Page 1

EASYLIFE

S U S T A I N A B L E C O M F O R T

®

KALIKO

MW-C004128-03

en

Installation and Service Manual

Thermodynamic water heater

KALIKO

TWH 200 EV

Page 2

Contents

1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1.1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1.2 Water connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.1.3 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1.4 Website . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1.5 Others . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 Liabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3.1 Manufacturer's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3.2 Installer's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4 Safety data sheet: refrigerant fluid R-134a . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4.1 Product identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4.2 Hazard identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4.3 Composition of/Information on the ingredients . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.4.4 First aid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.4.5 Fire prevention measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.4.6 In the event of accidental spillage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.4.7 Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

1.4.8 Personal protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.4.9 Considerations on disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.4.10 Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2 About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.1 Symbols used in the manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.2 Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3 Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1 Homologations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1.1 Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1.2 Accessibility of the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3.2 Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4 Description of the product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.1 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.2 Main components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.3 Operating principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.3.1 Linear network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.3.2 Direct connection to the thermodynamic water heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.3.3 Multi-duct network with collector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.3.4 Schematic diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.1 Installation regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.2 Package list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

5.2.1 Standard delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

5.2.2 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.2.3 System configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.3 Storing and transporting the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.3.1 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.4 Choice of the location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.4.1 Data plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.4.2 Position of the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.4.3 Main dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.5 Positioning the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.5.1 Unpacking the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.5.2 Positioning the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

5.5.3 Levelling the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.6 Water connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.6.1 Connecting the water heater to the domestic water circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.6.2 Fitting the dielectric union . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.7 Air duct connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.8 Condensate discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.9 Fitting and connecting the control module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Contents

2 TWH 200 EV EN-7602142 - v11 - 24042019

Page 3

5.9.1 Radio connection (installation strongly recommended) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.9.2 Wire connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

5.9.3 Integration into the front panel of the water heater (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.10 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.10.1 Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

5.10.2 Peak rate/off-peak rate electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

5.10.3 Connection with peak rate/off-peak rate signal connected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.10.4 Connection with timer programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.10.5 Connection with timer programming and photovoltaic signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.11 Schematic wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

5.12 Filling the thermodynamic water heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.1 Control panel description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.1.1 Description of the keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.1.2 Description of the display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

6.1.3 Browsing in the menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.2 Points to check before commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.3 Commissioning the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.3.1 Initial commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.3.2 Pairing the control module and the tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.4 Checks and settings after commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

6.5 Selecting the operating mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.6 Reading out measured values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.6.1 Measurements menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

6.6.2 Counters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.7 Modifying the installer parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.7.1 Accessing the parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.7.2 List of parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6.7.3 Adjusting the air duct vacuum pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

6.7.4 Control system sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6.7.5 Restoring the factory settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6.8 SERVICE menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6.9 Radio test menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7 Decommissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.1 Shutting down the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

7.2 Frost protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

8 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

8.1 General instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

8.2 Standard inspection and maintenance operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

8.2.1 Refrigerant circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

8.2.2 Check the hydraulic circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

8.2.3 Aeraulics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

8.2.4 Impressed current anode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

8.2.5 Checking the safety valve or safety unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

8.2.6 Drain the thermodynamic water heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

8.2.7 Descaling the tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

8.2.8 Cleaning the casing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

8.2.9 Cleaning the condensate discharge pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

8.3 Accessing the bottom inspection trap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

8.4 Cleaning the installation's extractor outlets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

8.5 Maintenance form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

9 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

9.1 Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

9.1.1 Lockout ( or type code) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

9.1.2 Lockout ( type code) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

9.2 Log of messages and faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

9.2.1 Error display Err . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

9.2.2 Displaying lockouts bL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

9.2.3 Resetting the lockout and error memory to zero . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

10 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

10.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Contents

EN-7602142 - v11 - 24042019 TWH 200 EV 3

Page 4

10.2 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

10.2.1 Heat pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

10.2.2 Water heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

11 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

11.1 Information on the ecodesign and energy labelling directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

11.1.1 Specific information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

11.2 EC Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Contents

4 TWH 200 EV EN-7602142 - v11 - 24042019

Page 5

1 Safety

1.1 Safety

Danger

This appliance can be used by children aged from

8 years and above and persons with reduced

physical, sensory or mental capabilities or lack of

experience and knowledge if they have been

given supervision or instruction concerning use of

the appliance in a safe way and understand the

hazards involved. Children shall not play with the

appliance. Cleaning and user maintenance

should not be carried out by children without adult

supervision.

1.1.1

Installation

Ensure sufficient space is available to allow correct

installation of the appliance.

See

Position of the appliance section (Installation and

Service Manual).

1.1.2

Water connections

The appliance is intended to be permanently

connected to the water mains.

Maximum / minimum water inlet pressure:

See

Technical specifications section.

The safety valve (not supplied) must be regularly

operated in order to remove limescale deposits and

ensure that it is not blocked.

Draining: shut off the domestic cold water inlet. Open

a hot water tap in the installation and then open the

drain valve on the cold water inlet. When the water

stops flowing, the appliance has been drained.

A pressure reducer (not provided) is necessary when

the supply pressure exceeds 80% of the calibration of

the safety valve or safety unit and it must be located

upstream of the appliance.

As water may flow out of the discharge pipe on the

pressure limiter device, the discharge pipe must be

kept clear and open.

1 Safety

EN-7602142 - v11 - 24042019 TWH 200 EV 5

Page 6

Connect the pressure limiter device to a drain pipe,

kept open to the air, in a frost-free environment, and

at a continuous downward gradient.

1.1.3 Electrical connections

A disconnection device must be fitted to the

permanent pipes in accordance with installation rules.

If the power cable is damaged, it must be replaced by

the manufacturer, its after sales service or persons

with similar qualifications in order to obviate any

danger.

This appliance must not be powered through an

external switch, such as a timer, or be connected to a

circuit which is regularly switched on and off by the

electricity provider.

Install the appliance in accordance with national rules

on electrical installation.

The control panel for the appliance must remain

switched on to ensure that the impressed current

anode can operate. Failure to comply with this

instruction may cause deterioration to the water

heater tank and cancel its warranty.

Wiring diagram:

See

Wiring diagram section (Installation and Service

Manual).

Connecting the appliance to the mains:

See

Electrical connections section (Installation and

Service Manual).

Fuse type and calibre:

See

Electrical connections section (Installation and

Service Manual).

1.1.4

Website

The installation manual can also be found on our

website.

1 Safety

6 TWH 200 EV EN-7602142 - v11 - 24042019

Page 7

1.1.5

Others

Danger

If flue gas is released or there is a refrigerant

leak:

Do not use a naked flame, do not smoke, do not

operate electrical contacts or switches (doorbell,

light, motor, lift, etc.).

Open the windows.

Switch off the appliance.

Avoid contact with the refrigerant. Danger of

frost injuries.

Locate the probable leak and seal it

immediately.

Warning

According to the appliance settings:

Do not touch the refrigerant connection pipes

with bare hands when the appliance is

operating. Risk of scalding.

Caution

Do not neglect to service the appliance.

In order to limit the risk of being scalded, a

thermostatic mixing valve must be installed on

the domestic hot water flow pipes.

1.2

Recommendations

Warning

Only a certified professional who has complete

suitable training is authorised to work on the

appliance and on the installation.

Warning

Before any work, switch off the power supply to

the appliance.

1.3

Liabilities

1.3.1 Manufacturer's liability

Our products are manufactured in compliance with the

requirements of the various Directives applicable. They

are therefore delivered with the

marking and any

documents necessary. In the interests of the quality of

our products, we strive constantly to improve them. We

therefore reserve the right to modify the specifications

given in this document.

1 Safety

EN-7602142 - v11 - 24042019 TWH 200 EV 7

Page 8

Our liability as manufacturer may not be invoked in the

following cases:

Failure to abide by the instructions on installing and

maintaining the appliance.

Failure to abide by the instructions on using the

appliance.

Faulty or insufficient maintenance of the appliance.

1.3.2 Installer's liability

The installer is responsible for the installation and initial

commissioning of the appliance. The installer must

observe the following instructions:

Read and follow the instructions given in the manuals

provided with the appliance.

Install the appliance in compliance with prevailing

legislation and standards.

Carry out initial commissioning and any checks

necessary.

Explain the installation to the user.

If maintenance is necessary, warn the user of the

obligation to check the appliance and keep it in good

working order.

Give all the instruction manuals to the user.

1.4

Safety data sheet: refrigerant fluid R-134a

1.4.1

Product identification

Name of the refrigerant fluid: R–134a.

Emergency call: Anti-poison Centre INRS/ORFILA:

+33 (0) 1 45 42 59 59.

1.4.2

Hazard identification

Effects harmful to health:

The vapours are heavier than air and may lead to

asphyxia owing to reduced oxygen levels.

Liquefied gas: Contact with the liquid may cause

serious frost and eye injuries.

Product classification: This product is not classified as a

"hazardous preparation" according to European Union

regulations.

1 Safety

8 TWH 200 EV EN-7602142 - v11 - 24042019

Page 9

Caution

If the refrigerant is mixed with air, it may cause

pressure surges in the refrigeration pipes and

lead to an explosion and other hazards.

1.4.3 Composition of/Information on the

ingredients

Chemical nature: R-134a 1,1,1,2-Tetrafluoroethane.

Ingredients that may lead to hazardous situations:

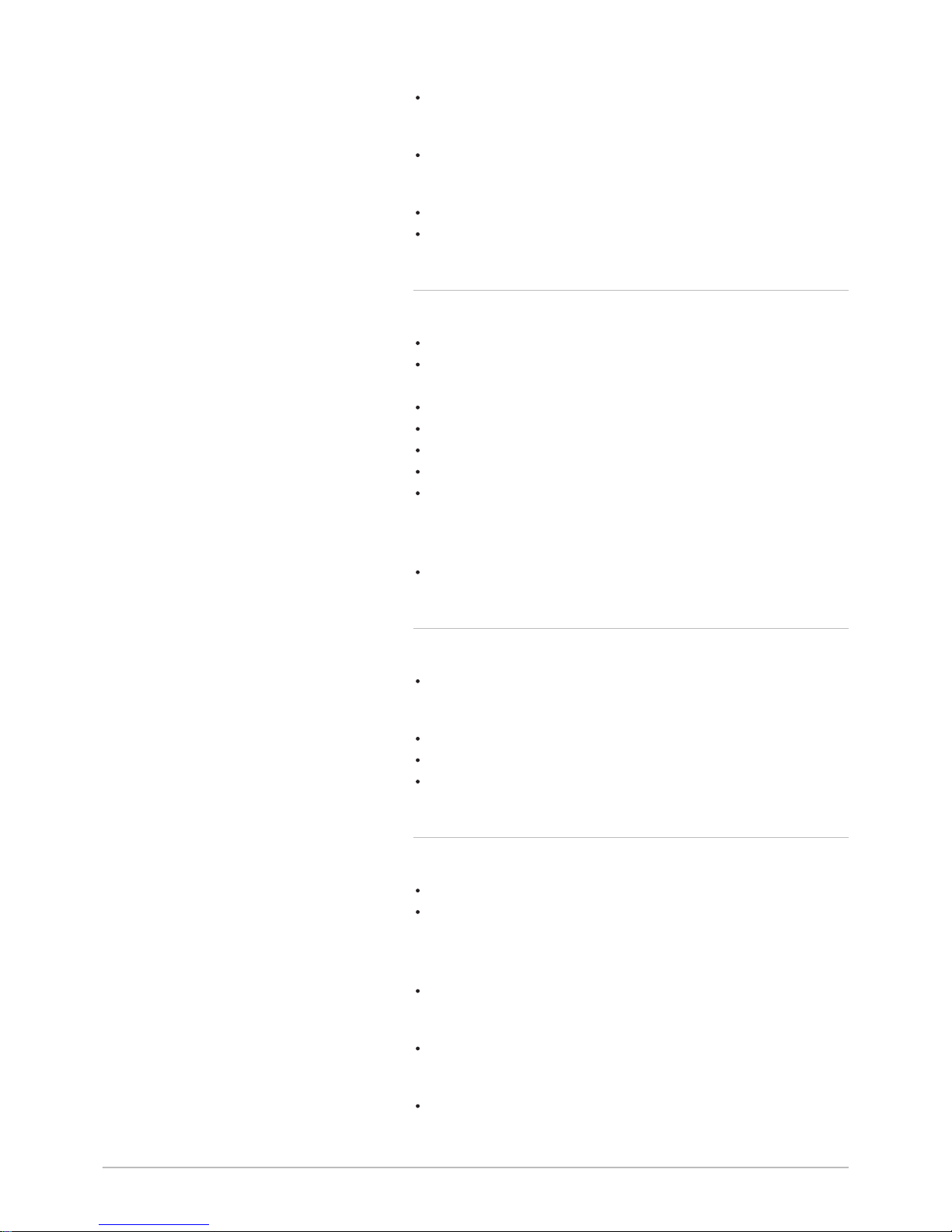

Tab.1

Substance

name

Concentration CAS number CE number Classification GWP

R-134a

1,1,1,2-Tetra

fluoroethane

100% 811-97-2 212-377-0 1430

1.4.4

First aid

If inhaled:

Evacuate the subject from the contaminated area and

take him into the open air.

If feeling unwell: call a doctor.

In the event of contact with the skin:

Treat frost injuries like burns. Rinse with copious

amounts of tepid water, do not remove clothing (risk of

adhesion to the skin).

If skin burns appear, call a doctor immediately.

In the event of contact with the eyes:

Rinse immediately in water, holding the eyelids well

apart (at least 15 minutes).

Consult an ophthalmologist immediately.

1.4.5 Fire prevention measures

Appropriate extinguishing agents:

All extinguishing agents can be used.

Inappropriate extinguishing agents:

None to our knowledge. In the event of fire nearby,

use the appropriate extinguishing agents.

Specific hazards:

Pressure elevation: in the presence of air, an

inflammable mixture may form under certain

temperature and pressure conditions.

1 Safety

EN-7602142 - v11 - 24042019 TWH 200 EV 9

Page 10

Effect of heat: release of toxic and corrosive vapours.

Special intervention methods:

Cool the volumes exposed to heat with water spray.

Protection of the firemen:

Full self-contained breathing apparatus.

Complete body protection.

1.4.6

In the event of accidental spillage

Individual precautions:

Avoid contact with the skin and eyes.

Do not intervene without appropriate protective

equipment.

Do not inhale the vapours.

Evacuate the hazardous area.

Stop the leakage.

Eradicate all sources of ignition.

Ventilate the spillage area mechanically (risk of

asphyxia).

Cleaning / Decontamination:

Allow residual product to evaporate.

1.4.7 Handling

Technical measures:

Ventilation.

Precautions to be taken:

No smoking.

Prevent the build-up of electrostatic charges.

Work in a well ventilated place.

1.4.8 Personal protection

Respiratory protection:

If ventilation is insufficient: AX type cartridge mask.

In confined spaces: self-contained breathing

apparatus.

Hand protection:

Protective gloves in leather or nitrile rubber.

Eye protection:

Safety glasses with side protection.

Skin protection:

Clothing made mostly of cotton.

Industrial hygiene:

1 Safety

10 TWH 200 EV EN-7602142 - v11 - 24042019

Page 11

Do not drink, eat or smoke in the work place.

1.4.9 Considerations on disposal

Product waste:

Consult the manufacturer or the supplier for

information on recovery or recycling.

Soiled packaging:

Reuse or recycle after decontamination. Destroy in

authorised installations.

Warning

Disposal must be completed in compliance with

prevailing local and national regulations.

1.4.10

Regulations

Regulation (EU) No. 517/2014 of the European

Parliament and of the Council of 16 April 2014 on

fluorinated greenhouse gases and repealing

Regulation (EC) No. 842/2006.

Classified installations No. 1185.

1 Safety

EN-7602142 - v11 - 24042019 TWH 200 EV 11

Page 12

2 About this manual

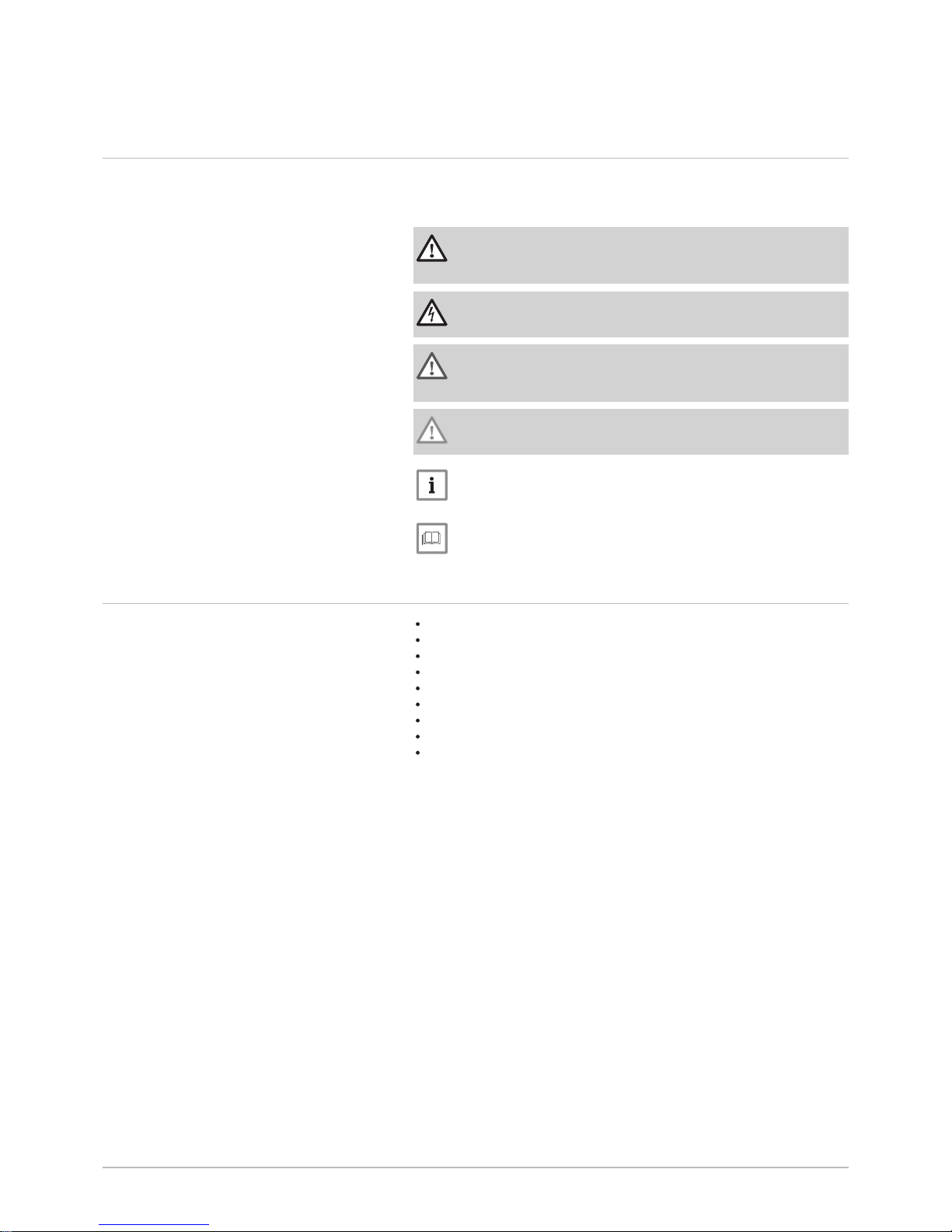

2.1 Symbols used in the manual

This manual uses various danger levels to draw attention to special

instructions. We do this to improve user safety, to prevent problems and to

guarantee correct operation of the appliance.

Danger

Risk of dangerous situations that may result in serious personal

injury.

Danger of electric shock

Risk of electric shock.

Warning

Risk of dangerous situations that may result in minor personal

injury.

Caution

Risk of material damage.

Important

Please note: important information.

See

Reference to other manuals or pages in this manual.

2.2 Abbreviations

HP: Heat pump

DHW: Domestic Hot Water

LP: Low pressure

HP: High pressure

CFC: Chlorofluorocarbon

Pes: Power absorbed at stabilised rate

COP: Coefficient of performance

HP/HC: Peak rate / Off-peak rate

CMV: Controlled mechanical ventilation

2 About this manual

12 TWH 200 EV EN-7602142 - v11 - 24042019

Page 13

3 Technical specifications

3.1 Homologations

3.1.1 Certifications

CSTBat certification

This product:

complies with Technical Specification 14.5/17–2285_V1 and its

commercial extension 14.5/17–2285_V1–E1.

is CSTBat Humidity-Controlled Ventilation certified (www.certita.fr):

CSTBat–71/01–CHY5–2285

NF certification

Specifications LCIE 103-15/B 07/2011 for NF Electricity Performance

Marking

This product complies with the requirements of the following NF

Electricity Standards:

EN 60335-1:2002 +A1:2004 +A11:2004 +A12:2006 +A2:2006

+A13:2008 +A14:2010

EN 60335-2-21:2003 +A1:2005 +A2:2008

EN 60335-2-40:2003 +A11:2004 +A12:2005 +A1:2006 +A2:2009

EN 62233:2008

Directives

This product complies with the requirements of the following European

Directives and Standards:

Pressure Equipment Directive 2014/68/EU

Low Voltage Directive 2014/35/EU

Generic standard: EN 60335-1

Relevant standards: EN 60335-2-21, EN 60335-2-40

Electromagnetic Compatibility Directive 2014/30/EU

Generic standards: EN 61000-6-3, EN 61000-6-1

Relevant Standard: EN 55014

3.1.2 Accessibility of the appliance

Classification of the appliance: Appliance not accessible to the public.

3.2 Technical specifications

Tab.2

Capacity l 214

Output (heat pump) at 20°C Air W 780

Absorbed electrical power for heating at 150 m3/h (heat pump)

W 225

COP at minimum air flow of 59 m3/h

(1)

2.9

COP at maximum air flow of 150 m3/h

(2)

3.29

Immersion heater output W 2400

Maximum operating pressure bar (MPa) 10 (1)

Power supply voltage V 230

Circuit breaker A 16

Heating time at 150 m3/h (10-54°C)

(1)

h 13.6

Heating time at 59 m3/h (10-54°C)

(1)

h 15.6

Pes kW 0.020 – 0.027

Heating temperature (Minimum/Maximum) °C 7 / 35

3 Technical specifications

EN-7602142 - v11 - 24042019 TWH 200 EV 13

Page 14

Maximum domestic hot water temperature without electrical back-up °C 65

Maximum domestic hot water temperature with electrical back-up °C 75

Vmax (Maximum usable volume of hot water)

(1)

l 303.1

Modulating air flow rate (Maximum)

m3/h

265

Modulating air flow rate (Minimum)

m3/h

35

Available air pressure

(3)

Pa 100 or 125

Sound output dB(A) 54

R–134a refrigerant kg 0.85

R-134a refrigerant

(4)

tCO2e 1.22

Tilting dimension mm 1755

Weight (empty) kg 92

(1) Value obtained with an air temperature of 20°C and a wet temperature of 16.5°C. Water inlet temperature of 10°C. Cycle L

(2) Value obtained with an air temperature of 20°C and a wet temperature of 16.5°C. Water inlet temperature of 10°C. Cycle L

(3) According to the configuration, see the Operating principle section

(4) Quantity of refrigerant calculated in tonnes of CO2 equivalent.

Important

The R-134a refrigerant is contained in equipment that has been

hermetically sealed.

For more information, see

Operating principle, page 16

3 Technical specifications

14 TWH 200 EV EN-7602142 - v11 - 24042019

Page 15

4 Description of the product

4.1 General description

The TWH 200 EV water heater has the following specifications:

Floor-standing thermodynamic storage water heater

Thermodynamic unit extracting energy from the air

Remote control panel (wireless) with display of the volume of heated

water and timer programming

Steatite immersion heater (2.4 kW)

Enamelled tank, protected by impressed current anode

Very thick insulation (0% CFCs)

The thermodynamic water heater is a hot water tank heated by:

The heat pump (up to 65°C)

The immersion heater (Electrical back-up – AUTO and BOOST mode)

(up to 75°C)

Management of the energy consumption:

To provide energy savings, the water heater is designed to be connected

to a day/night or HP/HC switch. This switch will authorise the water heater

to automatically start up at the energy provider's scheduled off-peak rate,

therefore at the lowest tariff. The switch has three positions enabling the

water heater to run in auto or continuous mode, or be switched off.

4 Description of the product

EN-7602142 - v11 - 24042019 TWH 200 EV 15

Page 16

4.2 Main components

1 Air discharge connection, Ø160

2 Filter access hatch

3 Cover

4 Fan

5 Evaporator

6 Expansion valve

7 Control system

8 Control module

9 Housing for temperature sensor

10 Impressed current anode

11 Safety thermostat

12 Steatite immersion heater

13 Housing for temperature sensor

14 Cold water inlet

15 Condenser

16 Domestic hot water outlet

17 HP pressure switch

18 LP pressure switch

19 Pressure measurement point – High pressure (HP)

20 Compressor

21 Pressure measurement point – Low pressure (LP)

22 Air filter

23 Air intake connection, Ø160

24 Domestic air fitting, Ø80

25 Plug, Ø80

4.3

Operating principle

The thermodynamic water heater groups the domestic hot water tank and

controlled mechanical ventilation functions. The calories contained in the

air extracted from the building are used for the production of domestic hot

water.

The refrigerant circuit is a closed circuit in which the R-134a refrigerant

plays the role of an energy carrier.

The heat from the intake air is transferred to the refrigerant in the finned

heat exchanger at a low evaporation temperature.

The refrigerant is drawn in, in vapour form, by a compressor which raises it

to a higher pressure and temperature and sends it to the condenser. In the

condenser, the heat extracted in the evaporator and some of the energy

absorbed by the compressor are released into the water.

The refrigerant is depressurised in the thermostatic expansion valve and

then cooled. The refrigerant can again extract the heat contained in the

intake air from the evaporator.

Fig.1

M002826-G

9

13

14

15

16

23

22

20

8

17

18

21

19

10

11

12

5

4

6

7

1

2

3

25

24

4 Description of the product

16 TWH 200 EV EN-7602142 - v11 - 24042019

Page 17

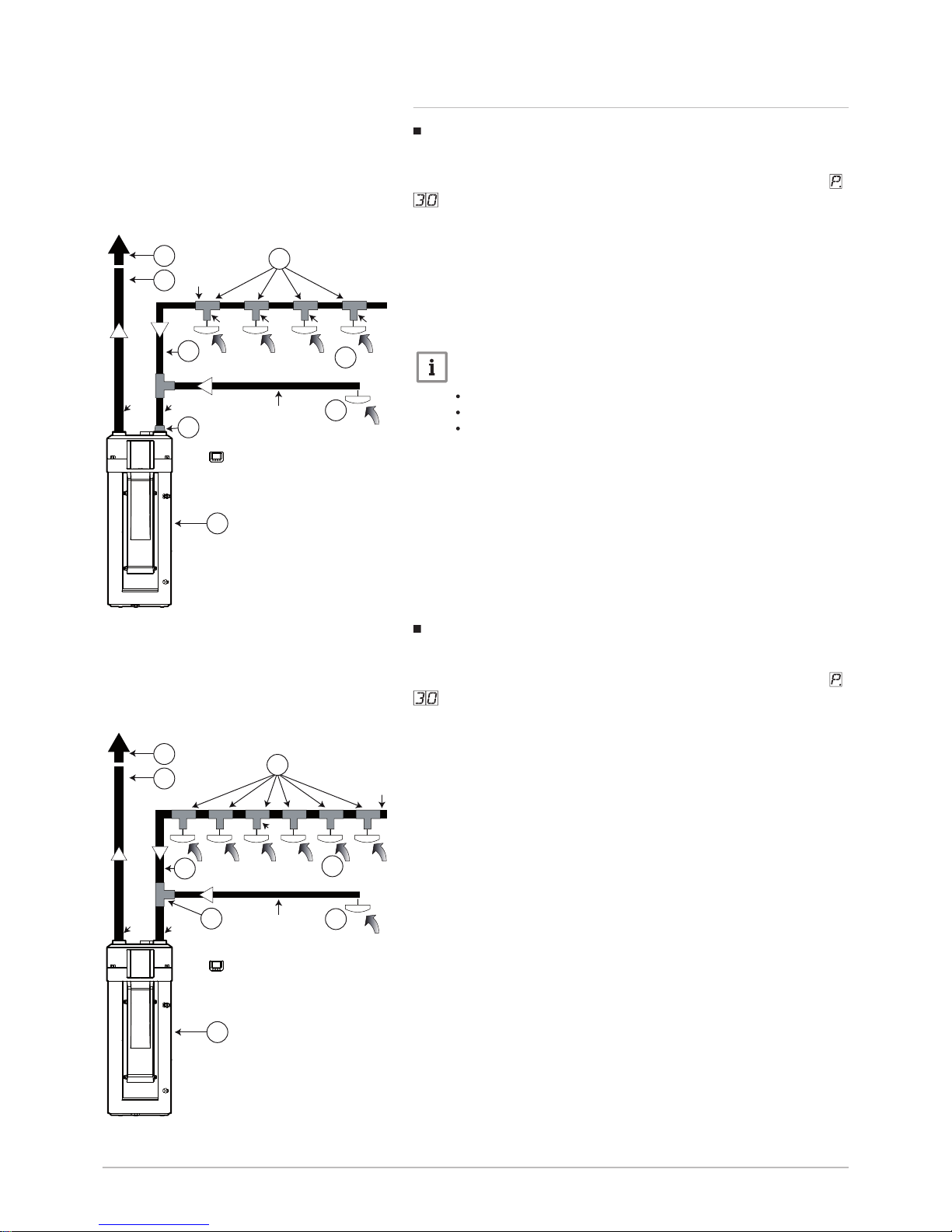

4.3.1 Linear network

Linear network with a maximum of four sanitary extractor fan

outlets

In this configuration, the air duct vacuum pressure set point (parameter

) must be set to 1 (= 100 Pa).

1 Sanitary extractor fan outlets, Ø 80 mm (bathroom/WC)

2 Kitchen extractor fan outlet, Ø 125 mm

3 Thermodynamic water heater

4 Roof-mounted discharge

5 Duct (insulated if outside of the heated area)

6 125/80 Tee fitting

7 160 Tee fitting + 160/125 reduction sleeve

Important

This configuration may include a maximum of:

2 bathrooms

2 WCs

1 kitchen

Linear network with a maximum of 6 sanitary extractor fan

outlets

In this configuration, the air duct vacuum pressure set point (parameter

) must be set to 1 (= 100 Pa).

1 Sanitary extractor fan outlets, Ø 80 mm (bathroom/WC)

2 Kitchen extractor fan outlet, Ø 125 mm

3 Thermodynamic water heater

4 Roof-mounted discharge

5 Duct (insulated if outside of the heated area)

6 160/80 Tee fitting + 160/80 reduction sleeve

7 160/80 reduction sleeve

Fig.2

M002827-E

1

7

5

2

Ø125

Ø125

Ø160

Ø125

Ø80 Ø80 Ø80 Ø80

4

5

6

3

Fig.3

C004747-A

1

5

7

2

Ø125

Ø160

Ø160

Ø160

Ø80

4

5

3

6

4 Description of the product

EN-7602142 - v11 - 24042019 TWH 200 EV 17

Page 18

Important

This configuration may include a maximum of:

3 bathrooms

3 WCs

1 kitchen

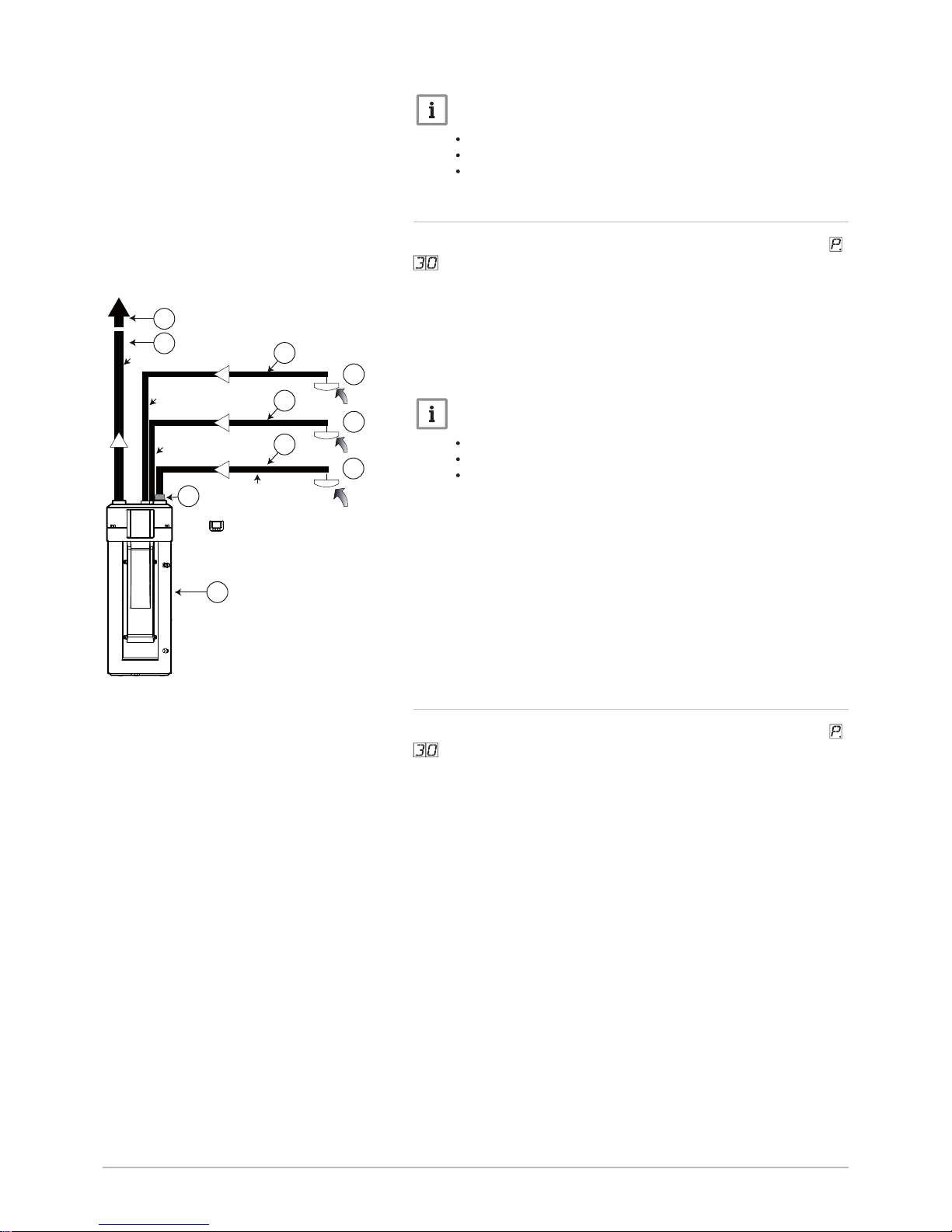

4.3.2 Direct connection to the thermodynamic water heater

In this configuration, the air duct vacuum pressure set point (parameter

) must be set to 1 (= 100 Pa).

1 Sanitary extractor fan outlets, Ø 80 mm (bathroom / WC)

2 Kitchen extractor fan outlet, Ø 125 mm

3 Thermodynamic water heater

4 Roof-mounted discharge

5 Duct (insulated if outside of the heated area)

6 160/125 reduction sleeve

Important

This configuration may include a maximum of:

1 bathroom

1 WC

1 kitchen

4.3.3 Multi-duct network with collector

In this configuration, the air duct vacuum pressure set point (parameter

) must be set to 2 (= 125 Pa).

Fig.4

C004496-B

1

1

6

2

Ø125

Ø160

Ø80

Ø80

4

5

5

5

5

3

4 Description of the product

18 TWH 200 EV EN-7602142 - v11 - 24042019

Page 19

1 Sanitary extractor fan outlets, Ø 80 mm (bathroom/WC)

2 Kitchen extractor fan outlet, Ø 125 mm

3 Thermodynamic water heater

4 Duct (insulated if outside of the heated area)

5 Wall-mounted discharge

6 Collector

7 160 Tee fitting + 160/125 reduction sleeve

Important

This configuration may include a maximum of:

3 bathrooms

3 WCs

1 kitchen

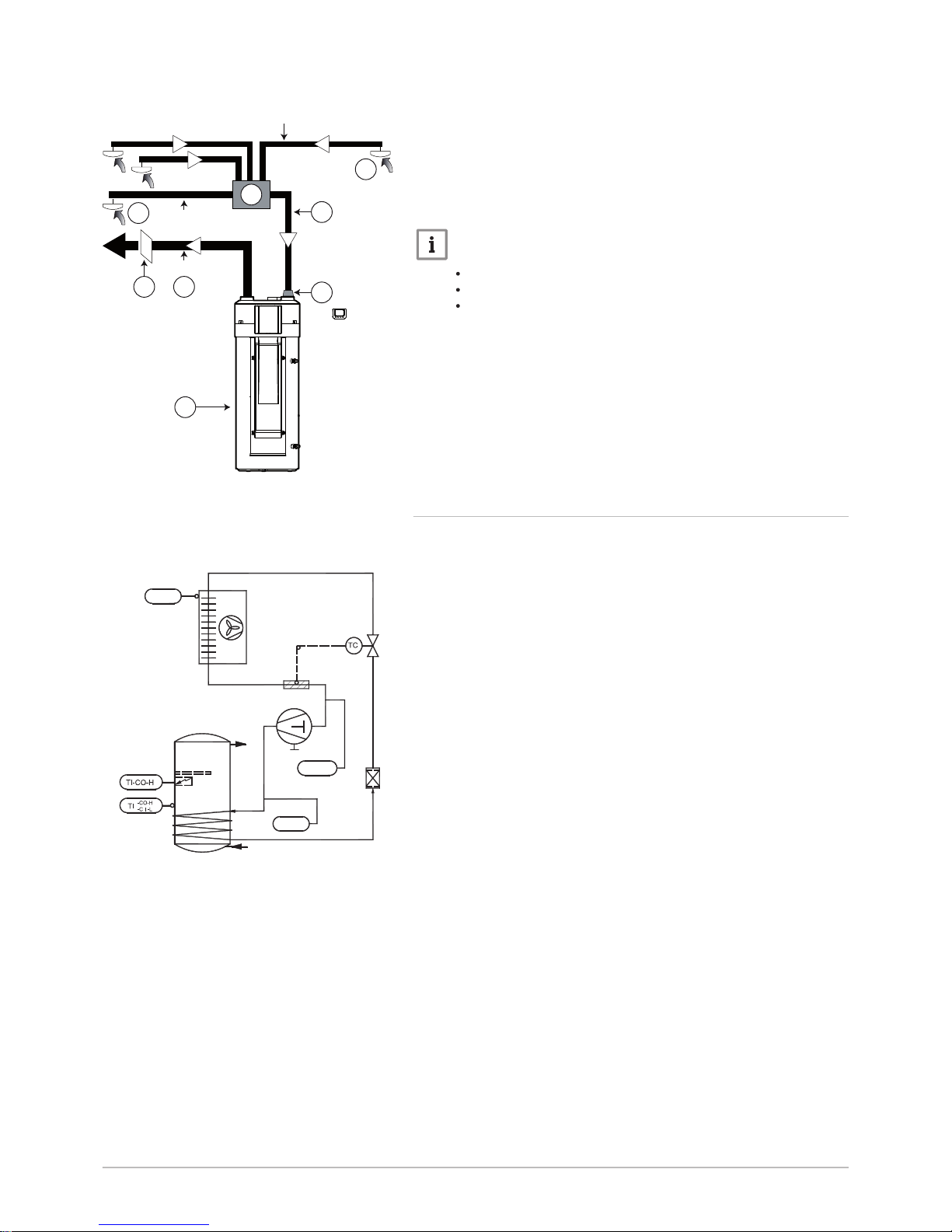

4.3.4 Schematic diagram

1 Compressor

2 LP pressure switch

3 Condenser

4 Domestic hot water tank

5 Steatite immersion heater

6 Impressed current anode

7 Temperature controller (heat pump)

8 Safety thermostat (immersion heater)

9 Filter-drier

10 Thermostatic expansion valve

11 HP pressure switch

12 Ambient air sensor

13 Evaporator with air filter

14 Expansion valve bulb

Fig.5

M002828-E

1

2

3

4

7

Ø80

6

Ø125

Ø160

45

Fig.6

M002829-C

11

2

1

14

13

12

4

5

6

8

7

3

9

10

4 Description of the product

EN-7602142 - v11 - 24042019 TWH 200 EV 19

Page 20

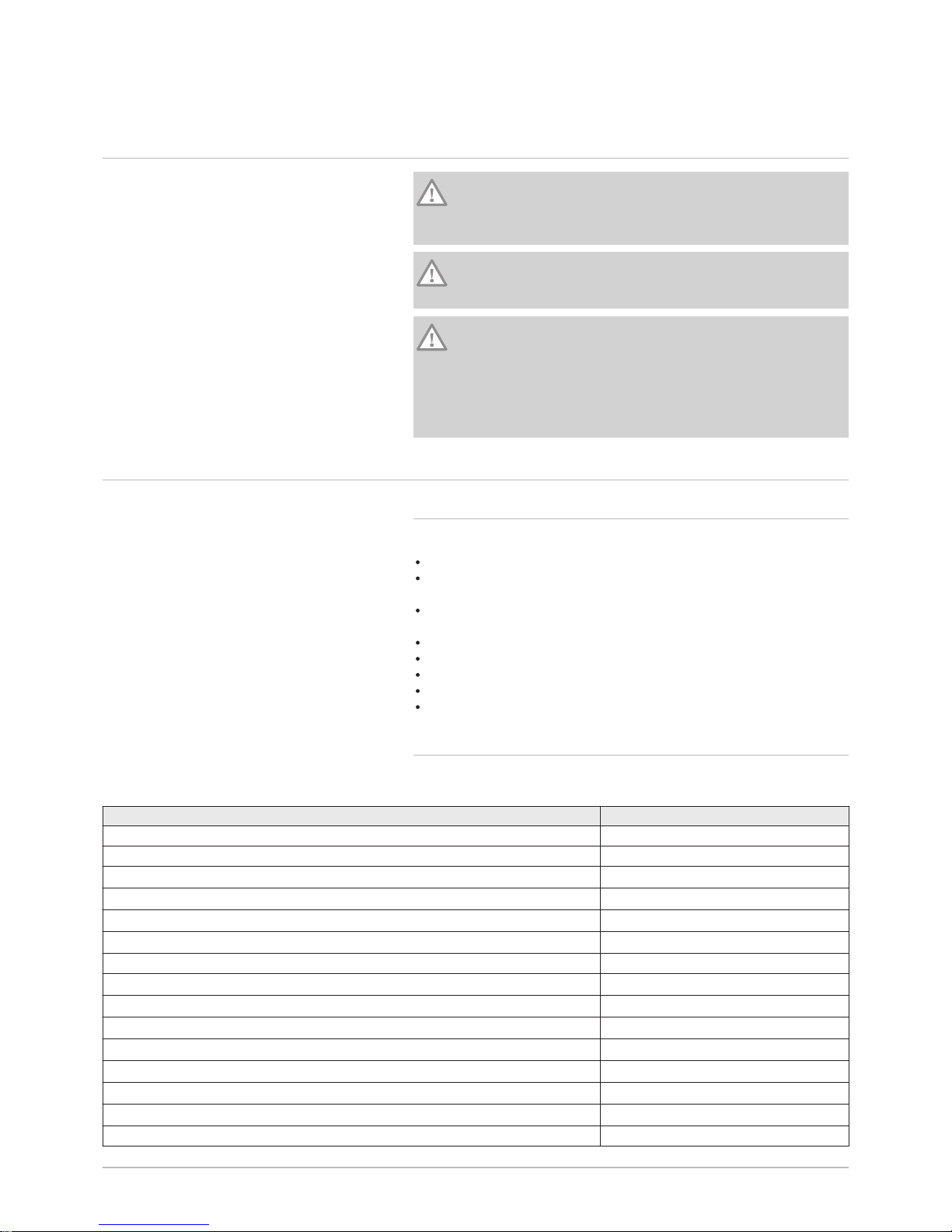

5 Installation

5.1 Installation regulations

Caution

The appliance must be installed and maintained by a certified

professional in accordance with prevailing statutory texts and

codes of practice.

Caution

Install the thermodynamic water heater in a dry, frost-free location

which is within the thermal envelope of the home.

Caution

Attach the CMV network ducts to the water heater using adhesive

tape or a clamp, ensuring compliance with the requirements of

standard 60 335-1 article 22.111 relating to the strength of this

assembly. Ensure that there are no gaps in the sealing, as this will

prevent issues including excess energy consumption, poor

ventilation in the home, or a lack of domestic hot water.

5.2

Package list

5.2.1 Standard delivery

The delivery includes:

The thermodynamic water heater

The control system display, not fitted so it can be installed in the desired

room

A dielectric union (supplied in the documentation bag for the water

heater)

A condensates discharge hose

One screw bag

A refrigerant sticker with its manual

The Installation and Service Manual

The User Guide

5.2.2 Accessories

Tab.3

Accessories Package

Gripping kit ER239

Trim for fitting the control module on the appliance EH290

Battery-powered humidity-controlled extractor fan for kitchens 10/40/90 m3/h

EH703

Battery-powered humidity-controlled extractor fan for kitchens 10/45/135 m3/h

EH293

Humidity-controlled extractor fan with pull-cord for kitchens 10/40/90 m3/h

EH707

Humidity-controlled extractor fan with pull-cord for kitchens 10/45/135 m3/h

EH297

Battery-powered humidity-controlled extractor fan for bathrooms 5/40 m3/h EH299

Humidity-controlled extractor fan for bathrooms 5/40/30 m3/h

EH882

Humidity-controlled extractor fan for bathrooms 15/45/40 m3/h

EH883

Battery-powered humidity-controlled extractor fan for bathrooms 10/45 m3/h

EH302

Battery-powered humidity-controlled extractor fan for bathrooms 15/45/45 m3/h

EH712

Battery-powered humidity-controlled extractor fan for bathrooms 10/40 m3/h

EH301

Battery-powered humidity-controlled extractor fan for WC 5/30 m3/h

EH303

Humidity-controlled air intake kit 5/45 m3/h

EH715

Plastic sleeve, Ø 125 for extractor fan EH307

5 Installation

20 TWH 200 EV EN-7602142 - v11 - 24042019

Page 21

Accessories Package

Roof cowl, Ø 160 (tile colour) EH309

Roof cowl, Ø 160 (slate colour) EH370

Wall duct with grille, Ø 160 EH208

External grille, Ø 160 (aluminium) EH209

Flexible insulated duct, Ø 80 (insulation thickness 50 mm and length 6 m) EH312

Flexible insulated duct, Ø 125 (insulation thickness 50 mm and length 6 m) EH313

Flexible insulated duct, Ø 160 (insulation thickness 50 mm and length 6 m) EH314

Collector unit with 6 x Ø 80 connections and 2 x Ø 125 connections EH315

PPE duct, Ø 125, length 2x1 m + sleeve (2x) EH317

PPE duct, Ø 160, length 2x1 m + sleeve (2x) EH272

90° elbow (PPE) Ø 160 (2x) + sleeve (2x) EH273

90° elbow (PPE) Ø 125 (2x) + sleeve (2x) EH319

PPE sleeve, Ø 160 (2x) EH274

PPE sleeve, Ø 125 (2x) EH321

Galvanised straight Tee fitting, 90°, Ø 125 EH322

Galvanised straight Tee fitting, 90°, Ø 160 EH323

Galvanised straight Tee fitting, 90°, Ø 125x80 EH324

Galvanised straight Tee fitting, 90°, Ø 160x125 EH325

Galvanised reduction, Ø 125x80 EH326

Galvanised reduction, Ø 160x80 EH327

Galvanised reduction, Ø 160x125 EH328

Galvanised sleeve, Ø 125 EH329

Galvanised sleeve, Ø 160 EH330

Set of 10 clamps, Ø 80 - Ø 125 EH331

Set of 2 clamps, Ø 160 EH207

Filter EH334

5.2.3 System configuration

The system configuration must comply with the Technical Specification

14.5/17-2285_V1 and its commercial extension 14.5/17-2285_V1-E1.

For more details, consult the Technical Specification.

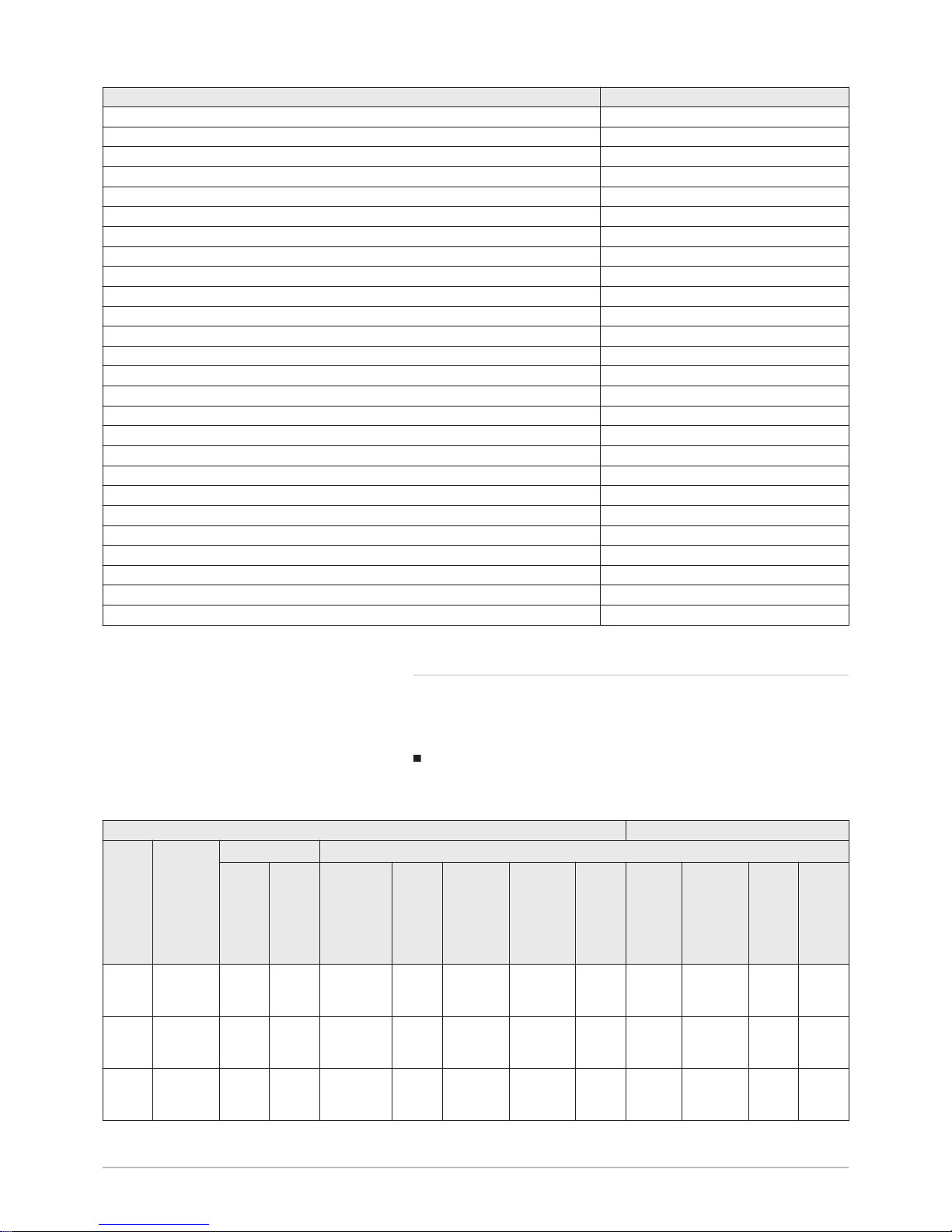

Sizing a type A humidity-controlled VMC

Tab.4

Basic configuration Additional technical components

Type

of

home

Humid

rooms

Air inlet module

Extractor fans: flow rate (m3/h) / package no.

Living

room

Flow

rate

(m

3

/h)

Per

bed

room

Flow

rate

(m

3

/h)

Kitchen Bath

room

BthRm /

WC1

Bath

room /

WC2

WC Other

bath

room

Other

bath

room /

WC

Other WCWash

room

Studio

flat

1 bath

room/WC

2x45 – 10/40/90

EH707 or

EH703

– 15/45/45

EH712

- - 5/40

EH299

15/45/45

EH712

– 5/40

EH299

Studio

flat

1 bath

room/WC

2x45 – 10/40/90

EH707 or

EH703

– 15/45/45

EH712

- - - 15/45/45

EH712

5/30

EH303

5/40

EH299

Studio

flat

1 bath

room +

1 WC

2x45 – 10/40/90

EH707 or

EH703

10/40

EH301

- - 5/30

EH303

10/40

EH301

5/40/30

EH882

5/30

EH303

5/40

EH299

5 Installation

EN-7602142 - v11 - 24042019 TWH 200 EV 21

Page 22

Basic configuration Additional technical components

Type

of

home

Humid

rooms

Air inlet module

Extractor fans: flow rate (m3/h) / package no.

Living

room

Flow

rate

(m3/h)

Per

bed

room

Flow

rate

(m3/h)

Kitchen Bath

room

BthRm /

WC1

Bath

room /

WC2

WC Other

bath

room

Other

bath

room /

WC

Other WCWash

room

1-bed

flat

1 bath

room/WC

2x30 30 10/40/90

EH707 or

EH703

– 15/45/40

EH883

- - 5/40

EH299

15/45/45

EH712

– 5/40

EH299

1-bed

flat

1 bath

room/WC

2x30 30 10/40/90

EH707 or

EH703

– 15/45/40

EH883

- - - 15/45/45

EH712

5/30

EH303

5/40

EH299

1-bed

flat

1 bath

room +

1 WC

2x30 30 10/40/90

EH707 or

EH703

10/45

EH302

- - 5/30

EH303

10/45

EH302

5/40/30

EH882

5/30

EH303

5/40

EH299

2-bed

flat

1 bath

room/WC

2x30 30 10/45/135

EH297 or

EH293

– 15/45/40

EH883

- - 5/40

EH299

15/45/45

EH712

– 5/40

EH299

2-bed

flat

1 bath

room/WC

2x30 30 10/45/135

EH297 or

EH293

– 15/45/40

EH883

- - - 15/45/45

EH712

5/30

EH303

5/40

EH299

2-bed

flat

1 bath

room +

1 WC

2x30 30 10/45/135

EH297 or

EH293

10/45

EH302

- - 5/30

EH303

10/45

EH302

5/40/30

EH882

5/30

EH303

5/40

EH299

3-bed

flat

1 bath

room/WC

45 30 10/45/135

EH297 or

EH293

– 15/45/40

EH883

- - 5/40

EH299

15/45/45

EH712

– 5/40

EH299

3-bed

flat

1 bath

room/WC

45 30 10/45/135

EH297 or

EH293

– 15/45/40

EH883

- - - 15/45/45

EH712

5/30

EH303

5/40

EH299

3-bed

flat

1 bath

room +

1 WC

45 30 10/45/135

EH297 or

EH293

10/45

EH302

- - 5/30

EH303

10/45

EH302

5/40/30

EH882

5/30

EH303

5/40

EH299

4-bed

flat

1 bath

room/WC

45 30 10/45/135

EH297 or

EH293

– 15/45/40

EH883

- - 5/40

EH299

15/45/45

EH712

– 5/40

EH299

4-bed

flat

1 bath

room/WC

45 30 10/45/135

EH297 or

EH293

– 15/45/40

EH883

- - - 15/45/45

EH712

5/30

EH303

5/40

EH299

4-bed

flat

1 bath

room +

1 WC

45 30 10/45/135

EH297 or

EH293

10/45

EH302

- - 5/30

EH303

10/45

EH302

5/40/30

EH882

5/30

EH303

5/40

EH299

5-bed

flat

2 bath

rooms/W

C

45 30 10/45/135

EH297 or

EH293

– 15/45/40

EH883

15/45/40

EH883

– 5/40

EH299

15/45/45

EH712

– 5/40

EH299

5-bed

flat

2 bath

rooms/W

C

45 30 10/45/135

EH297 or

EH293

– 15/45/40

EH883

15/45/40

EH883

- - 15/45/45

EH712

5/30

EH303

5/40

EH299

5-bed

flat

1 bath

room/WC

1 bath

room +

1 WC

45 30 10/45/135

EH297 or

EH293

10/45

EH302

15/45/40

EH883

– 5/30

EH303

– 15/45/45

EH712

5/30

EH303

5/40

EH299

6-bed

flat

2 bath

rooms/W

C

45 30 10/45/135

EH297 or

EH293

– 15/45/40

EH883

15/45/40

EH883

– 5/40

EH299

15/45/45

EH712

– 5/40

EH299

5 Installation

22 TWH 200 EV EN-7602142 - v11 - 24042019

Page 23

Basic configuration Additional technical components

Type

of

home

Humid

rooms

Air inlet module

Extractor fans: flow rate (m3/h) / package no.

Living

room

Flow

rate

(m3/h)

Per

bed

room

Flow

rate

(m3/h)

Kitchen Bath

room

BthRm /

WC1

Bath

room /

WC2

WC Other

bath

room

Other

bath

room /

WC

Other WCWash

room

6-bed

flat

2 bath

rooms/W

C

45 30 10/45/135

EH297 or

EH293

– 15/45/40

EH883

15/45/40

EH883

- - 15/45/45

EH712

5/30

EH303

5/40

EH299

6-bed

flat

1 bath

room/WC

1 bath

room +

1 WC

45 30 10/45/135

EH297 or

EH293

10/45

EH302

15/45/40

EH883

– 5/30

EH303

– 15/45/45

EH712

5/30

EH303

5/40

EH299

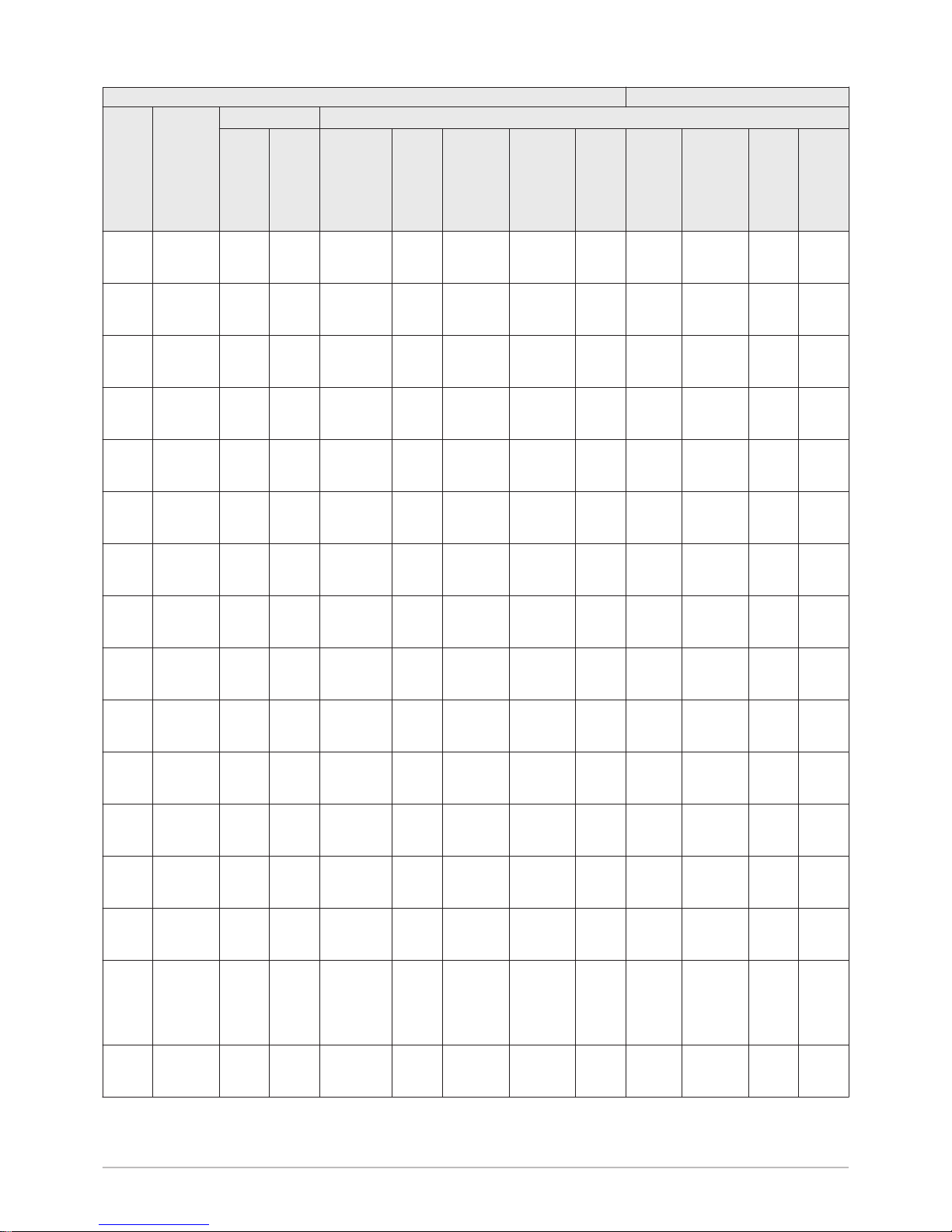

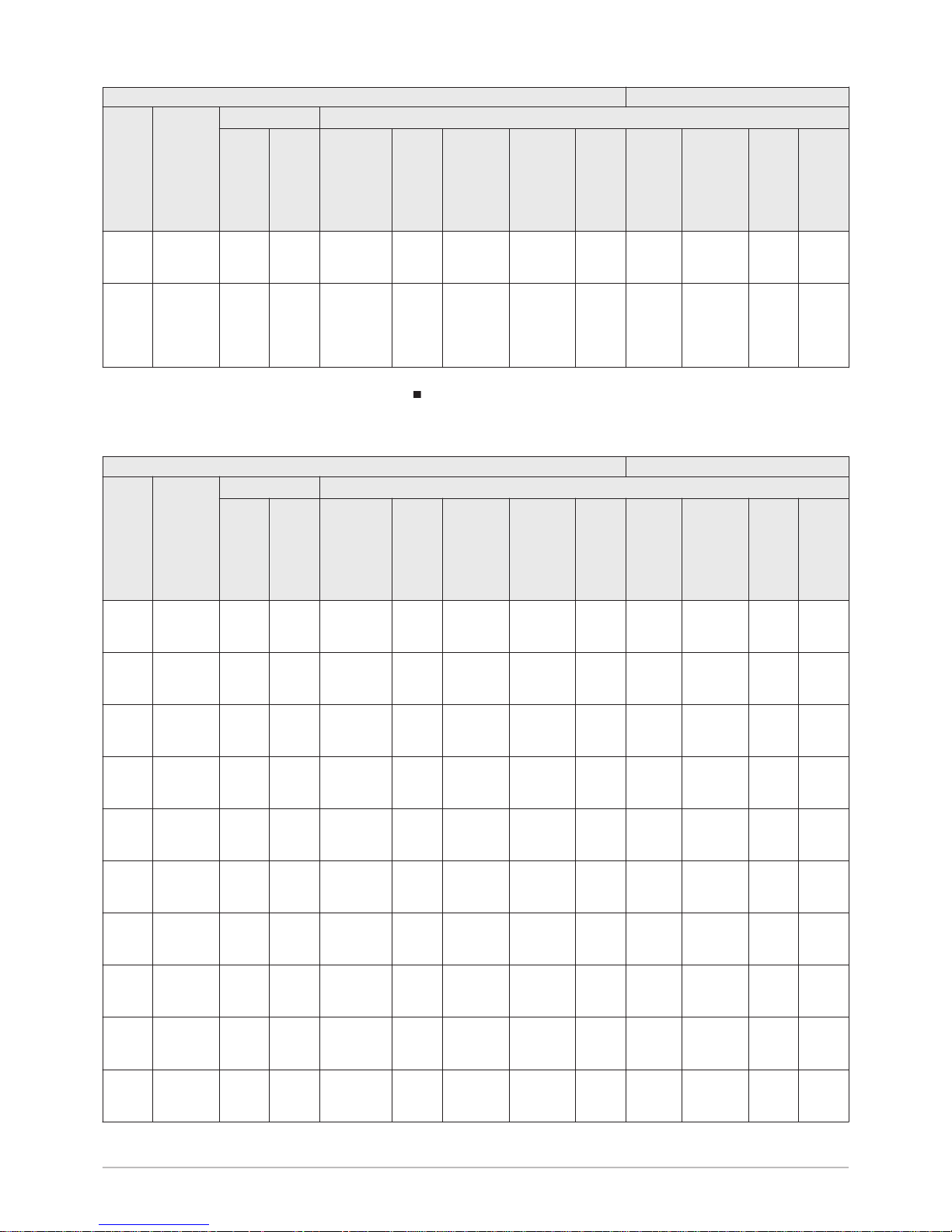

Sizing a type B humidity-controlled VMC

Tab.5

Basic configuration Additional technical components

Type

of

home

Humid

rooms

Air inlet module

Extractor fans: flow rate (m3/h) / package no.

Living

room

Flow

rate

(m

3

/h)

Per

bed

room

Flow

rate

(m

3

/h)

Kitchen Bath

room

BthRm /

WC1

Bath

room /

WC2

WC Other

bath

room

Other

bath

room /

WC

Other WCWash

room

Studio

flat

1 bath

room/WC

2x5/45

EH715

or 45

– 10/40/90

EH707 or

EH703

– 15/45/45

EH712

- - 5/40

EH299

15/45/45

EH712

– 5/40

EH299

Studio

flat

1 bath

room/WC

2x5/45

EH715

or 45

– 10/40/90

EH707 or

EH703

– 15/45/45

EH712

- - - 15/45/45

EH712

5/30

EH303

5/40

EH299

Studio

flat

1 bath

room +

1 WC

2x5/45

EH715

or 45

– 10/40/90

EH707 or

EH703

10/40

EH301

- - 5/30

EH303

10/40

EH301

5/40/30

EH882

5/30

EH303

5/40

EH299

1-bed

flat

1 bath

room/WC

5/45

EH715

5/45

EH715

10/40/90

EH707 or

EH703

– 15/45/45

EH712

- - 5/40

EH299

15/45/45

EH712

– 5/40

EH299

1-bed

flat

1 bath

room/WC

5/45

EH715

5/45

EH715

10/40/90

EH707 or

EH703

– 15/45/45

EH712

- - - 15/45/45

EH712

5/30

EH303

5/40

EH299

1-bed

flat

1 bath

room +

1 WC

5/45

EH715

5/45

EH715

10/40/90

EH707 or

EH703

10/40

EH301

- - 5/30

EH303

10/40

EH301

5/40/30

EH882

5/30

EH303

5/40

EH299

2-bed

flat

1 bath

room/WC

5/45

EH715

5/45

EH715

10/45/135

EH297 or

EH293

– 15/45/45

EH712

- - 5/40

EH299

15/45/45

EH712

– 5/40

EH299

2-bed

flat

1 bath

room/WC

5/45

EH715

5/45

EH715

10/45/135

EH297 or

EH293

– 15/45/45

EH712

- - - 15/45/45

EH712

5/30

EH303

5/40

EH299

2-bed

flat

1 bath

room +

1 WC

5/45

EH715

5/45

EH715

10/45/135

EH297 or

EH293

10/40

EH301

- - 5/30

EH303

10/40

EH301

5/40/30

EH882

5/30

EH303

5/40

EH299

3-bed

flat

1 bath

room/WC

5/45

EH715

5/45

EH715

10/45/135

EH297 or

EH293

– 15/45/45

EH712

- - 5/40

EH299

15/45/45

EH712

– 5/40

EH299

5 Installation

EN-7602142 - v11 - 24042019 TWH 200 EV 23

Page 24

Basic configuration Additional technical components

Type

of

home

Humid

rooms

Air inlet module

Extractor fans: flow rate (m3/h) / package no.

Living

room

Flow

rate

(m3/h)

Per

bed

room

Flow

rate

(m3/h)

Kitchen Bath

room

BthRm /

WC1

Bath

room /

WC2

WC Other

bath

room

Other

bath

room /

WC

Other WCWash

room

3-bed

flat

1 bath

room/WC

5/45

EH715

5/45

EH715

10/45/135

EH297 or

EH293

– 15/45/45

EH712

- - - 15/45/45

EH712

5/30

EH303

5/40

EH299

3-bed

flat

1 bath

room +

1 WC

5/45

EH715

5/45

EH715

10/45/135

EH297 or

EH293

10/40

EH301

- - 5/30

EH303

10/40

EH301

5/40/30

EH882

5/30

EH303

5/40

EH299

4-bed

flat

1 bath

room/WC

5/45

EH715

5/45

EH715

10/45/135

EH297 or

EH293

– 15/45/45

EH712

- - 5/40

EH299

15/45/45

EH712

– 5/40

EH299

4-bed

flat

1 bath

room/WC

5/45

EH715

5/45

EH715

10/45/135

EH297 or

EH293

– 15/45/45

EH712

- - - 15/45/45

EH712

5/30

EH303

5/40

EH299

4-bed

flat

1 bath

room +

1 WC

5/45

EH715

5/45

EH715

10/45/135

EH297 or

EH293

10/40

EH301

- - 5/30

EH303

10/40

EH301

5/40/30

EH882

5/30

EH303

5/40

EH299

5-bed

flat

2 bath

rooms/W

C

5/45

EH715

5/45

EH715

10/45/135

EH297 or

EH293

– 15/45/45

EH712

15/45/40

EH883

– 5/40

EH299

15/45/45

EH712

– 5/40

EH299

5-bed

flat

2 bath

rooms/W

C

5/45

EH715

5/45

EH715

10/45/135

EH297 or

EH293

– 15/45/45

EH712

15/45/40

EH883

- - 15/45/45

EH712

5/30

EH303

5/40

EH299

5-bed

flat

1 bath

room/WC

1 bath

room +

1 WC

5/45

EH715

5/45

EH715

10/45/135

EH297 or

EH293

10/40

EH301

15/45/40

EH883

– 5/30

EH303

– 15/45/45

EH712

5/30

EH303

5/40

EH299

6-bed

flat

2 bath

rooms/W

C

5/45

EH715

5/45

EH715

10/45/135

EH297 or

EH293

– 15/45/45

EH712

15/45/40

EH883

– 5/40

EH299

15/45/45

EH712

– 5/40

EH299

6-bed

flat

2 bath

rooms/W

C

5/45

EH715

5/45

EH715

10/45/135

EH297 or

EH293

– 15/45/45

EH712

15/45/40

EH883

- - 15/45/45

EH712

5/30

EH303

5/40

EH299

6-bed

flat

1 bath

room/WC

1 bath

room +

1 WC

5/45

EH715

5/45

EH715

10/45/135

EH297 or

EH293

10/40

EH301

15/45/40

EH883

– 5/30

EH303

– 15/45/45

EH712

5/30

EH303

5/40

EH299

5 Installation

24 TWH 200 EV EN-7602142 - v11 - 24042019

Page 25

5.3 Storing and transporting the appliance

Caution

Have 2 people available.

Use a 3-wheel hand truck.

Handle the appliance with gloves.

The appliance cover cannot be used for transport operations.

The cover is not capable of withstanding heavy weights.

Ensure the room height is a minimum of approximately 2.10 m.

Important

To facilitate handling of the appliance and prevent damage, it is

recommended that the ER239 gripper kit is used.

The thermodynamic water heater must be stored and transported in its

packaging and not filled with water.

Permissible ambient transport and storage temperatures: -15 to +60°C.

5.3.1

Transport

Important

We recommend shipping the appliance vertically.

It is possible to transport the appliance horizontally over short distances

and only whilst resting on its rear panel.

5 Installation

EN-7602142 - v11 - 24042019 TWH 200 EV 25

Page 26

Caution

It is prohibited to stack or set down the appliance any of its other

sides, as this may lead to malfunctions or faults.

5.4

Choice of the location

5.4.1

Data plate

The data plate must be accessible at all times.

The data plate identifies the product and provides the following

information:

Appliance type

Date of manufacture (Year - Week)

Serial number

5.4.2

Position of the appliance

Caution

When installing the appliance, comply with the IP21 protection

rating.

Caution

Do not position the air intake in areas exposed to gas, vapours

or dust. Do not position the air intake in an atmosphere with

chlorine (swimming pool) or fluorine (aerosols, detergents,

solvents, etc.).

Temperature of the air extracted by the heat pump, for optimum

operation: approximately 20°C.

Important

Fig.7

MW-1000371-1

Fig.8

M002830-D

5 Installation

26 TWH 200 EV EN-7602142 - v11 - 24042019

Page 27

Recommended positions

Install the appliance in a dry, frost-free room at a minimum temperature

of 7 °C (optimum temperature: 20 °C).

Install the appliance on a flat, solid surface.

Install the appliance on a base frame. The base frame must be able to

support the load sufficiently at all times.

Free installation

1. Allow sufficient space around the appliance to allow access and

facilitate maintenance.

Installation in a cupboard

1. Provide a movable partition to allow access to the appliance and

facilitate maintenance operations.

Fig.9

=

=

650

min.

400

1675

min. 700

C004118-D

Fig.10

C004136-B

650

50°

Fig.11

C004137-B

650

700

50°

5 Installation

EN-7602142 - v11 - 24042019 TWH 200 EV 27

Page 28

5.4.3 Main dimensions

Fig.12

M002832-E

1675

1332

1069

249

667

50°

133°

1

2

3

(1)

o 632

o 160

o 160

o 80

o 80

346

360

266

154

18

147

1 Domestic hot water outlet G 3/4" – Dielectric union

fitted

2 Domestic cold water inlet G 3/4"

3 Condensates outlet

(1) Adjustable feet

For more information, see

Positioning the appliance, page 29

5 Installation

28 TWH 200 EV EN-7602142 - v11 - 24042019

Page 29

5.5 Positioning the appliance

5.5.1 Unpacking the appliance

Caution

Remove all packaging materials. Check that the contents are

intact. If you notice a defect, do not use the appliance and contact

the supplier.

1. Remove the 3 retaining screws.

2. Lift and remove the cover.

Warning

Lift the cover, ensuring it remains along the vertical axis. Risk of

damage to the insertion guides.

Fig.13

C004122-D

1

2

5 Installation

EN-7602142 - v11 - 24042019 TWH 200 EV 29

Page 30

3. Undo the 3 nuts placed on top of the compressor retaining

components and discard.

4. Remove the compressor retaining components and discard.

5. Remove the control system display from its transport housing.

6. Refit the cover.

Warning

Check that no foreign bodies have made their way inside the

cover.

7. Put the retaining screws in place.

Fig.14

3

4

M002965-B

Fig.15

6

5

7

M002966-B

5 Installation

30 TWH 200 EV EN-7602142 - v11 - 24042019

Page 31

5.5.2 Positioning the appliance

See

Instructions affixed to the appliance packaging

Caution

After positioning the appliance, wait 3 hours before

commissioning.

5.5.3

Levelling the appliance

1. Level the appliance using the adjustable feet.

(1)

Adjustable feet

Basic dimension: 4 mm

Possible adjustment: from 4 mm to 21 mm

5.6 Water connections

Caution

Before attaching the water connections, it is essential to flush the

circuits to remove any particles which risk causing damage to

certain components (safety valve, pumps, valves, etc.).

If flushing has to be done using an aggressive product, neutralise

the rinsing water before disposing of it in the waste water network.

Important

Using hoses which are too short or too rigid encourages the

transmission of vibrations and the production of noises.

5.6.1 Connecting the water heater to the domestic water circuit

When making the connection, it is imperative that the standards and

corresponding local directives be respected.

Fig.16

M002833-C

(1)

19

5 Installation

EN-7602142 - v11 - 24042019 TWH 200 EV 31

Page 32

Specific precautions

Caution

Do not connect the domestic hot water connection directly to

copper pipes in order to prevent galvanic couplings in iron/copper

(risk of corrosion).

It is compulsory to fit the domestic hot water connection with a

dielectric union (provided).

Safety valve or safety unit

Caution

Germany: In accordance with the safety regulations, a safety

unit calibrated to 0.6 MPa (6 bar) must be fitted on the domestic

cold water inlet on the domestic hot water tank.

Belgium: In accordance with the safety regulations, a safety unit

calibrated to 0.7 MPa (7 bar), and approved by Belgaqua, must

be fitted on the domestic cold water inlet on the domestic hot

water tank.

Other countries: In accordance with the safety regulations, a

safety unit calibrated to 0.7 MPa (7 bar) must be fitted on the

domestic cold water inlet on the domestic hot water tank.

We recommend NF-marked hydraulic diaphragm safety units.

Integrate the safety valve in the cold water circuit.

Install the safety valve close to the water heater in a place with easy

access.

Sizing

The diameter of the safety unit and its connection to the water heater must

be at least equal to the diameter of the domestic cold water inlet on the

water heater.

There must be no cut-off devices between the safety valve or unit and

the water heater.

The discharge pipe in the safety valve or unit must not be blocked.

To prevent the flow of water being hindered or obstructed in the event of a

pressure surge:

The discharge pipe from the safety unit must have a continuous and

sufficient gradient, and its cross section must be at least equal to the

cross section of the opening of the safety unit outlet (to prevent the flow

of water being hindered if the pressure is too high).

The cross section of the discharge pipe from the safety unit must be at

least equal to the cross section of the opening on the safety unit outlet

Pressure reducer

If the supply pressure exceeds 80% of the safety valve or unit calibration

(e.g.: 0.55 MPa/5.5 bar for a safety unit calibrated to 0.7 MPa/7 bar), a

pressure reducer must be located upstream of the appliance.

Install the pressure reducer downstream of the water meter in such a way

as to ensure the same pressure in all of the system's pipes.

Measures to take to prevent hot water flow return

Fit a non-return valve to the domestic cold water circuit.

5 Installation

32 TWH 200 EV EN-7602142 - v11 - 24042019

Page 33

5.6.2 Fitting the dielectric union

Important

The dielectric union and its gasket are provided in the

documentation bag.

1. Screw the dielectric union onto the domestic hot water outlet, inserting

the gasket.

5.7

Air duct connections

1. Ensure that the intake and outlet tubes are held in place with clamps.

2. If the ducts are routed outside of the heated area, they must be

insulated.

3. Check the tightness after assembly.

Caution

Do not route the intake and outlet ducts on top of the filter.

Fig.17

C004590-C

1

Fig.18

C004123-C

5 Installation

EN-7602142 - v11 - 24042019 TWH 200 EV 33

Page 34

5.8 Condensate discharge

1. Fit a siphon into the condensate discharge duct.

Caution

If no siphon is fitted, there is a risk of problems with the discharge

of condensates when the compressor is running.

2. Attach the run-off collector.

5.9

Fitting and connecting the control module

The regulator control module is not fitted on the water heater when

delivered, so that it can be installed in one of the living areas, to make it

easier to use.

This control module can be installed remotely with a wire or radio

connection, or integrated.

5.9.1 Radio connection (installation strongly recommended)

Fitting the control module

Warning

Choose a location which enables good radio reception.

See

To test the quality of the radio reception, see the section: “Radio

test menu”.

Important

The quality of the radio reception may be affected by the

construction materials used within the home (thickness of the

walls or floor tiles, types of materials used).

Placing a hand in front of the control module may affect the

reception.

Fig.19

M002834-E

1

min. 200

5 Installation

34 TWH 200 EV EN-7602142 - v11 - 24042019

Page 35

Fig.20

C004121-D

1

2

3

6

7

6

1,5V

1,5V

5

4

1. Drill 2 holes 6 mm in diameter.

2. Put the plugs in place.

3. Attached the wall bracket (washers + screws provided).

Important

The screws and plugs are supplied in the bag of hardware.

4. Remove the protective cover from the battery compartment (batteries

provided) at the back of the control module.

5. Remove the protective tab from the batteries and discard it.

6. Position the control system module.

7. The water heater and the control module will communicate.

Important

Type of batteries: AA – LR6 – 1,5 V

Do not use rechargeable batteries.

Do not discard used batteries in the dustbin. Take them to an

appropriate collection place.

Important

When powering on for the first time, the control module will

automatically pair with the water heater control system PCB.

For more information, see

Pairing the control module and the tank, page 48

5 Installation

EN-7602142 - v11 - 24042019 TWH 200 EV 35

Page 36

5.9.2 Wire connection

Fig.21

C004124-D

8

9

1

2

3

6

7

6

4

5

1. Drill 2 holes 6 mm in diameter.

2. Put the plugs in place.

3. Attached the wall bracket (washers + screws provided).

Important

The screws and plugs are supplied in the bag of hardware.

4. Remove the cover from the control panel on the front of the appliance:

insert a screwdriver into the opening located underneath the control

panel cover, pushing it in as far as it will go.

5. Pull the bottom of the cover forward to release it.

6. Remove the cover from the control panel on the front of the appliance.

7. Connect the 2 wires (not provided) on the water heater PCB.

8. Route the wire between the wall and the control module wall bracket.

5 Installation

36 TWH 200 EV EN-7602142 - v11 - 24042019

Page 37

9. Connect the wire to the back of the control module then clip the

control module into its bracket.

Important

Remove the batteries from the control module.

A Control module

B Water heater PCB

Important

Type of cable: H05VV-F 2x1.0 mm2 (for example)

5.9.3

Integration into the front panel of the water heater

(optional)

Fig.23

C004127-D

4

5

6

7

NEW

3

1

2

1. Remove the cover from the control panel on the front of the appliance:

insert a screwdriver into the opening located underneath the control

panel cover, pushing it in as far as it will go.

2. Pull the bottom of the cover forward to release it.

3. Dispose of the cover.

Fig.22

C004125-C

A

B

5 Installation

EN-7602142 - v11 - 24042019 TWH 200 EV 37

Page 38

4. Fit the control module onto the front panel supplied in the option

package (washers + screws provided).

Important

The screws and washers are supplied in the EH290 accessories

package.

5. Connect the 2 wires on the control panel side.

6. Clip the bracket onto the front of the water heater.

7. Clip the control module into its bracket.

Important

Remove the batteries from the control module.

5.10

Electrical connections

5.10.1

Recommendations

Warning

Only qualified professionals may carry out electrical

connections, always with the power off.

Do not connect the power supply directly to the HP/HC contact.

Earthing must comply with the NFC 15-100 standard.

Power the appliance via a circuit that includes a type D curve omnipolar 16

A circuit breaker with a contact opening distance of 3 mm or more.

The appliance is supplied with a power supply cable. If the power cable is

damaged, it must be replaced by the manufacturer, its after sales service

or persons with similar qualifications in order to prevent any danger.

Electrical power is supplied by means of a power cord (~230 V, 50 Hz)

and an electrical socket.

Separate the sensor cables from the 230 V cables.

5.10.2

Peak rate/off-peak rate electrical connection

1. Access the PCB:

Radio or wire-connected control

module

Remove the cover from the appli

ance's front panel

Integrated into the front panel of

the water heater

Unclip the control module and re

move its support from the appli

ance's front panel

5 Installation

38 TWH 200 EV EN-7602142 - v11 - 24042019

Page 39

2. Connect the electrical connection using a cable with a cross section of

1.5 mm2.

For more information, see