Page 1

T

Technical Sales

Documentation Department

Wall-hung gas condensing boilers

Service tool / After Sales Service information

P5253 JS F 67580 Mertzwiller N° IT2598 15/02/2013

Technical information

Heading No 5

NANEO EMC ... - PMC...

Package HR83 (option)

EN

1. Service tool

The service tool is required to modify the factory settings of

EMC... / PMC... boilers

For example:

- Settings in case of gas conversion

- Modification of the heating gradient

- Modification of the maximum boiler temperature

- Modification of the fan speed

etc...

05257-D

The service tool can also help in the diagnosis by displaying error codes.

Only the service tool assembly instructions are delivered with package HR83.

The user manual (first version attached) can be downloaded from our website in Product section.

2. After Sales Service information

A website with simplified After Sales Service information for different products is available:

Access from a computer: Access via smartphone or tablet (QR code)

http://sav.dedietrich-thermique.fr

After Sales Service information is currently available for the following products (NANEO to come):

INNOVENS MCA MODULENS AGC MIV II for ALEZIO VIVADENS MCR

or

PKR 1 / 1 IT2598

Page 2

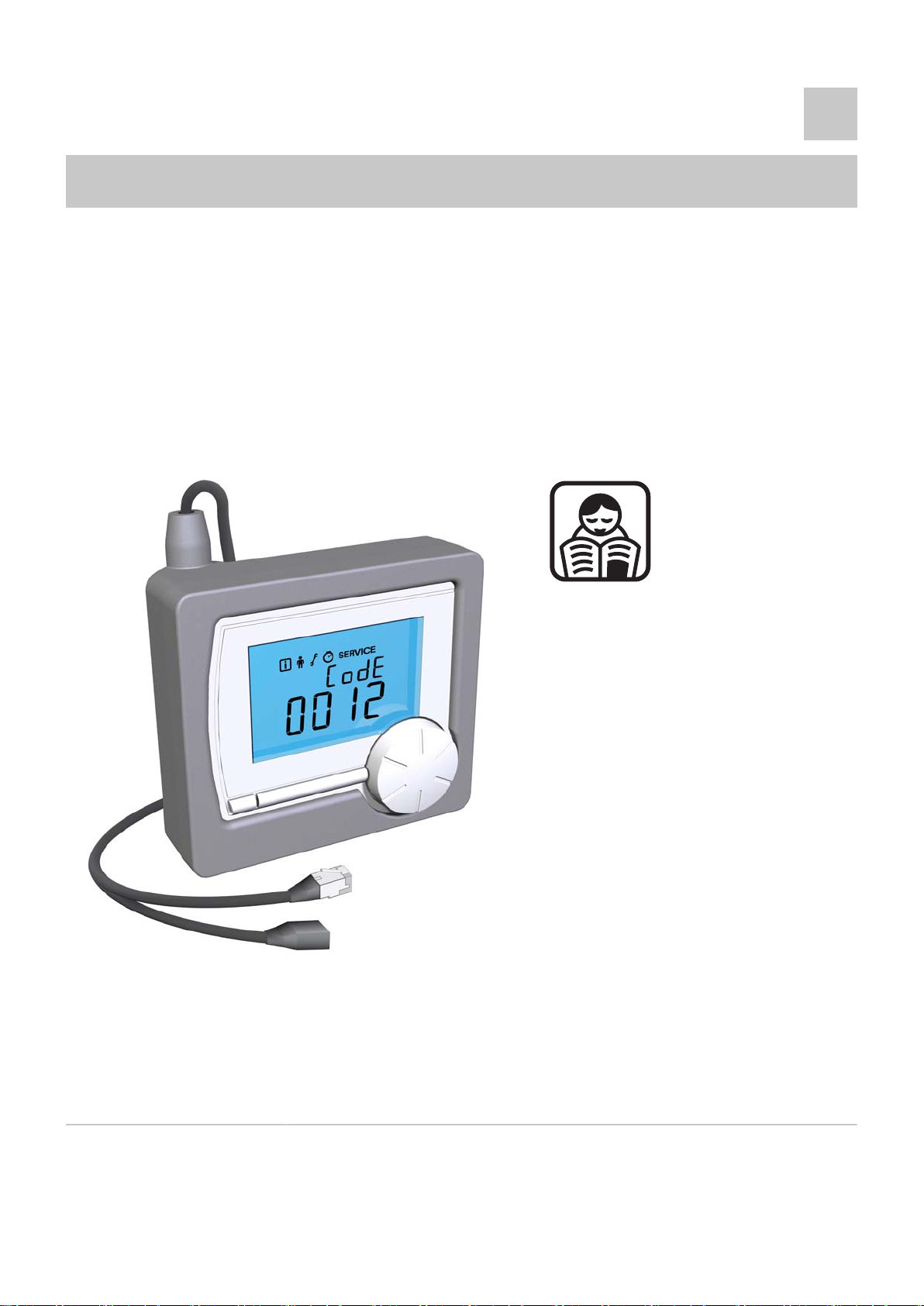

Service tool

EN

User Guide

7603161-01

Page 3

Contents

1 Control panel ..............................................................................................2

1.1 Description ............................................................2

1.1.1

Meaning of the symbols on the display ...................2

2 Settings .......................................................................................................3

2.1 Menu structure .....................................................3

2.2

2.3

2.4

2.5

2.6

Information menu Q ............................................3

User menu W .........................................................4

Installer menu ? ..................................................4

Counter menu \ ..................................................5

Service menu K .............................................5

3 Messages ....................................................................................................7

3.1 Error messages .....................................................7

4 Technical specifications ............................................................................8

4.1 Technical specifications ......................................8

1

280113 - 7603161-01

Page 4

R000057-D

1

2

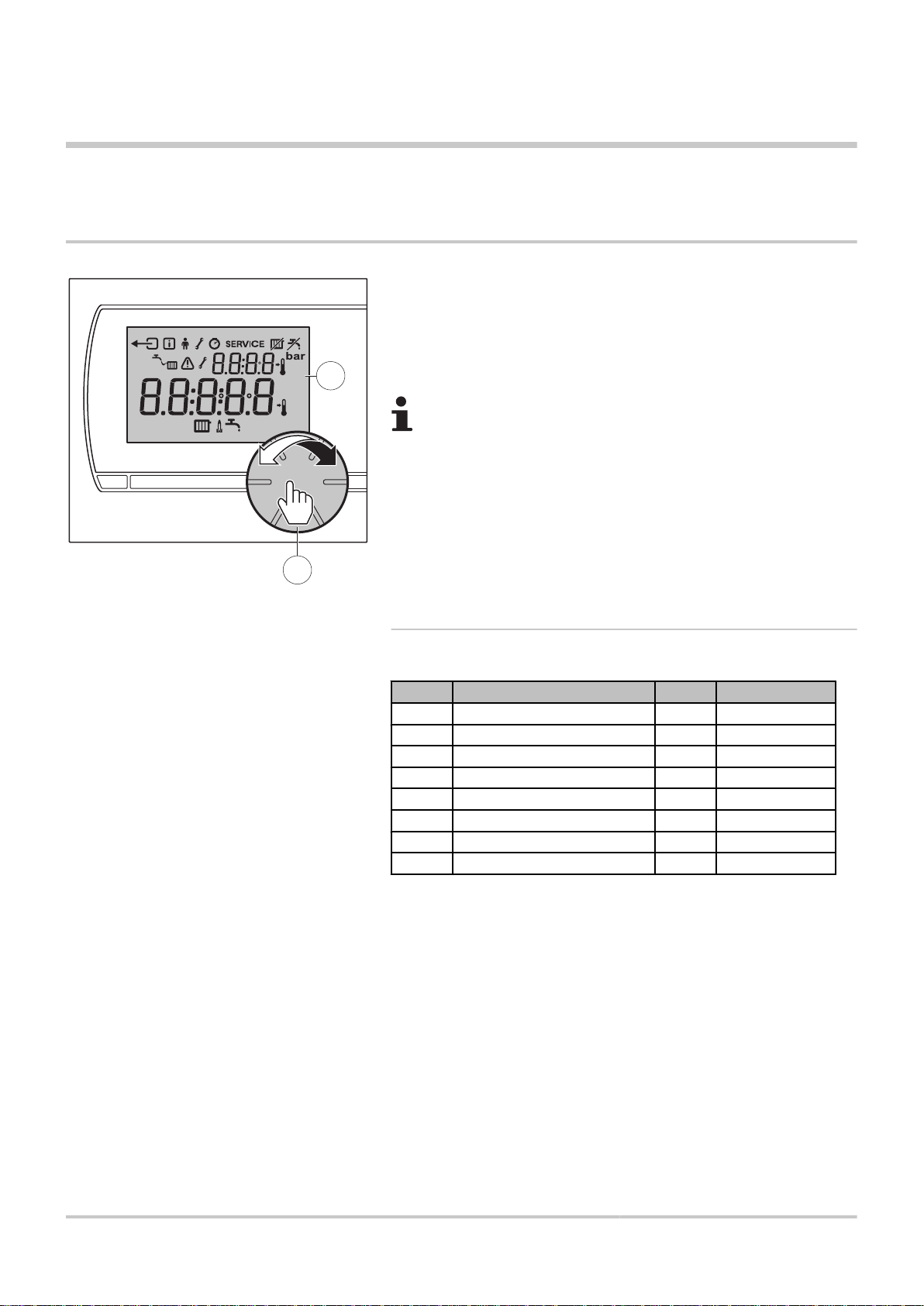

Service tool 1. Control panel

1 Control panel

1.1 Description

1

2

Display

Rotary and push button for operating the service tool

The service tool is menu-controlled, making it very easy to operate.

The service tool has just one button.

4 The button is both a rotary button and a push button.

4 Turn it to scroll through menus or change values.

4 Press it to confirm choices (Such as menu

selections).

1.1.1. Meaning of the symbols on the display

Symbol Meaning Symbol Meaning

T

e

c

?

H

M

D

N

ECO mode on

Water pressure too low

Defect

Boiler service required

Current temperature

Set temperature

Central heating function on

Domestic hot water function on

>

K

Back

Information menu

Q

User menu

W

Installer menu

?

Counter menu

\

Service menu

Burner on

I

280113 - 7603161-01

2

Page 5

R000064-C

3s

1x

2. Settings Service tool

2 Settings

2.1 Menu structure

To access the menu, proceed as follows:

4 Press the rotary and push button for at least 3 sec.

4 Turn the button until you reach the required menu.

4 Press the button to confirm.

4 Amend the selected menu item.

4 Press the button to confirm.

4 Exit the menu by pressing >.

WARNING

2.2

Information menu Q

The values to be read may differ depending on the

connected heating unit.

See the installation and service

manual for the boiler.

This menu provides access to various kinds of information about the

boiler and any connected accessories.

Symbol Meaning

5t

5v

tf

tr

tdh

t;vt

t5;l

fl

Mf

pr

p;

5;ft

State

Sub-status

Current inlet temperature (℃)

Current return temperature (℃)

Current tank temperature (℃)

(Only if an DHW sensor is connected)

Current outside temperature (℃)

(Only if an outside temperature sensor is connected)

Current solar tank temperature (℃)

(Only with the sensor connected)

Current ionization current

Current fan speed rpm

Current water pressure

(Only boilers with a water pressure sensor)

Current heat output of boiler

Service tool software version

3

280113 - 7603161-01

Page 6

Service tool 2. Settings

2.3

User menu W

Changes to parameter settings in this menu are only used while the

service tool is connected.

Use the Fitter menu ? to change the

parameter settings permanently.

Code Meaning Information Settings Factory

setting

Zvt; = Automatic

position

0M = Start

0ff = Stop

30 to 75 °C

0 to 100 °C

Zvt;

60°CN

90°CD

0

0

em;

tdh

tmh

hvp

cdM

2.4

The ECO mode turns off the DHW standby

ECO mode

DHW standby function

Maximum central

heating water

temperature

Not applicable This function does not apply to the service tool. Not applicable

Not applicable This function does not apply to the service tool. Not applicable

function. In combi boilers the waiting time

increases. Calorifiers are no longer kept warm.

Setting the required tap water temperature, for

calorifiers with a temperature programme.

Setting the required central heating water

temperature.

Installer menu ?

In this menu, the installer can—depending on the boiler—adjust some

of the functions and access information.

The following is applicable to all installer settings:

4 The values to be read may differ depending on the

connected heating unit.

4 The meaning of the various codes may differ for

different boilers.

4 After

selection of a parameter, it takes 1 s before the

parameter is retrieved.

Settings > Installer menu ? 0012

Parameter Description Adjustment range Factory setting

p01

to

p44

df and dV

Zd

(1) If the boiler is not using a specific parameter, a value of 255 is displayed. ¼See the installation and service manual for the boiler.

Consult the boiler manual when changing the boiler parameters.

If an invalid value is entered, fk1l appears on the screen.

(1)

To restore the factory settings or when replacing the main

Factory setting

Detection of connected SCUs

PCB, enter the values dF and dU from the type plate in

parameters df and dV

0 = No detection

1 = Detection

X

Y

0

280113 - 7603161-01

Parameters p"7 and p30 can also be set to a negative value.

Use the following formula to read or change the required negative

value;

Setting value - 256 = Desired value.

If setting value 246 is displayed, this corresponds to the required

negative value of -10 (246 - 256 = -10)

.

4

Page 7

2. Settings Service tool

2.5

Counter menu \

To change a required negative value to -15,

the setting value must be

set to 241 (241 - 256 = -15).

Desired value

Setting value

0 -1 -5 -10 -15 -20 -25 -30

0 255 251 246 241 236 231 226

Setting value 0 = Desired value 0.

The history of various boiler functions can be checked in this menu.

Settings > Counter menu \

Code Meaning

m1

m2

m3

m4

m5

m6

m7

m8

m9

Unsuccessful starts

Number of times with no or low flame

Number of successful starts

Number of central heating pump starts

Number of DHW pump starts

Number of DHW burner starts

Total operating hours

Number of central heating pump operating hours

Number of DHW pump operating hours

2.6

Service menu K

Boiler service messages can be reset here.

Settings > Service menu K

WARNING

Reset the service message after the boiler service has

been carried out. This can be the active message or the

next message.

4 If zzzz is displayed in the service menu, the

boiler will not show a service code.

4 The mleZr message indicates that a (pre-)

service reset is possible.

The message

mleZr Z, B or c indicates that service

message Z, B or c can be reset.

4 The boiler determines which service message can be

reset.

Code Meaning

mleZr

Service reset

Only a qualified engineer may carry out the following

operations.

5

280113 - 7603161-01

Page 8

Service tool 2. Settings

When the mleZr message is displayed, you can choose to

either

retain the service message or reset it. If no action is taken, the

service message will remain. To reset the service message, proceed

as follows:

1. Press the rotary and push button.

2. Turn the button to

ml[ye5

.

3. Press the button to confirm.

4. The service tool will then return to the

zzzz

screen.

Multiple resets are not possible.

Operations to be carried out

K

mleZr

Z

B

c

K

Z

ml[ n0

K

Z

ml[ye5

280113 - 7603161-01

6

Page 9

R000125-A

3. Messages Service tool

3 Messages

3.1 Error messages

If an error is present, a fault code and a fault indication will appear on

the display.

Error codes Fault

indication

f203

f214

f215

f217

n;

5p

c

c

c

c + e

c

Probable causes Solution

Faulty connection to boiler. Check the boiler’s connection to the service tool.

Incorrect room temperature

reading.

Service tool faulty. Replace service tool

Water pressure too low. Top up the water in the central heating system. See the

Your boiler may not support

the

OpenTherm SmartPower.

Room temperature reading is incorrect. The temperature sensor

may be defective if the room temperature is between

65℃.

installation and service manual for the boiler.

OpenTherm SmartPower is required for the backlight.

In boilers without OpenTherm SmartPower

functional but without backlight.

To clear the message, press the button.

, the Servicetool is

-5℃ and

For the boiler’s error codes, see the corresponding

installation and service manual.

7

280113 - 7603161-01

Page 10

Service tool 4. Technical specifications

4 Technical specifications

4.1 Technical specifications

Dimensions

Power supply

Service tool OpenTherm OpenTherm

Electrical connection

Service tool OpenTherm OpenTherm communication. Low-voltage connection

Ambient conditions

Storage conditions Temperature: -25℃ +60℃

Operating conditions 0℃ - 60℃

Temperature

Room temperature Measurement range: -5℃ +65℃

Features of service tool

Backlight Colour: blue

Controls Rotary and push button

Mounting See the assembly instructions provided

Quality marks and compliance with standards

Protection classification IP20

80 x 90 x 32,5 (l x b x h) mm

Relative humidity 5% - 90% no condensation

Maximum temperature deviation at 20℃: 0,3℃

4 EMC: 2004/108/EC, 55014

4 Emission EN61000-6-3

4 Immunity: EN61000-6-2

4 Drop test: IEC 68-2-32

4 RoHs Compliant

4 OpenTherm V3.0 Smartpower

280113 - 7603161-01

8

Page 11

Page 12

Page 13

© Copyright

7603161

technical and technological information contained in these technical instructions,

All

as well as any drawings and technical descriptions supplied, remain our property

and shall not be multiplied without our prior consent in writing.

280113

Loading...

Loading...