in compliance with the requirements

of the various applicable European Directives. They are therefore

delivered with 1 marking and all relevant documentation.

In the interest of customers, we are continuously endeavouring to

make improvements in product quality. All the specifications stated in

this document are therefore subject to change without notice.

Caution

Risk of material damage.

Specific information.

Reference

Z

Refer to another manual or other pages in this instruction

manual.

` DHW: Domestic hot water.

Our liability as the manufacturer may not be invoked in the following

cases:

` Failure to abide by the instructions on using the appliance.

` Faulty or insufficient maintenance of the appliance.

` Failure to abide by the instructions on installing the appliance.

1.2.2 Installer's liability

The installer is responsible for the installation and inital start up of the

appliance. The installer must respect the following instructions:

` Read and follow the instructions given in the manuals provided

with the appliance.

` Carry out installation in compliance with the prevailing

legislation and standards.

1.2.3 User's liability

To ensure the optimum operation of your appliance, we strongly

recommend that you abide by the following instructions:

` Read and follow the instructions given in the manuals provided

with the appliance.

` Call on qualified professionals to carry out installation and initial

start up.

1.2.4 Compliance of design and manufacture

This product conforms to the requirements of european directive 97 /

23 / EC, article 3, paragraph 3, on pressure equipment.

` Perform the initial start up and carry out any checks necessary.

` Explain the installation to the user.

` If a maintenance is necessary, warn the user of the obligation

to check the appliance and maintain it in good working order.

` Give all the instruction manuals to the user.

` Get your installer to explain your installation to you.

` Have the required checks and services done.

` Keep the instruction manuals in good condition close to the

appliance.

17/10/12 - 300028005-001-03 TRIO DT 250 - TRIO DT 350

3

Page 4

1.2.5 Electrical compliance / Marking

1

This product complies to the requirements to the european directives

and following standards:

• 2006/95/EC Low Voltage Directive

Reference Standard: EN 60.335.1.

• 2004/108/EC Electromagnetic Compatibility Directive

Reference Standards: EN 50.081.1 / EN 50.082.1 / EN 55.014.

2 Safety instructions and recommendations

2.1 Safety instructions

Any work on the installation must be done by a qualified

professional in compliance with the codes of practice and

according to the instructions provided.

2.2 Recommendations

Have the installation regularly serviced to guarantee that it operates

correctly over time.

It is essential to check the magnesium anode in the DHW tank and

the installation and heat transporting fluid pressure every two years.

Never cut the power to the solar control system, even

during extended absences. The control system protects

the installation against overheating in summer when it is

running.

During extended absences, we recommend lowering the set

point temperature in the solar DHW calorifier to 50°C. When the

user is present, the set point must be set to 60°C.

Never drain the installation. Do not replace or add water or

solar fluid to the installation. These actions must be carried

out by a qualified technician.

Do not modify the control system parameters unless fully

conversant with them.

4

TRIO DT 250 - TRIO DT 350 17/10/12 - 300028005-001-03

Page 5

3 Technical description

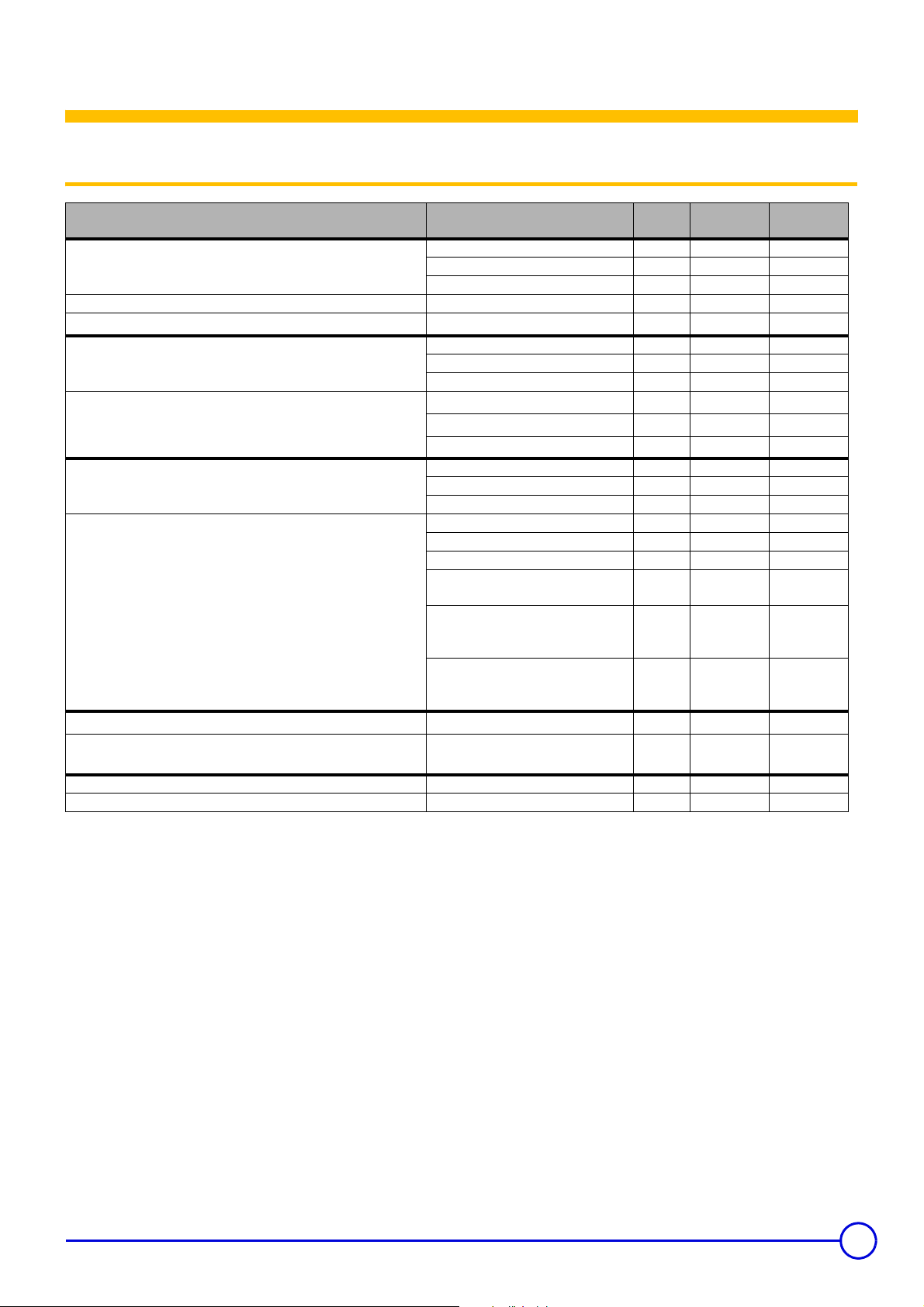

3.1 Technical specifications

DIETRISOL

TRIO DT 250

Solar exchangers °C 120 120

Maximum operating temperature

Maximum operating pressure bar 7 10

Maximum operating pressure in accordance with W/TPW

Water content

Surface area

Operation with boiler back-up

Operation with electrical back-up

Continuous output

Flow rate for 10 minutes where

(4)

Maintenance consumption kWh/24h - 2.7

Cooling constant Cr Wh/lKj 0.22 0.19

(1) Swiss Directives

(2) Domestic cold water input at 10°C - Primary inlet temperature at 80 °C

Values measured with a wall-mounted boiler

(3) Domestic hot water temperature: 45 °C

(4) Domestic hot water temperature: 40 °C

(5) Domestic cold water inlet 15 °C

(6) Values measured only on the back-up volume

Domestic hot water load setting: 60 °C

∆T = 35 K (2) (3)

∆T = 30 K (on make-up volume) (2)

(1)

Boiler heat exchanger °C 90 90

tank °C 90 90

bar 6 6

Solar exchangers litres 9 8.1

Boiler heat exchanger litres 4.3 4.9

tank litres 250 350

Upper solar heat exchanger

Lower solar heat exchanger

Boiler heat exchanger

Top up volume litres 105 127

Solar volume litres 145 223

Power exchanged (2) (3) kW 21 23

Top up volume litres 130 160

Solar volume litres 120 190

Output of the electrical back-up kW 2.4 3

Back-up volume heating time (from 15

to 60°C)

Vecs 40 (5) (6)

Domestic hot water storage

temperature: 55 °C

Vecs40 (5) (6)

Domestic hot water storage

temperature: 60 °C

2

m

2

m

2

m

h 2h50 2h50

litres 355 420

litres 385 450

l/h 515 565

l/10 mm 190 230

0.48 0.48

0.86 0.96

0.64 0.72

DIETRISOL

TRIO DT 350

17/10/12 - 300028005-001-03 TRIO DT 250 - TRIO DT 350

5

Page 6

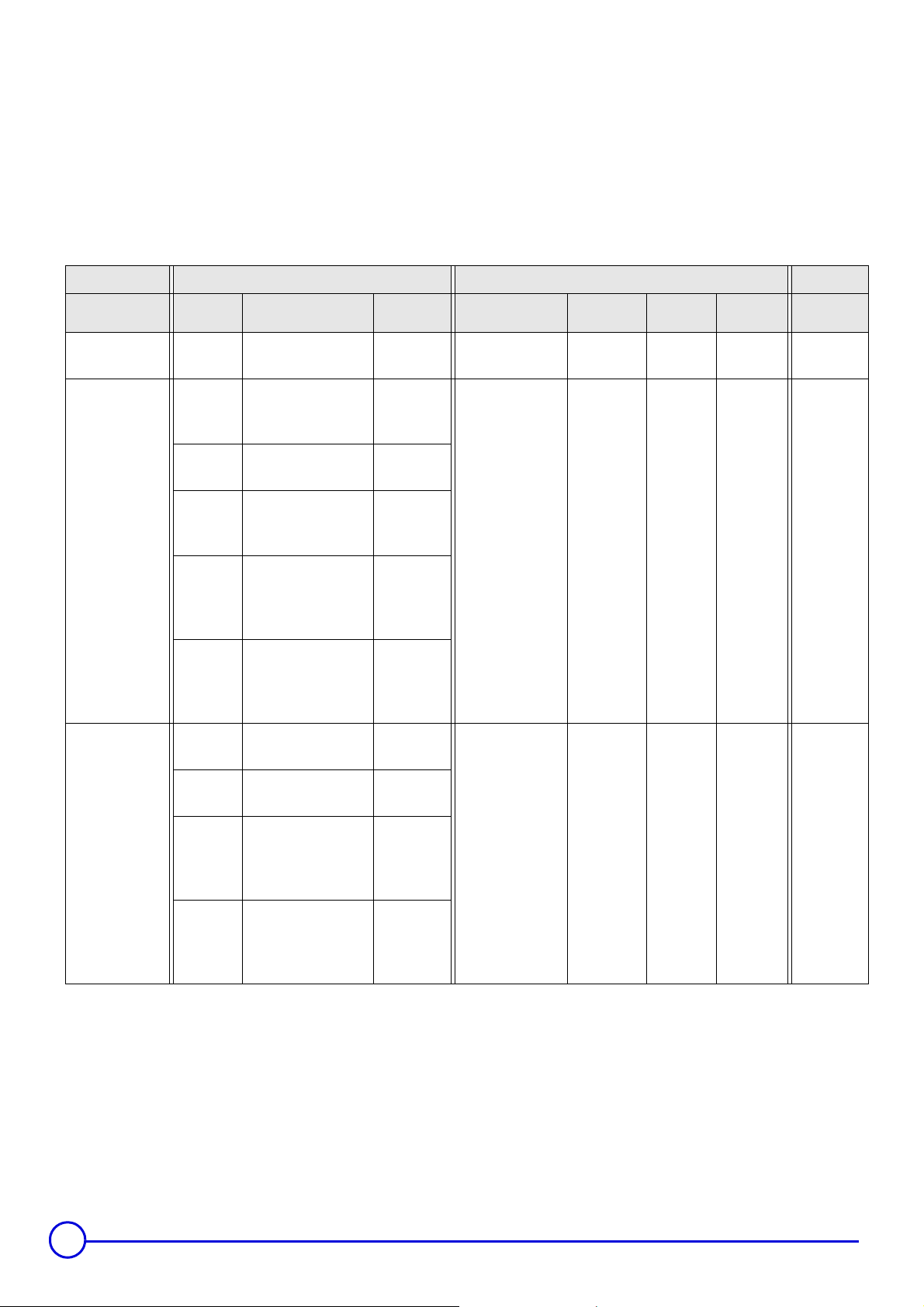

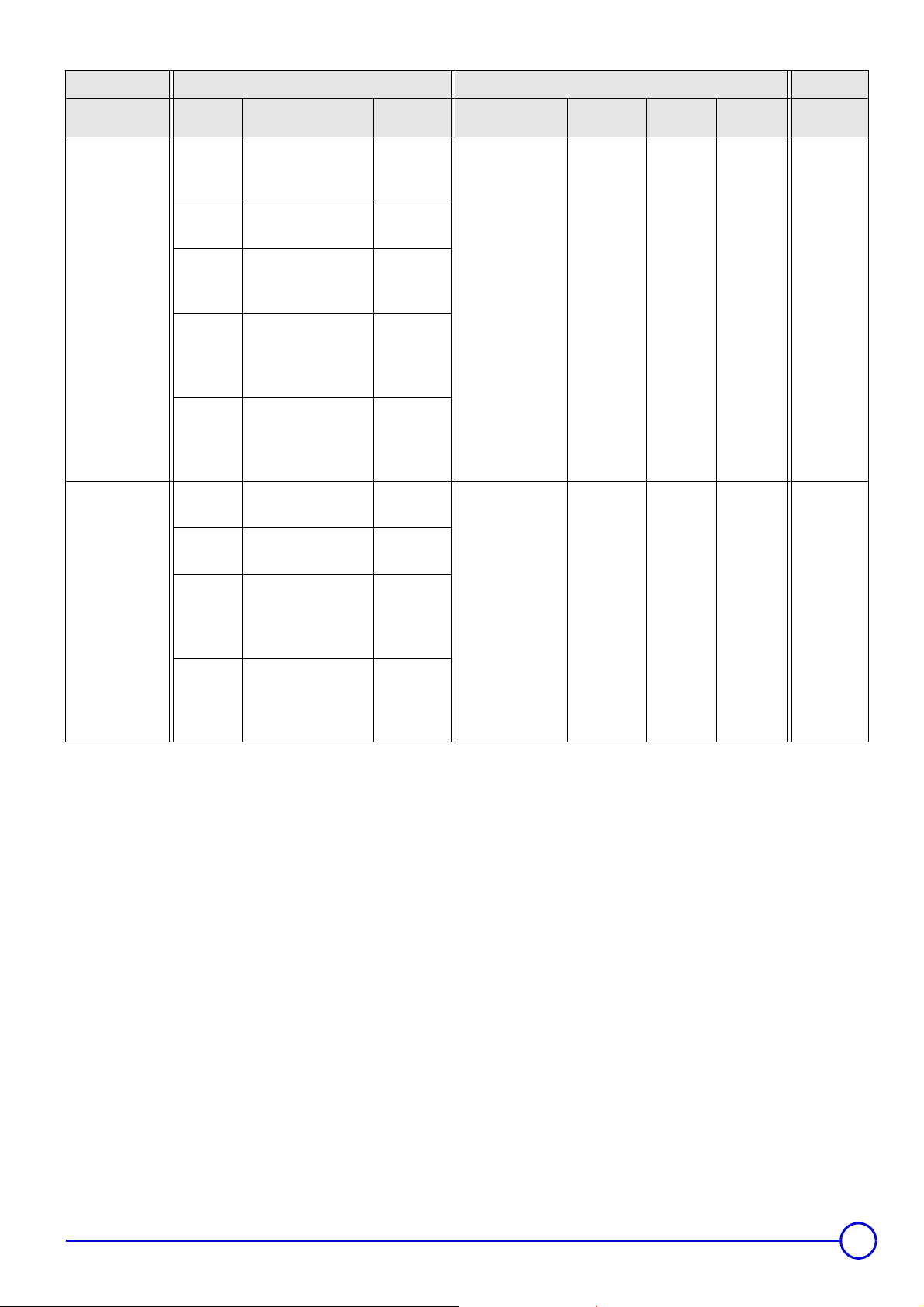

Composition of the NF CESI DIETRISOL TRIO solar systems packages (for France only)

Check the composition of the CESI solar system, which complies

with the requirements of the NF CESI mark, using the table below.

The references and packages listed must be shown on the invoice for

the system sold by the installer.

A system is complete and functional according to the NF CESI mark

if all system references appear on the invoice.

The system is composed of the following elements:

• A collector field with 1 or 2 solar collectors.

• A solar domestic hot water tank to which a solar station

incorporating a heating pump, an expansion vessel and a

Diemasol A control system is to be mounted.

• The solar fluid that protects the installation from frost and

corrosion.

The system is delivered to the installer in two units: a roof pack

containing the collectors, their mounting system and the hydraulic

connections on the one hand, and a cellar pack containing the

calorifier, the system components and the solar fluid on the other

hand.

CESI System Array of collectors Domestic hot water production Solar fluid

DIETRISOL TRIO

250-3

DIETRISOL TRIO

D 250-4

Number of

panels

1On roof

2

2

2

2

Type of mounting

On roof

(mechanical tiles -

Universal hook)

On roof

(Slates)

On roof

(mechanical tiles - On

rafter)

Roof-integral

Installation

(> 20°)

(mechanical tiles)

package /

Reference

ER 234

100019328

ER 432

100019695

ER 433

100019696

ER 434

100019697

ER 442

100019705

DHW calorifier type

DT 250

DT 250

package /

Reference

EC 340

100007796

EC 340

100007796

Volume

(litres)

250 Mixed

250 Mixed

Back-up

type

package /

Reference

89807792

89807792

EG 100

EG 100

DIETRISOL TRIO

250-5

2

2

2

2

2

(Delivered vertically)

(Delivered horizontally)

(Delivered vertically)

(Delivered horizontally)

Roof-integral

Installation

(> 20°)

(Slates / Flat tile)

On roof

On roof

Roof-integral

Installation

(> 20°)

Roof-integral

Installation

(> 20°)

ER 446

100019709

EC 521

100007869

EC 580

100009302

EC 531

100007879

EC 586

100009308

DT 250

EC 340

100007796

250 Mixed

EG 100

89807792

6

TRIO DT 250 - TRIO DT 350 17/10/12 - 300028005-001-03

Page 7

CESI System Array of collectors Domestic hot water production Solar fluid

Number of

panels

2

Type of mounting

On roof

(mechanical tiles -

Universal hook)

package /

Reference

ER 432

100019695

DHW calorifier type

package /

Reference

Volume

(litres)

Back-up

type

package /

Reference

DIETRISOL TRIO

D 350-4

DIETRISOL TRIO

350-5

2

2

2

2

2

2

2

(mechanical tiles - On

(Delivered vertically)

(Delivered horizontally)

(Delivered vertically)

On roof

(Slates)

On roof

rafter)

Roof-integral

Installation

(> 20°)

(mechanical tiles)

Roof-integral

Installation

(> 20°)

(Slates / Flat tile)

On roof

On roof

Roof-integral

Installation

(> 20°)

ER 433

100019696

ER 434

100019697

ER 442

100019705

ER 446

100019709

EC 521

100007869

EC 580

100009302

EC 531

100007879

DT 350

DT 350

EC 339

100007795

EC 339

100007795

350 Mixed

350 Mixed

EG 100

89807792

EG 100

89807792

2

See chapter: NF CESI data sheet.

Z

Roof-integral

Installation

(> 20°)

(Delivered horizontally)

EC 586

100009308

17/10/12 - 300028005-001-03 TRIO DT 250 - TRIO DT 350

7

Page 8

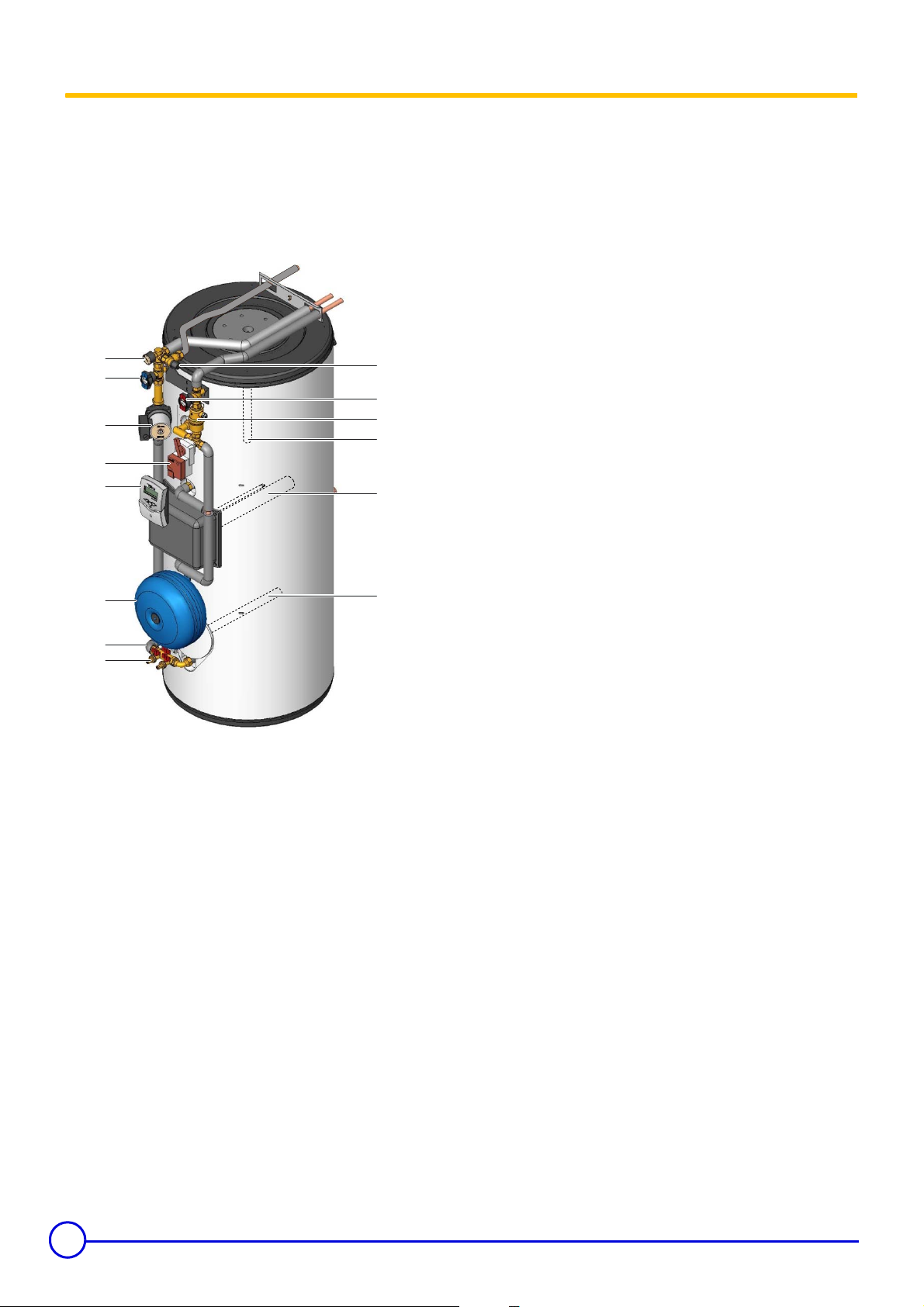

3.2 Main parts

Dietrisol TRIO DT ... is a high performance solar DHW tank/calorifier

designed to be connected to Dietrisol NEO or POWER solar

collectors and an De Dietrich central heating boiler.

It is designed in such a way as to be able to cope with a solar collector

surface area of up to 4.5 m

conditions set out in the chapter "Hydraulic Connection Primary Solar

Circuit".

1

2

(DT 250) and 6.5 m2 (DT 350) under the

2

3

4

5

6

12

7

8

13

tank

The high quality steel tank is lined with food standard quality

vitrified enamel, which protects it from corrosion and preserves

all the qualities of the domestic water.

The Dietrisol TRIO DT ... tank is fitted with 2 heat exchangers

per zone for solar heating and one heat exchanger for

supplementary heating by means of a fuel oil or gas boiler.

Protection against corrosion

The tank is also protected from corrosion by two magnesium

anodes which must be inspected every 2 years and replaced if

necessary.

Heat exchanger

The thermal exchanger welded into the tank is made of smooth

piping, the inside of which, which is in contact with the domestic

water, is enamelled.

Insulation

The tank is strongly insulated with high strength rigid

polyurethane foam with no chlorofluorocarbons (CFC), 50 mm

thick to minimise heat loss.

9

10

11

Pressure gauge - Primary solar circuit

1

Safety control unit for the solar circuit (6 bar)

2

Blue thermometer (tank solar heat exchangers outlet)

3

Red thermometer (tank solar heat exchangers inlet)

4

Primary solar circuit pump

5

Manual bleed degasser

6

2-position 3-way directional valve

7

Diemasol B regulator

8

8 l/6 bar expansion vessel, 2-bar pre-load

9

Automatic connection for expansion vessel

10

Primary solar circuit filling and draining device

11

Magnesium anode

12

Electric heating resistance

13

Magnesium anode

14

M001003

14

Casing

The outside casing is made of painted steel sheeting.

The top and side covers are made of ABS.

Solar station

The solar heating pump unit comprises the solar circuit safety

unit, a pressure and temperature gauge and a flowmeter to

visualise circulation of the solar fluid between the panels and the

DHW tank. An expansion vessel is connected to the solar unit; it

is used to compensate for the expansion of the solar fluid in

which the temperature varies between 0 and 150°C.

Diemasol B regulator

The control system is the solar system's brain; it makes the solar

heating pump run at variable speeds according to the difference

in temperature between the bottom of the DHW tank and the

solar panels. The control system manages the set point

temperature (temperature to be attained in the DHW tank),

overheating and nighttime cooling. The control system also

displays the various operating modes, the temperatures in the

collectors and in the bottom of the DHW tank, as well as

signalling any malfunctions.

8

TRIO DT 250 - TRIO DT 350 17/10/12 - 300028005-001-03

Page 9

4 Setting the DHW calorifier outlet temperature

4.1 Programming and setting the electrical back-up

The temperature of the volume of water heated by the electrical

resistor is set by the installer on commissioning of the installation

according to the size of the home.

Using the programming device installed in the electrical panel, it is

possible to adjust the volume of water heated to 40°C by the resistor

in two ways:

4.2 Setting the thermostatic mixing valve

57

` By forcing contunuous heating by the resistor (off-peak hours

contact) for significant unforeseen needs.

` By programming the heating time outside off-peak periods (2

hours maximum according to the DHW volume at 40°C

required) to compensate for the lack of sunshine in winter, for

example. The programmed period outside off-peak hours must

preferably be between 12 h and 18 h.

28

28. Domestic cold water inlet

57. DHW tank domestic hot water outlet

The mixing valve is set in the factory for a DHW outlet temperature of

60°C (position 6). To lower this temperature, remove the top cover

and turn the wheel anti-clockwise. In position 1, the outlet

temperature is lowered to 35°C.

C003732-A

17/10/12 - 300028005-001-03 TRIO DT 250 - TRIO DT 350

9

Page 10

5 Diemasol B solar regulator

Always fitted to installation type 1 (Parameter ANL 1).

Z

5.1 General description of how the unit operates

In automatic mode, the Diemasol B regulator operates in

accordance with the following principles:

` The sun's rays heat the transfer fluid in the collector. For the

regulation process to be triggered, a minimum temperature of

30 °C is required in the collector and there must be a

temperature difference of 10 K by comparison with the tank.

` During the self-calibration phase that follows (adjustment

parameter tu, factory setting: 3 minutes), the solar pump (relay

1) operates at full speed (100 %).

` Subsequently, the solar pump regime is calculated dynamically

depending on a difference between the reference temperature

(parameter DT, factory setting 20 K) and the calorifier

temperature.

` When the zonal reversal temperature is reached in the

collectors (adjustment parameter SZ, factory setting 55°C), the

relay R2 switches the reversal valve to the upper zone in the

calorifier. The user therefore has immediate access to domestic

hot water at the set temperature.

Installation 1

See next page (Start-up).

- If the heating return temperature is equal to or greater than the

temperature of the solar tank, heating return is direct to the boiler.

- If the temperature in the solar tank is higher than the heating

return temperature, heating return passes via the solar tank. The

energy coming from the sun's rays or from a biomass boiler is thus

exploited to heat the home.

` When the zonal reversal temperature is reached (adjustment

parameter SZ, factory setting 55°C), the set reference

temperature difference is lowered from 20 K to 10 K.

` Depending on the heat available, the system heats up the solar

tank and cuts off when the tank storage temperature is reached

(adjustment parameter SX, factory setting: 60 °C).

` When the temperature in the collectors reaches the maximum

value (adjustment parameter CX, factory setting 100°C), the

solar pump is triggered to cool the collectors. The pump

continues to operate until the temperature in the collectors is

lower than 5 K at parameter CX and/or the maximum storage

temperature (80°C) is reached in the hot water storage tank. As

soon as the temperature in the collectors drops below the

temperature in the calorifier, the calorifier is cooled down to its

set temperature. The installation is thus protected against

overheating and repeated stoppages, allowing thus the

prolonged absence of the user even in the summer period.

` The amount of heat transferred from the collectors to the tank

is displayed as parameter AH. The value is cumulative and is

constantly updated.

` The Diemasol B regulator (installation 2- ANL2 with heating

back-up) includes an additional function: A temperature sensor

S3 is located on the heating return.

Installation 2

5.2 Start-up

%

10

If the temperature in the solar collectors is higher

than 120°C, the control system operates in safety mode.

Wait until the evening before start-up or cool down (cover)

the solar collectors.

TRIO DT 250 - TRIO DT 350 17/10/12 - 300028005-001-03

Page 11

Switch on the device. The regulator starts an initialisation phase

during which the LED flashes red and green. When initialisation is

complete, the regulator changes to automatic mode. The factory

settings for this mode give optimum performance with most

installations.

The regulator is configured in the factory for installation type 1

(parameter ANL=1).

If special conditions make it necessary to change the settings, the

corresponding adjustment parameters can be reset.

5.3 Adjustment keys

Installation 1

Installation 2

The regulator is controlled by the 3 keys only located below the

display.

The right-hand key (>) takes you to the next menu or increases the

adjustment values.

The left-hand key (<) does the opposite.

The adjustment parameters are displayed after the measured values.

To access these parameters, press and hold the right-hand key for 2

sec. from parameter TC. When the display shows an adjustment

parameter, the word SET appears. To set the value displayed, press

the middle button SET.

1. Select the required parameter using keys > and <.

2. Press the SET key: The word SET flashes.

3. Adjust the value using keys > and <.

4. Press the SET key: The set value is stored. The word SET stops

flashing.

17/10/12 - 300028005-001-03 TRIO DT 250 - TRIO DT 350

11

Page 12

5.4 LED message code

Continuously green

At least one relay is closed.

Regulation operating normally (System Operating). Solar system

Operating. The temperature of the hot water tank (parameter TS)

- Initialisation phase

- Sensor fault.

increases.

- The installation is in manual mode.

Continuously red

All relays are open.

- Maximum tank temperature exceeded.

The installation is stopped. The solar collectors are not hot enough

(parameter TC) to enable operation.

- Maximum temperature of the solar collectors exceeded.

5.5 Measured values and adjustment parameters

Channel Abbreviation Range Increment Factory setting

Collector temperature

Calorifier temperature

Amount of heat

Pump regime

Self-calibration time

Return temperature

Additional temperature

Type of installation

Temperature difference enabling the passage of the heating

return via the solar tank

Temperature difference enabling heating return directly to the

boiler

Reference temperature difference

Zone changeover temperature (tank)

Set temperature of the solar calorifier

Maximum collector temperature

Self-calibration phase

Pump minimum speed

Tubular solar collector function

Maximum flow rate

Manual mode

Software version

Hardware version

TC [-50.0 ... 250.0] °C - -

TS [-50.0 ... 250.0] °C - -

kWh [0 ... 9999] kWh - -

PC [0 ... 100] % - -

tc [0 ... 5] minutes - -

TR -50...250°C - -

TM -50...250°C - -

ANL

DO [0.5 ... 19.5] K 0.1 6

DF [0.4 ... 19.5] K 0.1 4

DT [10 ... 20] K 0.1 20

SZ [20 ... 80] °C 0.1 55

SX [20 ... 80] °C 0.1 60

CX [100 ... 125] °C 0.1 100 °C

tu [1 ... 5] minutes 1 3

PN [50 ... 100] % 5 50

FT [0 ... 1] 1 0

Fx [0 … 20] l/min 0.1

MM [0 ... 4] 1 4

VN - - 1

PG - - 64.30

Flashing green/red

See chapter Sensor fault.

For automatic operation, set parameter MM to 4.

The hot water tank has reached the set temperature and the

installation is in overheating safety mode or in cooling mode.

The installation is in safety mode. It remains in this mode until the

temperature of the solar collectors has fallen back below the

maximum temperature.

Installation 1

Installation 2

- Installation 1

Installation 1: 6.7

Installation 2: 4.2

Measured values

Adjustment parameter

The regulator has a safety system that cuts off the tank at

temperatures of over 80°C.

12

TRIO DT 250 - TRIO DT 350 17/10/12 - 300028005-001-03

Page 13

Measured value TC - Collector temperature

The value TC shows the temperature in °C given by the collector

sensor in real time.

Measured value TS - DHW sensor temperature

Solar installation for the preparation of domestic hot water with a DC

mixed calorifier and for heating back-up with temperature control on

the heating return circuit. The temperature control on the heating

return circuit prevents the boiler having to maintain the temperature

of the back-up volume in the calorifier in the event of prolonged

absence of sunshine.

The value TS shows the temperature in °C given by the tank sensor

in real time

Measured value kWh - Amount of heat

The value kWh shows in kWh the total amount of heat produced by

the installation since the regulator was put into service.

The quantity of heat (kWh value) can only be used for checks

carried out for personal reasons.

Measured value tc - Self-calibration time

The value tc shows the self-calibration phase time remaining in

seconds. During the self-calibration phase, the pump operates at full

speed (100 %); its speed is only controlled after the self-calibration

phase.

Measured value TM - Additional temperature

An optional additional temperature sensor can be connected to

terminals 7 and 8. For example: Temperature in the top of the

calorifier.

Adjustment parameter ANL -Type of installation

Adjustment parameter DO - Temperature

difference enabling the passage of the heating

return via the solar tank

Adjustment range: 0.5 ... 19.5 K

Factory setting: 6 K

The parameter DO is used to set the temperature difference above

which heating return is directed via the 3-way valve to the solar tank.

Heating return thus passes via the solar tank if the solar tank

temperature is higher by at least 6°C than the heating return

temperature.

If the parameter ANL is set to 1 (installation 1), the parameter

DO is deactivated

Adjustment parameter DF - Temperature

difference enabling heating return directly to the

boiler

Adjustment range: 0.4 ... 19.5 K

Factory setting: 4 K

The parameter DF is used to set the temperature difference below

which heating return is directed from the 3-way valve directly to the

boiler. The solar energy stored in the solar tank is insufficient to

The adjustment parameter ANL is used to select the following

installation configurations:

ANL 1 = Installation 1:

- Preparation of domestic hot water using a DIETRISOL TRIO

calorifier.

- Preparation of domestic hot water using a tank with 2 exchangers

connected to the solar circuit.

ANL 2 = Installation 2:

17/10/12 - 300028005-001-03 TRIO DT 250 - TRIO DT 350

reheat the heating return. Heating return is thus directed directly to

the boiler if the solar tank temperature is lower by at least 4°C than

the heating return temperature.

If the parameter ANL is set to 1 (installation 1), the parameter

DF is deactivated

13

Page 14

Adjustment parameter DT - Reference

temperature difference

Adjustment range: 10 ... 20 K

Factory setting: 20 K

Switching-on difference: Non-adjustable value 10 K

Switching-off difference: Non-adjustable value 5 K

The regulator reads the temperatures measured by sensors S1 (TC)

and S2 (TS) and compares the resulting temperature difference with

the switching-on difference which is preset to 10 K. Regulation is

activated when the temperature difference ∆T is equal to or greater

than the preset value. The display shows . The LED changes to

green. When the value falls below the preset 5 K switching-off

difference, the regulator switches off. The regulator tries to achieve a

temperature difference of 20 K (factory setting) between the collector

and the tank to produce high temperature hot water as rapidly as

possible. To do this, it uses dynamic speed control.

Adjustment parameter SZ - Zone changeover

temperature

Adjustment parameter SX - Set temperature of the

solar calorifier

Adjustment range: 20 ... 80 °C

Factory setting: 60 °C

Maximum tank temperature (emergency cut-off): Non-

adjustable value 80 °C

The set temperature Sx is the desired temperature for the solar

calorifier.

If the maximum tank temperature is exceeded, tank heating is

interrupted to prevent damage due to overheating. The display

shows and (flashing) and the LED changes to flashing red/

green.

The higher the set temperature for the calorifier, the greater the

energy stored. Setting to 60 ... 75°C is suitable for normal use with

daily draw-offs.

In the event of prolonged absences (weekend, holidays):

- Reduce the calorifier temperature to 50°C

- Turn off the back-up (boiler or electrical resistance)

Adjustment range: 20 ... 80 °C

Factory setting: 55 °C

If the temperature in the collectors reaches value SZ, the relay R3

closes.

If the temperature in the collectors is lower than value SZ, the arrow

flashes.

"

If the temperature in the collectors is higher than value SZ, the arrow

flashes.

#

We advise you to set the domestic hot water booster

temperature to 50°C. If the customer wants a higher

temperature, parameter SZ will have to be changed. SZ is

set to 55°C in the factory and must always be 5K higher

than the DHW booster circuit temperature setting(s).

If the domestic hot water boiler circuit is set at more than

50°C, SZ must be adjusted to 5K above this DHW circuit

temperature setting.

If the booster is electric, the resistance thermostat must be

set at 50°C.

The installation is thus protected against overheating and the

longevity of the heat conducting fluid is conserved.

14

TRIO DT 250 - TRIO DT 350 17/10/12 - 300028005-001-03

Page 15

Adjustment parameter CX - Maximum collector

temperature

Adjustment parameter PN - Pump minimum

speed

Adjustment range: 100 ... 125 °C

Factory setting: 100 °C

Maximum collector temperature (overheating safety): Non-

adjustable value: 130 °C.

If the temperature in the collector rises above its maximum

temperature CX even though the solar circuit is stopped (tank set

storage temperature reached), the solar pump (R1) switches on and

cools the collector (system cooling). In these conditions, the tank

temperature rises, but it can't exceed 80 °C (safety cut-off).

If the calorifier reaches the maximum temperature of 80°C (safety

shutdown), the regulator switches off the solar pump.

The collectors may reach a temperature of 160 ... 200°C, which

is normal for a solar installation.

The cooling functions allows heat to dissipate; the system thus

remains operational longer during hot summers. When it leaves the

factory, the collector's maximum temperature is preset to 100 °C;

however, it is possible to change this within the range 100 ... 125 °C.

If the maximum collector temperature is exceeded, the display shows

, and (flashing) and the LED changes to flashing red/

green.

Adjustment parameter tu - Self-calibration phase

Adjustment range: 50 ... 100%

Factory setting: 50%

Adjustment parameter PN sets a minimum value for the solar pump

speed at the relay R1 output. The lower the pump regime, the lower

its flow.

Adjustment parameter FT - Tubular solar collector

function

Adjustment range: 0/1

Factory setting: 0

0: no

1: yes

If the regulator detects a temperature rise in the collector of 2 K

compared to the last measurement, the solar pump runs at full speed

for 30 seconds to measure the current average temperature.

The measured temperature thus becomes the new reference

temperature.

If the measured temperature (new reference) then increases again

by 2 K, the solar pump starts again for 30 seconds.

The regulator switches automatically to solar heating mode if the

temperature difference between the collector and the calorifer

exceeds the switching-on temperature difference when the solar

pump is operating or the system is stopped.

Adjustment range: 1 ... 5 minutes

Factory setting: 3 minutes

When the solar collector reaches a minimum temperature of 30 °C

and a preset temperature difference of 10 K from the tank

temperature, the regulator switches on the solar circulating pump at

full speed for the time period set by parameter tu. During this phase,

any air bubbles present in the solar collectors or the pipes are moved

to the complete solar station by the high circulation speed in the pipes

and eliminated by the Airstop system (manual bleed degasser).

After this phase, the regulator changes to "matched flow" mode. The

remaining self-calibration time is displayed with parameter tc.

17/10/12 - 300028005-001-03 TRIO DT 250 - TRIO DT 350

If the collector temperature falls by 2 K while the system is stopped,

the tubular solar collector activation temperature is rechecked.

Adjustment parameter Fx - Maximum flow rate

C000191

Adjustment range: 0 ... 20 l/min

Factory setting: Installation 1: 6.7 - Installation 2: 4.2

15

Page 16

In order for the regulator to calculate the quantity of heat produced by

the installation (parameter kWh), input parameter Fx. The parameter

Fx is equal to the flow in litres per minute in the solar circuit.

Determine the value Fx using the following tables, according to the

configuration of the installation and the number or surface area of the

collectors. When the flow is input incorrectly, the display kWh will also

be incorrect.

The quantity of heat (kWh value) can only be used for checks

carried out for personal reasons.

` Flat solar panels

Solar panel

installation

Area

2

m

3 ... 5 1 or 2 400 6.7

6 ... 8 3 or 4 300 5

8 ... 10 4 or 5 250 4.1

8 ... 10 2x2 750 12.5

12 ... 15 2x3 670 11.2

16 ... 20 2x4 450 7.5

12 ... 15 3x2 850 14.2

18 ... 23 3x3 800 13.4

24 ... 30 3x4 650 10.9

16 ... 20 4x2 1200 20

24 ... 30 4x3 850 14.2

Number of

panels

Flow rate

l/h

Flow rate

l/min

` Tubular solar panels

Number of panels

minimum: 1x4 820 13.7

1x5 750 12.5

1x6 680 11.4

1x7 610 10.2

1x8 540 9

1x9 470 7.8

1x10 250 4.1

2x3 1400 20

2x4 1250 20

2x5 1100 18.4

2x6 950 15.9

2x7 750 12.5

2x8 600 10

2x9 540 9

2x10 400 6.7

Adjustment parameter MM - Operating mode

Flow rate

l/h

Flow rate

l/min

Adjustment range: 0 ... 4

Factory setting: 4

For inspection and maintenance work, it is possible to operate the

regulator in manual mode. To operate the regulator in manual mode,

it is necessary to input parameter MM from the following table.

MM1 R1 R2 LED

0 Open Open Flashing green/red

1 Closed Open Flashing green/red

2 Open Closed Flashing green/red

3 Closed Closed Flashing green/red

4 automatic automatic automatic

16

TRIO DT 250 - TRIO DT 350 17/10/12 - 300028005-001-03

Page 17

6 Checking and maintenance

6.1 Solar installation

We recommend that you take out a preventive maintenance contract

to check the fluid level, antifreeze protection, pressure in the system,

leak test and general operation every year or every two years.

6.2 Tank

6.2.1 Magnesium anodes

The magnesium anode must be checked by a qualified professional

at least every 2 years.

6.2.2 Safety valve or safety unit

Have the condition of the anode checked after the first year. The

magnesium anode must be checked by a qualified professional at

least every 2 years.

6.2.3 Descaling

In hard water regions, it is advisable to ask the fitter to descale the

DHW tank exchanger once a year in order to maintain its level of

performance.

6.2.4 Casing

The casing of the DHW tank can be cleaned with soapy water.

6.2.5 Vent device

If the vent device is not used, the installer must check the seal on the

top vent connection.

6.3 Solar circuit

To check operation of the solar system, consult the display on the

control system. A steady red indicator light in fine weather indicates

a malfunction.

The pressure in the solar circuit can be checked on the solar station's

pressure gauge. If the pressure shown is lower than 0.5 bar, call the

installer.

Never carry out work on the solar circuit yourself. Never

work on the safety valve yourself.

17/10/12 - 300028005-001-03 TRIO DT 250 - TRIO DT 350

17

Page 18

Warranty

You have just purchased one of our appliances and we thank you

for the trust you have placed in our products. Please note that your

appliance will provide good service for a longer period of time if it is

regularly checked and maintained. Your fitter and our customer

support network are at your disposal at all times.

Warranty terms

Starting from the purchase date shown on the original fitter's

invoice, your appliance has a contractual guarantee against any

manufacturing defect.

The length of the guarantee is mentioned in the price catalogue.

The manufacturer is not liable for any improper use of the appliance

or failure to maintain or install the unit correctly (the user shall take

care to ensure that the system is installed by a qualified fitter). In

particular, the manufacturer shall not be held responsible for any

damage, loss or injury caused by installations which do not comply

with the following:

- applicable local laws and regulations

- specific requirements relating to the installation, such as national

and/or local regulations

- the manufacturer's instructions, in particular those relating to the

regular maintenance of the unit

- the rules of the profession

The warranty is limited to the exchange or repair of such parts as

have been recognised to be faulty by our technical department and

does not cover labour, travel and carriage costs. The warranty shall

not apply to the replacement or repair of parts damaged by normal

wear and tear, negligence, repairs by unqualified parties, faulty or

insufficient monitoring and maintenance, faulty power supply or the

use of unsuitable fuel. Sub-assemblies such as motors, pumps,

electric valves etc. are guaranteed only if they have never been

dismantled.

Italy

The duration of our warranty is shown on the certificate delivered

with the appliance.

Our liability as manufacturer may not be invoked in respect of

incorrect use of the appliance, incorrect or insufficient maintenance

thereof, or incorrect installation of the appliance (you must

therefore ensure that installation and maintenance operations are

carried out respectively by a qualified professional and by an after

sales service company).

The legislation laid down by European Directive 99/44/EEC,

transposed by Legislative Decree No. 24 of 2 February 2002

published in O.J. No. 57 of 8 March 2002, continues to apply.

Russia

The foregoing provisions in no way affect the rights of the

consumer, which are guaranteed by the legislation of the Russian

Federation as regards hidden defects.

The terms and conditions of warranty and the terms and conditions

of application of the warranty are indicated on the warranty form.

The warranty shall not apply as regards the replacement or repair

of wearing parts under normal use. Such parts include

thermocouples, injection nozzles, flame control and ignition

systems, fuses and gaskets.

Turkey

Due to the laws and regulations the product life for this product is

10 years. During that time the producer and/or the distributor has

to provide after sales services and spare parts.

Other countries

The above provisions do not restrict the benefit of the legal laws

regarding hidden defects applicable in the buyer's country.

France

The preceding dispositions are not exclusive of benefits for the

purchaser of the legal guarantee as stated in Civil Code articles

1641 to 1648.

Poland

Warranty conditions are included in the warranty card.

Switzerland

The application of the warranty is subject to the terms and

conditions of sale, delivery and warranty of the company marketing

our products.

Belgium

The preceding dispositions about the contractual guarantee are not

exclusive of profit if the need arises for the purchaser in Belgium of

the applicable legal dispositions on hidden defects.

18

TRIO DT 250 - TRIO DT 350 17/10/12 - 300028005-001-03

Page 19

Warranty certificate

Date of purchase: .............................................................................

Name and address of the purchaser: ...............................................

..........................................................................................................

..........................................................................................................

..........................................................................................................

..........................................................................................................

..........................................................................................................

Tel.:...................................................................................................

Information on the appliance (to be found on the nameplate):

Model: ...............................................................................................

Serial number: ..................................................................................

Retailer's stamp:

17/10/12 - 300028005-001-03 TRIO DT 250 - TRIO DT 350

19

Page 20

7NF CESI data sheet

(l)

(°C)

7.1 *1 data sheet (for France only)

AFNOR Certification 11, RUE FRANCIS DE PRESSENSE

93571 LA PLAINE SAINT-DENI S CEDEX

La marque NF garantit

la qualité de cette article

suivant les normes françaises

et Règles de certification de l'application

NF Chauffe-eau solaires individuels

DEFINIES PAR LES REGLES DE CERTIFI CATION

DE LA MARQUE NF CHAUFFE-EAU SOLAIRES INDIVIDUELS

FICHE INFORM ATIVE

NF 441 03/12

CONFORME AUX SPECIFICATIONS

CARACTERISTIQUES CERTIFI EES:

Résultat avec appoint électrique:

CESI certifié

TRIO 250-3 1,74

TRIO 250-5 3,24

TRIO 350-5 2,60

Résultat avec appoint hydraulique:

CESI certifié

TRIO 250-3 1,8

TRIO 250-5 3,59

TRIO 350-5 2,65

INFORMATI ONS COMPLEMENTAIRES:

CESI certifié

Efficacité

énergétique

Efficacité

énergétique

Type

d'appoint

A

c

(m²)

A

c

(m²)

Nbr de

capteurs

U

c

(Wm-2K-1)

U

c

(Wm-2K-1)

Volume

nominal

ballon

U

s

(WK-1)

U

s

(WK-1)

Puissance

(W)

C

s

(MJK-1)

C

s

(MJK-1)

T°

consigne

55

60

f

aux

f

aux

Relance

diurne

Ves 40

(l)

553h200420521E3-052 OIRT

553h200420522E5-052 OIRT

024h200030532E5-053 OIRT

583h200420521E3-052 OIRT

83h200420522E5-052 OIRT

5

054h200030532E5-053 OIRT

L000690-A

20

TRIO DT 250 - TRIO DT 350 17/10/12 - 300028005-001-03

Page 21

17/10/12 - 300028005-001-03 TRIO DT 250 - TRIO DT 350

21

Page 22

22

TRIO DT 250 - TRIO DT 350 17/10/12 - 300028005-001-03

Page 23

17/10/12 - 300028005-001-03 TRIO DT 250 - TRIO DT 350

23

Page 24

@

DE DIETRICH THERMIQUE S.A.S

Ȼɢɡɧɟɫɰɟɧɬɪ©ɑɚɣɤɚɉɥɚɡɚª

ɊɨɫɫɢɹɝɆɨɫɤɜɚ

Ɂɭɛɚɪɟɜɩɟɪɟɭɥɨɤɞ

ɨɮɢɫ

+7 (495) 221-31-51

IT

DUEDI S.r.l.

www.duediclima.it

Distributore Ufficiale Esclusivo

De Dietrich-Thermique Italia

Via Passatore, 12 - 12010

San Defendente di Cervasca

CUNEO

+39 0171 857170

+39 0171 687875

duediclima.it

info

ES

DE DIETRICH THERMIQUE Iberia S.L.U.

www.dedietrich-calefaccion.es

Av. Princep d’Astúries 43-45

08012 BARCELONA

+34 932 920 520

+34 932 184 709

© Copyright

All technical and technological information contained in these technical instructions, as well as any

drawings and technical descriptions supplied, remain our property and shall not be multiplied

without our prior consent in writing.

Subject to alterations.

17/10/12

DE DIETRICH THERMIQUE

300011678- 001- 02300011730- 001- 02300011679- 001- 02300021907- 001- 02300021907- 001- 02300012998- 001- 02300011677- 001- 02300012999- 001- 02300013050- 001- 02300013603- 001- 02300023459- 001- 02300017972- 001- 02300014428- 001- 02300021041- 001- 02300028003- 001- 03300028004- 001- 03300028005- 001- 03

57, rue de la Gare F- 67580 MERTZWILLER - BP 30

AD001NU-AH

Loading...

Loading...